#Rotating Shaft Tube Cleaning Machine

Explore tagged Tumblr posts

Text

Hydrojetenergy: Rotating Shaft Tube Cleaning Machine Provider

Hydrojetenergy proudly presents its cutting-edge Rotating Shaft Tube Cleaning Machine, designed to revolutionize industrial cleaning processes. This innovative machine offers unparalleled efficiency and effectiveness in removing stubborn deposits and contaminants from tubes and shafts.

With its advanced rotating shaft technology, this cleaning machine ensures thorough and precise cleaning, even in hard-to-reach areas. Engineered with precision and reliability in mind, Hydrojetenergy's Rotating Shaft Tube Cleaning Machine is the ideal solution for industries requiring meticulous cleanliness, such as manufacturing, power generation, and petrochemical plants.

Visit for more info : https://www.hydrojetindia.com/manufacturers/rotating-shaft-tube-cleaning-machine.html

Address:Hydro Jet Energy, 29/2, Parishikhar Cottage Industrial Estate, Near Ramol Toll Plaza, SP Ring road, Ramol, Ahmedabad-382449,Gujarat,India

Mail : [email protected]

Phone no: 8686862582

0 notes

Text

Essential Components for Crushing and Milling Equipment: A Detailed Overview

In the industrial and mining sectors, the efficiency and longevity of machinery depend heavily on the quality of its components. This guide explores key parts and accessories for crushing and milling equipment, including cone crusher parts, jaw crusher parts, impactor blow bars, vertical roller mills rollers or tires, hammer mills hammers, wear blocks, cutting edges, storage shelters, stretch hood tubes, and general crusher parts.

Cone Crusher Parts

Cone crushers are used extensively in various industries for secondary and tertiary crushing. Key parts include the mantle, concave, main shaft, and bushings. These components are essential for the efficient functioning and durability of the machine. High-quality materials and precision engineering ensure that cone crusher parts can withstand the high levels of pressure and abrasion they encounter during operation.

Jaw Crusher Parts

Jaw crushers are primary crushers widely used in mining and aggregate production. Important parts include jaw plates, toggle plates, and cheek plates. These components play a critical role in breaking down large rocks into smaller, manageable pieces. Durability and strength are crucial for jaw crusher parts to handle the constant impact and wear they endure.

Impactor Blow Bars

Impactor blow bars are vital for impact crushers, which are used to crush materials by striking them with high-speed rotating bars. These bars must be tough and wear-resistant to handle the intense impact and abrasion. High-chrome and manganese steel blow bars are commonly used for their durability and ability to provide a consistent crushing performance.

Vertical Roller Mills Roller or Tire

Vertical roller mills are used in the cement and mining industries to grind raw materials. The rollers or tires are critical components that apply pressure to the material being ground. These parts must be made from wear-resistant materials to ensure longevity and efficiency. Proper maintenance and timely replacement of rollers or tires can significantly enhance the performance of vertical roller mills.

Hammer Mills Hammers

Hammer mills are used to crush and pulverize materials in various industries. The hammers, which repeatedly strike the material, must be robust and wear-resistant. Alloy steel or manganese steel hammers are commonly used due to their high impact resistance and durability. Regular inspection and replacement of hammers are essential for maintaining the efficiency of hammer mills.

Wear Blocks

Wear blocks are protective components used in various types of crushing and milling equipment to prevent excessive wear and extend the lifespan of the machinery. They are often made from hardened steel or other wear-resistant materials. Proper installation and regular monitoring of wear blocks can help reduce maintenance costs and downtime.

Cutting Edge

Cutting edges are critical for earthmoving and construction equipment, such as bulldozers and graders. These parts are designed to withstand high levels of stress and abrasion while maintaining a sharp edge. High-carbon steel and carbide-tipped cutting edges are popular choices due to their durability and cutting efficiency.

Storage Shelter

Storage shelters are essential for protecting machinery and equipment from the elements. These structures can significantly extend the lifespan of equipment by shielding it from rain, snow, and UV radiation. Properly designed storage shelters also help in maintaining a clean and organized work environment.

Stretch Hood Tube

Stretch hood tubes are used in packaging to secure and protect products during transportation and storage. They provide a tight and secure cover, which helps in preventing damage and contamination. Stretch hood tubes are widely used in various industries, including construction, agriculture, and manufacturing.

Crusher Parts

General crusher parts encompass a wide range of components used in various types of crushers, including jaw crushers, cone crushers, and impact crushers. These parts include bearings, shafts, liners, and gears. High-quality crusher parts are crucial for the reliable and efficient operation of crushing equipment. Regular maintenance and timely replacement of worn-out parts can prevent breakdowns and extend the service life of crushers.

Understanding the essential components of crushing and milling equipment and their respective roles is crucial for maintaining efficient and reliable operations. Whether it's cone crusher parts, jaw crusher parts, or impactor blow bars, using high-quality materials and ensuring proper maintenance can significantly enhance the performance and longevity of machinery. Additionally, protective measures such as wear blocks and storage shelters play a vital role in safeguarding equipment and reducing operational costs.

0 notes

Text

Common troubleshooting of laboratory centrifugal pumps

What faults can centrifugal pumps encounter in the laboratory, and how can these conditions be eliminated? Let's take a look. Diaphragm pumps 1. During use, the motor often fails to start, such as when the main power indicator light is on. At this time, the degree of carbon brush wear should be checked. If the carbon brush wear exceeds one-third of the total amount, it should be replaced with a new one in a timely manner. When the main power indicator light is not on, check if the indicator light fuse and indoor distribution board fuse are blown, and also check if the power cord is in good contact. If the fuse is broken, replace the fuse and keep the circuit smooth. The screw pump should also check the vacuum pump gauge and oil pressure indicator values. If the oil pressure is too high and the main engine cannot be started, it is necessary to check whether each oil circuit is blocked, especially whether the throttle hole is smooth. If it is not smooth, it should be cleaned to make it smooth. 2. If the bearing is damaged or its rotation is hindered, there is a lack of oil in the bearing or there is a lot of dirt in the bearing, which causes an increase in friction resistance. If the motor cannot reach the rated speed, the bearing should be cleaned or replaced in a timely manner. There is a layer of oxide on the surface of the commutator, even if it is burnt into unevenness or the brush does not match the outer edge of the commutator, which can cause a decrease in speed. The commutator and brush should be cleaned to ensure good contact. If there is a short circuit or open circuit in the rotor coil of a centrifugal pump, a multimeter can be used to check and rewind the coil. The rotor can cause rupture of the centrifuge tube, sample leakage, and rotor damage during use due to metal fatigue, overspeed, overstress, chemical corrosion, improper selection, imbalance of the rotating head during use, and temperature runaway. For the above situations, it is mainly required for the operator to master the operating procedures proficiently, select appropriate centrifugal pipes and rotors correctly, pay attention to strictly controlling each step of operation sequence, minimize unnecessary human damage, and use the rotor within the safety factor and warranty period. Magnetic pump 3. One of the reasons for the poor starting and cooling performance of the refrigerator is that the power supply is not available, and the power supply and fuse should be checked separately. If the voltage is too low and the safety device malfunctions, it can also prevent the refrigerator from starting. If the voltage is too low, it may be due to the low voltage of the power grid; Excessive wiring on the distribution board; The power cord is too long (ideal length is 3 meters), etc. Insufficient power cord capacity not only reduces voltage, but also causes accidents. Sewage pump 4. When the power supply voltage drops to 180-190VJ, the refrigerator cannot start, affecting the cooling effect. Poor ventilation performance, such as when the instrument is installed in direct sunlight or poorly ventilated areas, poor radiator effect, or the radiator cover is covered with dust, can also affect the cooling effect. The weight of the centrifuge tube is unbalanced and placed asymmetrically; There are foreign objects in the rotor hole, causing imbalanced load; Loose fixing nut at the upper end of the shaft, friction or bending of the shaft; The motor rotor will generate noise if it is not in the center of the magnetic field; Damage to the rotor itself can cause severe vibration and abnormal noise in the body. Self priming pump Many times, it is caused by incorrect operation. After identifying the cause, correct operation can eliminate the abnormal phenomenon. During the work process, if any abnormal phenomena occur, the machine should be immediately shut down and forced operation is not allowed to avoid unnecessary losses or accidents. Chemical pumps.Liquid Ring Compressor In Flash Steam Recovery On Offshore Platforms

0 notes

Photo

From Mecum In 1956, the new BMW R60 was introduced as the foundation of a new model line. The engine and gearbox were a development of the R67 2,600cc plunger-frame model, but with a newly uprated swingarm frame, at both the front and rear wheels. The swingarm front fork was developed by Englishman Ernie Earles, and was made under license by BMW. The rigidity of the designed solved the problem of fork-flex when hauling a sidecar, a duty for which the R60 was designed. The new frame was extremely robust, made from expensive oval tubing and could handle the torsional stress of sidecar work without distortion. Changing spring rates at the rear was as simple as rotating the metal adjuster on the shocks, and the “trail” of the front forks could be altered for solo or sidecar work by changing the position of the front swingarm pivot-pin. The gearbox of the new swingarm models was entirely new, using three shafts with an improved shock-absorber on the input shaft. The driveshaft was fully enclosed within the rear swingarm, and long-lasting universal joints were used to compensate for rear-wheel travel. The clutch, still housed within the flywheel (which was attached directly to the crankshaft), now sported a single-diaphragm spring.

In 1960, the twin-cylinder BMW range was improved, and the R60 added a “/2” to denote changes which weren’t visible. The crankshaft and camshaft were strengthened, the main-bearing housings thickened, the cam followers and the clutch spring were improved, crankcase ventilation was freed up and the compression ratio increased to 7.5:1. The engine now produced 30 HP, giving this gentle beast a feeling of surprising power when the expensive chain-pull throttle assembly was rolled back. Cruising at 70 MPH is easy, the top speed (solo) reaching into the 90 MPH range. While the motorcycle was hurtling forward in near-total silence, the suspension took on all surface irregularities with aplomb, and with an additional sprung saddle (as found on this immaculate machine), there was never a more comfortable machine for the long-haul ride. Plus, with its enormous brakes on the interchangeable wheels, the BMW was the best stopper on the road, period, during much of the 1950s and ‘60s, until disc brakes became the new standard. Many collectors feel that the R50/60/69 series of BMWs was the marque’s finest effort ever, and the motorcycles’ strong collectability reflects the esteem in which they are held.

This 1966 BMW R60/2 has been comprehensively restored, and is clean enough to eat from. It’s had a nut-and-bolt restoration, with an indicated 49,396 miles, and it comes complete with a gorgeous matching Steib S500 sidecar. Motorycling doesn’t get any more elegant than this

23 notes

·

View notes

Text

Electric Bike Winter Maintenance Guide!

The weather is getting colder and colder, presumably many friends are still rain or shine, and can't bear to close the car. If a worker wants to do a good job, he must first sharpen his tools. Electric bicycles can be said to be sports machines. To make this machine exert its maximum power, you must pay attention to the maintenance of your car when riding in winter. A comprehensive inspection of your car after leaving the car can not only prolong the service life of the car. It can eliminate many hidden dangers and improve safety! Let's take a look at the winter maintenance guide for electric bike!

Maintenance description and purpose of each part of the bicycle:

1. Head

Maintenance description: Check whether the bearings at the upper and lower ends of the head tube can be used normally, clean and oil the bearings.

Maintenance purpose: to clean the dust and sludge of the bearings in the head tube, to prevent bearing damage, rust and abnormal noise.

2. Axis

Maintenance description: Check whether the center shaft can be used normally, clean and oil the bearings.

Maintenance purpose: to clean the dust and sludge in the bottom bracket and bottom bracket to prevent damage, rust and abnormal noise of the bottom bracket.

3. Wheel front and rear hubs

Maintenance description: Check whether the hub can be used normally, clean and oil the balls in the hub.

Maintenance purpose: Check whether the hub can be used normally, clean and oil the balls in the hub.

4. Wheel set adjustment (front and rear wheels)

Maintenance description: Put the wheel set on the ring adjustment table to check whether it is deflected, and adjust it according to the situation (Nalong)

Maintenance purpose: to reduce the deflection of the wheel set to make the handling better.

5. Transmission system (front and rear derailleurs, flywheels, chains, cranksets)

Maintenance description: Check the transmission system: whether the front and rear derailleurs, flywheels, chains, and chainrings can be used normally, clean the dust and sludge, replace with new oil, and adjust the gear.

Maintenance purpose: reduce excessive wear caused by sludge and other sundries, and prolong the service life of flywheel and chain.

6. Frame

Care Description: Clean the body and remove stains.

Electric bike maintenance process

Step 1: Clean the Dirt

If the body is not very dirty, just wipe it with a damp soft cloth; if there are many mud spots, you can wash it with a water hose. It should be noted that the pressure of the water column should not be too high. At the same time, the rotating parts such as triaxial and headset cannot be washed directly with water. A toothbrush can be used for places that cannot be wiped by a rag, and the upper tube of the front fork should also be removed with a toothbrush to avoid scratches during shock absorbers. Both the rim and the brakes need to be cleaned to remove the impurities embedded in the brakes and reduce unnecessary wear and tear. Brakes and shift cables should also be wiped clean. If there is a lot of mud and sand, the wire tube can be removed and the internal chain can be cleaned with the spray pressure of the anti-rust agent. The most dust-absorbing place on the whole car, wipe off the stains with a rag. If it is very dirty, you can use an anti-rust agent to clean it. Remember to dry the chain after completion to facilitate subsequent chain oiling.

Step 2: Lubricate

Brake and shifting line pipes need to be re-oiled after cleaning, and grease lubricating oil with weak fluidity is suitable for use on the line pipes. The chain is an important part of the transmission, and it also has high requirements for oiling. Generally, 5-6 drops can be added at a time. After adding, let the chain fully rotate, and at the same time bring lubricating oil to each tooth piece, and dry the chain with a rag after adding. After cleaning the upper tube of the front fork, special lubricating oil should be used to keep the front fork moving smoothly in winter.

Step 3: Prevent Rust

After riding, it is recommended to apply some anti-rust agent to the various screws and transfer points on the bicycle. Firstly, it is anti-rust, and secondly, it is also good for future disassembly.

Electric Bike Winter Maintenance Guide!

3 notes

·

View notes

Text

Product introduction of gas curry Paste sauce cooking mixer machine

Analysis on the advantages of gas curry paste paste sauce cooking jacketed kettle In foreign market, the heat preservation of gas cooking jacketed kettle is a very important factor to measure its market value. The price of gas cooking jacketed kettle with good heat preservation performance is about 20% higher than that of gas cooking jacketed kettle with poor heat preservation performance. Do not underestimate that 20% will be a very large number when it comes to cost and profit. ① Heating method of gas curry paste sauce cooking jacketed kettle: the company's special annular burner is adopted, the flame is more uniform; the energy-saving effect is obvious, 20% less than that of ordinary burner. Equipped with blower device, the gas is more abundant and the fire power is more powerful; electronic pulse automatic ignition and ion flameout automatic protection; ignition is more stable and flameout detection is more sensitive; ② Furnace structure: the flue is built-in, and the flue gas is discharged from the centralized flue to the outdoor, without open fire, which is safer; the furnace body is attached with a thermal insulation layer, which can reduce energy loss and avoid personnel scalding, and is safe and energy-saving. The outer layer is of stainless steel water jacket structure, and the inner part of the water jacket is connected with tap water, which ensures that the outer furnace body does not burn, and the hot water after recycling can wash the ground. ③ Temperature control: The direct connected temperature measuring device is adopted, the temperature measuring rod is in direct contact with the material, and the material temperature is directly measured; The temperature measuring rod is equipped with a sheath to better protect the temperature measuring rod, which is durable, stable and reliable. Ltemperature and fire power can be linked to realize automatic constant temperature frying; ④ Mixing mode of gas curry paste sauce cooking jacketed kettle: frequency conversion speed regulation of mixing, unique scraper. Using the method of revolution and double rotation, six mixing devices (divided into three groups, two groups of revolution and one group of revolution) are used. The mixing effect is better when the mixing hand is added to the rotating mixing rod; the mixing material is more uniform; the scraping pot is more thorough, and the problem of some materials' paste pot can be effectively controlled. ⑤ Discharging mode: adopt the discharging mode, the discharging mechanism is composed of air cylinder, lifting valve rod, valve head and valve seat. Discharging is convenient, fast and safer. ⑥ Control mode: full intelligent control, each product can be independently prepared process, operators only need to select; The gas curry paste sauce cooking jacketed kettle is automatically controlled by PLC program from ignition, oiling, feeding (manual auxiliary feeding is required) to fire power until the completion of frying. The gas curry paste sauce cooking jacketed kettle is fried in strict accordance with the frying process (user can set it by himself), automatically realizing hot pot, automatic quantitative fueling, automatic heating to the specified temperature, regular flipping, voice warning fueling; The gas curry paste sauce cooking jacketed kettle has complete protection functions: flameout protection function, over temperature shutdown function, feeding delay protection function and accompanying sound and light alarm function, making the equipment more safe and reliable; The function of log recording, statistics and printing of material frying. User friendly voice operation prompt, visual operation interface. Performance of gas curry paste sauce cooking jacketed kettle: 1. Volume: 50L, 100L, 200l, 300L, 400L, 500L, 600L, 800L, 1000L. 2. Structural form: tilt type and vertical structure, with or without agitation as required by the process. 3. Material of the pot body: ① stainless steel (SUS304) of the inner pot body, carbon steel of jacket and bracket (Q235-B) are coated with anti rust paint; ② stainless steel is applied inside and outside. 4. Pot body with mixing device: Center mixing at the top, looper connection between the output shaft of reducer and mixing paddle shaft, convenient for disassembly and cleaning. 5. Mixing speed: 36R / min (a certain speed can be selected according to the customer's requirements); mixing paddle form: ordinary mixing (anchor type) and bottom scraping mixing. 6. Fixed electric cooking jacketed kettle foot form: ① vertical pot body: pyramid type, round tube type; ② tilting pot body: trough bracket type. 7. Equipment configuration: dial pointer thermometer, steam inlet, discharge port, etc. (vertical structure). 8. The body of the large-scale sandwich type cooking pot Zui can be tilted 90 °, and the tilting mode is manual turning. The main products of Longze machinery are: 1. The overall solution for the production line of seasoning sauce in bags (hot pot bottom material, fish seasoning, chicken seasoning, instant noodle sauce bag, etc.); 2. The overall solution for the production line of bottled sauce (mushroom sauce, beef sauce, chili sauce, flavored Douchi, etc.); 3. Automatic quantitative, proportioning, mixing and packaging production lines for all kinds of particles and powders; 4. Intelligent cooking jacketed kettle: all kinds of self turning, discharging and box type cooking jacketed kettle, including electromagnetic heating, gas heating, oil heating and other heating methods. It can be used to stir fry sauce materials, granular materials, silk materials and dishes; 5. All kinds of hot oil pot, fryer, pot, cooling pot, transfer pot, dry fry machine, etc; 6. Intelligent stir fry robot, commercial stir fry robot, automatic stir fry machine, horizontal stir fry machine; 7. We can design and manufacture non-standard production lines of various specifications and performances according to customers' requirements; 8. Industrial control system engineering; Longze machinery produces all kinds of vertical cooking jacketed kettle all year round. The horizontal cooking mixer machine can tilt the cooking jacketed kettle, the horizontal cooking mixer machine can tilt the cooking jacketed kettle with mixing, the planetary stir fry pot, etc. welcome new and old customers. Contact Us:Shandong Longze Machinery Co.,LtdTel:+86 17560687501Whatsapp/Wechat: +86 17560687501Company website: https://www.candyfiremixer.com/E-mail: [email protected]: Zhucheng Economic Development Zone, Shandong Province, the first five lines westContact:Ms. Gussie

1 note

·

View note

Text

An Extravagant Construction Machine Used For Many Purposes – An Auger Machine

An auger machine is a device that is used to drill horizontally into the earth. It is made of a cutting head, a flighted drive tube, and the drive mechanism that supplies the force necessary to propel the auger through the ground. The cutting head makes its way through the ground, and the excavated material is brought back to the entrance pit with the auger coil.

This Auger Machine is utilized in the construction technique known as horizontal auger boring (HAB), which is used to drill below the surface of the earth. The jack and bore method is another name for this approach. The casing pipe is jacked up while the revolving augers help remove the excavated earth from the casing. This is how the system works.

In construction, auger drilling is frequently utilized for the installation of pipes under railway lines, roads, and levies. This is done since there is a worry about soil settling in the areas.

Purpose of Auger Machine

Auger Machines are utilized in the process of installing horizontal pipes without the necessity of excavating trenches. An auger machine has a cutting tip that can slice through the surface of the soil, reducing it to sand and loose dirt as it goes. This dirt, sometimes known as "spoil," is extracted from the tunnel as a result of the action of the helical coils of the auger itself, which spins inside a steel casing.

After being deposited in the entrance hole, the waste is subsequently taken away. The force that is necessary to rotate the auger and push the cutting head into the ground is provided by hydraulic jacks.

There are a staggering number of applications for augers. Among the many possible applications are the following:

· Toto plant a tree, one must first bore into the ground.

· Creating a hole that is spotless and perfectly straight for a fence post or a telephone pole

· Cleaning out a sink that was blocked with debris

· Ice fishing requires first creating a hole in the ice.

· The process of extracting syrup from maple trees by drilling into the trees.

· Work being done on the irrigation trenches

· Tilling garden beds

· Creating holes in the wood for woodworking.

When it comes to commercial buildings, augers that are attached to large machines are what is utilized to bore holes as deep as possible into the earth. Foundation drilling rigs often come equipped with auger attachments, which are used to construct drilled shafts in the earth. To offer sufficient stability, taller buildings and structures like huge bridges require a different kind of concrete foundation than the one utilized in residential construction.

Piling is the term used to describe the method that is utilized to produce this extra stability. The holes for the piles can be drilled using large augers, and the piles themselves can be made of concrete, wood, steel, or steel-reinforced concrete. The load is moved away from the surface and into a depth that is better equipped to support larger buildings and structures as a result of the construction of these building supports.

There are a few routes to take to achieve this goal. The continuous flight augering (CFA) method is the usual way. This method involves using a continuous flight auger to make a hole that is then pumped full of concrete via a hollow stem while the auger is removed from the ground. It is often the method of choice when dealing with unstable ground containing stuff like gravel or sand. It is imperative that the length of the auger match that of the hole that is to be drilled.

Other drilling methods that use augers include down-the-hole drilling, which involves the use of a hammer and compressed air to break up particularly hard and rocky soils; open-bored piling, which is used for cohesive soils; full displacement drilling.

CONCLUSION:

Augers are versatile equipment that may be used for a wide range of endeavors, from digging shallow holes to extracting oil to large-scale gardening and landscaping jobs. Auger machine can be used for tasks of any kind. There is a wide variety of augering equipment accessible to you, ranging from hand augers and post-hole augers to bigger augers that need to be operated by heavy-duty motorized equipment; these are just some of the alternatives.

If you are doing a significant one-time task, you might want to think about renting the necessary equipment instead of purchasing it. This way, you won't have to make a significant expenditure for a project that will only happen once. But, if you are going to be operating heavy machinery, be sure that you have received the proper training and that you have the necessary safety gear. While using any form of tool or piece of equipment, ensuring one's own safety should always come first.

0 notes

Text

Hydrojetenergy: Leading Rotating Shaft Tube Cleaning Machine Manufacturers

Hydrojetenergy stands as a leading force in the realm of industrial cleaning equipment, specializing particularly as Rotating Shaft Tube Cleaning Machine Manufacturers. Their dedication lies in engineering innovative solutions tailored specifically for the thorough cleaning and maintenance of rotating shaft tubes in various industrial settings.

With a focus on precision and efficiency, Hydrojetenergy's machines boast cutting-edge technology designed to effectively remove contaminants and deposits from shaft tubes, ensuring optimal performance and longevity of critical machinery. As Rotating Shaft Tube Cleaning Machine Manufacturers, Hydrojetenergy prioritizes quality craftsmanship, reliability, and customer satisfaction, positioning themselves as trusted partners for industries reliant on precise and efficient cleaning solutions.

Visit for more info : https://www.hydrojetindia.com/manufacturers/tube-cleaning-triplex-pump.html

Address : Hydro Jet Energy, 29/2, Parishikhar Cottage Industrial Estate, Near Ramol Toll Plaza, SP Ring road, Ramol, Ahmedabad-382449,Gujarat,India

Mail : [email protected]

Phone no : 8686862582

0 notes

Text

Essential Components for Crushing and Milling Equipment: A Detailed Overview

In the industrial and mining sectors, the efficiency and longevity of machinery depend heavily on the quality of its components. This guide explores key parts and accessories for crushing and milling equipment, including cone crusher parts, jaw crusher parts, impactor blow bars, vertical roller mills rollers or tires, hammer mills hammers, wear blocks, cutting edges, storage shelters, stretch hood tubes, and general crusher parts.

Cone Crusher Parts

Cone crushers are used extensively in various industries for secondary and tertiary crushing. Key parts include the mantle, concave, main shaft, and bushings. These components are essential for the efficient functioning and durability of the machine. High-quality materials and precision engineering ensure that cone crusher parts can withstand the high levels of pressure and abrasion they encounter during operation.

Jaw Crusher Parts

Jaw crushers are primary crushers widely used in mining and aggregate production. Important parts include jaw plates, toggle plates, and cheek plates. These components play a critical role in breaking down large rocks into smaller, manageable pieces. Durability and strength are crucial for jaw crusher parts to handle the constant impact and wear they endure.

Impactor Blow Bars

Impactor blow bars are vital for impact crushers, which are used to crush materials by striking them with high-speed rotating bars. These bars must be tough and wear-resistant to handle the intense impact and abrasion. High-chrome and manganese steel blow bars are commonly used for their durability and ability to provide a consistent crushing performance.

Vertical Roller Mills Roller or Tire

Vertical roller mills are used in the cement and mining industries to grind raw materials. The rollers or tires are critical components that apply pressure to the material being ground. These parts must be made from wear-resistant materials to ensure longevity and efficiency. Proper maintenance and timely replacement of rollers or tires can significantly enhance the performance of vertical roller mills.

Hammer Mills Hammers

Hammer mills are used to crush and pulverize materials in various industries. The hammers, which repeatedly strike the material, must be robust and wear-resistant. Alloy steel or manganese steel hammers are commonly used due to their high impact resistance and durability. Regular inspection and replacement of hammers are essential for maintaining the efficiency of hammer mills.

Wear Blocks

Wear blocks are protective components used in various types of crushing and milling equipment to prevent excessive wear and extend the lifespan of the machinery. They are often made from hardened steel or other wear-resistant materials. Proper installation and regular monitoring of wear blocks can help reduce maintenance costs and downtime.

Cutting Edge

Cutting edges are critical for earthmoving and construction equipment, such as bulldozers and graders. These parts are designed to withstand high levels of stress and abrasion while maintaining a sharp edge. High-carbon steel and carbide-tipped cutting edges are popular choices due to their durability and cutting efficiency.

Storage Shelter

Storage shelters are essential for protecting machinery and equipment from the elements. These structures can significantly extend the lifespan of equipment by shielding it from rain, snow, and UV radiation. Properly designed storage shelters also help in maintaining a clean and organized work environment.

Stretch Hood Tube

Stretch hood tubes are used in packaging to secure and protect products during transportation and storage. They provide a tight and secure cover, which helps in preventing damage and contamination. Stretch hood tubes are widely used in various industries, including construction, agriculture, and manufacturing.

Crusher Parts

General crusher parts encompass a wide range of components used in various types of crushers, including jaw crushers, cone crushers, and impact crushers. These parts include bearings, shafts, liners, and gears. High-quality crusher parts are crucial for the reliable and efficient operation of crushing equipment. Regular maintenance and timely replacement of worn-out parts can prevent breakdowns and extend the service life of crushers.

Understanding the essential components of crushing and milling equipment and their respective roles is crucial for maintaining efficient and reliable operations. Whether it's cone crusher parts, jaw crusher parts, or impactor blow bars, using high-quality materials and ensuring proper maintenance can significantly enhance the performance and longevity of machinery. Additionally, protective measures such as wear blocks and storage shelters play a vital role in safeguarding equipment and reducing operational costs.

0 notes

Text

Some advantages of carbon fiber composite roller

Today Coreco briefly introduces some advantages of carbon fiber composite roller.

1. Carbon fiber composite roller is beneficial to improve the productivity of machinery and equipment

Carbon fiber composite rollers are less dense and stronger, and can reduce weight by about 70% compared with the same type of steel tube body, and about 30% compared with the same type of aluminum alloy tube body. The use of carbon fiber material to make rollers on paper machine equipment can not only effectively reduce the self-weight of the equipment in the application, but also significantly reduce the movement inertia of the rollers, which is conducive to the high-speed and stable operation of the rollers and improve the production efficiency of machinery and equipment as a whole.

2. The coefficient of thermal expansion of carbon fiber composite rollers is close to zero

The carbon fiber composite roller has the designability to increase the stiffness in the main direction and control the thermal expansion coefficient through the optimized lay-up scheme according to the actual needs of the structure.

3. The precision of carbon fiber composite rollers is more controllerable

The dimensional accuracy and surface quality of carbon fiber tubes depend mainly on the forming process and strict product quality control. Good process level can effectively reduce the quality defects on the surface of the finished product, make it smooth and flat, and ensure the dimensional tolerance. The mechanical processing of traditional metal pipe parts has the risk of deformation, and higher dimensional accuracy is especially important for some high precision instruments and equipment.

4. Longer service life of carbon fiber composite rollers

Carbon fiber composite rollers have good fatigue resistance, and the lightness of the material itself can reduce the load-bearing of the parts, and the friction is small when the weight is light. When it is used for rotating the roller body, even if the speed is very fast, the roller body is not easy to produce large deflection, which can effectively avoid the damage to the surface protection layer of the roller body and the shaft head and other related parts, and reduce the cost of replacement and maintenance. Carbon fiber composite material is also very resistant to corrosion and can resist the corrosion of general industrial chemicals (except strong alkali and acid), and it is easy to maintain and clean.

5. Carbon fiber composite roller amplitude is small

The stiffness of carbon fiber composite roller is much higher than the ordinary steel tube, and using it as the roller body produces less vibration in the high-speed operation of mechanical equipment. Compared with traditional metal rollers, it can not only achieve higher speed, but also higher printing quality.

6. Small deformation of carbon fiber composite rollers

Carbon fiber composite rollers perform better in tensile, compression, bending, bending shear and torsion, etc. Carbon fiber composite rollers have less deformation in long-term mechanical operation and can provide better working condition for equipment. For example, the use of carbon fiber composite pile rollers in textile machinery has good dimensional stability and is not easily deformed, especially in longer roller bodies, and the twist deformation rate of carbon fiber composite rollers is much lower than that of traditional steel rollers.

Coreco is a professional manufacturer and exporter of carbon fiber rollers. Our products are widely used in nonwoven, lithium battery, converting, printing and polymer film industries, welcome your inquiry and look forward to cooperating with you!

0 notes

Text

Rubber Roller Construction

Roller Core: The roller core is the rigid structural member which supports the load. It is typically made of high-strength materials such as carbon steel, stainless steel, alloy tool steel, and aluminum alloys. Roller cores are designed according to their applications. They can be further broken down into several parts.Cores can be as simple as a tube with installed bearings in each end mounted on a shaft, or as complete as a fully constructed body, with welded end plates and shaft (or journal). Bearings can be fitted on each journal end to allow for free rotation, or have an extended shaft with a key to allow the roller to be driven by the process. This can be further broken down into several parts.

Shaft: The shaft is the machine part that connects the whole roller to the motor, sprocket, or other drive units. It is typically solid in construction with high strength and uniform hardness. The shaft is designed to endure bending and torsional stresses. Bending stresses are caused by the radial forces against the roller; while torsional stresses are from the torque generated by rotating the roller to tangentially move loads. The shaft can be coupled to the drive unit by means of a key and keyway, or by set screws or machined flats, or in the case of a free spinning roller, the bearings are mounted in some type of housing or pillow block fixture.

Cylinder: The cylinder is a hollow part typically in the form of a pipe or tube. This is where the rubber lining is wrapped and bonded. The metal has sufficient thickness to resist deflection upon application of load. The cylinder is usually made from steel, though other rigid but light materials can be used such as aluminum and reinforced plastics. The ends of the cylinder are typically machined to either receive pressure in bearings or a metal flange (end plate).

Flange: The flange or end plate connects the cylinder onto the shaft. The shaft, cylinder, and flange are held together by welds.

Bearings: Bearings are used to reduce friction against the static and rotating parts. The configuration, mounting, and type of bearing can vary depending on the design of the roller. The configuration described previously has the shaft installed together with the roller cylinder. In other designs, the bearing can be installed on the roller while the shaft is static on the main equipment.

Rubber Cover: The rubber lining is the outer cover that comes into contact with the load or process material. This part takes the most wear and tear with the intention of protecting the roller core and the surface of the load. The type of rubber material and grade are based on the roller application. Summarized below are the types of rubber that are recommended for providing a specific property, though all are formula specific..

Hardness: SBR and FKM for high hardness (Shore A 60 to 95); NBR and PUR for a wider range (Shore A 10 to 95)

Abrasion Resistance: SBR, PUR, XNBR, HNBR, CSM Tear Strength: SBR, PUR, XNBR, HNBR, CSM Compression Set: NBR, CR, Silicone, PUR Thermal Resistance: SBR, EPDM, Silicone, FKM, CSM Low-Temperature Toughness: NBR, CR, EPDM, Silicone Aging Resistance: Butyl, CR, EPDM, Silicone Acid and Alkali Resistance: Halogenated Butyl, EPDM, CSM Water Resistance: Halogenated Butyl, Silicone, EPDM, CSM Oil Resistance: NBR, CR, FKM Solvent Resistance: NBR for petroleum-based solvents; CR, EPDM, Silicone, and Butyl for alcohol-based solvents; CR, EPDM, CSM, and Butyl for ketone and ester-based solvents.

Articles You May be Interested in

When to use roller conveyors, Applications of polyurethane rubber, How to do Anilox Roller Cleaning to Print Good Products?Conveyor Roller Design: How to Create a Better, More Efficient Roller

0 notes

Text

Ribbon Mixer Machine

https://www.nielmachinery.com/products/ribbon-mixer-machine.html

The ribbon mixer machine consists of a U-shape tank, spiral and drives parts. The spirals dual structure. Outer spiral makes the material move from the sides to the center of the tank and the inner screw conveyor the material from the center to the sides to get the convective mixing.

Description of Ribbon Mixer Machine

Generally, ribbon mixer machines are used for mixing a viscous or cohesive mixture of particulates and the addition of liquid and paste-like material in powder or granule. Since Viscous materials are difficult to clean, the spiral ribbon mixer is suitable for mass production and other occasions such as infrequent replacement mixing.

Our NRD series ribbon type mixer can mix many kinds of materials especially for the powder and granular which with viscosity or cohesion character, or add a little liquid and paste material into powder and granular material. The mixture effect is high. The cover of the tank can be made in open-type so as to clean and change parts easily. If you are interested and want to know our ribbon blender machine price, please feel free to contact us.

Structural Characteristics of Ribbon Blender Mixer

The U-shaped elongated body of the tube structure ensures the resistance movement of the mixed materials within the barrel (powder, semifluid). Reverse rotation of a ribbon attached to the same horizontal axis, forming a low-power efficient mixing environment, generally made of ribbon blade helical double or triple, the outer spiral pooled material from both sides toward the center, the inner spiral conveying material from the center to both sides, the material can be formed more vortices in the flow. Horizontal ribbon blender can accelerate the mixing speed and mixing improve uniformity.

Application of Ribbon Blender

Milk powder

Foodstuff

Medicinal

Chicken powder

Cosmetic Pigment

Other industries

Main Features of Ribbon Mixer Machine

1. Horizontal tank, single shaft with dual spiral symmetry circle structure.

2. Under the bottom of the tank, there has a flap dome valve (pneumatic control or manual control) of the center. The valve is an arc design that assures no material accumulated and without any dead angle when mixing. Reliable regular- seal prohibit the leakage between the frequent close and open.

3. The disconnection ribbon of the mixer can make the material mixed with more high speed and uniformity in a short time

4. This mixer also can be designed with the function to keep cold or heat. Add one layer outside the tank and put it into medium into the interlayer to get the mixing material cold or heat. Usually, use water for cool and hot steam or use electricity for heat.

Technical Data of Ribbon Blender

Model

NRD-200L

NRD-300L

NRD-500L

NRD-1000L

NRD-1500L

NRD-2000L

NRD-3000L

Effective volume

200L

300L

500L

1000L

1500L

2000L

3000L

Fully volume

280L

400L

680L

1275L

1820L

2450L

3680L

Turning speed

53RPM

53RPM

45RPM

45RPM

39RPM

39RPM

37RPM

Total weight

400KG

650KG

980KG

1300KG

1600KG

2200KG

2600KG

Total power

4KW

5.5KW

7.5KW

11KW

15KW

18.5KW

22KW

Length

1800MM

1900MM

2050MM

2500MM

2950MM

3330MM

3350MM

Width

860MM

900MM

1050MM

1200MM

1350MM

1500MM

1850MM

Height

860MM

900MM

1250MM

1350MM

1400MM

1650MM

2050MM

Power supply

3P AC208-415V 50/60HZ

0 notes

Photo

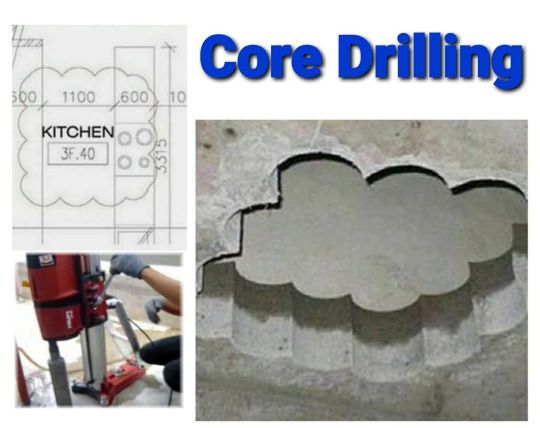

Core drilling is a fast, accurate and clean way to drill holes in concrete to run pipes through. Concrete core drilling involves drilling perfectly rounded holes in concrete walls, and floors. Diamond concrete-core drills are the most commonly used tools for this process. The core drill bit tends to consist of a steel tube impregnated with diamond segments on the drilling end. The concrete coring drill is mounted on the rotating shaft of a concrete core-drilling machine and is secured to the wall or floor in question. A solid cylindrical concrete core or “slug” is removed from the hole once the drilling is complete. Core drilling is costly and can be labor intensive in occupied spaces because of water usage you will need 2 people. Much like the picture on the prints pay attention to where you will be penetrating floor and walls. The symbol on the prits does NOT mean to drill holes in tha manor, it shows an exploded veiw of floor penetration. Some buildings require x-ray before because of the way the concrete is supported. www.571plumber.com (703) 878-7800 (571) PLUMBER #woodbridgeva #lakeridgeva #montclairva #dumfriesva #alexandriava #arlingtonva #dalecityva #manassasva #manassasparkva #occoquanva #herdonva #dumfriesva #fairfaxva #annandaleva #springfieldva #cilftonva #tysonscorner #tysonsva #greatfallsva #mcleanva #viennava #burkeva #oaktonva #centrevilleva #northernvirginia #fairfaxcountyva #princewilliamcountyva #plumber #plumbers #plumbing #571plumber https://www.instagram.com/p/CFW5poUDtg_/?igshid=1c9k4bmq9sbs1

#woodbridgeva#lakeridgeva#montclairva#dumfriesva#alexandriava#arlingtonva#dalecityva#manassasva#manassasparkva#occoquanva#herdonva#fairfaxva#annandaleva#springfieldva#cilftonva#tysonscorner#tysonsva#greatfallsva#mcleanva#viennava#burkeva#oaktonva#centrevilleva#northernvirginia#fairfaxcountyva#princewilliamcountyva#plumber#plumbers#plumbing#571plumber

0 notes

Text

Linear Motion Elements: How Motors And Much More Can Gain Generation

Power and Motors the base on which manufacturing has been assembled. Motors drive nearly all powered tools, from turning fans and running conveyor straps on driving pumps and repainting gear. Sadi Transmisiones is a key aspect when converting the ability generated out of a engine into usable work for both fabricating. Furthermore, many motors generate the rotary motion and power transmission pushes which can be utilised to change rotary strength into linear motion. In this fashion, motors have been flexible work-horses which can induce nearly any tool or manufacturing practice.

The Basic Layout Basics Of Allergic Motion

The coupling among a engine and also a shaft is your purpose where rotary engines can output rotational movement. This transformation of electricity has been got, in the most straightforward kind, of only a couple components working in live performance.

The preparation is made up of the rotary motor that spins a shaft that is threaded. A nut is connected to the threads of the rotating shaft. As it rotates, the nut doesn't revolve. Fairly, the rotary movement compels the nut over the amount of this shaft. This movement is now linear movement, and successfully switched from the rotation of the shaft. This could be the easiest type of converting between several types of energy. The nut is currently traveling at a direct line instead of in an circular fashion. By coupling the nut into a slumping tube or other aperture, then the rotating motor can create aerodynamic motion.

The Acme Lead Screw

There are many techniques and applications which are somewhat more diverse compared to the aforementioned instance. The guide thread works to the sample theory, however, at a different style. Inside this scenario, the nut is repaired in place and rotates along side the motor. The threaded screw is quite pushed forwards by the turning nut. Stilla rotary motor has the ability to drive a shaft in a line.

Total, the lead thread remains a straightforward and compact style. This installation unfortunately generates quite a bit of warmth and friction and so the efficacy of Sadi endures. A more regular lead thread only exerts energy with an efficacy evaluation within the variety of 20% to 70% in the optimal. However, this loss in power will be offset by the simplicity of style and design, low cost, and ease in fabricating.

Versions on this design additionally alter the thread angles and orientations. However, finally, they are a highly effective device to generate a shaft ahead by using a rotating motor.

A More Elaborate Example - The Ball Screw

In order to deal with friction and efficacy problems, the chunk screw utilizes ball bearings to achieve the very same power-transmission to linear motion affect. The threaded shaft inside this machine results in a spiral'raceway' for chunk bearings to traveling. Acting like a precision screwthread, the shaft will be tilted forwards from the moving ball bearings. Using these transferring chunks, friction is paid down exceptionally and an efficiency score of nearly 90 percent is accomplished. However, the drawback, but this setup necessitates notably clean threads which are free from debris and obstructions to get effective operation.

The end consequence of this setup is really a highly effective tool for machining, precision fabricating equipment, and in monitors control producing processes. Ball-screws are somewhat more complicated and expensive on account of their layout, however, the higher efficiency can offset the cost by simply necessitating a powerful motor since less energy is lost throughout motion transmission. A protecting bellows, created of rubber or lace , keeps the shaft and chunk system relatively sterile and free from obstructions.

0 notes

Text

Top Features of a Reliable & Efficient Oil Expeller

Multi-functional oil expellers press several types of oilseed for instance – peanuts, sesame, canola seed, camellia, flax seeds, and sunflower seeds. Additionally of extracting oil, cake developed from the dried seeds is another commercial product. A trusted oil mill ensures a top quality of the final product.

Oil milling industry cultivates the oil-producing harvest. The procedure of oil extraction begins with the purchase of oilseeds. Top quality seeds are chosen which are stored in a dried and aerated store to keep up seed quality.

The mechanical processes used basically include pressing grains, flowers or fruits through worm screwed presses that compress the materials. It provides an effective way to press the precise vegetable plants and seeds containing high oil content.

Oil seeds bought from farms contain unnecessary contaminants such as for instance soil, leaves, wooden twigs etc that ought to be cleared before seed processing otherwise they’ll get combined with oil. Different cleaning methods are utilized with regards to the type and magnitude of contaminants. Common cleaning methods are stationary seed cleaning, vibratory cleaning, rotation seed cleaning, and brushing.

Structure of Oil Expeller

Once the seeds are ready for expelling, quality oil expellers are utilized that comprises of an outside shaft mounted with multiple worms. An expeller machine includes a feeder joined to the worm screw, an axle is driven by way of a gear motor. An area of the worm screw exit is roofed a gas expeller. The important thing feature with this machine can it be is manufactured in one unit and has openings on the wall on the tube length along with cavities in the tube.

Seeds are squeezed under great pressure release an oil. The released oil flows through various perforations. The rest of the seed cake happens through the opening zone. A top quality expeller machine squeezes the all the seed releasing the oil, and hence leaving nominal magnitude of remainders for cake.

Options that come with oil expellers:

• Compact design with superior components needs nominal maintenance

• User-friendly

• Top quality and reliable structure

• High oil yield ability and automatic operation

• Economical price and high efficiency

Great things about Oil expeller machine:

• Commonly useful for pressing different oilseeds. The oil expeller can be useful for medium and large sale cooking mills and units

• Professionally designed expeller machinery increases the breaking and pressing of oil seeds

• Cake produced after pressing has low oil content. High-quality cake production for reuse

• Lowers labor cost and energy use.

Get more information about oil machinery from here: http://www.reliablemachinery.in/oil-mill-plant.html

Source: https://reliablemachine.wordpress.com/2019/02/18/top-features-of-a-reliable-efficient-oil-expeller/

0 notes

Text

Essential Components for Crushing and Milling Equipment: A Detailed Overview

In the industrial and mining sectors, the efficiency and longevity of machinery depend heavily on the quality of its components. This guide explores key parts and accessories for crushing and milling equipment, including cone crusher parts, jaw crusher parts, impactor blow bars, vertical roller mills rollers or tires, hammer mills hammers, wear blocks, cutting edges, storage shelters, stretch hood tubes, and general crusher parts.

Cone Crusher Parts

Cone crushers are used extensively in various industries for secondary and tertiary crushing. Key parts include the mantle, concave, main shaft, and bushings. These components are essential for the efficient functioning and durability of the machine. High-quality materials and precision engineering ensure that cone crusher parts can withstand the high levels of pressure and abrasion they encounter during operation.

Jaw Crusher Parts

Jaw crushers are primary crushers widely used in mining and aggregate production. Important parts include jaw plates, toggle plates, and cheek plates. These components play a critical role in breaking down large rocks into smaller, manageable pieces. Durability and strength are crucial for jaw crusher parts to handle the constant impact and wear they endure.

Impactor Blow Bars

Impactor blow bars are vital for impact crushers, which are used to crush materials by striking them with high-speed rotating bars. These bars must be tough and wear-resistant to handle the intense impact and abrasion. High-chrome and manganese steel blow bars are commonly used for their durability and ability to provide a consistent crushing performance.

Vertical Roller Mills Roller or Tire

Vertical roller mills are used in the cement and mining industries to grind raw materials. The rollers or tires are critical components that apply pressure to the material being ground. These parts must be made from wear-resistant materials to ensure longevity and efficiency. Proper maintenance and timely replacement of rollers or tires can significantly enhance the performance of vertical roller mills.

Hammer Mills Hammers

Hammer mills are used to crush and pulverize materials in various industries. The hammers, which repeatedly strike the material, must be robust and wear-resistant. Alloy steel or manganese steel hammers are commonly used due to their high impact resistance and durability. Regular inspection and replacement of hammers are essential for maintaining the efficiency of hammer mills.

Wear Blocks

Wear blocks are protective components used in various types of crushing and milling equipment to prevent excessive wear and extend the lifespan of the machinery. They are often made from hardened steel or other wear-resistant materials. Proper installation and regular monitoring of wear blocks can help reduce maintenance costs and downtime.

Cutting Edge

Cutting edges are critical for earthmoving and construction equipment, such as bulldozers and graders. These parts are designed to withstand high levels of stress and abrasion while maintaining a sharp edge. High-carbon steel and carbide-tipped cutting edges are popular choices due to their durability and cutting efficiency.

Storage Shelter

Storage shelters are essential for protecting machinery and equipment from the elements. These structures can significantly extend the lifespan of equipment by shielding it from rain, snow, and UV radiation. Properly designed storage shelters also help in maintaining a clean and organized work environment.

Stretch Hood Tube

Stretch hood tubes are used in packaging to secure and protect products during transportation and storage. They provide a tight and secure cover, which helps in preventing damage and contamination. Stretch hood tubes are widely used in various industries, including construction, agriculture, and manufacturing.

Crusher Parts

General crusher parts encompass a wide range of components used in various types of crushers, including jaw crushers, cone crushers, and impact crushers. These parts include bearings, shafts, liners, and gears. High-quality crusher parts are crucial for the reliable and efficient operation of crushing equipment. Regular maintenance and timely replacement of worn-out parts can prevent breakdowns and extend the service life of crushers.

Understanding the essential components of crushing and milling equipment and their respective roles is crucial for maintaining efficient and reliable operations. Whether it's cone crusher parts, jaw crusher parts, or impactor blow bars, using high-quality materials and ensuring proper maintenance can significantly enhance the performance and longevity of machinery. Additionally, protective measures such as wear blocks and storage shelters play a vital role in safeguarding equipment and reducing operational costs.

0 notes