#Torque Sensors in Steering Systems

Explore tagged Tumblr posts

Text

#Automotive Steering System Market#Power Steering Technology#Electric Power Steering (EPS)#Hydraulic Power Steering (HPS)#Steering Column Innovations#ADAS & Steering Systems#Autonomous Vehicle Steering Solutions#Steer-by-Wire Technology#Automotive Steering Components#EPS vs HPS Steering#Next-Gen Steering Systems#Advanced Steering Wheel Sensors#Automotive Steering Market Trends#Vehicle Safety & Steering Control#Steering System Suppliers & OEMs#Self-Driving Car Steering Mechanisms#Steering Angle Sensors in Vehicles#Torque Sensors in Steering Systems#Automotive Chassis & Steering Integration#EV Steering Systems & Innovations

0 notes

Text

1st gen Subaru Alcyone. Sold as a Vortex in Australia but we never got these FLAT-6 versions, only flat-4 in NA and turbo with choice of FF or AWD

Hyper technology for greater driver loyalty. Intelligent Express.

Alcyone 2.7ℓ FLAT-6

ALCYONE 2700/1800

The Alcyone is a car with a new concept that anticipates the motorization of the near future. Everything about it has been developed to ensure that the driver feels no burden or stress under any driving conditions and always performs at 100% of its potential. It features a number of electronically controlled mechanisms that realize the ultimate in speed through advanced automatic control, including the next-generation 4WD, Active Torque Split 4WD, and the high-performance 2.7-liter FLAT-6. These intelligent mechanisms dramatically improve the vehicle's dynamic performance and create an unprecedented feeling of high-speed movement.

PHOTO: 4WD 2.7L VX Black Mica

Next-generation intelligent mechanisms create a new driving experience.

FLAT-6

2.7ℓ FLAT-6 Engine with EGI System

EGI Horizontally opposed 6-cylinder 2.7-liter engine

Subaru's traditional horizontally opposed engine has been made into a 6-cylinder engine, the FLAT-6, with a large displacement of 2.7 liters. The ideal rotation and vibration characteristics of the horizontally opposed 6-cylinder engine create a smooth rotation feeling. The flat and powerful torque is only possible with a large displacement. And the excellent basic performance has been carefully tuned with the latest electronic control technology to achieve refined speed. The unparalleled individuality invites you to the pleasure that only the Alcyone can provide. (VX)

EGI turbocharged flat-four 1.8-liter engine

The unrivaled horizontally opposed engine is equipped with a high-performance turbo. In addition to smooth and powerful acceleration from low speeds, the response has been greatly improved by the advancement of the EGI system and tuning of the intake system. (VR, VS)

Electronically controlled active torque split 4WD

"Active Torque Split 4WD" maximizes the potential of 4WD. This drive force control system uses a computer to accurately determine the driving situation and road surface conditions, precisely controlling the torque distribution between the front and rear wheels. Always achieving ideal high-speed, easy driving. (VX, VR•AT)

All-range electronically controlled 4-speed automatic E-4AT

Smooth and soft shifting feeling, sharp response, and automatic control of power/economy shifting modes, highly accurate lock-up control, engine brake control, etc. are some of the latest technologies that have been incorporated into the shifting mechanism of this highly functional transmission (VX, VR-AT, VS-AT).

For more reliable operation of automatic transmission vehicles

●Key interlock

•shift lock

•reverse alarm

●AT select indicator is adopted

Electronically controlled air suspension system EP-S

Precise vehicle posture control and vehicle height adjustment. The optimal spring rate setting that makes the most of the characteristics of the air spring and the synergistic effect of the variable damper provide exquisite high-speed stability and a smooth ride.

ABS (4-wheel anti-lock braking system)

The sensor detects wheel lock in advance, which can easily occur when driving at high speeds or when braking suddenly on slippery surfaces.

The ABS detects the vehicle's position and electronically controls the brake pressure, providing excellent danger avoidance capabilities. The 4-sensor diagonal select low system provides excellent control even on roads with different friction coefficients for the left and right wheels.

Electronically controlled motor drive power steering

The latest power steering system uses an electronically controlled motor-driven pump for hydraulic control.

The system determines driving patterns based on vehicle speed and frequency of steering operation. In addition to speed-sensitive control, it also provides optimal steering feel even at a constant speed. (VX)

Cd=0.29*. High performance aerodynamic form

The first Japanese car to break the Coefficient of Air Resistance Co = 0.30 barrier

Breakthrough. Improved maneuverability at high speeds (CD=0.29) and quietness.

PHOTO: 4WD 1.8L VR Medium Gray Metallic/Fine Silver Metallic

10 notes

·

View notes

Text

Maruti Ertiga ZXi Plus AT 2022-2023 Price, Specs & Features

The Maruti Suzuki Ertiga has carved a solid reputation in the Indian automobile market as a practical, feature-rich, and family-friendly MPV. With the 2023 Ertiga ZXI variant, Maruti continues to strengthen this legacy by offering a blend of premium features, improved fuel efficiency, and stylish design elements at a competitive price. Positioned as one of the most balanced trims in the lineup, the 2023 Ertiga ZXI offers an excellent mix of comfort, convenience, and technology.

In this comprehensive guide, we will explore everything you need to know about the 2023 Maruti Suzuki Ertiga ZXI including its features, specifications, design, performance, comfort, safety, pricing, and whether it makes sense to buy it in 2025.

A Quick Overview of the Ertiga Lineup

The Ertiga is Maruti Suzuki’s answer to the ever-growing demand for spacious 7-seater MPVs in India. Known for its reliability and affordability, the Ertiga comes in several variants: LXi, VXi, ZXi, and ZXi+. Among these, the ZXI trim stands out for its value-for-money proposition, offering premium features at a mid-range price point.

2023 Maruti Suzuki Ertiga ZXI Specifications

The 2023 Ertiga ZXI is powered by the 1.5L K15C Smart Hybrid petrol engine paired with either a 5-speed manual or a 6-speed automatic transmission. It delivers a smooth and refined driving experience suitable for both city and highway travel.

Key specifications include:

Engine: 1.5L K15C Smart Hybrid

Power Output: 103.06 PS @ 6000 rpm

Torque: 136.8 Nm @ 4400 rpm

Transmission: 5-speed Manual / 6-speed Automatic with Paddle Shifters

Fuel Type: Petrol / CNG (CNG available in lower trims only)

Fuel Efficiency: Approx. 20.51 km/l (Petrol, MT)

Seating Capacity: 7

Drive Type: Front-Wheel Drive

Exterior Design and Style

The 2023 Ertiga ZXI boasts a fresh and modern look while staying true to its MPV roots. The chrome-studded front grille, body-colored bumpers, and ORVMs with integrated turn indicators give it a premium appearance. The 15-inch dual-tone alloy wheels add an element of sportiness and are exclusive to the ZXI and higher variants.

Headlamps are halogen projector units which offer decent illumination, while the tail lamps feature a 3D LED design that enhances rear visibility and style. The overall stance of the Ertiga ZXI is muscular yet elegant, making it appealing to families and fleet buyers alike.

Interior and Cabin Experience

Step inside the Ertiga ZXI, and you are welcomed with a dual-tone interior theme that uses beige and brown tones to create a spacious and airy feel. The quality of materials has improved compared to older models, with faux wood inserts on the dashboard and door panels giving it an upmarket vibe.

The seats are well-cushioned with good under-thigh support. The second-row features a one-touch recline and slide function for easy access to the third row. The ZXI variant also offers an adjustable headrest for all three rows, enhancing comfort on long journeys.

Rear AC vents, power windows for all doors, a height-adjustable driver’s seat, and foldable third-row seats make the cabin functional and user-friendly.

Infotainment and Technology

One of the major highlights of the 2023 Maruti Ertiga ZXI is its feature-loaded infotainment system. The variant comes equipped with a 7-inch SmartPlay Studio touchscreen infotainment unit that supports Android Auto and Apple CarPlay.

Key features include:

7-inch SmartPlay Studio with USB, AUX, Bluetooth

Steering-mounted audio and phone controls

Four-speaker sound system

Electrically adjustable and foldable ORVMs

Keyless entry with push-button start

Multi-information display with fuel efficiency statistics

Rear parking sensors and reverse parking camera support (camera available in ZXI+)

Though it misses out on connected car tech and built-in navigation, the system remains intuitive and responsive for daily use.

Comfort and Space

Comfort has always been one of Ertiga’s strongest points, and the ZXI variant continues this legacy. With ample legroom and headroom across all three rows, the MPV provides a relaxed ride for both short city trips and long outstation drives.

Second-row passengers benefit from adjustable seats and dedicated AC vents, while the third-row is usable for adults on shorter trips or kids for long journeys. Boot space is adequate when third-row seats are folded down.

The air conditioning is powerful and ensures uniform cooling throughout the cabin, even in peak summer. NVH levels are well-controlled for a petrol MPV in this segment.

Performance and Drive Quality

Under the hood, the 1.5L K15C engine paired with Smart Hybrid technology ensures smooth performance and respectable fuel economy. The mild-hybrid system provides torque assist and auto start-stop, making it both peppy and efficient.

The 5-speed manual gearbox is smooth with light clutch operation, ideal for urban traffic. The 6-speed automatic (optional in ZXI+) comes with paddle shifters and is refined, making highway cruising effortless.

Suspension is tuned for comfort, easily absorbing potholes and uneven roads. The steering is light for city use but weighs up decently on the highway. Braking performance is satisfactory with front disc and rear drum setup.

Safety Features

Maruti has stepped up its safety game in recent years, and the Ertiga ZXI reflects that effort. The MPV is built on the HEARTECT platform, designed to improve structural rigidity and crash protection.

Standard and offered safety features in ZXI include:

Dual front airbags

ABS with EBD

Electronic Stability Program (ESP)

Hill Hold Assist (with AT)

ISOFIX child seat anchors

Reverse parking sensors

Speed-sensing auto door lock

These features make the ZXI variant a safe choice for families. The car has not been tested by Global NCAP recently, but it adheres to India’s crash safety norms.

Fuel Efficiency and Mileage

Fuel efficiency is one of the most critical factors for Indian buyers. The 2023 Maruti Ertiga ZXI delivers a certified mileage of around 20.51 km/l (manual) and 20.30 km/l (automatic), thanks to the Smart Hybrid tech.

In real-world conditions, users can expect around 16–18 km/l in the city and 18–20 km/l on highways, depending on driving habits and traffic.

Maintenance and Service

Maruti Suzuki has one of the largest service networks in India, which translates to low maintenance costs and easy availability of parts. The Ertiga ZXI follows a regular service schedule with affordable charges.

Estimated service cost for 5 years ranges between Rs. 20,000 to Rs. 25,000, excluding wear-and-tear items. Maruti also offers extended warranty and service packages for peace of mind.

Pricing and Value for Money

As of 2023, the ex-showroom price of the Ertiga ZXI variant was approximately Rs. 10.5 lakhs for the manual version. On-road pricing varies by state and taxes but generally falls in the range of Rs. 12 to 13.5 lakhs.

Compared to the base and mid-level trims, the ZXI offers significantly better features and a more premium experience without stretching the budget too much. It sits just below the ZXI+ which adds a few cosmetic upgrades and additional tech.

For buyers looking for a practical 7-seater without breaking the bank, the ZXI stands out as the sweet spot.

Who Should Buy the 2023 Maruti Ertiga ZXI?

The 2023 Ertiga ZXI is ideal for:

Families needing a spacious, reliable, and fuel-efficient 7-seater

Buyers upgrading from a hatchback or sedan

Those looking for an occasional highway cruiser with good luggage space

People who want modern features without going for the top-end variant

Pros and Cons

Pros:

Excellent space and comfort

Fuel-efficient mild-hybrid engine

User-friendly infotainment system

Good build quality and ride comfort

Value-for-money features

Cons:

No turbocharged engine option

Third-row space best for kids or short journeys

Misses connected car tech

Basic alloy design and halogen headlamps

Final Verdict

The 2023 Maruti Suzuki Ertiga ZXI is a practical, reliable, and well-balanced 7-seater MPV that delivers on multiple fronts. It combines premium features, solid mileage, good driveability, and excellent after-sales support, all in a price range that remains accessible for most Indian buyers.

If you are in the market for a family-friendly vehicle that offers value without compromising on essentials, the Ertiga ZXI should be on your shortlist. It may not have the flashiness of more expensive MPVs, but it scores high on practicality, efficiency, and peace of mind.

FAQs on 2023 Maruti Suzuki Ertiga ZXI

Q1. What is the price of the 2023 Maruti Suzuki Ertiga ZXI? The ex-showroom price in 2023 was around Rs. 10.5 lakhs. On-road prices may vary depending on your city and additional charges.

Q2. Does the Ertiga ZXI come with an automatic transmission? Yes, the Ertiga ZXI is available with a 6-speed automatic transmission along with paddle shifters.

Q3. What is the mileage of the 2023 Ertiga ZXI? The ARAI-certified mileage is approximately 20.51 km/l for manual and 20.30 km/l for automatic. Real-world figures range between 16 to 20 km/l.

Q4. How many airbags are there in the Ertiga ZXI? The ZXI variant comes with dual front airbags as standard.

Q5. Is the Ertiga ZXI good for long drives? Yes, the Ertiga ZXI offers comfortable seating, ample boot space (with seats folded), and efficient performance, making it suitable for long drives.

Q6. Does the Ertiga ZXI have a sunroof? No, the Ertiga ZXI does not come with a sunroof. This feature is not available in any variant of the Ertiga.

Q7. What colors are available in the Ertiga ZXI variant? Color options may include Pearl Metallic Auburn Red, Metallic Magma Grey, Pearl Arctic White, and others, subject to availability.

Q8. Is CNG available in the ZXI variant? No, CNG is not available in the ZXI variant. CNG options are limited to lower trims like VXi.

Q9. How many people can the Ertiga ZXI seat comfortably? The Ertiga ZXI is a 7-seater MPV and can seat 7 adults, though the third row is best suited for children or shorter journeys.

Q10. What is the warranty offered on the Ertiga ZXI? Maruti offers a standard warranty of 2 years or 40,000 km, which can be extended up to 5 years or 1 lakh km.

0 notes

Text

Torque Sensor Market Size Powering Precision Measurement and Control Across Industries

The Torque Sensor Market Size is witnessing substantial expansion, driven by growing demand across automotive, industrial automation, and robotics sectors. As precision, safety, and efficiency become paramount, torque sensors are proving indispensable in applications where force and rotational performance must be closely monitored and controlled. According to Market Size Research Future, the global torque sensor Market Size is projected to reach USD 15.37 billion by 2032, growing at a CAGR of 7.50% during the forecast period (2024–2032).

Market Size Overview

Torque sensors, also known as torque transducers, measure the torque (rotational force) on a rotating system such as an engine, crankshaft, gearbox, or rotor. With their increasing adoption in electric vehicles (EVs), aerospace engineering, and automated manufacturing systems, these sensors are becoming critical components in modern engineering.

Industries are investing in real-time monitoring solutions, and torque sensors offer precise measurements that help prevent failures, improve performance, and ensure compliance with safety and quality standards. Moreover, the shift toward Industry 4.0 and smart manufacturing is opening new opportunities for sensor-based monitoring and automation.

Market Size Segmentation

To better understand the dynamics, the torque sensor Market Size is segmented based on type, technology, application, and region:

By Type:

Rotary Torque Sensors (widely used in automotive and industrial machinery)

Reaction Torque Sensors (ideal for static torque measurements)

By Technology:

Strain Gauge

Surface Acoustic Wave (SAW)

Optical

Magnetoelastic

MEMS

By Application:

Automotive

Aerospace

Industrial

Medical

Test & Measurement

Robotics

By Region:

North America

Europe

Asia-Pacific

Rest of the World

Key Market Size Trends

1. Rising Demand from Electric Vehicles (EVs):

Torque sensors are integral in monitoring motor output and optimizing energy consumption in EVs. Their role in battery efficiency and safety systems is increasing as EV adoption accelerates globally.

2. Integration with Industrial IoT (IIoT):

As factories embrace digital transformation, torque sensors are increasingly being linked with cloud and edge computing platforms for predictive maintenance and real-time performance analytics.

3. Miniaturization of Sensors:

Advancements in MEMS technology are driving the development of compact, lightweight, and high-performance torque sensors for wearable medical devices, portable tools, and small-scale robotics.

4. Robotics and Automation Boom:

Torque sensors are critical in collaborative robots (cobots) to enhance tactile sensing and force feedback. As automation spreads across small and mid-sized enterprises, the Market Size for embedded torque sensing is expanding rapidly.

Segment Insights

Rotary Torque Sensors Dominate

Rotary torque sensors hold the largest Market Size share due to their versatility in rotating machinery, including transmission testing, dynamometers, and electric motor applications. Their wide adoption in automotive R&D and factory automation is a major driver of growth.

Strain Gauge Technology Leads

Among all technologies, strain gauge-based sensors are most commonly used due to their accuracy and reliability. However, SAW and optical torque sensors are gaining momentum, especially in high-speed and wireless applications.

Automotive Sector Remains Key End-User

Torque sensors are vital for powertrain testing, steering systems, brake-by-wire, and transmission efficiency in automobiles. With EVs and autonomous driving technologies evolving, the demand for advanced torque sensing continues to rise.

End-User Insights

Automotive Industry:

From combustion engine diagnostics to EV motor efficiency, torque sensors are used in drivetrain testing, power steering systems, and hybrid motor control.

Aerospace:

In aircraft engine performance monitoring, torque sensors ensure safe and efficient operation of critical propulsion systems and flight components.

Medical:

Torque sensors are used in surgical robotics, prosthetics, and medical device testing, helping ensure precision and safety in sensitive applications.

Industrial Machinery:

Predictive maintenance and process optimization rely on torque data in motors, pumps, compressors, and robotic arms, boosting productivity and reducing downtime.

Key Players in the Market Size

Leading companies are investing in innovation, strategic partnerships, and expanding global footprints to remain competitive:

Honeywell International Inc.

ABB Ltd.

Crane Electronics Ltd.

Futek Advanced Sensor Technology Inc.

Interface Inc.

Kistler Group

TE Connectivity Ltd.

HBM (Hottinger Baldwin Messtechnik GmbH)

Datum Electronics Ltd.

Magtrol Inc.

These players focus on enhancing sensor precision, reducing size, and enabling wireless connectivity, which align with growing demand for real-time data in various industries.

Conclusion

The torque sensor Market Size is primed for strong growth, fueled by its pivotal role in optimizing industrial performance, advancing automotive innovation, and enabling precision in robotics and healthcare. As industries push toward greater automation, safety, and energy efficiency, torque sensing technology will remain at the forefront of this transformation.

Trending Report Highlights

Explore more insightful reports from emerging and adjacent Market Sizes:

Proximity Sensor Market Size

Wi-Fi Adapter Card Market Size

5G Processor Market Size

Kids Tablet Market Size

Laser Projector Market Size

Underwater Lighting Market Size

Static Random-Access Memory (SRAM) Market Size

Wafer Fabrication Market Size

Plasma Lighting Market Size

Fluorescent Lighting Market Size

Body Area Network Market Size

Gyroscope Market Size

0 notes

Text

Precision in Motion: The Role of Torque Sensors and Star EMBSYS’s Technological Edge

In today’s high-performance industrial and engineering environments, the ability to accurately measure torque—the force that causes rotation—is more important than ever. Whether in manufacturing, automotive testing, robotics, or aerospace, torque sensors play a crucial role in ensuring safety, efficiency, and performance. One company that stands out in the field of torque sensing and embedded technology integration is Star EMBSYS, a trusted name in smart sensor-based systems.

What is a Torque Sensor?

A torque sensor (or torque transducer) measures the rotational force applied to an object. This force can be dynamic (while rotating) or static (at rest). Depending on the application, torque sensors may be rotary or reaction types. The most common operating principle in modern torque sensors involves strain gauge technology, where a strain-sensitive element deforms under torque, changing its electrical resistance. This change is then converted into an electrical signal that corresponds to the applied torque.

Why Torque Measurement Matters

Torque measurement is essential for:

Product Testing: Ensuring motors, engines, and gearboxes perform under expected loads.

Preventive Maintenance: Detecting anomalies or overloads before they lead to failures.

Process Control: Maintaining consistent output in automated manufacturing systems.

Energy Efficiency: Optimizing power consumption in electric drives and machines.

Accurate torque data helps industries improve operational efficiency, meet safety standards, and enhance product reliability.

Applications of Torque Sensors

Torque sensors are integral to a wide range of industries:

Automotive: Engine testing, powertrain diagnostics, and steering systems.

Aerospace: Actuator and turbine torque monitoring.

Industrial Automation: Robotics, conveyor systems, and torque-limited assembly tools.

Medical Equipment: Surgical instruments and prosthetic testing.

Renewable Energy: Wind turbine shaft monitoring.

Star EMBSYS – Empowering Torque Sensing Solutions

Star EMBSYS brings a new level of intelligence to torque measurement systems by combining sensor technology with embedded electronics. The company specializes in developing custom embedded solutions that seamlessly integrate torque sensors with microcontrollers, digital displays, data acquisition modules, and IoT connectivity.

Their solutions cover:

Sensor Interface Design: Amplification, filtering, and signal conditioning for precise torque measurement.

Embedded Control Systems: Real-time processing using ARM Cortex, AVR, or PIC microcontrollers.

Wireless Monitoring: Integration with Bluetooth, Wi-Fi, or LoRa for remote diagnostics.

Custom Software & UI: Visual dashboards and PC/mobile apps for live monitoring and control.

Why Partner with Star EMBSYS?

Industry Experience: Proven track record in automotive, aerospace, and industrial automation.

Tailored Solutions: Every system is customized to fit the mechanical, electrical, and software needs of the client.

Advanced R&D: Continuous innovation in sensor technologies and embedded design.

Support & Scalability: From prototype to production, Star EMBSYS offers full lifecycle support.

Conclusion

Torque sensors are a cornerstone of modern mechanical measurement and control. They ensure that machines operate at peak performance, products are tested thoroughly, and safety is never compromised. With its deep expertise in embedded systems and sensor integration, Star EMBSYS is your ideal partner for implementing precise and reliable torque sensing solutions across any industry.

Visit:- https://www.starembsys.com/torque-sensor.html

#torque sensor#rotary torque sensor#servo#spring testing machine#torque wrench calibration machine#load cell

0 notes

Text

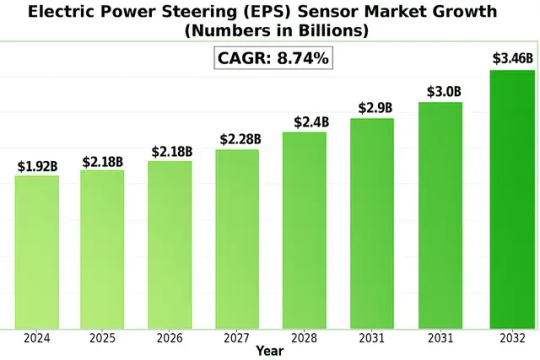

Electric Power Steering (EPS) Sensor Market - Trends, Growth, including COVID19 Impact, Forecast

Global Electric Power Steering (EPS) Sensor Market Research Report 2025(Status and Outlook)

The global Electric Power Steering (EPS) Sensor Market size was valued at US$ 1.92 billion in 2024 and is projected to reach US$ 3.46 billion by 2032, at a CAGR of 8.74% during the forecast period 2025-2032. The increasing adoption of fuel-efficient vehicles and stringent government regulations on vehicle emissions are key drivers propelling market growth.

EPS sensors are critical components in modern automotive steering systems that detect driver input torque and steering wheel position, enabling precise electric motor assistance. These sensors include Torque-Only Sensors (TOS) and Torque-Angle Sensors (TAS), which provide real-time data to control modules for optimized steering performance. The transition from hydraulic to electric power steering systems across passenger and commercial vehicles has significantly boosted sensor demand, with over 85% of new vehicles globally now equipped with EPS technology.

Market expansion is further supported by the automotive industry’s shift toward autonomous driving features, where EPS sensors play a vital role in advanced driver-assistance systems (ADAS). Leading manufacturers like Robert Bosch and Valeo are investing heavily in sensor miniaturization and reliability improvements to meet evolving OEM requirements. The Asia-Pacific region dominates the market, accounting for 48% of global EPS sensor demand in 2023, driven by rapid vehicle production in China, Japan, and India.

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://semiconductorinsight.com/download-sample-report/?product_id=95884

Segment Analysis:

By Type

Torque Angle Sensor (TAS) Segment Leads the Market Due to Better Accuracy and Reliability

The market is segmented based on type into:

Torque Only Sensor (TOS)

Torque Angle Sensor (TAS)

By Application

Passenger Vehicle Segment Dominates Due to Increasing Demand for Fuel-Efficient Steering Systems

The market is segmented based on application into:

Passenger Vehicle

Subtypes: Hatchbacks, Sedans, SUVs

Commercial Vehicle

Subtypes: Light Commercial Vehicles, Heavy Commercial Vehicles

By Vehicle Type

Electric Vehicles Segment Shows Rapid Growth Due to Government Incentives and Environmental Regulations

The market is segmented based on vehicle type into:

Internal Combustion Engine Vehicles

Hybrid Electric Vehicles

Battery Electric Vehicles

By Sales Channel

OEM Segment Holds Majority Share Due to Direct Integration in Vehicle Manufacturing Process

The market is segmented based on sales channel into:

Original Equipment Manufacturers (OEM)

Aftermarket

Regional Analysis: Global Electric Power Steering (EPS) Sensor Market

North America The North American EPS sensor market is characterized by high technological adoption and stringent regulatory standards prioritizing vehicle safety and efficiency. The U.S. leads the region due to strong demand from OEMs and stringent fuel economy regulations (e.g., Corporate Average Fuel Economy standards). Canada and Mexico are witnessing gradual growth, supported by regional manufacturing expansions. Key players like Robert Bosch and Methode Electronics dominate the market, supplying advanced torque sensors compatible with autonomous driving systems. The shift toward electrification and Advanced Driver Assistance Systems (ADAS) is accelerating demand, with EPS sensors playing a critical role in steering precision.

Europe Europe’s EPS sensor market is driven by strict emissions regulations (EU Euro 7 norms) and rapid electrification of vehicles. Germany remains the hub for innovation, hosting R&D centers of major automotive suppliers like HELLA and Valeo. The UK and France follow closely, with increasing investments in autonomous vehicle technologies. Eastern Europe is emerging as a cost-effective manufacturing base, attracting sensor suppliers. The dual focus on fuel efficiency and safety compliance positions EPS sensors as a key component, particularly in luxury and electric vehicles.

Asia-Pacific As the largest automotive production hub globally, the Asia-Pacific region dominates EPS sensor adoption. China accounts for over 40% of global demand, fueled by its booming EV market and government mandates favoring EPS systems. Japan and South Korea contribute significantly due to their technologically advanced automotive sectors. India is a high-growth market, with cost-sensitive consumers gradually transitioning from hydraulic to EPS systems. Local players compete aggressively on price, though international brands maintain a stronghold in premium segments. The region’s focus on affordability and localized production shapes sensor design and sourcing strategies.

South America The South American EPS sensor market faces challenges due to economic instability and fluctuating vehicle production volumes. Brazil is the largest market, though adoption rates lag behind global averages due to consumer preference for low-cost vehicles. Argentina and Colombia show potential, driven by urbanization and gradual automotive modernization. While foreign suppliers operate here, local manufacturing remains limited. The market’s growth hinges on economic recovery and reinvestment in the automotive sector.

Middle East & Africa This region presents a nascent but opportunistic market for EPS sensors. The UAE and Saudi Arabia lead in luxury vehicle sales, driving demand for advanced steering systems. Africa’s automotive industry is fragmented, with South Africa acting as a regional hub for assembly plants. Challenges include low vehicle electrification rates and aftermarket dominance of hydraulic systems. However, infrastructure developments and urbanization are expected to gradually boost EPS adoption.

List of Key Electric Power Steering (EPS) Sensor Companies Profiled

Robert Bosch GmbH (Germany)

HELLA GmbH & Co. KGaA (Germany)

LG Innotek (South Korea)

Valeo SA (France)

Methode Electronics, Inc. (U.S.)

Denso Corporation (Japan)

Continental AG (Germany)

TT Electronics plc (UK)

Infineon Technologies AG (Germany)

The global shift toward electric vehicles (EVs) is creating significant momentum for Electric Power Steering (EPS) sensors due to their critical role in energy efficiency and vehicle dynamics. Unlike traditional hydraulic systems, EPS systems reduce power consumption by up to 4% in combustion engines and are even more efficient in EVs where energy conservation is paramount. With EV sales projected to reach 30 million units annually by 2030, automakers are prioritizing lightweight and precise steering solutions that integrate advanced EPS sensors for optimal performance.

Global emission standards continue to tighten, with regions like Europe targeting a 55% reduction in vehicular CO2 emissions by 2030. EPS systems directly contribute to fuel savings by eliminating hydraulic fluid requirements and reducing engine load. Automakers complying with these regulations are increasingly adopting column-assist and dual-pinion EPS systems that rely on torque sensors for precise directional control. This regulatory push has resulted in EPS systems now being fitted in approximately 90% of new passenger vehicles worldwide, creating sustained demand for associated sensors.

Emerging magnetoelastic and optical sensing methods eliminate mechanical wear in EPS systems while improving measurement resolution below 0.1°. These technologies align with the automotive industry’s shift toward maintenance-free components, particularly in high-mileage commercial vehicles where traditional contact sensors show degradation after 200,000 operational cycles. Leading suppliers anticipate non-contact variants will capture 40% of the EPS sensor market within five years.

The evolution toward autonomous vehicles presents transformative potential for EPS sensor manufacturers. Level 3+ autonomy requires redundant sensor architectures with fail-operational capabilities, effectively doubling the sensor content per vehicle. Collaboration between steering system suppliers and autonomous tech developers has already resulted in prototype systems featuring triple-redundant torque sensing with cross-validation algorithms.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=95884

Key Questions Answered by the Electric Power Steering (EPS) Sensor Market Report:

What is the current market size of Global Electric Power Steering (EPS) Sensor Market?

Which key companies operate in Global Electric Power Steering (EPS) Sensor Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014

[+91 8087992013]

0 notes

Text

Global Electric Power Steering (EPS) Sensor Market 2025 - Detailed Analysis Of Current Industry Demand with Forecasted Growth

Global Electric Power Steering (EPS) Sensor Market size was valued at US$ 1.92 billion in 2024 and is projected to reach US$ 3.46 billion by 2032, at a CAGR of 8.74% during the forecast period 2025-2032. The increasing adoption of fuel-efficient vehicles and stringent government regulations on vehicle emissions are key drivers propelling market growth.

EPS sensors are critical components in modern automotive steering systems that detect driver input torque and steering wheel position, enabling precise electric motor assistance. These sensors include Torque-Only Sensors (TOS) and Torque-Angle Sensors (TAS), which provide real-time data to control modules for optimized steering performance. The transition from hydraulic to electric power steering systems across passenger and commercial vehicles has significantly boosted sensor demand, with over 85% of new vehicles globally now equipped with EPS technology.

Market expansion is further supported by the automotive industry’s shift toward autonomous driving features, where EPS sensors play a vital role in advanced driver-assistance systems (ADAS). Leading manufacturers like Robert Bosch and Valeo are investing heavily in sensor miniaturization and reliability improvements to meet evolving OEM requirements. The Asia-Pacific region dominates the market, accounting for 48% of global EPS sensor demand in 2023, driven by rapid vehicle production in China, Japan, and India.

Get Full Report with trend analysis, growth forecasts, and Future strategies : https://semiconductorinsight.com/report/global-electric-power-steering-eps-sensor-market/

Segment Analysis:

By Type

Torque Angle Sensor (TAS) Segment Leads the Market Due to Better Accuracy and Reliability

The market is segmented based on type into:

Torque Only Sensor (TOS)

Torque Angle Sensor (TAS)

By Application

Passenger Vehicle Segment Dominates Due to Increasing Demand for Fuel-Efficient Steering Systems

The market is segmented based on application into:

Passenger Vehicle

Subtypes: Hatchbacks, Sedans, SUVs

Commercial Vehicle

Subtypes: Light Commercial Vehicles, Heavy Commercial Vehicles

By Vehicle Type

Electric Vehicles Segment Shows Rapid Growth Due to Government Incentives and Environmental Regulations

The market is segmented based on vehicle type into:

Internal Combustion Engine Vehicles

Hybrid Electric Vehicles

Battery Electric Vehicles

By Sales Channel

OEM Segment Holds Majority Share Due to Direct Integration in Vehicle Manufacturing Process

The market is segmented based on sales channel into:

Original Equipment Manufacturers (OEM)

Aftermarket

Regional Analysis: Global Electric Power Steering (EPS) Sensor Market

North America The North American EPS sensor market is characterized by high technological adoption and stringent regulatory standards prioritizing vehicle safety and efficiency. The U.S. leads the region due to strong demand from OEMs and stringent fuel economy regulations (e.g., Corporate Average Fuel Economy standards). Canada and Mexico are witnessing gradual growth, supported by regional manufacturing expansions. Key players like Robert Bosch and Methode Electronics dominate the market, supplying advanced torque sensors compatible with autonomous driving systems. The shift toward electrification and Advanced Driver Assistance Systems (ADAS) is accelerating demand, with EPS sensors playing a critical role in steering precision.

Europe Europe’s EPS sensor market is driven by strict emissions regulations (EU Euro 7 norms) and rapid electrification of vehicles. Germany remains the hub for innovation, hosting R&D centers of major automotive suppliers like HELLA and Valeo. The UK and France follow closely, with increasing investments in autonomous vehicle technologies. Eastern Europe is emerging as a cost-effective manufacturing base, attracting sensor suppliers. The dual focus on fuel efficiency and safety compliance positions EPS sensors as a key component, particularly in luxury and electric vehicles.

Asia-Pacific As the largest automotive production hub globally, the Asia-Pacific region dominates EPS sensor adoption. China accounts for over 40% of global demand, fueled by its booming EV market and government mandates favoring EPS systems. Japan and South Korea contribute significantly due to their technologically advanced automotive sectors. India is a high-growth market, with cost-sensitive consumers gradually transitioning from hydraulic to EPS systems. Local players compete aggressively on price, though international brands maintain a stronghold in premium segments. The region’s focus on affordability and localized production shapes sensor design and sourcing strategies.

South America The South American EPS sensor market faces challenges due to economic instability and fluctuating vehicle production volumes. Brazil is the largest market, though adoption rates lag behind global averages due to consumer preference for low-cost vehicles. Argentina and Colombia show potential, driven by urbanization and gradual automotive modernization. While foreign suppliers operate here, local manufacturing remains limited. The market’s growth hinges on economic recovery and reinvestment in the automotive sector.

Middle East & Africa This region presents a nascent but opportunistic market for EPS sensors. The UAE and Saudi Arabia lead in luxury vehicle sales, driving demand for advanced steering systems. Africa’s automotive industry is fragmented, with South Africa acting as a regional hub for assembly plants. Challenges include low vehicle electrification rates and aftermarket dominance of hydraulic systems. However, infrastructure developments and urbanization are expected to gradually boost EPS adoption.

MARKET OPPORTUNITIES

Advancements in Non-Contact Sensing Technologies

Emerging magnetoelastic and optical sensing methods eliminate mechanical wear in EPS systems while improving measurement resolution below 0.1°. These technologies align with the automotive industry’s shift toward maintenance-free components, particularly in high-mileage commercial vehicles where traditional contact sensors show degradation after 200,000 operational cycles. Leading suppliers anticipate non-contact variants will capture 40% of the EPS sensor market within five years.

Integration With Autonomous Driving Platforms

The evolution toward autonomous vehicles presents transformative potential for EPS sensor manufacturers. Level 3+ autonomy requires redundant sensor architectures with fail-operational capabilities, effectively doubling the sensor content per vehicle. Collaboration between steering system suppliers and autonomous tech developers has already resulted in prototype systems featuring triple-redundant torque sensing with cross-validation algorithms.

GLOBAL ELECTRIC POWER STEERING (EPS) SENSOR MARKET TRENDS

Rising Demand for Fuel-Efficient Vehicles to Drive EPS Sensor Adoption

The global automotive industry is witnessing a significant shift toward fuel-efficient and lightweight vehicles, directly influencing the demand for Electric Power Steering (EPS) sensors. EPS systems reduce mechanical complexity while improving fuel efficiency by approximately 3-6% compared to hydraulic steering systems. These sensors play a crucial role in detecting driver input and adjusting steering assist accordingly. Governments worldwide are implementing stringent fuel economy regulations, such as the Corporate Average Fuel Economy (CAFE) standards, accelerating OEM adoption of EPS technology. With passenger vehicles accounting for nearly 75% of EPS sensor installations, automakers are integrating advanced torque and angle sensors to meet both regulatory and consumer demands.

Other Trends

Automotive Electrification Surge

The rapid expansion of electric vehicle (EV) production is reshaping the EPS sensor landscape. Unlike internal combustion engine vehicles, EVs rely entirely on electrically assisted systems for steering, creating a 100% penetration rate for EPS in this segment. Major markets like China and Europe are leading this transition, with China contributing over 50% of global EV sales. Sensor manufacturers are responding by developing ruggedized designs capable of handling high-voltage environments alongside improved noise immunity. Hybrid vehicles also present growth opportunities, as they require seamless integration between electric and mechanical steering components.

Advancements in Autonomous Driving Technologies

The development of autonomous vehicles (AVs) is pushing EPS sensors toward higher precision and reliability standards. Modern driver-assistance systems (ADAS) such as lane-keeping assist and automated parking require real-time steering feedback with near-zero latency. This has spurred innovations in non-contact sensor technologies like magnetostrictive torque sensors, which outperform traditional contact designs in durability and resolution. Industry leaders are now focused on achieving ASIL-D functional safety certification for EPS components, critical for Level 3+ autonomous applications. The ADAS market is projected to maintain double-digit growth, further validating investments in next-generation EPS sensing solutions.

COMPETITIVE LANDSCAPE

Key Industry Players

Strategic Innovation Defines Competition in the EPS Sensor Segment

The global Electric Power Steering (EPS) sensor market exhibits a moderately consolidated structure, dominated by established automotive suppliers with strong technological expertise and global manufacturing footprints. Robert Bosch GmbH leads the market with an estimated 25% revenue share in 2024, owing to its comprehensive EPS solutions integrating torque and angle sensors with advanced steering control units. The company’s dual focus on OE partnerships and aftermarket distribution ensures continuous market penetration.

HELLA GmbH & Co. KGaA maintains a robust position through its specialized steering sensor division, contributing approximately 18% of global EPS sensor revenues. Their recent development of contactless torque sensors for heavy-duty vehicles demonstrates strategic vertical expansion. Similarly, Valeo SA has strengthened its market position through the 2023 acquisition of a Japanese sensor manufacturer, enhancing its Asia-Pacific production capabilities.

Meanwhile, LG Innotek has emerged as a disruptive force, leveraging its electronics expertise to introduce cost-competitive EPS components. The company’s 2023 joint venture with a major Chinese automaker exemplifies the growing East-West technology collaborations reshaping the competitive dynamic. Smaller innovators like Methode Electronics compete through patented sensor technologies, particularly in the premium vehicle segment.

Product refinement remains the primary battleground, with companies investing heavily in:

Miniaturization of sensor components

Enhanced signal processing algorithms

Integration with ADAS functionalities

The shift toward steer-by-wire systems is prompting accelerated R&D across all market participants.

List of Key Electric Power Steering (EPS) Sensor Companies Profiled

Robert Bosch GmbH (Germany)

HELLA GmbH & Co. KGaA (Germany)

LG Innotek (South Korea)

Valeo SA (France)

Methode Electronics, Inc. (U.S.)

Denso Corporation (Japan)

Continental AG (Germany)

TT Electronics plc (UK)

Infineon Technologies AG (Germany)

Learn more about Competitive Analysis, and Global Forecast of Global Electric Power Steering (EPS) Sensor Market : https://semiconductorinsight.com/download-sample-report/?product_id=95884

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Electric Power Steering (EPS) Sensor Market?

-> Electric Power Steering (EPS) Sensor Market size was valued at US$ 1.92 billion in 2024 and is projected to reach US$ 3.46 billion by 2032, at a CAGR of 8.74% during the forecast period 2025-2032.

Which key companies operate in Global EPS Sensor Market?

-> Key players include Robert Bosch, HELLA, Valeo, LG, Methode Electronics, and Infineon Technologies, among others.

What are the key growth drivers?

-> Growth drivers include increasing vehicle production, rising demand for fuel-efficient systems, and government mandates for vehicle safety standards.

Which region dominates the market?

-> Asia-Pacific holds the largest market share (45% in 2023), driven by automotive production in China, Japan and South Korea.

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 +91 8087992013 [email protected]

Follow us on LinkedIn: https://www.linkedin.com/company/semiconductor-insight/

0 notes

Text

"Dynamic Steering Torque Service Required": What This Warning Means for Your Safety

https://autorepairlebanontn.com/?p=3870 "Dynamic Steering Torque Service Required": What This Warning Means for Your Safety When your vehicle displays the “ever-changing steering torque service required” message, it’s not just another dashboard alert to ignore. This warning indicates a potential issue with your car’s advanced steering system that helps maintain stability and control during challenging driving conditions. We’ve helped thousands of drivers understand and resolve this concerning notification. Left unaddressed, this warning could lead to decreased handling performance, unpredictable steering response, and even safety risks on the road. The good news? Most ever-changing steering torque issues can be fixed quickly when properly diagnosed by qualified technicians. In this comprehensive guide, we’ll explain what triggers this warning, the risks of ignoring it, and the steps you should take to get your vehicle’s steering system back to optimal performance. Table of Contents Toggle Understanding Dynamic Steering Torque SystemsHow Ever-changing Steering Technology WorksCommon Manufacturers and Models with DSTWhat Does “Dynamic Steering Torque Service Required” Mean?Warning Signs and Dashboard IndicatorsSeverity of the WarningCommon Causes of DST Service WarningsElectronic Control Unit FailuresSteering Sensor MalfunctionsHydraulic System IssuesDiagnosing Dynamic Steering Torque ProblemsCommon CausesProfessional Diagnostic ProceduresDIY Troubleshooting StepsRepair Options and CostsDealer Service vs. Independent MechanicsTypical Repair ExpensesPreventive Maintenance TipsRegular Inspection RecommendationsExtending the Life of Your Steering SystemSafety Considerations When Driving with DST IssuesImpact on Vehicle StabilityPotential RisksWhen to Stop Driving ImmediatelyTemporary WorkaroundsConclusionFrequently Asked QuestionsWhat is the “Ever-Changing Steering Torque Service Required” warning?Is it safe to drive with this warning light on?What causes the DST service warning?How much does it cost to fix this issue?Can I troubleshoot this warning myself?Which car models commonly experience DST issues?How can I prevent DST issues?Will the warning reset itself after fixing the issue? Understanding Dynamic Steering Torque Systems Ever-changing Steering Torque (DST) systems represent a important advancement in vehicle control technology. These sophisticated systems continuously adjust steering resistance based on driving conditions, improving both safety and driving comfort. How Ever-changing Steering Technology Works Ever-changing steering technology operates through a complex integration of electronic and mechanical components. Sensors throughout the vehicle monitor factors like speed, road conditions, and driver input, sending this data to a central control unit. The control unit then calculates the optimal steering resistance and transmits commands to the power steering actuator. This actuator adjusts the steering torque in real-time, providing firmer resistance at high speeds for stability and lighter steering at low speeds for easy maneuverability. The system’s adaptability extends to compensating for crosswinds and road crown effects, automatically counteracting these forces to maintain a straight path without driver intervention. Common Manufacturers and Models with DST Audi pioneered ever-changing steering systems with their progressive steering technology found in models like the A4, A6, and Q7. BMW incorporates a similar system called Variable Sport Steering in their 3 Series, 5 Series, and X5 models. Mercedes-Benz features Direct-Steer in C-Class, E-Class, and GLC vehicles, offering varying resistance ratios depending on steering angle. Volvo’s Speed-Dependent Steering in the XC60 and XC90 adjusts steering weight based on vehicle speed. Ford implements Adaptive Steering in their Edge and F-150 models, while General Motors equips select Cadillac models with Variable Effort Steering. These manufacturer-exact systems, though branded differently, share the fundamental goal of optimizing steering response across diverse driving scenarios. What Does “Dynamic Steering Torque Service Required” Mean? The “Ever-changing Steering Torque Service Required” warning indicates a problem within your vehicle’s steering system. This sophisticated system doesn’t operate in isolation but works alongside other crucial vehicle components including the Anti-lock Braking System (ABS), power steering mechanisms, and various electronic control modules. Several factors can trigger this warning, ranging from minor software glitches and faulty sensors to more serious mechanical issues like a malfunctioning ABS pump or power steering pump problems. Warning Signs and Dashboard Indicators Dashboard indicators provide important clues when a ever-changing steering torque issue arises. The warning message typically appears prominently on your dashboard display, often accompanied by other error messages related to the ABS, Electronic Stability Control (ESC), and electronic parking brake systems. Low voltage in the electrical system sometimes triggers this warning as part of a cluster of messages, potentially preventing your vehicle from starting properly. Many drivers report experiencing multiple error messages simultaneously, which suggests a broader system issue affecting various interconnected components rather than an isolated steering problem. Severity of the Warning Understanding the severity level of this warning helps you determine how quickly to address the issue. While not always critical, this warning deserves prompt attention to maintain your vehicle’s safety and optimal performance. Ignoring these alerts risks disrupting essential steering and braking functions, potentially compromising vehicle control. In more severe cases, your vehicle might become difficult to start or even completely unusable until the problem is resolved. Fortunately, many causes behind this warning can be fixed with relatively straightforward and cost-effective answers, such as checking electrical connections, replacing faulty components, or addressing low voltage issues in the vehicle’s battery system. Common Causes of DST Service Warnings Ever-changing Steering Torque (DST) service warnings typically appear due to several exact system failures. These warnings indicate problems that require attention to maintain your vehicle’s optimal steering performance and safety features. Electronic Control Unit Failures Electronic Control Unit (ECU) issues frequently trigger DST service warnings in modern vehicles. The Anti-lock Braking System (ABS) pump or control module directly interfaces with the ever-changing steering torque system, sending crucial operational signals. Faulty ABS components often transmit incorrect data to the steering system, immediately triggering the “Service Required” message on your dashboard. These electronic failures compromise not only steering performance but also affect related safety systems that depend on accurate communication between vehicle control modules. Steering Sensor Malfunctions Steering sensor issues represent another common cause of DST warnings in vehicles equipped with this technology. These sensors continuously monitor steering angle, torque input, and wheel position to provide real-time data to the vehicle’s electronic systems. Any malfunction in these precision instruments disrupts the normal functioning of ever-changing steering torque, creating inconsistent steering feel or resistance. Sensor problems typically develop from electrical connection issues, physical damage, or gradual degradation over time, affecting the system’s ability to accurately adjust steering resistance based on driving conditions. Hydraulic System Issues Hydraulic component failures significantly impact DST functionality and can prompt service warnings. The power steering pump serves as the heart of the hydraulic system, generating necessary pressure to assist steering operations. Low fluid levels, pump wear, or pressure line leaks create inconsistent hydraulic pressure that the DST system detects as abnormal. Also, contaminated power steering fluid degrades system components over time, leading to erratic steering assistance and triggering warning messages. Many DST-related hydraulic issues manifest first as unusual noises (whining or groaning) during steering maneuvers before the warning light appears. Diagnosing Dynamic Steering Torque Problems Identifying the root cause of ever-changing steering torque issues requires a systematic approach to troubleshooting. Problems triggering the “Ever-changing Steering Torque Service Required” warning often stem from several interconnected components including the ABS system, power steering mechanisms, sensors, and electronic systems. Common Causes Ever-changing steering torque warnings typically appear due to exact vehicle malfunctions. Faulty ABS pumps or control modules can disrupt steering functionality since these systems share critical communication networks. Power steering pump failures frequently trigger these warnings through inconsistent steering assistance. Sensor issues send incorrect signals to the steering system, confusing the electronic control unit. Electronic glitches, particularly those related to low voltage conditions, commonly activate multiple dashboard warnings simultaneously. Environmental factors like moisture intrusion into electrical components can also initiate steering system alerts. Professional Diagnostic Procedures Professional technicians use specialized equipment and follow comprehensive protocols when diagnosing ever-changing steering torque problems. Mechanics begin by connecting diagnostic scanners to retrieve error codes stored in the vehicle’s computer systems. They perform thorough component inspections of the ABS pump, control modules, power steering pump, and associated sensors to identify visible damage. Electrical system checks verify proper voltage and current throughout the steering and braking subsystems. Functional testing of the ABS and power steering components helps pinpoint exact mechanical or electronic failures that might not be immediately apparent during visual inspection. DIY Troubleshooting Steps Several home diagnostic steps can help identify or potentially resolve ever-changing steering torque issues before visiting a repair shop. Start by checking the ABS pump and control module connections for corrosion, looseness, or physical damage. Examine the power steering pump for fluid leaks, unusual noises, or difficulty turning the wheel at low speeds. Inspect sensors around the steering column and wheel wells for secure connections and signs of physical damage. Test your vehicle’s electrical system with a multimeter, focusing on battery voltage which should measure between 12.4-12.7 volts when the engine is off. Try performing a system reset by disconnecting the battery for 30 minutes, which occasionally clears transient electronic faults. Look for moisture accumulation around electronic components, particularly after driving in heavy rain or through flooded areas. Consult your exact vehicle’s manual for model-exact troubleshooting procedures that address known issues with your car’s steering system. Repair Options and Costs Addressing a “Ever-changing Steering Torque Service Required” warning involves several repair pathways with varying costs. Let’s explore your options for getting this critical steering system back to optimal performance and what you can expect to pay. Dealer Service vs. Independent Mechanics Dealerships provide repairs using original equipment manufacturer (OEM) parts that match exactly what came with your vehicle. These dealer technicians receive specialized training specifically for your vehicle make and model, ensuring thorough familiarity with complex systems like Ever-changing Steering Torque. Their top-notch facilities and diagnostic equipment often detect issues more precisely, though these advantages come with significantly higher labor rates ranging from $75 to $150 per hour. Independent mechanics offer a more cost-effective alternative while still providing quality repairs. They typically use aftermarket parts that meet industry standards but cost less than OEM components. Many independent shops maintain lower overhead costs, resulting in labor rates between $50 and $100 per hour. When selecting an independent mechanic for DST repairs, verify they have experience with your exact vehicle’s electronic steering systems to ensure proper diagnosis and repair. Typical Repair Expenses Repair costs for Ever-changing Steering Torque issues vary widely depending on the underlying cause. Simple fixes like securing loose connections or replacing minor sensors might cost between $100-$500 total. Electronic Control Unit (ECU) reprogramming typically falls in the mid-range of expenses, often costing $300-$700 depending on complexity. More substantial repairs involving component replacement create higher expenses. ABS pump replacements range from $1,000 to $2,500, while power steering pump replacements typically cost $800 to $2,000. These prices reflect important differences between OEM and aftermarket parts—OEM components generally cost 20-40% more than their aftermarket counterparts. Repair Type Dealer Cost (OEM) Independent Shop (Aftermarket) Connection fixes $150-$300 $100-$200 Sensor replacement $400-$700 $300-$500 ECU reprogramming $500-$700 $300-$500 ABS pump replacement $1,800-$2,500 $1,000-$1,800 Power steering pump $1,500-$2,000 $800-$1,500 Labor costs constitute a important portion of these repairs, especially for components requiring extensive disassembly. Diagnostic fees apply at most repair facilities, though many shops waive this charge if you proceed with their recommended repairs. Some independent mechanics offer payment plans or financing options for higher-cost repairs, making them more manageable for unexpected steering system issues. Preventive Maintenance Tips Proactive maintenance significantly reduces the likelihood of seeing the “Ever-changing Steering Torque Service Required” warning on your dashboard. Regular checks and proper care extend your steering system’s lifespan and help avoid costly repairs. Regular Inspection Recommendations Routine inspections form the foundation of preventing steering system failures. Check your ABS pump and control module connections every 6-12 months for signs of corrosion or damage. Examine power steering components regularly, looking for fluid leaks or unusual wear patterns that might indicate developing problems. Verify that all sensor connections remain secure and free from moisture damage, as environmental factors often trigger steering system warnings. Monitor your vehicle’s electrical system voltage levels, as low voltage commonly causes multiple error messages including steering torque warnings. These inspections don’t require specialized tools and can easily become part of your regular maintenance routine. Extending the Life of Your Steering System Following manufacturer-recommended maintenance schedules dramatically increases steering system longevity. Check and maintain proper power steering fluid levels monthly, replacing fluids according to your vehicle’s service manual specifications. Address any warning messages promptly rather than hoping they’ll resolve themselves, as minor issues can quickly develop into major mechanical failures. Have a qualified mechanic perform repairs when you’re uncomfortable doing them yourself, especially for complex electronic components. Protect your vehicle’s electronic systems from excessive moisture by parking in covered areas during extreme weather conditions. Maintain optimal battery health through regular testing and replacement when necessary, preventing the low voltage issues that commonly affect ever-changing steering torque systems in models like the Jeep Compass and Jeep Renegade. These preventive measures typically cost under $100 annually but can save thousands in potential repair costs. Safety Considerations When Driving with DST Issues Ever-changing Steering Torque system issues can significantly compromise your vehicle’s safety and handling capabilities. When your dashboard displays the “Ever-changing Steering Torque Service Required” warning, understanding the potential risks and appropriate responses is crucial for maintaining control of your vehicle. Impact on Vehicle Stability Ever-changing Steering Torque problems directly affect your vehicle’s stability, particularly during critical maneuvers like emergency braking or sudden steering corrections. The system’s integration with the Anti-lock Braking System (ABS) means that malfunctions can disrupt multiple safety features simultaneously. A compromised ABS pump or control module throws off your vehicle’s balance, making it noticeably harder to control in challenging situations. This reduced stability becomes particularly dangerous on wet roads, during high-speed driving, or when handling sharp turns. Potential Risks Continuing to drive with DST issues substantially increases accident risk, especially during adverse weather conditions like rain or snow. Your vehicle’s Electronic Stability Control (ESC) and Hill Holder functions may also become compromised as these systems share electronic components with the Ever-changing Steering Torque system. The steering response might become unpredictable, with inconsistent resistance that makes precise handling difficult. This unpredictability creates dangerous situations where you might over-correct or under-correct when steering, potentially leading to loss of control. When to Stop Driving Immediately Multiple simultaneous error messages demand immediate attention. If your dashboard displays combinations of warnings such as “Service ESC System,” “Service Hill Holder,” and “Service Transmission” alongside the DST warning, pull over safely as soon as possible. These clustered warnings indicate widespread electronic system failures that make continued driving hazardous. Steering wheel misalignment presents another critical situation requiring immediate action. A steering wheel that’s turned 90 degrees from its normal position or feels unusually difficult to control signals severe DST system failure. Continuing to drive with such symptoms dramatically increases accident risk. Electrical system issues, particularly low voltage, often trigger DST warnings and can prevent your vehicle from starting if left unaddressed. If your electrical system shows signs of malfunction alongside the DST warning, stopping and addressing the issue prevents being stranded in potentially dangerous locations. Temporary Workarounds Checking your electrical system components provides a good starting point for troubleshooting. Low voltage commonly triggers multiple error messages, including the DST warning. Inspect your battery connections for corrosion or looseness and ensure your alternator is functioning properly. A quick inspection of ABS and power steering components might reveal obvious issues. Look for fluid leaks around the power steering pump, damaged wiring connections to the ABS module, or loose electrical connectors. Securing any disconnected components sometimes resolves temporary DST warnings. Driving technique adjustments can help manage the vehicle until proper repairs are completed. Reduce your speed, avoid sharp steering inputs, and maintain greater following distances to compensate for potentially compromised handling characteristics. Gentle acceleration and braking minimize strain on affected systems. Remember that these workarounds only serve as temporary measures. Professional diagnosis and repair remain essential for restoring your vehicle’s safety systems to proper working condition and ensuring your continued safety on the road. Conclusion The “Ever-changing Steering Torque Service Required” warning shouldn’t be ignored or taken lightly. It’s a critical indicator that your vehicle’s sophisticated steering system needs attention. While the potential causes range from minor electrical issues to more serious mechanical problems the answers are typically straightforward when addressed promptly. We recommend taking immediate action when this warning appears to ensure your safety and maintain optimal vehicle performance. Regular preventive maintenance can help you avoid these issues altogether saving you time and money in the long run. Remember that your vehicle’s steering system is essential for control and stability especially in challenging driving conditions. Investing in proper diagnosis and repair will protect both your investment and everyone’s safety on the road. Frequently Asked Questions What is the “Ever-Changing Steering Torque Service Required” warning? This warning indicates a potential issue with your vehicle’s Dynamic Steering Torque (DST) system, which continuously adjusts steering resistance based on driving conditions. It could stem from problems with the electronic control unit, steering sensors, or hydraulic components. This warning should not be ignored as it affects your vehicle’s handling, stability, and safety, especially in challenging driving conditions. Is it safe to drive with this warning light on? It’s not recommended to drive with this warning active. The DST system is crucial for vehicle stability, especially during emergency maneuvers or in adverse weather. Continuing to drive could compromise your ability to control the vehicle, increasing accident risk. If the warning appears with multiple error messages or if your steering feels unusual, safely pull over and arrange for professional assistance. What causes the DST service warning? Common causes include ECU failures (often linked to ABS components), steering sensor malfunctions (from electrical issues or physical damage), and hydraulic system problems (like low fluid levels or pump wear). The warning can also be triggered by software glitches, electrical connection issues, or integration problems with other vehicle systems such as the ABS or electronic stability control. How much does it cost to fix this issue? Repair costs vary widely depending on the underlying cause. Simple fixes like electrical connections or software updates range from $100-$500. More substantial repairs, such as replacing an ABS pump or power steering component, can cost between $800-$2,500. Dealership repairs tend to be more expensive than independent mechanics, though they offer manufacturer-specific expertise and original parts. Can I troubleshoot this warning myself? Yes, you can perform some basic troubleshooting before seeking professional help. Check electrical connections for corrosion or damage, inspect the power steering system for fluid leaks, test the battery and alternator, and try resetting the vehicle’s computer system (by disconnecting the battery for 15 minutes). However, for accurate diagnosis, specialized diagnostic equipment is usually required. Which car models commonly experience DST issues? DST systems are found in many modern vehicles from manufacturers including Audi, BMW, Mercedes-Benz, Volvo, Ford, and General Motors. While different brands may use various names for their systems, they all serve similar functions. Higher-end models with advanced driver assistance features are more likely to have these sophisticated steering systems and potentially experience related warnings. How can I prevent DST issues? Regular maintenance is key to prevention. Inspect the ABS pump, power steering components, and sensor connections every 6-12 months. Maintain proper power steering fluid levels and quality. Address minor warning messages promptly before they escalate. Keep electronic systems protected from moisture and extreme temperatures. These preventive measures typically cost under $100 annually but can save thousands in repairs. Will the warning reset itself after fixing the issue? In most cases, the warning needs to be reset using a diagnostic scanner after repairs are completed. While some minor issues might temporarily resolve themselves (like intermittent electrical connections), properly fixing the underlying problem and clearing the error codes is essential for ensuring the system functions correctly. Most repair facilities will include this reset as part of their service. https://autorepairlebanontn.com/?p=3870 Absolute Auto Repair

0 notes

Text

Launch X431 Update on Toyota and Mitsubishi

Launch X431 diagnostic software update for Toyota and Mitsubishi.

Check more details and update your software now to extend your diagnostic functions.

Make sure your Launch Software Subscription is active.

MITSUBISHI V35.40

Added multiple system data stream. Optimize special function and software structure.

TOYOTA V51.40

Added special function for Toyota models, including VIN Clear, Reset Memory, Height Offset, Online State Transition, Remote Engine Starter Initial Registration, Remote Engine Starter ID Registration, Hydrogen Tank Over temperature Count Reset. Optimized special function for Toyota models, including Torque Sensor Adjustment, Steering Angle Adjust, Wireless Code Registration, Wireless Code Erasure, Key Code Erasure, Key Code Registration, ID Registration, Learning Values Save, Learning Values Write, Pilot Quantity Learning.

Stay tuned!

0 notes

Text

Automotive Gear Market Overview: Global Trends and Forecast 2025–2030

The Automotive Gear Market stands as a fundamental component of the automotive industry, powering vital mechanisms in vehicle transmissions, engine systems, and steering assemblies. As the global auto sector transitions toward electrification, automation, and sustainability, the role of gears is evolving—spurring demand for innovation in design, materials, and manufacturing processes.

Between 2025 and 2030, the Automotive Gear Market is expected to witness dynamic changes shaped by the growth of electric vehicles (EVs), fuel efficiency standards, and increasing vehicle production in emerging economies. This article offers an in-depth overview of global market trends, growth forecasts, and the future trajectory of this essential automotive segment.

Market Size and Forecast (2025–2030)

The global Automotive Gear Market is projected to grow at a compound annual growth rate (CAGR) of approximately 5% during the forecast period, reaching a market value exceeding USD 45 billion by 2030. Key contributors to this growth include:

Rising global vehicle production

Accelerated adoption of automatic and hybrid transmissions

Surge in electric vehicle sales

Technological innovation in lightweight and noise-reducing gear solutions

Market Composition and Gear Applications

Automotive gears are integral to multiple systems, such as:

Transmission systems (manual, automatic, dual-clutch)

Steering mechanisms

Differential systems

Timing systems in engines

Powertrain and driveline assemblies

The most common gear types include spur gears, helical gears, bevel gears, and worm gears, each selected based on torque, speed, noise, and cost considerations.

Global Trends Shaping the Market

1. Shift Toward Electric Mobility

Electric vehicles use fewer gears than internal combustion engine (ICE) vehicles, but require precision-engineered, high-efficiency gearboxes for silent operation and higher torque delivery.

2. Focus on Fuel Efficiency and Lightweighting

To meet strict emission regulations, automakers are reducing vehicle weight. Gear manufacturers are responding with aluminum alloys, carbon composites, and powder metallurgy for lighter yet durable gears.

3. Digital Transformation in Manufacturing

The use of CNC machining, 3D printing, and digital twin technologies in gear design and prototyping is enhancing precision, reducing lead times, and cutting costs.

4. Noise, Vibration, and Harshness (NVH) Optimization

Demand is increasing for gear systems that deliver smooth, quiet operation, especially in premium and electric vehicles. Innovations in tooth profile design, surface finishing, and advanced lubricants are addressing these needs.

5. Growth in Aftermarket Services

Gear replacement and customization are booming in the automotive aftermarket, driven by DIY culture, motorsports tuning, and the aging vehicle population.

Regional Insights

North America

Strong demand for automatic transmissions

Technological innovations led by OEMs in the U.S. and Canada

Growing EV infrastructure boosting demand for specialized gear units

Asia-Pacific

Fastest-growing region due to China, India, and Southeast Asia

Expanding vehicle production and export markets

Significant investment in domestic gear manufacturing

Europe

Regulatory push for low-emission and fuel-efficient vehicles

Home to some of the world’s leading gear manufacturers

Focus on precision gear design and hybrid drivetrain solutions

Opportunities Ahead (2025–2030)

Smart gears with integrated sensors for real-time diagnostics and predictive maintenance

3D printed gears for prototyping and short-run production

Use of bio-based lubricants and eco-friendly coatings

Increased demand from autonomous vehicle drivetrains

OEM partnerships for custom, brand-specific transmission solutions

Market Challenges

Cost pressures due to raw material volatility and need for precision

Complexity of gear design in hybrid and electric vehicles

High tooling and R&D investment for next-gen gear technologies

Regional disparity in manufacturing standards and workforce skills

Competitive Landscape

The Automotive Gear Market is moderately consolidated, with major players including:

ZF Friedrichshafen AG

BorgWarner Inc.

GKN Automotive

AAM (American Axle & Manufacturing)

Eaton Corporation

Schaeffler Group

These companies are actively engaged in product development, joint ventures, and global expansion to meet evolving industry demands.

Conclusion

The Automotive Gear Market is positioned at the intersection of tradition and transformation. While gears remain a cornerstone of vehicle mechanics, their roles, materials, and manufacturing processes are evolving rapidly. From powering electric motors to integrating with digital control systems, gears are becoming smarter, lighter, and more efficient. As automakers prepare for the next generation of mobility, gear manufacturers who embrace innovation and sustainability will lead the global market through 2030 and beyond.

0 notes