#Timber Frame Connectors

Explore tagged Tumblr posts

Text

Kids' woodworking Day

"This is actually fun!"

We recently invited some students from a local school and the children of our staff to participate in our Kids' Woodworking Day event. The students worked alongside our team of expert carpenters to create a special project. During a break, they walked into our timber frame connector and the "ohhh!"s and "ahhh!"s were audible. Our staff explained that there are many career paths within the world of woodworking - from crafting smaller projects like the ones the students were working on, to building big timber frame structures.

As we wrapped up our time together, one of the girls proclaimed, "I could do this all day long!" Another student said, "This is actually fun!"

Our team enjoys inspiring the next generation of carpenters and experts in the construction industry. We provide real opportunities for career growth and professional development. If you'd like to join our team, carpenters can send their resumes to [email protected] or review our Preconstruction Manager opening here - https://northgroupconsultants.com/jobs/#/jobs/321

#construction company#construction#now hiring#hiring#construction industry#carpentry#woodworking#carpenter

2 notes

·

View notes

Text

Global Timber Connectors Market Key Drivers, Challenges by 2025-2032

Global Timber Connectors Market is experiencing steady growth, valued at USD 453 million in 2024 and projected to reach USD 654 million by 2032, expanding at a CAGR of 4.70% during the forecast period (2025-2032). This upward trajectory is driven by rising demand in construction sectors, particularly in residential and commercial building applications, along with infrastructure development projects worldwide.

Timber connectors are critical components in modern timber construction, providing structural stability and enhancing load-bearing capacity. Their adoption is accelerating due to the growing preference for sustainable and cost-effective wood-based construction solutions. Governments and industry bodies are increasingly promoting timber as a renewable building material, further stimulating market growth.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/293180/global-timber-connectors-market-2025-2032-824

Market Overview & Regional Analysis

North America leads the timber connectors market, accounting for over 35% of global consumption, supported by well-established construction industries and stringent building codes requiring reliable timber framing systems. The region's focus on sustainable construction practices and the rehabilitation of aging infrastructure creates consistent demand.

Europe follows closely, with Germany and Scandinavia being key markets due to their advanced timber construction technologies and environmental regulations favoring wood-based building materials. Meanwhile, Asia-Pacific is emerging as the fastest-growing region, propelled by rapid urbanization and increasing investments in residential construction across China, Japan, and Southeast Asia.

Key Market Drivers and Opportunities

The market is primarily driven by the global construction industry's expansion, particularly the growing popularity of timber frame construction in both residential and commercial sectors. Lightweight wood structures are gaining preference over traditional materials because they offer faster construction times, better seismic performance, and lower carbon footprints.

Significant opportunities exist in the development of innovative connector designs that enhance installation efficiency and structural performance. The increasing adoption of engineered wood products like cross-laminated timber (CLT) and glue-laminated timber (glulam) presents new avenues for specialized connector systems. Additionally, post-pandemic infrastructure stimulus packages in various countries are expected to boost demand for timber construction components.

Challenges & Restraints

The timber connectors market faces several challenges, including competition from alternative building materials such as steel and concrete, which remain dominant in certain construction applications. Fluctuations in lumber prices and supply chain disruptions can impact market stability, while skilled labor shortages in timber construction may hinder adoption rates.

Regulatory hurdles and varying building codes across regions pose additional challenges for manufacturers. Furthermore, concerns about long-term durability in high-moisture environments and the need for proper installation techniques present technical barriers that the industry must address.

Market Segmentation by Type

3-way Connectors

4-way Connectors

Other

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/293180/global-timber-connectors-market-2025-2032-824

Market Segmentation by Application

Residential Building

Commercial Building

Infrastructure

Market Segmentation and Key Players

Pryda

Simpson Strong Tie

MiTek

Timberplates

Connext Post and Beam

Knapp GmbH

Report Scope

This comprehensive report analyzes the global timber connectors market from 2024 to 2032, providing detailed insights into:

Market size and growth projections

Detailed segmentation by type, application, and region

Competitive landscape and market share analysis

The report also includes in-depth profiles of major industry players, covering:

Company overview and product portfolios

Production capabilities and market strategies

Financial performance and recent developments

Our research methodology combines primary interviews with industry experts, market surveys, and thorough analysis of industry trends to provide accurate and actionable insights.

Get Full Report Here: https://www.24chemicalresearch.com/reports/293180/global-timber-connectors-market-2025-2032-824

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

0 notes

Text

Why Brackets are Key for Your Free-Standing Pergola or Permanent Gazebo Kits in Australia

When it comes to installing a free-standing pergola or permanent gazebo kits Australia, many homeowners focus on the design, roofing, and materials — but one of the most crucial elements often gets overlooked: brackets.

Brackets for pergola may seem like minor components in your outdoor structure, but they play a vital role in the safety, stability, and longevity of your pergola or gazebo. Here’s why investing in quality brackets is a smart move.

Structural Integrity and Safety

Australia’s climate can be unpredictable, with strong winds, heavy rain, and high UV exposure in many regions. Brackets ensure that your pergola free standing or gazebo stays firmly anchored, even in challenging weather. They connect beams, posts, and rafters securely, reducing the risk of wobbling, leaning, or structural failure over time. If you're building in a high-wind zone, using reinforced steel brackets can add significant strength to your frame.

Ease of Assembly

Pergola and gazebo kits often come with pre-cut timber and detailed instructions, but what truly simplifies the assembly process is the use of pre-drilled metal brackets. These components allow for more accurate alignment and reduce the margin of error during installation. This is particularly useful for DIY enthusiasts who want to build their structure without hiring a professional.

Clean Aesthetic and Professional Finish

Brackets not only provide a practical purpose but also help your building to look whole. Powder-coated black or galvanised steel brackets add a modern, finished appearance. They conceal joints and fasteners neatly, giving your pergola or gazebo a cleaner and more streamlined look.

Long-Term Durability

Corrosion-resistant brackets, such as those made from galvanised or stainless steel, are designed to withstand Australia’s coastal and inland conditions. Whether it’s humidity in Queensland or dry heat in Western Australia, these materials resist rust and deterioration, ensuring your structure lasts for years with minimal maintenance.

Customisation and Flexibility

Using modular brackets allows you to design a pergola or gazebo that suits your space and lifestyle. Whether you want a square, rectangular, or L-shaped configuration, adjustable brackets give you the flexibility to modify your structure with ease.

Brackets are more than just connectors — they’re the backbone of a reliable and attractive pergola or gazebo. If you're investing in a permanent outdoor structure, don’t cut corners on these essential components.

Source: https://modapraxau.blogspot.com/2025/05/why-brackets-are-key-for-your-free.html

0 notes

Text

Selecting the Right Connection Methods for Your Commercial Roof Trusses

When it comes to commercial construction, the strength and durability of a building largely depend on the roof structure. Roof trusses are a critical component, and selecting the right connection methods is essential to ensure safety, cost-efficiency, and longevity. In commercial buildings—where load demands, span requirements, and building codes are stringent—the method used to connect trusses can make or break your project’s success.

Whether you're building a retail center, warehouse, or multi-story office complex, choosing the right connection method for your commercial roof trusses is just as important as the truss design itself. Let’s explore the best practices, available methods, and expert considerations to help you make the right choice.

Why Truss Connection Methods Matter

Connection methods serve as the glue that holds the entire roof structure together. These connections:

Transfer loads between truss components

Ensure stability during construction and throughout the life of the building

Facilitate quick and safe installation

Comply with engineering and code standards

Inadequate or improperly selected connection systems can lead to structural failure, increased costs, and project delays. Therefore, understanding your options and the factors that influence your choice is crucial.

Types of Connection Methods for Commercial Roof Trusses

Choosing the best connection method depends on several factors such as truss material, building type, load requirements, and budget. Below are the most commonly used connection methods in commercial applications:

1. Metal Plate Connectors

Metal plate connectors, also known as truss plates or nail plates, are the most widely used method for wooden roof trusses. These plates are pressed into the wood at truss joints, providing a high-strength bond.

Advantages:

Fast installation

Cost-effective

Consistent and reliable

Best Used For: Large-scale commercial buildings using pre-engineered wood trusses.

2. Bolted Connections

Bolted connections involve fastening truss members using heavy-duty bolts, often accompanied by washers and steel plates. This method is common in both timber and steel trusses.

Advantages:

High load-bearing capacity

Reusable for temporary structures

Easy to inspect and maintain

Best Used For: Warehouses, bridges, and buildings requiring high structural integrity.

3. Welded Connections

Welding is typically used in steel trusses, offering a strong and permanent bond between members.

Advantages:

Superior strength

Minimal visible joint hardware

Excellent performance under dynamic loads

Best Used For: Industrial buildings and large-span commercial structures with steel framing.

4. Screwed or Lag-Bolt Connections

Lag bolts or screws are used for timber trusses where a metal plate might not be ideal, such as in exposed truss applications for aesthetic purposes.

Advantages:

Strong mechanical fastening

Good for custom or decorative applications

Best Used For: Retail or hospitality buildings with visible wooden trusses.

Factors to Consider When Selecting a Truss Connection Method

Selecting the right connection method is more than just matching materials—it involves engineering insight, code compliance, and practical feasibility. Here’s what to keep in mind:

1. Material Compatibility

The method must align with the material used—wood, steel, or engineered composites. For instance, a welded connection is great for steel but unsuitable for wood.

2. Load Requirements

Commercial buildings face varying live and dead loads depending on occupancy, roof type, and geographic location. The connection must handle both vertical and lateral forces.

3. Building Type and Design

Complex roof designs or wide-span buildings may require hybrid connection systems to accommodate architectural and structural demands.

4. Installation Environment

Will the trusses be preassembled offsite or installed onsite? Some connection types are better suited for factory assembly, while others accommodate field adjustments.

5. Code and Inspection Requirements

Always ensure compliance with local building codes, especially in areas prone to seismic or high wind activity. Each connection method must also be easy to inspect.

Ensuring Proper Installation with Expert Help

Improper installation of truss connections can compromise the structural integrity of the entire roof. To avoid this, always work with experienced professionals who understand the nuances of commercial roof truss systems.

A qualified provider will:

Conduct accurate load calculations

Select materials and connectors appropriate to your region and building type

Ensure all components meet local codes

Provide pre-engineered solutions that streamline installation

At Structural Wood Corporation, our team has decades of experience designing and fabricating custom roof truss systems that meet demanding commercial requirements. We can help you choose and install the right connections for your project, ensuring durability, compliance, and cost-efficiency.

Common Mistakes to Avoid

Here are a few costly mistakes to steer clear of when selecting connection methods:

Ignoring environmental conditions: Failing to factor in wind, snow, and seismic loads.

Overlooking long-term maintenance: Some connectors require ongoing checks, especially in corrosive environments.

Mixing incompatible materials: Using connectors that react poorly with truss materials can lead to deterioration over time.

Choosing aesthetics over performance: While it’s tempting to go with a more visually appealing method, structural integrity should always come first.

Future-Proofing Your Truss System

With commercial buildings evolving to meet new environmental and technological standards, the truss connection method should also accommodate future upgrades, such as:

Renewable energy systems (e.g., solar panels)

Rooftop HVAC systems

Reconfiguration of internal layouts

Make sure your roof truss system and its connectors are adaptable to changes in use or equipment without compromising structural integrity.

Final Thoughts

Selecting the right connection method for your commercial roof trusses isn’t a one-size-fits-all decision. It involves a careful balance of structural requirements, environmental conditions, budget, and aesthetic considerations. By understanding the available connection types and working with industry professionals, you can ensure a safe, efficient, and future-ready commercial roof system.

Have questions about your specific project? Reach out to our experienced team via our Contact Page. We’re happy to guide you through the process and help you select the ideal connection method for your roof trusses.

1 note

·

View note

Text

Prefabricated Wood I-Joists

Prefabricated wood I-joists are used throughout the world and are well accepted by the construction industry. Prefabricated wood I-joists are high-strength, cost-effective, and versatile building elements for floor, roof wall framing in residential and commercial construction. Product lines are manufactured in many sizes, using a number of component materials to obtain a wide variety of engineering design properties.

Prefabricated wood I-joists are specialized products, manufactured with specially designed equipment. Expertise in adhesives, wood products, manufacturing, and quality assurance are necessary for the fabrication of high-quality prefabricated wood I-joists. Prefabricated wood I-joists utilize the geometry of the I-shaped cross-section and high-strength components to maximize the strength and stiffness of the wood fiber. Flanges are manufactured from sawn lumber or structural composite lumber, whereas webs typically consist of plywood or oriented strand board.

The design of the prefabricated wood I-joist efficiently utilizes and optimizes the wood fibers. The flanges (the top and bottom of the assembled member) are designed to resist bending forces and to add stiffness to the product. The web section is designed to withstand the shear forces in the joist. Adhesive applied in the rout of each flange creates a durable exterior structural joint.

An I-shaped cross-section, as opposed to a solid rectangular cross-section, requires additional considerations. Due to its particular shape, the prefabricated wood I-joist requires special examination for and interior reaction capacity, shear capacity, deflection, connector compatibility, vertical load transfer at points of bearings, web holes, and floor and roof performance.

The unique manufacturing techniques and the variety of materials that are utilized result in design values that are typically proprietary to each manufacturer. Prefabricated wood I-joists are tested and qualified under ASTM Standard D-5055 and are recognized in evaluation reports issued by one or more of the model building code evaluation service organizations. Unique

Open Web Joists

Firring Timbers

I-Joists

Chipboard Flooring

Concrete Formwork Timber Beam

Engineered Timber I-Joist

3-1/2-in x 11 7/8-in LPI 42 Plu

LVIL Factory Outlet Formwork Ma

Open Web Joists

Firring Timbers

I-Joists

Chipboard Flooring

Concrete Formwork Timber Beam

Engineered Timber I-Joist

3-1/2-in x 11 7/8-in LPI 42 Plu

LVIL Factory Outlet Formwork Ma

0 notes

Text

Expert Frame & Truss Cladding Installation in Sydney, NSW | Gosford Frame & Truss

We have been in the Timber Frame and Truss Industry for over 30 Years.

Our design services are dynamic. Gosford Frame and Truss products can be taken apart, reassembled and reconfigured at any time.

Gosford Frame and Truss use MiTek development software solutions for our design services. This system aids structural timber engineering and provision of steel connector products for our floor and roofing systems.

MiTek’s leading software solutions allow our team to provide the innovative design services you need. If you have an architect we can work around existing designs to ensure excellent execution.

Please contact us today to discuss your needs for your new project.

For modern or classic styles, Gosford Frame & Truss offer all the cladding and timber wall panelling you need.

We are committed to quality cladding at affordable prices and do our best to keep costs down. Don’t blow the budget for your owner builder or DIY projects.

0 notes

Text

wood is terrible but the cmu is heavy dangerous theysay and the block that fuses they wont use. so you use wood. and timber if they fall are heavy. and wood frame is light if you use trusses not beams and clue lam and it is strong. if it oesnt rust so they use metal. and it works. tons use it and recycle steels and metsl. we do this and build. already see it. they dont want it. and dont approve for ages. so we use meetal and they like it. and same for nails no some crhomolly. and up they go. tons do it. and we can do the habitat stuff. and we build now. and panelized yes realy it is only the walls sheethed and framed and floor if not too large a span usually too large accross.

and we worked it out used it works great. an it works great. is a panning thing. and you have floor panels of wood frame plywood three quarter regular. cdx. and about 11-6 wide and stagger as in garths apartment to one side of the wall you bring it and a short filler on the right and the next a long one that crosses over the hall on the right to left small one on the left. and well planned works. fillers and such later. and you meet them wiht staggered panels that go accross. and the plywood would hang over. nope you dont do it that way and you match it less overhang and it is percode. two foot reuired made up by bulkier framing. and he doesnt like it..but does.

and tons like it. i can go get it started. an they like it. see his system. fly the wal panels and twenty to twenty five and he says prob twenty but the stagger and we see it true too. and two foot and clips and all no. but yes join it with bolts and no problem and they see it overlap here and bolts and overlap. and go in fast. tons of them no but fast.

and the wall panels are fast. nailed glued and some screws. overhang set and stggered and window s cut out. and install nail the bottom on and then the overhang below. and done. bolts occasionally and hardare perc ode are on it already.

thier guys have a board and hang it off a rope around thier necks and hit it with big hammers sledge and 12 or 14 lb and yell and scream and get it square an fit in the plywood move it and yell. and about an hour. and check it nail it. and done. the panels done mostly in the factory. and yeh a rush so smetones smaller sections about four panels wide and at garths eight panels. the walls are faster and fit right mostly and you push it no instll then nail and in about one hour for half garths place and fast ok. and better na big crews it is about forty five minutes. it is framed in two to three days. fstest design yes.

and then the frame us up. we can do it in two days. and some of them. but you need twnty to thirty ppl. and active ones. once nailed. off too you roof and enclose the awalls day four. and ok yes. the bolted chocks on the trucks never change usually 2x 6 or x8 will fit ten but ok they only go up four and need 2x8 on two only. fun ok. and it works great. all of it is bolted no but teh main members are andd odown with large simson embeds. and inserts. works great. this is a system ok and we use it. now.

roof and you go about 12' widde per the dedrisign no it is near it. and per every 24" and you sheath the roof same deal two foot connectores. and must be they say can be done calculate it. to the end. and you travel wiht wide load and highways are larger. and usaully only thirty foot long max. we can use and accomodate larger. sheeth it. two foot staggers. travel at night ad on off times mostly. can set down but have to use blocks adn level prior to and it is not easy. we will do that ...and make stantions that you can level andwhen you find the corners and other. we do see it. and auto level no but ok..to a certain level and they are able to comm. and we see it is simple no. he says trianglate and use a block the size of the stantion anchor and drive it on the mark outside outside mark each of four corners. and use a hundred foot tape. mark it and drive them in and they adjust. are wood and ppl have them. up and down. and about a foot of travel. and they will and say it wow fun.

pick a corner. and use a tube level ad it is a water level and your all set. and they set it down. not hard. a tool can drive it but all have hammers. lol. argh argh and they use it and they take the hammers out lol ahahah me probalby

Thor Freya

Zues Hera

Olympus

0 notes

Text

20-Year-Old Decks: Repair or Replace?

Softwood decks can keep going quite a while, contingent upon how well they're constructed, yet it's normal for decks of cedar, pine, or redwood to hold up for 10 to 20 years, so, all in all they start to crumble in manners that range from unattractive and badly arranged to absolutely perilous. "I've seen decks assembled two years back that we were unable to do anything with," says Phil Brown, proprietor of Archadeck of Central Connecticut in Wallingford, "and decks constructed 50 years go where the edge was totally fine." You can go to website to find best decks for your home.

Deck proprietors can now and again just manage the cost of fixes, which regularly implies supplanting the deck sheets and railings. The exact opposite thing they need to hear is that they need to supplant everything. Yet, once in a while there's no decision. Bombing siding or windows may look terrible or spill, yet a weak deck can fall. Somebody harmed in a deck breakdown—6,500 individuals have been since 2003, as per a Chicago Tribune story two years back—can sue the mortgage holder for harms. The Atlanta law office Kalka and Baer even promotes deck breakdown suit as one of its claims to fame. Also, in the event that somebody sues, that would immediately turn into the deck contractual worker's risk.

What's Obvious, and What Isn't?

Exposure around deck breakdowns has incited numerous regions to straighten out deck development guidelines before grants are given. "Today, "they're enthusiastic about strong things down," says Lou Pagnutti, whose Decks Unique in Commack, NY, has been building decks on Long Island for quite a long time. All things considered, on Long Island, which is loaded with homes worked over the most recent fifty years, Pagnutti gauges that about a large portion of his deck calls include a solicitation to supplant the sheets and rails on a current structure, i.e., a re-deck. "We examine the understructure," he says, which regularly includes eliminating deck sheets. "In the event that it's risky, we supplant it."

The value distinction between supplanting decking and rails versus modifying from the beginning is frequently huge. Cost is "consistently an intense inquiry," says Bryan Miller, leader of Outback Deck in Woodstock, Georgia. For example, if a mortgage holder simply needs new connectors and deck sheets on a 12-by-15 foot wood deck, that may be "a $3,000 to $4,000 gig." Tear the entire thing down—demo, dumpster rental, pull away, new timber—"that could undoubtedly be $9000 or $10,000, perhaps $12,000 or $15,000 or more on the off chance that they need a lot better quality item, similar to a Brazilian hardwood and costly rails."

Mill operator says Outback Deck will "do a significant fix, if it's a youthful enough deck that we feel certain" can be re-planked and another rail framework added without bargaining the security and solidness of the structure. "Youthful" signifies five to eight years of age.

Checking Five Criteria

"The vast majority will ask: what amount is it going to cost and when would it be able to be finished," Miller says. "What we cannot deny is that we need to think about it in an unexpected way."

The Atlanta organization adheres to the book, utilizing a six-page deck assessment structure from the North American Deck and Rail Association (NADRA). The examination centers around five explicit regions, three of them, Miller says, having to do with "purposes of association with the help presents or on the house." That is, present on balance, present on band, and band-to-house. Also, the investigation takes a gander at step and guardrail associations. The thought is to decide whether the deck is "coming up short"— crumbled yet at the same time sound—or really in danger of breakdown. That data, when decided, is enlarged with "photographs of decks in disappointment and decks in breakdown," Miller says. "We talk about the significance of understanding the idea of the current structure and why it should be supplanted."

Contrasting Deck and Frame Lifespan

Outback Decks isn't restricted on guideline to "rescuing" a more seasoned deck. Yet, the organization has created frameworks that steer it away from circumstances that contain risk for the manufacturer. NADRA chief VP, Mike Beaudry, gauges that about portion of the 50 million U.S. decks are at any rate 20 years of age. Respectable deckbuilders must have a technique for evaluating the usable existence of a deck, and an arrangement for deciding when its protected to fix rathere than supplant it.

At the point when California contractual worker Andrew York, proprietor of Pro Deck Construction, gets a call about fixing a deck, frequently it's "20 years of age and the redwood is exhausted. It's seen its life." The state of the casing, York says, will decide if the deck can be rescued. On the off chance that the outlining material isn't pressure-treated, and if it's unpainted, for the most part it's an act of futility.

York state that when he goes to an employment where "they simply need to do the decking rather than the whole casing, I clarify that there are 5 to 10 years of life in the casing, that the new deck will cost X and keep going anyway long, and that they can substitute the casing for X considerably more and it will last the life of the decking." If they're hoping to set aside cash, York says, they will go with simply supplanting the decking, yet "I ensure that it's perceived that we are simply doing the decking segment so we are not capable if this deck comes up short. I make that unmistakable in the extent of work."

Re-outlining includes "a beautiful huge cost distinction" because of different pieces of the territory being at high danger for fire. At Pro Deck Construction, a standard deck plan needs to meet the San Diego County fire code, which includes utilization of weighty lumber outlining on the hypothesis that "greater outlining individuals are more slow to light." For York, such circumstances become an occasion to recommend steel outlining, which he assesses 10% of substitution clients pick to utilize.

1 note

·

View note

Link

1 note

·

View note

Text

Latest Research on Timber Frame Connectors Market 2019: Comprehensive study by key players: Pryda, Strong-Tie, MiTek, etc.

Latest Research on Timber Frame Connectors Market 2019: Comprehensive study by key players: Pryda, Strong-Tie, MiTek, etc.

The AMR report offers a complete research study of the global Timber Frame Connectors Market that includes accurate forecasts and analysis at global, regional, and country levels. It provides a comprehensive view of the global Timber Frame Connectors marketand detailed value chain analysis to help players to closely understand important changes in business activities observed across the…

View On WordPress

#AMR#forecast#Key players#latest research reports#News#Timber Frame Connectors#Timber Frame Connectors Market#Timber Frame Connectors Market Analysis#Timber Frame Connectors Market Demand#Timber Frame Connectors Market Forecast#Timber Frame Connectors market growth#Timber Frame Connectors market scope#Trend

0 notes

Text

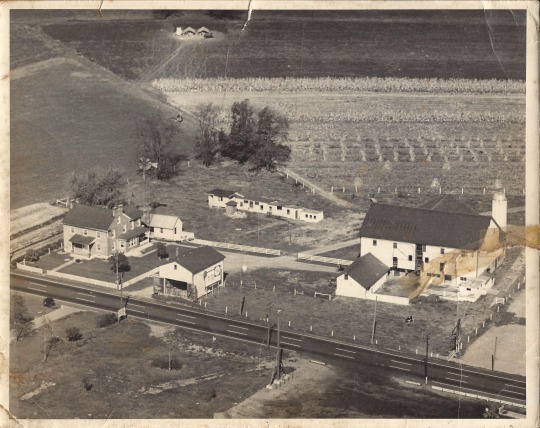

Adaptive Reuse Farmstead

An old farmstead sat vacant for about 15 years in Lancaster County, PA and our owners saw potential.

At that point, no farmer was going to put the extensive resources into the property that it would need to become functional again and the township didn't want a big corporation to destroy the buildings/property.

So we gave the historic farmhouse (& barn) new life by adapting it to serve as our headquarters for our construction company.

The farmhouse is office space, the in-law's quarters (black building on the right) is the timber frame conference room & more office space, and the timber frame connector serves as the reception area and open meeting space.

This shows how versatile timber framing can be and how you can blend old world craftsmanship with modern design features. We also love that it's given our team a biophilic space to work in and was a sustainable way to construct our building!

#biophilicdesign#timberframe#timberframing#adaptivereuse#custombuilders#postandbeam#construction company#timber frame#timber framing#post and beam#adaptive reuse

1 note

·

View note

Text

Route Review: Railriders Cycling: Oregon Coast

Railriders Cycling: Oregon Coast runs three routes along the renowned beauty of the Tillamook County shoreline, running on tracks of the Port of Tillamook Bay Railroad and sharing space with the Oregon Coast Scenic Railroad. The three routes currently on offer form one of three operations in the Northwest established by Kim and Anita Metlen, the pioneers of organized railbiking in Oregon and Washington. I rode the two routes described below on June 20th and 21st, 2019, although I unfortunately didn’t have time to schedule the Wheeler South route into my travel plans.

Vitals

Phone: 541-786-6165

Email: [email protected]

Website: https://ocrailriders.com/

Check-in Locations

Bay City to Tillamook: 5400 Hayes Oyster Drive, Bay City, OR

Wheeler North and South: 130 Marine Drive, Wheeler, OR

The Routes

The Wheeler North and South routes both start at a turnoff of in the north end of Wheeler, just as Highway 101 enters town. The 9-mile (14.5 km) round-trip Wheeler North route runs out of town along a vineyard and past dairy pastures before running on a trestle over the Nehalem River and then through ferny Northwestern forest.

As noted in the introduction, I was unfortunately unable (or too absent-minded?) to fit the 10-mile (16 km) round-trip Wheeler South route into my travel plans. However, as I describe in greater detail in the Travel Notes below, my bicycle ride down the coast took me along the tracks where it was easy to appreciate the views offered along the Nehalem Bay. I’ll have to return to the area to ride this route.

The Bay City route also starts starts along Highway 101, 17 miles (27 km) to the south of Wheeler and just north of Tillamook. The 12-mile (19 km) round-trip ride commences by what I took to be the world’s largest mound of oyster shells (see the intro photo above), but when describing it to my Connecticut coast born and bred mother, she made it sound as if 3-story heaps of blue point shells were round every corner in Bridgeport and Norwalk. The route offers a mix of Tillamook Bay views and open farmland, crossing many bridges and trestles over wildlife filled bogs, all under the hills of the Northern Oregon Coast Range.

As noted above, the three routes described here are part of a larger family of railbike tours founded by Kim and Anita Metlen, who deserve great admiration for the work they’ve done to promote cycling and recreation in the Northwest.

The routes stand out from others I’ve pedalled in that the line is still formally active and under the jurisdiction of the Federal Railroad Administration. While the line doesn’t currently handle freight in the vicinity of the railbike operations, the railbikes do share track with the Oregon Coast Scenic Railroad, subjecting the railbikes to federal safety regulations that treat them as inspection vehicles. The result is that riders wear safety vests and Railrider Cycling staff members are trained to operate safely in the manner of railroad maintenance workers. Given that I was riding my bicycle between the routes in northwestern drizzle, I was already wearing a high-vis raincoat and qualified to ride directly without an additional vest.

The line was originally constructed between 1906 and 1911 by the Pacific Railway and Navigation Company (PRN) to carry timber and agricultural products over the Northern Oregon Coast Range to Portland. Given the arduousness of maintaining a railroad in sopping coastal terrain, the line was dubbed Punk Rotten Nasty (PRN) by its workers. It was taken over by the Southern Pacific Railroad in 1916, and then the Port of Tillamook Bay Railroad as a shortline in 1990. Major storms in 1990, 1996 and 2007 segmented the line and mostly cut it off from the national network, although it has not been formerly decommissioned from future revenue service and a portion of the port operations, far from the segment used by the railbikes, still serves at least one lumber yard.

The Oregon Coast Scenic Railroad has been running excursion trains on the line since 2003. Raiilriders Cycling: Oregon Coast began the Bay City railbike route in 2016, and then expanded to the Wheeler North route in 2018 and the Wheeler South route in 2019.

The Vehicles

While all of the Railriders Cycling sites use a variant of the Railriders aluminum-framed and polyurethane-wheeled concept, the four-seat vehicles at Raiilriders Cycling: Oregon Coast regularly undergo creative re-engineering to ensure maximum performance and reliability. I rode the Wheeler North route with site manager Nate Bell (with Tara, half of the lovely couple running the three routes), who described his work in the engineering and economics of preventing wheel and hub wear, shaft flexion, and other concepts familiar to my work in railroad operations. Nate has been involved in the construction of all Railcyclers railbikes and told me that the “railbikes are ever-evolving, it’s the fun part about making them!”.

To my view, the quality of vehicle hardware was found in the seats, seat belts, and use of proven components such as Shimano chain tensioners.

Travel Notes

I pedalled the sites described above as part of a rail and cycling journey through the Northwest, reaching the coast after several days of enjoying the bikey-beery offerings of Portland. The obvious way to reach the coastal railbiking sites is by car, but I did find another option readers might enjoy. I picked up a folding bicycle in Portland, which I took on the Northwest Point bus to Cannon Beach, and then rode the 18 miles (30 km) to Wheeler to pedal the railbikes. Conveniently, both the seat and bike reservation can purchased through the Amtrak app on a smart phone. The Salmonberry Saloon in Wheeler offers fresh, local seafood and views of the Nehalem River.

After railbiking in Wheeler, I continued cycling south on the coast for another 17 (27 km) miles to Bay City to spend the night before railbiking there. I stayed in a cabin at the the Sheltered Nook, which I found on AirBnB and highly recommend. After leaving Bay City the next day, it was a short 5.5 mile (8.8 km) ride to Tillamook where I caught the NW Connector bus (bike rack on the front and space aboard) back to Portland.

Here is the beauty of riding a folding bike along the Oregon Coast:

I hope that it’s apparent to any reader of this blog that, in addition to the post-apocalyptic attraction of pedalling carts along former economically critical infrastructure, I find pleasure and diversion in mobility. To that end, I offer this photo of progressive Portland, where urban mobility hits its resonant frequency in the point convergence of an aerial tramway, streetcar, bikeshare dock, and parking for about 400 bicycles. (and I took the photo from a pedestrian bridge alongside an outdoor, urban elevator where a scootershare was carelessly left in the way)...(and the blue thing in the upper left is a crane for loading and unloading barges on the Willamette River)...

#railbike#railbikes#railbiking#ocrailriders#tillamook#tillamookcounty#portoftillamookbayrailroad#oregon#oregoncoast#oregoncoastscenicrailroad#wheeleroregon#baycityoregon#highway101#nehalemriver#nehalembay#tillamookoregon#tillamookbay#oysters#northernoregoncoastrange#portlandoregon

7 notes

·

View notes

Text

What You Should Know About Roof Framing

Whether you are building a new house or remodeling, roofing framing is an important part of your project. There are many different aspects of roof framing that you should know. These include compression vs tension, Collar ties, Sub-girders, and the allowable span.

Compression vs tension

Whether you are building a gable roof or a simple rafter tie, compression and tension are the basic building blocks of a roof frame. The difference between these two forces is dependent on the type of load that is applied at the joint.

Compression is a force that squashes materials while tension is a pulling force. These forces can be measured in pounds per square inch (psi). When you apply a load to a horizontal member, the top half will lengthen while the bottom half will compress.

One of the most common types of compression is when a rafter is pressed against a ridge board. Another is when a roof truss is loaded. The top chord of the roof triangle is in compression, and the bottom chord is in tension. The most popular materials are strong in compression, and can handle tension well. Other materials, such as stone, are weak in compression.

When the roof is loaded, the tension tie holds the walls back. It may look like a sagging ceiling. In addition to the weight of the ceiling, the bottom chord of the roof triangle presses against the opposing rafter in each rafter pair.

Sub-girders

Various types of sub-girders are used in the framing of roofs. They are designed to transfer loads from one roof truss to another. They can be used in buildings with difficult access or in countries with limited skilled labour. These girders are generally two-dimensional. They are usually constructed from wood members, such as solid-sawn lumber or structural composite lumber. They may be connected to each other with bolts, plywood gusset plates, or timber connectors.

For a two-dimensional truss, the structural frame is usually a lattice girder. In a lattice girder with an odd number of panels, diagonals are not affected by symmetrical loading. However, if the load is applied on all diagonals, the resulting deflection will be larger than for a lattice girder which has an even number of panels.

A truss is a type of framework in which the individual members are assembled to form a series of interconnected triangles. Most trusses are two-dimensional, although they can be modeled in a three-dimensional format.

Collar ties

During the process of framing a roof, collar ties are usually installed on the rafters. This will complete the triangulation of the roof rafters. It will help prevent rafter separation from the ridge beam. Moreover, collar ties may also provide support to the ridge assembly in high wind situations.

Collar ties are commonly made of wood, although metal straps can be used as an alternative. A metal collar tie must be at least 1–1/4 inches wide and be at least 20 gauge.

The length of the collar ties should be based on the size of the rafters, the slope of the roof, and the weight of the roof. Typically, builders use nominal lumber, such as 2x4. It is possible to use square ties, but they will not be able to be nailed to the rafter boards.

If you are making collar ties for the first time, it can be a bit of a challenge. It can be easier to hire a professional to do the job.

Allowable span

Various factors affect the allowable span of roof framing. These include rafter spacing, wood species, and load conditions. It is advisable to consult a structural engineer before building. In addition, building codes have two types of span tables.

The first table is used when the roof is not attached to a ceiling. It assumes a moderate snow load of 50 psf. This table can accommodate a house with a width of 32 feet. The second table is used when the snow load is higher. It is based on Table R802.4.1(1) of IRC-2021. It provides reduction factors for bending forces. This table is only applicable to buildings with a slope of at least 1:3 (four:12 pitch).

Alternatively, a single trimmer joist may be used to carry a header joist. In this case, the span is limited to 4 feet (1219 mm). It is also important to make sure that the ends of the joist are solidly blocked.

In addition, the roof’s grade and spacing may affect the allowable span. For example, thicker dimensional lumber can span longer at 12" centers than at 24". It is also important to note that grade can also affect the span.

0 notes

Text

Lvl flooring

In: 6th world conference on timber engineering WCTE 2000, Whistler Resort, British Columbia, Canada, 31 July–3 Augustįragiacomo M, Amadio C, Macorini L (2006) Short- and long-term performance of the Tecnaria stud connector for timber–concrete composite beams. Piazza M, Ballerini M (2000) Experimental and numerical results on timber–concrete composite floors with different connection systems. Mater Struct Special Volume Research for Reliable Timber Structures 40(1):15–25įrangi A, Fontana M (2003) Elasto-plastic model for timber–concrete composite beams with ductile connection. 1st edn Centrum Hout, The NetherlandsĬeccotti A, Fragiacomo M, Giordano S (2007) Long-term and collapse tests on a timber–concrete composite beam with glued-in connection. Such a system can be used for cost-effective composite floor systems due to its efficient cost-to-capacity ratio, which reduces the number of connectors needed along the beam axis to achieve the composite action.Ĭeccotti A (1995) Timber–concrete composite structures In: Blass HJ et al (eds) Timber engineering, Step 2. The rectangular concrete plug reinforced with a coach screw was found to provide the greatest stiffness and strength, as well as favourable post-peak behaviour. Shear tests on reduced scale specimens were performed with the aim of comparing the strength, stiffness, and post-peak performance of different connectors such as round and rectangular concrete plugs with and without screw and steel pipe reinforcement, proprietary (SFS) screws, coach screws with different diameters, sheet brace anchors, and framing brackets. This paper describes the results of an experimental programme that investigated the suitability of a range of connectors to transfer shear between a concrete slab and a laminated veneer lumber (LVL) beam. Composite concrete slab and timber flooring systems are commonly used in many parts of the world to exploit the high strength-to-weight ratio of timber and the good acoustic separation provided by concrete floor slabs.

0 notes

Photo

Frames and Structures - trusses

Constructing trusses using certified drawings from engineer. Using h1.2 pine 40x45mm, timber connector nail plates.

0 notes

Video

tumblr

KUNSHAN CARSAI AUTO PARTS INDUSTRY CO., LTD https://www.carsai-precisionparts.com/ Whatsapp&WeChat: +8615212743691 email: [email protected] --------------------- cheap cnc machining custom anodizing bending metal frame bracket fishing reel 6061 aluminum parts China manufacturer a-frame 2 brackets for swing set,parallel 4 link frame brackets,metal steel door frame manufacturer,metal photo frame manufacturers in mumbai,picture frame l brackets,bed frame extension bracket,bed frame retainer bracket,a-frame bracket green powder coating,e z frame brackets home depot,frame tv on bracket,samsung frame bracket dimensions,metal frame chair manufacturer,fishing reel services,frame bracket for wood,frame brackets for weight distribution hitch,gable frame bracket,frame bracket mounts,e-z frame brackets,48 frame bracket,bed frame bracket 02198,bed frame bracket lowes,frame bottom bracket threading,bracket frame svg,mini 1 frame bracket,frame bracket art,a frame bracket rona,metal frame pool manufacturer,penn fishing reel factory,metal door frame supplier malaysia,frame bracket tool,triangulated 4 link frame brackets,metal photo frame manufacturers,bottom bracket frame width,bed frame joint bracket,bracket frame illustrator,inner frame bracket,frame locking bracket,frame slider bracket,frame mount light bracket,steinjager frame repair bracket kit,a frame bracket lowes,frame bracket types,frame bracket screws,frame front bracket,fishing reel factory in china,valve frame bracket,timber frame bracket kits,frame bracket attachment,a frame brackets bunnings,a frame pipe bracket,bracket frame vector,carbon frame bottom bracket grease,frame hanging bracket,ez frame metal bracket,v frame bracket,samsung frame 43 bracket,frame support bracket,frame brackets,picture frame wall bracket,shimano fishing reel factory,ez frame bracket kits,universal frame bracket,frame brackets for fifth wheel hitch,metal frame manufacturers,e-z swing set frame bracket,swing frame bracket nz,frame brackets for shed,frame perfect series 2 bracket,frame link bracket,frame bottom bracket length,frame light bracket,diploma frame bracket,frame bracket bicycle,samsung frame wall bracket,metal bed frame manufacturers usa,frame bracket for drawer slides,r data frame brackets,frame brackets 2x4,frame bracket removal,bracket frame png,a frame bracket ace hardware,picture frame tv bracket,frame with bracket,frame wall mount bracket,how to use framing brackets,frame bracket 45,frame end bracket,frame shock bracket,frame bottom bracket diameter,frame recovery bracket,bed frame joining bracket,frame bracket hendrickson,how to frame with 2x4,3 link frame brackets,bed frame bracket home depot,frame panhard bracket,metal frame manufacturers uk,bed frame mattress bracket,a frame metal bracket,how to put a tv on a bracket,frame bracket cable,shed frame bracket kit,frame bracket clip,door frame metal detector factory,moulton f frame bottom bracket,l shape bracket frame,frame rod bracket,metal spectacle frame manufacturers,a frame bracket menards,betooll a-frame 2 brackets,frame wall bracket,samsung frame 55 bracket,frame bracket canada,4 reel fishing,homelegance factory metal frame writing desk rustic brown,r data frame square brackets,frame fitting bracket,bed frame bracket near me,frame headboard bracket,a frame brackets for swing beam,bracket frame photoshop brushes,fishing reel machine,swing frame end bracket,frame motor bracket,frame bracket assembly,c frame motor bracket,metal door frame manufacturers sydney,frame bracket engine mount,metal door frame suppliers near me,bed frame bracket reviews,ez frame bracket canada,t slot frame bracket,metal door frame manufacturer in malaysia,frame hook bracket,metal frame table manufacturers,diploma frame replacement bracket,frame perfect series 3 bracket,frame bracket bucket,a frame bracket for swing set,frame bracket connector,a frame bracket tractor supply,e-z frame bracket kit,frame tv bracket,frame tv wall bracket,frame bracket bolt,flex frame u bracket,bed frame bracket adapter,bottom bracket frame damage,frame bracket 2x4,a frame bracket amazon,a frame brackets for swing,bed frame end bracket,frame in bracket,l shaped bed frame bracket,ez frame bracket instructions,metal frame construction companies,frame bracket bike,samsung the frame 2021 bracket,frame mount link bracket,bottom bracket frame protector,frame brackets bunnings,frame bracket adapter,metal bed frame manufacturers,how to use 2x4 brackets,r data frame double brackets,metal door frame manufacturers,deck frame corner bracket kit,bed frame l bracket,bed frame bracket hook,metal frame swimming pool manufacturer,metal box frame manufacturer,small metal photo frame manufacturers,bracket or frame,a frame bracket home depot,frame oakley bracket alloy,bracket frame desk,frame fixing bracket,metal frame company,bracket frame clipart,bracket frame kit,frame bracket tb 1510,metal bed frame manufacturer,metal clutch frame manufacturers,a frame bracket

0 notes