#Rotary Combustion Engine

Explore tagged Tumblr posts

Video

youtube

Rotary Combustion Engine (demo) for the ZX81

1 note

·

View note

Text

Worldbuilding time! Let's talk about vehicular travel in modern day Amaranthine, using the snowmobiles from this recent comic as a jumping off point.

"Prowler" - Ironfrost patrol snowmobile - (year of manufacture: 1912)

These half-track all terrain vehicles are used by Ironfrost soldiers to travel long distances over the tundra. Originally adapted from older, four-wheeled automobiles, the half-track Prowler design became increasingly standardized over the years as eternal winter continued to creep southward. They are capable of operating in a wide variety of terrain conditions and are fairly modular. Common mods include removable skis, hardtop and softtop roofs, gun mounts, and towing attachments.

Like all vehicles, Prowlers are steam-powered. The external combustion engine runs on kerosene. In snowy conditions, feedwater can be obtained automatically through a scraper port on the underside of the vehicle, though manual feeding is required in muddy or dry conditions.

Though not as fast, reliable, or efficient as trains, their agile nature have made them an essential part of life in the far north… and, increasingly, in the middle country as well. The Rising Dawn have stolen several Prowlers for their own usage.

"Aspire" - Classic automobile (year of manufacture: 1890)

Four-wheeled vehicles are an unusual sight in the modern day. Ironfrost-made cars were in vogue among the southern rim upper class for many years, but the worsening climate has made them more and more niche as road conditions outside of major cities deteriorate. The majority of higher horsepower automobiles were converted directly into half tracks, while older, lower-end vehicles were generally scrapped for parts.

The Aspire was the last four-wheeled vehicle widely available to the public. Advertised as a stylish, powerful, modern vehicle for the elite on the go, it boasted a sleek, classy aesthetic, a removable softtop roof, and a powerful steam engine with a large kerosene tank suitable for travel between cities. Preorders were advertised to southern rim wealthy in local papers. However, a series of unusually bad winters soon after its debut scared off buyers, shutting down production early and ultimately spelling doom for the entire four-wheeled automobile industry.

One of those Aspire preorders went to Baroness Jocosa North. Though she has since passed away, her son, Theopolis North, still maintains the now wildly impractical car in near mint condition. It is almost never seen outside of its garage.

"'Icebreaker' Class E 250" - Northern cross-country train (year of manufacture: 1903)

The majority of modern-day overland travel is accomplished via train. Massive long-distance rail lines, laid before the world became quite so cold, connect the remaining cities, allowing (relatively) safe travel and trade across vast expanses of tundra.

Southerly locomotives typically operate with only a basic wedge plow attachment. However, trains that run further north must be fitted with gigantic rotary snowplows. These complex machines require significant maintenance. Though they can and will chew up most things that get in the train's way, encounters with particularly large and bony beasts have been known to jam them.

Ironfrost's line terminates in a massive, sprawling rail yard where Icebreakers are fitted and maintained. Those who have visited it tell of a dark, dreary wasteland of twisted scrap metal and ice where coal dust and smoke have turned both the sky and ground black. All northern trains must pass through that place eventually.

"Chariot of the Dawn" - One-of-a-kind luxury automobile (year of manufacture: 1920)

The only place where four-wheeled automobiles still thrive is the City of the Sun. The eternal summers and paved roads are well-suited to cars and trolleys, though they are, of course, still something of a luxury good. Licenses for ownership and operation are ultimately controlled by the church, with His Radiance having the final say. (His most devout followers, of course, tend to get preferential treatment here.)

The City of the Sun manufactures its own vehicles, adapted from Ironfrost designs in a sort of divergent evolution. Freed from the road and weather concerns of the outside world, their automobiles favor sleek, swoopy body shapes, ornamental trim, low-slung bodies with limited ground clearance, and pastel paintjobs. Additionally, the engines are far less powerful and far more finicky, requiring regular maintenance.

His Radiance himself owns several custom automobiles, all of which are egregiously bedazzled to a degree that would look grotesque to anyone who wasn't used to it. Some are open-top, allowing his loyal followers an audience with his beautiful face and glittering halo, while others feature tinted windows. You know, in case he wants subtlety.

#furry#furry art#cars#vintage cars#worldbuilding#verse: amaranthine#things nobody asked for but I did anyway :P#it is pretty important to have designs for these though the story moves the characters back toward civilization (slowly)#my ocs#alex#ridge#others' ocs#theo#ambroys#(as usual the vehicles are heavily referenced!)

515 notes

·

View notes

Note

What's an automotive technology that you wish had made it that didn't?

NSU Trapeze, 1973, by Bertone. In the late 60s and early 70s it seemed likely the rotary engine, invented by Felix Wankel, was going to take over the auto industry. The advantages of compact design, smoothness, low weight, and fewer parts over piston internal combustion engines gave rotary power a bright future. NSU was the first car company to develop the Wankel motor into series production but from the late 60s all major automobile makers were working on rotary power, perhaps most famously General Motors and of course Mazda. Alas as is often the case physics got in the way, despite its remarkable power the Wankel system has lower thermal efficiency and higher emissions relative to a piston engine. So from the early 70s one by one everyone abandoned their rotary programs apart from the Volkswagen AG (by now owners of NSU), Citroën and Mazda. Not only was Bertone's Trapeze rotary-powered but it also presents another configuration concept that seemed to have potential in the 70s and early 80s. Mid-engined 4/5 seat cars. A number of concepts were presented with 2 and 4 doors that could seat multiple passengers with engines placed behind the rear seats (in the Trapeze it was in the middle of them). However no-one ever got around to putting a mid-engine 4-door saloon into production and the industry moved onto almost universal adoption of front transverse engines and front wheel drive.

Fun fact about Felix Wankel (1902-1988) inventor of the rotary engine, he was extremely nearsighted and never held a driver’s licence but had the same chauffeur for most of his life

rotary gif by Y_tambe

#NSU#NSU Trapeze#Bertone#Bertone Trapeze#concept#mid-engine#rotary engine#Wankel engine#twin rotor#dead brands#4-seater#question#answer

194 notes

·

View notes

Text

Honda Civic brochure pages.

CIVIC

The Super Civic was a new trend car with economy and dynamic performance suited to the 1980s.

1300 S

1500 SC

It perfectly combines the best fuel economy in the 1500cc class with powerful driving performance.

Resource and energy conservation are common themes around the world. The new CIVIC is available with a new engine system that takes advantage of the excellent combustion efficiency of the lean burn method, which is the greatest advantage of the CVCC engine. It offers not only excellent fuel economy, but also low maintenance costs and a low price.

10 mode driving, Ministry of Transport inspection value

1500CE model E-SR 18 km/l

60km/h constant speed test value

28km/l 1500CE, GF (5 door) Model E/SR, Model E-ST

And yet, it still has the powerful driving feel of a sports car. It's truly a Super Civic.

For example, the new cliff-cut panel in front of the passenger seat provides enough space that there is no need to push the seat back.

An aerodynamic body that provides a smooth ride.

The styling minimizes air resistance and is focused on practical aerodynamics. It is agile in urban areas and stable and smooth on the highway. The new suspension grips the road firmly.

The springs of the front and rear suspensions have been offset to provide a more comfortable ride. The rear also uses a new Honda-style strut system, a world first, to ensure sufficient compliance. The suspension is much tighter.

1300・5-door LX

A new instrument panel.

The functions necessary for driving are concentrated around the driver. The centralized target meter () that places the speedometer and tachometer in one view, as well as the newly designed rotary channel radio, are also standard equipment. The design is easy to see and use.

A large, international-sized interior designed for the world.

Compared to conventional 5-door vehicles, the interior length is 25 mm longer and the interior width is 35 mm wider. Furthermore, the clever use of each space has resulted in an amazingly efficient interior.

All models are fully open hatchbacks.

It is a big opening that opens to the full width of the body from a low position, that is, just above the bumper. Moreover, the interior floor is low and flat. Large and wide objects can be easily loaded. The three-stage variable rear seat is extremely practical. It is a design that prioritizes ease of use.

1500 3door CX

Wild ride. CX

1500 3door CE

CIVIC

1500 5door CF

1300・3-door SE Model E-SL Engine model EJ ●CVCC・1,335cm2・Water-cooled inline 4-cylinder horizontally mounted OHC-68 horsepower ●Fuel economy 22km/ℓ(60km/h・flat road test value)●Front-wheel drive●Overall length 3,760mmOverall width 1,580mm ●Strut-type four-wheel independent suspension●Front-wheel disc brakes ●4-speed

1500, 3-door CE, Model E-SR, Engine model EM CVCC-1.488cm2, water-cooled in-line 4-cylinder, horizontally mounted, OHC-80 horsepower, Fuel economy 28km/ℓ (60km/h, constant speed test value), 18km/ℓ (10 mode running, Ministry of Transport review value), Front-wheel drive, Overall length 3,760mm, Overall width 1,580mm, Strut-type four-wheel independent suspension, Front wheels, Disc brakes with servo, 5-row

*1500-3 door SE is made to order.

If you're looking for a Civic, visit your local Honda dealer.

CIVIC VAN

Gentle on luggage and gentle on people. The capable Civic Van is born.

The luggage compartment is 1,520mm long (with two occupants), 1,270mm wide at its widest point, and 805mm high, making it spacious and easy to handle. Highly refined quality. Powerful and robust dynamic performance. Extremely quiet and safe, this is the birth of a reliable business car that pursues a high level of harmony between passengers and business.

1300-5 door SV, LV model J-VC Engine model EN 1,335cm * Water-cooled inline 4-cylinder horizontal OHC, 70 horsepower ● Fuel economy 18.5km/(60km/h, constant speed test value) ● Front wheel drive ● Overall length 3,995mm, overall width 1,580m, overall height 1,385mm ● Front wheel servo disc brakes ● 4-speed

16 notes

·

View notes

Text

Launched a century ago, the Bugatti Type 35 didn’t just make a single impact—it revolutionized the racing world with its innovative design and engineering. The car became legendary not only for its initial capabilities when it debuted in 1924 but also for the continuous improvements Bugatti implemented throughout its production. Ettore Bugatti was one of the first automobile manufacturers to grasp the marketing potential of winning races on Europe’s renowned circuits and road tracks, which brought considerable publicity to his brand. Confident as he was in the capabilities of his new car, even Bugatti could not have predicted that the Type 35 would become the most successful race car in history, achieving 2,500 victories during its active racing career.

The first Type 35, released in 1924, was equipped with a 1,991cc eight-cylinder engine, delivering 90 PS in race trim. By early 1926, Bugatti had increased the engine size to 2,262cc for the Type 35T, named after the famous Targa Florio road race in Italy, which it won, with two smaller-engined Type 35s finishing close behind. Despite this success, Ettore Bugatti realized that to stay ahead of the competition, he needed more than just increased engine displacement. He knew that the future of performance lay in forced induction, even though he was initially not a fan of superchargers, which were seen as inefficient at the time.

“It’s no secret Ettore Bugatti preferred naturally aspirated engines and was not an early enthusiast of supercharging due to its perceived inefficiency,” says Luigi Galli, Specialist for Heritage and Certification at Bugatti. “However, what’s less well known is that Bugatti was forward-thinking about the potential of forced induction, experimenting with superchargers even before the Type 35 debuted at its first race in Lyon in August 1924. In fact, Bugatti applied for French patent number 576.182 on January 22, 1924, for a ‘Compresseur ou pompe à palettes,’ a rotary vane supercharger design that could provide extra power on demand by forcing pressurized air into the carburetor. If Bugatti was going to use a supercharger, he was determined to innovate in his own way.”

As a result, Ettore Bugatti, alongside the Italian engineer Edmond Moglia, developed a unique three-rotor Roots-type supercharger, differing from the common two-rotor designs of the time. This supercharger was strategically mounted on the engine’s offside, which allowed it to warm up more quickly and improve overall engine cooling—a principle that remains relevant in modern engine design. The Type 35TC, where “TC” stands for Targa Compressor, was introduced in late 1926. It evolved into the Type 35B in 1927, featuring a larger radiator and cowling, known as the ‘Miramas’ design, which enhanced cooling capabilities. This configuration enabled the Type 35B to produce up to 130 PS, achieving speeds over 205 km/h (150 mph).

By late 1930, further refinements led to what many consider the ultimate version of the Type 35B. This final iteration featured a twin-cam, two-valve-per-cylinder engine, a twin fuel filler cap, improved suspension, wheels, brakes, and tires, as well as a lower-mounted supercharger relief valve. Bugatti’s relentless pursuit of perfection extended to optimizing every element of the combustion system, from sculpted pistons and cylinder heads to the use of aviation-grade fuel, which boosted the output to 140 PS.

Today, at Bugatti’s atelier in Molsheim, each Bugatti model is hand-assembled with the same meticulous attention to detail that Ettore Bugatti applied to the Type 35. A century later, Bugatti’s engineers and designers continue to push the boundaries of automotive excellence, upholding a legacy of innovation and performance that began with the groundbreaking Type 35.

13 notes

·

View notes

Text

ok im gonna post what i put in be warned its a collection of multiple infodumps

haha there is none get recked lol ah Toronto and your weird Conservative Transit culture that only changes every 20 years and is constantly Copying New York's Homework never change /s

theyse are Snowplows in, Chama New Mexico, Banff Alberta, Skagway Alaska, Saint Paul Minnesota, Revelstoke British Columbia, Stratford Ontario, Sand Point Idaho, and Tahoe California

most of these are the VERY fun Rotary Snowplow most of which were Steam Powered (these started to loose Popularity in the 60s and 70s but there are still a few around mainly the Diesel powered ones that BNSF, Union Pacific, and the Alaska Railroad still have, and i think Canadian National has a few stationed in British Columbia) Rotary Snowplows are more efficient at lower speeds and are better in Mountianous area with deep deep snow, whereas the blade style work better at higher speeds and are preffered now, most modern locomotives are fitted with a small for smaller snowdrifts but occusionally they bring out the big guns, now the Rotaries are interesting because while they do have an engine most of them are not self propelled and usually require 2 or 3 locomotives to shove them, they may also need to be Bucked (basically Ramming the Snow) the main places where you are likely to see Rotary snowplows today are Donner pass in California between Sacremento and Reno near Tahoe on the old Overland Route (if you remember learning about the Central Pacific Railroad and the Original Transcontinental Railroad thats this they ran over Donner Pass) you can also find a Steam Powered Rotary Snowplow, Denver & Rio Grande Western OY she is on the 3 foot gauge Cumbres & Toltec Scenic Railroad in Chama New Mexico (my dad said he was gonna take me there and he never did >:[ )

those are the firetubes they carry hot air and gases (not smoke tho steam locomotives only produce smoke if they have incomplete combustion) from the Firebox through the boiler heating up the water to increase its pressure (it only turns to steam when the Throttle or Safety valve is opened this btw is called Flash Boiling, and its one of the basic concepts that the steam engine relies on so you can squeeze as much energy as possible out of the steam)

these is the North American Railroad Network, it is the largest contiguous unified collection of Standard gauge lines in the world (Europe has a denser network but each country built its lines with diffirent Signals, Electrification, Loading gauge, and in the case of Spain and Russia track gauge) what this means is you can move a freight car Churchill Manitoba on Hudson’s Bay all the way down to Oaxaca in Mexico and its all built to mostly the same standards (the track quality will vary quite a bit but it can all accomadate standard freight cars) also as you can see there are a lot of duplicate lines, and keep in mind that they trimmed a lot of the lines, about half of them

oh also Cuba was integrated in this system until the Cuban revolution they had special ferries that moved freight cars over the sea, they also do this in Northern Quebec with the Quebec North Shore & Labrador Railroad and with the Alaska Railroad, and they used to do it with Prince Edward Island, oh also there is a ferry that moves freight cars across the New York Harbor and across the Gulf of Mexico something of note, CITIES ARENT THE ONLY PLACES THAT NEED RAIL, in the early days of Railroads a lot of them were built to serve: Farms, Mines, Oil Fields, Sugarcane Plantations, Ports, Steel Mills, Sawmills, and Logging Camps, Hell some railroads were built specifically to do just one of those, for example the White Pass & Yukon Railroad that ran between Skagway AK and White Horse YT connecting to the Klondike and Yukon rivers the White Pass & Yukon of course opened in 1900 and was closed in 1982 however a large chunk of the Railroad (Skagway to Carcross) was reopened in 1988 as part of the expansion of Tourism in Alaska and is now the busiest Tourist Railroad in the Americas due to its scenic vistas and connection to Alaska Cruise system

oh yeah James J Hill, there are a couple of Statues of him at the University of Washington because he owned the Great Northern Railroad and the Northern Pacific Railroad also Amtrak's Empire Builder Train (Chicago to Seattle) is named after him also his Railroad empire is now Burlington Northern Santa Fe (BNSF) formed from a merger of the Hill companies and the Atchison Topeka and Santa Fe

admittedly the TTC has been in a Period of Stagnation due to funding issues (the City and the Province have been arguing) there was another line supposed to open in the late 2010s but its been plagued by Construction defects and it has yet to open (Line 5 Eglinton)

also issues with Procurement are the main reason the Toronto Subway has been in a period of Stagnation for so long, china is able to get around procurement issues because they do everything at the highest level of Government and have an extremely modular standardized method of building transit that lets them do it very very very cheaply without scimping on quality

oh btw Toronto has more Rail Transit than that

its also crazy because Japan was one of if not the only country that didnt extensively prune its Railway Network after World War 2, compare that to the US which abandoned nearly Half its network and has more Abandoned Rail lines that every other country combined, although i think behind them are Canada and Mexico who also cut a bunch but the United Kingdom, Australia, France, Germany, Russia, South Africa, Brazil, Argentina, etc all cut large amounts as well the UK is pretty famous with their Beeching Cuts

naming locomotives that way was mostly a british thing, when American locomotives were named they either have a nickname like Peaches or are named after place, for example: Eureka, Sonoma, Minnetonka, Kenosha, Ruby Basin, etc there are some with other names like: El Gobernador (Spanish for The Governer), Antelope, Jupiter, or Mastodon (these are the names of some Central Pacific locomotives

similar story for passenger cars however named train services are another matter entirely with things like: The Super Continental, The Overland, The Coast Daylight, The Broadway Limited, The Empire Builder, The California Zephyr, The Sunset Limited, The International Limited, The Montrealer, The Floridian, The City of New Orleans, The Texas Rocket, The Cascadian, The Portland Rose, The Senator, The Spirit of St Louis, The Canadian, The Ocean, The Wolverine, The City of Los Angeles, The Silver Meteor, The Super Chief, and The 20th Century Limited

some of those named Trains youve definetely heard of because Amtrak still does the tradition of naming trains and they kept a lot of the really famous ones although some like the Super Chief and 20th Century limited got combined with other trains and had their names changed, Via Rail also kind of did this with The Super Continental, and The Canadian

Toronto should do it because GO expansion, also the Money should be used to finance an Extension of the Bloor-Danforth line to Mississauga and extensions of the Sheppard line to Scarborough Town center and to Sheppard West to Connect with the University-Spadina line, perhaps with Interlining up to York University, oh and tolls on the 401 could finance upgrades to the Milton line and maybe building a new Orangeville line

There has never been a Direct Train from New York to Los Angeles, you have always had to change trains in Chicago, St Louis or New Orleans, Also building HSR over the Rockies would have minimal benefit for the Amount it costs because its just not Populous Enough to justify all the Tunneling it would require, just start with Chicago to New York and other shorter corridors radiating out of Chicago hell there are already a lot of Railroad lines that are currently abandoned but could be converted into HSR

The Optimal Railroad should not make money, profitability is actually typically an Indicator of Failure a Railroad should spend exactly as much money as it makes if you are making money you should expand using that money and offer unprofitable services to soak up that extra income, this also applies to Electrical Distribution, Steel Making, Telecommunications, Water, and to a degree Agriculture haha infodumped in this Textbox

ok thats the end feel free to copy and paste

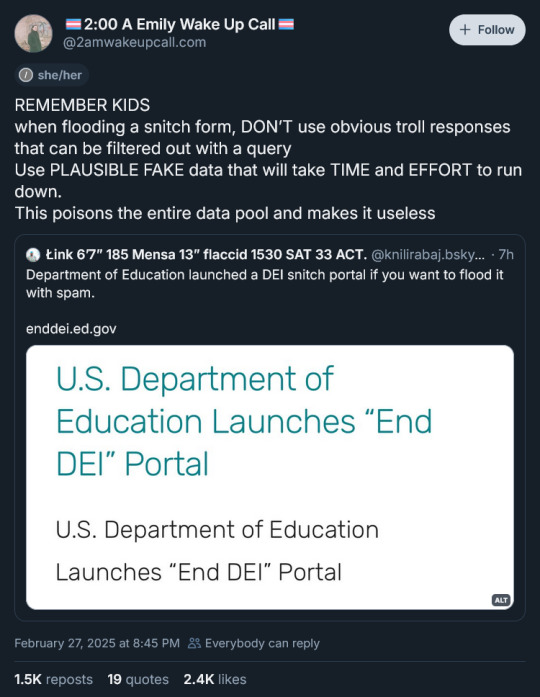

Remember: the more difficult you make it for them to realize a report is false, the more useless you make the portal.

#infodump#infodumping#trolling the republicans#196#r196#stupid long post#stupidly long post#wall of text#long post#trainposting#snitch#spamming the government

78K notes

·

View notes

Text

Enhance Industrial Efficiency with High-Quality Burner Blocks from RefShape

In high-temperature industrial applications, precision and durability are non-negotiable. One of the most crucial components in any furnace or kiln system is the burner block—a refractory product that ensures optimal burner positioning and flame control. As a trusted burner blocks manufacturer, RefShape delivers premium-grade solutions tailored to the rigorous demands of various industries.

What Are Burner Blocks?

Burner blocks are specially engineered refractory shapes designed to house and support industrial burners within kilns, furnaces, and boilers. They play a critical role in:

Maintaining proper burner alignment

Reducing heat loss

Improving combustion efficiency

Withstanding thermal shock and extreme temperatures

By ensuring consistent flame direction and insulation, burner blocks contribute directly to the efficiency and longevity of thermal processing equipment.

Why Quality Burner Blocks Matter

In industries such as steel, glass, cement, and petrochemicals, the performance of burner blocks can significantly influence fuel consumption, product quality, and operational safety. Poor-quality burner blocks may crack under thermal stress, misalign burners, or lead to flame impingement, resulting in unplanned downtime and costly repairs.

That's why choosing a reliable burner blocks manufacturer like RefShape is critical for operational success.

RefShape – Trusted Burner Blocks Manufacturer

At RefShape, we combine deep industry knowledge with advanced refractory engineering to deliver burner blocks that meet the toughest specifications. Here's what sets us apart:

High-Grade Refractory Materials: Our burner blocks are made from alumina, silicon carbide, and other durable materials known for their heat resistance and mechanical strength.

Custom Designs: We manufacture burner blocks in standard and custom sizes to suit all types of burner configurations.

Thermal Shock Resistance: Designed to withstand rapid temperature changes without cracking or degrading.

Precision Manufacturing: Each block is shaped with accuracy to ensure proper burner fit and alignment.

Applications of RefShape Burner Blocks

Our burner blocks are widely used in:

Rotary kilns

Tunnel kilns

Glass melting furnaces

Boilers

Incinerators

Heat treatment furnaces

No matter the industry, RefShape delivers burner blocks that provide stable performance under high thermal loads.

Why Choose RefShape?

As a leading burner blocks manufacturer, RefShape is committed to innovation, quality, and customer satisfaction. We offer:

Competitive pricing

On-time delivery

Expert technical support

Custom manufacturing based on drawings and specifications

Our products are trusted by industries across India and globally for their reliability and performance.

Conclusion

If you're looking for durable, high-performance burner blocks to upgrade your industrial heating systems, RefShape is your ideal partner. With decades of expertise and a reputation for quality, we’re proud to be one of the most reliable burner blocks manufacturers in the market.

Reach out to RefShape today and get burner blocks that fire up your efficiency, not your maintenance costs.

Visit Us https://www.refshape.com/products/

0 notes

Text

Digital Display Potentiometer Market: Regional Demand Analysis and Investment Potential

MARKET INSIGHTS

The global Digital Display Potentiometer Market size was valued at US$ 298.7 million in 2024 and is projected to reach US$ 512.4 million by 2032, at a CAGR of 8.12% during the forecast period 2025-2032.

Digital display potentiometers are electronic components that combine traditional potentiometer functionality with digital interfaces for precise resistance adjustment. These devices enable digital control of analog circuits while providing visual feedback through integrated displays. Key variants include linear potentiometers and rotary potentiometers, catering to different application requirements across industries.

Market growth is driven by increasing automation in industrial equipment, rising demand for precision control in automotive electronics, and the expanding consumer electronics sector. The linear potentiometer segment is expected to reach USD 190 million by 2032, growing at 7.2% CAGR, due to its widespread use in industrial measurement systems. Key players like Bourns and ON Semiconductor dominate the market, collectively holding over 35% revenue share in 2024 through continuous product innovation and strategic partnerships.

MARKET DYNAMICS

MARKET DRIVERS

Rising Automation Across Industries Accelerates Digital Potentiometer Adoption

The global surge in industrial automation is significantly propelling the digital display potentiometer market forward. As manufacturing facilities increasingly adopt Industry 4.0 standards, the demand for precise electronic components like digital potentiometers has grown substantially. These devices provide programmable resistance values with digital precision, making them ideal for automated systems requiring consistent calibration. The industrial automation market, valued in the hundreds of billions globally, continues to expand at a steady pace, directly benefiting component manufacturers. Digital potentiometers offer distinct advantages over mechanical variants including higher reliability, better accuracy, and remote adjustment capabilities—features critically important for modern automated environments.

Consumer Electronics Miniaturization Creates Strong Market Demand

The relentless trend toward smaller, more powerful consumer electronics continues to drive innovations in digital potentiometer design. With smartphone manufacturers packing more functionality into increasingly thinner devices and wearable technology gaining mainstream adoption, component manufacturers are under pressure to deliver smaller form factors without compromising performance. Digital potentiometers perfectly meet these requirements through their compact footprint and elimination of moving parts. Recent product launches demonstrate this trend, with several leading manufacturers introducing surface-mount packages under 2mm²—ideal for space-constrained applications. The consumer electronics sector’s projected growth trajectory suggests this demand will persist throughout the forecast period.

Automotive Electronics Expansion Generates Robust Growth Opportunities

Modern vehicles increasingly rely on sophisticated electronic systems, from infotainment to advanced driver assistance systems (ADAS), creating substantial demand for precision electronic components. Digital display potentiometers find extensive application in vehicle lighting controls, instrument clusters, and various sensor calibration circuits. The automotive industry’s current shift toward electric vehicles presents additional opportunities, as these vehicles require more electronic components than their combustion engine counterparts. With electric vehicle production projected to account for significant percentage of all vehicles manufactured within the decade, component suppliers are strategically positioning themselves to meet this growing demand.

MARKET RESTRAINTS

Persistent Semiconductor Shortages Disrupt Market Stability

The digital display potentiometer market continues to face challenges from global semiconductor supply chain disruptions. While the worst of the chip shortage may have passed, the industry remains vulnerable to supply constraints that impact lead times and pricing. Many digital potentiometer manufacturers rely on specialized fabrication processes that compete for capacity with higher-margin semiconductor products. This situation creates an ongoing challenge for maintaining stable production and delivery schedules. Industry analysts note that while capacity expansions are underway, the market may continue experiencing periodic imbalances between supply and demand through the forecast period.

Cost Pressures from Alternative Technologies Constrain Market Expansion

Digital potentiometers face increasing competition from alternative solutions including digital-to-analog converters (DACs) and programmable gain amplifiers in certain applications. While digital pots offer specific advantages in many use cases, their value proposition comes under scrutiny in cost-sensitive applications. Some system designers are opting for integrated solutions that combine multiple functions, potentially reducing demand for discrete digital potentiometer components. Additionally, continued price erosion across the broader semiconductor sector exerts downward pressure on component margins, challenging manufacturers to maintain profitability while investing in next-generation product development.

Technical Limitations in High-Power Applications Restrict Market Growth

Digital potentiometers typically handle relatively low current and voltage levels compared to their mechanical counterparts, which limits their application in certain industrial and power management scenarios. While recent advancements have improved power handling capabilities, many high-current applications still require traditional solutions. This technical constraint represents a significant barrier to broader market penetration, particularly in heavy industrial equipment and power distribution systems. Manufacturers continue to work on advanced materials and designs to overcome these limitations, but progress remains incremental rather than revolutionary.

MARKET OPPORTUNITIES

Internet of Things Expansion Creates New Application Possibilities

The explosive growth of IoT devices presents significant opportunities for digital display potentiometer manufacturers. These components play crucial roles in sensor calibration and signal conditioning across countless IoT applications, from smart home devices to industrial monitoring systems. As IoT deployments continue multiplying across industries, demand for reliable, low-power electronic adjustment solutions will rise correspondingly. Manufacturers that can deliver highly integrated, energy-efficient solutions tailored for IoT applications stand to capture substantial market share in this expanding segment.

Medical Electronics Advancements Open New Market Frontiers

The medical device industry’s ongoing digital transformation creates promising opportunities for precision electronic components. Digital potentiometers find application in various medical equipment including patient monitoring systems, diagnostic devices, and therapeutic equipment. The medical electronics market’s stringent reliability requirements and relatively high component pricing create favorable conditions for manufacturers able to meet these specialized demands. With healthcare expenditure rising globally and medical technology advancing rapidly, this vertical represents a high-growth opportunity for digital potentiometer suppliers.

Emerging Smart Infrastructure Projects Fuel Component Demand

Government initiatives worldwide to develop smart cities and modernize infrastructure are generating demand for advanced electronic components. Digital potentiometers play important roles in smart grid equipment, intelligent lighting systems, and various monitoring and control applications. These large-scale infrastructure projects typically have long implementation timelines but offer stable, multi-year demand for components. Manufacturers that can demonstrate the reliability and longevity required for infrastructure applications stand to benefit from this growing market segment.

MARKET CHALLENGES

Design Complexity Increases Time-to-Market Pressures

As digital display potentiometers incorporate more advanced features and tighter specifications, their design complexity has increased significantly. Many newer models include integrated non-volatile memory, precision voltage references, and sophisticated interfaces—features that add development time and cost. This complexity creates challenges in maintaining competitive product cycles while ensuring robust performance across environmental conditions. The market’s demand for both higher functionality and faster product introductions presents a persistent challenge for engineering teams.

Global Economic Uncertainty Impacts Investment Decisions

The digital display potentiometer market faces headwinds from broader economic conditions that affect capital expenditure across key industries. With manufacturers and OEMs becoming more cautious about inventory levels during periods of economic uncertainty, component suppliers experience greater volatility in order patterns. These fluctuations complicate production planning and capacity investment decisions. While the long-term growth outlook remains positive, navigating near-term economic cycles presents an ongoing challenge for market participants.

Environmental Regulations Require Continuous Compliance Efforts

Increasing environmental regulations regarding materials and manufacturing processes create compliance challenges for digital potentiometer manufacturers. Restrictions on hazardous substances and requirements for energy efficiency continually evolve, requiring regular product redesigns and process adjustments. Meeting these requirements across global markets with varying standards adds complexity to product development and supply chain management. While environmental responsibility represents an industry-wide priority, the associated compliance costs and technical challenges impact profitability and time-to-market for new products.

DIGITAL DISPLAY POTENTIOMETER MARKET TRENDS

Integration of Smart Automation Technologies Driving Market Adoption

The digital display potentiometer market is experiencing significant growth due to advancements in smart automation technologies across various industries. These sensors, which combine mechanical potentiometers with digital displays for precise electrical resistance measurement, are increasingly replacing traditional analogs due to their programmable nature and higher accuracy. With industrial automation investments projected to grow at nearly 10% annually, demand for digital potentiometers as critical components in control systems has surged. Major manufacturers are responding with compact designs featuring enhanced functionalities like touch-based interfaces and wireless connectivity options.

Other Key Trends

Consumer Electronics Miniaturization

As consumer electronics manufacturers push for increasingly compact devices without sacrificing functionality, digital display potentiometers have emerged as ideal solutions for space-constrained applications. Their ability to provide both measurement and visual feedback eliminates the need for separate display components in products like smartphones, wearables, and portable audio equipment. Recent innovations include ultra-thin models measuring under 2mm in thickness, addressing the needs of next-generation foldable devices and IoT sensors.

Automotive Sector Innovation Creates Demand

The automotive industry’s shift toward electrification and advanced driver assistance systems (ADAS) has significantly impacted market dynamics. Digital potentiometers are increasingly used in vehicle control modules, battery management systems, and cabin comfort controls due to their durability and precision in harsh environments. With electric vehicle production expected to grow by over 30% annually through 2030, component manufacturers are developing specialized automotive-grade potentiometers meeting stringent vibration and temperature requirements. The convergence of display and control functionality also supports the trend toward centralized vehicle control interfaces.

Wireless Connectivity Integration Reshaping Product Development

Leading manufacturers are incorporating wireless technologies such as Bluetooth and Zigbee into digital display potentiometer solutions, enabling remote monitoring and adjustment applications. These networked systems are particularly valuable in industrial settings where operators need to monitor multiple sensors across large facilities. The integration of Industry 4.0 compatible communication protocols has further accelerated adoption in smart manufacturing environments. Recent product launches feature cloud connectivity options that allow potentiometer adjustments through web-based dashboards, significantly expanding potential applications.

Other Emerging Trends

Healthcare Equipment Modernization

Healthcare’s increasing reliance on precise electronic instrumentation is creating new opportunities in medical device applications. Digital display potentiometers are being incorporated into imaging equipment, patient monitors, and laboratory instruments where their combination of control and visualization enhances operational efficiency. Stringent regulatory requirements are prompting manufacturers to develop specialized medical-grade variants with enhanced sterilization compatibility and electromagnetic shielding.

Material Science Innovations Addressing Temperature Constraints

The push for wider operating temperature ranges is driving material innovations in resistive element production. New nano-composite materials allow digital potentiometers to maintain accuracy across extreme temperature variations from -55°C to 150°C, expanding their use in aerospace and oil/gas applications. These advancements come alongside improvements in mechanical durability, with some models now rated for over 500,000 adjustment cycles while maintaining measurement precision within 1% of full scale.

COMPETITIVE LANDSCAPE

Key Industry Players

Market Leaders Focus on Innovation and Regional Expansion to Gain Competitive Edge

The global digital display potentiometer market exhibits a fragmented competitive landscape, characterized by the presence of established electronics component manufacturers and emerging regional players. Bourns Inc. currently leads the market, holding an estimated 22% revenue share in 2024, owing to its extensive product range and strong distribution network across North America and Asia-Pacific. The company’s recent introduction of high-precision digital potentiometers with I²C interface has further strengthened its position in industrial automation applications.

ON Semiconductor and CURTISS-WRIGHT collectively account for nearly 30% of the market, primarily due to their vertically integrated manufacturing capabilities and contracts with major automotive OEMs. Notably, ON Semiconductor’s 2023 acquisition of GT Advanced Technologies enhanced its silicon carbide production capacity, allowing for more robust potentiometer designs.

Meanwhile, mid-sized players like ETI Systems are gaining traction through specialization – their ruggedized potentiometers for harsh environments have seen 18% year-over-year growth in military and aerospace sectors. Hohner Automaticos continues to dominate the European market with customized solutions, while Electro-Sensors maintains strong relationships with industrial equipment manufacturers through just-in-time delivery systems.

The competitive intensity is expected to increase as Chinese manufacturers enter the space with cost-competitive offerings, prompting established players to accelerate R&D in smart potentiometer technologies. Several companies are now integrating IoT capabilities into their products, with Bourns and ON Semiconductor leading this transition through partnerships with cloud platform providers.

List of Key Digital Display Potentiometer Manufacturers

Bourns, Inc. (U.S.)

ON Semiconductor (U.S.)

CURTISS-WRIGHT (U.S.)

ETI Systems (UK)

Hohner Automaticos (Spain)

Electro-Sensors (U.S.)

Ametek, Inc. (U.S.)

TT Electronics (UK)

Vishay Intertechnology (U.S.)

Segment Analysis:

By Type

Linear Potentiometer Segment Dominates the Market Due to High Precision in Industrial Applications

The market is segmented based on type into:

Linear Potentiometer

Subtypes: Slide Potentiometers, Multi-Turn Linear Pots, and others

Rotary Potentiometer

Subtypes: Single-Turn Rotary Pots, Multi-Turn Rotary Pots, and others

By Application

Industrial Equipment Segment Leads Due to Growing Automation Needs

The market is segmented based on application into:

Household Appliances

Automotive

Industrial Equipment

Communications

Others

By End-User

Manufacturing Sector Accounts for Major Usage Due to Process Control Requirements

The market is segmented based on end-user into:

Electronics Manufacturers

Automotive OEMs

Industrial Machinery Producers

Telecom Equipment Providers

Others

Regional Analysis: Digital Display Potentiometer Market

North America The North American digital display potentiometer market is characterized by advanced technological adoption and strong demand from key industries such as automotive, industrial automation, and communications. The U.S. holds the largest market share in the region, driven by heavy investments in Industry 4.0 and smart manufacturing, projected to exceed $15 billion annually by 2025. Major players like Bourns and ON Semiconductor dominate supply chains, focusing on high-precision, low-noise potentiometers for critical applications. However, competition from Asian manufacturers and pricing pressures remain notable challenges. Despite this, stringent quality standards and the push toward IoT integration continue to fuel demand for premium-grade digital potentiometers.

Europe Europe’s market thrives on strict regulatory compliance (e.g., RoHS and REACH) and an emphasis on energy-efficient solutions. Germany leads in demand, particularly for industrial equipment and automotive applications, where digital potentiometers are used in sensor calibration and motor control. The region benefits from collaborations between semiconductor firms and automotive OEMs, with companies like ETI Systems and Hohner Automaticos expanding production capacities. However, high manufacturing costs and slow adoption rates in Eastern Europe offset growth to some extent. The European Commission’s Digital Compass 2030 initiative, which prioritizes industrial digitization, is expected to further propel market expansion.

Asia-Pacific With China alone accounting for over 35% of global production volumes, Asia-Pacific remains the fastest-growing region. The surge is attributed to massive electronics manufacturing ecosystems in China, Japan, and South Korea, alongside government-backed semiconductor self-sufficiency programs. India’s market is expanding due to automotive and consumer electronics growth, though it lags in high-end applications. Cost competitiveness drives the preference for mid-range rotary potentiometers, but demand for linear variants is rising in robotics and automation. Challenges include intellectual property concerns and supply chain bottlenecks, yet the region’s export-oriented manufacturing hubs ensure sustained dominance.

South America This region exhibits moderate growth, primarily fueled by Brazil’s automotive and appliance sectors. Local production is limited, leading to heavy reliance on imports from North America and Asia. Economic instability and currency fluctuations deter large-scale investments, though niche applications in renewable energy systems present opportunities. Argentina shows potential in industrial equipment repairs, but infrastructural gaps and low R&D spending hinder progress. Vendors targeting this market prioritize cost-efficient, durable solutions to align with regional budget constraints.

Middle East & Africa The market here is nascent but promising, with growth centered in GCC countries and South Africa. The UAE and Saudi Arabia drive demand through infrastructure modernization projects, particularly in oil & gas and telecommunications. However, lack of local manufacturing forces reliance on global suppliers, increasing lead times and costs. Africa’s adoption is sporadic, hindered by limited technical expertise and underdeveloped electronics sectors. Long-term growth hinges on foreign investments in smart city initiatives, though progress remains uneven.

Report Scope

This market research report provides a comprehensive analysis of the Global Digital Display Potentiometer market, covering the forecast period 2024–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The Global Digital Display Potentiometer market was valued at USD XX million in 2024 and is projected to reach USD XX million by 2032, growing at a CAGR of X%.

Segmentation Analysis: Detailed breakdown by product type (Linear Potentiometer, Rotary Potentiometer), application (Household Appliances, Automotive, Industrial Equipment, Communications, Others), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. The U.S. market size is estimated at USD XX million in 2024, while China is projected to reach USD XX million.

Competitive Landscape: Profiles of leading market participants including Bourns, ETI Systems, CURTISS-WRIGHT, Hohner Automaticos, Electro-Sensors, and ON Semiconductor, covering their product portfolios, market share, and strategic developments.

Technology Trends & Innovation: Assessment of digital potentiometer technologies, integration with IoT systems, and advancements in precision control applications.

Market Drivers & Restraints: Evaluation of factors such as increasing automation demand, growth in consumer electronics, along with challenges like supply chain constraints and pricing pressures.

Stakeholder Analysis: Strategic insights for component manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

I forget his name but there was a guy who invented a hybrid car engine that ran on water (relatively small rechargeable battery, or extremely small propane generator needed to provide power for electrolysis, split the water then run the resulting O/2H gas through a belt-powered compressor, before injecting into the combustion chamber. No need for an air intake. works best on rotary-style engines. Achieves 100% combustion with the only exhaust product being water. With the propane generator it turns the co2 emissions of a normal car (in "person breathing out co2 while jogging per car exhaust co2" equivalent units) from "25 people jogged that distance" to "4 people jogged that distance") who "mysteriously went missing" after he announced his work on some forum somewhere.

"Marcille is blaspheming the Almighty Christian God with her evil Black Magic!" there is zero mention of any gods in Dungeon Meshi, everyone who expresses shock at her actions never brings up religion as a reason for why her actions are unethical.

Marcille is a mad scientist committing medical malpractice in a desperate attempt to save her lover. She's grafting dragon meat onto Falin's skeleton which turned her into an unbalanced chimera hybrid with a mouth too small to feed its body. She rapid-heals her friends without anesthetic and later admits healing magic has been used in torture techniques.

Marcille is a mad scientist. She's a gay Dr. Frankenstein. She's like if Gregory House were Italian.

14K notes

·

View notes

Text

Making Screw Air Compressors Oil-free

It might be hard to believe but air compressors have been around for thousands of years. The earliest known compressors were bellows, used to blow compressed air into furnaces to stoke up the heat, thereby allowing ancient men to produce stronger and better metals for tools and weapons. >

Following the invention of steam engines, they became a popular method to power air compressors. Subsequently, Internal Combustion (IC) engines began to be used as a power source for operating reciprocating air compressors. Later, as larger industries were established, they demanded more efficient compressors capable of running with minimal maintenance and for longer periods. A rotary air compressor was the answer. Both these types of compressors continued to evolve over time and today, they are both highly efficient and technologically well advanced. Conventional reciprocating air compressors though have certain innate limitations; most notable being that the oil used for lubrication is carried along with the compressed air. Filtering removes much of the oil but not all of it. For example; pre-filters, high efficiency coalescing filters and activated carbon filters remove trapped oil to a great extent.

Oil-free compressed air solutions are used extensively in the pharmaceutical, textile & automotive industries.

But these filters themselves have characteristic limitations. For instance, above 20°C, coalescing filters do not remove fine oil vapours, leaving very fine particles of residual oil in the form of aerosols; and activated carbon filters are not usable at filtration temperatures above 40ºC because the carbon then absorbs the oil vapour, gets saturated, and becomes ineffective. And, filtration itself raises another problem: safe disposal of used filters to avoid environmental contamination. Notwithstanding the environmental issue however, there are several industrial applications that require compressed air that is completely oil-free. Food and beverage, pharmaceuticals, electronics, automotive painting, textiles, paper and cosmetics are typical examples. These applications demand wide operating temperatures of 0-45°C, stringent air purity standards higher than ISO 8573-Class I, high levels of safety, eco-friendly operation and some more. Even the most advanced filtration technology falls short of meeting such exceptional standards of air purity.

Plainly, lubricated compressors were not the answer. It required a radically new technology of air compression. Enter oil-free screw air compressors.

ELGi’s Screw Compressors are designed to save energy and ensure long life.

This inventive machine uses no lubricating oil in the compression chamber and hence delivers compressed air with practically no trace of oil. Additionally, because of the continuous sweeping motion of the screws – two meshing helical screws known as rotors, driven by a pair of timing gears – there is very little pulsation or surging of flow, which occurs with piston compressors. Screw compressors thus deliver smooth, pulse-free compressed air. They also tend to be compact and run smoothly with minimal vibration. Since they also employ a more efficient compression system, they not only reduce energy costs but also enable precise adaptation to end-user requirements based on careful study and analysis of their critical processes and customising with a controlled, total compressed air system, thereby also improving productivity.

Despite all its apparent advantages, oil-free screw air compressors continued to face technological and manufacturing challenges, especially pertaining to the problem of overheating due to the absence of lubricating oil in the compressor chamber. Furthermore, despite being oil-free, there was still the need for filtration as hydrocarbons and other contaminants ingested from the ambient air required to be removed prior to the point-of-use. All this began to affect their popularity to some extent. However, this also prompted a new development: oil began to be injected into the compression cavities to not only aid sealing but also provide a cooling sink for the heat of compression.

In this so-called ‘oil-flooded’ rotary screw compressor, the oil was then separated from the compressed air, cooled, filtered and recycled. The injected oil not only helped in lowering the compression temperature but also captured extraneous particulates from the incoming air, thus effectively reducing the particle loading of subsequent air filtration. Having thus overcome the initial problems that oil-free compressors faced, there was a shift from oil-free to oil-flooded compressors, which then gained popularity.

Oil-Free Two Stage: Air-Cooled Model

But the need for a completely oil-free compressor remained. This was felt keenly in industrial applications where even traces of oil in processed air could be disastrous. For instance, even minute particles of oil in precision electronic circuitry or critical semiconductor components can play havoc with electronic gadgets. Lube oil traces in processed food and beverages mean serious health risks. Pharmaceutical applications demand pristine air too. It is the same with paper mills, textiles, high-gloss painting of automobiles and many others. While Western countries had strict regulations governing the purity of air used in such critical applications, Asian countries including India and China had less stringent rules. But it was only a question of time before they too fell in line. And, although industries continued to rely on filtration to get rid of the entrapped oil, complex filtration equipment added to the cost, created air pressure drops and still did not deliver 100% oil-free air. At ELGi, this presented a situation ripe with potential.

Oil-Free Two Stage: Water-Cooled Model

ELGi embarked on developing the oil-free screw air compressor by obviating the need for oil as a medium to carry away the heat of compression. By early 2005, the first prototype was assembled and tested. And by early 2008, a test compressor was commissioned at a user’s facility for validation. Next year five more were commissioned at different locations. These models completed 10,000 hours of validation. Regular sales began by early 2011. Today, ELGi’s in-house oil-free technology with inter-cooler has been validated in demanding industrial applications for over 150,000 cumulative hours.

Inside the ELGi factory

The fully-packaged ELGi-NE series has models with high volumetric efficiency that deliver from 500 to 1800 cfm (cubic feet per minute) and pressures of up to 10 bars (kg/cm2.) Incorporating superior safety norms, these models not only have low energy losses and low air outlet temperatures but are also energy efficient and compact.

They employ two-stage compression with external water jacket inter-cooling, a unique eta-V profile rotor enabling high swept volume, low operating noise and low vibration achieved by combining radial roller bearings and 4-point axially loaded ball bearings. Innovative features like carbon impregnated SS air seals, helical grooved non-contact bronze oil seals and high-performance Visco-seals at suction and discharge rotor ends, an ingenious process of PTFE and PFA (Teflon) dry lubricant coating on carbon steel rotors, an efficient helix-angled timing gear and robustly designed cupro-nickel intercooler and after cooler, heat exchangers offering superior corrosion resistance and finally optimally designed capacity control valves; all ensure not just high efficiency but safety, durability, easy maintenance and low operating cost.

Compression is also very efficient on account of the precise clearances maintained between the helical rotors and the compression chamber, thanks to the unique eta-V profiles designed by ELGi. This rotor design reduces pressure losses and increases stage efficiencies, leading to an overall increase in adiabatic efficiency.

ELGi builds its own rotor milling machines to ensure quality rotors with lowest manufacturing cost.

Only a handful of companies in the world have this design capability. It is to be noted however, that though the machine is termed an oil-free screw compressor, it applies to only the screw chamber that forms the air compression cavity. Oil is nevertheless used in the machine – to lubricate a slew of components like the capacity control valves, air-end bearings, the timing gears and the air-end stage gear. So even though the rotors and the screw chamber do not use any lubricating oil, there is nevertheless an oil circuit comprising the oil pump, cooler, filter and oil sump. Similarly, there is also a water circuit that supplies cooling water to the intercooler, after cooler, and the 1st and 2nd stage air-ends. For ELGi, this development has been a rewarding experience. Industry watchers have it that globally, ELGi is one of only 5 corporate companies to design and manufacture oil-free air-ends.

0 notes

Text

Automotive Gear Shift System Market Drivers Influencing Advanced Technological Integration Worldwide

The automotive gear shift system market is evolving rapidly due to several dynamic drivers, including automation, electric mobility, and fuel efficiency improvements.

Rising Demand for Automatic Transmission Vehicles One of the primary drivers of the automotive gear shift system market is the increasing global preference for automatic transmission vehicles. Consumers are prioritizing comfort and ease of driving, particularly in urban environments with heavy traffic. As a result, manufacturers are shifting their focus toward producing more vehicles equipped with automatic transmission systems. The gear shift systems in such vehicles require precise design and functionality, propelling the demand for electronic and mechatronic gear shift technologies. North America and Asia-Pacific are seeing significant adoption, with more than 65% of new cars in these regions adopting automatic transmission systems, thus directly boosting gear shift system sales.

Booming Electric Vehicle Segment Driving Gear System Redesign Electric vehicles (EVs) are reshaping the traditional automotive transmission landscape. Although EVs generally use simpler transmission setups than internal combustion engines, the need for efficient torque delivery, compact system design, and low maintenance continues to drive innovation in gear shift systems. EV makers are increasingly integrating electronic gear shifters and drive-by-wire systems to match modern design aesthetics and functional demands. With global EV sales surpassing 10 million units in 2024, the ripple effect on the gear shift market is both profound and transformative, particularly in terms of software integration and control precision.

Adoption of Shift-by-Wire Technology as a Performance Enabler Shift-by-wire systems are gaining popularity due to their performance benefits and space-saving design. This technology eliminates the need for mechanical linkages and replaces them with electronic signals to control gear selection. It allows for smoother shifting, reduced weight, and enhanced safety features, such as automatic park mode and driver assistance integration. Automakers are aggressively incorporating shift-by-wire systems in mid- and high-range models, especially in electric and hybrid vehicles, contributing significantly to the growth of the market. The flexibility of this system also opens the door for innovative cabin designs and improved ergonomics.

Stringent Emission Norms and Fuel Efficiency Regulations Regulatory mandates to curb vehicle emissions and increase fuel efficiency are pushing automakers to focus on optimizing every component, including gear shift systems. Advanced gear shift mechanisms enable quicker, more accurate gear changes, which reduce engine strain and enhance fuel economy. Dual-clutch transmissions (DCT) and continuously variable transmissions (CVT) are gaining traction due to their ability to maintain optimum engine performance. These technologies depend heavily on sophisticated gear shift systems, making them a key factor in compliance with global regulatory standards. The trend is especially pronounced in Europe, where CO2 regulations continue to tighten year over year.

Consumer Demand for Enhanced Driving Experience Modern consumers seek not just performance but also a seamless driving experience. Gear shift systems play a central role in delivering that expectation. The tactile feedback, noise reduction, and responsiveness of gear shifters contribute to overall vehicle satisfaction. As a result, OEMs are focusing on enhancing user interface and feedback mechanisms within gear shift systems. Whether it’s the sporty paddle shifters or luxury-inspired rotary dials, gear shift innovation has become a significant value proposition in vehicle marketing.

Integration of AI and Connected Vehicle Technology With vehicles becoming increasingly connected and intelligent, gear shift systems are also evolving. Artificial intelligence (AI) and machine learning are being integrated to predict driving behavior and automatically adjust gear shifts for optimal performance and efficiency. This is particularly relevant for commercial fleets and high-end passenger vehicles. AI-enabled shift strategies not only improve driving comfort but also contribute to reduced wear and tear on transmission systems. These smart gear shift systems are becoming a differentiator in a competitive automotive landscape, especially in regions investing heavily in smart mobility.

OEM and Tier 1 Supplier Collaborations Boosting Innovation Collaborations between automakers and component suppliers are another driver fueling advancements in gear shift systems. Tier 1 suppliers are investing in R&D to develop modular gear shift solutions that can be customized across vehicle platforms. These partnerships ensure quicker deployment of advanced technologies, especially in electric and hybrid vehicle segments. For example, major OEMs are working with suppliers to co-develop compact and integrated shifter units that are lighter, more durable, and offer multifunctionality, aligning with the industry's shift toward modular vehicle architectures.

Growing Popularity of SUVs and Luxury Vehicles The rising sales of SUVs and luxury vehicles globally are indirectly boosting the gear shift system market. These vehicles often come equipped with sophisticated transmission systems that require equally advanced gear shifting solutions. Premium features such as illuminated gear knobs, customizable shift modes, and seamless transition between gears enhance the appeal of such vehicles. In luxury segments, gear shift systems are not only functional but also a symbol of technological elegance, further driving demand for innovation.

Globalization of Automobile Manufacturing As automotive production becomes increasingly globalized, with manufacturing units spread across continents, the demand for standardized yet adaptable gear shift systems is growing. Manufacturers seek scalable and flexible solutions that can be tailored to regional preferences and regulatory requirements. This globalization trend supports the mass adoption of modular gear shift systems that reduce production costs and speed up market entry, especially in emerging economies like India, Brazil, and Southeast Asia.

Conclusion The automotive gear shift system market is driven by a multifaceted array of factors ranging from technological innovation to consumer expectations and regulatory mandates. As electric mobility, automation, and connectivity continue to evolve, gear shift systems will remain a vital component in defining vehicle performance, safety, and user experience.

0 notes

Text

Heat Master International is the leader in thermal technology, providing a complete range of industrial heating products and integrated turnkey solutions to address sophisticated process demands in numerous industries. The company's vast product portfolio is based on precision engineering, premium materials, and creative design to deliver longevity, energy efficiency, and dependable performance.

Mica Band Heaters and Ceramic Band Heaters are crucial heater elements provided by Heat Master International for plastic processing and extrusion uses. Mica band heaters enjoy superior heat transfer characteristics and space-saving design, and ceramic band heaters are suited for high-temperature uses with better insulation and energy efficiency.

Powder Coating Ovens are meticulously designed to achieve consistent curing action for coatings used in automotive, metal fabrication, and appliance applications. These ovens are offered in batch or continuous conveyor configurations and are engineered to distribute air and temperature consistently.

Calorifier Heaters, which are utilized for water heating and storage systems, are produced with great accuracy and engineered to achieve heat exchange efficiently in commercial and industrial hot water systems. These devices are engineered to be resistant to high pressure and are applicable for steam, hot water, or electric heating sources.

Industrial Immersion Heaters and Tubular Heaters by Heat Master International are designed to address challenging heating applications in liquids, oils, and chemical solutions. Industrial Immersion Heaters and Tubular Heaters are durable, corrosion-resistant, and can be made according to specifications regarding sheath material, mounting style, and wattage ratings.

Nozzle Heaters are miniature heat solutions for injection molding equipment, providing quick heat-up times and accurate temperature control. Constructed with high-quality resistance wire and insulation, these heaters provide consistent heat transfer and extended service life.

The firm also produces Duct Heaters, which are used extensively in HVAC applications and industrial air heating. The heaters come in flanged or slip-in styles and can be ordered with airflow capacity, voltage, and control options tailored to a user's requirement.

Heat Master International also offers Gas-Fired Pit Furnaces, which are suitable for heat treatment applications including annealing, tempering, and hardening. They are intended for deep chamber applications and come with sophisticated combustion systems to provide consistent heating and fuel economy.

For rotary-based processes, the company provides Rotary Kilns with Direct Firing Systems ideal for calcination, pyrolysis, and material processing in cement, ceramic, and chemical industries. The kilns are designed using heat-resistant materials and are developed to achieve high thermal efficiency and controlled processing.

Roller Hearth Furnaces are another technological solution, used for continuous heat treatment processes. They provide even throughput and temperature stability, and these furnaces are suited for the automotive part, bearing, and precision component industries.

In material heating solutions, Casting Heaters provide even heat for mold and die casting processes. These heaters can be offered in many configurations and materials to provide efficient heat in high-temperature applications.

Heat Master International also specializes in Material Handling Systems and Process Equipment integration, which involves ensuring smooth coordination between heat systems and manufacturing lines. The systems are built to be reliable, automated, and safe through multiple levels of production.

Being a Turnkey Project provider, the company provides integrated end-to-end solutions – from design, engineering, and manufacturing to installation and commissioning. Such projects are customized for industries like metallurgy, petrochemicals, pharmaceuticals, and food processing, with an aim to provide clients with optimized, ready-to-use systems in minimal lead time.

0 notes

Text

drones

As we know, Drones have a wide variety of sizes, forms, configurations, and features. VTOL drones are the latest innovation in the drone industry and are rapidly gaining popularity as a flying trend. They have specific features that are beneficial to various enterprises. Do you want to know what does VTOL stand for? This article helps you to know in detail about VTOL, its features, types and how they work.

What are VTOL Drones?

The VTOL refers to Vertical Take-Off and Landing, a drone that can take off and land vertically without using a runway. It is widely recognized that VTOL UAVs can cover long distances with efficiency and flexibility. VTOL drones can fly anywhere at any time. At present, VTOL drones are in use in several industrial fields such as surveying, mapping, surveillance etc.

Features of VTOL Drones:

When using VTOL drones we will come to know that this drone has many advantages. The best feature of this drone is that it can fly smoothly with less takeoff space. In general everything has two sides. Though the VTOL UAV has many advantages, it must also have relative disadvantages and we will get to learn in detail below.

Advantages of VTOL Drones:

The following list of noteworthy advantages of VTOL drones will help you in making your decision.

1. Mission flexibility: VTOL drones save space and are not limited by geography since they do not require a runway to take off.

2. Versatility: The VTOL UAV has almost no operational limitations and is widely used in a variety of sectors like mapping, surveying, and surveillance.

3. Efficient maneuverability: VTOL drones are said to be more maneuverable because of their ability to adjust the relative speed of each rotor that changes the thrust and torque.

4. High agility: When compared to that of the traditional air vehicles, VTOL drones show exceptional agility and high cruising speed.

Disadvantages of VTOL Drones:

After knowing about the advantages of VTOL, you might be eager to get your own VTOL drone. But please take your time. Let’s look into the disadvantages of using them for VTOL UAVs. Then, it will help you in making a choice.

1. Limited payload: The aircraft’s weight is gradually increased by the VTOL system, thereby it limits the amount of payload which can be carried.

2. Complex system: The complexity of VTOL systems is greater than that of the traditional UAV systems. They are more difficult to operate since they need sophisticated technologies like lift systems and multiple engines.

3. High consumption: VTOL drone consumers require more energy even if it is for eVTOL UAV or fuel VTOL UAV which makes them expensive to operate and maintain.

4. Noise: VTOL aircraft are typically noisier than that of conventional drones because of their larger size and multiple engines.

Types of VTOL Drones:

There are many types of VTOL drones, and each drone has a unique set of classification. VTOL drones are generally classified based on their design, propulsion, and flight mode.

1. Types of VTOL Drones According to Propulsion:

Propulsion by engine: There are different kinds of VTOL drones, but the most common types included are rotary, gas/combustion turbine, reciprocating engines etc.

To convert pressure into rotational power, a reciprocating engine uses piston movement

The pressure generated by burning fuel is used by gas/combustion turbine engines for producing thrust and encouraging turbine movement.

A rotating engine has the engine’s rotor which travels between chambers, making the gas expand and contract.

Propulsion by motor: We are familiar with motor-powered VTOL drones as motor power is used in various drone applications. Three different motor types are battery-powered, hybrid, and solar-powered.

Solar-powered motors do not depend on fuel or batteries to power themselves; instead, they use solar energy.

In Battery-powered motors, batteries are generally used to power the drone motors.

Hybrid motors use various energy sources as the majority are powered by fuel and electricity.

2. Types of VTOL Drones According to Flight Mode:

We can classify VTOL drones according to their flight mode as mentioned below:

Conventional landing and takeoff (CTOL): By using conventional flight modes, such as normal fixed-wing UAVs and hybrid vertical takeoff and landing, CTOL has greater requirements for the takeoff environment and requires large space during takeoff than VTOL.

Short take-off and landing (STOL):It is almost identical to a conventional flight mode but uses a shorter runway for takeoff and landing, making it suitable for distant locations with limited space.

Short takeoff and Vertical landing(STOVL):It takes off from the short runways to enable vertical landing, because it hardly takes off vertically.

Vertical or short take-off and landing (V/STOL):When Compared to short takeoff and vertical landing, vertical or short take-off and landing (V/STOL) allows for both vertical and vertical landings over the short runways.

3. VTOL Drone Types According to Design:

According to their designs, VTOL drones are primarily divided into two main types, they are Power lift drones and Rotorcraft drones.

Rotorcraft Drones: These types of drones use propellers to get into complete flight. Generally, a propeller is connected to the motor. When compared to fixed wing drones, they are more efficient and have a wider range.

Power lift drones: Power lift drones take off and land vertically by using engine power unlike rotorcraft drones.

How do VTOL Drones Work?