#Solution for Textile

Explore tagged Tumblr posts

Text

End to End Solution for Textile and Garment Industries

Are you able to trace all the orders through all stages of production?

Do you know the reason behind your low profits?

If you are searching for answers to these questions you are on the right page. After reading this you could get answers to these questions and maybe more.

Textile Industry is booming in today’s market, it is one of the oldest industries dating back several decades. Clothing is the basic need of every man despite his age and income. So the area of influence for the textile industry is relatively limitless. Maintaining a proper business and fulfilling the basic needs of the customers is crucial for the textile industry.

From pre-production to the final stage of product manufacturing each step should be carried out precisely leaving no room for errors achieving maximum ROI. A fashion industry without an equipped ERP solution is difficult to deal with. If you are on social media then a tweet, pin, or like can bring demand instability to handle this ERP system This will help you foresee demand patterns, and customers’ wish lists and attain clients whenever needed. Without ERP Advantages and Features of a Textile ERP

In a survey of 255 companies looking to purchase ERP software, 89% identified accounting as the most critical ERP function. Other responses included inventory and distribution (67%), CRM, sales (33%) and technology (21%).

Need for ERP in the Textile Industry

Technology nowadays is the bottom line for every business. ERP here helps in designing footwear and apparel, production and supply chain management. The road map designed here includes cost and time efficiencies, traceability, visibility, getting detailed orders, effectively monitoring the operations, drafting quick responses, scheduling the order and predicting data in a much better way.

Marketing Management

Many enterprises still have to structure a plan for the front end to leverage ERP data. To improve the market share it is crucial to use data logically to streamline demand analytics, data history, trends and much more.

Manufacturing Management

In the process of creating finished products with a combination of raw materials and various ingredients, many businesses are adopting manufacturing ERP software to deal with their challenges.

Finance Management

The ERP finance management module handles the accounting and financial management systems of the company. I am starting from standard accounting records, balance sheets, financial reports and handling transactions.

Supply chain Management

Feature-rich ERP solution adds value to the supply chain from selecting proper raw materials to end-product delivery. The solution takes care of the physical aspects of the chain including storage.

HR Management

HR management has automated features for handling all the aspects of personal management, starting from recruiting to onboarding to attendance and payroll. It bridges the gap between management and employees.

By this, you learned the importance of ERP Solution in the Textile Industry Stay connected to explore the advantages of implementing ERP.

This Blog is Already Published in Need for ERP in the Textile Industry

Contact No: +91 97370 45567

Email: [email protected]

#Need for ERP in the Textile Industry#importance of ERP Solution in the Textile Industry#Solution for Textile#erp software

0 notes

Text

Step inside this enchanting tiny home and feel the warmth of a space that radiates comfort and personal expression. The rustic wooden walls enclose a sanctuary filled with vibrant, tribal textiles, each detail telling a story of craftsmanship and connection to the earth. Plush pillows and layered patterns draw you into the built-in daybed, where you can curl up with a good book as soft light filters through the forest outside. With its open yet intimate design, this tiny retreat proves that even the smallest spaces can be filled with big style and soul. Every corner whispers of a life lived in harmony with nature, where simplicity meets artistry in the most inviting of ways.

#tiny house interior#cozy living#bohemian home#rustic charm#tiny home decor#cabin vibes#boho interior#native textiles#forest home#small space solutions#warm and cozy#earthy tone interior#wooden walls#tiny space big style#tribal design#mountain living#nature inspired decor#tiny house movement#woodland retreat#boho chic#handmade interiors#pattern play#bohemian living#minimalism with soul#cozy life#tiny home goals#rustic luxury#wooden interiors#natural living#AI generated

12 notes

·

View notes

Text

parental issues so bad, my boss called me ‘my [their] son’ as a joke and I almost cried

#xjl thoughts#there’s sm context to this#1. is that my boss is only in their 30’s (BARELY in their 30’s) so that makes it doubly unreasonable#2. is that we’re a lot more casual (and boss is rlly relative bc they’re actually very kind) bc I’m their social carer#social carer in the loosest sense but idk how/what else to describe it#3. is that it was a joke at first bc I see them on weekends and they always feed me and now I stay over at times (first time#was bc the train back home was suddenly delayed an hour and the other times are either so I can continue social caring™️ the next day or bc#I’m escaping my actual parents)#and then I said it as a joke when I asked if I was applying the lacquer to a wood thing right#and now this most recent time was bc I texted them at 10pm abt a laundry emergency#(the emergency was that my pillow wasn’t drying in the dryer after washing and the solution was that I shunt it off to my actual mother)#and they said ‘good night my son’ as definitely a joke#also I texted them bc they sew and are very well-versed in textiles™️#yeah that’s current crisis#good GAWD I hope they don’t somehow see this#ik they also have tumblr (yet another reason we are more casual is bc we’re both insane and in fandom)#but idk what their tumblr is#they would most certainly deduce this is abt them and this is me if they somehow saw this

2 notes

·

View notes

Text

#facehugger#xenomorph#alien 1979#textiles#textile art#soft sculpture#crocheting#fiber art#my upl#i like how you can see different solutions used to make their tails

31 notes

·

View notes

Text

1 note

·

View note

Text

Top Synthetic Dyes Companies Driving Innovation & Sustainability in 2025

The global synthetic dyes market is undergoing a transformative shift. As the demand for sustainable, high-performance dyes surges across textiles, coatings, packaging, and plastics, industry leaders are stepping up with advanced technologies, eco-innovations, and bold strategic investments.

The synthetic dyes market is expected to grow at a CAGR of 5.0% to reach USD 9.05 billion by 2029

Here’s a deep dive into the top synthetic dye companies and how they’re shaping the future of colorants worldwide.

Top Synthetic Dyes Manufacturers

The synthetic dyes market is dominated by several major players—known for their innovation, sustainability, and expansive portfolios. Here are the standout companies shaping the industry:

1. BASF SE

Germany-based BASF leads the field with high-performance and eco-friendly synthetic dyes. With a strategic €70 million investment in bio-based Natupal® TS colorants, they’re committed to renewable feedstocks and strong collaborations—like with Nestlé for plant-based meat color solutions

2. Huntsman Corporation

A major US player offering a wide range of dyes for textiles, plastics, coatings, and cosmetics. Huntsman champions sustainability, with innovations like Eriopon® E3-Save reducing water and energy use during application

3. Clariant AG

Swiss-based Clariant integrates circular economy principles with technologies like Reaxol®, which recycles textile dye wastewater and cuts effluent by 90%. Their global partnerships, such as with ITC in India, showcase their capability

4. Archroma

Known for sustainable and high-performance dyes, Archroma offers eco-conscious ranges like EarthColors and innovations like metal-free acid dyes. Their comprehensive portfolio includes AVITERA SE, Diresul, and LUMAPLAST

5. DyStar Group

A global leader in textile dyes and chemicals, DyStar focuses on vertical integration and cost-effective production. Their Eco-Advanced Black and EcoFast Pure technologies improve dyeing efficiency and sustainability

6. DIC Corporation / Sun Chemical

Japan’s DIC—with its Sun Chemical subsidiary—leads in industrial and packaging dyes, offering UV- and heat-resistant pigments for coatings and printing

7. Kiri Industries Ltd.

An Indian powerhouse, Kiri focuses on cost-effective reactive dyes and is expanding capacity with a new Gujarat plant. Their Axill Series targets international markets with price-competitive solutions

8. Atul Ltd.

Another Indian leader with a broad product portfolio, Atul serves over 4,000 customers globally with specialty dyes and chemicals, emphasizing both diversity and customization

9. Zhejiang Longsheng (DyStar), Sumitomo Chemical, Lanxess AG, Heubach Colorants & Aarti Industries

These firms are essential players with offerings across textiles, coatings, plastics, and food; many are scaling up with eco-innovations and regulatory compliance in mind

Download PDF Brochure :

Industry Trends & Competitive Strategies

Sustainable Chemistry: Emphasis on low-VOC, bio-based dye systems like BASF’s Natupal® and Archroma’s EarthColors.

Circular Solutions: Clariant and DyStar focus on wastewater recycling and resource-efficiency technologies.

M&A & Partnerships: Huntsman’s acquisition of Gabriel Performance and Archroma’s alliances bolster portfolios and technology reach.

Digital & High-Performance Dyes: Oil- and UV-resistant pigments for industrial coatings and automotive OEMs are gaining traction.

Regional Market Insights

Asia-Pacific dominates with >70% market share, driven by China, India, Bangladesh, and Vietnam’s textile sectors

North America focuses on high-performance, specialty dyes in automotive, packaging, and construction.

Europe demands advanced technical and eco-friendly dyes in automotive, coatings, and packaging industries.

Why These Companies Lead

Robust R&D: Leaders like BASF, Huntsman, and Clariant invest heavily in sustainable, high-performance innovations.

Global Reach: Strong manufacturing and distribution networks across Asia, Europe, and North America.

Regulatory Agility: Strength in global compliance—from REACH to OEKO-TEX and ZDHC.

Diversified Portfolios: Serving multiple sectors—textiles, plastics, coatings, packaging, and specialty industries.

To maintain a competitive edge, companies must continue:

Pushing green chemistry and sustainability-focused product lines.

Scaling production of low-environmental-impact dyes.

Digitalizing operations for custom, high-performance dye formulation.

Partnering strategically to enter new verticals and regions.

Get Sample Report Now : The global synthetic dyes industry is no longer just about color—it's about sustainability, innovation, and resilience. As top players invest in cleaner technologies and smarter strategies, the future of synthetic dyes is vibrant in more ways than one.

#synthetic dyes manufacturers#top dye companies 2025#textile dyes market#eco-friendly dyes#BASF dyes#Archroma EarthColors#DyStar sustainability#reactive dyes India#bio-based colorants#textile chemical leaders#dye industry trends#pigment market leaders#dyeing innovation#global dyes market#sustainable dyeing solutions

0 notes

Text

PFAS Compliance 2025: U.S., Canada & EU Regulatory Deadlines Explained

PFAS compliance is no longer a future concern — it’s a current crisis. In this short podcast clip, Kunal Chopra breaks down the critical 2025 PFAS regulations across the U.S., Canada, and the EU, including major bans in California, Minnesota, and Maine, and reporting requirements under Canada’s CEPA. Manufacturers must act now to avoid costly disruptions. Learn how Certivo's AI-powered compliance solutions help businesses stay ahead of changing chemical regulations.

📺 Watch this clip: https://youtube.com/shorts/qnyVuQ3acao

🎥 Watch the full podcast: https://youtu.be/kA86gqKMBIk

🔗 PFAS Compliance Help: https://www.certivo.com/solutions

🌐 Visit Certivo: https://www.certivo.com/

#PFAS compliance solutions for manufacturers#2025 PFAS regulations USA#Canada CEPA PFAS reporting rules#EU REACH PFAS restrictions 2025#PFAS textile product bans by state#AI tools for chemical regulation compliance#How to meet PFAS reporting deadlines#Certivo PFAS compliance software#PFAS supply chain compliance guide#Regulatory compliance automation tools

0 notes

Text

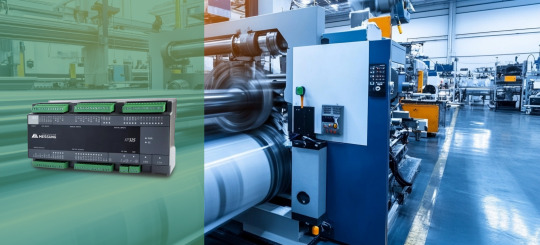

Enhancing Textile Machinery Efficiency with Messung's NX-ERA Xpress PLC

The textile industry, being a part of global manufacturing, has witnessed a massive transformation in recent years due to accelerated technological advancements. From yarn making to dyeing yarns with complex patterns, each process of textile production has been streamlined for higher productivity, accuracy, and efficiency. The need for high-quality products and shorter production cycles has generated fertile ground for automation, especially with the use of Programmable Logic Controllers (PLCs)in textile manufacturing.

This is where we at Messung Industrial Automation come in the picture with our cutting-edge automation solutions. With our strong heritage of delivering strong and scalable automation solutions, we have been the industry leader in industrial automation. Our innovative and compact PLC, NX-ERA Xpress has been crafted to specifically address the specific requirements of industries such as textile manufacturingwith the ideal combination of performance, flexibility, and energy efficiency. In this blog, let’s explore the revolutionary potential of NX-ERA Xpress PLCand its impact on textile machinery, with an emphasis on how it improves operational efficiency, cuts costs, and accelerates the journey towards Industry 4.0.

The Role of PLCs in Modern Textile Manufacturing

Programmable Logic Controllers (PLCs) form the foundation of automation in textile manufacturing, especially in the "cotton to yarn" and "yarn to fabric" segments where their role is most critical. These rugged, industrial-grade controllers ensure precision, speed, and efficiency by managing machinery and processes in real time. From ginning and bale plucking to spinning, carding, drawframe, combing, ring frame machines, and autoconers, PLCs are deeply embedded in every stage of the cotton-to-yarn journey.

In the yarn-to-fabric sector, PLCs continue to play a significant role in the operation of warping machines, twisting machines, and various types of looms such as shuttle, airjet, and rapier looms. They are equally vital in fabric processing lines, managing singeing, bleaching, dyeing, and a wide range of finishing machines designed to enhance textile properties like softness, wrinkle resistance, or water repellency. Printing lines, including rotary and flat bed printing machines, also rely heavily on PLC-controlled automation.

Across these applications, PLCs are integrated with Human Machine Interfaces (HMI), Variable Frequency Drives (VFDs), and in high-speed machines like spinning lines, Servo amplifiers and Servo motors are used for superior speed and torque control.

While the garment sector (fabric to garment) does involve automation, Messung’s core expertise and solutions, including the NX-ERA Xpress PLC and NX-ERA Jet PLC, are primarily focused on the earlier and more automation-intensive stages of textile manufacturing.

Benefits of Implementing PLCs on Textile Machinery

Increased Efficiency: PLCs allow streamline operations by automating processes that were previously manual, significantly reducing downtime and increasing throughput

Improved Accuracy: The high-level precision control afforded by PLCs ensures each activity in the fabric process, whether spinning or weaving, is undertaken with perfection.

Real-Time Monitoring: PLC-based systems make equipment monitoring in real-time a certainty, where defects are flagged off early and avoid costly downtime along with plant operation performance improvements.

As the textile industry advances, compact PLCs are not an indulgence but a must-have. Automation is the key to staying competitive, and industrial automation PLC systems like the NX-ERA Xpress are at the forefront of this revolution.

Learning More About NX-ERA Xpress PLC

The NX-ERA Xpress PLC is our response to the increasing needs of the textile industry. By harnessing the capability of Programmable Logic Control Systems and the flexibility of contemporary communication protocols, the NX-ERA Xpress provides a powerful and scalable solution for numerous industrial automation applications.

Features of NX-ERA Xpress PLC:

High-Density Digital and Analog I/O: The NX-ERA Xpress PLC features a high-density I/O design that is capable of processing vast amounts of data input and output at one time. This is important for the textile industry, where real-time data from many machines need to be processed efficiently in order to optimize performance.

Programming through Codesys® (IEC 61131 Standard): Among the most impressive aspects of the NX-ERA Xpress PLC is its support for Codesys®, an open-source programming platform. This standardization enables seamless integration with industrial equipment across the board, which makes it an attractive option for PLC manufacturing companies.

Integrated Communication Protocols: With inbuilt compatibility for communication protocols such as Ethernet TCP/IP, Modbus, and CANopen, the NX-ERA Xpress PLC facilitates smooth connectivity among various machines and devices on the shop floor. This connectivity is vital for ensuring smooth operation throughout the complete manufacturing process.

Industry 4.0 Readiness: NX-ERA Xpress PLC comes with OPC-UA and MQTT readiness, making it Industry 4.0-ready. These are technologies that support data exchange over different platforms, and they simplify the integration of machines by manufacturers into a smart factory environment.

Integrated HTML Web Server for Remote Monitoring: Remote monitoring has never been simpler. The integrated HTML web server enables operators to monitor and control the PLC remotely, offering flexibility and real-time visibility into machine performance.

The high-performance features and compact PLC design of NX-ERA Xpress PLC make it perfect for the textile industry. Whether you're automating cotton spinning, weaving, or dyeing, the NX-ERA Xpress provides all the power you need to optimize your operations.

Advantages of NX-ERA Xpress in Textile Applications

The textile industry requires solutions that are capable of providing not just high performance but also cost-effectiveness and sustainability. Our NX-ERA Xpress PLC provides a number of benefits for applications in textile machinery, such as:

Energy Efficiency

In the textile industry, energy consumption is a major operational expense. The NX-ERA Xpress PLC is built to maximize control and minimize power consumption, especially in power-hungry processes such as spinning. Through automation processes and optimizing machine efficiency, the PLC ensures textile plants make substantial savings on energy.

High-Speed Processing

Textile production processes often involve rapid and adaptive control systems that are necessary for handling high-speed manufacturing lines. The processing of high speeds facilitated by the NX-ERA Xpress PLC helps data move faster to provide instant adjustment capabilities, ensuring minimum lags in manufacturing processes.

Precision Control

The clothing industry is based on the effective control of variables like thread tension, fabric alignment, and dying processes. NX-ERA Xpress PLC ensures accurate control in order to match every parameter in the manufacturing process to the prescribed specifications. The result is repetitive product quality, and less it is defective.

Scalability

As textile factories develop and expand, scalable automation systems become increasingly relevant. NX-ERA Xpress PLC uses a modular construction that means that automation systems can be expanded as they are required by manufacturers, presenting a great solution for expanding businesses in the textile industry in the long term.

Cost-Effectiveness

Automation must not be expensive. The NX-ERA Xpress PLC is an affordable solution for textile producers that offers high-end features without an exorbitant price tag. It is meant to offer high-performance at an affordable rate, so any textile firm can use it.

Textile Machinery Applications: PLC Precision for a Modern Mill

As textile factories embrace digital transformation, the NX-ERA Xpress PLC emerges as a compact yet powerful solution tailored for automation-ready textile machinery. With its robust control features and Industry 4.0 connectivity, the NX-ERA Xpress brings intelligence and agility to a wide range of textile processes.

Let’s explore key use cases across the textile value chain:

Yarn Steaming Machine:

Steaming is a critical stage in yarn preparation where temperature, pressure, and timing must work in harmony. The NX-ERA Xpress PLC ensures:

Precise control of temperature and steam pressure for consistent yarn conditioning

Regulation of steaming duration to match different yarn types and production speeds

Automation of loading and unloading mechanisms, reducing manual intervention and boosting throughput

With its real-time responsiveness and compact design, the NX-ERA Xpress PLC enhances efficiency, consistency, and reliability in yarn steaming operations.

Heat Setting and Space Dyeing Machine Integration:

In advanced textile finishing, seamless integration between heat setting and dyeing is essential. NX-ERA Xpress PLC brings synchronization and control to:

Temperature management for precise heat setting, improving dimensional stability and dye fixation

Control of dye application in the space dyeing process, enabling unique patterns with consistent results

Coordination of material flow between machines, ensuring smooth transitions and avoiding process bottlenecks

The result is an integrated, high-performance workflow for specialty dyeing applications, digitally governed for optimal output and reduced waste.

Integration with Messung's Automation Ecosystem

One of the major strengths of the NX-ERA Xpress PLC is that it can integrate smoothly with all our other products, like the XM-PRO remote I/O modules. This makes it possible to have a unified automation solution that simplifies the control and monitoring of your entire textile plant.

With a single provider for all automation needs, textile manufacturers can enjoy streamlined operations, reduced complexity, and improved support. The synergy between the NX-ERA Xpress PLC and our other products ensures that your factory is fully equipped to tackle the challenges of modern textile manufacturing.

Conclusion

In summary, our NX-ERA Xpress PLC is a game-changer in the textile sector, providing powerful, scalable, and affordable automation. With its high-performance capabilities, energy efficiency, and accurate control, the NX-ERA Xpress PLC is ideally positioned to address the changing needs of textile producers.

With the NX-ERA Xpress PLC, you can elevate your textile manufacturing process to the next level. Whether you want to optimize spinning, weaving, or dyeing processes, Messung's automation solutions provide the reliability and performance that you require to remain ahead in a competitive market.

So, why wait? Consult Messung today for a customized automation solutionthat suits your textile manufacturing needs. It’s time to embrace the future of textile production with the NX-ERA Xpress PLC - where automation meets innovation

#textile manufacturers#Programmable Logic Controllers (PLCs)#textile manufacturinG#cutting-edge automation solutions#compact PLC#NX-ERA Xpress PLC#textile machinery#Industry 4.0#spinning#carding#drawframe#combing#ring frame machines#autoconers#singeing#bleaching#dyeing#PLC-controlled automation.#NX-ERA Jet PLC#industrial automation#PLC systems#IEC 61131 Standard#Ethernet TCP/IP#Modbus#CANopen#cotton spinning#automation processes#remote I/O modules#automation needs#customized automation solution

0 notes

Text

The Smart Factory Has Arrived—And It's Sewing the Future

Textiles aren’t just about thread and cloth anymore. With Industry 4.0, your factory becomes a high-tech hive of sensors, AI, and automated efficiency. Think predictive maintenance, robotic handling, and data that drives every decision.

And yes, it’s happening now. 🧠🤖

But can your manufacturing line keep up?

We’ve written a full piece diving into how Operational Technology (OT) and digital transformation are revolutionizing textile factories worldwide.

🎯 Don’t miss the big trends—visit the full article here: 🔗 Read the complete blog here Visit us at Daitan Solutions

0 notes

Text

Jig Dyeing Machines Market set to hit $1203.4 million by 2035

The global Jig Dyeing Machines market is poised for significant growth, with industry revenue projected to rise from $521.4 million in 2024 to $1203.4 million by 2035, reflecting a compound annual growth rate (CAGR) of 7.9% from 2024 to 2035.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/jig-dyeing-machines-market-research-report

Jig Dyeing Machines are essential in the textile industry, playing a crucial role in applications such as fabric dyeing, garment dyeing, industrial material dyeing, and home textiles. The market's growth is primarily driven by the increasing demand for automated textile dyeing solutions and the emergence of sustainable dyeing technologies.

Competitive Landscape and Market Leadership

The Jig Dyeing Machines industry is highly competitive, with several key players leading innovation and market penetration. Major companies in this space include:

Benninger

Singularity

Bosen

Fong's National Engineering

Thies

Loris Bellini

Brazzoli

Sclavos

A.T.E. Enterprises

Goller

Tong Geng Enterprise

Tecnorama

These companies are investing heavily in research and development to introduce energy-efficient, sustainable dyeing solutions and improve automation capabilities. This ongoing innovation is helping them maintain leadership in the market.

Key Growth Drivers and Market Opportunities

Several factors are driving the growth of the Jig Dyeing Machines market:

Technological Advancements: Innovations in dyeing machine technology are increasing efficiency, reducing water and energy consumption, and improving dyeing quality.

Sustainability Focus: The rise of eco-friendly dyeing solutions, such as reduced chemical use and water recycling, is creating significant opportunities for market growth.

Automated Dyeing Solutions: Increased demand for automation in textile manufacturing is pushing the adoption of advanced jig dyeing machines.

Expanding Textile Industry: The growing textile industry in developing economies is driving demand for high-efficiency dyeing machinery.

Sustainable Production: Manufacturers are focusing on developing dyeing machines that comply with environmental regulations and sustainability standards.

Emerging Markets and Regional Shifts

North America and Europe remain the most active regions in the Jig Dyeing Machines market, with established textile industries and strong regulations supporting sustainable practices. However, emerging markets such as China, India, Vietnam, South Africa, and Colombia are becoming increasingly important for revenue diversification and market expansion. These regions offer significant growth potential due to rising industrialization, increased demand for textiles, and growing environmental concerns.

As the market faces challenges related to high initial investment, maintenance costs, and regulatory compliance, the supply chain is expected to evolve. Companies will focus on improving their supply chain efficiencies and exploring new markets to maximize growth opportunities.

About DataString Consulting

DataString Consulting is a trusted provider of market research and business intelligence solutions, offering comprehensive services for both B2C and B2B markets. With over 30 years of combined industry experience, DataString specializes in delivering actionable insights that help businesses make informed, strategic decisions.

The company’s expertise spans multiple industries, and it provides tailored research services in areas like strategy consulting, opportunity assessment, competitive intelligence, and market forecasting. DataString Consulting helps clients navigate complex markets and capitalize on emerging trends to achieve long-term success.

#Jig Dyeing Machines#Textile Industry#Market Growth#Sustainable Dyeing Solutions#Automated Textile Dyeing#Dyeing Technology#Textile Machinery#Fabric Dyeing#Garment Dyeing#Industrial Material Dyeing#Home Textiles#Energy-Efficient Dyeing#Eco-Friendly Dyeing#Textile Manufacturing Automation#Emerging Markets#Industrialization#Global Market Trends#Competitive Landscape#Technological Advancements#Market Forecast#DataString Consulting#Textile Machinery Market#Sustainability in Manufacturing#Market Research

0 notes

Text

Colours do more than just brighten our world—they influence emotions, set moods and create powerful impressions! Whether you want to energize, soothe or inspire, every shade has its own unique impact.

At Rathi Dye Chem, we create high-quality dyes that bring your vision to life with unmatched precision and vibrancy. Serving diverse industries, we help colours work their magic in every application!

Explore our world of Colours today! www.rathicolours.com

#RathiDyeChem #Dyes #coloursolutions #Pigments #Innovation #EcoFriendly #Sustainable #Solutions #ColourInnovation #Quality #Industry #solventdyes

#solvent dye#colour solutions#Dye#DyeChemicals#Pigments#Colours#Wool#Textile#Applications#Industries#solutions

0 notes

Text

Dynamic Looms | Weaving Machine Manufactures in Gujarat, India

Dynamic Autolooms India Pvt. Ltd. was established in 1976 itself as a pioneer in the weaving industry, serving both domestic and international markets. The company specializes in advanced rapier looms and shuttle looms, catering to fabric manufacturers across diverse sectors such as apparel, technical textiles, and industrial textiles. Known for integrating decades of experience with cutting-edge technologies, Dynamic Autolooms delivers innovative, high-quality solutions for its customers, ensuring that quality outshines cost.

With over 1,50,000 weaving machines installed globally and a trusted clientele of more than 3,000 companies, Dynamic Autolooms has revolutionized fabric manufacturing with its modernized looms. From high-speed rapier looms to specialized technical fabric looms, the company’s engineering excellence has set industry benchmarks for innovation and reliability.

Products:

Dynamic Autolooms provides advanced textile machinery, including:

Rapier Looms: Precision looms with modern technologies, approved under the Government’s TUF subsidy scheme.

Shuttle Looms: High-speed looms for durable, quality fabric production.

Electronic Jacquards: Configurations from 640 to 5,376 hooks for intricate weaving.

Specialized Equipment:

Electronic Let-off and Take-up Systems

Truck-in Devices

Custom technical developments for specific fabrics.

Industries Served:

Dynamic Autolooms provides solutions across various textile sectors:

Apparel Textiles:

Sarees: Fine cotton and silk fabrics with intricate patterns.

Light Denim: Fashionable, high-speed woven denim.

Corduroy: High-density fabrics with superior texture.

Ethnic Wear: Precision-woven sherwanis, dupattas, and salwars.

Household Textiles:

Furnishing: Premium fabrics for curtains, shawls, and blankets.

Bed Sheets: Soft, durable materials for homes and businesses.

Technical Textiles:

Glass Fiber: Specialized looms for industrial applications.

Filtration Materials: High-performance fabrics for filtration.

Packaging: HDPE and HTPP heavy-duty fabrics.

Certifications:

ISO 9001:2008 Certification: First Indian weaving machinery manufacturer to achieve this milestone.

Member of:

Ahmedabad Textile Industry’s Research Association (ATIRA)

Textile Machinery Manufacturers Association (TMMA)

Engineering Export Promotion Council (EEPC)

Indian Textile Accessories & Machinery Manufacturers Association (ITAMMA)

Ahmedabad Engineering Manufacturers Association (AEMA)

Gujarat Chamber of Commerce and Industry (GCCI)

Indian Technical Textile Association (ITTA)

Micro, Small & Medium Enterprises (MSME)

National Small Industries Corporation (NSIC)

Infrastructure: Dynamic Autolooms operates a 1,50,000 sq. ft. facility on a 2,60,000 sq. ft. plot in Ahmedabad, Gujarat, featuring cutting-edge technologies for precision manufacturing. Key features include induction furnaces for casting, CNC and VMC machines for machining, and Mitsubishi EX laser cutting for accuracy. The in-house foundry, active since 1984, supports internal and external casting needs. Advanced design software like Solid Edge ST4 aids the R&D team in driving innovation and maintaining industrial standards.

Quality Assurance: Dynamic Autolooms ensures quality at every stage of production with stringent ISO-compliant processes. From material sourcing to final assembly, the company uses advanced manufacturing technologies, backed by dedicated quality control and R&D teams, to deliver durable and reliable products.

Customer-Centric Approach: Dynamic Autolooms places the customer at the core of its operations. The company is dedicated to understanding and fulfilling customer needs, offering tailored solutions and robust after-sales support. Ensuring clarity in all customer interactions, Providing high-quality products backed by dependable services, Fostering long-term relationships by exceeding customer expectations.

Technological Innovations: Dynamic Autolooms thrives on innovation, with a focus on continuous research and development. With Velvet Looms, Electric Jacquards and Infinity-I Sample Loom.

As a leading weaving machinery manufacturer in India, Dynamic Autolooms continues to provide the best weaving solutions for fabric manufacturers, setting industry benchmarks in quality and innovation.

#Dynamic Looms#Dynamic Production in Gujarat#Electronic Jacquard#Rapier Loom#Shuttle Loom#Power Loom#Jacquard Rapier Loom#Looms for Technical Textiles#Wire Weaving looms#Shuttleless Rapier Loom#Rapier Weaving Machine#Electronic Let-off Mechanism#Flexible Rapier Loom#Trendy Rapier Weaving Machine#High Speed Shuttle Loom#Heavy Duty Flexible Rapier Loom#Semi Automatic Drop Box Shuttle Looms#Largest Rapier Loom Manufacturer#Electronic Jacquard in Gujarat#Looms Factory#Automatic Shuttle Loom#Automatic Shuttle Loom Suppliers#Rapier Loom Manufacturer#Power Loom Machine Manufacturers in India#Looms Company#Loom India#Automatic Shuttle Loom in India#Rapier Loom Manufacturers in India#Textile Weaving Machine Manufacturer in India#Best Weaving Solutions

1 note

·

View note

Text

Premium Textile Solutions by The Fabrima: Quality Fabrics for Every Need

The Fabrima provides premium fabric manufacturing solutions, offering a wide range of textile products. Our eco-friendly and durable fabrics are perfect for various industries, ensuring quality and sustainability.

1 note

·

View note

Text

1 note

·

View note

Text

"The substances behind the slimy strings from okra and the gel from fenugreek seeds could trap microplastics better than a commonly used synthetic polymer.

Texas researchers proposed in 2022 using these sticky natural polymers to clean up water. Now, they’ve found that okra and/or fenugreek extracts attracted and removed up to 90% of microplastics from ocean water, freshwater, and groundwater.

With funding from the U.S. Department of Energy, Rajani Srinivasan and colleagues at Tarleton State University found that the plant-based polymers from okra, fenugreek, and tamarind stick to microplastics, clumping together and sinking for easy separation from water.

In this next stage of the research, they have optimized the process for okra and fenugreek extracts and tested results in a variety of types of water.

To extract the sticky plant polymers, the team soaked sliced okra pods and blended fenugreek seeds in separate containers of water overnight. Then, researchers removed the dissolved extracts from each solution and dried them into powders.

Analyses published in the American Chemical Society journal showed that the powdered extracts contained polysaccharides, which are natural polymers. Initial tests in pure water spiked with microplastics showed that:

One gram of either powder in a quart (one liter) of water trapped microplastics the most effectively.

Dried okra and fenugreek extracts removed 67% and 93%, respectively, of the plastic in an hour.

A mixture of equal parts okra and fenugreek powder reached maximum removal efficiency (70%) within 30 minutes.

The natural polymers performed significantly better than the synthetic, commercially available polyacrylamide polymer used in wastewater treatment.

Then the researchers tested the plant extracts on real microplastic-polluted water. They collected samples from waterbodies around Texas and brought them to the lab. The plant extract removal efficiency changed depending on the original water source.

Okra worked best in ocean water (80%), fenugreek in groundwater (80-90%), and the 1:1 combination of okra and fenugreek in freshwater (77%).

The researchers hypothesize that the natural polymers had different efficiencies because each water sample had different types, sizes and shapes of microplastics.

Polyacrylamide, which is currently used to remove contaminants during wastewater treatment, has low toxicity, but its precursor acrylamide is considered toxic. Okra and fenugreek extracts could serve as biodegradable and nontoxic alternatives.

“Utilizing these plant-based extracts in water treatment will remove microplastics and other pollutants without introducing additional toxic substances to the treated water,” said Srinivasan in a media release, “thus reducing long-term health risks to the population.”

She had previously studied the use of food-grade plant extracts as non-toxic flocculants to remove textile-based pollutants from wastewater and thought, ‘Why not try microplastics?’"

-via Good News Network, May 10, 2025

#watere#water pollution#microplastics#plastic#plastic pollution#pollution#solarpunk#environment#okra#fenugreek#united states#north america#texas#environmental science#good news#hope

16K notes

·

View notes

Text

0 notes