#Types of Modular Jacks

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/interconnect--modular-ethernet-connectors--modular-jacks/5569381-1-te-connectivity-2140444

Modular telephone jack, telephone jacks, Applications for Modular Jacks

8 Position 2x1 Right Angle Through Hole Stacked RJ45 Modular Jack

#TE Connectivity#5569381-1#Connector#Modular/Ethernet Connector#Modular Jacks#Modular telephone jack#Applications#phone jack#keystone jack#Telephone applications#Ethernet jacks#Cat 5e jacks#modular jack connector#Types of Modular Jacks

1 note

·

View note

Note

Another mad scientist idea

He's constructed what he's called "remote body use" and with it you can transfer your conscience to a robot body, your body will still be here, and mind as well, strapped to this large machine, but from your perspective you're a robot girl now! Thou issue arises if both you and robot you see each other but not to worry, won't happen.

If only he wasn't a square cause you wake up in a bog standard box robot body, and scold him for not making a proper body! So the next project is making you the best body ever, no, the best fem bot ever, with all the features you could ever want. Working tirelessly, sparking flying, soldering, 3d modelling, etc.

Until it's completely, laying in it's charging table is your dream fembot body, just waiting to be transferred. You jack yourself in to the rbu and find yourself now in your new body, exploring it before the mad scientist is even done running diagnostics!

But now to stress testing!

Aww~ that sounds lovely!~ I'd have to make sure he makes the chest modular though, having huge tits can be inconvenient at time~ maybe even a specially designed inflatable type chest that I can grow to whatever size I see fit. It would be extra fun watching him try and remain professional, assuring he's not staring and actually just observing but from the way he's drooling I know exactly what he's doing~

13 notes

·

View notes

Text

Here’s Your First Peek at Blake Shelton’s Las Vegas Honky Tonk Bar

Blake Shelton’s sprawling country bar will offer some of the best views in Las Vegas

by Janna Karel Jan 4, 2024, 1:49pm PST

Janna Karel is the Editor for Eater Vegas.

Blake Shelton’s Ole Red, a sprawling, multi-story bar, dance hall, music venue, and restaurant, opens soon, and when it does, it may offer the best rooftop view of the Las Vegas Strip. Shelton broke ground on Ole Red in January of 2023 in front of the Horseshoe Las Vegas. Since then, construction crews have been building the four-story Tennessee-born restaurant, chefs have been developing a menu with dishes that are exclusive to Las Vegas, and Shelton’s team has been bulking up the roster of musical acts that will perform on stage beneath the 4,500-pound ceiling-mounted tractor.

The roughly 27,000-square-foot country bar has four levels. On the first floor is a stage in front of a 38-foot-tall LED screen that can project images to complement shows or be divided into smaller screens for broadcasting sports and other events. The second and third stories overlook the stage and each floor has a bar at the back and fully modular seating — meaning that each floor can offer traditional restaurant-style tables, lounge-style seating, or even have the furniture cleared away to make room for dancing.

The second floor has a first for Las Vegas — a direct walkway into the honky tonk. The elevated pedestrian walkway stretches from the Bellagio Las Vegas Hotel and Casino side of Las Vegas Boulevard to right inside the bar. Both stories have outdoor balconies, offering views of the Grand Bazaar Shops to the East and the Fountains at Bellagio to the west.

The fourth floor is up on the rooftop and will offer a more exclusive experience. Reservations will be encouraged for evening VIP dining, with semi-private cabanas and lounge seating reserved with table minimums. The rooftop will have regular dining at lunch time, then transition to nightlife service around 9 p.m. every night, with cocktail menus and entertainment unique to the fourth floor.

The view from the center Strip rooftop is panoramic, offering views from the Mandalay Bay at the south end of the Strip to the Mirage at the north end. It’s primed for viewing big events like the Formula One Las Vegas Grand Prix and parades for the Golden Knights or Las Vegas Aces, with more than a mile of visibility in either direction. Ole Red can seat about 670 people, or offer standing room for more than 1,100. It’s a capacity that warrants the facility’s two kitchens.

Rendering of Ole Red.

The menu will have about 17 items from Ole Red’s locations in Tennessee, Florida, and Shelton’s hometown of Tishomingo, Oklahoma. Chef Mark Boor spent months developing a further 17 dishes that will be unique to Las Vegas. There will be appetizers like the Turnin’ Me On loaded tots, which are rounds of house-made crispy tots piled high with truffle salt, bacon, parmesan, herbs, a sweet bourbon onion and tomato jam, and a smoked black bean aioli. Shrimp corn dogs are Boor’s answer to “Vegas-ifying” the corn dog — coating skewers of shrimp in a light and flaky batter, served with three types of aioli. Boor says his favorite dish, and one he expects to be a crowd-pleaser, is the blackberry crispy chicken sliders. The three mini sandwiches are layered with sweet blackberry compote, a tangy whipped goat cheese spread with jalapenos, cabbage, and super crispy chicken on brioche buns.

Leaning into the West Coast-adjacent location, the menu will have a street corn salad with roasted corn and cotija cheese and mahi-mahi tacos with slaw and avocado. The Hell Right burger is 10 ounces of ground short rib, brisket, and chuck with hatch green chiles, pepper jack cheese, and smoked mushrooms — the result a super juicy burger requiring a two-hand grip. And there’s also the Ole Red ribeye, a 20-ounce bone-in ribeye with spiced chipotle butter, horseradish mashed potatoes, and crunchy slaw.

Ole Red Las Vegas and Ryman Hospitality Properties say that this will be the chain’s largest location to date. With a focus on live country music, the bar will predominantly boast a soundtrack of acoustic solo artists during the day, bands in the evening, and even DJs performing after dark. General manager, Ryan Klaasen says that on most days, the restaurant will be organized for lunch service through the afternoon, and then the tables and booths may take on whatever redecorating is needed to accommodate the night’s entertainment.

“I’ve been coming here a long time. I hosted award shows and worked concerts and was a fan and witness to Gwen Stefani’s residency,” Shelton said at an announcement for the bar last January. “And every time I’m here, I want to see some damn country music.” Shelton said he expects that Ole Red will welcome talent from unsigned singers and artists previously featured on The Voice. He’s also pitched a night in which visitors play talent scouts, listening to music from country artists in a venue with concert-quality production.

While Ole Red doesn’t have an opening date yet, it is expected to open within the next few weeks.

9 notes

·

View notes

Text

Ladders

Trojan Trolleys: Engineered Mobility That Moves Industries Forward

In a market crowded with generic suppliers of material handling equipment, Trojan Trolleys emerges as a leader with a core philosophy rooted in durability, versatility, and industry-specific solutions. Serving South Africa and beyond, Trojan Trolleys has built a reputation for producing high-quality castors, trolleys, pallet jacks, platform trolleys, and scaffolding systems that cater to a broad range of industries, including retail, warehousing, logistics, manufacturing, and construction.

While many suppliers focus solely on product volume or surface-level variety, Trojan Trolleys takes pride in offering engineered solutions that prioritize performance, safety, and longevity—distinguishing it from the competition in a meaningful and measurable way.

A Unique Feature: Custom-Engineered Castors and Wheels for Every Application

The defining feature that sets Trojan Trolleys apart is its dedicated focus on precision-engineered castors and wheels. While other brands offer limited options in standard sizes, Trojan Trolleys delivers a comprehensive, customizable range of castors that can meet the demands of virtually any working environment.

Whether you’re searching for castors online for light-duty use in retail displays, or heavy-duty castors and wheels for industrial machinery and logistics equipment, Trojan Trolleys provides solutions tailored for impact resistance, load-bearing capacity, floor protection, thermal endurance, and even corrosion resistance.

Trojan’s ability to deliver castors designed for specific roles—be it for high-heat manufacturing zones, clean-room medical settings, or rugged construction sites—demonstrates their understanding that mobility isn’t one-size-fits-all. This nuanced approach to material mobility truly elevates them beyond other castors suppliers in South Africa.

Total Material Handling Solutions Under One Roof

Trojan Trolleys is not just about mobility parts—it’s a one-stop solution for complete handling and logistics systems. The brand offers a rich catalog of industrial-grade trolleys, including platform trolleys, foldable trolleys, and utility carts, which are ideal for warehouses, retail chains, and back-end operations. These are designed with both maneuverability and strength in mind, ensuring smooth transport of goods across various surfaces and through confined spaces.

Businesses seeking trolleys for sale can rely on Trojan’s commitment to product integrity, ergonomic designs, and after-sales service, which many competitors overlook. Additionally, their modular design approach allows customers to customize trolleys for specific weight capacities, handle configurations, or wheel types, depending on the operational requirements.

Advanced Pallet Handling and Vertical Mobility

When it comes to warehouse operations and distribution, Trojan Trolleys stands out with its industrial-grade pallet jacks, stackers, and platform lifters. Their range of pallet jacks for sale is engineered to handle heavy-duty loads with minimal operator effort, making warehouse logistics safer and more efficient. These jacks are ideal for both short-distance transport and precise maneuvering in high-density storage areas.

Moreover, Trojan doesn’t stop at ground-level movement. With a full selection of aluminium ladders, fibreglass ladders, mobile safety ladders, and scaffolding, the company ensures that businesses can work at height with the same level of confidence as they do on the floor. Their scaffolding for sale includes both light-weight aluminium frames and heavy-duty steel structures, adhering to safety standards while maintaining flexibility for various job site needs.

Innovation Meets Safety and Compliance

Trojan Trolleys goes the extra mile by designing products that comply with national and international safety standards. Every product, from castors to scaffolding, is engineered with operator safety and operational durability in mind.

Features like anti-slip ladder rungs, lockable swivel castors, and robust powder-coated finishes show the brand’s attention to detail. Furthermore, the company frequently updates its product range based on customer feedback and emerging industry needs, ensuring their equipment remains at the forefront of both innovation and safety.

Product Diversity for Cross-Industry Applications

Few companies offer the wide spectrum of product categories that Trojan Trolleys does. Their catalog covers everything from platform trolleys for food processing units, lockers for sale for educational institutions, to pallet jacks for cold storage warehouses. Their stackers and lifting equipment are equally effective in electronics manufacturing, heavy engineering, and automotive assembly.

This broad relevance to multiple sectors makes Trojan Trolleys a strategic partner, not just a vendor. For industries that demand a mix of heavy-duty machinery and light transport accessories, Trojan eliminates the need to source from multiple suppliers.

Designed for South Africa’s Realities

A major advantage of choosing Trojan Trolleys lies in their deep understanding of South African industrial and commercial conditions. Whether it’s the climate, terrain, or local regulatory requirements, every product is built to handle the realities of South African business environments. Their scaffolding systems, ladders, and handling equipment are designed for durability in fluctuating temperatures, rough terrain, and intensive daily use.

Conclusion: Trojan Trolleys Moves with Purpose

In a world where efficiency, safety, and reliability define success in logistics and operations, Trojan Trolleys is more than just a brand—it’s a movement solution architect. The company’s unique focus on engineered castors and wheels, combined with a holistic portfolio of trolleys, pallet jacks, scaffolding, and ladders, places them well ahead of their competitors.

By addressing both the minute mobility needs and large-scale handling challenges of modern industries, Trojan Trolleys has positioned itself as a true partner in progress—helping businesses across South Africa and beyond to move smarter, safer, and faster.

Whether you are an industrial warehouse, a construction contractor, or a logistics provider, Trojan Trolleys ensures your operations are not just mobile—but intelligently mobile.

Visit for more information :- https://trojantrolleys.co.za/

0 notes

Text

How Our Machinery Transportation Service Ensures Safety and Precision

Expert Planning and Pre-Move Survey :

Safety starts with thorough preparation. We carry out a detailed site survey and pre-move assessment to analyze the machinery’s size, weight, type and sensitivity. This allows us to create a customized transport plan covering every aspect from disassembly and secure packaging to route planning and reinstallation. Our team also works closely with your on-site personnel to understand operational limitations and scheduling needs, ensuring minimal impact on your business operations.

2. Use of Advanced Handling Equipment :

Precision is impossible without the right tools. We use state-of-the-art lifting and moving equipment such as hydraulic jacks, cranes, forklifts, air-ride trailers and skates. For extremely delicate or oversized machines, we use modular transport systems and self-propelled trailers that allow for fine maneuvering in tight industrial spaces. This advanced equipment ensures safe loading, steady transit and smooth unloading.

3. Skilled and Trained Crew :

Our crew is our biggest asset. Every member of our team undergoes regular technical training in equipment handling, safety protocols and transport logistics. Whether it’s dismantling a CNC machine or securing a printing press onto a flatbed, our crew executes each step with precision. They are well-versed in managing high-value, sensitive equipment and follow strict procedures to prevent damage, mishandling, or injury.

4. Custom Packing and Protection :

Each machine has unique structural and mechanical features that require customized packing solutions. We use heavy-duty crates, moisture-resistant wraps, shock-absorbing padding and anti-rust coatings to protect machines during transit. For electronic or vibration-sensitive units, we incorporate anti-static packaging and cushioning materials. Every component from bolts to control panels is securely packed and labeled to ensure nothing is misplaced or damaged.

5. Route Planning and Risk Assessment :

Transporting machinery is a complex process that goes beyond simple loading and driving. Our logistics experts perform detailed route planning, considering factors like road conditions, bridge heights, weight limits and traffic regulations. We also evaluate external risks such as weather, loading dock capabilities and permit requirements for oversized cargo. This meticulous approach ensures safe, on-time delivery while reducing the risk of delays or incidents.

6. Insurance and Risk Coverage :

To ensure your piece of mind, we provide extensive insurance coverage for all equipment transfer projects. Our insurance choices are intended to safeguard your investment from unintentional damage and theft, as well as natural catastrophe. Our experts will walk you through the insurance choices and ensure you have the appropriate amount of coverage depending on the value and type of your equipment.

7. Dismantling, Transport and Reinstallation :

We don't simply relocate equipment; we disassemble, transfer and reinstall it at your new site. Our personnel are educated in equipment disassembly and reassembly, so every bolt, gear and control panel is handled properly. We also do post-move testing to verify that machines are correctly aligned, functioning and ready to use. This turnkey solution removes the need for several providers and speeds up the operational restart.

8. Minimal Downtime, Maximum Efficiency :

We understand that downtime can affect production and profitability. That’s why our services are designed for minimum disruption. From night moves and weekend relocations to staggered equipment transfers, we adapt to your schedule to keep operations running smoothly. Our efficiency ensures your business transitions swiftly with minimal interruption.

9. Specialized Transport for All Industries :

Our machinery transport service caters to a wide range of industries including manufacturing, printing, construction, automotive, pharmaceuticals, food processing and textiles. Whether it’s moving injection molding machines, boilers, generators, or HVAC units, we customize our approach based on the industry’s specific needs and equipment sensitivities.

10. Green and Sustainable Practices :

Wherever possible, we adopt eco-friendly practices such as reusable packing materials, fuel-efficient transport vehicles and optimized routing to reduce emissions. We also responsibly dispose of old packaging and components in line with local environmental regulations.

11. Why Choose Us?

Decades of Experience in industrial and machinery relocation

Specialized Equipment Fleet for all types of machinery

ISO-Certified Processes ensuring high standards and consistency

24/7 Customer Support throughout the move

Nationwide and International Reach

Proven Track Record with clients from various sectors

Conclusion :

Safe and accurate equipment movement requires more than simply logistics; it also requires trust, reliability and competence. We are expert Packers and Movers in OMR, combining innovative equipment, qualified personnel and specialized planning to provide top-tier machinery transportation solutions. Our meticulous care to detail, devotion to safety and client-first attitude have established us as a reliable partner for organizations across sectors. If you want to transfer large gear with no sacrifice on quality, contact us immediately. Let us make your equipment move easy, safe and stress-free.

Read More...

#home relocation#office relocation#commercial relocation#corporate relocation services#furniture relocation#glassware relocation#industrial relocation#machinery transportation#bike relocation#car relocation#packers and movers omr

0 notes

Text

Advantages of Ring Lock Scaffolding for Complex Structures

Key Structural Benefits of Ring Lock Scaffolding Modular Design Flexibility for Complex Layouts Ring lock scaffolding offers remarkable modular design flexibility, which is invaluable for architects and construction teams facing complex layouts. Its customizable configurations make it adaptable to various architectural plans and challenges, enabling precise alignment with unique project demands. What further enhances its appeal is the ease of assembly and disassembly, facilitating quick adjustments according to project progress or design changes. This scaffolding system shines particularly in jobs requiring intricate layouts like circular, triangular, or multi-story designs, proving its versatility across diverse job sites. My experience has taught me that embracing such modular scaffolding increases efficiency and effectiveness in problem-solving onsite.

Enhanced Load Distribution Capabilities The robust load distribution capabilities of ring lock scaffolding are a significant advantage, providing enhanced stability and reducing the risk of scaffolding collapses. This system achieves even and efficient weight distribution, bolstered by empirical findings showing that its load capacities can exceed traditional systems by up to 30%. The integration of strong horizontal and vertical braces ensures optimized structural integrity, making the scaffolding viable for diverse applications across various industries. With ring lock scaffolding, I find peace of mind knowing that the improved load distribution contributes to a safer and more stable work environment.

Corrosion Resistance in Harsh Environments Ring lock scaffolding is engineered to withstand harsh environmental conditions, thanks to its construction using high-grade steel with galvanizing and powder coating. Studies substantiate that galvanized scaffolding can last up to 50% longer than its non-galvanized counterparts, offering cost-saving benefits, especially in adverse environments. This durability translates to reduced maintenance costs, promoting operational efficiency for projects located in coastal or industrial areas. I've observed firsthand how the enhanced longevity and resilience against weather and chemical exposure prove advantageous for long-term, outdoor scaffolding needs, ensuring that investments in ring lock systems pay off in terms of durability and reliability.

Engineering Solutions for Challenging Geometries Multi-Angle Connection Systems When dealing with complex structures, the use of sophisticated multi-angle connection systems is invaluable. These systems are designed to form various geometric configurations needed for intricate architectural projects, providing the flexibility necessary for custom scaffolding designs. They facilitate quick and secure connections between components, significantly reducing assembly time. By accommodating dynamic loads, these systems ensure that scaffolding remains stable and performs efficiently even under varied and demanding conditions. This adaptability is crucial for projects requiring specialized arrangements to support complex geometries.

Adaptive Base Jacks for Uneven Terrains Adaptive base jacks are essential for construction projects on uneven grounds, as they allow for adjustable footing, crucial for maintaining stability and safety. By using these jacks, projects on uneven terrains can see improved safety outcomes. Research indicates that adjustable jacks help reduce the risk of tipping, which is a significant concern in such environments. Furthermore, these jacks are engineered to accommodate varying load pressures and heights, enhancing usability across diverse job sites. This adaptability ensures that scaffolding systems are versatile enough to provide a solid and secure platform for construction.

Integration with Other Scaffolding Types The compatibility of ring lock scaffolding with systems such as cuplock and frame scaffolding offers enhanced project efficiency. This adaptability allows for combining different scaffolding systems, creating tailored solutions to meet specific structural needs. Studies and expert tests have confirmed that integrated scaffolding solutions provide superior safety and support across multifaceted construction projects. This integration not only optimizes the use of existing scaffolding resources but also ensures comprehensive safety and effectiveness across challenging environments, ultimately driving better project outcomes.

Premium Ring Lock Scaffolding Solutions Cuplock Scaffold System: CE-Certified Heavy-Duty Performance The Cuplock scaffold system stands out for its remarkable load-bearing capacity, ensuring compliance with CE safety standards required for heavy-duty applications. This capability makes it an ideal choice for high-rise construction projects where reliability and safety are paramount. By combining the Cuplock system with ring lock scaffolding, we can enhance the overall structural stability of complex scaffolding setups. Real-world case studies consistently show that projects utilizing Cuplock systems encounter fewer delays and achieve higher safety ratings compared to traditional scaffolding options.

Cuplock Scaffold System Types of Scaffolding Cuplock Scaffolding Accessories CE Certified for Construction With its unique cup-lock node system, rapid assembly without loose components, and high load capacity, this system is extensively used in commercial construction, power plants, and bridges. Its modular design reduces labor costs by up to 30% and enhances safety. 6M Electric Scaffold Platform: Automated Height Adjustments The 6M Electric Scaffold Platform is revolutionizing construction sites with its automated height adjustment capabilities, significantly boosting efficiency for tasks that require frequent elevation changes. This electric system minimizes the need for manual labor, thereby reducing occupational hazards and increasing overall productivity on the job site. Many companies report that the integration of such platforms drastically shortens project timelines, as the automated systems facilitate quicker setup and transition times, further promoting efficient project execution.

6M Electric Indoor/Outdoor Scaffold Platform with Remote Control Automatic Lifting for Sale This platform offers electric lifting with smooth operation and labor-saving features. High-strength steel structure ensures durability, while safety mechanisms like limit switches and emergency stop systems ensure safe operation, making it perfect for both indoor and outdoor construction. Bowling Cuplock System: Circular Configuration Mastery Specially crafted for circular structures, the Bowling Cuplock System exemplifies versatility and mastery in scaffolding solutions, making it a go-to choice for challenging architectural projects. Its seamless integration with existing scaffolding systems enables tailored solutions that are customized to the unique requirements of intricate designs. Construction site experiences have demonstrated that the use of such specialized systems can significantly expedite project completion times, thereby enhancing productivity and cost-efficiency in complex projects.

High Quality Bowling Cuplock Scaffolding for Construction Cuplock Scaffolding System Scaffolding Platform This multi-purpose Cuplock system is perfect for formwork and building access, featuring a unique locking method that allows easy and swift connections, ensuring versatile and economic scaffold configurations that are maintenance-free and ready for immediate use. Cost Efficiency in Large-Scale Projects Reduced Labor Costs Through Rapid Assembly Optimizing labor costs is crucial for large-scale projects, and ring lock scaffolding offers a significant advantage. The quicker assembly times typically associated with this system can lead to labor cost reductions of 20-30%. This efficiency not only cuts down on the time required for setup but also allows for easier training of workers, thereby reducing downtime. In fact, faster assembly directly translates to quicker project timelines, enabling projects to meet deadlines more effectively. Studies suggest that such efficiencies can significantly reduce overhead costs, making ring lock scaffolding an optimal choice for cost efficiency in large-scale construction.

Long-Term Savings from Galvanized Durability Galvanized scaffolding is an investment that promises long-term savings. Its extended durability surpasses that of non-galvanized options, reducing the need for frequent replacements. This durability contributes to lower maintenance costs for projects, which in turn leads to overall financial savings. Additionally, by minimizing worksite incidents due to its sturdy nature, galvanized scaffolding reduces liability costs and enhances profit margins. Reports consistently highlight how choosing durable scaffolding systems benefits projects through minimized maintenance and associated costs, thereby supporting financial efficiency over time.

Safety Advancements for Irregular Structures Rosette Locking Mechanism Reliability The rosette locking mechanism significantly enhances safety by ensuring that scaffolding components remain securely fastened, offering reliable support for workers even in complex configurations. Safety statistics underline the effectiveness of these systems, with evidence showing a marked decrease in fall incidents when superior locking mechanisms like the rosette system are employed. This mechanism is particularly beneficial in securing complex, irregular structures, where traditional methods may struggle to provide stability. By simplifying the process of securing components in stacked configurations, the rosette system proves invaluable in maintaining worker security and project efficiency.

Integrated Fall Arrest Systems Integrated fall arrest systems add a crucial layer of safety, especially when working on irregular scaffolding structures. Projects that utilize these systems display a significant reduction in fall-related injuries, as corroborated by industry statistics. By adhering to rigorous safety protocols and integrating these systems, companies not only ensure the safety of their workers but also demonstrate their dedication to maintaining a safe work environment. Furthermore, these systems promote compliance with safety regulations, forming part of a comprehensive approach to worker safety. Implementing fall arrest systems reflects the company's strong commitment to minimizing risks and safeguarding its workforce.

0 notes

Text

Mac vs. Windows Laptop Repair – What’s Easier in Chicago?

If your laptop breaks down in Chicago, one question might immediately come to mind: Is it easier to fix a Mac or a Windows laptop here? Whether you’re dealing with a cracked screen, a dead battery, a failing motherboard, or just a sluggish system, the type of laptop you own can make a big difference in the repair experience—especially in terms of cost, turnaround time, and availability of parts.

Let’s break down the differences between Mac and Windows laptop repairs in Chicago, and help you figure out which is easier (and cheaper) to deal with when tech trouble strikes.

Chicago’s Laptop Repair Scene at a Glance

Chicago is home to dozens of laptop repair shops ranging from Apple-authorized service providers to independent tech repair centers and mom-and-pop PC repair stores. Most shops offer both Mac and Windows laptop services, but that doesn’t mean both platforms are treated equally when it comes to cost and convenience.

Here’s what you need to know.

🖥️ Mac Laptop Repairs in Chicago

MacBook repairs—especially on newer models like the MacBook Pro or MacBook Air with Apple Silicon chips—can be complicated and costly.

🔧 Common Mac Repairs:

Cracked Retina displays

Liquid damage cleanup

Logic board repair

Keyboard or trackpad replacements (especially with butterfly keyboards)

Battery replacements

Software reinstallations (macOS recovery or reset)

💡 Pros of Mac Repair in Chicago:

Authorized Apple Service Centers like Simply Mac or Best Buy’s Geek Squad are plentiful in Chicago and nearby suburbs.

Standardized parts and procedures: Apple-certified technicians follow specific protocols, so repairs are consistent.

AppleCare+ availability: If you purchased coverage, many repairs are low-cost or free.

High resale value post-repair: A fixed MacBook retains its value better than most PCs.

⚠️ Cons of Mac Repair in Chicago:

Higher repair costs: Screen replacements can cost $400+, and logic board repairs even more.

Limited part availability for older or very new models.

Proprietary components: Third-party repair shops have fewer options unless they’re certified and using Apple-authorized parts.

Minimal upgradeability: Most modern MacBooks have soldered components (RAM, SSD), making repair and replacement harder.

⏱️ Typical Turnaround Time:

2 to 5 business days, sometimes longer for parts ordering or logic board repairs.

💻 Windows Laptop Repairs in Chicago

Windows laptops—ranging from Dell, HP, Lenovo, ASUS, Acer, and gaming brands like MSI or Razer—tend to be more flexible and affordable to repair.

🔧 Common Windows Repairs:

Broken hinges and cracked screens

Power jack issues

Overheating and fan replacement

Blue screen (BSOD) and software corruption

RAM/SSD upgrades

Battery swaps

💡 Pros of Windows Repair in Chicago:

Wider availability of parts: Most Chicago tech shops stock parts for common Windows models.

Lower average repair costs: You can get a screen replaced for $100–$200 in many cases.

Easier internal access: Most PCs are modular and easier to open, making DIY or quick tech fixes feasible.

Tons of repair shops: You’ll find countless Chicago-area shops (especially in the Loop, Wicker Park, and Lincoln Park) that specialize in Windows repairs.

⚠️ Cons of Windows Repair in Chicago:

Variety in design: Not all Windows laptops are created equal. Some ultrabooks or gaming laptops have hard-to-find or proprietary parts.

Inconsistent build quality: Some low-end models are difficult or not worth fixing due to fragile parts or poor internal layouts.

No unified repair standard: Unlike Apple’s service manuals, PC repair procedures vary widely between brands and models.

⏱️ Typical Turnaround Time:

1 to 3 business days, depending on the issue and part availability.

Note: AppleCare+ may reduce Mac repair costs significantly if still under warranty.

🧠 Which Is Easier to Repair in Chicago?

✅Windows Laptops, Why?

More repair shops available

Faster turnaround times

Lower part costs

Easier to disassemble and upgrade

Less proprietary hardware

That said, Mac laptops still have a major advantage if you’re near an Apple Store or authorized repair center—especially if you’re covered under warranty or AppleCare+.

🏙️ Top Chicago Repair Shops for Each Type

🛠️ Best for Mac Repairs:

Apple Lincoln Park – Official Apple Store with Genius Bar support

uBreakiFix by Asurion (authorized Apple repair partner)

Techserve Chicago – Offers logic board and soldering services

Micro Center Westmont – Some Apple-certified repairs

🛠️ Best for Windows Repairs:

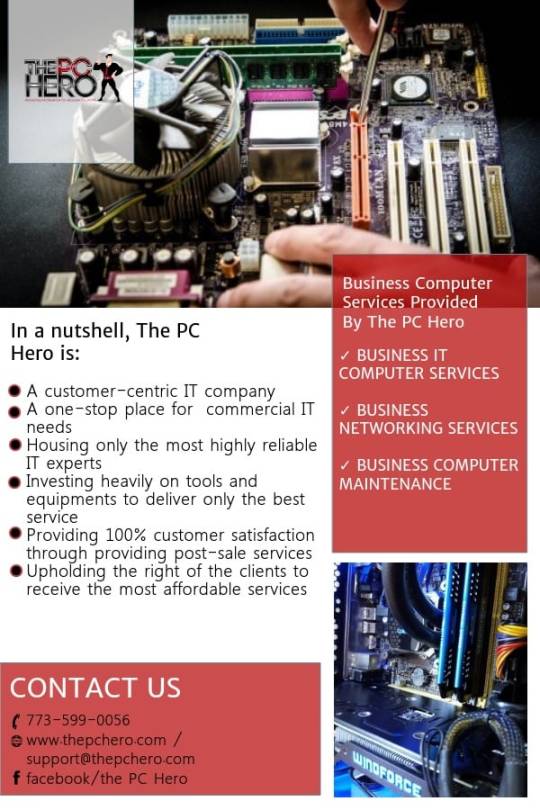

The PC Hero – Specializes in cracked screens, hinges, and custom builds

Chicago ComputerLand – Great for Dell, HP, Lenovo models

Lapin Systems – Excellent for diagnostics and hardware troubleshooting

Fix It Guy Chicago – Popular in the West Loop for walk-in repairs

🔐 What About Data Recovery?

Both platforms have strong options in Chicago for data recovery. However, Macs with T2 or M1/M2 chips may require Apple-authorized service for encrypted data access, while Windows laptops are generally easier to extract data from using SATA/USB adapters.

🛡️ How to Protect Your Laptop from Needing Repairs

Chicago technicians recommend a few simple steps to avoid costly repairs:

Use a padded case or sleeve, especially for MacBooks with fragile Retina displays

Clean vents regularly to avoid overheating

Update your OS and drivers to prevent software-related crashes

Avoid using third-party chargers, especially with Apple laptops

Back up your data regularly—external drives or cloud backups are a must

Which Is Easier to Fix in Chicago?

If you’re prioritizing cost, flexibility, and speed, Windows laptops have a clear edge when it comes to repairs in Chicago. There’s no shortage of skilled technicians and affordable options for screen repairs, charging issues, or software fixes.

However, if you’re part of the Apple ecosystem, Chicago has a strong network of Apple-authorized service providers. While repairs may be more expensive and restricted, they’re also reliable and consistent—especially under warranty.

youtube

Bottom line: Both Mac and Windows laptops can be repaired effectively in Chicago, but your experience will vary based on the type of issue, the model, and whether you’re still under warranty.

Need fast and affordable laptop repair in Chicago? Whether you’re using a MacBook or a Windows laptop, check out The PC Hero for expert service, free diagnostics, and quick turnaround.

#PC Repair Chicago#Laptop Repair Near Me#PC Repair Near Me#Computer Repair Chicago#IT Support Chicago#Computer Repair Shop Chicago#Youtube

0 notes

Text

Been a while since I did an Art and showed it

This guy is for the revised version of my Wizard City setting, doing a "signature character" for each of the six active Conspiracies, the Anarchivists, Contrabandits, Hexecutives, Nemessaries, Sigilantes, and Trespastors. The Fair Folk character who resulted from the "Help Me Make A Character" poll series will be one of these, as soon as I figure out a look for him that I like.

A name is still pending for this character, but here's the idea:

ANCESTRY: Exemplar (Those folk who were created by the Architects, way back at the dawn of the [relatively young] universe, by modifying existing humans to thrive in specific magically unusual environments. Some Exemplar folk get prideful about having been around since the early chapters of known history, but honestly the Architects are mostly seen as such a bunch of cosmic fuck-ups that being one of their direct creations isn't seen as something worthy of bragging about. Technically the Exemplar Races are Elves, Dwarves, Goblins, Giants, and so-called Empyrean Humans... but Gremlins are numbered as a sixth, as the only large discrete culture drawing from two of those types. Others with a mixture of Exemplar ancestries are certainly out there, as well as those mixed with non-Empyrean Humans, and an emerging number of Fae hybrids since Fae seem to be able to breed true with literally anyone or anything, but Gremlins are noteworthy for being numerous enough to have their own language, customs, and communities. Most Gremlins today can trace their ancestry back for hundreds of years before finding a pure-blooded Dwarf. Relations with other Goblin clans are a little more likely, but still uncommon since Gremlins are the only clan whose population centers are in the Material Realm rather than the Umbral Depths.)

CULTURE: Gremlin (Gremlins inherited a knack for machinery and engineering from their Dwarven kin and a spiritual affinity for death and entropy from their Goblin kin. The intersection makes them peerless designers of weapons and traps, as well as skilled demolitionists, and many Gremlins cultivate the ability to see the world through something like "Jason Bourne Vision" where they intuitively understand how to use every common item they encounter to inflict maximum injury.)

JOB: The Pillar (A laborer or craftsperson whose command of their Trade Skills is sufficient to put them at equal utility for a Revolutionary Cell with Soldiers, Spies and Wizards. This guy is a contractor for Baetylus city maintenance, not actually a full-time HummingBIRD employee, who habitually sabotages worksites so he can return weeks or months later and extract all the valuable materials.)

SPECIALIZATION: Freelancer (An individual who does enough odd jobs that they're capable of stepping into nearly any variety of labor and performing adequately. Basically a modular jack-of-all-trades skill set that makes them particularly useful for missions with uncertain technical requirements. All of which makes calling it a Specialization a bit silly, but whatever.)

CONSPIRACY: Contrabandit (Those empowered by Haagenti the Toad to be experts in procurement and smuggling, including an array of supernatural gifts to aid those tasks. Their most infamous trick is the ability to divert their mouths to an extradimensional pocket space, open their jaws impossibly wide, and lash out with a prehensile Yoshi tongue to slurp up the stuff they want to smuggle in their belly.)

#aclodoc#gremlin#contrabandit#the baetylus-illiaster research directorate#the buer valley#arcanamachy#wall of text#ttrpg rambling

0 notes

Text

Rack Pallet

This image showcases a heavy-duty pallet racking system commonly used in industrial and warehouse environments for efficient vertical storage. The rack features robust steel uprights and cross beams, typically painted in safety colors—orange for horizontal beams and blue for vertical supports. Each level includes wire mesh decking for added safety and load distribution.

Ideal for storing palletized goods, this rack pallet system maximizes space utilization while allowing easy access using forklifts or pallet jacks. The modular design supports adjustability and scalability, making it suitable for a wide range of industries, including logistics, manufacturing, and retail distribution.

Key Features:

High-strength steel construction

Adjustable shelving levels

Wire mesh decking for enhanced safety

Designed for forklift access

Suitable for high-density storage needs

This type of pallet rack is essential for improving inventory organization and operational efficiency in any large-scale storage facility.

0 notes

Text

Exploring the Role of the Stage Jack Adjustable System in India’s Construction Industry

India’s construction industry is evolving rapidly. From high-rise buildings to modular infrastructure, the demand for faster, safer, and more efficient construction tools and systems is on the rise. One such tool that’s playing a critical role in shaping this growth is the Stage Jack Adjustable System.

Widely used in scaffolding and support systems, the stage jack adjustable system provides a sturdy, adaptable base for platforms during construction. It ensures safety, allows height adjustments, and delivers the stability needed on uneven ground. In this blog, we’ll explore its growing relevance in the Indian construction sector and how companies like MM Infrastructure are enhancing the industry with innovative infrastructure solutions.

What Is a Stage Jack Adjustable System?

A stage jack adjustable system is a type of scaffold support device that helps in levelling and securing platforms, especially during staging, roofing, or elevated construction work. It consists of a jack base and an adjustable screw that allows workers to modify the height of a scaffold leg or support post.

This system is extremely valuable in scenarios where the working surface is uneven, or where precise height adjustment is necessary for proper alignment of the structure above. In short, it's all about stability, accuracy, and ease of use.

Why Stage Jacks Matter in Indian Construction

India’s terrain and work conditions vary greatly. Construction might happen on rocky, sloped, or soft-soil land. In such cases, fixed supports are not enough. You need something adaptable, and that’s where stage jack adjustable systems come into play.

Here’s why they’re vital:

Height Precision: Workers can raise or lower the scaffold level with accuracy.

Improved Safety: A stable foundation reduces accidents on-site.

Durability: Made from tough metals, they can bear heavy loads for long durations.

Cost-Efficient: Reusable and long-lasting, they reduce project overheads.

Whether you're building an industrial warehouse or setting up temporary structures like canopy mini tents in India, stage jacks provide the foundational reliability required to get the job done efficiently.

MM Infrastructure: Pioneers in Construction Solutions

At MM Infrastructure, we understand the importance of quality, reliability, and innovation in modern construction. Our Stage Jack Adjustable Systems in India are crafted to meet rigorous industry standards. With easy height adjustment features and solid material engineering, our systems are trusted by builders, contractors, and event organizers alike.

But we don’t stop there. Alongside staging systems, MM Infrastructure is also a leading name in:

Aluminium tents in India

Aluminium hanger tent in India

Roofing MS Iron Trusses in India

Canopy Mini Tents in India

Every product we offer is built to withstand harsh weather, heavy use, and demanding construction schedules.

Use Cases: Where Stage Jack Adjustable Systems Shine

Let’s take a closer look at some practical scenarios where stage jacks make a big difference:

1. Event Infrastructure

Large-scale events often use aluminium hanger tents in India. These massive structures require an even base and precise leveling. Stage jacks help maintain structural balance even when the ground is uneven, making installation quicker and safer.

2. Modular Tent Installations

Temporary structures such as canopy mini tents in India often need to be erected quickly at varied locations. Whether for weddings, exhibitions, or emergency response centres, stage jacks play a crucial role in stabilising tent bases.

3. Roofing Support

During roofing work using roofing MS iron trusses in India, workers need elevated, stable platforms. Stage jacks offer the flexibility to adjust the platform height, which is essential for roof alignment and beam placement.

4. Industrial Construction

In heavy-duty construction projects involving aluminium tent manufacturers in India, modular structures and warehouses are often built with prefabricated components. Stage jacks assist in aligning floors, decks, and temporary platforms before the final installation.

A Closer Look at Aluminium Tent Hangers

When discussing modular infrastructure in India, one cannot ignore the rising popularity of aluminium tents. Lightweight, corrosion-resistant, and easy to assemble, aluminium tents are now a top choice for industries, events, and emergency facilities.

At MM Infrastructure, we offer premium-quality aluminium tents in India that are designed for quick setup and long-term use. Our solutions include:

Aluminium hanger tent in India – perfect for large-scale coverage like exhibitions, storage, or sports facilities.

Canopy Mini Tents in India – ideal for smaller events or temporary installations.

Roofing MS Iron Trusses in India – robust trusses to support tent and roof structures.

We also offer transparent aluminium tent hanger price in India, ensuring clients get high value without compromising quality.

Quality You Can Rely On

With MM Infrastructure, quality is non-negotiable. Every stage jack adjustable system we provide in India goes through multiple checks to ensure strength, stability, and user safety. Similarly, our aluminium tents are designed with precision fittings and tested for resistance against wind, rain, and sun.

Moreover, we’re not just manufacturers—we’re partners in your project. From choosing the right model to post-installation support, our team walks with you every step of the way.

The Demand for Stage Jacks in Urban and Rural Projects

India’s infrastructure is growing in both urban and rural landscapes. Stage jack systems play a versatile role in both scenarios.

Urban Projects: Skyscrapers, metro stations, and malls need reliable scaffolding solutions.

Rural Projects: Temporary schools, health camps, and storage units require flexible infrastructure.

As aluminium tent manufacturers in India, we’ve seen first-hand how the need for portable, adaptable solutions is rising in both city and rural settings. Our products meet this demand with ease.

Factors Influencing Aluminium Tent Hanger Price in India

If you're planning to invest in aluminium tents, it’s natural to ask about costs. The aluminium tent hanger price in India can vary based on several factors:

Size and Specifications: Larger tents with reinforced frames will naturally cost more.

Custom Add-ons: Windows, doors, insulation, and ventilation systems can increase pricing.

Usage Duration: Long-term usage tents may require thicker materials and stronger joints.

Location and Transport: Accessibility of the installation site also affects final pricing.

At MM Infrastructure, we focus on offering competitive prices without compromising the build quality or service.

Why Choose MM Infrastructure?

Whether you’re looking for a stage jack adjustable system in India, a roofing MS iron truss, or a high-durability aluminium hanger tent, MM Infrastructure delivers consistent excellence.

Here’s what makes us different:

✅ Quality Assurance: Rigorous quality checks at every stage.

✅ Custom Solutions: Tailored designs for your specific requirements.

✅ Affordable Pricing: Transparent and competitive quotes.

✅ On-Time Delivery: Fast turnaround for urgent projects.

✅ Expert Support: From planning to installation, we guide you at every step.

We are proud to be one of the few companies in India that offer a full range of modular construction support products under one roof.

Final Thoughts

The stage jack adjustable system is more than just a scaffolding accessory—it’s a critical piece of construction safety and efficiency. Its flexibility, stability, and precision make it indispensable in today’s infrastructure projects.

When combined with other essential offerings like aluminium tents in India, roofing MS iron trusses, and canopy mini tents, it becomes clear that smart, reliable construction tools are key to modern project success.

MM Infrastructure is committed to leading this shift. With a wide range of dependable, high-quality products and a customer-first approach, we continue to support India's growing infrastructure, one stable stage at a time.

#aluminium tent hanger price in india#aluminium tent hanger price#aluminium tents in india#aluminium hanger tent in india

0 notes

Text

Exploring the Role of the Stage Jack Adjustable System in India’s Construction Industry

India’s construction industry is evolving rapidly. From high-rise buildings to modular infrastructure, the demand for faster, safer, and more efficient construction tools and systems is on the rise. One such tool that’s playing a critical role in shaping this growth is the Stage Jack Adjustable System.

Widely used in scaffolding and support systems, the stage jack adjustable system provides a sturdy, adaptable base for platforms during construction. It ensures safety, allows height adjustments, and delivers the stability needed on uneven ground. In this blog, we’ll explore its growing relevance in the Indian construction sector and how companies like MM Infrastructure are enhancing the industry with innovative infrastructure solutions.

What Is a Stage Jack Adjustable System?

A stage jack adjustable system is a type of scaffold support device that helps in levelling and securing platforms, especially during staging, roofing, or elevated construction work. It consists of a jack base and an adjustable screw that allows workers to modify the height of a scaffold leg or support post.

This system is extremely valuable in scenarios where the working surface is uneven, or where precise height adjustment is necessary for proper alignment of the structure above. In short, it's all about stability, accuracy, and ease of use.

Why Stage Jacks Matter in Indian Construction

India’s terrain and work conditions vary greatly. Construction might happen on rocky, sloped, or soft-soil land. In such cases, fixed supports are not enough. You need something adaptable, and that’s where stage jack adjustable systems come into play.

Here’s why they’re vital:

Height Precision: Workers can raise or lower the scaffold level with accuracy.

Improved Safety: A stable foundation reduces accidents on-site.

Durability: Made from tough metals, they can bear heavy loads for long durations.

Cost-Efficient: Reusable and long-lasting, they reduce project overheads.

Whether you're building an industrial warehouse or setting up temporary structures like canopy mini tents in India, stage jacks provide the foundational reliability required to get the job done efficiently.

MM Infrastructure: Pioneers in Construction Solutions

At MM Infrastructure, we understand the importance of quality, reliability, and innovation in modern construction. Our Stage Jack Adjustable Systems in India are crafted to meet rigorous industry standards. With easy height adjustment features and solid material engineering, our systems are trusted by builders, contractors, and event organizers alike.

But we don’t stop there. Alongside staging systems, MM Infrastructure is also a leading name in:

Aluminium tents in India

Aluminium hanger tent in India

Roofing MS Iron Trusses in India

Canopy Mini Tents in India

Every product we offer is built to withstand harsh weather, heavy use, and demanding construction schedules.

Use Cases: Where Stage Jack Adjustable Systems Shine

Let’s take a closer look at some practical scenarios where stage jacks make a big difference:

1. Event Infrastructure

Large-scale events often use aluminium hanger tents in India. These massive structures require an even base and precise leveling. Stage jacks help maintain structural balance even when the ground is uneven, making installation quicker and safer.

2. Modular Tent Installations

Temporary structures such as canopy mini tents in India often need to be erected quickly at varied locations. Whether for weddings, exhibitions, or emergency response centres, stage jacks play a crucial role in stabilising tent bases.

3. Roofing Support

During roofing work using roofing MS iron trusses in India, workers need elevated, stable platforms. Stage jacks offer the flexibility to adjust the platform height, which is essential for roof alignment and beam placement.

4. Industrial Construction

In heavy-duty construction projects involving aluminium tent manufacturers in India, modular structures and warehouses are often built with prefabricated components. Stage jacks assist in aligning floors, decks, and temporary platforms before the final installation.

A Closer Look at Aluminium Tent Hangers

When discussing modular infrastructure in India, one cannot ignore the rising popularity of aluminium tents. Lightweight, corrosion-resistant, and easy to assemble, aluminium tents are now a top choice for industries, events, and emergency facilities.

At MM Infrastructure, we offer premium-quality aluminium tents in India that are designed for quick setup and long-term use. Our solutions include:

Aluminium hanger tent in India – perfect for large-scale coverage like exhibitions, storage, or sports facilities.

Canopy Mini Tents in India – ideal for smaller events or temporary installations.

Roofing MS Iron Trusses in India – robust trusses to support tent and roof structures.

We also offer transparent aluminium tent hanger price in India, ensuring clients get high value without compromising quality.

Quality You Can Rely On

With MM Infrastructure, quality is non-negotiable. Every stage jack adjustable system we provide in India goes through multiple checks to ensure strength, stability, and user safety. Similarly, our aluminium tents are designed with precision fittings and tested for resistance against wind, rain, and sun.

Moreover, we’re not just manufacturers—we’re partners in your project. From choosing the right model to post-installation support, our team walks with you every step of the way.

The Demand for Stage Jacks in Urban and Rural Projects

India’s infrastructure is growing in both urban and rural landscapes. Stage jack systems play a versatile role in both scenarios.

Urban Projects: Skyscrapers, metro stations, and malls need reliable scaffolding solutions.

Rural Projects: Temporary schools, health camps, and storage units require flexible infrastructure.

As aluminium tent manufacturers in India, we’ve seen first-hand how the need for portable, adaptable solutions is rising in both city and rural settings. Our products meet this demand with ease.

Factors Influencing Aluminium Tent Hanger Price in India

If you're planning to invest in aluminium tents, it’s natural to ask about costs. The aluminium tent hanger price in India can vary based on several factors:

Size and Specifications: Larger tents with reinforced frames will naturally cost more.

Custom Add-ons: Windows, doors, insulation, and ventilation systems can increase pricing.

Usage Duration: Long-term usage tents may require thicker materials and stronger joints.

Location and Transport: Accessibility of the installation site also affects final pricing.

At MM Infrastructure, we focus on offering competitive prices without compromising the build quality or service.

Why Choose MM Infrastructure?

Whether you’re looking for a stage jack adjustable system in India, a roofing MS iron truss, or a high-durability aluminium hanger tent, MM Infrastructure delivers consistent excellence.

Here’s what makes us different:

✅ Quality Assurance: Rigorous quality checks at every stage.

✅ Custom Solutions: Tailored designs for your specific requirements.

✅ Affordable Pricing: Transparent and competitive quotes.

✅ On-Time Delivery: Fast turnaround for urgent projects.

✅ Expert Support: From planning to installation, we guide you at every step.

We are proud to be one of the few companies in India that offer a full range of modular construction support products under one roof.

Final Thoughts

The stage jack adjustable system is more than just a scaffolding accessory—it’s a critical piece of construction safety and efficiency. Its flexibility, stability, and precision make it indispensable in today’s infrastructure projects.

When combined with other essential offerings like aluminium tents in India, roofing MS iron trusses, and canopy mini tents, it becomes clear that smart, reliable construction tools are key to modern project success.

MM Infrastructure is committed to leading this shift. With a wide range of dependable, high-quality products and a customer-first approach, we continue to support India's growing infrastructure, one stable stage at a time.

#aluminium hangers tents infrastructure#modern a type canopy tents#pre engineered building manufacturers in india#aluminium hangers tents manufacturers#aluminium tent hanger price#services offered by a construction company#pre engineering building company in india#steel building construction company#pre engineered building manufacturers#aluminium hanger tent in india

0 notes

Text

Windmill Lattice Towers: Installation and Maintenance Guide

Windmill lattice towers are vital components of wind turbine systems, providing the basic foundation of the turbines and being specifically engineered for strength, flexibility, and efficiency. Their lightweight lattice tower construction with an open framework makes them suitable for use in various terrains and high-wind areas.

In this guide, we explore the installation process of windmill lattice towers, as well as their maintenance, after which we hope for their safe, efficient and long-lasting energy generation.

What is a Lattice Tower?

Before we get into the installation and maintenance process, it is vital to understand: what is a lattice tower? A lattice tower is simply a steel structure made up of many components crossed by others formed typically into a triangular or square base tapering toward the top.

With this design, the wind load impact is drastically reduced, which also helps to lighten and improve material efficiency. It is most often applied in communication towers, transmission lines, and, above all, wind turbines.

Installation Steps of Windmill Lattice Towers

1. Site Assessment and Feasibility

This includes the geography, wind speed data, soil test, and accessibility. Engineers must ensure that the site can take the load of the tower and wind turbine in general, environmental, and safety terms.

2. Design and Engineering

The engineering cycle of the lattice tower consists of making designs to suit demands of height, weight, and wind resistance to meet load requirements on the basis of concern for load distribution, vibrations, and torque balancing. Custom solutions adhering to industry standards and optimizing the structural performance are therefore the forte of KP Green Engineering Limited, a reputed provider of windmill lattice towers in India.

3. Foundation Work

Any lattice steel tower needs a strong foundation. Depending upon the soil condition, the engineers may provide either a reinforced concrete pad type of foundation if the foundation soil is strong or, if the soil is relatively weaker, a pile type of foundation. The depth and width of the foundation would be determined by the height of the tower and the expected wind loads. Leveling and alignment will be done accurately for easy assembly of the tower.

4. Tower Assembly

Windmill lattice towers are assembled in a few modular sections. These prefabricated sections may be assembled either on the ground and lifted or constructed piece-by-piece in a vertical stress arrangement by a crane. The modular nature of lattice towers allows easy transportation and on-site assembly, especially in remote locations.

5. Erection of the Tower

Mechanical jacks or cranes have been used to hoist the tower segments. Once mounted, every component is bolted down and aligned for accuracy in vertical and structural integrity. Because lifting and alignment operations are hazardous, strict safety practices are followed by workers.

6. Wind Turbine Installation

Also, described above, when the lattice tower is completely assembled, nacelle and rotor hub and rotor blades are placed at the top. This phase requires quite high accuracy and favorable weather to prevent accidents or damages to such parts.

For further benefits and uses of wind lattice towers in energy projects, Visit: How Wind Lattice Towers Empower Wind Farms and Impact Energy Production.

Maintenance Guide for Windmill Lattice Towers

Good and proper maintenance extends windmill lattice towers life and efficiency. Regular inspections and prompt actions really help in the early detection of wear, corrosion, or structural problems.

1. Routine Visual Inspections

These inspections will include rust spots, paint wear, loosened bolts, and metal fatigue on the lattice tower structures periodically scheduled by the operators for checks. Normally, these inspections are made either quarterly or biannually, depending on environmental exposure.

2. Corrosion Control

Especially along shorelines and within high-moisture areas, corrosion poses as severe a threat as any to steel lattice towers. Galvanization, epoxy coating, or weatherproof paint should be applied, and regularly renewed. Check weld joints, bolt states, and base sections for any signs of rust.

3. Bolt Tightening and Component Alignment

The many high-strength bolts used for assembling lattice towers have to be periodically checked regarding their tightness by a torque wrench. Improperly tightened joints may misalign the components or even cause structural failure, thereby affecting the performance of the wind turbine.

4. Structural Load Checks

Windmill towers experience dynamic loads that may lead to fatigue cracks or deformation. The use of either drone surveys or SHM (structural health monitoring) systems could reveal whatever signs of stresses or cracks present- particularly at the anchor points and mid-sections.

5. Access System Maintenance

Technicians gain access to lattice towers by using ladders for staircases. Such access systems also need to be inspected and maintained.

6. Documentation and Audits

Keeping a detailed log of all inspection, repair, and service activities ensures consistent performance over the years. The log supports possible warranty claim back, future audits, and well-researched decision-making for upgrades.

Ready to elevate your wind project? Contact KP Green Engineering Limited today!

Advantages of Windmill Lattice Towers

windmill lattice towers offer engineering and economic advantages over the tubular towers:

Cost-Effective: The lattice tower structures require less steel, hence, material and fabrication costs are lower.

Modular Design: More easily transported and erected in rugged or remote areas.

Superior Airflow: The open-frame design allows wind to pass through, reduces the wind drag and load stress.

Flexibility in Height: Easily scalable for projects requiring tall structures without sacrificing stability.

Conclusion

Installation and maintenance of windmill lattice towers are strategic processes involving one-off expert planning, precision engineering, and continued maintenance. Well-executed, it leads to sustainably and efficiently generating wind energy. KP Green Engineering Limited, makes all the difference with respect to project success and long-term reliability.

Whether you are a developer, EPC contractor, or investor in wind energy, understanding the details of lattice steel towers and their maintenance protocols ensures that your infrastructure will be built to last, performing optimally for decades.

0 notes

Text

Why Every Warehouse Needs Rack Safety Barriers for Optimal Safety?

Warehouses are bustling environments where efficient operations and safety go hand in hand. With forklifts, pallet jacks, and large inventory constantly moving, the risk of accidents is ever-present. To safeguard against this risk, rack safety barriers have become an indispensable tool in modern warehouse safety protocols.

In this blog, we will dive into the crucial role rack safety barriers play in enhancing warehouse safety, reducing accidents, and maintaining the integrity of your storage systems. We will also explore why these barriers are essential for businesses looking to streamline their operations and minimize risk.

Understanding the Need for Rack Safety Barriers

Rack safety barriers are designed to protect your racking systems from collisions, which could otherwise lead to costly damage and disruptions in your warehouse. Racks are built to store heavy goods, and any damage to these racks can compromise the safety and stability of your entire storage system. Rack safety barriers act as a defense mechanism, absorbing impacts and preventing damage before it occurs.

They also contribute significantly to reducing safety hazards. Workers are often in close proximity to racks, and an accident involving a forklift or another heavy vehicle could cause severe injury. Rack safety barriers provide an additional layer of protection for both personnel and equipment.

Advantages of Rack Safety Barriers in Warehouse Operations

Rack safety barriers provide several key advantages that contribute to smoother operations:

Prevention of Inventory Loss: Damaged racks often lead to disorganized inventory, which can slow down operations. With rack safety barriers, you ensure that your racks remain intact, which helps keep your inventory organized and accessible.

Reduced Risk of Accidents: Accidents in warehouses can lead to serious injuries or even fatalities. Rack safety barriers help mitigate the risk of accidents by preventing collisions between machinery and racks. This ensures that workers remain safe and the flow of operations isn’t interrupted.

Improved Efficiency: Damaged racks slow down operations as inventory may need to be reorganized or replaced. By using rack safety barriers to protect your racks, you reduce downtime and improve the efficiency of your warehouse. Workers can move more freely and confidently, knowing the racks are well-protected.

Lower Maintenance Costs: With less damage to your racks and equipment, you can avoid the need for frequent repairs and replacements. This leads to significant cost savings in terms of maintenance and replacements, freeing up resources to focus on other aspects of your business.

Selecting the Right Rack Safety Barriers for Your Warehouse

Choosing the right rack safety barriers depends on factors like the layout of your warehouse, traffic volume, and the type of machinery used. Consider whether your warehouse requires heavy-duty protection or if lighter barriers will suffice.

For high-traffic areas with frequent forklift use, steel rack barriers are ideal as they provide maximum protection against collisions. On the other hand, if your warehouse is less busy, plastic barriers may offer sufficient protection at a lower cost. Modular barriers provide the flexibility to adjust your protection as your needs change.

How Rack Safety Barriers Save Money and Improve ROI

The upfront investment in rack safety barriers is a small price to pay compared to the costs associated with warehouse accidents, damaged inventory, and repair expenses. By preventing collisions and damage, rack safety barriers extend the lifespan of your equipment and inventory, ultimately improving the overall return on investment (ROI) for your warehouse operations.

Conclusion: SupplyBliss – Your Trusted Partner for Rack Safety Barriers

At Supply Bliss, we are committed to providing high-quality rack safety barriers that help businesses optimize their warehouse operations while keeping safety a top priority. Whether you're looking for steel, plastic, or modular rack protection solutions, Supply Bliss offers durable and customizable options designed to meet your specific needs. Explore our range of products and learn how we can help you create a safer, more efficient warehouse by visiting SupplyBliss today.

For more information on our rack protection systems, check out our Rack Safety Barriers page.

0 notes

Text

What is a Connector Plug and Why is it Vital for Electrical Connections?

In the world of electronics, tools, and modern wiring systems, achieving safe and efficient connections is critical. One essential component that plays a key role in this process is the connector plug. Whether you're dealing with industrial automation, consumer gadgets, or automotive systems, this compact yet powerful element enables reliable and quick interconnectivity across devices and circuits.

This blog takes an in-depth look at what a connector plug is, how it functions, and why it's a must-have in electrical and electronic setups.

What is a Connector Plug?

A connector plug is the male component of an electrical connector system, designed to fit into a corresponding socket or jack. It is responsible for establishing an electrical connection by inserting its conductive pins or terminals into the mating connector.

These plugs come in various designs, sizes, and configurations to serve specific functions, such as transmitting power, signals, or data across different systems. You’ll find them in everything from fans and relays to sensors, control panels, and electronics kits.

How Does a Connector Plug Work?

The connector plug works by aligning its pins or terminals with the corresponding contacts of a socket connector. Once inserted, it enables a continuous electrical path, allowing current or signals to pass through seamlessly.

Pin Layout: Varies based on application—ranging from simple 2-pin plugs to multi-pin designs.

Outer Shell: Typically made from durable plastic or thermal-resistant materials to protect inner conductors.

Locking Mechanism: Some plugs include snap-fit or threaded couplings to prevent disconnection.

Polarity Protection: Keyed configurations ensure correct alignment and avoid damage during insertion.

The simplicity and reliability of the connector plug make it indispensable in countless technological applications.

Where is a Connector Plug Commonly Used?

Connector plugs are highly versatile and are used across a wide range of electrical and electronic systems.

Typical applications include:

Select the Right Plug – Choose the type and pin configuration that matches your socket.

Prepare the Wires – Strip insulation and tin the ends if soldering, or get crimp terminals ready.

Insert and Secure – Solder or crimp the wires into the plug’s terminals.

Assemble the Housing – Slide on the shell or cap and secure it with screws or snap-fit.

Plug into Socket – Align the plug with the mating connector and insert carefully.

Test the Connection – Check for continuity and ensure the connection is secure.

The use of connector plugs simplifies the complexity of wiring and allows for structured and maintainable setups.

Why Use a Connector Plug?

The connector plug not only makes wiring systems more flexible, but also improves efficiency and safety in both installation and operation.

Modular Design: Allows components to be connected or replaced without disturbing other parts of the system.

Quick Setup: Enables fast and tool-less assembly in many cases.

Durable Build: Withstands repeated plugging and unplugging cycles.

Enhanced Safety: Prevents exposed wires or loose connections that could lead to failures.

Universal Compatibility: Comes in standardized forms that match with various socket connectors.

These benefits make it an essential item in both permanent and portable wiring solutions.

Key Features of a Connector Plug

Whether for high-power applications or delicate signal transmission, connector plugs are packed with functional features.

Key features include:

Secure Fit – maintains a tight connection to avoid accidental disconnection

Insulated Body – made from non-conductive material to prevent short circuits

Multiple Pin Options – available in 2, 4, 8, 12-pin and more for versatile use

Color Coding – helps with wire identification and system organization

Vibration Resistance – designed to maintain stable contact in mobile environments

Simple Installation – compatible with standard crimping and soldering tools

These attributes allow the connector plug to be used confidently in high-performance environments involving wires, cables, sensors, and safety equipment.

How to Use a Connector Plug

Connector plugs are designed for easy integration into your wiring system. With a few tools and basic preparation, you can quickly set them up.

Basic usage steps:

Select the Right Plug – Choose the type and pin configuration that matches your socket.

Prepare the Wires – Strip insulation and tin the ends if soldering, or get crimp terminals ready.

Insert and Secure – Solder or crimp the wires into the plug’s terminals.

Assemble the Housing – Slide on the shell or cap and secure it with screws or snap-fit.

Plug into Socket – Align the plug with the mating connector and insert carefully.

Test the Connection – Check for continuity and ensure the connection is secure.

The plug’s robust design ensures a lasting and interference-free connection when used correctly.

Advantages of Using a Connector Plug

Streamlines Wiring Systems: Reduces clutter and improves maintenance

Provides Strong Mechanical Hold: Prevents loose connections and intermittent signals

Supports Various Environments: Suitable for indoor, outdoor, mobile, and static applications

Works with Existing Standards: Matches commonly used connectors in electronics and technology

Enhances System Safety: Avoids open wire ends and electrical shorts

This makes the connector plug a critical tool in electrical safety, circuit integrity, and ease of use.

Conclusion: Is a Connector Plug the Right Choice for Your Next Project?

If your project involves any sort of modular wiring, temporary setup, or device connectivity, using a connector plug is the smart approach. Its ease of use, versatility, and reliability make it an ideal choice for engineers, hobbyists, and technicians alike.

From wiring fans and sensors to assembling complex control panels and gadgets, the connector plug ensures quick, safe, and professional-grade connections. Add it to your toolset and simplify your wiring challenges with confidence.

0 notes

Text

Equipment Needs for a Startup Manufacturing Plant

Starting a manufacturing plant is an exciting yet challenging venture. One of the most critical aspects of setting up a successful operation is selecting the right equipment. The machinery you choose will impact production efficiency, product quality, and overall profitability.

In this blog, we’ll discuss the essential equipment needed for a startup manufacturing plant, factors to consider when selecting machinery, and tips to optimize your investment.

1. Understanding Your Manufacturing Requirements

Before purchasing any equipment, it’s crucial to define Machinery Solutions your production needs. Consider the following:

Type of Products: What are you manufacturing? (e.g., food, textiles, machinery, electronics)

Production Volume: Will you operate at small, medium, or large scale?

Automation Level: Do you need manual, semi-automated, or fully automated machines?

Budget Constraints: How much can you invest in machinery without compromising cash flow?

Once you have clarity on these factors, you can proceed with selecting the right equipment.

2. Essential Equipment for a Startup Manufacturing Plant

A. Production Machinery

The core of your manufacturing plant lies in the machines that transform raw materials into finished products. Depending on your industry, these may include:

CNC Machines – For precision cutting, drilling, and milling (metalworking, automotive parts).

Injection Molding Machines – For plastic product manufacturing.

3D Printers – For prototyping and small-batch production.

Assembly Line Robots – For automated assembly in electronics or automotive industries.