#Steel Structure Building

Explore tagged Tumblr posts

Text

Why Is a Steel Structure Building the Smartest Choice for Modern Construction?

In recent years, construction trends have shifted drastically towards more sustainable, durable, and cost-efficient solutions. Among these, a steel structure building has gained immense popularity due to its unmatched strength, flexibility, and modern appeal. Whether it's for industrial, commercial, or residential use, steel buildings are redefining how we approach structural design and functionality.

0 notes

Text

The Geometry of Strength – Joint Detailing in Steel Hollow Sections

Steel hollow sections are used in many buildings. You see them in bridges, stadiums, and warehouses. These sections look clean and modern. They are also strong and reliable. But strength depends on more than just the steel. It also depends on how the parts connect.

Let’s talk about joint detailing. It plays a big role in keeping steel structures safe and stable. A weak joint can make the whole system fail. Also Read : Advantages of Steel TMT Bars

How Do Steel Hollow Section Joints Affect the Strength of a Structure?

Think of a tent. You can use the best poles. But if the connectors are weak, the tent will collapse. Steel hollow sections work the same way. Joints hold everything together.

These sections are closed and smooth. That makes them hard to connect. Engineers need to think carefully when designing the joints.

Here are some common types of joints:

Welded joints: Neat and strong. But hard to inspect and fix later.

Bolted joints: Easier to install. Need extra plates or supports.

Mixed joints: Use both welding and bolts.

Each type has its pros and cons. The choice depends on the job. Some joints are easier to build. Some are stronger under pressure. Also Read : Basics of Structural Steel Construction

Why Joint Detailing Matters in Steel Structures

You might ask why joint detailing is such a big deal. Isn’t steel strong enough on its own? Not always.

Joints affect many things:

Strength: A poor joint creates weak points. These can crack under pressure.

Cost: Complicated joints take more time and money.

Speed: Simple joints help the work move faster.

Safety: Well-planned joints help prevent accidents.

Here’s an example. A team used square hollow sections in a warehouse. They used full welds for every joint. It took a long time and needed special tools. Later, they changed the design. They used bolts instead of full welds. Work got faster. Costs went down. The structure stayed strong.

This shows why joint detailing is so important. Good design saves time, money, and effort.

How to Pick the Right Type of Joint for Hollow Sections

There is no one best joint for every job. You have to ask some questions first.

What kind of load will the joint carry?

Is the area easy to reach?

How much will it cost to build and maintain?

Here are some joint types used with hollow sections:

T-joint: A branch meets a main part at a right angle.

K-joint: Two braces connect to a main member.

N-joint: Similar to K-joint but with different angles.

Sleeve joint: Uses a sleeve to connect two members.

Each type works in different ways. Some spread the load better. Some are faster to install. Engineers pick the type based on the needs of the building.

Final Thoughts

Steel hollow sections are strong and clean. But joints hold the structure together. A bad joint puts everything at risk.

Joint detailing is not just a small part. It affects safety, cost, and speed. It shapes how the whole structure performs.Next time you see a steel building, look closer. Behind the clean lines are joints doing the hard work.

Learn how to make strong and reliable joints in steel hollow sections. A helpful guide for better design and construction.

0 notes

Text

Durable Coated Steel for Commercial Buildings | Tata DigECA

Enhance steel construction with Tata Galvano from DigECA—durable, eco-friendly coated steel backed by Tata Steel’s expertise for commercial projects

#coated steel#tata galvano#steel structure building#steel building construction#commercial steel building contractors

0 notes

Text

Steel Structure Commercial Buildings by Entegra Signature Structures

Explore Entegra Signature Structures' expertise in commercial infrastructure construction, including industrial sheds, steel structure offices, and commercial buildings. Discover innovative steel designs perfect for modern businesses. Watch now: https://www.youtube.com/watch?v=9JMCN6jXW2k

#commercial infrastructure construction#industrial shed office#steel structure building#steel structure commercial building#commercial infrastructure#Entegra Signature Structures

0 notes

Text

Elevate your project with top steel structure manufacturers. Discover high-quality, durable solutions tailored to your construction needs.

#steel structure manufacturers#steel structure company#steel structure design#steel structure building

0 notes

Text

1 note

·

View note

Text

Expandable Container House- 8 Hours One House!

PTH, expandable container homes Builder realize your dream house

Zhejiang Putian Integrated Housing Co., Ltd., also known as "PTH," has committed itself to providing comprehensive solutions for low-rise prefabricated houses. Our services encompass every aspect of the process, including architectural design, production, storage, transportation, installation guidance, and post-sales support. PTH is headquartered in the Keqiao District of Shaoxing City, with a dedicated team of over 200 employees and a rich history. Since 1998, PTH has been manufacturing steel structural components. Today, our primary product offerings fall into four distinct categories: steel structure buildings, lightweight steel villas, container houses, and Double-C structures.

What advantage of PTH expandable container house?

This expandable container house incorporates German passive house technology, resulting in a remarkable 70% reduction in energy consumption compared to traditional homes. The house is equipped with five cutting-edge smart air technologies, ensuring:

Steady Temperature (Maintained at 20-26°C)

Steady Humidity (Kept at 40%-60%)

Steady Oxygen Levels (CO2: ≤1000PPm)

Continuous Air Purification

Consistent Quiet Environment

The window is equipped with a thermally insulated aluminium frame and double-glazed insulation. The foundation employs a spiral pile design, providing both durability and an environmentally friendly construction approach, eliminating the necessity for excavation or cement pouring. For walls, roofs, and floors, the components are filled with high-performance thermal insulation and flame-retardant materials known as PIR. An upgraded solid structure enhances Bamboo fibre interior walls for improved impact resistance. The thickened light luxury membrane coating enhances water resistance and resists mildew. To ensure the quality of the goods from the source, PTH specially set up a collaboratory to reject unqualified raw materials. The raw materials must pass strict strength tests, bending tests and galvanised layer tests. Our products have passed ANSI, AS and EN certification, and follow the lSO 9000 quality management system.

About Aftersale Service-expandable container house

The lead time typically averages around 20 days, and the minimum order quantity is just 1 unit, so there's no need to worry about the quantity you wish to order. We provide comprehensive custom services until you are fully satisfied. The entire house will be packed for a 20ft container and shipped directly, eliminating the need for additional container packing. You can set up utilities on-site as per your requirements, be it a water tank or solar panels; they connect seamlessly to the PrefabX, just like regular utilities.

Our PrefabX series is designed for permanent residential structures, offering superior energy efficiency, soundproofing, and thermal insulation. The house exhibits excellent rust resistance, featuring a wall frame constructed from 6063 reinforced aluminum alloy and a roof steel sheet made of aluminum alloy magnesium with a 100g painting finish. Each structural component undergoes industrialized design and precise calculations. The steel frame employs Q355 low-alloy carbon structural steel, providing high structural strength, while the aluminum frame is crafted from 6063-T5 reinforced aluminum alloy, extruded at high temperatures to ensure strength and toughness.

Regarding heating, we utilize thermally insulated aluminum window frames and double-glazed insulation. The walls, roof, and floor are filled with high-performance thermal insulation and use flame-retardant PIR materials. Additional heating options are also available. Furthermore, the comfort style includes a 5-point smart air system, particularly suitable for colder climates. Electrical and plumbing components are prefabricated in the factory, reducing the need for on-site labor. For more details abotCustom Container Home Builders visit our website.

welcome to contact us!

86-571-83513788

0 notes

Text

Experience the strength and durability of Steel Structure Buildings at https://www.steelcoqatar.com. Explore innovative construction solutions.

0 notes

Text

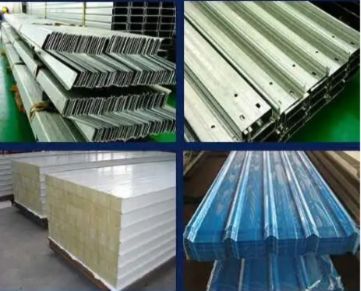

Best Industrial plant and steel structure building

Qingdao Omiga Construction Engineering Co., Ltd., as a leading supplier and manufacturer in the field of steel structure construction, specializes in the export of steel structure building materials and related products. The company Located in the beautiful coastal city of Qingdao, with over 20 years of experience in steel structure projects and are a key incubation enterprise in the Qingdao Park of China Science and Technology Development Institute. Omiga is committed to providing high-quality steel structure building solutions for global customers. Our products cover various fields, including industrial plants, commercial buildings, sports arenas, residential buildings, bridges, etc. We have a first-class design team and advanced production equipment, enabling us to provide customized solutions based on customer requirements.

We offer one-stop procurement services, including product design, raw material procurement, production processing, quality control, logistics distribution, and installation guidance. In the field of steel structure building exports, we have established long-term partnerships with well-known domestic steel structure manufacturers. This enables us to meet customer requirements with competitive prices and high-quality products, ensuring the quality and delivery time of our products. We introduce and apply international advanced steel structure building technologies and equipment, strictly implementing quality management systems to ensure that our product quality meets international standards.

Advantages of Steel Structure Buildings:

Exceptional Strength: Steel is renowned for its high strength-to-weight ratio. Steel structure buildings can withstand heavy loads, making them ideal for tall skyscrapers, industrial facilities, and bridges. This strength provides long-lasting durability and structural integrity.

Speedy Construction: Steel structures can be fabricated off-site, allowing for faster construction compared to traditional methods. This reduces construction time, labor costs, and disruptions to nearby areas.

Design Flexibility: Steel allows for creative and flexible architectural designs. The material's ability to span large distances without the need for numerous columns or supports enables open, spacious interiors and innovative aesthetics.

Sustainability: Steel is a recyclable material, making it environmentally friendly. The recycling process does not compromise its structural integrity, making steel structures an eco-conscious choice. Additionally, steel can be repurposed for other construction projects.

Cost-Effective: Despite initial higher material costs steel structure buildings often provide long-term cost savings due to their durability, minimal maintenance, and shorter construction times.

Innovations in Steel Structure Buildings:

Advanced Coatings:Innovations in coatings have enhanced the corrosion resistance of steel structures, increasing their lifespan and reducing maintenance requirements. These coatings also offer aesthetic options and energy-efficient features.

Prefabrication and Modular Construction:

Prefabrication techniques have improved efficiency in steel construction. Components can be manufactured off-site with precision and then assembled on-site, reducing construction time and waste.

High-Strength Steel Alloys: The development of high-strength steel alloys allows for lighter and stronger structural elements, reducing material usage and enabling more sustainable construction.

Building Information Modeling (BIM):

industrial plant BIM technology enables precise planning and coordination of steel structure projects. It helps optimize designs, reduce errors, and improve project management, resulting in cost savings and better project outcomes.

Sustainable Practices: Innovations in steel production have led to more sustainable practices, such as energy-efficient manufacturing processes, reduced emissions, and responsible sourcing of raw materials.

Steel structure buildings continue to be a fundamental part of the construction industry, offering numerous advantages and benefiting from ongoing innovations. Their strength, versatility, sustainability, and cost-effectiveness make them an attractive choice for a wide range of construction projects, from residential buildings to large-scale industrial complexes. As technology and materials continue to evolve, steel structures will likely play an increasingly vital role in shaping the future of modern construction.

Steel warehouses are essential components of the supply chain and industrial infrastructure. These structures provide storage solutions that are durable, cost-effective, and versatile, making them integral to various industries.

Structural Integrity and Durability:

Steel is renowned for its strength and resilience. Steel warehouses can withstand extreme weather conditions, seismic activity, and heavy loads, ensuring the safety and security of stored goods over the long term.

Spacious Interiors: Steel's high strength-to-weight ratio allows for large, open interior spaces without the need for numerous columns or support structures. This design flexibility makes steel warehouses ideal for efficiently storing and accessing goods.

Quick Construction: Prefabrication techniques in steel construction enable rapid assembly. This reduces construction time, minimizes disruptions to operations, and leads to faster ROI for warehouse owners.

Customizable Designs: Steel warehouses can be customized to meet specific storage needs. This includes adjustable shelving, racks, and mezzanines, enabling efficient space utilization and organization.

Cost-Efficiency: While initial construction costs may be higher than other materials, steel's longevity, minimal maintenance requirements, and energy-efficient features make it a cost-effective choice over the long term.

Sustainability: Steel is recyclable and environmentally friendly. Many steel warehouse structures incorporate eco-conscious features such as energy-efficient insulation, lighting, and roofing systems.

Innovations in Steel Warehouses:

Automated Storage and Retrieval Systems (AS/RS): AS/RS technology optimizes warehouse operations by automating the retrieval and storage of goods, reducing labor costs, and increasing efficiency.

Energy-Efficient Design: Innovative designs incorporate natural lighting, solar panels, and energy-efficient HVAC systems to reduce energy consumption and environmental impact.

Security and Surveillance Systems: Modern steel warehouses often feature advanced security systems, including surveillance cameras, access control, and fire suppression systems to safeguard valuable inventory.

Inventory Management Software: Integration of warehouse management software streamlines inventory tracking, order fulfillment, and overall warehouse operations, increasing accuracy and efficiency.

Distributed Warehousing Networks:

Companies are increasingly adopting distributed warehousing networks, strategically locating smaller steel warehouses in proximity to customers to reduce shipping times and costs. Steel warehouses are indispensable assets in today's industrial landscape, providing the durability, flexibility, and efficiency required for modern supply chain management. As technology and sustainability practices continue to evolve, steel warehouses will play an even more crucial role in optimizing storage and distribution processes. Their resilience, cost-effectiveness, and adaptability make steel warehouses a cornerstone of the global logistics industry, supporting economic growth and innovation.

0 notes

Text

0 notes

Text

L’Atelier, Bordeaux - A6A

#A2A#architecture#design#building#modern architecture#interiors#minimal#modern#atelier#office#studio#office design#open plan#meeting room#plywood#timber#stone#stone building#glass doors#courtyard#planting#light#beautiful design#cool architecture#desk#design studio#storage#steel structure#old and new#old building

315 notes

·

View notes

Text

Headquarters of DHV (1967-70) in Amersfoort, the Netherlands, by David Zuiderhoek

#1960s#office building#glass#steel#structuralism#structuralist#architecture#netherlands#architektur#david zuiderhoek

135 notes

·

View notes

Text

Top-Quality Coated Steel for Commercial Use | DigECA - Tata Steel

Explore DigECA by Tata Steel for premium coated steel solutions. Choose Tata Galvano for reliable, durable materials for commercial buildings.

#coated steel#tata galvano#steel structure building#steel building construction#commercial steel building contractors

0 notes

Text

had a dream a drag queen with slicked back green and black hair and a latex suit with really big shoulderpads was reading me a poem about black tar pits and i dont remember the poem but it made me want to cry when she told me it

#it was in this building that was almost like a laundromat but had more steel structures and less washing machines?#text

4 notes

·

View notes

Text

Multi-storey metal frame structure prefabricated warehouse steel structure building

#steel structure#multi-storey metal frame structure#multi-storey steel structure buildings#steel structure building

1 note

·

View note

Text

youtube

Top steel space frame manufacturer in China

#architecture#design#space frame#steel structure#manufacturer#roofing#contractor#graphic design#skylight#glasses#construction#modern design#building#Youtube

2 notes

·

View notes