#Textile Processing Solutions

Explore tagged Tumblr posts

Text

Textile Chemicals Market Size to Expand Significantly by the End of 2030

The Textile Chemicals Market is undergoing a significant transformation, driven by advancements in textile chemicals. These specialized chemicals play a crucial role in enhancing the quality, durability, and aesthetic appeal of textiles. The global textile chemicals market has seen substantial growth in recent years, influenced by technological innovations, increasing demand for high-performance textiles, and a heightened focus on sustainability.

Market Overview

According to market research, the Textile Chemicals Market was valued at USD 30.5 billion in 2023-e and will surpass USD 46.5 billion by 2030; growing at a CAGR of 5.6% during 2024 - 2030. The textile chemicals market encompasses a wide range of products, including colorants and auxiliaries, finishing agents, surfactants, and coating and sizing chemicals. These chemicals are integral to various stages of textile manufacturing, from pre-treatment and dyeing to finishing and printing.

Get a Sample Report: https://bit.ly/46rlU68

Key Drivers of Growth

Technological Advancements: Innovations in textile chemistry have led to the development of new products that offer improved performance and functionality. Nanotechnology, smart textiles, and eco-friendly chemicals are some of the notable advancements driving market growth.

Sustainability Initiatives: With increasing environmental concerns, the demand for sustainable and eco-friendly textile chemicals has surged. Manufacturers are focusing on producing biodegradable and non-toxic chemicals to reduce the environmental footprint of textile manufacturing.

Rising Demand for High-Performance Textiles: The demand for textiles with enhanced properties such as water resistance, stain resistance, and flame retardancy is on the rise. This trend is particularly prominent in sectors like sportswear, protective clothing, and home textiles.

Growing Apparel Industry: The booming fashion and apparel industry, particularly in emerging markets, is a significant driver of the textile chemicals market. Rapid urbanization, rising disposable incomes, and changing fashion trends are fueling the demand for high-quality textiles.

Challenges and Opportunities

Despite the positive growth trajectory, the textile chemicals market faces several challenges. Stringent environmental regulations, the high cost of eco-friendly chemicals, and the need for continuous innovation pose significant hurdles.

Innovation and R&D: Continuous investment in research and development is crucial for creating innovative and sustainable chemical solutions. Companies that prioritize R&D can gain a competitive edge by offering cutting-edge products that meet evolving consumer demands.

Expansion in Emerging Markets: Emerging economies in Asia-Pacific, Latin America, and Africa offer significant growth opportunities due to their expanding textile and apparel industries. Companies can tap into these markets by establishing local production facilities and forming strategic partnerships.

Adoption of Green Chemistry: The shift towards green chemistry is gaining momentum. Manufacturers that adopt sustainable practices and develop eco-friendly products are likely to benefit from regulatory incentives and increased consumer preference for green products.

Regional Insights

The Asia-Pacific region dominates the textile chemicals market, accounting for the largest share in terms of both production and consumption. Countries like China, India, and Bangladesh are major textile manufacturing hubs, driving the demand for textile chemicals. North America and Europe are also significant markets, characterized by high demand for technical textiles and stringent environmental regulations.

Get an insights of Customization: https://bit.ly/3ykLVHO

Future Outlook

The future of the textile chemicals market looks promising, with sustainability and innovation at the forefront. As the industry continues to evolve, the focus will be on developing chemicals that not only enhance textile performance but also minimize environmental impact. The growing trend towards circular economy practices, where waste is minimized, and resources are reused, will further influence the market dynamics.

In conclusion, the textile chemicals market is poised for steady growth, driven by technological advancements, sustainability initiatives, and the rising demand for high-performance textiles. Companies that embrace innovation and sustainable practices will be well-positioned to capitalize on the emerging opportunities and navigate the challenges in this dynamic market.

0 notes

Text

Enhancing Textile Machinery Efficiency with Messung's NX-ERA Xpress PLC

The textile industry, being a part of global manufacturing, has witnessed a massive transformation in recent years due to accelerated technological advancements. From yarn making to dyeing yarns with complex patterns, each process of textile production has been streamlined for higher productivity, accuracy, and efficiency. The need for high-quality products and shorter production cycles has generated fertile ground for automation, especially with the use of Programmable Logic Controllers (PLCs)in textile manufacturing.

This is where we at Messung Industrial Automation come in the picture with our cutting-edge automation solutions. With our strong heritage of delivering strong and scalable automation solutions, we have been the industry leader in industrial automation. Our innovative and compact PLC, NX-ERA Xpress has been crafted to specifically address the specific requirements of industries such as textile manufacturingwith the ideal combination of performance, flexibility, and energy efficiency. In this blog, let’s explore the revolutionary potential of NX-ERA Xpress PLCand its impact on textile machinery, with an emphasis on how it improves operational efficiency, cuts costs, and accelerates the journey towards Industry 4.0.

The Role of PLCs in Modern Textile Manufacturing

Programmable Logic Controllers (PLCs) form the foundation of automation in textile manufacturing, especially in the "cotton to yarn" and "yarn to fabric" segments where their role is most critical. These rugged, industrial-grade controllers ensure precision, speed, and efficiency by managing machinery and processes in real time. From ginning and bale plucking to spinning, carding, drawframe, combing, ring frame machines, and autoconers, PLCs are deeply embedded in every stage of the cotton-to-yarn journey.

In the yarn-to-fabric sector, PLCs continue to play a significant role in the operation of warping machines, twisting machines, and various types of looms such as shuttle, airjet, and rapier looms. They are equally vital in fabric processing lines, managing singeing, bleaching, dyeing, and a wide range of finishing machines designed to enhance textile properties like softness, wrinkle resistance, or water repellency. Printing lines, including rotary and flat bed printing machines, also rely heavily on PLC-controlled automation.

Across these applications, PLCs are integrated with Human Machine Interfaces (HMI), Variable Frequency Drives (VFDs), and in high-speed machines like spinning lines, Servo amplifiers and Servo motors are used for superior speed and torque control.

While the garment sector (fabric to garment) does involve automation, Messung’s core expertise and solutions, including the NX-ERA Xpress PLC and NX-ERA Jet PLC, are primarily focused on the earlier and more automation-intensive stages of textile manufacturing.

Benefits of Implementing PLCs on Textile Machinery

Increased Efficiency: PLCs allow streamline operations by automating processes that were previously manual, significantly reducing downtime and increasing throughput

Improved Accuracy: The high-level precision control afforded by PLCs ensures each activity in the fabric process, whether spinning or weaving, is undertaken with perfection.

Real-Time Monitoring: PLC-based systems make equipment monitoring in real-time a certainty, where defects are flagged off early and avoid costly downtime along with plant operation performance improvements.

As the textile industry advances, compact PLCs are not an indulgence but a must-have. Automation is the key to staying competitive, and industrial automation PLC systems like the NX-ERA Xpress are at the forefront of this revolution.

Learning More About NX-ERA Xpress PLC

The NX-ERA Xpress PLC is our response to the increasing needs of the textile industry. By harnessing the capability of Programmable Logic Control Systems and the flexibility of contemporary communication protocols, the NX-ERA Xpress provides a powerful and scalable solution for numerous industrial automation applications.

Features of NX-ERA Xpress PLC:

High-Density Digital and Analog I/O: The NX-ERA Xpress PLC features a high-density I/O design that is capable of processing vast amounts of data input and output at one time. This is important for the textile industry, where real-time data from many machines need to be processed efficiently in order to optimize performance.

Programming through Codesys® (IEC 61131 Standard): Among the most impressive aspects of the NX-ERA Xpress PLC is its support for Codesys®, an open-source programming platform. This standardization enables seamless integration with industrial equipment across the board, which makes it an attractive option for PLC manufacturing companies.

Integrated Communication Protocols: With inbuilt compatibility for communication protocols such as Ethernet TCP/IP, Modbus, and CANopen, the NX-ERA Xpress PLC facilitates smooth connectivity among various machines and devices on the shop floor. This connectivity is vital for ensuring smooth operation throughout the complete manufacturing process.

Industry 4.0 Readiness: NX-ERA Xpress PLC comes with OPC-UA and MQTT readiness, making it Industry 4.0-ready. These are technologies that support data exchange over different platforms, and they simplify the integration of machines by manufacturers into a smart factory environment.

Integrated HTML Web Server for Remote Monitoring: Remote monitoring has never been simpler. The integrated HTML web server enables operators to monitor and control the PLC remotely, offering flexibility and real-time visibility into machine performance.

The high-performance features and compact PLC design of NX-ERA Xpress PLC make it perfect for the textile industry. Whether you're automating cotton spinning, weaving, or dyeing, the NX-ERA Xpress provides all the power you need to optimize your operations.

Advantages of NX-ERA Xpress in Textile Applications

The textile industry requires solutions that are capable of providing not just high performance but also cost-effectiveness and sustainability. Our NX-ERA Xpress PLC provides a number of benefits for applications in textile machinery, such as:

Energy Efficiency

In the textile industry, energy consumption is a major operational expense. The NX-ERA Xpress PLC is built to maximize control and minimize power consumption, especially in power-hungry processes such as spinning. Through automation processes and optimizing machine efficiency, the PLC ensures textile plants make substantial savings on energy.

High-Speed Processing

Textile production processes often involve rapid and adaptive control systems that are necessary for handling high-speed manufacturing lines. The processing of high speeds facilitated by the NX-ERA Xpress PLC helps data move faster to provide instant adjustment capabilities, ensuring minimum lags in manufacturing processes.

Precision Control

The clothing industry is based on the effective control of variables like thread tension, fabric alignment, and dying processes. NX-ERA Xpress PLC ensures accurate control in order to match every parameter in the manufacturing process to the prescribed specifications. The result is repetitive product quality, and less it is defective.

Scalability

As textile factories develop and expand, scalable automation systems become increasingly relevant. NX-ERA Xpress PLC uses a modular construction that means that automation systems can be expanded as they are required by manufacturers, presenting a great solution for expanding businesses in the textile industry in the long term.

Cost-Effectiveness

Automation must not be expensive. The NX-ERA Xpress PLC is an affordable solution for textile producers that offers high-end features without an exorbitant price tag. It is meant to offer high-performance at an affordable rate, so any textile firm can use it.

Textile Machinery Applications: PLC Precision for a Modern Mill

As textile factories embrace digital transformation, the NX-ERA Xpress PLC emerges as a compact yet powerful solution tailored for automation-ready textile machinery. With its robust control features and Industry 4.0 connectivity, the NX-ERA Xpress brings intelligence and agility to a wide range of textile processes.

Let’s explore key use cases across the textile value chain:

Yarn Steaming Machine:

Steaming is a critical stage in yarn preparation where temperature, pressure, and timing must work in harmony. The NX-ERA Xpress PLC ensures:

Precise control of temperature and steam pressure for consistent yarn conditioning

Regulation of steaming duration to match different yarn types and production speeds

Automation of loading and unloading mechanisms, reducing manual intervention and boosting throughput

With its real-time responsiveness and compact design, the NX-ERA Xpress PLC enhances efficiency, consistency, and reliability in yarn steaming operations.

Heat Setting and Space Dyeing Machine Integration:

In advanced textile finishing, seamless integration between heat setting and dyeing is essential. NX-ERA Xpress PLC brings synchronization and control to:

Temperature management for precise heat setting, improving dimensional stability and dye fixation

Control of dye application in the space dyeing process, enabling unique patterns with consistent results

Coordination of material flow between machines, ensuring smooth transitions and avoiding process bottlenecks

The result is an integrated, high-performance workflow for specialty dyeing applications, digitally governed for optimal output and reduced waste.

Integration with Messung's Automation Ecosystem

One of the major strengths of the NX-ERA Xpress PLC is that it can integrate smoothly with all our other products, like the XM-PRO remote I/O modules. This makes it possible to have a unified automation solution that simplifies the control and monitoring of your entire textile plant.

With a single provider for all automation needs, textile manufacturers can enjoy streamlined operations, reduced complexity, and improved support. The synergy between the NX-ERA Xpress PLC and our other products ensures that your factory is fully equipped to tackle the challenges of modern textile manufacturing.

Conclusion

In summary, our NX-ERA Xpress PLC is a game-changer in the textile sector, providing powerful, scalable, and affordable automation. With its high-performance capabilities, energy efficiency, and accurate control, the NX-ERA Xpress PLC is ideally positioned to address the changing needs of textile producers.

With the NX-ERA Xpress PLC, you can elevate your textile manufacturing process to the next level. Whether you want to optimize spinning, weaving, or dyeing processes, Messung's automation solutions provide the reliability and performance that you require to remain ahead in a competitive market.

So, why wait? Consult Messung today for a customized automation solutionthat suits your textile manufacturing needs. It’s time to embrace the future of textile production with the NX-ERA Xpress PLC - where automation meets innovation

#textile manufacturers#Programmable Logic Controllers (PLCs)#textile manufacturinG#cutting-edge automation solutions#compact PLC#NX-ERA Xpress PLC#textile machinery#Industry 4.0#spinning#carding#drawframe#combing#ring frame machines#autoconers#singeing#bleaching#dyeing#PLC-controlled automation.#NX-ERA Jet PLC#industrial automation#PLC systems#IEC 61131 Standard#Ethernet TCP/IP#Modbus#CANopen#cotton spinning#automation processes#remote I/O modules#automation needs#customized automation solution

0 notes

Text

Jet Dyeing Machines Market Set to Hit $1569.3 Million by 2035

The Jet Dyeing Machines market is projected to experience substantial growth, with industry revenue estimated to rise from $596.0 million in 2024 to $1569.3 million by 2035. This growth represents a Compound Annual Growth Rate (CAGR) of 9.2% from 2024 to 2035. As industries across the globe adopt advanced technologies and prioritize sustainability, the demand for Jet Dyeing Machines is expected to surge, driven by key applications such as textile dyeing, wool processing, plastic coloring, and leather treatment.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/jet-dyeing-machines-market-research-report

Key Applications Driving Market Growth

Jet Dyeing Machines are critical in a wide range of applications where precision and efficiency are necessary. The major sectors relying on these machines include:

Textile Dyeing: Essential for the mass production of textiles, ensuring uniform and high-quality dyeing for fabrics used in various industries, including fashion and home textiles.

Wool Processing: Used to achieve optimal dyeing for wool fibers, which are sensitive to heat and require gentle treatment.

Plastic Coloring: Important in the plastic industry for achieving consistent and uniform coloring of plastic materials.

Leather Treatment: Plays a vital role in achieving consistent dyeing results for leather products, which are used in fashion, furniture, and automotive industries.

Industry Leadership and Competitive Landscape

The Jet Dyeing Machines market is characterized by fierce competition, with several leading players such as Thies GmbH & Co. KG, Fong's Industries Company Limited, Sclavos TVE ESCE, Brazzoli S.p.A., CHTC Fong's International Co. Ltd., Jeanologia S.L., and others dominating the market. These companies are actively innovating and expanding their operations to meet growing demand across multiple industrial sectors.

Technological advancements in jet dyeing machines, coupled with the rise of sustainable manufacturing processes, are expected to significantly drive the market's expansion. Efficiency improvements, reduced water consumption, and enhanced dye quality are key areas where innovation is helping to capture more market share.

Growth Opportunities in Emerging Markets

The Jet Dyeing Machines market presents substantial growth opportunities in emerging markets, where rapid industrialization, urbanization, and increasing environmental concerns are driving demand for more efficient and sustainable dyeing solutions. Key countries such as China, India, Germany, U.S., and Italy continue to lead the market, while emerging markets like Vietnam, Ethiopia, and Bangladesh represent significant revenue opportunities for manufacturers.

Regional Shifts and Evolving Supply Chains

North America and Europe are the two primary regions driving the demand for Jet Dyeing Machines. These regions benefit from high industrialization levels and technological advancements in manufacturing processes. However, the market dynamics are shifting as manufacturers look to streamline their supply chains and cater to the growing demand in emerging markets. Challenges such as high equipment costs, regulatory hurdles, and environmental concerns are also pushing the market to evolve.

Emerging markets such as Vietnam, Ethiopia, and Bangladesh are expected to present strong opportunities for revenue diversification and Total Addressable Market (TAM) expansion as local industries adopt more advanced technologies to meet the increasing demand for high-quality and eco-friendly dyeing processes.

Future Outlook

The Jet Dyeing Machines market is set to undergo significant growth over the next decade, driven by technological advancements, sustainability trends, and expanding industrial automation. The adoption of green dyeing technologies and improvements in dyeing efficiency will continue to play a critical role in shaping the future of the market. With the strategic expansion into emerging markets and a focus on technological innovation, the Jet Dyeing Machines market will likely witness substantial transformation, presenting new opportunities for both established players and new entrants.

About DataString Consulting

DataString Consulting is a global leader in market research and business intelligence, offering comprehensive solutions for both B2B and B2C markets. With more than 30 years of combined experience in market research and strategy advisory, DataString Consulting provides tailored services designed to meet the specific needs of businesses across various industries.

Through its unique approach to market research and insights, DataString helps clients navigate emerging market trends, optimize strategies, and unlock new opportunities in an ever-evolving marketplace.

#Jet Dyeing Machines#Textile Machinery#Textile Dyeing#Industrial Dyeing Equipment#Dyeing Technology#Textile Manufacturing#Sustainable Dyeing#Wool Processing#Plastic Coloring#Leather Dyeing#Industrial Automation#Eco-Friendly Dyeing Solutions#Fabric Dyeing Machines#Textile Industry Trends#Dyeing Machine Market Forecast#Emerging Markets#Market Research#DataString Consulting#Industrial Equipment Market#Global Textile Market

0 notes

Text

"The substances behind the slimy strings from okra and the gel from fenugreek seeds could trap microplastics better than a commonly used synthetic polymer.

Texas researchers proposed in 2022 using these sticky natural polymers to clean up water. Now, they’ve found that okra and/or fenugreek extracts attracted and removed up to 90% of microplastics from ocean water, freshwater, and groundwater.

With funding from the U.S. Department of Energy, Rajani Srinivasan and colleagues at Tarleton State University found that the plant-based polymers from okra, fenugreek, and tamarind stick to microplastics, clumping together and sinking for easy separation from water.

In this next stage of the research, they have optimized the process for okra and fenugreek extracts and tested results in a variety of types of water.

To extract the sticky plant polymers, the team soaked sliced okra pods and blended fenugreek seeds in separate containers of water overnight. Then, researchers removed the dissolved extracts from each solution and dried them into powders.

Analyses published in the American Chemical Society journal showed that the powdered extracts contained polysaccharides, which are natural polymers. Initial tests in pure water spiked with microplastics showed that:

One gram of either powder in a quart (one liter) of water trapped microplastics the most effectively.

Dried okra and fenugreek extracts removed 67% and 93%, respectively, of the plastic in an hour.

A mixture of equal parts okra and fenugreek powder reached maximum removal efficiency (70%) within 30 minutes.

The natural polymers performed significantly better than the synthetic, commercially available polyacrylamide polymer used in wastewater treatment.

Then the researchers tested the plant extracts on real microplastic-polluted water. They collected samples from waterbodies around Texas and brought them to the lab. The plant extract removal efficiency changed depending on the original water source.

Okra worked best in ocean water (80%), fenugreek in groundwater (80-90%), and the 1:1 combination of okra and fenugreek in freshwater (77%).

The researchers hypothesize that the natural polymers had different efficiencies because each water sample had different types, sizes and shapes of microplastics.

Polyacrylamide, which is currently used to remove contaminants during wastewater treatment, has low toxicity, but its precursor acrylamide is considered toxic. Okra and fenugreek extracts could serve as biodegradable and nontoxic alternatives.

“Utilizing these plant-based extracts in water treatment will remove microplastics and other pollutants without introducing additional toxic substances to the treated water,” said Srinivasan in a media release, “thus reducing long-term health risks to the population.”

She had previously studied the use of food-grade plant extracts as non-toxic flocculants to remove textile-based pollutants from wastewater and thought, ‘Why not try microplastics?’"

-via Good News Network, May 10, 2025

#watere#water pollution#microplastics#plastic#plastic pollution#pollution#solarpunk#environment#okra#fenugreek#united states#north america#texas#environmental science#good news#hope

16K notes

·

View notes

Text

Diesel Fired Thermic Fluid Heater

Introducing our cutting-edge Diesel Fired Thermic Fluid Heater – an epitome of innovation in industrial heating solutions. This advanced heater redefines heat transfer, offering a seamless blend of speed, reliability, durability, and precision temperature control for diverse industrial applications.

Key Features:

Experience the efficiency of quick and uniform heat transfer using thermic fluid with Avon engineering Diesel Fired Thermic Fluid Heater. Rapid Heat Transfer ensures a reliable exchange of heat for various operational needs. Additionally, it adeptly converts diesel fuel into heat, providing seamless and efficient energy utilization.

Moreover, Powered by Reliable Diesel Fuel, our heater harnesses the reliability of diesel fuel as an energy source. It utilizes this dependable fuel type, offering continuous and dependable heat for a wide range of applications, ensuring uninterrupted operation.

Furthermore, Designed with longevity in mind, our heater boasts Durable Construction for Lasting Use. Its robust construction can withstand the demands of industrial environments, ensuring consistent performance and reliability over time.

Lastly, Achieve accurate temperature control within your processes with our product. Precise Temperature Control is enabled through its advanced control systems, allowing you to maintain desired temperature ranges crucial for applications requiring specific heat levels.

#Diesel fired thermic fluid heater#Thermic fluid heater#Diesel heater for heat transfer#Rapid heat transfer fluid heater#Efficient diesel-fired heater#Industrial thermic fluid heater#Uniform heat transfer heater#Reliable diesel fuel heater#Durable construction heater#Precise temperature control heater#Process heating solutions#Heat exchange equipment#Thermic fluid heating system#Quick heat transfer heater#Uniform heat distribution heater#Reliable diesel fuel utilization heater#Robust construction for industrial use#Accurate temperature control heater#Dependable heat source heater#Energy-efficient heating solution#Industrial-grade thermic fluid heater#Long-term reliability heater#Versatile heat transfer equipment#Industrial heating solution for manufacturing#Heater for process industries#Heat transfer equipment for textile industry#Heater for food processing#Heater for pharmaceutical industry#Heater for chemical industry#Benefits of diesel-fired thermic fluid heaters

0 notes

Text

Dress for Success: Sustainable Fashion Tips for the Modern Workforce with Sri Shakthi Tex

In today’s dynamic and eco-conscious world, dressing for the office isn’t just about looking professional — it’s also about making ethical and sustainable choices. Sri Shakthi Tex, a leading manufacturer of quality textiles in Erode, offers a stunning range of natural fabrics that are perfect for creating chic and comfortable workwear ensembles.

So, ditch the bland, synthetic suits and embrace the power of conscious fashion! Here are some sustainable style tips to help you achieve a polished and professional look while feeling confident and comfortable all day long:

1. Embrace the Versatility of Natural Fabrics:

Sri Shakthi Tex offers a treasure trove of breathable and eco-friendly fabrics like organic cotton, linen, and rayon. These natural fibers not only drape beautifully but also keep you cool and comfortable throughout the workday.

2. Play with Prints and Patterns:

Subtle prints and textures can add visual interest to your outfit without compromising professionalism. Sri Shakthi Tex boasts a collection of exquisite prints inspired by nature and Indian heritage, perfect for making a statement without going overboard.

3. Invest in Classic Staples:

Build your workwear wardrobe with versatile pieces that can be easily mixed and matched. A crisp white shirt, a well-fitted blazer, and tailored trousers from Sri Shakthi Tex can be adapted to create countless professional looks.

4. Accessorize Wisely:

The right accessories can elevate your outfit and add a touch of personality. Opt for simple yet elegant jewelry, a statement scarf, or a sleek leather bag for a polished finish.

5. Comfort is Key:

Remember, you’ll be sitting and moving around throughout the day, so prioritizing comfort is essential. Choose pieces that allow for freedom of movement without compromising on style. Sri Shakthi Tex’s natural fabrics are naturally soft and breathable, ensuring you stay comfortable all day long.

6. Embrace the Ethical Choice:

By choosing sustainable fabrics from Sri Shakthi Tex, you’re not just making a statement about your personal style, you’re also contributing to a healthier planet and fairer working conditions for textile workers. Sri Shakthi Tex is committed to ethical production practices and sustainable sourcing, making them the perfect choice for the conscious consumer.

Conclusion:

Dressing for success in the modern workplace doesn’t have to be boring or unsustainable. With Sri Shakthi Tex’s quality textiles in erode and these styling tips, you can create a professional and polished look that reflects your commitment to both style and sustainability. So step into the office feeling confident and empowered, knowing that you’re making a positive impact on the planet one outfit at a time.

#Textile Manufacturing#Fabric Production#Textile Industry#Quality Fabrics#Yarn Manufacturing#Weaving Services#Knitting Solutions#Fabric Export#Sustainable Textiles#Textile Innovation#Textile Products#Yarn Suppliers#Dyeing and Finishing#Textile Processing#Apparel Fabrics

0 notes

Text

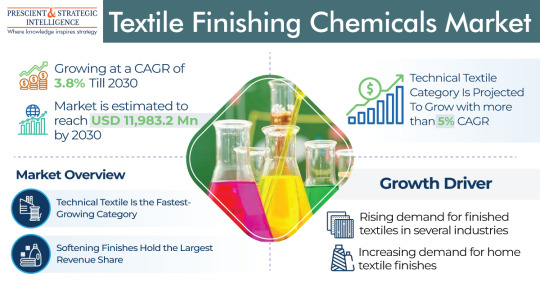

Unveiling Opportunities in the Textile Finishing Chemicals Market

The global textile finishing chemicals market is projected to be worth USD 11,983.2 million by 2030, growing at a CAGR of 3.8%, according to P&S Intelligence. These chemicals are consumed in significant volumes in furniture, textile, and other sectors. In this regard, the growing demand for unique finishes for residential upholstery and advanced textiles is propelling the market. The main aim of…

View On WordPress

#Eco-friendly Solutions#Fabric Enhancement#Global Industry#Innovation#Manufacturing Processes#market trends#Performance Textiles#Specialty Chemicals#Sustainable Finishes#Textile Finishing Chemicals

0 notes

Text

"The substances behind the slimy strings from okra and the gel from fenugreek seeds could trap microplastics better than a commonly used synthetic polymer.

Texas researchers proposed in 2022 using these sticky natural polymers to clean up water. Now, they’ve found that okra and/or fenugreek extracts attracted and removed up to 90% of microplastics from ocean water, freshwater, and groundwater.

With funding from the U.S. Department of Energy, Rajani Srinivasan and colleagues at Tarleton State University found that the plant-based polymers from okra, fenugreek, and tamarind stick to microplastics, clumping together and sinking for easy separation from water.

In this next stage of the research, they have optimized the process for okra and fenugreek extracts and tested results in a variety of types of water.

To extract the sticky plant polymers, the team soaked sliced okra pods and blended fenugreek seeds in separate containers of water overnight. Then, researchers removed the dissolved extracts from each solution and dried them into powders.

Analyses published in the American Chemical Society journal showed that the powdered extracts contained polysaccharides, which are natural polymers. Initial tests in pure water spiked with microplastics showed that:

One gram of either powder in a quart (one liter) of water trapped microplastics the most effectively.

Dried okra and fenugreek extracts removed 67% and 93%, respectively, of the plastic in an hour.

A mixture of equal parts okra and fenugreek powder reached maximum removal efficiency (70%) within 30 minutes.

The natural polymers performed significantly better than the synthetic, commercially available polyacrylamide polymer used in wastewater treatment.

Then the researchers tested the plant extracts on real microplastic-polluted water. They collected samples from waterbodies around Texas and brought them to the lab. The plant extract removal efficiency changed depending on the original water source.

Okra worked best in ocean water (80%), fenugreek in groundwater (80-90%), and the 1:1 combination of okra and fenugreek in freshwater (77%).

The researchers hypothesize that the natural polymers had different efficiencies because each water sample had different types, sizes and shapes of microplastics.

Polyacrylamide, which is currently used to remove contaminants during wastewater treatment, has low toxicity, but its precursor acrylamide is considered toxic. Okra and fenugreek extracts could serve as biodegradable and nontoxic alternatives.

“Utilizing these plant-based extracts in water treatment will remove microplastics and other pollutants without introducing additional toxic substances to the treated water,” said Srinivasan in a media release, “thus reducing long-term health risks to the population.”

She had previously studied the use of food-grade plant extracts as non-toxic flocculants to remove textile-based pollutants from wastewater and thought, ‘Why not try microplastics?’"

-via Good News Network, May 10, 2025

#microplastics#plastic#plastic pollution#okra#fenugreek#biotechnology#solarpunk#water pollution#pollution#united states#north america#texas#good news#hope

210 notes

·

View notes

Text

when i took a dye workshop on bali last year i worked with a traditional dye, ceriops tagal (indian mangrove), made from the heartwood and bark of the tree. it's been used as a very strong orange through russet through brown dye for thousands of years across the indian ocean world (so coastal eastern africa through south and southeast asia) and is notably used for dyeing orange through brown in indo-malay batik. it's a difficult dye to access now, though, especially if you're trying to do so ethically because the indian mangrove is endangered. there are some orgs that have sustainable grow ops across indonesia that harvest the dye only every few years and do so as a by-product of local industry, because ceriops tagal is an important tree for many villages across the region for wood and other necessary purposes. not harvesting the wood at all isn't helpful as a solution, so these orgs harvest at a sustainable pace and use as much of the trees as possible to reduce waste (and i believe they run as workers co-ops, so all workers are paid fair wages and decide their working conditions)

all that is to say that i got my hands on some of the dye extract from one of these orgs and made a dye vat a few days ago and left it to sit so the colour can improve while i prepare some cotton and silk yarns to be dyed. i started doing the actual dyeing today, and the process is a lot like working with indigo, in the sense that the dye sits cold in a large bucket and you dip the fiber for five minutes before wringing and letting it hang to dry. successive dips in the vat deepen the colour, and the vat can be used until it's exhausted (ie no more colour comes out of it). it gets stronger with age, and a unique characteristic of the ceriops dye is that the dye gets darker in the sun. the chemicals in the plant that cause this unique uv-darkening aspect are also found in unripe fermented persimmons, which have been used as a dye in japan (kakishibu) for centuries. both dyes also have a unique feature in that they create a textile that is water resistant, so the dyes have been used to create waterproof stencils and the sails of ships.

the ceriops bark is in the right cup in the top left photo; the orange dye in the other two photos is the colour typical of ceriops tagal.

#mine#these photos were taken when i was in indonesia#i'll take photos of my current dye experiments once theyre done

330 notes

·

View notes

Text

Every week, Bastián Barria ventures into the Atacama desert in northern Chile looking for items of discarded clothing in the sand. About half of the hundreds of garments he finds are in perfect condition. He collects what he can and adds them to the two-tonne pile of clothes he has stored at a friend’s house.

On 17 March, 300 of those items, including Nike and Adidas shorts, Calvin Klein jeans and a leather skirt, were listed for sale online for the first time. The price? Zero. Customers had only to pay shipping costs. The first batch sold out in five hours, bought by customers from countries including Brazil, China, France, the US and the UK.

Re-commerce Atacama is part of a campaign to raise awareness of the mountains of discarded clothes in Chile and of textile waste globally. It was set up after a fashion show staged in the desert last year, where models walked a catwalk of sand wearing outfits made out of the surrounding waste.

“We want people to feel involved and be agents of change – not from a passive position of seeing content, but by purchasing something, showing people and telling our story of what is happening here in the desert,” says Barria, 32, a civil engineer and co-founder of Desierto Vestido (Dressed Desert), an organisation dedicated to raising awareness of textile waste.

“At first, there was a certain disbelief on my part to see this happening. I asked myself why garments in perfect condition were being discarded in the desert when there are many people who might like to wear them. It’s sad. It really makes you feel powerless.”

Chile has long been a destination for secondhand and unsold clothing, most of it made in China or Bangladesh and passing through Europe, Asia or the US before arriving in the country. In 2022, more than 131,000 tonnes of clothing arrived in the country, most of it in the city of Iquique in northern Chile, home to one of the most important duty-free ports in South America.

Some is resold, but sources in the region say up to 70% ends up in rubbish dumps in the desert every year; in Chile it is forbidden to dump textile waste in legal landfills because it generates soil instability. The desert is one of the country’s most popular tourism destinations, known for its otherworldly landscapes, but for those living near the dump sites it has become a place of devastation. Pictures of a mountain of clothes taken from space went viral in 2023. In recent years, people have resorted to burning the waste in an attempt to hide the extent of it. The resulting toxic clouds of smoke are an environmental and health concern for the surrounding communities.

Determined to do something about the crisis, Barria’s organisation teamed up with fashion activists Fashion Revolution Brazil, the Brazilian advertising agency Artplan and the e-commerce platform Vtex, to tell the world about the situation.

The Re-commerce Atacama operation involves a careful process of selecting and restoring the garments to ensure they are in good condition for resale. They are cleaned and made available for free, bar shipping costs, on the digital platform.

In advance of the first drop of clothes, influencers and personalities including Dudu Bertholini, a judge on Drag Race Brasil, posted about the campaign on social media. The next drop is expected in April. Anyone interested can add their email to be notified when more clothes become available.

Fernanda Simon, director of Fashion Revolution Brazil, sees the project as “an act of activism that reveals what is behind fashion and proves we can do things differently”.

She says: “More than removing clothes from the desert, we wanted to inspire solutions, rethink the fashion model and show that we must talk about circularity.”

About 92m tonnes of textile waste are created annually and every second, the equivalent of a lorry load of clothes ends up on a landfill site somewhere around the world.

This phenomenon is a consequence of an increase in clothing consumption and the fast-paced production model of the fashion industry, says Simon. “How we produce fashion is wrong,” she says. “We produce more and more and the velocity of production is getting faster and faster. There is no transparency about how these clothes are made.”

While 20 years ago, most labels would release four collections of clothes annually, she says, now with the rise of fast fashion and ultra-fast fashion, there can be as many as 52 collections a year.

Unsold inventory and unwanted secondhand clothes, most of which come from markets in the US, Europe and Asia, are dumped in countries in the global south. Another place where this problem is particularly visible is Accra, Ghana’s capital, where tangled webs of clothes line the shore.

Simon labels this practice “racist and colonialist”. Most of the raw materials required to make clothes come from countries in the global south, she says. European countries and the US are the biggest consumers, and when they don’t want the clothes, they end up back in countries in the global south.

“It’s a massive problem. It’s not just Chile, it’s not just Ghana. It’s a global problem. We are facing this waste and it is proof that we need to rethink the fashion system.”

16 notes

·

View notes

Text

When you do not know a thing about the issue at stake...

...perhaps it's better to remain silent.

Some of you know, others don't - and that's fine - but my main field of expertise is labor law.

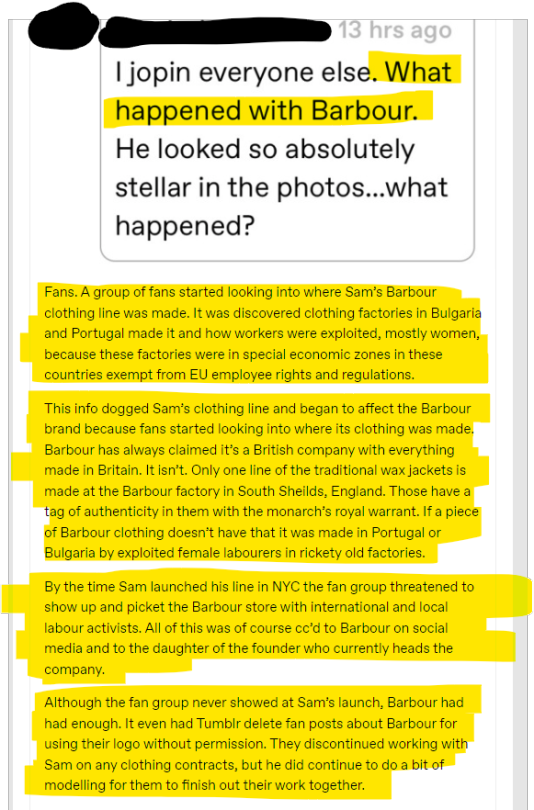

I just read this in anger and disbelief:

Look, lady. I don't care who the hell you are, what you do for a living or why you felt entitled to answer those insistent questions on your side of the fandom. I suppose you are North American and have no idea of how things work on this side of the pond. It is fine: I might know what a Congress filibuster is, for example, but I'd be severely unable to judge the finer points of competence sharing between Fed and state level.

The difference between you and me?

I keep my mouth shut and/or do my own research before opening it in public.

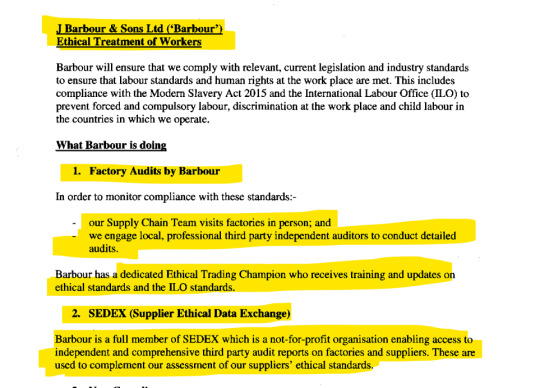

Have you no shame to write things like: 'It was discovered clothing factories in Bulgaria and Portugal made it and how workers were exploited, mostly women, because these factories were in special economic zones in these countries exempt from EU employee rights and regulations.'

HOW DARE YOU? What strange form of illiterate entitlement possessed you to utter such things with confidence, comfortably hidden behind a passive voice ('it was discovered')?

Portugal joined the EU in 1986. Bulgaria (and my country) joined the EU in 2007. I have given 5 relentless years of my life to make this collective political project a reality, along with hundreds of other people my age who chose to come back home from the West and put their skills to good use for their country. In doing so, I rejected more than 10 excellent corporate job offers in France and China. To see you come along and write such enormities is like having you spit in my face.

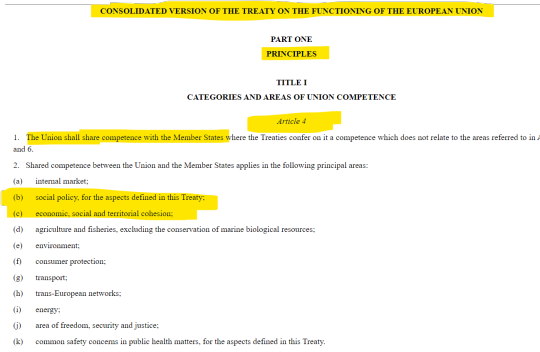

Article 4 of the Treaty on the Functioning of the European Union (aka The Treaty of Rome) is formal and clear, as far as competence sharing between the EU and its Member States goes (the UK was still, back then, a full member of the EU - it quit on February 1st 2020):

That means that ALL the EU regulations are being integrated into the national legislation of the Member States. This is not a copy/paste process, however. And because it is a shared competence area, the Member States have a larger margin of appreciation into making the EU rules a part of their own. While exceptions or delays in this process can be and are negotiated, the core principles are NEVER touched.

Read it one hundred times, madam, maybe you'll learn something today:

THERE ARE NO SPECIAL ECONOMIC ZONES IN THE EUROPEAN UNION. THE WHOLE FUCKING EUROPEAN UNION IS A SPECIAL ECONOMIC ZONE, THIS IS WHY IT IS CALLED THE SINGLE MARKET.

What the fuck do you think we are, Guangzhou? We'd wish, seeing the growth statistics!

Now, for the textile industry sector and particularly with regard to the Bulgarian market, a case very similar to my own country. Starting around 1965, many big European textile players realized the competitive advantage of using the lower paid, readily available Eastern European workforce. In order to be able to do business with all those dour Communist regimes, the solution was simple and easy to find: toll manufacturing.

It worked (and still does!) like this:

The foreign partner brings its own designs, textiles and know-how into the mix - or more simply put, it outsources all these activities. The locals transform it into the finished product, using their own workforce. The result is then re-exported to the foreign partner, who labels it and sells it. In doing so, he has the legal obligation to include provenance on the label ('made in Romania', 'made in Indonesia', 'made in Bulgaria' - you name it).

The reason you might find less and less of those 'made in ' labels nowadays at Primark and more and more at Barbour, Moncler and the such is the constant raise of the workers' wages in Eastern Europe since 1990 (things happened there, in 1989, maybe you remember?). We are not competitive anymore for midrange prêt-à-porter - China (Shein, anyone?), Cambodia and Mexico do come to mind as better suppliers. To speak about 'exploited female labourers in rickety old factories' is an insult and a lie. They weren't exploited back in the Eighties, as they are not now (workers in those factories were and still are easily paid about 50% more than all the rest) and the factories being modernized and constantly updated was always a mandatory clause in any contract of the sort. Normal people in our countries rarely or ever saw those clothes. You had to either be lucky enough for a semi-confidential store release or bribe someone working there and willing to take the risk, in order to be able to buy the rejected models on the local market.

If I understood correctly, you place this critical episode at the launch of the limited SRH & Barbour collection, for the fall of 2018. How convenient for you, who (I am told by trusted people) were one of the most vocal critics of S during Hawaii 2.0!

And as far as Barbour goes, it never pretended to manufacture everything in the UK only:

This information is absolutely true. You can read the whole statement, signed in October 2017 by one of their Directors, Ian Sime, here: https://www.barbour.com/us/media/wysiwyg/PDF/Ethical_Statement_October_2017.pdf

And a snapshot for you:

Oh, and: SEDEX is a behemoth in its world, with more than 75.000 companies joining as a member (https://www.sedex.com/become-a-member/meet-our-customers/). Big corporations like TESCO, Dupont, Nestle, Sainsbury's or Unilever included.

I am not Bulgarian, but I know all of this way better than you'll probably ever do. The same type of contracts were common all over Eastern Europe: Romania, Poland, the GDR (that's East Berlin and co, for you) and even the Soviet Union. I am also sure your Portuguese readers will be thrilled to see themselves qualified by a patronizing North American as labor exploiters living in a third-world country with rickety factories.

You people have no shame and never did. But you just proved with trooping colors you also have no culture and no integrity. More reasons to not regret my unapologetic fandom choice.

I expect an angry and very, very vulgar answer to this, even if I chose to not include your name/handle. The stench of your irrelevance crossed an ocean.

126 notes

·

View notes

Text

"South African entrepreneur Phumla Makhoba is on a mission to solve the “global south housing crisis.” And she’s doing it by using clothing waste.

Her invention, Texiboard, is a material that combines fibers found in textile waste with lime cement to create a durable, affordable, and circular building material.

The result is a textured, white square, almost tile-like, that is created with recycled materials — not emission-generating wood or concrete.

“It can be used to make furniture, flooring, walls, or even your entire home,” Makhoba said in a video for social media account We Got Earth.

The first iterations of the Texiboard included colorful cotton threads that were compressed together, with multiple attempts to remove cracks and seams and perfect the ratios of size, shape, and material mass.

With her design firm, Studio People, Makhoba has been working since 2022 to perfect the TexiBoard.

Makhoba has since created a solid panel, with shredded textile fiber and natural lime cement fully cured. Finally, it can be formed into a full sheet of building material.

Once realized, the Texiboard will confront the estimated 92 million tons of clothing waste generated around the globe each year. But it will also provide safe and stable housing that Makhoba says only 20% of South Africans can afford.

“Growing up, I saw two worlds: one with polished buildings, and one built from scrap,” she said in a video. “I always wondered, why do some people get homes that last and others get homes that leak?”

Now, the Texiboard design is available as an open-source resource, and Makhoba and her team host in-person workshops for locals living in shacks to learn how to build their own supportive and sustainable housing.

“Just having a roof isn’t enough,” Makhoba said. “A real home should protect you from the weather, work for your daily life, and not fall apart in five years.”

Her approach includes a full theory of change. Right now, Studio People is in the input process, building partnerships and funding to scale their operation. From there, they hope to develop a fully sustainable supply chain to manufacture and sell Texiboards and help build affordable housing for people in need.

Once that dream is realized, Makhoba outlines the tangible output of this work: Economically inclusive waste management, circular building materials, green jobs, and a sustainable housing and manufacturing market.

“Informal settlements can be transformed when we all work together,” she shares on the Studio People website. “Texiboard is the seed of innovation that will create updated trade jobs in the innovative building industry.”

Although the Texiboard is still being completely perfected, the goal is to provide a weather-proof, cost-effective, and circular way to house people by democratizing the act of building.

“Our goal is to create an egalitarian and sustainable urban environment, helping shack dwellers and youth out of poverty,” Studio People shared on LinkedIn.

“We empower the underdog, including people and businesses, to co-create solutions in our fight against the housing crisis, unsustainable building materials, and unemployment — one board at a time.”"

-via GoodGoodGood, May 28, 2025

#south africa#africa#entrepreneur#black excellence#black women#textiles#textile waste#clothing#clothing industry#housing#sustainability#circular economy#architecture#sustainable architecture#good news#hope

1K notes

·

View notes

Text

Best ETP STP Plant Manufacturers in Gurgaon

Gurgaon, also known as Gurugram, is one of the fastest-growing industrial hubs in India, characterized by a thriving economy and a diverse range of industries. As industrial activities increase, the necessity for effective wastewater management solutions becomes more critical. This is where Effluent Treatment Plants (ETP) and Sewage Treatment Plants (STP) play a pivotal role. Among the prominent…

#3D Aqua#Effluent Treatment Plant#ETP#food processing#Gurgaon#pharmaceutical industry#sewage treatment plant#STP#sustainable solutions#textile industry#Wastewater Management#Water Treatment

0 notes

Text

Roomscapes

The Decorative Architecture of Renzo Mongiardino

Renzo Mongiardino, Fiorenzo Cattaneo

Rizzoli, New York 1993, 208 pages, 320 col.ill., 24,5x28,5 cm, ISBN 978-0847815531

euro 60,00

email if you want to buy [email protected]

On the international design scene, Milan-based architect Renzo Mongiardino is renowned as the consummate creator of spectacular, atmospheric spaces. His dramatic, theatrical approach to design has produced elegant period interiors that have influenced many other designers. This handsome monograph, the first complete presentation of Mongiardino's work, explores his philosophy of space, design, and life itself. Extraordinary color photographs illustrate the brilliant arrangements of objects, art, and antiques and the rich array of textiles and painted effects-- faux wood, marble, and other materials, extravagant full-scale trompe l'oeils-- that epitomize his style. Mongiardino draws from sources that range from ancient Greek, Roman, and Etruscan artifacts to the work of the Renaissance and baroque masters Michelangelo, Palladio, Bernini, and Borromini and to antique fabrics, carpets, and objets; he also adds poetic recollections of important personal and historical spaces and incorporates his view of nature as a collaborator in the design process. Equally important is his ability to reflect the personality and lifestyle of his distinguished clients, whether in New York, London, Milan, Rome, or Paris. The resulting interior landscapes transform rooms into evocative surroundings of startling beauty. Practical considerations of design are discussed in Mongiardino's own words. He shares his insights into particular spaces-- small or large, study or grand gallery-- and traces the solutions he originated to create them. Through early sketches, impressionistic drawings and watercolors, and detailed photographs, he unfolds the story of each space, highlighting both its particular challenges and the lessons to be learned from its ultimate success as a stunning environment for living.

22/11/24

21 notes

·

View notes

Text

Single-step coating offers scalable, non-toxic flame protection for fabrics

Although extremely flammable, cotton is one of the most commonly used textiles due to its comfort and breathable nature. However, in a single step, researchers from Texas A&M University can reduce the flammability of cotton using a polyelectrolyte complex coating. The coating can be tailored for various textiles, such as clothing or upholstery, and scaled using the common pad-dry coating process, which is suitable for industrial applications. This technology can help to save property and lives on a large scale. "Many of the materials in our day-to-day lives are flammable, and offering a solution to protect from fire benignly is difficult," said Maya D. Montemayor, a graduate student in the Department of Chemistry at Texas A&M and the publication's lead author. "This technology can be optimized to quickly, easily, and safely flame retard many flammable materials, offering vast protection in everyday life, saving money and lives of the general population."

Read more.

17 notes

·

View notes

Text

Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad 7337443480

Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad is not just hot water and cold water; it also purifies pure water and safe water. Voltas Dispenser Service Centre Near Banjara Hills Hyderabad presents a new range of Water Dispensers that you want to choose between Hot water Normal water & Cold water and also Volta's water dispenser puts every drop through a 4-stage filtration process. It is better Voltas Dispenser Service Center Near Banjara Hills Hyderabad than other Dispensers. For any repairs, eServe supports Voltas Water Dispenser Service center Near Banjara Hills. Voltas Bottom Loaded Water Dispenser Service Center Near Banjara Hills: The New Voltas Bottom Mounted Water Dispenser Service Centre Near Banjara Hills has with water bottle loaded inside the cabinet. If there is any problems contact eServe for Voltas water dispenser Service Center Phone Number Hyderabad. Voltas Table Top Water Dispenser: Compact Voltas Table Top Water Dispenser Water Dispenser Service Center Near Banjara Hills range with hot water, cold water, and normal water dispensing features. Take the support of eServe for any repairs with Volta's water dispenser service center in Madhapur. Voltas Floor Mounted Water Dispenser Service Center Near Banjara Hills: Voltas Floor Mounted Water Dispenser range with hot water, cold water, and normal water dispensing features with refrigerator and storage cabinet options. If there are any repairs are there, Take eServe support by searching the Voltas water dispenser service center near me, Voltas water dispenser service repair near me. Voltas Visi Cooler: Specially designed To Cool Uniformly As well As Showcase the Products Inside like cool drinks and other beverages. Key Features of Voltas VISI Cooler UV Grade Plastic Material For Long-Lasting Appearance of Voltas Visa Cooler Low Glazing Glass to Avoid Cooling Loss of Voltas Visi Cooler Compact Design - which suits everywhere soft and Aesthetic Design Energy-Efficient Compressor to reduce power consumption Anti-Corrosive Pre-Coated Body - Which fit's any corner in INDIA

If there are any repairs in Voltas Water Dispenser Service Center Near Banjara Hills Visi Cooler Features take the support of eServe you can search for us like Voltas Water Dis Service center near me, Voltas Service Center number near me Hyderabad to get best from our team.

Tata voltas service Center near me : Voltas restricted is associate Indian company specializing in air con and cooling technology the corporate is broadly speaking structured into comes and product business the comes business is split into Domestic comes cluster and International Operations Business cluster. Voltas Water Dispenser Service Center Near Banjara Hills , established in 1954, operates in 3 segments - Unitary Cooling product, Electro-Mechanical comes & Services, and Engineering product & Services. Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad is India's largest air conditioning company, and one among the world's premier engineering solutions suppliers and comes specialist.

Founded in India in 1954, Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad restricted offers engineering solutions for a large spectrum of industries in areas like heating, ventilation and air conditioning, refrigeration, electro-mechanical comes, electrification, textile machinery, mining and construction instrumentality, water management & treatment, cold chain solutions, building management systems, and indoor air quality. Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad is India's largest air conditioning company and India's No. one air conditioning complete, Voltas Water Dispenser Service Center Near Banjara Hills besides being the well-liked EPC contractor within the comes house and one among India's most trustworthy names in textile machinery and mining & construction instrumentality.

Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad includes a pan-India presence through its network of sixteen branches and over 300 textile engineers. On five could 2015 Voltas Water Dispenser Service Center Near Banjara Hills proclaimed its invade air coolers business with the launch of fresh-air coolers below the Voltas complete. Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad The new vary comes with engaging options like exclusive honeycomb cooling pads carbonized dirt filters and powerful air throw. On 27 March 2017 Voltas restricted proclaimed that it's fortified its leadership position within the cooling class by crossing one.5 million units within the year 2016-17. Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad On 23 could 2017 Voltas restricted and Ardutch B.V. in agreement to determine a venture Company (JVC) in India to enter the patron consumer goods market within the country.

The new company to be incorporated in Asian nation are associate equal partnership venture. The projected JVC can leverage the sturdy complete presence and wide sales and distribution network of Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad which is the market leader for residential air-conditioners in the Asian nations the JVC its sturdy R&D and producing artistry additionally to a good product vary and world sourcing capabilities. Voltas Water Dispenser Service Center Near Banjara Hills Bako the worldwide complete has been the quickest-growing home appliances complete of Europe for the past seven years. The projected JVC can launch refrigerators laundry machines microwaves and alternative white goods/domestic appliances in Asian nations. Voltas Dispenser Service Center Near Banjara Hills Hyderabad On a pair of February 2018 Voltas Water Dispenser Service Center Near Banjara Hills launched India's 1st Window cooling system with DC electrical converter technology.

Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad It works on a singular Steady Cool electrical converter mechanical device that could be a variable speed mechanical device providing steady cooling and steady savings. With this launch, Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad Voltas has strengthened its commitment of unceasingly Transferal the latest technology within the Indian market.

#Voltas Water Dispenser Service Center Near Banjara Hills#Voltas Water Dispenser Service Center At Banjara Hills#Voltas Dispenser Service Center Near Banjara Hills Hyderabad#Voltas Dispenser Service Center Center Near Banjara Hills.

22 notes

·

View notes