#Rigid-flex PCBAs

Explore tagged Tumblr posts

Video

youtube

Rigid flex PCB board China -- Hitech Circuits

https://www.hitechpcba.com/rigid-flex-pcb-manufacturer

Rigid Flex Printed Circuit Board Manufacturer

Rigid flex printed circuit boards (PCBs) are manufactured by combining rigid and flexible board technologies. These circuit boards are made up of multiple flexible circuit inner layers. An epoxy pre-preg bonding film is used to attach together these inner layers. The key benefit of these boards is that they are a combination of the best quality of flexible and rigid circuit boards. This can have several further benefits as far as stability, assembly, signal transmission, and overall size of the circuit are concerned. Hitechpcb provides a number of variants in rigid flex PCBs, which include 4 layer rigid flex with ENIG finish, 10 layer rigid flex with 4 layer flex, 12 layer rigid flex with heat sink, 14 layer rigid flex circuit boards, and many more. It is one of the leading rigid flex PCB manufacturers.

0 notes

Text

PCB boards after solder paste printing should enter reflow soldering oven after 30 minutes of solder paste printing to stop solder paste from being exposed to the air for long time with product quality reduced.

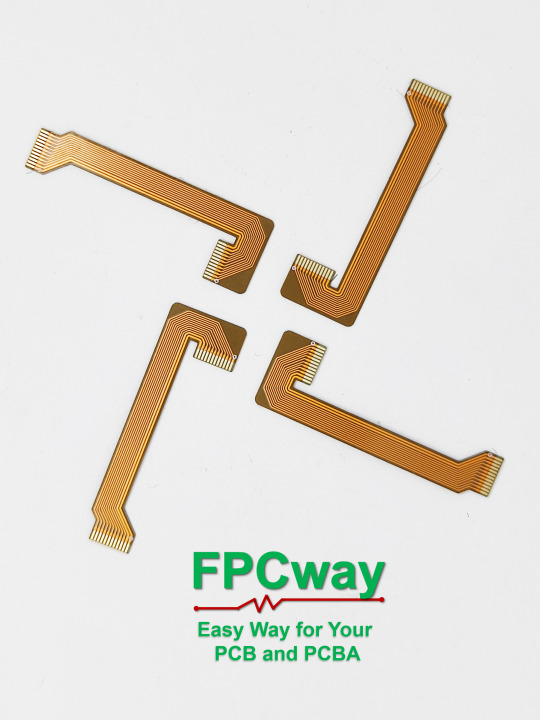

#FPCway #flexPCB#pcb#pcba#fpc# assembly#rigid-flex pcb #fpcway.com

#FPCway#flexPCB#pcb#pcba#fpc#assembly#rigid-flex pcb#fpcway.com#www.fpcway.com#flex pcb#flex circuit pcb#flexible pcb board#flexible circuit board#today on tumblr

0 notes

Text

Precision PCBA Solutions by SFXPCB: Global Excellence in Electronics Manufacturing

In today’s fast-paced technological world, PCBA (Printed Circuit Board Assembly) is a fundamental process that powers every modern electronic device—from smartphones and medical instruments to aerospace equipment and industrial control systems. As electronic design becomes more complex, the need for a reliable and precise PCBA partner becomes even more crucial.

At the forefront of innovation and quality in PCBA manufacturing stands SFXPCB, a global provider trusted by industries in Germany, USA, UK, Austria, and Canada. SFXPCB delivers high-quality assembly, superior engineering support, and efficient global logistics—all while maintaining competitive pricing.

What is PCBA?

PCBA (Printed Circuit Board Assembly) refers to the process of assembling electronic components onto a bare PCB (Printed Circuit Board). This process involves:

Applying solder paste to board pads

Placing surface mount or through-hole components

Reflow or wave soldering

Inspection (AOI, X-ray, or visual)

Functional and quality testing

The final product is a fully functional electronic board, ready for integration into a finished device.

SFXPCB – Your Trusted PCBA Manufacturing Partner

With a strong manufacturing base in China and a broad international customer base, SFXPCB provides end-to-end PCBA services tailored to meet the highest industry standards. From prototype assembly to mass production, their process is defined by precision, consistency, and speed.

Why choose SFXPCB for your PCBA needs?

✅ 1. One-Stop PCBA Services

SFXPCB provides a complete PCBA solution, including:

PCB fabrication

Component sourcing (including hard-to-find parts)

SMT & THT assembly

Functional and in-circuit testing

Quality assurance and packaging

This streamlined approach minimizes delays and errors, ensuring your projects run smoothly from start to finish.

✅ 2. Advanced Technology & Capabilities

Equipped with state-of-the-art SMT lines, reflow ovens, AOI systems, and BGA placement equipment, SFXPCB can handle:

Fine-pitch ICs

BGA, QFN, CSP components

High-density interconnects (HDI)

Rigid, Flex, and Rigid-Flex PCBs

Their advanced capabilities make them a top choice for industries demanding high precision and miniaturization.

✅ 3. Unmatched Quality Control

SFXPCB strictly adheres to ISO9001, RoHS, and UL certifications. Each project undergoes:

Automated Optical Inspection (AOI)

X-ray inspection (for BGA and hidden joints)

Manual inspection by experienced technicians

Functionality testing based on customer requirements

You can trust that every assembly meets the highest standards.

Industries That Trust SFXPCB’s PCBA Services

SFXPCB’s ability to handle complex projects and deliver on time has made it the preferred PCBA manufacturer for companies in:

🚗 Automotive Electronics

Reliable and rugged PCBA for engine control units, infotainment, and safety systems.

🏥 Medical Devices

Precision PCBA used in imaging systems, diagnostics, monitoring devices, and wearables.

📡 Telecommunications

High-frequency, high-speed PCBs used in routers, base stations, and IoT gateways.

⚙️ Industrial Automation

Durable assemblies for sensors, controllers, and factory automation systems.

🛰 Aerospace & Defense

High-reliability PCBA for communication, navigation, and surveillance applications.

Global Reach, Local Focus

Though headquartered in China, SFXPCB is a global player, serving clients in:

Germany

United States

United Kingdom

Austria

Canada

Their responsive English-speaking support team and efficient international shipping make it easy to work with them, no matter where you're located.

Fast Turnaround and Competitive Pricing

SFXPCB understands that time-to-market is critical. That’s why they offer:

Rapid prototyping services

Flexible volume production (from 1 to 10,000+ units)

Competitive pricing without sacrificing quality

Through strong relationships with component suppliers and efficient manufacturing practices, SFXPCB delivers high-value PCBA services at a cost-effective rate.

How to Start Your PCBA Project with SFXPCB

Getting started with SFXPCB is simple and fast:

Visit the website: https://sfxpcb.com/

Upload your Gerber files and BOM

Get a fast and accurate quote

Review DFM suggestions from their engineers

Approve and track your order online

You’ll benefit from responsive communication, transparency, and a seamless production process from quote to delivery.

Customer Testimonials

“SFXPCB is our go-to partner for PCBA. They consistently deliver high-quality boards and help us hit tight deadlines.” — CTO, IoT Startup (Germany)

“The team at SFXPCB is incredibly responsive and knowledgeable. We’ve trusted them with multiple projects and never been disappointed.” — Procurement Manager, Medical Device Company (USA)

Contact SFXPCB Today

Have a question or ready to place an order? Reach out directly:

📧 Email: [email protected] ���� Phone: +86 0755 21012004

In the world of modern electronics, the importance of a reliable PCBA provider cannot be overstated. From prototyping to full-scale production, SFXPCB combines precision, speed, and service excellence to help businesses across the globe bring their products to life.

Whether you're an electronics startup or a global OEM, SFXPCB delivers quality you can trust—on time and on budget.

0 notes

Text

Applications of rigid-flex PCB boards

The rigid-flex PCB boards provide a wide range of applications from smart devices to mobile phones and digital cameras. Rigid-flex board manufacturing has been increasingly used in medical devices such as pacemakers to reduce their space and weight. The use of rigid flexible PCB has the same advantages and can be applied to intelligent control systems.

Email Cynthia: [email protected] if you are interested in PCB and PCBA service.

0 notes

Text

At GreatPCB, our hybrid laminating process integrates FR-4 with high-frequency materials like PTFE and ceramics, ensuring top performance while reducing costs. We also offer rigid-flex structures for complex 3D assembly needs, providing flexibility and reliability.

1 note

·

View note

Text

Rigid Flex PCB PCB or PCBA quotation, please email to [email protected] Learn more: https://lnkd.in/gAhdxTUx

#pcb#pcb assembly#pcb manufacturer#electronic#electrical design#pcb design#assembly#flexible pcb board#flex pcb#hardware#electronic components#components#precision machined components#digikey#mouser

0 notes

Text

Pioneering Excellence in EMS Manufacturing with Absolute Electronics Inc

In the rapidly evolving world of technology, Silicon Valley is where innovation has no bounds, and companies vie with each other to come up with novel products in markets like aerospace, medical devices, high-performance computing, and AI. To shape these innovations, companies require reliable and cutting-edge Electronics Manufacturing Services (EMS). Absolute Electronics Inc. is at the forefront when it comes to this, delivering EMS manufacturing services in Silicon Valley that ensure precision, speed, and quality beating all others.

Setting the Standard for EMS Manufacturing

As one of the leading EMS providers in the region, Absolute Electronics Inc. offers end-to-end EMS manufacturing solutions in Silicon Valley that streamline the entire production process, from concept to end assembly. Their advanced capabilities enable companies to optimize product development without having to sacrifice on industry standards.

Expert PCB Assembly & System Integration

Printed Circuit Board ( assembly (PCBA) is the basis of contemporary electronics manufacturing. Absolute EMS excels in:

Automated Surface Mount Technology (SMT) for scalable, defect-free assembly.

Automated Solder Paste Inspection ((SPI), Automated Optical Inspection (AOI) and X-ray Inspection, eliminating defects before final production.

Conformal Coating For parts intended to withstand harsh conditions.

Unwavering Commitment to Quality with Industry-Leading Certifications

Absolute EMS has a commendable reputation for maintaining the best quality level at all times. With internationally renowned certifications, Absolute EMS ensures its operations not just meet but surpass industry requirements. Some of these significant certifications are:

AS9100D & ISO 9001: These are the central pillars of Absolute EMS's quality management system. They guarantee improved product qulaity as well as strict adherence to industry norms. AS9100D specifically ensures conformity to aerospace and defense-focused projects with utmost quality and reliability standards.

ISO 13485: This certification demonstrates Absolute EMS's emphasis on the medical device industry, in which its manufacturing processes meet rigid regulatory standards for dependability and safety.

J-STD-001: A testimony to the firm's superiority in electronics assembly, this certification of all operators provides assurance that the soldering and assembly operations at Absolute EMS comply with the superior durability and performance requirements.

By holding these elite certifications, Absolute EMS solidifies its commitment to providing top-notch quality across many high-reliability industries.

Innovative Manufacturing Solutions for Diverse Industries

Partnering with Absolute EMS is equivalent to gaining access to the most up-to-date manufacturing solutions tailored for different industries. The firm has multi-industry expertise with precision, reliability, fast time-to-market turnarounds, and performance. Some of the most important industry solutions include:

AI & High-Performance Computing (HPC): As a preeminent Silicon Valley EMS company, Absolute EMS is on the leading edge of facilitating the HPC sector. Absolute EMS is skilled at producing high-speed, advanced assemblies created to exact specifications for enhanced performance and reliability.

Automotive: At the forefront of the evolving automotive sector, Absolute EMS supports next-generation technologies, including Advanced Driver-Assistance Systems (ADAS) and key components like LiDAR and RADAR for autonomous driving.

Aerospace & Satellite Systems: Absolute EMS provides lightweight but highly robust PCB assemblies for aerospace and satellite applications. With its rigid-flex assembly capabilities, Absolute EMS offers solutions for harsh space conditions.

With innovation and quality at its core, Absolute EMS continues to advance technology across industries.

Smart Manufacturing: The Future of EMS

Absolute EMS isn’t just keeping up with the future—it’s building it. Their award-winning Factory 4.0 approach integrates:

End-to-end automation for increased accuracy and production efficiency.

Real-time process monitoring to minimize errors and optimize yield rates.

Predictive maintenance systems to prevent downtime and improve reliability.

Why Choose Absolute Electronics Inc.?

Why choose EMS manufacturing services in Silicon Valley? The area houses a number of the world's most technologically sophisticated businesses, providing:

Access to World-class Engineering Expertise: Work with engineers who are experts in electronic manufacturing.

State-of-the-Art Technology: Utilize the latest computer-aided manufacturing technology.

Shorter Turnaround Times: With less complicated prototyping and manufacturing, you can get to the market sooner with your products.

Companies can tap into the best of Silicon Valley innovation and the finest manufacturing expertise by partnering with Absolute Electronics Inc.

Partner with Absolute EMS for Next-Level Manufacturing

Whether you are a startup looking for rapid prototyping or an existing company looking for high-quality EMS manufacturing services in Silicon Valley, Absolute EMS is your best bet. With a sterling track record of success, stringent quality control measures, and a customer-centric approach, they are dedicated to producing every project that adheres to the industry's highest standards.

Let’s Build the Future Together

Seeking a reliable EMS partner to turn your concepts into realities? Reach out to Absolute Electronics Inc. now and discover how their state-of-the-art electronics manufacturing services can take your next game-changer idea to new heights.

0 notes

Text

GREATPCB SMT LIMITED established PCB factory in Shenzhen 2002,and built PCB Assembly factory in 2008 . We are professional PCB &PCB assembly manufacturer for more than 15 year. we can provide one stop services from PCB (1-20 layers) to PCBA including sourcing Components ,Programming IC,Conformal Coating, Function and Aging Testing.

0 notes

Text

1 note

·

View note

Video

youtube

Custom Flex & Rigid Flex PCB's Manufacturer

With the use of a rigid flex PCB(rigid FPC), flexible circuit substrates and rigid circuit substrates are covered together. Rigid-flex PCBs cross the limits of conventional rigid PCBs and the one of a kind properties of flex circuits that utilization high-flexibility electrodeposited or moved strengthened copper conductors photograph carved onto a flexible protecting film.

Rigid flex PCBs is a complicated product that demands a lot of interaction between our and your technicians. Please contact us for more information.

Hitech Circuits Co., Limited

0 notes

Text

Advantages of SMT Assembly:a High Assembly DensityCompared with traditional through-hole components, chip components call for smaller real estate of board surface.

#FPCway#flexPCB#pcb#pcba#fpc#flexible circuit board#flex PCB and assembly#fpcway.com#rigid-flex pcb#flex pcb#flexible pcb board#flex circuit pcb#today on tumblr#www.fpcway.com

0 notes

Text

Dienstleistungen zur Bestückung von Leiterplatten

Die Bestückung von Leiterplatten ist eine unserer Hauptdienstleistungen. HITECHPCB bietet alles, von der Herstellung starrer Leiterplatten und flexibler gedruckter Schaltungen über die Beschaffung von Bauteilen bis hin zur Leiterplattenbestückung.

Hier ist eine Liste einiger unserer hochwertigen Dienstleistungen zur Bestückung von Leiterplatten:

One-Stop PCB-Fertigung und -Bestückung:

Schnell, hochwertig, kompliziert, eine schlüsselfertige Komplettlösung: PCB-Herstellung + Bauteilbeschaffung + PCB-Bestückung + Gehäusemontage + PCBA-Tests, die alle Kundenanforderungen erfüllt.

2. Dienstleistungen zur PCB-Bestückung:

SMT-Bestückung, THT- und Mischbestückung, Package on Package (POP), starre Leiterplatten, flexible Leiterplatten, Rigid-Flex-Leiterplatten, HDI-Leiterplatten, Aluminium-Leiterplatten, Keramik-Leiterplatten, Hochfrequenz-Leiterplatten, Rogers-Leiterplatten usw. – wenn es eine Art von Leiterplatte gibt, die bestückt werden kann, machen wir es fast sicher.

3. Flexible Volumenmontage-Alternativen:

Prototypen-PCB-Bestückung: Sehen Sie, wie gut Ihr PCB-Design funktioniert, bevor Sie eine Großbestellung aufgeben. Unsere qualitativ hochwertige Prototypen-PCB-Bestückung ermöglicht es uns, schnell einen Prototyp zu liefern, damit Sie mögliche Herausforderungen in Ihrem Design schnell identifizieren und die Qualität Ihrer endgültigen Leiterplatten optimieren können.

Niedrigvolumige, hochgemischte PCB-Bestückung: Wenn Sie verschiedene Leiterplatten für spezielle Anwendungen benötigen, ist HITECHPCB Ihre beste Wahl.

Hochvolumige PCB-Bestückung: Wir sind ebenso geschickt darin, große Bestellungen zur PCB-Bestückung wie kleine zu erledigen.

Zugelieferte & Teil-PCB-Bestückung: Unsere zugelieferten PCB-Bestückungsdienste erfüllen die IPC-Klassen 2 und 3, sind nach ISO 9001:2015, IATF16949, ISO 14001 zertifiziert und UL- und RoHS-konform.

Vollständige schlüsselfertige PCB-Bestückung: Unsere schlüsselfertige PCB-Bestückung ermöglicht es uns, Ihr gesamtes Projekt von Anfang bis Ende zu übernehmen, sodass Sie sofort mit dem fertigen Produkt arbeiten können.

0 notes

Text

The advantages of rigid-flex PCB board

1). It can effectively save the space on the circuit board and eliminate the use of connectors

Because the FPCB and rigid pcb board has been combined, the space that originally needed to use the connector can be saved. For some circuit boards with high-density requirements, less connectors will be better. In this way, it also saves the cost of parts using the connectors. In addition, the space between the two boards can be made tighter by eliminating the need for connectors.

2). The signal transmission distance is shortened and the speed is increased, which can effectively improve the reliability

The traditional signal transmission through the connector is “circuit board→connector→flexible pcb board→connector→circuit board”, while the signal transmission of the rigid-flex PCB board is reduced to “rigid circuit board→flexible pcb board→rigid circuit board”, signal transmission distance between different media is shortened, and the problem of signal transmission attenuation between different media is also reduced. Generally, the circuit on the PCB board is made of copper, while the contact terminal of the connector is gold-plated, and the solder pin is fully tin-plated. Moreover, solder paste is required to be soldered on the circuit board, and the signal transmission between different media will inevitably be attenuated. If you switch to a rigid-flex PCB board, these media will become less, and the signal transmission ability can be relatively improved. For some products that require higher signal accuracy, it helps to improve their reliability.

3). Simplify product assembly and save assembly time

The use of a rigid-flex PCB board can reduce the man-hours for SMT parts, because the number of connectors is reduced. It also reduces the man-hours for assembly of the whole equipment, because it eliminates the assembly action of inserting the FPC board into the connector. It also reduces the cost of parts management and inventory, because the required parts is reduced, so the management cost becomes less.

Email Cynthia: [email protected] if you are interested in PCB and PCBA service.

0 notes

Text

Designing Tomorrow: Aimtron’s Impactful PCB Assembly Solutions

In the ever-evolving landscape of technology, Printed Circuit Boards (PCBs) play a pivotal role. These intricate electronic platforms serve as the backbone for countless devices, from smartphones to medical equipment. Among the trailblazers in this field is Aimtron, a company that doesn’t just design PCBs; it engineers solutions that shape the future.

Aimtron’s Vision and Expertise

Driven by a passion for progress and societal advancement, Aimtron excels in sourcing, building, and launching innovative products that enrich society globally. Their expertise in Electronic Design and Manufacturing Services sets them apart. Let’s delve into their impactful PCB assembly solutions:

1. PCB Assembly Services

At Aimtron, the journey from concept to production is seamless. Their dedicated team handles all your PCB needs, ensuring top-quality performance and reliability. Here are the types of PCBs Aimtron works with:

a. Flex PCBs (Flexible PCBs)

For applications requiring flexibility and durability, Aimtron’s flex PCBs are the ideal choice. Designed to bend and flex during use, these PCBs fit into tight or unusual spaces, providing reliable performance in dynamic environments.

b. Rigid-Flex PCBs

Combining the stability of rigid PCBs with the flexibility of flex circuits, Aimtron’s rigid-flex PCBs offer versatile solutions for complex electronic applications. These hybrid PCBs ensure reliability and performance, even in the most challenging environments.

c. Single-Sided PCBs

Ideal for simple electronic applications, Aimtron’s single-sided PCBs provide a cost-effective and reliable foundation for your components. They work well for low-density designs, ensuring quality and durability.

d. Double-Sided PCBs

With conductive layers on both sides, Aimtron’s double-sided PCBs offer more flexibility for complex circuits. These PCBs accommodate a higher component density, meeting the needs of sophisticated electronics.

e. Multilayer PCBs

For advanced electronic challenges, Aimtron’s multilayer PCBs provide the solution. Featuring three or more layers of conductive material, these PCBs are perfect for high-speed and high-frequency applications. They ensure signal integrity and reduce electromagnetic interference (EMI).

f. Rigid PCBs

Aimtron’s rigid PCBs offer a solid foundation for most electronics. Available in single-sided, double-sided, and multilayer configurations, they provide a stable and durable platform for a wide range of applications.

2. Chip-on-Board (COB) Technology

Aimtron employs COB technology, allowing direct attachment of bare semiconductor dies to the PCB. This results in smaller and more cost-effective solutions. The integration of COB technology enhances performance and reliability.

3. Design for Excellence (DfE)

Aimtron’s DfE method ensures efficient integration of components like PCBAs, wire harnesses, and mechanical enclosures. Collaborative engineering strategies streamline manufacturing, resulting in superior end products.

Conclusion

As we design tomorrow’s innovations, Aimtron’s impactful PCB assembly solutions pave the way. From flex PCBs to advanced multilayer designs, Aimtron’s commitment to excellence drives progress in the electronics industry. So, when you think of shaping the future, think Aimtron.

For more information, visit Aimtron’s website: Aimtron

#electronicsdesign#electronicsmanufacturer#pcbassembly#pcbassemblysolution#multilayerpcb#pcbdesign#pcbassemblyservices

0 notes

Text

Basic PCB Assembly Overview

PCB Power Market is the only firm you need for full-service, high-quality PCB assembly. We specialize in one-stop electronic production, which includes PCB fabrication, component procurement, and PCBA. Some of the advantages of contacting us for PCB assembly include:

1. Fabrication and assembly at a single location

We have been able to provide both PCB manufacturing and PCB assembly services under one roof after more than ten years of development in this industry. You only need to wait and receive finished products based on their schedules if you give design files and specified manufacturing and assembly requirements.

2. Various PCB Assembly Services

We provide a variety of PCB assembly services to fulfill a wide range of demands at all levels and for a wide range of goods. We specialize in SMT, THT, and mixed assembly, Package on Package (POP), and other PCBA technologies with complexity levels ranging from low to high, traditional to advanced. We cover the greatest spectrum of PCB board types that can be assembled, from basic boards to exotic boards such as Rigid PCBs, Flex PCBs, or Metal Core PCBs, among others.

3. Alternatives for Flexible Volume Assembly

We must confess that each manufacturer likes bulk orders. PCB Power Market focuses on higher volume alternatives, such as prototype assembly, low volume high mix, and mid-volume to high volume assembly, when compared to single and repeated PCB assembly services.

4. Components Purchasing electrical components

We provide a parts-sourcing service to meet the demands of high-quality PCB assembly. We have maintained such a long-standing and solid working relationship with authorized electronic component manufacturers or distributors that customers may expect rapid and low-cost parts sourcing service. We guarantee that no bogus components will be given. Furthermore, prior to real-world uses of components, 100% stringent quality inspections must be performed to assure their reliability in PCBA. Furthermore, PCB Power Market offers adaptable choices that are totally consistent with your PCB assembly service demand. You can either rely entirely on us for part procurement or buy through your own channel and send it to us for PCB assembly. We all guarantee 100% quality inspection on each piece component before usage, no matter which route you take.

5. Extensive Quality Assurance Checks Throughout Each Phase

To summarize, the PCBA process consists primarily of PCB fabrication, component sourcing, and PCB assembly. Quality control must be conducted at each step of the PCB assembly service process at PCB Power Market in order for final products to be of excellent quality. Custom electrical tests must be used during the PCB manufacturing process to ensure that the PCB boards are completely complying to the designed functionality. Quality control steps must be 100% made for components, as shown in the prior content, whether purchased from approved producers or provided by customers. When it comes to PCB assembly, more quality control procedures are required. Visual inspection, AOI, and X-ray inspection are common quality control procedures used in the PCBA process.

6. Increased Efficiency and Lower Total Costs

We offer numerous must-have FREE services to complement our quick-turn PCB assembly services. Valor DFM/DFA check may automatically verify whether your designs can be fully converted into the intended product. Valor Manufacturing System Solution (MSS) aids in the optimization of manufacturing processes and the improvement of manufacturing efficiency. Furthermore, professional and experiential advice on cost-performance balance will be supplied to you. All of these items are free, but they all play an important role in improving efficiency and lowering costs.

7. Easier Meeting of Project Deadlines

Time to market is an important factor that businesses must consider, especially during the New Product Introduction (NPI) stage. One-stop electronic production enables the shortest time between each phase, which is also one of the reasons for choosing PCB Power Market PCB assembly services. We can reduce the time it takes for your items to reach the market and increase your profits because all phases are intimately linked.

8. The ability to devote more time and energy to PCB design

We have a skilled team of engineers in charge of evaluating and confirming design files, which leads to a seamless PCB assembly process. Furthermore, based on both your requirements and their accumulated knowledge, our engineers can give optimal solutions.

Original Source: https://nboxoffice.com/basic-pcb-assembly-overview/

0 notes

Text

Electronic devices all use rigid-flexible PCB?

Expensive and complex discrete interconnect cables can reduce design reliability, increase design cost and overall design size. In practice, discrete interconnect cables are a disadvantageous design. For electronic product sellers it goes against the trend of miniaturization of electronic products, and for PCBA manufacturers, it is an unreliable design. For project leaders, discrete interconnect cables are not only more expensive but also more complex. Fortunately, FS Technology's rigid-flex PCBA will be the perfect substitute.

The advantages of FS technology manufacturing rigid-flex PCB

FS Technology specializes in the production of this rigid-flex PCBA, which is designed for flexibility and reliability to provide a cost-effective and convenient solution for your electronic projects. Discrete interconnects have different conductor orientations, whereas flex PCBAs keep all conductors in a specific orientation fixed to each other. Accurate modeling and more predictable design of PCBA traces with reliability and flexibility.

In addition, in the part of the FPC, FS Technology provides gold finger contacts, allowing the edge of the FPC to be used as the male part of the connector and can be adapted to high-density designs. Today, in order to meet the needs of electronic product users, this rigid-flex PCB replaces almost all traditional discrete interconnect solutions and enables a highly modular design.

The benefits of rigid-flex PCBA for electronic projects

FS Technology's flexible PCBA not only provides an effective method for designing and producing interconnect solutions, but also enhances the accommodation of the circuit board and becomes the focus of the solution. The use of rigid-flex PCB can make the volume of electronic products smaller, which is unmatched by traditional circuit boards. Instead of mounting components to rigid PCBs, you can mount boards produced by FS Technologies on all flexible solutions. In addition to the above advantages, the rigid part of the rigid-flex PCBA can act as a stiffener, providing your electronic project with a reliability that a flexible PCB cannot. Most of the wearable devices, digital cameras, and medical devices used today use rigid-flex PCBs instead of just FPC or rigid PCBAs.

FS Technology believes that flexible rigid PCB is the best of all flexibility solutions. Features a flex-rigid design with built-in interconnect between the two boards. Using rigid-flex PCBAs manufactured by FS Technology in different solutions, designers can accommodate 3D solutions in one assembly step. The use of rigid-flex PCBA instead of traditional circuit boards or discrete connections can shorten the assembly time of mechanical assembly. As the demand for PCBs by electronic product sellers increases, it is proved that rigid-flex PCBs are a catalyst for any electronic solution.

Although rigid-flex PCBs are better than traditional PCBs, they are very similar in the design process. As a turnkey PCB manufacturer, special attention to mechanical quality is required when creating flexible parts. When creating a 2D layout of a flexible PCB design, it is best to use a 3D modeling software to create a mockup of the flexible design, or to create a paper mockup of the design. This method is convenient for testing whether the design meets the mechanical specifications of the flexible substrate. In addition to that, the PCB you design does not need to have a bend radius smaller than what a flex PCB allows.

FS Technology recommends that you pay attention to the following points when designing rigid-flex PCBs:

Increase board flexibility with staggered traces on each layer of the flex circuit.

Conductors must not be routed perpendicular to the bend radius

Termination areas should be reinforced with stiffeners

Use a cross-hatched pattern instead of a solid plane

Vias should be kept away from bend areas

Communication with turnkey rigid-flex PCB assembly company

Before sending manufacturing files of rigid-flex PCB to FS Technology, please consider the plan's executable in advance, such as the flex board is bendable and has the highest density when nested. If a specific dimension can be achieved by bending the PCB, usually we do not bend it in the initial design, but in the assembly step. Finally, I hope you know that the few rigid-flex PCBAs you design are more expensive than flexible PCBs. Try to use a smaller number of layers for your project needs, it will be more profitable for the electronics you sell. Flexible rigid solutions should only be considered if your design has very large layer count requirements.

Finally, filling a flex PCB is very similar to filling a rigid PCB. When doing flexible PCB assembly, consider the following tips:

Bake the flex PCBs for an hour, then fill them to remove any absorbed moisture.

Fix the flex PCB to a hard surface to provide dimensional stability when soldered to the device.

When hand-soldering the device to the flex PCB, skip the solder-intensive fixtures to avoid overheating parts of the flex PCB.

In conclusion, rigid-flex PCBs can greatly reduce the cost and complexity of your electronics manufacturing process. Rigid-flex PCBAs are an excellent alternative to traditional discrete routing solutions, offering the repeatability and reliability of PCBs in a flexible form factor. Additionally, rigid-flex PCBAs offer the opportunity to create highly complex 3D designs while maintaining low assembly costs, high levels of repeatability and reliability. In short, rigid-flex boards will allow you to handle designs that are too costly, complex or simply impossible to manufacture. Take your designs to the next level with rigid-flex boards.

1 note

·

View note