#Solvent Extraction

Explore tagged Tumblr posts

Text

Ethyl Acetate Market Poised for Growth by Rising Consumption in Asia Pacific region

The ethyl acetate market is poised for steady growth backed by increasing demand from numerous end-use industries such as textiles, paints & coatings, pharmaceuticals amongst others. Ethyl acetate acts as a superior solvent owing to its favorable properties such as low toxicity, fast evaporation rate and ability to dissolve wide range of organic compounds which makes it ideal for various industrial applications. Global ethyl acetate market is estimated to be valued at USD 6.25 Bn in 2024 and is expected to reach USD 9.91 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 6.8% from 2024 to 2031.

Key players operating in the ethyl acetate market are Berkshire Corporation, Kimberly-Clark Corporation, Contec, Inc., DuPont, Ansell Ltd., Illinois Tool Works Inc., Thermo Fisher Scientific Inc., Valutek Inc., Steris, Avantor, Inc., and KM Purely. Key Takeaways Key players: Berkshire Corporation, Kimberly-Clark Corporation, Contec, Inc., DuPont, Ansell Ltd., Illinois Tool Works Inc., Thermo Fisher Scientific Inc., Valutek Inc., Steris, Avantor, Inc., and KM Purely are the major players in the ethyl acetate market. Key players Berkshire Corporation and DuPont account for over 25% of the global ethyl acetate production and are focusing on capacity expansion plans to cater to the growing demand. Growing demand: The demand for ethyl acetate is high in Asia Pacific region mainly driven by increasing consumption from countries like China, India, Indonesia, Japan owing to growth in end-use industries and emerging applications. Rapid industrialization coupled with rising disposable income is fueling the regional Ethyl Acetate Market Growth. Global expansion: Leading players are strategizing global expansion plans by entering into long term supply agreements with major end-users and investing in new production facilities. For instance, in 2021, Avantor Inc opened a new manufacturing facility in India to leverage growth opportunities in South Asian markets. Market Key Trends Rise in coatings demand from construction industry: One of the key trends driving the ethyl acetate market growth is increasing application in paints & coatings industry especially from construction & infrastructure sector. The ongoing infrastructure development projects across emerging nations are propelling the demand for coatings which utilize ethyl acetate as a solvent.

Porter's Analysis Threat of new entrants: With a moderate capital requirement and long established supplier and customer relationships, the threat of new entrants entering the ethyl acetate market is low. Bargaining power of buyers: Large buyers such as downstream chemical producers can negotiate lower prices; however, the presence of many established suppliers mitigates pricing pressures exerted by buyers. Bargaining power of suppliers: Suppliers of raw materials such as ethanol have some bargaining power over ethyl acetate producers since ethanol is a key raw material with few substitutes. Threat of new substitutes: Some alternative organic solvents can replace ethyl acetate in certain applications, but a lack of direct substitutes that provide the same blend of properties keeps substitution threats low. Competitive rivalry: With major producers having sizable global presences and production capacities, competitive rivalry in the ethyl acetate market is strong as producers vie for market share. However, competition is based more on price and customer relationships than new product innovations. Geographical Regions North America accounted for the largest share of the global ethyl acetate market in terms of value in 2021 due to the presence of sizable end-use industries such as coatings, inks, and pharmaceuticals. Asia Pacific is expected to be the fastest growing regional market between 2024-2031 spurred by rising industrial activity and manufacturing in China, India, and other developing economies that boost demand for ethyl acetate. The ethyl acetate market in Europe holds significant value share owing to the well-established paints, coatings, and pharmaceutical manufacturing sectors. The solvent is widely used across various end-use industries in the region.

Get more insights on Ethyl Acetate Market

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Coherent Market Insights#Ethyl Acetate Market#Ethyl Acetate#Organic Compound#Chemical Synthesis#Ester#Solvent Extraction#Flavoring Agent#Fragrance#Nail Polish Remover

0 notes

Text

got off hold for The Stranger I Wed by Harper St. George and I'm excited to say there is a (likely) future hero who just announced he had cocaine wine and fucked the wife of a Prussian diplomat for 8 hours straight

#did you know cocaine wine was a thing#apparently the ethanol acts as a solvent and extracts the cocaine from the coca leaves in the wine#there's your science lesson for the day#he's also super pissy that his gay older brother has named him his heir#presumably bc he'd rather be drinking cocaine wine and fucking

3 notes

·

View notes

Text

Solvent Extraction Plant – PEMAC Projects

A Solvent Extraction Plant is a key component of the edible oil industry, utilizing specialized machinery to extract oils from seeds and other raw materials. Solvent extraction machineries are essential industrial equipment designed to efficiently extract oils and valuable compounds. The oil-rich miscella is then processed in an Oil Refinery Plant, where it undergoes degumming, neutralization, and other refining processes to produce high-quality edible oils. In contrast, Oil Expeller Plants use mechanical presses to extract oil from seeds without the use of solvents, and they are preferred for producing cold-pressed oils. Various Edible Oil Equipment and Cooking Oil Plants are integral to the industry, providing the necessary tools and machinery to efficiently process and refine oils for consumption and industrial applications.

#solvent extraction plant#solvent extraction machineries#oil refinery plant#oil expeller plants#edible oil equipment#cooking oil plants

2 notes

·

View notes

Text

Extractable and Leachable Testing for Packaging Safety

Protect patients and formulations with Synergy Bioscience’s extractable and leachable testing. Our advanced techniques detect chemical interactions between drug products and packaging. We help mitigate risks, validate container safety, and support compliance with FDA and global regulatory expectations.

#leachable testing#sterility testing lab#extractable and leachable testing#residual solvents testing#dissolution testing#synergybioscience

1 note

·

View note

Text

Ethanol: Versatile Solvent and Essential Ingredient in Various Industries

Ethanol, commonly known as ethyl alcohol, is a colorless, flammable liquid widely used as a solvent, disinfectant, and fuel. In industries ranging from pharmaceuticals to food and beverages, ethanol plays a crucial role in the extraction, formulation, and preservation of products. As a solvent, ethanol efficiently dissolves a broad range of substances, making it invaluable in the production of tinctures, extracts, and cosmetic products. It is also used in the manufacturing of alcoholic beverages, sanitizers, and as a renewable energy source in the form of ethanol fuel. Its versatility, combined with its relatively low toxicity, makes ethanol an essential compound in modern industrial applications. For more details visit our website: www.adchemgas.com

#ethanol#liquid nitrogen#dry ice for sale#denatured ethanol#nitrogen for sale#pure ethanol#co2 for sale#heptane for sale#dry ice pellets for sale#pentane for sale#high purity butane#extraction grade butane#food grade ethanol#high purity hydrocarbons#High Purity Hydrocarbons#Ethanol#Denatured Ethanol#Food Grade Ethanol#Pure Ethanol#High purity butane#High purity butane for sale#Extraction grade butane#Diamond grade butane#nbutane#Butane extraction gas#Propane extraction gas#isobutane extraction gas#Refined butane for extraction#Pure butane 99.5%#High purity solvents “for sale”

0 notes

Text

Exploring the Hexane Market: Trends, Challenges, and Future Outlook

Hexane might not be a household name, but it's certainly an unsung hero in several industries. From extracting edible oils to serving as a solvent in industrial cleaning and adhesives, hexane’s versatility gives it a solid standing in the global chemical market. As industries expand and innovate, this colorless liquid continues to be in demand—albeit with growing scrutiny over environmental and safety concerns.

A Solvent in the Spotlight

Hexane is primarily used in the extraction of vegetable oils from seeds such as soybeans, mustard, sunflower, and corn. Its popularity stems from its ability to extract oil efficiently without compromising the quality or nutritional value. This makes it indispensable for food processors, particularly in large-scale operations where yield and efficiency are paramount.

But the story doesn’t end in the kitchen. Hexane also plays a crucial role in industries like pharmaceuticals, adhesives, leather processing, and even rubber manufacturing. Its strong solvency properties make it ideal for dissolving resins, waxes, and oils, and it finds use as a cleaning agent in electronics and other precision equipment.

What’s Driving the Market?

The global hexane market was valued at USD 2.4 billion in 2022 and is projected to reach USD 3.1 billion by 2027, growing at a CAGR of 4.8%. This growth is no coincidence.

In the Asia Pacific region, particularly in countries like India and China, demand has been surging thanks to a booming food processing industry and rapid industrialization. These countries are major consumers of vegetable oils, and hexane is at the heart of that supply chain. Additionally, as these economies continue to urbanize, the demand for adhesives, sealants, and other chemical formulations also rises—further driving hexane consumption.

North America isn’t far behind. With a strong pharmaceutical sector and demand for industrial solvents, the region contributes significantly to global consumption.

Challenges on the Horizon

However, it's not all smooth sailing for the hexane market.

Environmental concerns are becoming a major point of contention. Hexane is classified as a volatile organic compound (VOC), and prolonged exposure can have harmful effects on both humans and the environment. As a result, regulatory bodies in the US and EU are tightening restrictions on its usage, especially in food and pharmaceutical applications.

This has sparked a growing interest in green solvents—bio-based or less toxic alternatives that offer similar performance with a smaller environmental footprint. While these substitutes are still gaining ground, they pose a long-term threat to traditional hexane demand.

Then there's the issue of raw material pricing. Hexane is derived from crude oil, and as anyone in the petrochemical industry knows, oil prices can be volatile. Fluctuating input costs can impact the profitability of hexane production and lead to pricing instability in end-user markets.

Looking Ahead: Is Hexane Here to Stay?

Despite the hurdles, the outlook for hexane remains optimistic. Analysts project the market to hit USD 3.9 billion by 2033, according to a separate study by Dimension Market Research, growing at a steady pace of 5% CAGR. That forecast suggests that while eco-friendly innovations are on the rise, the reliability and efficiency of hexane still make it hard to replace—at least for now.

There’s also room for innovation within the industry. Producers are exploring ways to minimize emissions and develop cleaner formulations. Recycling and recovery of solvents are also gaining traction, allowing manufacturers to strike a balance between performance and environmental responsibility.

Want to learn more? Click here to download the PDF brochure.

The hexane market is a classic case of a mature chemical commodity adapting to a changing industrial landscape. Its importance in food extraction and industrial manufacturing keeps demand steady, but the future will demand more accountability and innovation.

For businesses operating in this space—whether you’re a supplier, manufacturer, or end-user—the time is ripe to evaluate how your processes can evolve. Staying ahead means not just meeting today’s demand but preparing for tomorrow’s regulatory and sustainability standards. Hexane may be a small molecule, but in the grand scheme of things, it has a big role to play.

#Hexane Market#Industrial Solvents#Edible Oil Extraction#Chemical Industry Trends#Green Solvents#VOC Regulations#Petrochemical Industry

0 notes

Text

Natural product extraction machine

0 notes

Text

Role of Base Oil Solvent Extraction Plants in Lubricant Production

In the world of lubricant manufacturing, base oils are the backbone of the final product. They form the primary component of lubricants, providing essential properties such as viscosity, thermal stability, and oxidation resistance. However, not all crude oil is suitable for direct use in lubricants. This is where Base Oil Solvent Extraction Plants come into play. These specialized facilities are critical for refining crude oil into high-quality base oils that meet industry standards.

What is a Base Oil Solvent Extraction Plant?

A Base Oil Solvent Extraction Plant is a facility designed to remove undesirable components from crude oil, such as aromatics, sulfur compounds, and other impurities. The process involves using solvents to selectively extract these unwanted elements, leaving behind a purified base oil. The most commonly used solvent in this process is furfural, although other solvents like N-methyl-2-pyrrolidone (NMP) or phenol may also be used depending on the specific requirements.

How Does Solvent Extraction Work?

The solvent extraction process begins with the mixing of crude oil with the selected solvent. The solvent interacts with the aromatic compounds and other impurities, dissolving them and separating them from the desired base oil. The mixture is then sent to a separator, where the solvent and impurities are removed. The purified base oil is further processed through dewaxing and hydrofinishing to enhance its properties.

Why is Solvent Extraction Important?

Improved Quality: Solvent extraction removes impurities that can negatively affect the performance of lubricants, such as poor oxidation stability and thermal breakdown.

Environmental Benefits: By removing harmful compounds like sulfur and aromatics, the process reduces the environmental impact of lubricants.

Versatility: The process can be tailored to produce base oils of varying viscosities and properties, making it suitable for a wide range of applications.

Applications of Base Oils Produced

The base oils produced in these plants are used in a variety of industries, including automotive, industrial machinery, and aviation. They are the foundation for engine oils, hydraulic fluids, gear oils, and other specialized lubricants.

In conclusion, Base Oil Solvent Extraction Plants play a vital role in the production of high-quality lubricants. By refining crude oil into pure base oils, these facilities ensure that the final products meet the demanding requirements of modern machinery and engines.

0 notes

Text

Extracting And Recovering Phenol From Wastewater

CWL-M Centrifugal Extractor is a liquid-liquid extraction and separation equipment, mainly used for the extraction, separation, washing, stripping and other operations of two-phase liquids. Email: [email protected] Whatsapp: +86 19069612820

0 notes

Text

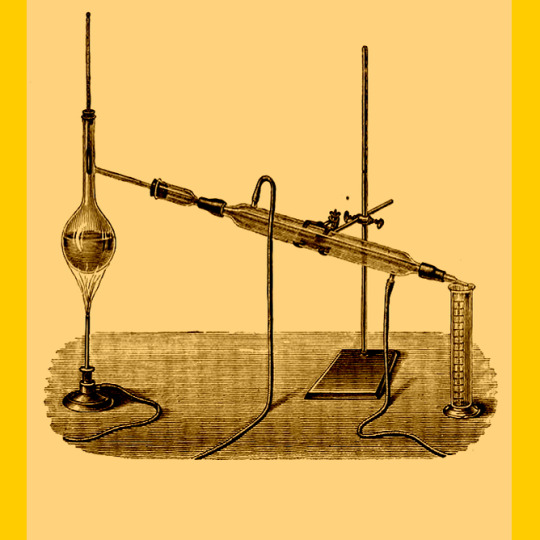

The distillation of a mixture of solvents to extract concentrated nonsense.

0 notes

Text

Boost Your Edible Oil Production with Advanced Oil Mill Plants

Maximize your efficiency and output with cutting-edge oil production machinery designed for all types of edible oil plants. From robust oil expeller plants to high-performance oil refinery machines, modern solutions cater to a wide range of oils, including those processed in vegetable oil refinery plants such as sunflower oil refinery plants, rice bran oil refinery plant, and soybean oil refinery plants. Trusted palm oil refinery plant manufacturers and lecithin plant manufacturers provide advanced vegetable oil processing equipment for superior quality and yield. Whether it’s shea butter extraction and fractionation or refining edible oils, these technologies ensure optimal results for your business.

#solvent extraction machineries#cooking oil plants#oil expeller plants#edible oil equipment#edible oil#oil production machinery

1 note

·

View note

Text

In my neighbourhood, people are busy. Every morning, they get up, and hop in their big cars to drive to their jobs. Sometimes they're too busy for coffee, so they all clog the main road outside my place waiting to turn into the Tim Hortons drive thru. After waiting there for way longer than it takes to make coffee, they're on their way to the office parking. In their haste, they have left something very valuable behind.

No, I'm not talking about the human soul. That kind of romantic shit is obsolete, save it for the next time the stock market implodes. What all these go-go careerists have abandoned in their homes is their dogs. Dogs that need to be walked. Dogs that need to be played with. Dogs that need to pee. To this problem have emerged the unique class of "dogwalkers."

When you pay a dog walker, they come to your house during the day, let themselves in, and extract your dog. Then, they enjoy the company of that dog, returning it once your pup is happy and tired out. For this, they charge you money. It is the perfect job, perhaps, except for the inconvenient fact that I don't like picking up poop. However, while I was cleaning my rusty subframe, a recent inhalation of some extremely warned-against solvents told me another idea: I could do this for cars.

You see, a lot of very rich people have very nice cars, ones that I could never afford. Porsches. Lamborghinis. Jaguars. Ford Focuses. And they let them sit. Sit and rot. This kind of boredom is not good for the car, whose rubber seals go dry, whose batteries go flat, and whose tires get vaguely square and unpleasant. They, too, need to be exercised. And that's exactly where I come in. For just fifty bucks an hour, I will let myself into your palatial mansion, beat the shit out of your sports automobile, and then put it back with the tank filled up (you're paying, of course.)

Trust me, too, that there will be plenty of "enrichment activities," such as taking the car to a race track or to heads-up no-prep drags in Mexico. This will help the car learn proper behaviour and socialization around other rich people's cars, which will reduce the chance that the valet at the country club will scoff at how you have ten-year-old tires on your exotic seven-figure race car and no evidence of having bombed an FIA curb at the better part of two hundred kilometres an hour.

Sign up with me today, and I might even drive you to work in your own car once or twice. That's the kind of experience that usually costs double – and it will for you, too.

206 notes

·

View notes

Text

Denatured Ethanol: A Versatile Solvent for Industrial and Consumer Applications

Denatured ethanol is ethanol that has been chemically altered by adding denaturants to make it undrinkable, thereby exempting it from alcohol taxes. This versatile solvent is widely used in industrial, laboratory, and consumer applications, including cleaning agents, cosmetics, pharmaceuticals, and fuel additives. Its effectiveness as a solvent for oils, resins, and other compounds makes it invaluable in various manufacturing processes. Denatured ethanol is also commonly used in the production of hand sanitizers and disinfectants due to its antimicrobial properties, making it an essential chemical in hygiene and sanitation. For more details visit our website: www.adchemgas.com

#ethanol#liquid nitrogen#dry ice for sale#denatured ethanol#nitrogen for sale#pure ethanol#co2 for sale#heptane for sale#dry ice pellets for sale#pentane for sale#high purity butane#extraction grade butane#food grade ethanol#high purity hydrocarbons#High Purity Hydrocarbons#Ethanol#Denatured Ethanol#Food Grade Ethanol#Pure Ethanol#High purity butane#High purity butane for sale#Extraction grade butane#Diamond grade butane#nbutane#Butane extraction gas#Propane extraction gas#isobutane extraction gas#Refined butane for extraction#Pure butane 99.5%#High purity solvents “for sale”

0 notes

Text

I really need people to understand that the things scientists do in their spooky, scary, mysterious labs full of strange and unnatural chemicals are the exact same things you do every day at home.

When I'm working with organic solvents, I use a ventilated fumehood so I don't breathe in toxic vapours, just like when you cook on a gas stove, you turn on the fan on your range hood so you don't breathe in toxic carbon monoxide (you'd better be doing this if you have a gas stove). When I need to add a specific amount of reagent, I'll use measuring instruments like a micropipette, just like when you need to add a specific amount of baking soda, you use measuring instruments like a teaspoon. When I want to analyze the chemicals in an environmental samples, I soak it in solvent so the chemicals leach out, just like when you want a coffee, you soak coffee grounds in hot water so the chemicals leach out (because yes, caffeine and all the other chemicals that make coffee, coffee, are chemicals). We are doing the exact same things, the difference is just what tools and ingredients we're working with.

But that's the same difference between you and a Michelin star chef. There are restaurants out there equipped with cutting-edge cooking equipment, things I don't know enough about to even give examples of just like you might not know enough about lab work to give examples of things I use. There are probably ingredients in dishes I've never even heard of because they're so far beyond what I can afford and just not necessary for the kind of food I make. But at most, people just scoff at how much money someone is willing to pay for a tiny plate of deconstructed fruit. Nobody pictures Gordon Ramsay the same way they picture scary chemical labs making scary chemical things.

You can also do science at home, and lots of people do! Not even just as cooking, kids especially like to do fun experiments like baking soda and vinegar explosions or separating the colours in a Sharpie or even extracting DNA from strawberries, which you can do with dish soap and rubbing alcohol. People even do the "fancier" experiments in garage labs, synthesizing organic molecules and such. Actual labs are just higher-tech for the same reason high end restaurants are higher-tech; you can't cure cancer in a garage, and you can't make chocolate sculptures in my tiny, student house kitchen without the proper molds and thermometers and supplies.

Obviously yes, scientists usually work with chemicals that are significantly more dangerous than what you find around your house, although your home is more dangerous than you think. People get food poisoning all the time, and I'd bet that more people die from eating spoiled food than from exposure to chemicals in a lab. And just because something starts out dangerous doesn't mean it stays that way. Raw chicken can make you sick or kill you, but cooked chicken is a delicious and healthy meal (as long as you season it, not seasoning your chicken automatically sends you to mega hell). Similarly, a lot of organic molecules are dangerous if you were to just chug them, but taken in correct dosages at appropriate times, the drugs that get made from those chemicals are completely safe.

I think there's this tendency to hold science as this separate, scary, complicated thing that only a few people are capable of doing and that anything coming out of a lab is unnatural and dangerous, and I think that scientists are responsible for that in a lot of ways. But with how significant anti-intellectualism is right now and how crucial that has been to the rise of fascism lately, I think it's just so important to understand that the only thing that makes science special is that my tools are just really expensive and when scientists make something that goes in your body, it's usually not food, because you don't need $2 000 measuring cups to make yourself some cookies.

Science is not special, labs are not unnatural, and this is so important to understand.

18 notes

·

View notes

Text

Hexane Market: Growth Insights and Key Trends for Diverse Industries

Hexane, a volatile, colorless liquid hydrocarbon, plays a crucial role in multiple industries due to its exceptional solvency properties and relatively low toxicity. Its versatile applications in oil extraction, pharmaceuticals, industrial cleaning and degreasing, and polymerization are pivotal in driving the steady growth of the global hexane market. This article provides an in-depth look at the key drivers, challenges, and opportunities shaping the future of this essential chemical.

Market Overview

The global hexane market has shown consistent growth in recent years, underpinned by its critical role in various industrial processes. Hexane Market was valued at USD 2.4 billion in 2022 and is projected to reach USD 3.1 billion by 2027, growing at a cagr 4.8% from 2022 to 2027.This robust expansion is fueled by increasing demand from developing economies, advancements in industrial applications, and the rising need for cost-effective extraction techniques.

Key Applications Driving Demand

1. Oil Extraction

Hexane has become a staple in edible oil production due to its unmatched efficiency in solvent extraction processes. Its ability to extract oils from seeds such as soybean, sunflower, and canola ensures optimal yields and quality. Moreover, its ease of recovery through distillation makes it an economically viable choice for manufacturers.

The rising demand for edible oils, particularly in regions like Asia-Pacific and Africa, is propelling the use of hexane. Changing dietary patterns and population growth in these areas have further emphasized the importance of solvent extraction, which outperforms traditional mechanical pressing in efficiency and output.

2. Pharmaceutical Applications

In the pharmaceutical industry, hexane serves as a crucial solvent for drug formulation and the purification of active pharmaceutical ingredients (APIs). Its inert nature ensures minimal interference with chemical reactions, thereby maintaining the integrity of pharmaceutical products.

India and China, emerging as global pharmaceutical hubs, are driving significant demand for hexane. Furthermore, its role in chromatographic separation processes for isolating specific compounds underscores its importance in drug development and research initiatives.

3. Industrial Cleaning and Degreasing

Industries widely use hexane for cleaning and degreasing mechanical components, equipment, and surfaces. Its rapid evaporation and superior ability to dissolve oils and grease make it indispensable for maintenance operations. Sectors like automotive and aerospace, which demand precision in manufacturing, heavily rely on hexane for cleaning purposes.

As industries continue to prioritize efficiency and cleanliness, the demand for hexane as a cleaning agent is expected to grow. The expanding industrial cleaning market in both developed and emerging economies further supports this trend.

4. Polymerization Processes

Hexane’s significance in polymerization processes, particularly in the production of polyethylene and polypropylene, cannot be overstated. Acting as a carrier and reaction medium, hexane ensures uniform polymerization and enhances the physical properties of final products.

Given the rising demand for plastics in packaging, construction, and automotive applications, hexane remains a cornerstone in polymer production.

Key Market Trends

Sustainability Initiatives and Regulatory Compliance

Growing concerns about the environmental and health impacts of hexane have led to increased regulatory oversight. Authorities like the Environmental Protection Agency (EPA) and European Chemicals Agency (ECHA) have imposed stringent guidelines to ensure safe handling and minimize emissions. In response, manufacturers are adopting advanced production methods and refining processes to align with these regulations.

Regional Market Insights

Asia-Pacific: This region dominates the hexane market, driven by strong demand from the oil extraction and polymer sectors. China and India are major contributors.

North America and Europe: Emphasis on sustainability and eco-friendly practices is fostering innovation in hexane applications.

Middle East and Africa: With growing edible oil and pharmaceutical industries, these regions present lucrative opportunities for hexane manufacturers.

Shift Towards Bio-Based Alternatives

As industries strive to reduce their carbon footprint, the exploration of bio-based hexane alternatives is gaining momentum. Although these substitutes are still in the early stages of development, they hold significant promise for companies committed to sustainability.

Future Outlook

The hexane market is set for steady growth, supported by advancements in extraction technologies and increasing demand from pharmaceutical and industrial sectors. However, addressing environmental concerns and meeting regulatory standards will be critical. Manufacturers investing in research and development to create greener hexane formulations are likely to gain a competitive edge in the evolving market.

Download PDF Brochure :

Hexane plays an indispensable role in diverse industries, from oil extraction to polymer production. For stakeholders in these sectors, understanding market dynamics and staying attuned to emerging trends is crucial for long-term success. As sustainability and innovation take center stage, the hexane market is poised for a transformative journey, offering new opportunities for growth and development.

#Hexane market#oil extraction#pharmaceutical solvents#industrial cleaning#polymerization processes#sustainability#market trends

0 notes