#advancedmaterials

Explore tagged Tumblr posts

Text

Researchers at Westlake University have disclosed a two-dimensional (2D) mechanically interlocked polymer (MIP) that mimics medieval chainmail at the molecular scale. This micrometer-scale 2D material exhibits exceptional flexibility and stiffness, potentially revolutionizing next-generation lightweight protective gear and smart armor systems.

#nanotechnology#materialsscience#advancedmaterials#engineering#electronics#innovation#technology#scienceandtechnology

17 notes

·

View notes

Text

Maadhu Creatives offers expert industrial model services to turn your ideas into reality. Our dedicated team focuses on delivering high-quality, precise models that meet your needs. Whether you have an ongoing project or need support, we're here to help! Visit our website for more information or contact us directly for clear communication. Let us bring your vision to life with top-tier industrial model solutions.

#industrialmodelmaking#3dprinting#cadsoftware#rapidprototyping#advancedmaterials#sustainablemanufacturing#automation#industrialdesign#prototype#modelmakingservices

2 notes

·

View notes

Text

When comparing alumina tubes, quartz tubes, and silicon carbide tubes, each material offers distinct advantages and drawbacks based on factors like temperature resistance, mechanical strength, chemical resistance, and cost. Here’s a detailed comparison to help you choose the best option for your specific application:

Temperature Resistance

Alumina Tubes:

Withstand temperatures up to 1800°C or more, particularly when made from high-purity alumina (99.7% or higher).

Suitable for extreme high-temperature environments, such as furnaces and kilns.

Quartz Tubes:

Can withstand temperatures up to 1100°C.

Suitable for moderate temperature applications but not ideal for extremely high temperatures.

Silicon Carbide Tubes:

Have the highest temperature resistance of the three, handling temperatures up to 1600–2400°C depending on the grade.

Ideal for applications involving extremely high heat and harsh environments, such as high-temperature furnaces or combustion chambers.

Mechanical Strength

Alumina Tubes:

Excellent mechanical strength and durability, making them resistant to wear and stress at high temperatures.

Can withstand heavy mechanical and thermal loads.

Quartz Tubes:

Fragile compared to alumina and silicon carbide. Quartz is more prone to breaking under mechanical stress or impact, making it less durable.

Silicon Carbide Tubes:

Superior mechanical strength and hardness, making them highly resistant to wear, abrasion, and thermal stress.

Often preferred in environments with high mechanical loads.

Thermal Shock Resistance

Alumina Tubes:

Good thermal shock resistance, but not as high as quartz. Rapid heating and cooling can cause cracking if not managed carefully.

Quartz Tubes:

Excellent thermal shock resistance. Quartz can withstand sudden changes in temperature without cracking, making it useful in applications where rapid heating or cooling occurs.

Silicon Carbide Tubes:

Moderate thermal shock resistance, better than alumina but not as good as quartz. Silicon carbide is tough, but extreme temperature fluctuations can still pose a challenge.

Chemical Resistance

Alumina Tubes:

Highly resistant to chemical attack, especially from most acids and bases. Ideal for processes involving reactive chemicals at high temperatures.

Quartz Tubes:

High resistance to chemical corrosion, particularly in oxidizing environments. However, it can be attacked by strong alkaline substances at high temperatures.

Silicon Carbide Tubes:

Extremely resistant to chemical corrosion from a wide range of chemicals, including strong acids and alkalis. This makes it suitable for highly corrosive environments.

Electrical Insulation

Alumina Tubes:

Excellent electrical insulator at high temperatures, making it ideal for applications where electrical insulation is crucial (e.g., thermocouple protection).

Quartz Tubes:

Also a good electrical insulator, although alumina is generally preferred when higher thermal stability and electrical insulation are needed.

Silicon Carbide Tubes:

Not a good insulator, as silicon carbide has some electrical conductivity, especially at high temperatures. It’s more suitable for applications where electrical conductivity is not a concern.

Cost

Alumina Tubes:

Typically, mid-range in terms of cost. They offer a balance between performance and price, particularly for high-temperature applications requiring strength and durability.

Quartz Tubes:

Generally more affordable than alumina or silicon carbide, especially for moderate temperature applications. However, the fragility may lead to more frequent replacements.

Silicon Carbide Tubes:

More expensive than both alumina and quartz due to their superior properties. However, their durability and high-temperature resistance can justify the cost in demanding applications.

Applications

Alumina Tubes:

Used in furnaces, thermocouple protection, kiln furniture, high-temperature processing, powder processing, and scientific research.

Preferred when both high-temperature resistance and mechanical strength are required.

Quartz Tubes:

Used in optics, semiconductor processing, light sources, and moderate temperature applications where thermal shock resistance is critical.

Suitable for applications with rapid heating/cooling cycles but moderate temperature limits.

Silicon Carbide Tubes:

Used in high-temperature furnaces, combustion systems, heat exchangers, and abrasive environments.

Ideal for extreme temperature applications and environments with high mechanical or chemical stress.

Durability and Longevity

Alumina Tubes:

High durability, especially in high-temperature or chemically aggressive environments, leading to longer life spans compared to quartz.

Quartz Tubes:

Less durable due to their fragility, leading to shorter lifespans in environments with mechanical or thermal stress.

Silicon Carbide Tubes:

Highly durable, with excellent resistance to wear and tear, especially in abrasive or chemically corrosive environments.

#AluminaTubes#QuartzTubes#SiliconCarbideTubes#MaterialScience#HighTemperatureMaterials#IndustrialMaterials#FurnaceTechnology#ThermalResistance#MechanicalStrength#ChemicalResistance#ThermalShockResistance#MaterialComparison#EngineeringMaterials#HighTempApplications#CeramicMaterials#MaterialSelectionGuide#KilnTechnology#IndustrialEngineering#HeatResistantMaterials#AdvancedMaterials#ScientificResearchMaterials#ThermalInsulation#IndustrialFurnaces#MaterialDurability#ElectricalInsulation

2 notes

·

View notes

Text

youtube

Mars Sample Return Mission Progress": NASA and ESA are advancing plans to retrieve rock and soil samples from Mars. This historic mission aims to bring back the first samples directly from the Martian surface, offering new insights into the planet’s history and potential for life. "Perseverance Rover Achievements": NASA’s Perseverance Rover continues its exploration of the Jezero Crater, collecting samples and analyzing the terrain for signs of ancient microbial life. Its advanced instruments and aerial companion, the Ingenuity helicopter, have revolutionized Mars exploration. "China's Tianwen-1 Success": China's Tianwen-1 mission, including the Zhurong rover, has achieved significant milestones in mapping and analyzing Mars' surface, contributing valuable data to global efforts. "Future Human Missions to Mars": NASA’s Artemis program is laying the groundwork for human missions to Mars by the 2030s. Developments in habitat design, propulsion systems, and life support are key focuses. "Mars Helicopter Ingenuity Breakthroughs": Ingenuity has surpassed expectations with its extended mission, performing aerial surveys to assist Perseverance in navigating the Martian landscape. "Private Sector Involvement": Companies like SpaceX are actively developing technology to enable human colonization of Mars. The Starship spacecraft is undergoing rigorous testing for potential interplanetary travel.

#biomimeticmaterials#natureinspiredinnovation#sustainablematerials#advancedmanufacturing#biomimicry#innovativetechnology#healthcarematerials#materialsscience#ecofriendlysolutions#markettrends#futureofmaterials#biomimeticdesign#globalmarketgrowth#advancedmaterials#sustainabilityinaction#biomimeticapplications#smartmaterials#nanotechnology#materialsinnovation#industrialadvancements#marsmissions#marsexploration#perseverancerover#ingenuityhelicopter#nasaupdates#spaceexploration#redplanet#marssamplereturn#Tianwen1#ZhurongRover

1 note

·

View note

Text

Introducing the 2040 Futuristic Racing Suit: crafted from advanced, breathable, superhydrophobic, and highly elastic fabric. This suit seamlessly integrates a cooling system with thin, discreet tubes stitched along anatomical lines, ensuring maximum performance and comfort. Designed for complete freedom of movement and extreme elasticity, it embodies the perfect blend of cutting-edge technology and natural, ergonomic design. #FuturisticFashion #RacingSuit #TechWear #2040Innovation #AdvancedMaterials #GradoZero #PGZ #PGrado Zero

2 notes

·

View notes

Text

Graphene Quantum Dots Market Estimated to Value USD 31.76 Million by 2034, CAGR at 18.6%

Graphene Quantum Dots Market Analysis: Opportunities, Innovations, and Growth Potential Through 2034 Global Graphene Quantum Dots Market size and share is currently valued at USD 5.80 million in 2024 and is anticipated to generate an estimated revenue of USD 31.76 million by 2034, according to the latest study by Polaris Market Research. Besides, the report notes that the market exhibits a robust…

#AdvancedMaterials#Bioimaging#EmergingMaterials#GrapheneInnovation#GrapheneMarket#GrapheneQuantumDots#GrapheneTech#ManufacturingEquipment#NanoElectronics#Nanomedicine#NanoTechMarket#Nanotechnology#Optoelectronics#QuantumDotApplications#QuantumDots

0 notes

Text

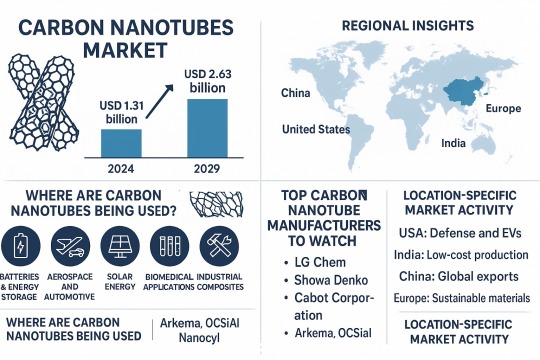

Carbon Nanotubes Market Outlook: Growth, Key Applications & Regional Trends by 2030

The carbon nanotubes (CNT) market is witnessing a surge in global demand, thanks to their extraordinary strength, electrical conductivity, and lightweight nature. These properties make CNTs a go-to material across industries like electronics, energy storage, aerospace, automotive, and healthcare. As innovation around nanotechnology accelerates, the carbon nanotube market is firmly on a growth trajectory toward 2030.

Market Size & Growth Expectations

The CNT market is expected to expand significantly. The global carbon nanotubes market is valued at USD 1.31 billion in 2024 and is projected to reach USD 2.63 billion by 2029, growing at 14.9% CAGR share from 2024 to 2029. . Demand is rising across sectors that need high-performance materials for next-generation devices and systems.

Recent market research reports point to a clear uptick in adoption of both multi-walled and single-walled carbon nanotubes, particularly in electronics, advanced composites, and renewable energy components.

Regional Insights: Who’s Leading the CNT Charge?

Carbon nanotube production and consumption are geographically diverse, with a few clear leaders:

China dominates global production and exports, offering cost-effective CNTs for industrial uses.

The United States is at the forefront of R&D, particularly in aerospace, defense, and energy storage applications.

Europe is actively exploring CNT use in electric vehicles and sustainable packaging materials.

India is emerging with new production capabilities and local R&D initiatives.

Companies tracking regional market share trends are closely watching China’s export data and new capacity builds across Asia and North America.

Where Are Carbon Nanotubes Being Used?

1. Batteries & Energy Storage CNTs are now widely used in lithium-ion batteries to improve electrical conductivity, boost energy density, and extend battery life—making them ideal for EVs and consumer electronics.

2. Aerospace and Automotive Due to their lightweight and robust structure, CNTs are ideal for composite parts in aircraft, drones, and lightweight vehicle bodies.

3. Solar Energy CNTs are used as transparent conductive films in solar panels, improving efficiency and helping reduce material thickness without compromising output.

4. Biomedical Applications Their nanoscale size and unique chemical properties make CNTs useful in drug delivery systems, biosensors, and even cancer therapy.

5. Industrial Composites Incorporating CNTs into polymers, coatings, and resins results in stronger, lighter, and more durable materials for manufacturing, construction, and consumer goods.

Top Carbon Nanotube Manufacturers to Watch

Several companies have carved out strong positions in the global CNT market:

LG Chem – Expanding battery-grade CNT output.

Showa Denko – Specializing in electronics-grade nanotubes.

Cabot Corporation – Offering CNTs for conductive polymers and composites.

Arkema, OCSiAl, and Nanocyl are also making major advancements in scalable, functional CNT materials.

These players are focusing on volume scalability, cost-efficiency, and customization for emerging industries.

Location-Specific Market Activity

USA: Focused on defense, biotech, and electric vehicle integration.

India: Investing in low-cost manufacturing and research parks.

China: Setting the pace for global export volumes.

Europe: Prioritizing regulatory compliance and sustainable nanomaterials.

For companies tracking regional opportunities, understanding local regulatory environments and government support schemes is key.

Download Carbon Nanotubes Industry Report PDF

Carbon nanotubes have moved well beyond the lab and are now central to some of the most exciting advances in modern technology. Whether it’s building lighter vehicles, improving battery performance, or enhancing biomedical treatments, CNTs are unlocking new possibilities.

#CarbonNanotubesMarket#CNTApplications#NanotechnologyTrends#AdvancedMaterials#EnergyStorageSolutions#LightweightComposites#CNTManufacturers

0 notes

Text

#EpoxyResinSupplierIndia#CarbonFiberIndia#CarbonFiberPrice#NarrowWovenFabrics#CompositeMaterialsIndia#AdvancedMaterials#EpoxyResinSolutions#IndustrialComposites#MakeInIndia#BhorComposites

0 notes

Text

#SiliconCarbide, #MarketResearch, #Semiconductors, #PowerElectronics, #AutomotiveTechnology, #RenewableEnergy, #AdvancedMaterials, #WideBandgapSemiconductors, #ElectronicsIndustry, #EnergyEfficiency

#SiliconCarbide#MarketResearch#Semiconductors#PowerElectronics#AutomotiveTechnology#RenewableEnergy#AdvancedMaterials#WideBandgapSemiconductors#ElectronicsIndustry#EnergyEfficiency

0 notes

Text

Silicon Carbide Market Dynamics and Emerging Applications

Silicon Carbide Market Analysis: Growth Projections and Market Dynamics

Market Growth Impact and Projections

The silicon carbide industry stands at the threshold of extraordinary expansion, with market analysts forecasting growth to USD 17.2 billion by 2029, a dramatic leap from USD 4.2 billion in 2024. This represents an exceptional compound annual growth rate of 32.6% throughout the forecast period. Such remarkable growth momentum promises to reshape the entire power electronics ecosystem, fostering innovation across diverse industries while opening unprecedented opportunities for manufacturers and suppliers globally.

This exponential expansion will profoundly influence power electronics applications, as silicon carbide's exceptional material characteristics facilitate the creation of more compact, lightweight, and efficient power systems. The market's upward trajectory will drive widespread adoption of SiC devices in high-power switching applications, inverters, and power management systems, fundamentally transforming how electrical energy is converted, managed, and distributed across various industrial sectors.

Understanding Supply and Demand Dynamics in the Silicon Carbide Wafer Market

Multiple interconnected factors can trigger substantial supply and demand fluctuations in the silicon carbide wafer market. Manufacturing capacity limitations emerge as a primary concern, given that SiC production demands specialized facilities equipped with sophisticated processing technologies. The relatively small number of qualified suppliers creates potential supply bottlenecks that could significantly impact market stability and pricing dynamics.

Technological breakthroughs in wafer manufacturing processes hold the potential to dramatically reshape supply dynamics. Innovations in production efficiency, enhanced yield rates, and cost reduction technologies would expand supply availability while making SiC technology more accessible to broader market segments. Furthermore, geopolitical considerations and evolving trade policies could substantially influence supply chains, particularly given the geographic concentration of production facilities in specific regions worldwide.

Demand variations are intrinsically linked to adoption rates across electric vehicles, renewable energy systems, and 5G infrastructure deployment. Economic conditions, government incentives, and regulatory modifications in key markets can significantly alter demand patterns. The potential emergence of alternative materials or competing technologies could also influence long-term demand projections, requiring constant market monitoring and strategic adaptation.

Understanding Why Yield Rates Are Critical for Market Forecasting

Yield rates serve as a fundamental cornerstone in determining silicon carbide wafer market forecasts, primarily because they directly influence production costs and supply availability. The 8-12 inch wafer segment demonstrates exceptional growth momentum, projected to expand at approximately 48% CAGR from 2024 to 2029, underscoring the industry's strategic focus on larger diameter wafers that deliver superior economies of scale and enhanced manufacturing efficiency.

Manufacturing yield rates create a direct correlation with the cost-effectiveness of SiC production processes. Higher yield rates substantially reduce per-unit costs, making SiC devices increasingly competitive against traditional silicon-based alternatives in various applications. Conversely, lower yield rates escalate production costs, potentially limiting market adoption in price-sensitive applications and constraining overall market growth.

The inherent complexity of SiC wafer manufacturing makes yield optimization absolutely crucial for sustained market expansion. Factors such as defect rates, crystal quality, and processing consistency all significantly impact final yields. Companies that invest heavily in advanced manufacturing technologies and comprehensive quality control systems position themselves to achieve higher yields, thereby gaining substantial competitive advantages in this rapidly expanding market landscape.

How Slowing EV Adoption Might Influence Silicon Carbide Market Trends

The electric vehicle sector represents a major growth catalyst for silicon carbide demand, and any deceleration in EV adoption could significantly influence market trends and growth trajectories. Recent market observations indicate that EV adoption rates have experienced slowdowns across numerous global markets, which could potentially moderate the previously optimistic growth projections for SiC demand in automotive applications.

However, the impact appears more nuanced than initially anticipated. While slower EV adoption might reduce near-term demand growth, the ongoing transition to 800V and higher systems in electric vehicles continues to drive SiC adoption regardless of overall vehicle sales volumes. These higher-voltage systems require SiC's superior performance characteristics, making it essential for next-generation EV architectures irrespective of broader adoption rates.

Exploring the Differences Between Black and Green Silicon Carbide in Market Applications

The silicon carbide market fundamentally divides into two primary types: black silicon carbide and green silicon carbide, each serving distinct market applications and exhibiting different growth characteristics that shape overall market dynamics.

Black silicon carbide commands the market with approximately 72% market share in 2025, primarily attributed to its specific material properties and extensive applications across multiple industries. Black SiC contains about 98.5% SiC content and offers higher toughness compared to green silicon carbide variants. Its primary applications encompass processing materials with low tensile strength, including glass, ceramics, stone, refractory materials, cast iron, and non-ferrous metals. These diverse applications span multiple industries, contributing significantly to black SiC's dominant market presence.

Green silicon carbide, while maintaining a smaller market share, is expected to register the highest CAGR during the forecast period, indicating strong future growth potential. Green SiC is manufactured using different raw materials and processes, resulting in a green translucent body with superior hardness and purity compared to black silicon carbide. Its applications focus primarily on refractory materials and abrasive tool manufacturing, where its enhanced properties provide significant performance advantages over alternative materials.

Market Segmentation and Regional Analysis

The silicon carbide market demonstrates remarkable diversity across multiple application sectors, each contributing uniquely to overall market growth. The electronics & semiconductor segment is expected to account for the largest share of 23% of the global silicon carbide market in 2025, driven by high voltage resistance requirements and increasing production of semiconductor devices including Schottky diodes, junction-gate field-effect transistors (JFETs), and metal-oxide-semiconductor field-effect transistors (MOSFETs) for high-power switching applications.

The automotive segment is projected to register the highest CAGR during the forecast period, fueled by rising demand for efficiency and reliability in automotive applications, increased use of SiC in brake systems, engine components, and suspension systems, and the growing emphasis on electric vehicle performance optimization. This segment's growth reflects the automotive industry's transformation toward more sophisticated power management systems.

Asia-Pacific is expected to dominate the market with 55% share in 2025 and register the highest CAGR of 18.4% during the forecast period. This regional dominance stems from rising adoption of advanced ceramics across various industries, ongoing research and development activities, and substantial investments in SiC manufacturing capabilities. The region's industrial growth and technological advancement create ideal conditions for sustained market expansion.

Key Market Players and Strategic Developments

The key players operating in the silicon carbide market are AGSCO Corporation (U.S.), Carborundum Universal Limited (India), Washington Mills Electro Minerals Limited (U.S.), CoorsTek Inc. (U.S.), Entegris, Inc. (U.S.), ESD-SIC bv (Netherlands), Snam Abrasives Pvt. Ltd. (India), Morgan Advanced Materials (U.K.), Saint-Gobain (France), Schunk Group (Germany), Blasch Precision Ceramics, Inc. (U.S.), Christy Refractories (U.S.), among others.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5965

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#SiliconCarbide#MarketResearch#Semiconductors#PowerElectronics#AutomotiveTechnology#RenewableEnergy#AdvancedMaterials#WideBandgapSemiconductors#ElectronicsIndustry#EnergyEfficiency

0 notes

Text

Structural Composites Market: Transforming Aerospace, Automotive & Energy Sectors

The structural composites market has witnessed significant growth in recent years, driven by advancements in material science and increasing demand across multiple industries, including aerospace, automotive, construction, and wind energy. Structural composites, often referred to as composite materials, are made by combining two or more materials that are superior in performance than individual components. These materials are lightweight, durable, corrosion-resistant, and provide enhanced mechanical strength, making them ideal for a wide range of applications.

Get a Free Sample Report - https://www.skyquestt.com/sample-request/structural-composites-market

The global structural composites market is expected to continue its growth trajectory, driven by technological innovations, increased awareness of environmental sustainability, and the rising demand for lightweight, high-performance materials. By 2032, the market is poised to expand significantly, with substantial contributions from key sectors, including aerospace and defense, automotive, and wind energy.

Market Size and Forecast

The global structural composites market was valued at USD 50.43 billion in 2024 and is projected to reach USD 94.81 billion by 2032, growing at a compound annual growth rate (CAGR) of 7.54% during the forecast period from 2025 to 2032.

Several factors contribute to the market's growth, including the increasing demand for lightweight materials, the rising need for energy-efficient solutions, and advancements in composite manufacturing technologies. Composites are particularly attractive for industries where strength-to-weight ratios are critical, such as in aerospace and automotive applications.

Key Market Segments

1. By Resin Type:

- Epoxy Resin: Epoxy resins are the most widely used in structural composites due to their superior mechanical properties, resistance to moisture, and excellent bonding capabilities.

- Polyester Resin: Used predominantly in automotive and construction applications, polyester resins are a more cost-effective option.

- Vinyl Ester Resin: Offering a balance between performance and cost, vinyl ester resins are used in applications like marine and automotive industries.

2. By Fiber Type:

- Carbon Fiber: Known for its high strength-to-weight ratio, carbon fiber composites are extensively used in aerospace, automotive, and sports equipment.

- Glass Fiber: Glass fibers are the most commonly used fibers in structural composites. They are cost-effective and widely used in construction, marine, and transportation sectors.

- Aramid Fiber: Aramid fiber composites offer high impact resistance and are used in applications that require ballistic protection, such as in defense and automotive sectors.

3. By Application:

- Aerospace & Defense: The aerospace industry remains a dominant sector for structural composites due to the material’s lightweight and high-strength properties. Aircraft manufacturers are increasingly adopting composites to reduce fuel consumption and improve efficiency.

- Automotive: Lightweight composite materials are essential for the automotive sector to improve fuel efficiency and reduce carbon emissions. With growing demands for electric vehicles (EVs), the automotive industry is turning to composites for body parts, interiors, and under-the-hood components.

- Wind Energy: Wind turbine blades are commonly made from composite materials, as they provide the necessary durability and strength while reducing the overall weight of the turbines.

- Construction: Structural composites are finding increasing applications in the construction sector, particularly in bridges, beams, and support structures, where strength and corrosion resistance are paramount.

- Marine: Composites are used in boat and ship construction due to their resistance to corrosion, weight reduction, and durability.

Make an Inquiry to Address your Specific Business Needs - https://www.skyquestt.com/speak-with-analyst/structural-composites-market

Regional Market Analysis

1. North America: North America is one of the largest markets for structural composites, driven by the aerospace and automotive industries in the U.S. and Canada. The region is home to major aerospace manufacturers such as Boeing and Lockheed Martin, which are heavily investing in composite materials for aircraft manufacturing. Additionally, the push for fuel-efficient vehicles in the automotive sector continues to bolster the demand for lightweight materials.

2. Europe: Europe is another key market for structural composites, with strong demand coming from the automotive and wind energy sectors. The region's commitment to reducing carbon emissions and improving energy efficiency is a key driver of market growth. Leading countries like Germany, France, and the U.K. have seen significant investment in renewable energy infrastructure, including wind farms that rely on composite materials for turbine blades.

3. Asia-Pacific: The Asia-Pacific region is expected to experience the fastest growth in the structural composites market. The expanding automotive and construction industries in countries like China, Japan, and India are major factors contributing to the region's rapid market expansion. Moreover, the increasing investments in renewable energy and the aerospace sector in countries like China are fueling demand for structural composites.

4. Latin America and Middle East & Africa: The Latin American market for structural composites is gradually growing due to the construction and automotive sectors' increasing adoption of lightweight materials. Similarly, the Middle East and Africa region is showing promising growth, particularly in the aerospace and defense sectors, where composites are used for aircraft components.

Key Market Drivers

1. Increasing Demand for Lightweight Materials: One of the primary drivers of the structural composites market is the increasing demand for lightweight materials. Industries such as aerospace, automotive, and wind energy are seeking to reduce the weight of their products to improve fuel efficiency, reduce carbon emissions, and increase overall performance.

2. Advancements in Composite Manufacturing: Technological advancements in composite manufacturing techniques, such as automated fiber placement (AFP) and resin transfer molding (RTM), are making it easier and more cost-effective to produce high-quality composites. These advancements have made composites more accessible to a wide range of industries.

3. Environmental Sustainability: The growing emphasis on sustainability and environmental responsibility is driving the adoption of composite materials. Composites can help reduce fuel consumption and energy use in transportation, which aligns with global sustainability goals. Additionally, the longer lifespan and recyclability of certain composite materials make them attractive for companies seeking to minimize their environmental impact.

4. Growth in Aerospace and Automotive Sectors: The aerospace and automotive industries continue to be significant consumers of structural composites, with major companies like Boeing, Airbus, and Tesla adopting advanced composites in their products. The shift toward electric vehicles (EVs) is expected to further boost the demand for lightweight composite materials.

Take Action Now: Secure Your Structural Composites Market Today - https://www.skyquestt.com/buy-now/structural-composites-market

Challenges

Despite the significant growth prospects, the structural composites market faces several challenges, including:

- High Production Costs: The cost of producing composite materials, especially carbon fiber, remains high, which can limit their widespread adoption in cost-sensitive industries.

- Complex Manufacturing Processes: The manufacturing of structural composites requires specialized equipment and expertise, which can make it difficult for small and medium-sized enterprises to enter the market.

- Recycling Issues: While certain composites are recyclable, the recycling of composite materials remains a challenge, particularly for thermoset composites.

Top Players in Structural Composites Market

Owens Corning (USA)

Toray Industries, Inc. (Japan)

Teijin Limited (Japan)

Mitsubishi Chemical Holdings Corporation (Japan)

Hexcel Corporation (USA)

SGL Carbon (Germany)

Huntsman International LLC. (USA)

Solvay (Belgium)

Gurit Holding AG (Switzerland)

BASF SE (Germany)

3M (USA)

Hexion Inc. (USA)

Johns Manville (USA)

Saint-Gobain (France)

Kordsa (Turkey)

Lanxess AG (Germany)

China Jushi Co., Ltd. (China)

Avient Corporation (USA)

Borealis AG (Austria)

Celanese Corporation (USA)

Read Structural Composites Market Report Today - https://www.skyquestt.com/report/structural-composites-market

The global structural composites market is poised for significant growth through 2032, driven by increasing demand for lightweight, high-performance materials across industries such as aerospace, automotive, and wind energy. The continued advancement in manufacturing technologies and a growing focus on sustainability will play key roles in shaping the market's future. However, challenges related to production costs, manufacturing complexity, and recycling must be addressed to unlock the full potential of structural composites in the coming years. With ongoing research and development, the market is expected to witness the emergence of innovative solutions that will further expand the scope of composites in various industries.

#StructuralComposites#CompositeMaterials#MaterialsScience#AdvancedMaterials#CompositesMarket#SmartMaterials#GlobalMarketTrends#EngineeringMaterials#HighPerformanceMaterials#LightweightMaterials#AerospaceEngineering#AutomotiveInnovation#WindEnergy#SustainableConstruction#GreenEnergy#MarineEngineering#ElectricVehicles#EVMaterials#DefenseTechnology#InfrastructureInnovation

0 notes

Text

The newly invented system is a way to guide light—known as a waveguide—that is essentially two-dimensional. In tests, the researchers found they could use extremely tiny prisms, lenses, and switches to guide the path of the light along a chip—all the ingredients for circuits and computations.

#nanotechnology#materialsscience#advancedmaterials#electronics#photonics#science#research#technology

122 notes

·

View notes

Text

youtube

Get Sample Report Copy From Here: https://www.acumenresearchandconsulti... The Global Biomimetic Materials Market, valued at USD 41.8 billion in 2023, is projected to reach USD 72.7 billion by 2032, growing at a CAGR of 6.4% from 2024 to 2032. Biomimetic materials, inspired by natural systems and biological processes, are designed to mimic the properties and functions of natural materials. These materials are revolutionizing industries such as healthcare, construction, automotive, and aerospace due to their superior properties, including high strength, lightweight nature, self-healing capabilities, and enhanced durability. Related Reports: https://www.acumenresearchandconsulti... https://www.acumenresearchandconsulti... https://www.acumenresearchandconsulti... https://www.acumenresearchandconsulti...

#biomimeticmaterials#natureinspiredinnovation#sustainablematerials#advancedmanufacturing#biomimicry#innovativetechnology#healthcarematerials#materialsscience#ecofriendlysolutions#markettrends#futureofmaterials#biomimeticdesign#globalmarketgrowth#advancedmaterials#sustainabilityinaction#biomimeticapplications#smartmaterials#nanotechnology#materialsinnovation#industrialadvancements#marketresearchreport#marketresearch#acumenresearchandconsulting#marketresearchcompany#news#Youtube

1 note

·

View note

Text

Trust epoxy fiberglass tubes for lightweight strength and reliable insulation ⚙️🔌 Fenhar:https://www.fenharxz.com

0 notes

Text

#medical imaging#solar energy#QuantumDots#Nanotechnology#DisplayTech#MedicalImaging#QuantumComputing#Visiongain#TechInnovation#Photonics#EnergyEfficiency#NextGenMaterials#AdvancedMaterials#MarketTrends2025#electronicsnews#technologynews

0 notes

Text

youtube

Get in-depth analysis of the Japan molybdenum market report 2025! In this comprehensive report, we provide insights into the key trends, market dynamics, and growth opportunities shaping the Japan molybdenum industry. Whether you're a industry professional, an investor, or looking to know about the market trends, this report is your go-to resource.

Key Highlights:

Market Overview: Get insights into the historical and forecast data of the Japan molybdenum market. Market Trends and Drivers: Explore the latest trends and factors influencing market sector, fund size, and funding type. Industry Segment Analysis: Understand Industry Segmentation the market based on product type, sales channel, and end user. Regional Analysis: Get regional Insights and market dynamics impacting different geographical areas. Competitive Landscape: Read about comprehensive overview of key players, their strategies, and market positioning. Report Edition: 2025-2033

Who Should Watch?

Industry Professionals Investors and Stakeholders Researchers and Analysts Food and Beverage Enthusiasts Business Owners and Entrepreneurs

Report Links: https://www.imarcgroup.com/japan-molybdenum-market

Follow us on LinkedIn: https://www.linkedin.com/company/imarc-group/.

Youtube Link: https://youtu.be/w3Sk3C65FMc

Contact Us: IMARC Group 134 N 4th St. Brooklyn, NY 11249, USA Email: [email protected] Tel No: (D) +91 120 433 0800 United States: +1-631-791-1145

#JapanMolybdenumMarket#MolybdenumTrends#AdvancedMaterials#GreenEnergy#MetalInnovation#AerospaceAlloys#EVMaterials#StrategicMetals#IndustrialGrowth#TechMetals#Youtube

0 notes