#Wind Turbine Operations and Maintenance

Explore tagged Tumblr posts

Text

/PRNewswire/ -- The global Wind Turbine Operations and Maintenance Market is anticipated to grow from estimated USD 39.61 billion in 2025 to USD 59.67 billion by 2030, at a CAGR of 8.5% during the forecast period. The major factors driving the Wind Turbine Operations and Maintenance Market include the increased need for energy efficiency and the global trends toward carbon neutrality and sustainability. There is a significant increase in the number of wind energy installations around the world. As installations rise, there is a corresponding increase in demand for effective O&M services to ensure the performance and longevity of wind turbines. O&M practice is changing quickly due to the development of new technology such as predictive maintenance, remote monitoring, and artificial intelligence. Technologies allow owners/operators to have a proactive approach to detecting issues and minimizing downtime. The support for renewable energy projects from government incentives and policy is also a driver of the market. From an environmental perspective, there is a shift towards sustainability. This drives the O&M market as many operators are adopting more sustainable practices for maintenance and retaining or refurbishing used components rather than eliminating them altogether.

#wind turbine operations and maintenance#wind turbine operations and maintenance market#wind turbine operations#wind turbine maintenance#wind turbines#wind turbine#offshore wind farms#offshore wind farm#offshore wind#wind energy#wind power#energy#energia#power generation#utilities#power#renewableenergy#renewable power#electricity#renewable resources#renewable energy#clean energy

0 notes

Text

Maximizing Wind Turbine Operations and Maintenance Efficiency

Wind turbines play a pivotal role in harnessing renewable energy and mitigating climate change. However, to ensure optimal performance and longevity, efficient operations and maintenance (O&M) practices are essential. By maximizing efficiency in wind turbine operations and maintenance, stakeholders can enhance energy production, minimize downtime, and improve overall project viability.

Implementing Proactive Maintenance Strategies

Proactive maintenance is crucial for optimizing Wind Turbine Operations and Maintenance efficiency.

By regularly inspecting components, identifying potential issues early, and performing preemptive repairs or replacements, operators can minimize downtime and prevent costly breakdowns.

Leveraging Advanced Monitoring Technologies

Advanced monitoring technologies, such as condition monitoring systems and predictive analytics, offer valuable insights into wind turbine health and performance.

By continuously monitoring key parameters such as vibration, temperature, and oil quality, operators can detect anomalies in real-time, allowing for timely intervention and optimized maintenance scheduling.

Optimizing Maintenance Scheduling

Effective maintenance scheduling is essential for maximizing wind turbine operations and maintenance efficiency.

By prioritizing tasks based on criticality and resource availability, operators can minimize downtime and ensure that maintenance activities are conducted in a timely and cost-effective manner.

Investing in Training and Skills Development

Well-trained and skilled personnel are vital for efficient wind turbine operations and maintenance.

Investing in comprehensive training programs and skills development initiatives ensures that maintenance teams are equipped with the knowledge and expertise required to perform their duties safely and effectively.

Get More Insights On This Topic: Wind Turbine Operations and Maintenance Market

Explore More Related Topic: Wind Turbine Operations and Maintenance Market

#Wind Turbine Operations and Maintenance#Renewable Energy#Sustainable Practices#Predictive Maintenance#Energy Efficiency#Environmental Stewardship#Wind Power#Green Technology

0 notes

Text

Wind Turbine Operation and Maintenance Market: Role in Extending Turbine Lifespan and Maximizing Efficiency

The Wind Turbine Operation and Maintenance Market size was valued at USD 16.46 billion in 2023 and is expected to grow to USD 29.58 billion by 2031 and grow at a CAGR of 7.6% over the forecast period of 2024–2031.

Wind turbine O&M plays a crucial role in ensuring the efficiency, reliability, and longevity of wind energy assets. With an increase in both onshore and offshore wind installations, the demand for skilled O&M services is rising rapidly. These services not only help maintain consistent power generation but also reduce unexpected breakdowns and downtime, resulting in improved return on investment (ROI) for wind energy developers.

The shift towards renewable energy, combined with advancements in digital tools like IoT and AI for predictive maintenance, is transforming the O&M sector. Predictive maintenance, remote monitoring, and advanced diagnostic systems are being adopted to identify potential issues before they escalate, minimizing operational interruptions and maintenance costs. As a result, the market is moving toward more efficient and cost-effective maintenance strategies, making wind energy more competitive and sustainable.

Key Market Drivers

Increasing Global Wind Power Installations: Rapid growth in wind turbine installations, driven by government policies, is creating substantial demand for ongoing O&M services to ensure operational efficiency.

Focus on Extending Wind Turbine Lifespan: Regular O&M services are essential for extending the lifecycle of turbines, enabling operators to maximize their investment by enhancing reliability and output.

Technological Advancements in Predictive Maintenance: IoT, AI, and big data analytics are enabling proactive maintenance, helping reduce unexpected failures and extending equipment lifespan, thereby reducing overall O&M costs.

Growing Offshore Wind Market: Offshore wind turbines, which operate in harsher conditions, require regular maintenance to ensure longevity, fueling demand for specialized O&M services.

Government Incentives and Renewable Energy Goals: Policies aimed at reducing carbon emissions and increasing renewable energy use are promoting wind power, further driving the O&M market to support these growing installations.

Market Segmentation

The Wind Turbine Operation and Maintenance Market can be segmented by service type, location, component, and region.

By Service Type

Preventive Maintenance: Scheduled inspections, lubrication, and minor repairs are performed to prevent unexpected issues. This service type is gaining popularity as it minimizes downtime and maximizes operational efficiency.

Corrective Maintenance: Unplanned maintenance is conducted to repair faults or malfunctions. Corrective maintenance is crucial for responding quickly to unexpected breakdowns that could hinder power generation.

Predictive Maintenance: Enabled by advanced monitoring and analytics, predictive maintenance involves forecasting potential issues before they occur, helping avoid costly repairs and enhancing asset reliability.

By Location

Onshore Wind Turbines: Onshore O&M services are more accessible and less expensive, as technicians can reach installations with relative ease, making it a significant market segment.

Offshore Wind Turbines: Offshore turbines require specialized maintenance due to their remote locations and exposure to harsh marine conditions. The offshore segment is expected to grow with increased offshore wind energy installations globally.

By Component

Blades: Blades undergo wear and tear from weather exposure, necessitating regular inspection, repair, or replacement to ensure performance.

Generator: The generator is essential for converting mechanical energy into electricity, and its upkeep is critical for maintaining energy output.

Gearbox: The gearbox requires routine maintenance to prevent breakdowns and enhance performance, as it experiences high mechanical loads and stress.

Others: Includes components such as the tower, yaw system, pitch system, and electrical components, each requiring regular O&M services.

Regional Analysis

North America: North America, particularly the United States, is a significant market due to the country’s large wind energy installations and government incentives for renewable energy. Technological advancements in predictive maintenance and growing offshore installations are also driving the market in this region.

Europe: Europe leads the wind energy sector, with countries like Germany, the U.K., and Denmark heavily investing in offshore wind farms. The European Union’s commitment to reducing carbon emissions and increasing renewable energy use is creating a robust demand for O&M services.

Asia-Pacific: Asia-Pacific is experiencing rapid growth, especially in China and India, where investments in wind energy are rising. The region’s focus on renewable energy expansion, coupled with government initiatives, supports the growth of the wind turbine O&M market.

Middle East & Africa: The wind energy sector in the Middle East & Africa is emerging, with several projects underway, especially in South Africa. Rising awareness and supportive policies for renewable energy are expected to drive market growth in this region.

Latin America: Latin America is witnessing increased wind power adoption, with countries like Brazil and Mexico investing in wind energy to diversify their energy mix and reduce dependence on fossil fuels.

Current Market Trends

Shift Toward Digital and Predictive Maintenance Solutions: The use of digital solutions, such as sensors, remote monitoring, and predictive analytics, is reducing downtime and maintenance costs. These technologies enable operators to detect potential issues early, improving maintenance planning.

Increase in Offshore Wind Projects: Offshore wind farms are growing rapidly, especially in Europe and North America, where coastal locations are ideal for high wind capacity. Offshore projects require specialized O&M services due to their remote locations and challenging environments.

Focus on Extending Turbine Lifecycle and Performance: Companies are investing in advanced O&M practices that maximize the operational lifespan of wind turbines, helping to maintain optimal power generation and minimize costly replacements.

Growth of Independent Service Providers (ISPs): Independent service providers are becoming more prominent, offering competitive and flexible O&M solutions to meet the diverse needs of wind farm operators.

Collaborations and Partnerships: Wind turbine manufacturers and service providers are increasingly forming partnerships to enhance service offerings, improve technology, and deliver comprehensive O&M solutions.

Read Complete Report Details of Wind Turbine Operation and Maintenance Market: https://www.snsinsider.com/reports/wind-turbine-operation-and-maintenance-market-2825

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us: Akash Anand — Head of Business Development & Strategy [email protected] Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

Wind Turbine Operations & Maintenance Market

0 notes

Text

Switchgear Solutions for Solar and Wind Energy Systems

Why Switchgear Matters in Solar and Wind Systems

Switchgear plays a central role in controlling, isolating, and protecting electrical equipment. In renewable energy applications, it helps:

· Manage power flow from variable energy sources.

· Protect systems from faults or overloads.

· Ensure seamless grid integration and disconnection when needed.

Unlike traditional power plants, solar and wind systems generate intermittent power, requiring switchgear that can handle dynamic loads and frequent switching.

Challenges in Renewable Energy Applications

Here are some of the unique challenges renewable energy systems face — and how they impact switchgear selection:

1. Variable Output

Solar and wind energy production fluctuates based on weather and time of day. This demands switchgear that can:

· Handle frequent load changes.

· Operate reliably under fluctuating voltages and currents.

2. Decentralized Generation

Unlike centralized grids, solar and wind systems are often spread out across multiple locations.

· Modular, compact switchgear is preferred for such installations.

· Smart monitoring becomes critical to manage performance remotely.

3. Harsh Environments

Wind turbines operate at high altitudes, and solar farms are often exposed to heat, dust, or salt.

· Switchgear needs to be rugged, weather-resistant, and have high IP ratings.

· Outdoor switchgear enclosures and temperature management are essential.

Key Features of Switchgear for Solar & Wind

When designing or upgrading renewable energy systems, look for switchgear that offers:

1. Remote Monitoring and Control

Smart switchgear integrated with IoT technology allows operators to track real-time data, detect faults early, and optimize system performance.

2. High Interruption Capacity

Wind and solar systems may experience voltage spikes. Modern switchgear provides high breaking capacities to safely interrupt fault currents.

3. Modular Design

Allows for easy upgrades and maintenance — crucial for scaling renewable installations.

4. Eco-Friendly Design

Look for SF₆-free switchgear that uses clean air or other sustainable alternatives to reduce environmental impact.

5. Hybrid Capabilities

Switchgear that can connect both AC and DC sources is increasingly valuable in mixed-source grids.

LV, MV, and HV Switchgear for Renewables

· Low Voltage (LV) Switchgear: Used in residential or small-scale solar systems. Compact, safe, and cost-effective.

· Medium Voltage (MV) Switchgear: Ideal for commercial and industrial solar/wind applications.

· High Voltage (HV) Switchgear: Essential for utility-scale wind farms or solar plants feeding into the national grid.

Each type requires specific protection, metering, and automation components tailored to its load and system requirements.

Final Thoughts

Switchgear is the backbone of any successful solar or wind energy system. As these technologies become more mainstream, the demand for resilient, intelligent, and environmentally friendly switchgear solutions will continue to rise.

Whether you’re an energy consultant, project developer, or facility manager, choosing the right switchgear today will set the stage for long-term efficiency, safety, and scalability.

8 notes

·

View notes

Text

Here’s a few, brief, cliff notes.

The UK plan is to shut down natural gas and so remove the back up to intermittent “renewables”.

Gas and nuclear rely on turbines rotating at 3,000 rpm to produce 50 cycles – renewables produce direct current – requiring an adjustment to convert to the alternating current used by the grid.

From here:

Gas powered electricity accounts for at leas 50% at all times. The Marxist lunatics want to turn it off by 2030.

Here is a 47-minute video:

Will blackouts come to Britain?

On 8 January 2025, wind provided just 2.5 GW (out of the claimed 17 GW) and imports of electricity from overseas interconnectors could only provide 5.7 GW – demand was for 47 GW.

Loss of load probability was 29% - it is usually zero – meaning power blackouts were possible.

NESO = National Energy System Operator - a quasi-autonomous non-government organisation – QANGO – formed when the Marxist Labour government bought out the grid assets from National Grid plc – with taxpayers money a few months ago.

Demark had to defer maintenance in order to supply 700 MW (not GW) from Demark – thy dd the UK a favour – the Danes were under no compulsion to send the electricity over.

2 notes

·

View notes

Text

Boom Truck Market Growth Secrets: Strategies Fueling the Top Players

Introduction to the Boom Truck Market Landscape

The global boom truck market is entering a transformative phase as industries demand more agile, efficient, and safe lifting solutions. Boom trucks, which merge the capabilities of flatbed transport with hydraulic lifting systems, have become indispensable assets in sectors ranging from construction to telecommunications. As of 2023, the global boom truck market was valued at $34.10 billion and is projected to rise significantly, reaching $56.30 billion by 2031, expanding at a CAGR of 5.5% during the 2024–2031 forecast period.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40469-global-boom-truck-market

Market Segmentation: Types of Boom Trucks

Articulating Boom Trucks: Precision in Compact Environments

Articulating boom trucks—commonly known as knuckle boom trucks—are engineered with multiple joints, allowing for angular flexibility and pinpoint precision. These models are widely favored in:

Urban infrastructure upgrades

Utility maintenance in narrow alleys

Tree pruning in dense landscapes

Their compact design and articulation enable seamless operations in confined spaces, making them ideal for precision lifts in urban centers and utility sectors.

Telescopic Boom Trucks: Unmatched Vertical Reach

Telescopic boom trucks are designed for height and heavy-duty lifting. Their straight, extendable booms provide the vertical range necessary for:

High-rise construction

Billboard installations

Wind turbine maintenance

Capable of reaching elevations well over 150 feet, these trucks are indispensable in projects where vertical access and stability are paramount.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40469-global-boom-truck-market

Boom Truck Market Segmentation: By Lifting Capacity

Below 10 Tons: Urban Efficiency

Compact boom trucks in this category are optimized for:

Residential roofing

Small-scale utility operations

Inner-city renovations

10–20 Tons: Mid-Sized Versatility

This segment balances power with mobility, making it suitable for:

Roadway enhancements

Telecom installations

Light industrial maintenance

21–40 Tons: Industrial Backbone

These models are crucial for:

Manufacturing logistics

Warehouse construction

Mid-rise commercial developments

41–60 Tons: Infrastructure-Grade Power

Primarily used in:

Highway and bridge construction

Factory-scale material lifts

Large-scale equipment installation

Above 60 Tons: Heavy-Lift Titans

These elite models dominate:

Offshore oil rigs

Shipbuilding yards

Aerospace component handling

Boom Truck Market Segmentation: By Boom Length

Below 50 Feet: Nimble and Compact

Perfect for light-duty tasks in:

Landscaping

Sign maintenance

Urban lighting installations

50–100 Feet: The Industry Standard

Widely used in:

Utility work

Regional construction

Rural development projects

101–150 Feet: Large-Scale Reach

Found in:

Skyscraper assembly

Wind energy projects

Bridge inspections

Above 150 Feet: Specialized Heights

Indispensable for:

Mega-structure engineering

Long-span bridge construction

Large-scale utility tower projects

Boom Trucks by Industry Application

Construction & Real Estate

Boom trucks streamline high-volume material transport and placement, significantly accelerating project timelines while ensuring site safety.

Energy & Power

Vital for line work, boom trucks play a central role in building and maintaining energy grids and renewable energy infrastructures like wind farms.

Transportation & Logistics

Crucial for moving heavy freight, these trucks enhance operational efficiency in warehouses, ports, and freight yards.

Telecommunications

Enable rapid deployment and maintenance of communication towers, reducing downtime and expanding network reach.

Utilities

Empower crews to safely and efficiently perform maintenance on overhead lines, water towers, and more.

Forestry

Facilitate the safe removal of trees and debris in challenging terrains, enhancing environmental management.

Others

Applications include emergency rescue, event logistics, and industrial maintenance—anywhere vertical lifting or secure positioning is essential.

Regional Boom Truck Market Insights

North America

Dominated by the U.S., the region benefits from extensive infrastructure investment and robust construction demand.

Europe

Germany, the UK, and France lead adoption, driven by smart city initiatives and sustainable infrastructure development.

Asia-Pacific

China, India, and Japan are investing heavily in infrastructure, making the region the fastest-growing boom truck market.

Middle East & Africa

Oil and gas sectors in the GCC countries fuel demand, alongside urbanization efforts in emerging economies.

South America

Brazil shows strong momentum, especially in urban redevelopment and energy infrastructure upgrades.

Competitive Landscape and Key Boom Truck Market Players

Leading companies drive innovation in safety, automation, and sustainability. Key players include:

Manitex International Inc

Terex Rough Terrain Cranes

Altec Industries

Elliott Equipment Company

PALFINGER AG

Tadano Ltd.

LIEBHERR

SANY Group

Zoomlion Heavy Industry Science & Technology Co., Ltd.

The Manitowoc Company, Inc.

Each of these players contributes through specialized product lines, global service networks, and R&D that pushes the boundaries of lifting technology.

Strategic Growth Drivers

Urbanization and smart city developments are prompting the need for compact, high-performance boom trucks.

Green construction initiatives push manufacturers toward electric-powered models.

Automation and remote operations are becoming standard, enhancing safety and precision.

Future Boom Truck Market Outlook (2024–2031)

The boom truck market is poised for significant expansion driven by technological integration, modular designs, and cross-industry demand. Manufacturers are expected to focus on:

Sustainable materials

Electrified drive systems

AI-based remote diagnostics

Autonomous lifting operations

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40469-global-boom-truck-market

Conclusion

The global boom truck market is evolving rapidly, with advances in technology, safety, and capacity. Strategic investments, emerging regional markets, and next-gen features are all set to redefine the industry's trajectory through 2031. Organizations that embrace innovation and operational efficiency will lead this competitive landscape.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

An immersed liquid-cooled load bank is a type of load bank that uses a liquid coolant, typically water or a dielectric fluid, to manage the heat generated during electrical testing. These load banks are designed to dissipate large amounts of heat efficiently, making them ideal for high-power applications where traditional air-cooled systems might be insufficient.

Key Features of Immersed Liquid-Cooled Load Banks:

Efficient Heat Dissipation: The use of liquid cooling allows for the rapid transfer of heat away from the resistive elements, maintaining optimal performance even during extended testing periods.

Compact Design: Because liquid cooling is more efficient than air cooling, these load banks can be more compact, fitting into smaller spaces while still handling significant power loads.

High-Power Capacity: Immersed liquid-cooled load banks are capable of handling very high power loads, making them suitable for testing large generators, UPS systems, and other high-power equipment.

Durability and Longevity: The liquid cooling system not only helps in managing heat but also extends the life of the resistive elements by preventing overheating and reducing thermal stress.

Versatile Applications: These load banks are used in various industries, including data centers, power generation, and renewable energy, where reliable load testing is crucial for maintaining system performance.

Applications:

Generator Testing: Ensures that generators can handle their maximum load without overheating, providing confidence in their reliability during operation.

Data Centers: Used for testing backup power systems to ensure they can sustain critical loads during power outages.

Renewable Energy Systems: Helps in testing the performance and reliability of renewable energy installations, such as wind turbines and solar power systems.

Advantages Over Air-Cooled Load Banks:

Higher Efficiency: Liquid cooling is more effective at heat removal than air cooling, which allows for continuous operation under high load conditions.

Smaller Footprint: The enhanced cooling efficiency allows for a more compact design, saving space in testing environments.

Reduced Noise: Liquid-cooled systems generally produce less noise compared to air-cooled systems, which rely on fans for cooling.

Considerations:

Maintenance: Liquid-cooled systems require regular maintenance to ensure the coolant is clean and the system is free of leaks.

Initial Cost: The upfront cost for an immersed liquid-cooled load bank may be higher than that of an air-cooled equivalent due to the complexity of the cooling system.

2 notes

·

View notes

Text

The Growing Importance of Load Banks in Renewable Energy

As the world pivots towards more sustainable energy sources, renewable energy is playing an increasingly pivotal role in our global energy landscape. Solar, wind, and other renewable resources are being harnessed to meet the ever-growing demand for power. However, as we integrate more renewable energy into our grids, the need for reliable and efficient systems to manage and test these power sources becomes paramount. This is where load banks come into play, and why EMAX Load Bank is at the forefront of supporting the continued growth of renewable energy around the world.

Understanding the Role of Load Banks

Load banks are essential tools used to test the performance and capacity of power systems, including those powered by renewable energy sources. They simulate the electrical load that a power source would experience during regular operation, allowing engineers to assess the efficiency, reliability, and safety of the system. This testing is crucial not only for new installations but also for ongoing maintenance, ensuring that the power systems continue to operate at peak performance.

In the context of renewable energy, load banks are particularly important. Unlike traditional energy sources, renewable energy can be more variable and unpredictable. For instance, solar energy production can fluctuate with weather conditions, and wind power can vary with wind speed. Load banks help mitigate these uncertainties by providing a controlled environment for testing and optimizing these systems, ensuring they can handle the demands of real-world conditions.

Supporting the Growth of Renewable Energy

The global shift towards renewable energy is not just a trend; it’s a necessity. As countries around the world commit to reducing their carbon footprints, the infrastructure supporting renewable energy must be robust and reliable. Load banks are an integral part of this infrastructure, providing the assurance that these systems will perform as needed, even under the most challenging conditions.

EMAX Load Bank is dedicated to supporting the renewable energy sector with high-quality load banks that meet the rigorous demands of modern power systems. Our load banks are designed to simulate real-world conditions accurately, offering precise testing capabilities that are crucial for the development and maintenance of renewable energy installations.

With the rise of large-scale solar farms, wind turbines, and other renewable energy projects, the demand for reliable testing solutions has never been greater. EMAX Load Bank is at the forefront of this demand, providing solutions that help ensure the safety, efficiency, and reliability of renewable energy systems worldwide.

Looking Forward

As we look to the future, the role of load banks will only become more important. The global energy landscape is rapidly evolving, with renewable energy expected to make up an increasing share of the world’s power supply. With this growth comes the need for advanced testing and maintenance solutions that can keep pace with the changing demands of the industry.

EMAX Load Bank is committed to being a part of this future. By providing high-quality load banks, we are helping to pave the way for the continued growth and success of renewable energy around the world. Our solutions are designed to meet the needs of today’s renewable energy projects, while also being adaptable to the innovations of tomorrow.

In conclusion, the future of renewable energy is bright, but it requires the support of reliable and efficient testing tools. Load banks are an essential part of this equation, ensuring that renewable energy systems are ready to meet the challenges of the future. With EMAX Load Bank, you can be confident that your renewable energy projects are in capable hands, backed by the expertise and quality that only a leader in the industry can provide.

2 notes

·

View notes

Text

I understand that there are wind power generating facilities operated by Lessee on a portion of Lessors' property and that I will be responsible for any damage that I inflict on the wind power generating facilities (whether or not such damage is intentional), including, but not limited to wind turbines, overhead power lines, splice boxes, junction boxes, maintenance vehicles, people, signs, maintenance facilities, substation, poles, fences or gates.

2. NO ACCESS of any kind within 300 feet (100 yards) of the wind turbines, buildings or substations.

3. NO ACCESS of any kind within 1000 feet (333 yards) of the wind turbines from the 3rd Sunday of November through the 3rd Sunday of February due to potential icing conditions.

13. PLEASE REMOVE GUT PILES to prevent attracting scavenging raptors to wind farm area.

11 notes

·

View notes

Text

Nuclear-Powered Gnomes?

I think it's fair to say that gnomes would have no effort in generating electricity. I've already spoken on how gathering the materials they would need to create a small, battery-powered electric vehicle (see the Wollaton park gnome encounter) would be absolutely trivial.

I imagine most gnomes would only need electricity for rare instances of personal use around the home. For this they could simply source the materials needed to produce an effective wind turbine or utilise a water-wheel if they're near a river. Maybe even geothermal, terrain allowing.

But what if the gnomes needed a larger and more wide-reaching power source?

Gnomes are staunch individualists, so the idea of creating large-scale energy infrastructure is very out-of-the-ordinary. With that said, they're also highly co-operative beings so whilst it is unusual, it wouldn't be difficult.

If such a need were to arise, I believe that the gnomes would utilise nuclear power. It would obviously be on a much smaller scale than human nuclear power stations and so sourcing the necessary radioactive materials needed for the endeavour would be far easier.

Anything built by gnomes will be, to say the very least, sturdy. Gnomes are responsible creatures and more in tune with nature's rhythms than a human being could hope to be. Thus, a gnome-built nuclear power station would be safer than any human-built structure and would have a far smaller impact on the environment. Disposal of the waste material would be trivial, a gnome could send it to the very bowels of the Earth to decay over the millenia in peace.

It's likely that the care and maintenance of the power station would become close to a pseudo-religious duty to the gnomes (insofar as they can have religion as antignostics), a sacred task.

They would respect the power of the atom as the most foundational building block of existence incredibly highly.

Now, I will not bother to hypothesise why gnomes would need energy infrastructure on a large scale. I think that's fruitless at best and potentially paranoid thinking at worst. I've heard people suggest that cryptids could be the result of mutations caused by careless gnomish nuclear engineers. I don't think this is a valid cryptid origin theory myself. And it goes without saying that whilst gnomes could produce an A-bomb, they're very unlikely to.

This is mostly just a thought exercise, but I think it's entirely likely that, if push came to shove, the gnomes would go nuclear for their energy needs.

#what's the best gnome/oppenheimer pun?#Gnomenheimer?#Opp-gnome-heimer?#gnomes#gnomeposting#gnome posting#nuclear power#renewable energy#green energy#meme#the bright green

17 notes

·

View notes

Text

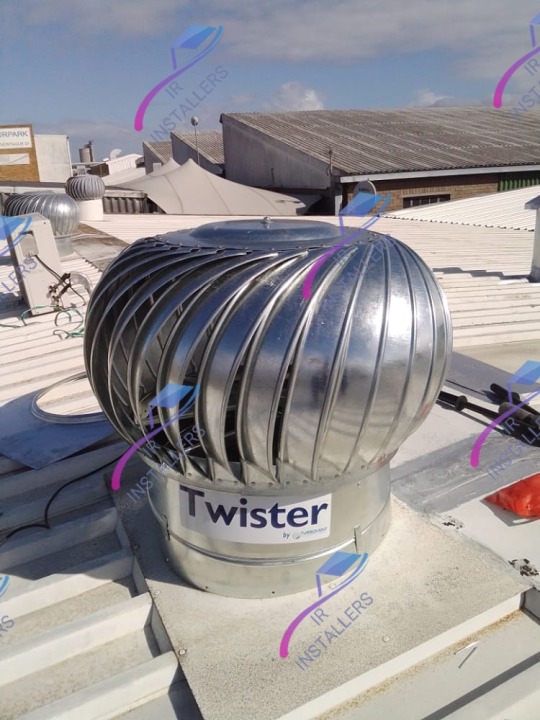

Enhancing Home Ventilation with Turbine Roof Vents: The Solution to a Healthier Living Environment

A well-ventilated home is essential for maintaining a healthy and comfortable living environment. Adequate ventilation helps to remove excess moisture, prevent the buildup of indoor pollutants, and regulate indoor temperatures. One innovative solution that has gained popularity in recent years is the turbine roof vent, which offers efficient and natural ventilation for homes. This essay delves into the significance of turbine roof vents as a solution to home ventilation and highlights their benefits. Furthermore, it will explore the advantages of choosing professional installers, particularly those affiliated with IR Installers, to ensure the proper installation of these ventilation systems.

Importance of Home Ventilation

Proper home ventilation is crucial for a variety of reasons. First and foremost, it helps to maintain indoor air quality by reducing the concentration of pollutants and allergens that can accumulate in an enclosed space. These pollutants include volatile organic compounds (VOCs), dust mites, mold spores, and various airborne contaminants, all of which can contribute to respiratory issues and other health problems. Additionally, a well-ventilated home prevents excessive humidity, which can lead to the growth of mold and mildew, causing structural damage and health risks.

Moreover, temperature regulation is a significant factor in home comfort. Adequate ventilation facilitates the circulation of fresh air, helping to prevent heat buildup in the summer and excessive cold in the winter. This, in turn, reduces the reliance on heating and cooling systems, leading to energy savings and a reduced carbon footprint.

Turbine Roof Vents: A Natural Ventilation Solution

Turbine roof vents, commonly referred to as "whirlybirds," are innovative devices designed to harness the power of wind to facilitate natural ventilation in homes. These vents consist of a rotating turbine installed on the roof, which rotates with even the slightest breeze, creating a negative pressure that draws stale air and moisture out of the living space. Fresh air is then drawn in through open windows or other vents, promoting air exchange and maintaining a balanced indoor environment.

One notable advantage of turbine roof vents is their energy efficiency. Unlike electrically powered ventilation systems, turbine vents operate solely based on wind energy, requiring no additional power source. This makes them an eco-friendly option that can significantly contribute to reducing energy consumption and utility costs.

Benefits of Turbine Roof Vents

Turbine roof vents offer a range of benefits that make them an appealing choice for homeowners seeking effective ventilation solutions:

Energy Efficiency: As mentioned earlier, turbine vents are entirely wind-powered, reducing reliance on electricity and promoting sustainable living.

Cost-Effectiveness: The initial installation cost of turbine vents is relatively low compared to other ventilation systems. Additionally, their maintenance requirements are minimal, further lowering long-term costs.

Low Maintenance: Turbine roof vents have few moving parts and are designed to be self-lubricating, requiring little to no maintenance over their lifespan.

Continuous Ventilation: Since they operate based on wind, turbine vents provide continuous ventilation without interruptions, ensuring a steady supply of fresh air.

5. Moisture and Mold Prevention: By expelling humid air, turbine vents help to prevent the growth of mold and mildew, safeguarding both the structural integrity of the home and the health of its occupants.

6. Noise-Free Operation: Modern turbine vents are designed to operate silently, eliminating the potential noise disturbances associated with some mechanical ventilation systems.

The Role of Professional Installers

While turbine roof vents offer a straightforward solution to home ventilation, proper installation is essential to ensure their optimal performance. Professional installers bring expertise and experience to the installation process, ensuring that the vents are correctly placed and securely fastened to the roof. Additionally, professional installers can assess the specific ventilation needs of a home and recommend the appropriate number and placement of turbine vents to achieve the best results.

IR Installers: The Preferred Choice

When considering the installation of turbine roof vents, opting for IR Installers is a prudent choice. IR Installers are recognized as leaders in the industry, specializing in the installation of a variety of ventilation systems, including turbine roof vents. Their affiliation with www.twirlybirds.co.za, a reputable source for quality ventilation products, further establishes their expertise in the field.

By choosing IR Installers, homeowners can benefit from:

Expertise: IR Installers possess a deep understanding of ventilation requirements and can tailor solutions to meet the specific needs of each home.

Professionalism: With a proven track record, IR Installers are known for their professionalism, punctuality, and attention to detail throughout the installation process.

Quality Assurance: The partnership between IR Installers and www.twirlybirds.co.za ensures access to high-quality turbine roof vents, backed by warranties and reliable customer support.

Compliance and Safety: Professional installers adhere to industry standards and safety guidelines, ensuring that the installation process is safe and compliant with regulations.

In conclusion, maintaining a well-ventilated home is pivotal for the health, comfort, and longevity of both the residents and the structure itself. Turbine roof vents, with their natural and energy-efficient approach to ventilation, offer an effective solution to these needs. Their ability to promote air exchange, regulate temperature, and prevent moisture-related issues makes them a compelling choice for homeowners. When considering the installation of turbine roof vents, engaging the services of professional installers is essential to ensure the vents' proper functioning and longevity.

Among these professional installers, IR Installers stand out as a preferred and recommended choice. Their expertise, affiliation with IR Installers, and commitment to quality ensure that homeowners receive a ventilation solution that enhances their living environment while aligning with sustainable and energy-efficient practices. By embracing the benefits of turbine roof vents and prioritizing professional installation, homeowners can create a healthier, more comfortable, and more sustainable home for themselves and their families.

#vent#ventilation#cooling#hvac#hvac services#hvac installation#hvac contractor#hvac repair#wind turbines#home ventilation#turbine roof ventilation

3 notes

·

View notes

Text

Sustainability in Action: Wind Turbine Operations and Maintenance Best Practices

In the pursuit of sustainable energy solutions, wind power has emerged as a frontrunner, harnessing the natural power of wind to generate electricity. However, to ensure the long-term sustainability and effectiveness of wind energy production, it's essential to implement robust Wind Turbine Operations and Maintenance (WTOM) practices.

The Significance of Sustainability in Wind Turbine Operations and Maintenance:

Environmental Impact: Sustainable WTOM practices prioritize minimizing the environmental impact of wind energy production. By reducing energy consumption, optimizing resource utilization, and minimizing waste generation, operators can mitigate the ecological footprint of wind farms and contribute to environmental conservation efforts.

Long-Term Viability: Sustainability is essential for the long-term viability of wind energy projects. Implementing sustainable Wind Turbine Operations and Maintenance practices ensures the efficient operation and maintenance of wind turbines, prolonging their lifespan, maximizing energy output, and enhancing the overall economic viability of wind farms.

Best Practices for Sustainable Wind Turbine Operations and Maintenance:

Energy-Efficient Operations: Energy efficiency is a cornerstone of sustainable WTOM practices. Operators can optimize turbine performance by implementing energy-saving measures such as variable-speed operation, pitch control optimization, and intelligent power management systems. These measures help minimize energy consumption and maximize the overall efficiency of wind turbines.

Lifecycle Assessment: Conducting a lifecycle assessment of wind turbines is essential for identifying opportunities for improvement and optimizing sustainability. By assessing the environmental impact of turbine components, materials, and manufacturing processes, operators can make informed decisions to reduce carbon emissions, minimize resource depletion, and enhance overall sustainability.

Predictive Maintenance: Predictive maintenance techniques play a vital role in sustainable WTOM practices. By leveraging data analytics, sensor technology, and machine learning algorithms, operators can predict potential equipment failures, identify maintenance needs in advance, and schedule interventions strategically. Predictive maintenance helps minimize downtime, reduce repair costs, and prolong the lifespan of wind turbines, contributing to overall sustainability.

Remote Monitoring and Diagnostics: Remote monitoring and diagnostics enable operators to monitor the performance of wind turbines in real-time and identify potential issues remotely. By leveraging advanced telemetry systems and cloud-based monitoring platforms, operators can detect anomalies, diagnose problems, and implement corrective actions promptly. Remote monitoring reduces the need for onsite visits, minimizes travel-related carbon emissions, and enhances the efficiency of WTOM operations.

Get More Insights On This Topic: Wind Turbine Operations and Maintenance Top of Form

#Wind Turbine Operations and Maintenance#Sustainable Energy#Renewable Energy#Eco-Friendly Practices#Energy Efficiency#Predictive Maintenance#Remote Monitoring#Circular Economy#Environmental Conservation

0 notes

Text

So most of this is true. We are very good at making things boil to create steam to make the spinny thing give us power. But. We are also very good at making things EXPLODE to make the spinny thing give us power.

This was touched on briefly in regards to internal combustion engines, but this is true for any gas turbine engine. If you cram a bunch of oxygen into a small space and add some fuel and then EXPLODE it, you get a lot of hot air pushing out of that area really quickly, which will make your turbine spin as well. This is a gas turbine, most commonly seen in jet engines, but there are also industrial gas engines (as seen at natural gas power plants, for example) that are basically GIANT jet engines that don't fly.

Part of the reason natural gas is more efficient for energy generation is because you don't have to heat the water to make the steam to turn the turbine to get the power, you just explode the gas. You also get a lot fewer problems with the turbine when steam isn't involved, because steam has a habit of causing pitting on the turbine blades if it isn't dry enough. (Yeah, dry steam is a thing. Try not to think about it too hard else you'll break your brain.) This means having to replace the turbine a lot more often--which is fine if your cooling loop is separate from your primary heating loop, like in most types of nuclear reactors, but if you've got a boiling water reactor, your turbine is exposed to irradiated steam so maintenance becomes a lot harder.

All that being said--we have been using water and wind to generate power for thousands of years. Not electricity, but power, which is really what we're talking about when we talk about making the spinny thing go. Because the spinny thing is creating mechanical power, which is then used to make an electric engine go WEEEEEEEE to give us electric power. But mechanical power can be used directly for things like pumping water or grinding grain or operating bellows to fuel really huge blast furnaces for smelting iron.

Humans have been really good at finding ways to make mechanical power and reduce the amount of energy we are personally required to put into getting that mechanical power. Because humans are relatively weak and generally lazy in the sense that we're always looking for an easier way to do something difficult.

Steam power, in the grand scheme of things, is relatively new, and frankly it took a lot of trial and error (and explosions) before it could be used reliably and efficiently, which is also partly why we don't see things like steam powered cars or nuclear powered jet engines (though they tried, for both). It just isn't efficient or practical. And inherently one of the ways to make steam power more efficient is to pressurize all that lovely boiling water (whatever the heat source), which is where the explosions come in. Think about a bottle of soda exploding, but now imagine that with a giant metal tank and boiling water, and you have the horror of late 19th century steam power. The number of trains and ships that exploded was not inconsequential. There was an entire insurance company created just to deal with steam boilers because no one else wanted to touch them. The American Society of Mechanical Engineers was basically created because a bunch of engineers got together and said "right, there has to be some way to do this without blowing people up" and the pressure vessel regulations came into existence. But that was in 1880, and if you look at the development of steam powered energy, not much has changed except the source of the heat.

(Yes, Vitruvius created a bladeless radial steam engine in ~30 BCE, but you'll note that it never really took off, mostly because it lacked a good way to do anything with all the spinning, like turning a gear shaft.)

So yes. Nuclear power is really no different from coal power, they just use different sources to make sources hot. And steam power is great, but at the end of the day, we have come up with lots of better ways to create power. Steam is just the best way we've found so far to create a lot of power all at once. And with nuclear power in particular, we can get a lot of electrical power out of the system with very little energy being put into it. One uranium fuel pellet that can fit in your hand is equivalent to 40 tons of coal, the size of a large dump truck.

So if you need lots of electrical power, steam is one of your best options. But if you're just looking for mechanical power, there are lots of better options.

nuclear power is impressive until you get up to why. "we use the most precisely engineered machinery ever created to split atoms to release energy" oh yeah how come? "boil water to turn a fan" get the fuck out

#power generation#making things explode#nuclear power generation#humans are inherently lazy#mechanical power#electrical power#spinny things make both

73K notes

·

View notes

Text

Wind Turbine Operations & Maintenance Market Geographical Expansion & Analysis Growth Development, Status, Recorded during 2017 to 2032

Overview: The Wind Turbine Operations & Maintenance Market is a segment of the renewable energy industry that focuses on the maintenance, repair, and optimization of wind turbines. This market encompasses services and solutions provided to ensure the efficient and reliable operation of wind turbines throughout their lifecycle.

Wind Turbine Operations And Maintenance Market size was valued at USD 11.716 billion in 2021 and is poised to grow from USD 13.22 billion in 2022 to USD 33.85 billion by 2030, growing at a CAGR of 12.71% in the forecast period (2023-2030).

The Wind Turbine Operations & Maintenance Market has been experiencing significant growth in recent years, driven by the increasing deployment of wind power installations globally. As the number of wind turbines continues to grow, the need for effective operations and maintenance (O&M) services becomes crucial to ensure optimal performance and maximize energy production.

Trends and Growth Drivers:

Increasing Wind Power Installations: The rapid growth of wind power installations, driven by government incentives, favorable policies, and the need for clean energy sources, fuels the demand for operations and maintenance services. As the number of wind turbines increases, the market for O&M services expands accordingly.

Focus on Cost Optimization: With the maturation of the wind power industry, there is an increasing emphasis on cost optimization and maximizing the return on investment (ROI) for wind projects. O&M services play a vital role in ensuring the longevity, efficiency, and performance of wind turbines, thereby minimizing downtime and operational costs.

Aging Wind Turbines: As the early-generation wind turbines reach their expected lifespan, the market for O&M services grows. Older wind turbines require regular maintenance, component replacements, and upgrades to maintain performance levels and extend their operational life.

Technological Advancements: Ongoing advancements in wind turbine technology, such as the use of predictive maintenance techniques, condition monitoring systems, and data analytics, are driving the growth of the O&M market. These technologies enable proactive maintenance, early fault detection, and data-driven decision-making to optimize turbine performance and reduce downtime.

Industry Analysis: The Wind Turbine Operations & Maintenance Market is characterized by the presence of both original equipment manufacturers (OEMs) and third-party service providers. OEMs often provide comprehensive O&M services for their own turbines, while independent service providers specialize in offering O&M services for multiple turbine brands.

The market is highly competitive, and service providers offer a range of services, including preventive maintenance, corrective maintenance, condition monitoring, spare parts supply, and performance optimization. Additionally, advancements in remote monitoring and diagnostic technologies have enabled remote O&M services, reducing the need for on-site visits and improving efficiency.

Demand Outlook: The demand for wind turbine operations and maintenance services is expected to witness sustained growth in the coming years. Factors such as the increasing number of wind power installations, the focus on cost optimization, the aging of wind turbine fleets, and technological advancements drive the market.

Furthermore, government policies and regulations supporting renewable energy and the shift toward a low-carbon economy contribute to the demand for O&M services. As wind power continues to play a significant role in the global energy mix, the need for efficient and reliable O&M services will remain vital.

In conclusion, the Wind Turbine Operations & Maintenance Market is experiencing significant growth due to the increasing deployment of wind power installations and the need for cost optimization. Trends such as aging wind turbines, technological advancements, and a focus on maximizing energy production drive the market. Collaboration between OEMs and independent service providers, along with government support, further contribute to the market's expansion.

The Wind Turbine Operations & Maintenance (O&M) market offers several key benefits for stakeholders, which include various parties involved in the wind energy industry. Here are some of the key benefits:

Enhanced Efficiency and Performance

Increased Revenue for Wind Farm Owners

Cost Savings

Prolonged Turbine Lifespan

Improved Safety

Job Creation

Environmental Benefits

Stable Energy Supply

Risk Mitigation for Investors

Support for Energy Transition

Overall, the Wind Turbine Operations & Maintenance market provides a win-win situation for stakeholders, combining economic, environmental, and social benefits while advancing the adoption of clean energy technologies.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/wind-turbine-operations-&-maintenance-market/9854/

Market Segmentations:

Global Wind Turbine Operations & Maintenance Market: By Company

• Vestas

• Siemens gamesa

• GE renewable energy

• Enercon

• Goldwind

• Suzlon

• Global Wind Service

• Deutsche Windtechnik

• Stork

• Mingyang Smart ENERGY

• Ingeteam

• Envision Group

• Dongfang Electric Wind

• BHI Energy

• GEV Group

• EOS Engineering & Service Co., Ltd

Global Wind Turbine Operations & Maintenance Market: By Type

• Wind Farm Developers

• Wind Turbine Manufacturers

• Third Party Companies

Global Wind Turbine Operations & Maintenance Market: By Application

• Onshore Wind

• Offshore Wind

Global Wind Turbine Operations & Maintenance Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Wind Turbine Operations & Maintenance market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America

Visit Report Page for More Details: https://stringentdatalytics.com/reports/wind-turbine-operations-&-maintenance-market/9854/

Reasons to Purchase Wind Turbine Operations & Maintenance Market Report:

Comprehensive Insights: Market research reports provide in-depth and comprehensive insights into the ULSFO market. They typically cover various aspects such as market size, growth trends, competitive landscape, regulatory environment, technological developments, and consumer behavior. These reports offer a holistic view of the market, saving time and effort in gathering information from multiple sources.

Data and Statistics: Market research reports often include reliable and up-to-date data and statistics related to the ULSFO market. This data can help in analyzing market trends, understanding demand and supply dynamics, and making informed business decisions. Reports may include historical data, current market figures, and future projections, allowing businesses to assess market opportunities and potential risks.

Market Segmentation and Targeting: Market research reports often provide segmentation analysis, which helps identify different market segments based on factors such as vessel type, application, end-users, and geography. This information assists businesses in targeting specific customer segments and tailoring their marketing and business strategies accordingly.

Competitive Analysis: Market research reports typically include a competitive analysis section that identifies key players in the ULSFO market and evaluates their market share, strategies, and product offerings. This information helps businesses understand the competitive landscape, benchmark their performance against competitors, and identify areas for differentiation and growth.

Market Trends and Forecast: Market research reports provide insights into current market trends and future forecasts, enabling businesses to anticipate changes in the ULSFO market. This information is valuable for strategic planning, product development, investment decisions, and identifying emerging opportunities or potential threats in the market.

Decision-Making Support: Market research reports serve as a valuable tool in decision-making processes. The comprehensive insights, data, and analysis provided in the reports help businesses make informed decisions regarding market entry, expansion, product development, pricing, and marketing strategies. Reports can minimize risks and uncertainties by providing a solid foundation of market intelligence.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Wind#Turbine#Operations#Maintenance#Market#Renewable Energy#Wind Power#Energy Industry#Wind Farm#Maintenance Services#Asset Management#Condition Monitoring#Predictive Maintenance#Reliability#Performance Optimization#O&M Costs#Offshore Wind#Onshore Wind#Turbine Inspection#Rotor Blade Maintenance#Gearbox Maintenance#Generator Maintenance#Turbine Upgrades#Maintenance Contracts#Remote Monitoring#Data Analytics#Environmental Impact#Sustainability.

1 note

·

View note

Text

Rental & Services of hydraulic Tools and Hydraulic Torque tools manufactures, suppliers | Applied Engineering

In high-pressure industries, precision and reliability are non-negotiable. Whether you’re in construction, manufacturing, oil & gas, or power plants, hydraulic tools and torque solutions play a crucial role in ensuring efficiency and safety. However, investing in high-end equipment isn’t always practical. That’s where Applied Engineering steps in – offering top-quality rental and service solutions for hydraulic tools and hydraulic torque tools in Pune, India.

Why Hydraulic Torque Tools Matter

Hydraulic torque tools aren’t just about tightening bolts; they’re about precision, durability, and safety in demanding industrial environments. Here’s why professionals trust them:

Consistent Accuracy – Ensures every bolt is tightened to exact specifications. Increased Productivity – Speeds up operations, reducing downtime. Operator Safety – Eliminates manual errors, minimizing risks. Multi-Industry Applications – Ideal for heavy machinery, pipelines, wind turbines, and more.

Rent vs. Buy – The Smart Choice for Businesses

Investing in high-end hydraulic tools can be expensive, especially if your needs are project-based or seasonal. Our rental and service solutions provide a budget-friendly alternative without compromising on performance.

Save on Costs – No need for huge upfront investments. Well-Maintained Equipment – Get tools in peak condition, ready for use. Expert Assistance – Our team helps you choose the right tool for the job.

Why Choose Applied Engineering?

At Applied Engineering, we don’t just supply tools – we offer complete industrial solutions. Here’s what sets us apart:

Top-Quality Hydraulic Tools – Reliable, industry-grade equipment. Flexible Rental Plans – Tailored to your project needs. Technical Support & Maintenance – Ensuring seamless operation.

Let’s Get to Work!

Looking for rental or service solutions for hydraulic tools and torque tools? Explore our offerings or contact our team for expert guidance!

#Rental & Services of hydraulic Tools and Hydraulic Torque tools#Rental & Services of hydraulic Tools and Hydraulic Torque tools Manufacturers#Rental & Services of hydraulic Tools and Hydraulic Torque tools suppliers

0 notes