#VoltageRegulation

Explore tagged Tumblr posts

Text

TPS65131 Split-Output Booster Supply

Generating a negative voltage over -5V is kinda annoying: most chargepumps max out at 5V inversion, and ones that can double-then-invert like the MAX232 aren't high current. We bumped into the TPS65131

https://www.digikey.com/en/products/detail/texas-instruments/TPS65131RGER/1672464

while working on our Floppsy design

- we need -12V to bias the Apple Disk ][ drive control system. It's a combo buck and boost: give it 3~5VDC and give you up to -15V and +15V output. The split supply part is particularly nice because you'll want +-12V or +-15V for analog projects. This standalone power supply breakout has two mini trim pots to help adjust the output voltages on both sides so you can have as little as +/-6V and up to +/-15V. With the 2A internal switches, you'll get a fair amount of current on either rail.

#electronicsdesign#voltageconversion#tps65131#powersupplydesign#analogprojects#diyelectronics#hardwareengineering#boostconverter#negativesupply#positivesupply#dcpowersupply#electronicscomponents#circuitdesign#powersupply#electronicsengineering#diyhardware#analogcircuits#voltageregulation#techgadgets#opendesign#opensourcehardware

7 notes

·

View notes

Text

Auto Transformers: Compact Efficiency for Voltage Control

Introduction

When efficient voltage regulation and cost-effectiveness are priorities, Auto Transformers stand out as a smart solution. Unlike traditional transformers, auto transformers use a single winding for both primary and secondary sides, reducing size, weight, and material costs while delivering reliable voltage transformation for a variety of applications.

What is an Auto Transformer?

An Auto Transformer is a type of electrical transformer where part of the winding is common to both the primary and secondary circuits. This design allows for voltage adjustment with less copper and iron material, making it more compact and efficient for specific voltage ranges.

How Does It Work?

The auto transformer has a single continuous winding with taps at different points.

The input voltage is applied across a portion of the winding (primary side).

The output voltage is taken from another tap on the same winding (secondary side).

By varying the tap points, the transformer either steps voltage up or down efficiently with reduced losses.

Purposes

To provide voltage regulation in power systems

To step up or step down voltage in a compact form

To save material and reduce transformer size and weight

To improve efficiency in applications where voltage differences are small

Key Features

Single winding used for both primary and secondary

Compact and lightweight design

High efficiency with reduced copper and core material

Cost-effective compared to conventional transformers

Suitable for small voltage adjustments

Quick voltage tap changing options

Benefits

✅ Reduced material and manufacturing costs ✅ Lower losses and higher efficiency ✅ Smaller size and lighter weight for easier installation ✅ Ideal for voltage stabilization and regulation ✅ Simplified design with fewer components ✅ Suitable for a wide range of industrial and commercial uses

Applications

Voltage regulation in power distribution networks

Motor starting and speed control

Railways and traction systems

Audio and radio frequency equipment

Industrial machinery and control panels

Conclusion

Auto Transformers offer a cost-effective and efficient way to regulate and transform voltage within limited ranges. Their compact design and high efficiency make them indispensable in many industrial, commercial, and utility applications, delivering reliable performance while saving space and materials.

Company Details:

📍 Company Name: Padmavahini Transformers 🌐 Website: Padmavahini Transformers 📞 Contact No: +91 99430 49222 📧 Email: [email protected] 📍 Address: S. F. No. 353/1, Door No. 7/140, Ruby Matriculation School Road, Keeranatham, Saravanampatti, Coimbatore, Tamil Nadu - 641035, India

🔗 Follow Us on Social Media: 📘 Facebook 📸 Instagram

#AutoTransformer#VoltageRegulation#EfficientPower#PadmavahiniTransformers#CompactTransformers#CostEffectivePower#PowerEfficiency#IndustrialElectricity#ReliableVoltage#SmartEnergy

0 notes

Text

RES Engineering Services: Reliable Electrical Shutdown Servicing

RES Engineering Services specializes in comprehensive electrical maintenance solutions that meet a variety of industrial needs. Our crew has the ability to limit downtime with careful planning and execution of service. Electrical shutdown servicing is an essential aspect of the electrical maintenance system. Electrical shutdown servicing will include the inspection, testing, and preventative servicing of electrical systems. By taking into consideration strict safety regulations and recommendations and utilizing professional practice methods based on the best industry standards, our team can ensure the best performance, compliance, and ultimately safety of your electric system. Whether you need electrical shutdown servicing to provide best practice servicing of your electrical system to be certain of proper and approved servicing, RES Engineering Services can assist with the delivery providing a cost effective, safe and effecient electrical shutdown servicing to protect your operation and allow for longivity..

#PowerOutage#ElectricalMaintenance#EnergyEfficiency#ElectricalRepairs#EmergencyServices#ExpertElectricians#ServiceSwitch#SafetyFirst#FaultFinding#ElectricalInspection#PowerManagement#HomeElectrical#CommercialElectrical#TechnicalServices#WiringSolutions#CircuitBreakers#LoadTesting#VoltageRegulation

0 notes

Text

Advanced Power Monitoring and Power Quality Solutions | CP Systems

Optimize energy efficiency with CP Systems' Power Monitoring and Power Quality solutions. We provide real-time power analysis, voltage regulation, and surge protection to ensure stable and reliable operations. Our expert services help businesses detect power fluctuations, reduce downtime, and improve energy performance. From industrial facilities to data centers, our advanced monitoring systems enhance power reliability and efficiency. Trust CP Systems for cutting-edge solutions that keep your electrical infrastructure running smoothly. Contact us today!

0 notes

Text

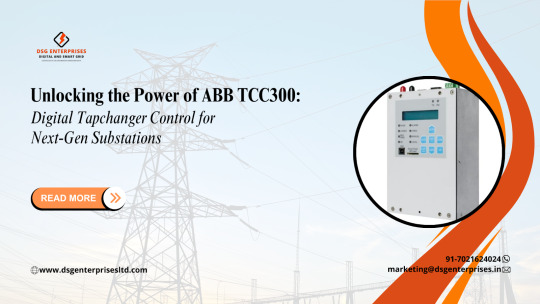

Unlocking the Power of ABB TCC300: Digital Tapchanger Control for Next-Gen Substations

In the ever-evolving landscape of power systems and smart grid technology, the demand for intelligent, reliable, and future-ready solutions is at an all-time high. Substations, acting as the nerve centers of electrical grids, require advanced tools to ensure seamless operation, adaptability, and security. Enter the ABB TCC300 Digital Tapchanger Control Numerical Relay—a modern marvel engineered to revolutionize the way substations manage on-load tap changers (OLTCs) in power transformers.

This comprehensive blog explores the capabilities, features, benefits, and real-world applications of the ABB TCC300, shedding light on how it empowers next-generation substations to meet evolving grid requirements.

Understanding the Role of Tapchanger Controls in Substations

Tapchangers are essential components in power transformers, responsible for regulating voltage levels in response to fluctuating load demands. By adjusting transformer tap positions, they maintain stable voltage at the consumer end, improving efficiency and reducing equipment stress.

Traditionally, OLTCs were controlled using mechanical or analog systems—adequate in their time but lacking the intelligence, communication, and adaptability needed in today’s digitally interconnected grids. With the integration of renewable energy sources, electric vehicles, and distributed generation, voltage stability has become more critical and complex than ever before.

That’s where ABB’s TCC300 steps in. It replaces aging analog controllers with a smart, digital, microprocessor-based solution that integrates seamlessly into modern substation automation systems, ensuring accuracy, visibility, and long-term sustainability.

What is the ABB TCC300?

The ABB TCC300 is a compact, powerful digital tapchanger control numerical relay designed for monitoring, metering, and controlling OLTC operations. It is optimized for both new installations and retrofit applications, allowing utility operators to future-proof their infrastructure without massive investments or extensive rewiring.

Whether you're replacing legacy tapchanger relays or deploying next-gen smart substations from scratch, the TCC300 delivers a blend of flexibility, precision, and intelligence to manage voltage regulation efficiently and securely.

Key Features and Benefits of ABB TCC300

Let’s explore the features that make the TCC300 a standout tapchanger controller in the industry:

1. Advanced Monitoring and Metering Capabilities: The TCC300 provides robust monitoring of essential transformer parameters. It supports:

Single and three-phase demand metering

Accurate time/date-stamped data logging

Real-time tracking of voltage, current, and power metrics

This high-resolution metering allows utility teams to gain granular insights into transformer performance, facilitating predictive maintenance, compliance reporting, and operational efficiency.

2. Harmonic Analysis and Smart Load Management: Power quality is a growing concern in today’s grid. The TCC300 supports 64 samples per cycle, enabling accurate harmonic monitoring up to the 31st harmonic of current and voltage. This level of detail helps utilities:

Detect and mitigate harmonic distortions

Protect sensitive equipment

Maintain power quality standards

It also features:

Line Drop Compensation (LDC) using R & X or Z methods

Smart Reverse Power Detection to prevent unwanted backfeeding, especially important in DER-rich grids

This enables operators to maintain voltage profiles and prevent undesirable conditions such as reverse power flows that could destabilize the system.

3. Powerful Communication Capabilities: In the age of Industry 4.0, connectivity is everything. The TCC300 offers:

Support for open communication protocols like IEC 61850, DNP 3.0, and Modbus

Optional RJ45 Ethernet, fiber optic Ethernet, and Bluetooth interfaces

Wireless configuration and remote diagnostics

This makes it easier than ever to integrate the TCC300 into SCADA, EMS, or other digital platforms, ensuring real-time data exchange, fast control response, and simplified remote management.

4. Cybersecurity Readiness: With growing threats to critical infrastructure, ABB has embedded multiple layers of cybersecurity in the TCC300:

Role-based access control

Encrypted communication

Secure firmware and configuration updates via SD card, eliminating laptop dependency

This reduces the attack surface and safeguards the system from unauthorized tampering or accidental configuration errors.

5. Easy Installation and Retrofitting: The TCC300 is engineered with a retrofit-friendly design, minimizing the challenges traditionally associated with equipment upgrades. ABB provides:

Adapter panels compatible with legacy systems

Built-in CT shorting protection

Flexible mounting configurations

This plug-and-play approach shortens project timelines, reduces installation costs, and avoids extended substation outages during transition.

6. Transformer Paralleling and Coordination: In many substations, multiple transformers operate in parallel. The TCC300 simplifies their coordination with support for:

Circulating current method

Master/Follower peer-to-peer circuitry

Reactive power (VAR) sharing

Up to 16 transformers in parallel

Such capabilities ensure load balance, voltage stability, and efficient transformer usage across complex electrical networks.

7. Wide Environmental Tolerance: With an operating range from -40°C to +80°C, the TCC300 is built to endure the most extreme environmental conditions—be it scorching heat, freezing cold, or high humidity. This durability ensures reliable operation in outdoor or remote substations where maintenance access is limited.

Integration with ABB TCC600 Software

Ease of configuration and diagnostics is critical for efficient relay management. The TCC300 integrates seamlessly with ABB’s TCC600 software, providing:

A menu-driven user interface for intuitive navigation

Remote or local access via modem or serial connection

Configuration, event log access, and performance diagnostics

This powerful tool reduces technician training time and ensures rapid fault resolution, enhancing operational continuity.

Applications and Use Cases

The versatility of the ABB TCC300 allows it to be deployed across a wide range of power environments:

Utility Companies Modernizing Legacy Infrastructure: Replacing outdated analog tapchanger relays in existing substations without full-scale upgrades.

Smart Grids and DER-Integrated Networks: Where real-time communication, fast response, and intelligent controls are essential for managing solar, wind, and other distributed energy sources.

Industrial Plants and Large Facilities: To maintain precise voltage regulation for sensitive manufacturing equipment and machinery.

Renewable Energy Installations: For managing voltage fluctuations and coordinating with fluctuating generation profiles.

Remote or Harsh Climate Substations: Where environmental resilience and remote monitoring are crucial to reduce operational risks and maintenance visits.

Why Choose ABB?

ABB is a trusted global leader in power technology with a legacy of delivering innovative, durable, and intelligent electrical solutions. With the TCC300, ABB brings a product that blends decades of industry expertise with modern digital advancements.

Unique Selling Points:

Compact footprint with maximum functionality

Global protocol compliance for easy integration

Intuitive software support with TCC600

Secure and firmware-friendly operation

Efficient retrofitting and minimal rewiring

Robust analytics and paralleling tools

Utilities, EPCs, and industrial clients gain long-term value through reduced operational risk, improved grid reliability, and optimized transformer performance.

Conclusion

The ABB TCC300 Digital Tapchanger Control Numerical Relay is more than just an upgrade—it's a strategic investment for a smarter, more connected, and more secure power grid. In an era of growing complexity, the TCC300 offers a reliable foundation for substation automation, advanced monitoring, and dynamic control.

By adopting this state-of-the-art controller, power operators can:

Modernize outdated systems

Improve grid reliability and efficiency

Ensure seamless communication and cybersecurity

Scale up for future energy trends and regulations

Whether you're transitioning into smart grid operations or seeking to enhance transformer performance, the ABB TCC300 is your gateway to next-generation voltage regulation.Click here to explore the product category and connect with Digital & Smart Grid Enterprises today. Discover how the ABB TCC300 can unlock operational excellence, reduce downtime, and deliver unmatched control over your voltage regulation needs.

#SmartGridSolutions#PowerSystemAutomation#SubstationInnovation#VoltageRegulation#ABBRelay#DigitalTapchanger#GridReliability#FutureReadyGrid#SubstationControl#IndustrialAutomation#EnergyEfficiency#PowerTransformer#GridModernization#RelayProtection#ElectricalEngineering

0 notes

Text

𝐗𝐋𝟔𝟎𝟎𝟗 𝐋𝐌𝟐𝟓𝟗𝟔𝐒 𝐃𝐂-𝐃𝐂 𝐒𝐭𝐞𝐩 𝐔𝐩 𝐃𝐨𝐰𝐧 𝐁𝐨𝐨𝐬𝐭 𝐁𝐮𝐜𝐤 𝐕𝐨𝐥𝐭𝐚𝐠𝐞 𝐏𝐨𝐰𝐞𝐫 𝐂𝐨𝐧𝐯𝐞𝐫𝐭𝐞𝐫 𝐌𝐨𝐝𝐮𝐥𝐞

Specification :-

Input: 3.5-28V

Output: 1.25V-26V

Maximum Input Current: 3A

Maximum Output: 3A

Rated Input: 1A, Output: 1A

Size: 60mm x 37mm

The XL6009 LM2596S DC-DC Step Up Down Boost Buck Voltage Power Converter Module is a versatile and efficient power regulation module that can both step up (boost) and down (buck) input voltage to deliver a stable output. Equipped with the XL6009 and LM2596S chipsets, this converter module allows for wide input voltage ranges and precise output voltage control, making it ideal for various electronic applications requiring different voltage levels. The module operates efficiently in both buck (step-down) and boost (step-up) modes, supporting input voltages typically ranging from 3V to 40V. It can output a regulated voltage anywhere from 1.25V to 35V, depending on the application needs. The built-in potentiometer allows users to adjust the output voltage easily. Additionally, its high conversion efficiency reduces energy loss, and the module is equipped with thermal and short-circuit protection for reliability and safety.

Applications :-

Power regulation in battery-operated devices.

Voltage conversion for microcontroller-based projects.

Solar power systems.

Car electronics and voltage regulation for automotive systems.

Robotics and automation projects require stable voltage levels.

XL6009 LM2596S DC-DC Step Up Down Boost Buck Voltage Power Converter Module

Product Description :

The XL6009 LM2596S DC-DC Step Up Down Boost Buck Voltage Power Converter Module is a versatile and efficient power regulation solution capable of both boosting and bucking input voltage to deliver a stable output. Powered by the XL6009 and LM2596S chipsets, this module offers wide input voltage compatibility and precise output voltage control, making it suitable for a broad range of electronic applications.

Key Features :

Bi-directional voltage conversion: Can step up or step down voltage.

Wide input voltage range: Typically operates from 3V to 40V.

Adjustable output voltage: Potentiometer allows for easy output voltage adjustment.

High conversion efficiency: Minimizes power loss and improves overall efficiency.

Thermal and short-circuit protection: Ensures reliability and safety.

Applications :

Battery-powered devices : Provides stable power supply for devices like smartphones, tablets, and portable speakers.

Microcontroller-based projects : Offers a reliable power source for various microcontroller applications.

Solar power systems : Regulates voltage from solar panels to match the requirements of connected devices.

0 notes

Text

Enhanced Power conditioning of capacitor

Enhanced power conditioning of capacitors refers to the utilization of advanced technologies and techniques to improve the performance and reliability of capacitors in electrical systems. By implementing innovative designs and materials, enhanced power conditioning capacitors can effectively regulate voltage, reduce noise and harmonics, and enhance power quality in various applications. These capacitors play a crucial role in stabilizing electrical systems, minimizing disruptions, and ensuring consistent power supply, making them essential components in modern power distribution networks and electronic devices.

0 notes

Text

Power Electronics Market 2024 Report Provides Pin Point Analysis of Changing Competition Dynamics, 2030

The qualitative report published by Exactitude Consultancy research on the “Power Electronics Market offers an in-depth examination of the current trends, latest expansions, conditions, market size, various drivers, limitations, and key players along with their profile details. The Power Electronics market report offers the historical data for 2018 to 2023 and also makes available the forecast data from the year 2024 to 2030 which is based on revenue. With the help of all this information research report helps the Market contributors to expand their market positions. With the benefit of all these explanations, this market research report recommends a business strategy for present market participants to strengthen their role in the market. This report analyzes the impact of the Covid 19 pandemic on the Power Electronics Market from a Global and Regional perspective.

The power electronics market is expected to grow at 5.1% CAGR from 2024 to 2030. It is expected to reach above USD 39.6 billion by 2030 from USD 26.6 billion in 2023.

For The Full Report Click here:

https://exactitudeconsultancy.com/reports/13742/power-electronics-market/

#PowerElectronics#ElectronicsIndustry#EnergyEfficiency#RenewableEnergy#ElectricPower#SmartGrid#PowerConversion#PowerSupply#Semiconductor#ElectricVehicle#SolarPower#WindEnergy#PowerSystems#EnergyStorage#IndustrialAutomation#IntegratedCircuits#VoltageRegulation#PowerManagement#ElectronicComponents#FutureTech

0 notes

Text

Optimizing Performance: Strategies for Successful Power Transformer Testing & Commissioning

Power transformers are the silent giants that form the backbone of electrical distribution networks. Ensuring their optimal performance is not just a matter of reliability but a critical component of maintaining the integrity and efficiency of the entire power system. The journey of a power transformer from installation to full operation involves meticulous testing and commissioning processes. This blog unravels the strategies and best practices essential for the successful testing and commissioning of power transformers, emphasizing the significance of this phase in optimizing overall performance.

The Vital Role of Power Transformers

Power transformers serve as the linchpin in the transmission and distribution of electrical energy. From stepping up voltages for efficient long-distance transmission to stepping down voltages for safe distribution to end-users, transformers play a crucial role in the power grid. The success of the entire power system depends on the reliability and efficiency of these transformers.

Our team of professionals provides all types of transformer testing and commissioning. We operate at all voltage ranges, including MV, EHV, HV, and LV. In addition, we handle ETC for GIS and AIS substations. We take great pride in having our cutting-edge testing apparatus so that we can rapidly complete the task on our own and do the essential testing of the transformers.

Unveiling the Strategies for Successful Testing & Commissioning

Thorough Pre-Commissioning Inspection: Before the testing process begins, a comprehensive pre-commissioning inspection is paramount. This involves a meticulous review of the transformer's construction, ensuring that all components are in place and meet design specifications. Visual inspections, oil and insulation checks, and examination of auxiliary systems are integral to this phase.

Functional Testing of Components: Each component of a power transformer must undergo functional testing to validate its individual performance. This includes tests on bushings, tap changers, cooling systems, and protective devices. Verifying the functionality of these components ensures that the transformer is equipped to handle various operating conditions.

Dielectric Testing: Dielectric tests are critical for assessing the insulation integrity of a transformer. Power transformers operate at high voltages, and ensuring the dielectric strength of insulation materials is crucial to prevent breakdowns. Common dielectric tests include the power factor test, dielectric absorption test, and insulation resistance test.

Ratio and Polarity Tests: The ratio and polarity tests are fundamental to confirm that the transformer windings are configured correctly. Any discrepancies in the turns ratio or polarity could lead to improper voltage transformation, affecting the overall performance of the transformer. Precision in these tests is vital to guarantee accurate voltage regulation.

Winding Resistance Measurement: Winding resistance measurements provide insights into the health of transformer windings and connections. Deviations from expected values could indicate issues such as loose connections or high-resistance joints. Addressing these concerns during the testing phase prevents potential failures during operation.

Oil Quality Analysis: For oil-immersed transformers, the condition of the insulating oil is a critical factor. Routine oil quality analysis assesses parameters such as moisture content, acidity, and the presence of contaminants. Clean and well-maintained oil contributes to enhanced insulation and cooling performance.

Insulation Resistance Measurement: Insulation resistance is a key parameter for evaluating the insulation condition of a transformer. Insulation resistance measurements help identify any leakage paths or insulation degradation. This test is particularly crucial for detecting issues such as moisture ingress or insulation aging.

Dynamic Short Circuit Withstand Test: The dynamic short circuit withstands test simulates the transformer's response to short-circuit conditions. This test evaluates the mechanical and thermal stability of the transformer under high-stress scenarios. Successful performance in this test ensures that the transformer can withstand fault conditions without catastrophic failure.

Temperature Rise Test: The temperature rise test assesses the thermal performance of a transformer under normal operating conditions. By measuring the temperature rise of key components during full-load operation, this test verifies that the transformer can dissipate heat effectively and avoids excessive temperature levels that could compromise insulation life.

Commissioning with Load: Commissioning a transformer with an actual load is the final step to validate its performance in real-world operating conditions. Monitoring parameters such as voltage regulation, load losses, and overall efficiency during commissioning provides a comprehensive assessment of the transformer's capabilities.

Elevating Transformer Performance through Testing & Commissioning

Reliability Assurance: Thorough testing and commissioning instill confidence in the reliability of a power transformer. Identifying and addressing potential issues during the testing phase mitigates the risk of unexpected failures during actual operation. This reliability assurance is fundamental for the transformer's long-term performance.

Optimal Efficiency: Efficiency is a cornerstone of power system performance, and transformers play a crucial role in energy transfer. Rigorous testing and commissioning ensure that the transformer operates at its peak efficiency, minimizing energy losses and contributing to the overall efficiency of the power grid.

Preventive Maintenance Insights: The data gathered during testing and commissioning provide valuable insights for future preventive maintenance. Understanding the transformer's performance characteristics under different conditions allows operators to develop targeted maintenance strategies, prolonging the transformer's lifespan and reducing the likelihood of unplanned outages.

Compliance with Standards: Adhering to industry standards and specifications is non-negotiable in the power sector. Testing and commissioning processes are designed to verify compliance with these standards, ensuring that the transformer meets the required performance and safety criteria. Compliance is not just a regulatory requirement but a commitment to delivering quality and reliability.

Enhanced Safety: Safety considerations are paramount in power transformer operations. Thorough testing and commissioning uncover potential safety hazards and allow for corrective measures to be implemented. This proactive approach contributes to a safer working environment for maintenance personnel and ensures that the transformer operates within established safety parameters.

Services provided for the testing and commissioning of power transformers.

Offline Testing

• Functional Checking of Protection Devices like PRV, Buchoze Relay, MOG, OTI, WTI

• Dielectric Frequency Response Analysis (DFR)

• Capacitance and Tan Delta Measurement of Transformer

• Transformer Turns Ratio Measurement Ratio

• Magnetic Balance Measurement

• Winding Resistance Measurement

• Insulation Resistance and Polarization Index Measurement

• OTI and WTI Meter Calibration

• Sweep Frequency Response Analysis Measurement

Online Testing

Partial Discharge Measurement and Localization

• Thermography

• Online moisture content Measurement

• Transformer Oil (Screening, DGA and Furan) Test

Conclusion

The journey of a power transformer from installation to full operation is a meticulous process that demands precision and attention to detail. Testing and commissioning are not merely procedural steps; they are integral to ensuring the transformer's optimal performance, reliability, and safety.

By adopting a strategic approach to testing, power utilities, and industries can elevate the performance of transformers, contributing to the overall efficiency and resilience of the power infrastructure.

As the energy landscape evolves, the role of power transformers becomes increasingly pivotal, and the success of this evolution hinges on the thoroughness of testing and commissioning practices. Please click here

#transformertesting#commissioning#powerinfrastructure#electricaltesting#gridperformance#energyefficiency#electricalengineering#utilities#transformermaintenance#powergrid#voltageregulation#testingandcommissioning#energymanagement#optimizedperformance#electricalsafety#powerquality

0 notes

Text

Universal 72W Adjustable Power Adapter 1.5V-24V 3A

Looking for a single power adapter that works with multiple devices? The Universal 72W Adjustable Power Adapter is your all-in-one solution for powering a wide range of electronics. With a wide adjustable voltage range from 1.5V to 24V and a maximum current output of 3A, this adapter offers powerful and reliable performance for everyday use.

Perfect for gadgets like routers, LED strips, CCTV cameras, speakers, monitors, and small appliances, this adapter is built for versatility. Thanks to its easy voltage selector, you can adjust the output voltage as needed, ensuring your device gets the correct power every time. No more juggling multiple adapters or worrying about compatibility issues!

The adapter comes with a set of interchangeable DC tips, making it universally compatible with most popular electronics. It’s a great backup adapter to have around the home, office, or workshop, and it's especially handy for travelers, technicians, and DIY enthusiasts.

Safety is a top priority with this adapter. It features built-in over-voltage, over-current, short circuit, and over-temperature protection, giving you peace of mind when charging sensitive electronics. Plus, its energy-efficient design helps reduce power consumption while maintaining consistent output.

The sleek, compact build ensures portability without sacrificing durability. Whether you're using it as a replacement adapter or a go-to power solution for multiple devices, this 72W adapter delivers convenience, safety, and efficiency in one smart package.

Make your life easier and your workspace neater with the Universal 72W Adjustable Power Adapter – a powerful solution for all your electronic needs.

#UniversalAdapter#PowerAdapter#AdjustableAdapter#72WCharger#MultiVoltageAdapter#SmartCharger#ElectronicAccessories#LaptopAdapter#HomeElectronics#TechEssentials#Callsa#PortableCharger#3ACharger#VoltageRegulator#PowerSupply

0 notes

Text

BQ25185 all-in-one Li-Poly board with 3.3V out 🔋🌞⚡

We had a previous version of this 3.3V buck output board with an MCP73831, but now we've replaced it with a BQ25185, which makes it a little more flexible: Vin can be up to 18V, and solar panels will work, too. There's also a power path and 4.5V regulated output. This charger chip can handle LiFePO4, but for that chip, we might swap the buck for a buck-boost or a boost / LDO to get the solid 3.3V output. Coming soon.

#BQ25185#ti#texasinstruments#lipoly#LiFePO4#adafruit#chargerboard#batterymanagement#solarpower#powerpath#voltageregulation#embeddedhardware#lithiumbattery#buckconverter#boostconverter#ldoregulator#hardwaredesign#powersupply#electronicsengineering#lowpowerdesign#comingsoon#ic

4 notes

·

View notes

Text

Padmavahini’s Auto Transformers: Efficient Voltage Regulation for Modern Industries

What is an Auto Transformer? An auto transformer is a type of electrical transformer with a single winding that acts as both the primary and secondary winding. This design allows for a portion of the winding to be common to both sides, enabling voltage transformation with improved efficiency and reduced material usage. Auto transformers are commonly used for voltage regulation, stepping up or stepping down voltages in various applications.

Purpose of Padmavahini’s Auto Transformers:

The primary purpose of an auto transformer is to regulate and adjust voltage levels efficiently in electrical systems where the voltage change is relatively small. Padmavahini manufactures auto transformers specifically to:

Stabilize Voltage Supply: Correct voltage drops during transmission and distribution, ensuring steady performance.

Enable Efficient Step-Up/Step-Down Operations: Especially useful when the difference between input and output voltage is minimal.

Reduce Equipment Size and Cost: By using a single winding design, material usage is minimized, lowering production and installation costs.

Support Industrial Applications: Ideal for industries requiring compact and cost-effective transformers for motor starting, lighting systems, and power distribution.

Key Features:

Voltage Regulation: Effectively corrects voltage drops, maintaining consistent output.

Robust Construction: Designed for durability and reliability in demanding environments.

Customizable Specifications: Tailored to meet specific customer requirements regarding capacity, primary voltage, and frequency.

Cooling Options: Available with ONAN, ONAF, or AN cooling systems.

Compliance with Standards: Manufactured in accordance with IEC 60076 and IS 2026 standards.

Benefits:

Cost-Effective: Reduced material usage leads to lower manufacturing costs.

Improved Efficiency: Better voltage regulation compared to traditional transformers.

Lightweight Design: Simplifies installation and reduces structural support requirements.

Versatile Applications: Suitable for use in various industries, including heavy engineering and electronics.

Conclusion: Padmavahini's auto transformers offer an efficient and economical solution for voltage regulation needs across diverse industrial applications. With their robust design, compliance with international standards, and customizable features, these transformers are well-suited to meet the evolving demands of modern industries.

#AutoTransformer#VoltageRegulation#PadmavahiniTransformers#EfficientPowerSolutions#IndustrialTransformers#MadeInIndia#ElectricalEngineering#PowerDistribution#TransformerTechnology#CoimbatoreManufacture

0 notes

Text

Enhancing Industrial Power Systems with Basler Electric Products

Introduction

Basler Electric is a reliable brand when it comes to industrial automation and power management and is renowned for its superior-quality voltage regulators, protection relays, and excitation systems. These are essential for maintaining power generation stability, efficient automation processes, and optimal industrial operations. We at Aeliya Marine provide a varied assortment of Basler Electric products to suit many power and automation requirements. This post discusses the relevance of Basler Electric solutions, their uses, and why Basler Electric is a great choice for industrial applications.

Why to Opt for Basler Electric Products?

Basler Electric has gained a good image in power control and automation technology with products that offer :

Exceptional voltage regulation for continuous power supply

Next-generation protection relays to secure industrial devices

Robust excitation systems to improve power generation

Efficient power management systems for improved performance

Durability and longevity, thus being economical in the long term

Most Important Basler Electric Products That You Can Find at Aeliya Marine

Aeliya Marine offers a range of Basler Electric products aimed at addressing the requirements of industrial automation and power generation. Some of the most important products include :

1. Basler Voltage Regulators :

Basler Electric voltage regulators provide stable and consistent power output by regulating voltage fluctuations in industrial systems. Basler regulators are used extensively in power plants, marine systems, and manufacturing industries to ensure operational efficiency.

2. Basler Protection Relays :

Protective relays of Basler play a crucial role in protecting electrical equipment from faults, overloads, and short circuits. Basler protection relays offer real-time monitoring and rapid response to avoid damage and downtime in power systems.

3. Basler Excitation Systems :

Basler Electric excitation systems are utilized in power generators to regulate and stabilize generator output for optimal performance. These systems play a crucial role in sustaining stable power generation in industrial and marine applications.

4. Basler Power Management Solutions :

Basler’s power management systems assist in maximizing energy use, minimizing operational expenses, and improving system reliability. They find extensive applications in industries with exacting power control requirements, like oil & gas, marine, and utility applications.

Applications of Basler Electric Products

Basler Electric products find extensive applications in various industries to maximize power stability and efficiency in automation. Some of their major applications are :

Power Generation Plants : Excitation systems and voltage regulation for stable power generation

Marine and Offshore Industry : Power management systems for ships and offshore platforms

Industrial Automation : Protection relays to protect equipment and avoid breakdowns

Oil & Gas Industry : Stable power systems for vital operations

Data Centers & IT Infrastructure : Stable power supply and system stability assurance

Why Buy from Aeliya Marine

Aeliya Marine is your one-stop supplier of Basler Electric automation and power solutions, providing :

Huge collections of excellent Basler Electric products

Competitive prices and discounts for bulk orders

Specialist technical advices and suggestions

Secure and fast shipping all over the world

Conclusion

Basler Electric products are fundamental in providing stable, efficient, and reliable power systems in industrial processes. If you require voltage regulators, protection relays, excitation systems, or power management solutions, Basler Electric provides innovative technology for smooth operation. Through Aeliya Marine, we offer a broad range of Basler Electric products to enable you to attain maximum performance and reliability.

Visit our Basler Electric product line at Aeliya Marine today!

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#Basler Electrical#automationbrand#brand blog#aeliyamarine#powermangment#voltageregulators#powergeneration#oilandgasindustrial#electricalegineering#automationtechnologi#reliablepower#powersupply

0 notes

Text

LNBP20PD

Power SO Tube LNB Supply and Voltage Regulator 15V to 25V 20-Pin

0 notes

Text

Siemens Building Technology S55155-A111-24Vac 0-10 Vdc Control Sr 300N | PartsHnC

The Siemens Building Technology S55155-A111 voltage regulator functions by converting a standard 24-volt AC input into a variable 0-10 volt DC output. This variable DC output then serves to control the speed of various HVAC equipment, including fans, pumps, and valves. By precisely regulating the speed of these components, the S55155-A111 enables efficient control of airflow, water flow, and other crucial system parameters within an HVAC system. This precise control ultimately translates to improved energy efficiency, optimized comfort levels, and reduced operational costs. In essence, the S55155-A111 acts as the maestro of an HVAC system, ensuring its components operate in perfect harmony to deliver optimal performance.

#partshnc#airconditionerparts#hvacparts#partshncbuzz#furnaceparts#SiemensBuildingTechnology#SiemensBuildingTechnologyParts#S55155-A111#VoltageRegulator

0 notes

Text

𝐋𝐌𝟕𝟖𝟏𝟐 𝟏𝟐𝐕 𝐃𝐂 / 𝐀𝐂 𝐓𝐡𝐫𝐞𝐞 𝐓𝐞𝐫𝐦𝐢𝐧𝐚𝐥 𝐕𝐨𝐥𝐭𝐚𝐠𝐞 𝐑𝐞𝐠𝐮𝐥𝐚𝐭𝐨𝐫 𝐏𝐨𝐰𝐞𝐫

The LM7812 12V DC/AC Three Terminal Voltage Regulator is a versatile and reliable component designed to deliver a stable 12V output from a higher and variable input voltage. Ideal for a wide range of electronic applications, this voltage regulator can handle input voltages between 15V and 24V, making it suitable for both DC and AC power sources. With a maximum output current of 1.2A, the LM7812 is perfect for use in regulated power supplies, voltage stabilization circuits, and various DIY electronics projects. It features built-in protection mechanisms, including thermal overload protection, short-circuit protection, and safe area protection, ensuring safe and reliable operation. The simple three-terminal design (input, ground, and output) allows for easy integration into circuits, while its durable construction ensures long-lasting performance. Whether for hobbyist projects or professional applications, the LM7812 provides a dependable solution for maintaining a consistent 12V power supply.

Applications :-

Power Supplies

Voltage Stabilization

DIY Electronics Projects

Used in automotive electronics

Features:-

Fixed Output Voltage

High Output Current

Wide Input Voltage Range

Short-Circuit Protection

Simple three-terminal design (input, ground, and output)

#Electronicspices#VoltageRegulator#12VPowerSupply#DCVoltage#ACVoltage#ElectronicsProject#DIYElectronics#PowerSupplyCircuit#ThreeTerminalRegulator#ElectronicComponents

0 notes