#Semi-automatic terminal machine, automatic terminal machine , automatic terminal crimping machine

Explore tagged Tumblr posts

Text

Revolutionizing Wire Harness Production with Automated Crimping Technology

The modern manufacturing landscape increasingly hinges on automation to boost both efficiency and accuracy. A standout innovation driving this transformation is the advent of automatic wire cutting and crimping machines. These sophisticated systems offer a host of compelling advantages, fundamentally reshaping the way wire harnesses are produced.

At the core of these machines' appeal is their ability to combine blazing-fast operation with a remarkably streamlined wire changeover process. Unlike older, more labor-intensive methods, these automated solutions harness cutting-edge Computer Numerical Control (CNC) technology. This allows for precise, computer-managed adjustments to both the leading and trailing wire ends, eliminating the need for tedious manual tweaks to cutting and stripping lengths. What's more, the integration of electrically controlled blades drastically simplifies the engineering challenges typically associated with adapting to different wire specifications. This built-in flexibility enables swift transitions between various wire types and dimensions, a critical factor in maximizing production agility and minimizing costly downtime.

Precision and Efficiency Through Digital Control

The operational backbone of automatic wire cutting and crimping machines lies in a fully digital and mathematically driven control system. Every crucial parameter—from cutting and stripping lengths to blade values, semi-stripping settings, and terminal crimping specifications—can be precisely configured via an intuitive interface. This comprehensive digital mastery, particularly the electrically adjustable blades, not only supercharges production efficiency but also positions these machines at the forefront of automation compared to other models. For instance, single-head automatic wire crimping machines are adept at handling multiple tasks: wire cutting, single-end stripping, double-end stripping, and single-end crimping, all executed with remarkable speed, stability, and intelligence. Their touchscreen interface further refines the setup experience, making all adjustments fully digitized and straightforward.

Workforce Optimization and Cost Savings

The advanced automation inherent in these machines empowers manufacturers to optimize their workforce deployment. By taking over repetitive and intricate tasks, these systems free up human capital, allowing employees to focus on more strategic, value-added activities. This shift often translates into significant reductions in overall operational costs. Another key benefit is the modular design of these machines. Their reliance on standardized components not only simplifies initial setup but also dramatically cuts down on ongoing maintenance expenses, thanks to readily available and easily replaceable parts. Equipped with cutting-edge electrical controls and proprietary software, these machines boast a highly user-friendly Human-Machine Interface (HMI). This accessibility means that even operators with minimal specialized training can efficiently manage complex wire processing, including wire and terminal changes, effectively "democratizing" the operation of such sophisticated equipment.

Conclusion

In essence, automatic wire cutting and crimping machines represent a monumental leap forward in manufacturing technology. Their synergy of high-speed performance, CNC-driven precision, electrically controlled blades, and intuitive digital interfaces offers compelling advantages over traditional approaches. These machines stand out across various categories of terminal equipment and have secured widespread adoption in today's market, garnering widespread acclaim from users for their innovative design and robust performance.

For in-depth technical resources on automatic terminal crimping machines, explore our specialized page.

2 notes

·

View notes

Text

The difference between fully automatic and semi-automatic terminal machine

The automatic terminal machine is one of the products we use more, but there is also a semi-automatic terminal machine, which means that half of these products also need manual work, and the two are different terminal machines. Therefore, the way of working is also different. It can be said that the difference is quite big, but have you ever understood the main difference between the automatic terminal machine and the semi-automatic terminal machine? You can listen to the introduction of the automatic terminal machine manufacturer Weijion. You can learn more about which one is right for you.

Let us understand the difference between automatic terminal machine and semi-automatic terminal machine

1. The automatic terminal machine is fully intelligent and automatic. It integrates integrated circuits, servers, robots, detection signals, and integrates all production steps of wire processing into one power cord processing equipment. When running, it can save a lot of manual operations. It only needs to set the working mode and give the servo a working signal. This signal will be transmitted to the working drive motor through a series of components, and then realize the start and stop of the work. The entire workflow is fully automated, so the work is more efficient and manpower-saving.

2. Semi-automatic terminal machine is a relatively common terminal machine equipment, and we all refer to it as a terminal machine. The semi-automatic terminal machine used to be the most used equipment on the market because of its strong applicability. The semi-automatic terminal machine is controlled by a foot-operated power-off clutch device to control the terminal action of the machine by manually stepping on it. The single processing action of the semi-automatic terminal machine is only to punch the terminal, and the wire also needs to be manually divided and fed, and the work efficiency is lower than that of the automatic terminal machine.

Because the price of automatic terminal machines is higher than that of semi-automatic terminal machines, most of the terminal machines of many enterprises are still semi-automatic terminal machines. However, with the progress of the times, the automatic terminal machine has become the core equipment of automatic wire processing enterprises. With the development of the enterprise, the automatic terminal machine will gradually replace the semi-automatic terminal machine, which is the trend of future enterprises. If you need these two products or terminal copper tape, automatic pipe cutting machine and other mechanical equipment, you can contact us.

Kunshan Weijiang Automation Equipment Co., Ltd. is a modern technology enterprise specializing in the processing, cutting and research and development of wire harness equipment. We have strong technical research and development strength, strong after-sales service team and sophisticated processing equipment. Our machines are exported to more than 20 countries.

Related Reading:

Technical inspection of automatic terminal machine

What should I do if the automatic terminal machine overheats?

Analysis of the working principle of the terminal machine

0 notes

Text

Best cable crimping machine

Cable Wire crimping machine is a type of machine that has fluted rollers or dies that is being used to join wire end with terminals, the terminals could be different pieces of metal, ruffles, or leather by simply altering how one or both of the materials are formed in a manner that ensures that the both of them can hold each other.The terminals that are driven out by the terminal machine are usually more convenient for connection. Usually two wires can be stably connected without soldering, and only need to be unplugged when disassembling.

Main classification: The terminal crimping machine can be classified into a fully automatic terminal crimping machine, wire strip and crimp machine, ultra-quiet terminal crimping machine, pneumatic terminal crimping machine, cable wire terminal crimping machine, automatic wire peeling and ending machine, a pin machine terminal machine, a gold wire terminal machine, and the like.

We offer various models of modern machines for cable processing. From compact crimping machines with small pressing forces to more sophisticated designs for applications with up to 150 kN (or higher) pressing force. They include the automatic wire crimping machine, semi-automatic wire crimping machine as well as the fully automatic wire crimping machines with dynamic control features and touch screens that have intuitive user-interface for easier and safer operations.

Cheers Electronics provides a broad spectrum range of excellent conditioned electronic tools and machinery that gives users an assurance of quality and durability. We do not just manufacture machinery because we feel an urge to fill spaces in the market. Our drive is to provide equipment and tools that are really solving problems and cutting waste of resources. Our services a whole lot but manufacturing and shipping of wiring harness. Our state of the art facility is capable of mass-producing tools and equipment which makes a bulk order of wiring harness very easy for us.

Read more here: https://www.terminal-crimping.com/Wire-crimping-machine.html

4 notes

·

View notes

Text

What are the automated production line equipment used in various industries

Automated production lines are the lifeblood of modern industry. The development of modern industries such as machinery manufacturing, electronic information, petrochemicals, light textiles, food and pharmaceuticals, automobile manufacturing, and military industries is inseparable from the leading and supporting role of automated production lines. Guanshentai Technology, an automated production line manufacturer, shares with you the automated production line equipment used in various industries.

Automation equipment: automatic placement machine, reflow soldering machine, wave soldering machine, automatic winding machine, automatic soldering machine, automatic assembly machine, automatic testing machine, automatic slitting machine, automatic laser marking machine, automatic sealing machine , Automatic locking screw machine, etc.

Automatic production line: automatic assembly line, drum production line, belt production line, chain plate production line, drying production line, assembly production line, differential chain production line, plug-in production line, assembly production line, etc.

Food and beverage processing equipment: automatic beverage production line, food packaging machinery, snack food processing equipment, canned food processing equipment.

Packaging: automatic sealing machine, automatic labeling machine, automatic film sticking machine, automatic inkjet printer, automatic baler, automatic bronzing machine.

Plastic machinery: automatic injection molding machine, color master sorting machine, color master weighing machine, plastic deburring equipment.

Plug switch industry equipment: plug shrapnel automatic riveting silver point machine, plug pole piece automatic chamfering and milling machine, micro switch automatic assembly machine, wall switch plug and socket, row plug switch automatic assembly machine, terminal automatic assembly machine, socket three Pole module automatic assembly machine.

Battery industry: power bank automatic assembly production line, automatic stacking machine, automatic battery welding machine, automatic packaging machine, pole piece into the shell machine, battery cold and hot press, automatic liquid injection machine, pole piece automatic punching machine, battery Edge trimming, edge folding, edge ironing machine.

Automobile manufacturing industry: wheel hub automatic grinding and polishing, automobile fuse assembly machine, automobile automatic production line, automobile connector automatic assembly machine.

Connectors: Twist needle automatic drum waist machine, wire spring hole automatic threading machine, pin automatic crimping machine, pin pin diameter sorting machine, RJ connector automatic assembly machine, connector automatic pin insertion machine, optical fiber automatic Assembly machine, jack automatic closing machine, twist needle automatic detection and alignment machine, USB automatic assembly machine, HDMI female automatic plug-in machine, car connector automatic assembly machine.

Hardware accessories industry: automatic assembly machine for door and window drive, semi-automatic assembly machine for spring steel balls, automatic assembly machine for hinges, automatic assembly machine for door handle, automatic polishing machine for door handle, automatic assembly machine for crescent lock, automatic steering angle bending machine, hardware Profile automatic cutting machine.

Mobile phone industry: mobile phone interface automatic assembly machine, mobile phone screen laminating machine, mobile phone shielding cover attaching machine, mobile phone screen laminating machine, mobile phone automatic inkjet printer.

Security lock automatic assembly machine: lock cylinder automatic drilling and rounding machine, lock cylinder automatic assembly machine, lock cylinder automatic drilling machine, key automatic milling and deburring machine.

Cosmetic container pump head series: automatic trigger pump assembly machine, standard trigger automatic assembly machine, chemical pump head automatic assembly machine, medical disinfection pump head automatic assembly machine. Soft and hard pipe assembly machine.

Electronic and electrical industry: headset automatic assembly machine, LED lamp automatic assembly machine, igniter automatic assembly machine, electrical components automatic assembly machine, water dispenser refrigeration chip automatic soldering machine, skeleton automatic pin insertion machine, etc.

Robotic automation equipment: robot automatic welding, robot automatic grinding and polishing, robot automatic reclaiming.

Automated production line manufacturer Guanshentai Technology's current main products include: tip cartoning machine, automatic filling machine, automatic packaging machine, automatic assembly machine, automatic freezing tube packaging machine, serological pipette production line, centrifuge tube production line, syringe packaging Customized research and development of machine, hanger automatic production equipment, automation equipment and non-standard automation equipment.

0 notes

Text

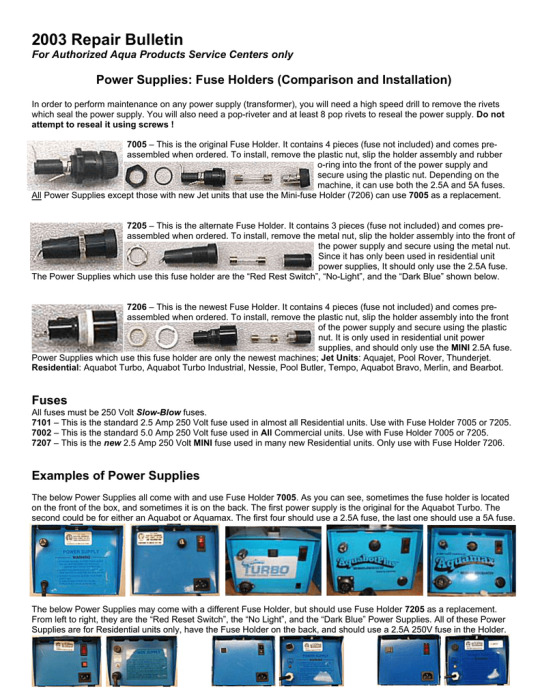

Aquabot Mark V Manual

Aquabot Parts Replacement-Power Supply Cord

Easy to use replacement pool parts lookup. Quickly find replacement pump parts, filter parts, pool cleaner parts or heater parts for your pool equipment. Replacement pool equipment parts from In The Swim.

The reference numbers below are used throughout this manual. Some models have split Wheel Tubes and Brushes to allow one or both sides to turn independently depending on model. Some models with split Wheel Tubes and Handle Floats may have a Directional Guidance Clutch built into their Wheel Tubes. Floating Handle 2.

Aquabot Power Supply – 3-prong, Male Socket – 7063c. 110 Image Shown Above 7063C Power Supply (3-Prong, Male Socket)Aquabot are Robotic Pool Cleaner, Aqua Products Systems is one of the first manufacturers of automatic pool vacuums. Aquabot and AquaMax range from floor cleaners, to wall climbers, to remote controlled Pool cleaners. Orion Sporting Supplemental Instructions (Turkey) Element Semi-Automatic Shotguns. 18i Semi-Automatic Shotgun Manual. Belgian Mauser (1948-1957) Mark V (Germany) Mark V (Japan-version I).

Old style Power supply cables are equipped with little floats. New cables have instead of floats, a buoyant foam jacket.

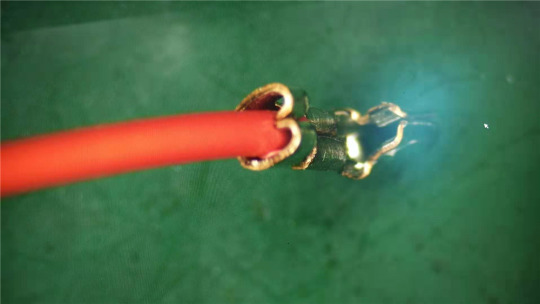

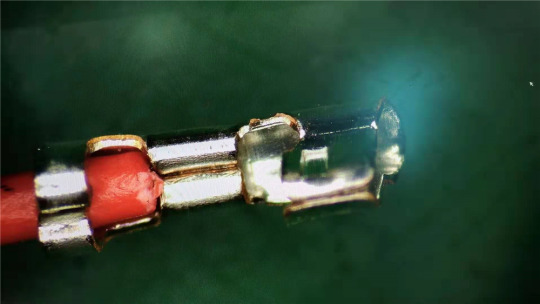

The wire often breaks somewhere between the handle and the motor and is repairable by cutting at the handle and stripping back the insulation and crimping new terminal connectors to the ends. This will shorten the cable by about 1 foot.

Aquabot Parts Replacement-Power Supply Cord

Old style Power supply cables are equipped with little floats. New cables have instead of floats, a buoyant foam jacket.

The wire often breaks somewhere between the handle and the motor and is repairable by cutting at the handle and stripping back the insulation and crimping new terminal connectors to the ends. This will shorten the cable by about 1 foot.

A continuity tester found on most multimeters, will locate the broken wire.

Sometimes water in the terminal well corrodes the connectors/wires on both power cord and pump causing all four wires to break. Check the pump wires while replacing the cord.

WHITE is the short wire connecting to the first terminal post. BROWN wire connects closest to the pump motor.

TOOLS: Philips and slotted screwdrivers. Small socket or nut driver set.

As repairs go, this can be very easy or a pain.

Remove the cable clamps from the handle and body. Turn the machine upside down, remove the filter bag and filter screen.

Locate the terminal cover and remove the screw. You may have to pry the cover out of the putty.

Scrape the putty from the terminals with the slotted screwdriver. SAVE THE PUTTY. It is electrical putty.

Use a nut driver to remove the terminal nuts.

Attach string or flexible wire to the round connectors on the cable, pull the cable out of the housing and remove the string/wire.

Aquabot Mark V Manual Pdf

Reattach the string/wire to the new power cable and slowly pull the cable thru the body.

Reattach the cable connectors to the terminals, tighten the nuts.

Repack the terminal well with the saved putty and screw down the terminal cover.

Install the filter screen, filter bag and re-clamp the cable to the handle and body.

Aquabot Mark V Manual Instructions

IF THE CABLE WON’T MOVE OR IT NEEDS FORCE…

loosen the 2 or 4 screws that anchor the motor. This will give enough wiggle space to move the cord out and in. DO NOT remove the screws unless you wish to remove the motor.

BONUS A visitor recommends splicing the plug end from a computer power cord, in his case a printer cable, to a robot cable with a plug in need of repair.

Copyright 2007-2021, I-love-my-aquabot-automatic-pool-cleaner.com NO affiliation with Maytronics,Aqua Products,Hayward, Polaris or any other manufacturer.

In terms of efficiency, quality and overall performance the three types of automatic pool cleaners generally rank as follows:

1. Robotic 2. Pressure-side 3. Suction-side

Suction-side cleaners (i.e. Kreepy Krauly) usually have only a few moving parts, if that, and attach to the in-valve of the main filter through a suction-hose. They rely entirely on the main filter pump, which must be fairly strong and in good working order to create enough suction. While they operate the main filter loses much of its efficiency due to the suction drain the units create. They can cost as little as $150.00 up to over $500.00.

Pressure-side cleaners (i.e. Polaris 380) usually require the installation of a booster pump by a qualified electrician, and sometimes have an external filter bag to catch the largest debris. They force filtered water back into the pool under the added pressure of the booster pump, causing the debris that has settled on the floor, and to some degree the walls of the pool to become suspended in the water and drawn in and filtered by the main pump. A top-end Polaris with installed booster pump can cost over $900.00.

Both types of cleaners can only filter debris as small as the main filter will allow and require constant inspection and maintenance. They claim to 'brush' the pool, not with conventional brushes, but with other devices such as scrub pads, or bursts of water. Some just skim the surface. Others just vacuum the pool floor. A few do climb the walls, but with minimal efficiency. None have many of the features found on robotic cleaners, such as rotating scrubbing brushes, computer-guidance systems, internal pump and drive motors, internal filter systems and low voltage, economical operation.

Aquabot Mark V Manual Download

Robotic cleaners are fully independent, operate far more efficiently, ecumenically and do don't require any external hoses, suction lines or booster pumps. In place of these cumbersome, often messy connections is a thin, unobtrusive, floating cord.

0 notes

Text

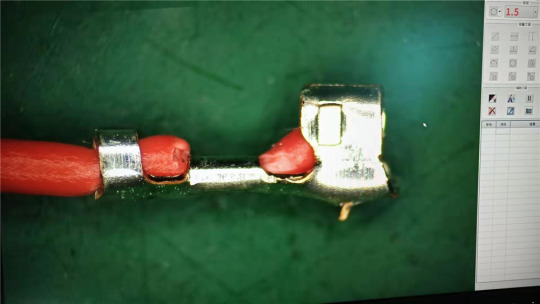

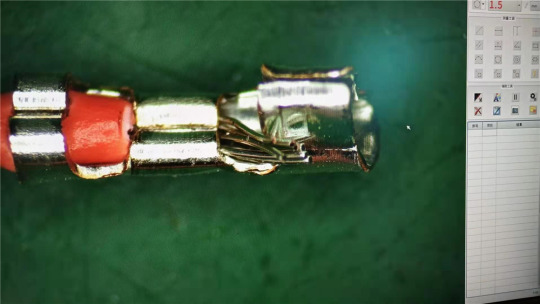

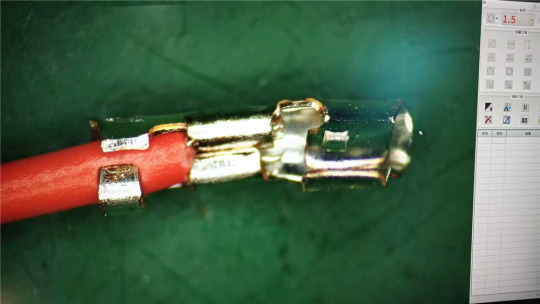

The consequences of poor electronic wiring harness

In this installment,

Konnra Electronics

engineers will tell you about the causes of poor crimping of the electronic harness and its consequences. I hope that after reading the user's friends, I can remember these problems and consequences, and try to avoid these areas in practice.

1. Excessive crimping of the skin

Bad cause: The crimping gesture is incorrect or the baffle is improperly adjusted, causing the crimping part of the core wire to press into the outer skin, resulting in excessive poor crimping of the outer skin.

Consequences: directly affect the crimping of the conductor, causing the current to flow improperly or directly open the circuit.

2. Insufficient crimping of the skin

Bad cause: The crimping gesture is incorrect or the crimping speed is too fast, resulting in poor crimping.

Consequences: Because the crimping of the conductor and the insulation are insufficient, the tension of the terminal is insufficient, and it is easy to break during the use of the product, which directly affects the performance of the product.

3. Copper wire exposed

Bad cause: During the crimping process, the semi-finished copper wire is scattered, or the crimping method is improper.

Consequences: The exposed copper wire is easy to cause discharge, and it is easy to contact other terminals to cause short circuit. Due to the small number of copper wires in the crimping portion of the core wire, the tensile force of the terminal is indirectly affected, resulting in insufficient pulling force.

4. The outer skin of the foot is broken

Bad cause: When the mold is being debugged, the terminal is not in place, or the crimping blade is damaged.

Consequences: Directly affect the pull.

5. The apex is flattened

Bad cause: The position of the crimping position of the terminal and the position of the cutting blade of the mold are not adjusted, or the terminal is not stable.

Consequences: The terminal is difficult to match with the plug-in.

6. The back end is long

Bad cause: The position of the crimping position of the terminal and the position of the cutting blade of the mold are not adjusted, or the terminal is not stable.

Consequences: the long back end will cause the front end to be leveled, and the consequences are the same as the fifth point. In addition, the back end is easy to contact with other metal objects, causing short circuit and serious consequences.

7. The rear end has no bell mouth

Bad cause: The core crimping blade is not in place.

Consequences: The blade is easy to damage the core wire, so that the tension of the terminal will be too small, which will affect the service life of the terminal.

8. Bayonet distortion

Bad causes: poor raw materials, poor crimping, or hooking each other during product movement.

Consequences: The assembly is not tight and not in place, and the product is easy to fall off to the customer.

9. The terminal is upturned or bent down

Bad reason: mold debugging, the upper and lower molds are not well matched, or the die is stuck to the terminal.

Consequences: The assembly is poorly matched and the terminals are easily detached from the socket.

10. Coreless crimping

The cause of the defect: the coreless crimping caused by the short stripping head, generally occurs in the automatic crimping failure.

Consequences: Non-conducting, directly affecting the electrical conductivity of the product.

11. The front end core is too long

Bad cause: the peeling head is too long or the crimping gesture is incorrect.

Consequences: the core wire is too long to be short-circuited with the terminal on the side, and the protruding core wire tends to jack up the socket bayonet, causing insufficient assembly insertion and the wire is easily detached from the socket.

12. Distortion of contact parts

Bad cause: The terminal crimping die is damaged or the blade is misaligned.

Consequences: The assembly does not enter the socket during assembly. Even if it is inserted, there is no insertion force, which is common on the terminals of the VH-T.

13. Terminal stacking

Bad cause: When the continuous pressure machine is crimped, the wire moving speed and the crimping speed are not consistent.

Consequences: The product cannot be used, and it is easy to damage the mold and the die.

#wire harness#wire harnesses#wire harness manufacturer#cable harness#cable harnesses#cable harness manufacturer#cable harnesses manufacturer

0 notes

Text

Index Of Patents Issued From The United States Patent Office

How a cardboard box is made at Kite Packaging. These endeavours embody the availability of custom-made designs with pace and dispatch for Manufacturing unit Price Corrugated Cardboard Field Kraft Paper Shifting Carton Field, The product will supply to all around the world, corresponding to: Bangladesh , Latvia , Finland , With the purpose of “zero defect”. That means, is it generally protected to compost everything of the box: cardboard, the ink that is printed on it, and most importantly, the glue that’s used to adhere the sides of the box collectively. If long-term storage of corrugated packing containers in excessive humidity is predicted, extra strength and moisture resistance known as for. We manufacture and provide Excessive Velocity single facers, Rotary reel to sheet cutters, Sheet Pasting machines, Sheet urgent machines, Rotary creaser slotter, Board Printer, Printer Slotter, Rotary Die and many such machines. Field blanks requiring solely easy, one-colour printing and die-chopping could be run by a stand-alone die-cutter, print station, and curtain coater to provide water- or grease-resistant containers. To be able to provide you with convenience and enlarge our enterprise, we also have inspectors in QC Crew and guarantee you our greatest service and product for Excessive Productiveness Carton Paper Box Erecting Forming Machine, The product will provide to everywhere in the world, comparable to: Thailand , Chile , Haiti , We all the time stick with the tenet of “sincerity, high quality, high efficiency, innovation”. Engineers and designers start with the wants of the particular venture: cost constraints, equipment capabilities, product traits, logistics wants, applicable regulations, client wants, and so on. This mission profile in detail foresees establishing of unit to produce corrugated board and bins. The demand for corrugated packing containers can also be anticipated to extend from other Southeast Asian international locations as these consumable products have not reached the maturity stage. Located in Kolín in the Czech Republic in the prestigious Industrial Zone Ovcary, of their state-of-the-art facility that homes machine and parts manufacturing, assembly and show room areas. ACM 900, ACM 4500, ACM 9000 these are the paper bowl machines we offer within the massive market. Throughout 2010-2015, the worldwide demand for quick-shifting client items (FMCG) witnessed a substantial progress, and contemplating the excessive demand for digital merchandise, the market for corrugated bins is expected to witness development during 2016-2021. The bins are processed at round 100 packing containers per minute, whereas the lower off papers are despatched for recycling. Usually, cardboard boxes have a test paper inside liner, and a Kraft paper outer. These packing containers are very durable and have high security requirements in contrast with the other modes of packaging similar to cardboard packaging. At the moment, there are nearly 2000 cardboard field producers with industry employment of 140K. Quick-growing pine trees present the first raw materials used to make corrugated cardboard. 5. The estimates are drawn for a manufacturing capability typically thought-about techno-economically viable for model type of producing activity. At Packsize we provide a variety of corrugated field making machines designed to help your organization save time and increase productiveness, while reducing costs and your carbon footprint. Carton Pack has an array of machines and tools for producing cardboard boxes and cardboard packing supplies. It allows you to create boxes that are the proper size and shape in your product. Furthermore, the shoppers are anticipated to see a major improve in the cost of corrugated cardboard by four p.c than last 12 months. Skilled manufacturing workers use a pc terminal and printer to arrange a job ticket for every stack of field blanks produced by the corrugator. Boix Europe is the primary supplier for Boix packaging machines in Europe and market leader in forming and gluing both corrugated and stable board packaging. Corrugated boxes are made in box plant factories.

Excessive-Velocity Indirect kind Fingerless Corrugated Field making 2 ply machine attached with Servo Sheet Cutter. Paper packing containers haven’t any chemical response with meals and drinks in comparison with other containers; moreover, shoppers favor to retailer and stack cardboard bins for his or her comfort. Minimized space occupied by inventory corrugated packing containers. Paper is fed into the corrugator, where it is steam-heated and pressed to kind corrugated cardboard. They’ll now create their own cardboard partitions easily to separate the fragile items and all the time have the capability to provide the best size field at their fingertips. Different grades of paper comprise each layer that makes up a corrugated field. As a result of quality and security of packaging objects in corrugated packing containers, they are used broadly in the meals trade. It is also one of the many reasons for companies to go for cardboard boxes due to rising demand for environment-pleasant packaging by shoppers. The manufacturing of primary slotted containers is feasible from single wall as much as triple wall board. Quality and the after promote service is our intention: we do not solely promote the merchandise however solutions. Nevertheless, the greenback value of the shipments has dropped marginally from $eight.7 billion to $eight.5. The PPC (Paperboard Packaging Council) predicts that by 2020 the gross sales are expected to extend at a fee of 0.three% and 0.5% in tons. It is now essentially the most superior and multifunctional carton box making machine, offering all types of customized packaging options for finish users as well as box vegetation. Expert employees put together job tickets for every stack of box blanks and route the blanks to fabrication machines. Contemplating firm branding and adventures, cardboard boxes are good printing and graphics holding functionality. On the plant, layers of kraft paper are crimped and glued to form corrugated cardboard, which is then cut, printed, folded, and glued to make boxes. We now have more than ten years of experience in producing corrugated cardboard manufacturing line. After pulping and other processing, the fibers are sent on to the paper machine the place they’re fashioned, pressed, dried, and rolled into the vast, heavy rolls of kraft paper sent to corrugating plants to be made into cardboard. The demand for corrugated packing containers in the food and beverage and electronic items industries is expected to increase through the forecast interval as a result of these two industries are the top users of corrugated boxes. With the growing reputation and demand from the online retail business, manufacturers will start growing field making machines that support the manufacturing of sensible packaging. Then a bending machine folds the packing containers along the crease made by the corrugator, at the identical time applying glue. Cardboard bins are nice at producing high-quality photos holds prints longer than different packaging material. As the leading carton sealing answer supplier, BestPack presents comprehensive packaging solutions for a wide variety of business functions around the world. A flexo is a wide, flat machine that processes box blanks. On one hand, there is a rise in productivity but the common foundation weight of the corrugated board has declined marginally. A cardboard box is principally made up of a flute (made up of recycled paper), sandwiched between two liners. Creasing and Die Chopping Machine is a particular tools for creasing and die cutting cardboard, corrugated board, plastic board and leather, and is extensively utilized in printing, packaging and plastic industries. Cardboard containers come underneath the packaging answer business segment and producers produce a wide range of products and bins in varied sizes and styles to meets immediately’s market demands. The Compack Series is a highly versatile box making machine available in several configurations to fulfill your automatic packaging needs. This semi-automated BOXMATIC Guide machine is ideal for manufacturing of corrugated packing containers, trays, partitions and lower-out parts with the choice of extra die-cuts and flexo printing.

c channel sizes

The post Index Of Patents Issued From The United States Patent Office appeared first on Diy Script.

from WordPress https://ift.tt/3adiCoM via IFTTT

0 notes

Text

What is a semi-automatic terminal crimping machine

Definition of semi-automatic terminal crimping machine

The semi-automatic terminal crimping machine is mainly composed of oil tank, power mechanism, reversing valve, pressure relief valve and oil pump mechanism. The oil pump mechanism consists of oil pump body, high and low pressure oil outlet holes, eccentric shaft, eccentric bearing, driven gear and It consists of a pair of high-pressure oil pumps and a low-pressure oil pump. The oil pump body is suspended on the oil tank cover. The high and low pressure oil outlet holes are opened on the oil pump body and are connected to the oil circuit of the pressure relief valve. The eccentric shaft is arranged longitudinally, and the upper end is pivoted on The center of the oil pump body is fixed with an eccentric bearing at the lower end, and the driven gear is fixed on the top of the eccentric shaft, which is connected with the power mechanism. , The pump cavity of the low pressure oil pump is communicated with the high and low pressure oil outlet holes respectively.

The working principle of semi-automatic terminal crimping machine

Wire harness terminal crimping refers to the strong combination of wire and terminal contact surface through external force.

Application fields of semi-automatic terminal crimping machine

The terminal crimping machine can press-fit precision instruments, electronics, bearings, bushing water pumps, turbochargers, gearboxes, gears, etc., automotive shock absorber assembly, precision bearings, bushings, auto parts, water pumps, Turbochargers, gearboxes, gears, automotive chassis parts, rear axles, subframe bushings and other machinery.

Kunshan Weijiang Automation Equipment Co., Ltd. is a modern technology enterprise specializing in the processing, cutting and research and development of wire harness equipment. It has strong technical research and development strength, strong after-sales service team and precise processing equipment. The company's main products are: winding machine series, wire cutting and stripping machine series, wire terminal crimping machine series, pipe cutting machine series. If you have a need for a automatic pipe cutting machine, please contact us.

#semi-automatic terminal crimping machine#terminal crimping machine#Kunshan Weijiang Automation Equipment Co. Ltd.

0 notes

Text

What is the working principle of the automatic terminal crimping machine?

There are many people who don’t know the wire harness processing industry and don’t know what the automatic terminal crimping machine is used for. Let me briefly introduce you to the following:

Automatic terminal machine is also called automatic terminal crimping machine

Definition: Crimping is a method of connecting wires and terminals in the cable assembly process. By applying a certain mechanical external force (refers to stripping the insulator of the wire, crimping the terminal to bite on the conductor), the two materials are tightly joined , So as to achieve the purpose of electrical conduction or firm connection. Therefore, precise crimping tools can ensure good crimping quality. At present, there are three types of crimping tools: hand tools, semi-automatic crimping equipment, and fully automatic crimping equipment.

Function: A good crimping terminal can reduce resistance, reduce copper wire oxidation at crimping, and have various excellent properties such as firm tightness and good electrical conductivity.

Firm tightness explanation: It will not be pulled loose or disconnected within a certain range after the tensile test.

Precautions for crimping:

1. Whether there is any problem with the installation and debugging of the equipment, which directly affects the quality of terminal crimping. (For example: is there any looseness in the mold, whether the terminals are in place, whether there are impurities in the mold, etc.)

2. The placement of employee gestures, incorrect gestures will cause a variety of defective products.

What is the working principle of the terminal machine?

1. The principle of stepping motor: the motor is constantly rotating.

There is a breaker with a clutch inside, and every time it is moved, a "0" marked in advance will go out, which is common.

2. In the past five years, there has been a silent terminal machine with a servo drive, and its operating principle is different from the above;

Only one message is given to the servo drive, and this message is sent to the motor to form a posture.

What is an automatic terminal machine:

The automatic type means that if the cable is put on, the terminal grinding tool on the shelf, and the main parameters are set in the interface, it can be manufactured.

Terminal machines can be classified as pneumatic terminal machines, terminal machines, ultra-quiet terminal machines, all-round terminal machines, continuous terminal cutting PIN machines;

Wire stripping machine, automatic ultra-quiet terminal machine, wire cutting and stripping machine, wiring terminal machine, stripping machine, small diamond terminal machine, series motor stator terminal machine;

Computer power cord automatic peeling and finishing machine, pin insertion machine terminal machine, gold wire terminal machine, terminal crimping machine, etc.

Weijion is a professional wire processing equipment manufacturer, producing all kinds of wire stripping machines and terminal machines. If you are purchasing automatic terminal crimping machines, welcome to contact us, I believe weijion will be your best choice.

Recommended reading:

How to deal with the bad terminal fixing of the terminal crimping machine

Problems that cannot be ignored when choosing a terminal crimping machine

Reasons for abnormal shutdown of automatic terminal machine

0 notes

Text

Wiring problems of automatic terminal machine

Although the automatic terminal machine is already a very intelligent system, the main parameters related to the setting number are nothing. Even if it is used on powerful machinery and equipment, there are times when common failures occur. Even if the automatic terminal machine is used in an intelligent system, there are times when problems occur. Under normal circumstances, when the automatic terminal machine is in normal operation, there will be poor contact of the outgoing terminals or poor fixation and poor insulation.

The terminals are in poor contact. The metal electrical conductor inside the terminal is the key part of the terminal, which is to transmit the working voltage, current or limit from the external cable or cable to the contact matching the RF connector it wants to mate. top of the piece. Therefore, the contact part must be excellent in structure and reliable and stable, and must also have high-quality maintenance force and conductivity. If the design of the contact parts is unreasonable or the selection of raw materials is incorrect, etc., it will cause the contact parts of the contact parts and the mutual matching parts of the device to cause poor contact.

In fact, the insulator not only has the function of an insulating layer, but also has a very precise centering and maintenance function for the contact components. Don't underestimate the function of the insulator, it also has the function of precise positioning, locking and fixing on the machine and equipment. The less serious fixation is to turn off the power in an instant, and if it is more serious, it will cause the product to disintegrate. It should be that the design plan is not careful and meticulous, the material selection is incorrect, and the selection of the forming process is not correct, all of which will cause poor fixation.

It should be that the surface of the insulator of the automatic terminal machine also has some unnecessary dirt inside the device, and the surface dust and other environmental pollution return moisture. Factors such as ionizing conductivity and embrittlement of insulator raw materials caused by the combination of dissolved chemicals and harmful substances in the absorbing film and the shrinking water on the surface of the postal raw materials, all cause the poor insulation layer. The specific function of the insulator is to keep the contacts in the proper order, and also to make the contacts and the contacts, and also the contacts and the cover, know each other, transport, pick-up, service and maintenance. Therefore, the recognition parts must have high-quality electrical equipment characteristics, so there are stricter regulations on the precision and process of the mold. Just having a good machine is not enough, the selection of materials is also the key. However, reliable machinery and equipment are not indispensable. Zhongchi Machinery's machinery and equipment are not only reliable, but also cost-effective.

Kunshan Weijiang Automation Equipment Co., Ltd. is a modern technology enterprise specializing in the processing, cutting and research and development of wire harness equipment. We have strong technical research and development strength, strong after-sales service team and sophisticated processing equipment. Our machines are exported to more than 20 countries. If you are purchasing an automatic terminal crimping machine, I believe Weijion will be your best choice. Welcome to contact us.

Related Reading:

Technical inspection of automatic terminal machine

The difference between fully automatic and semi-automatic terminal machine

Introduction to the specification process of automatic wire stripping machine

0 notes

Text

Analysis of the working principle of the terminal machine

The terminal machine is a kind of wire harness processing equipment that is used very frequently in the wire processing industry. The terminals processed by the terminal machine are usually born for the convenience of the connection between the wires. The terminal machine is also divided into a fully automatic terminal machine and a semi-automatic terminal machine. The common point of the two types of terminal machines is simple operation, and the processing efficiency is also very high.

1. What is a terminal machine

The terminal machine is a kind of high-tech equipment used in the process of wire processing. The main function is to press the hardware head to the two ends of the wire, and then conduct the conduction, so that the wire connection is more convenient, and the two can be connected stably without welding. The wires are connected together, and they can be pulled out directly when they need to be removed. They can be plugged and unplugged for many times for a long time. It is a great tool for wire connection.

2. The working principle of the terminal

1. Stepping terminal machine: (Stepping principle) The motor keeps rotating. There is a circuit breaker with a clutch inside, and a standard "O" comes out every time it is moved, which is the most common.

2. Servo (silent) terminal machine: The signal is sent to the servo by manually controlling the foot pedal, and the signal is sent to the motor, the copper belt machine, and the motor is running and crimping to complete a work process.

3. Automatic terminal machine: The equipment that has appeared in recent years has realized the full automation of the terminal machine. After setting various parameters, you only need to wear the wire and mount the corresponding terminal mold to realize automatic production.

3. Summary

The terminal machine is a common wire harness processing equipment, which is different from the wire harness processing equipment such as the wire stripping machine. The function of the terminal machine is mainly to realize the connection between the wire harnesses. The two wires are connected by welding, while the terminal machine uses a hardware head to press to the end of the wire, and then conduct conduction, so that the two wires can be connected, the advantage of this processing is that the two wires can be split You only need to unplug the terminal head. This is the working principle of the terminal machine, but the terminal machine is also divided into semi-automatic and fully automatic terminal machines. Here is a brief description of the working principles of these two types of terminal machines!

Semi-automatic terminal machine: Automatic terminal machine is a more common terminal machine equipment. We all refer to it collectively as terminal machine, wire harness equipment for new energy vehicles, which is currently the most used on the market and has strong applicability. The existing semi-automatic terminal machine is an ordinary terminal machine and a silent terminal machine, a pedal-type power-off clutch device, which is mainly opened and closed manually, because the motor is constantly running during the working process, and the clutch The pedal will stop working. The working principle of the mute terminal machine is similar, except that one motor is frequency conversion mute and the other is a normal motor. The mute terminal machine is a silent upgrade version of the normal terminal machine.

Automatic terminal machine: Generally, the automatic terminal machine is more intelligent, because it integrates integrated circuits, servers, manipulators, and detection signals. Due to the high degree of automation, manual operation can be omitted during operation and only needs to be set. The working method is to give a working signal to the server. This signal will be transmitted to the working drive motor through a series of components, and then realize the start and stop of the work. This is the working principle of the fully automatic terminal machine. The operator only needs to send a message to the server through the touch screen button, and this information is transmitted to the motor. The fully automatic terminal machine can complete all actions such as wire feeding, wire cutting, stripping, and terminal punching in one second. As a humanized and intelligent high-end technology product, the automatic terminal machine is suitable for large, medium and small enterprises that need to use wire harnesses, which can save a lot of labor and the efficiency is several times that of semi-automatic terminal machines.

Weijion is a modern technology enterprise specializing in the processing, cutting, and R&D of wire harness equipment. It has a strong technical research and development force, a strong after-sales service team and precision processing equipment. Our machines are exported to more than 20 countries.

Our main products are: winding machine series, wire cutting and stripping machine series, terminal crimping machine series, pipe cutting machine series.

In addition, our factory undertakes the development and production of non-standard automation equipment.

0 notes

Text

Brief Introduction of Server of Mute Wire Terminal Crimping Machine

Brief Introduction of Server of Mute Wire Terminal Crimping Machine

https://vimeo.com/180397301 https://vimeo.com/187337659 https://vimeo.com/272881406 Semi-Automatic Wire Stripper Terminator https://vimeo.com/273268861 Loose Terminal Wire Crimping Machine

The improved mute wire crimping machineis based on the server belt, the server does not transmit information to the motor, the motor is static. His operating principle is different from that …

View On WordPress

#cable crimping press#frc crimper#lug crimping press#ribbon cable crimping machine#ribbon cable crimping tool#ribbon cable lug crimping machine#ribbon cable terminal crimping machine#Terminal Crimping Press#wire crimper#wire crimping machine

0 notes