#automatic embossing machine

Explore tagged Tumblr posts

Text

What Are the Latest Trends in Paper Bag Manufacturing?

With plastic bans being enforced in many regions and consumers demanding eco-friendly packaging options, the paper bag industry is experiencing rapid growth and innovation. What began as a simple switch from plastic to paper has now evolved into a competitive, design-driven, and technology-led industry.

At Prakash Machineries Pvt. Ltd ,we closely follow market trends to help our clients stay ahead. Whether you're starting a paper bag business or expanding your production, understanding these trends can guide your investment decisions, marketing, and product innovation.

Let’s explore the latest trends shaping the paper bag manufacturing industry in 2025.

1. Square Bottom Paper Bags in High Demand

One of the biggest shifts is the increased demand for square bottom paper bags. Compared to V-bottom bags, square bottom bags offer:

A flat, stable base that helps bags stand upright

More space for branding and printing

Higher weight capacity for items like groceries, food boxes, and garments

As a result, many businesses are upgrading to automatic square bottom bag machines, which offer high output and premium-quality bags.

2. Rise of Automatic & High-Speed Machines

Modern businesses want speed, accuracy, and scalability. That’s why fully automatic paper bag machines are replacing manual setups. These machines come with:

Servo control systems for precise cutting and folding

Touchscreen HMIs for quick bag size adjustments

Inline Flex0 printing units

Handle pasting attachments for luxury paper bags

Automation reduces labor costs and improves consistency, making it a must for manufacturers handling bulk or export orders.

3. Eco-Friendly and Recycled Paper Usage

With growing concern for sustainability, businesses are opting for:

100% recycled Kraft paper

Food-grade paper for restaurants and bakeries

Bleach-free and biodegradable materials

Consumers now look for “green packaging” labels, and manufacturers who use eco-certified paper are gaining a competitive edge.

4. Printed & Custom Branded Bags

In 2025, a paper bag is not just packaging—it’s a marketing tool. More brands now demand:

Custom-printed paper bags with vibrant colors

QR codes, logos, and taglines on the bags

Brand-specific sizes and handles

This has increased the demand for multi-color flexographic printers and inline printing-equipped bag machines. Printed paper bags are especially popular among:

Clothing stores

Cafes and bakeries

Corporate events and exhibitions

5. Twisted & Flat Handle Bags on the Rise

Handles add value and convenience to paper bags. The two most trending styles are:

Twisted paper handles (premium look, used in boutiques and corporate gifting)

Flat paper handles (durable and affordable, used in food delivery and retail)

Modern machines now offer inline or separate handle pasting units, allowing manufacturers to meet this trend without slowing down production.

6. Government Support & Eco-Compliance

Many governments, including in India, offer:

Subsidies for eco-friendly packaging units under MSME schemes

Low-interest loans for sustainable manufacturing

Plastic ban enforcement, which increases paper bag demand

Manufacturers who adopt energy-efficient machines and biodegradable materials are better positioned for future regulations and partnerships with eco-conscious brands.

7. Niche Bag Categories Emerging

As the market matures, paper bag manufacturers are moving into specialized segments such as:

Food-grade paper bags with grease-resistant lining

Medical and pharma bags (sanitized, tamper-proof)

Luxury paper bags with foil printing, embossing, and rope handles

E-commerce packaging made of high GSM Kraft paper

By targeting these niches, manufacturers can differentiate themselves and achieve better margins.

8. Digital Integration & Smart Machines

The latest machines come with:

Remote diagnostics and servicing

Digital counters and fault alerts

Memory storage for repeat orders

IoT-based monitoring systems (for large factories)

These features help manufacturers reduce downtime, optimize maintenance, and increase efficiency.

How Prakash Machineries Pvt. Ltd Supports These Trends

At Prakash Machineries Pvt. Ltd, we continuously upgrade our paper bag machines to meet these latest trends. Our offerings include:

✅ Fully automatic square bottom paper bag machines ✅ Inline flex0 printing systems (2, 4, 6 colors) ✅ Handle pasting units (flat & twisted) ✅ Machines supporting eco-paper from 35 to 150 GSM ✅ Customizable bag sizes, shapes, and branding tools

Whether you're a startup or a large-scale manufacturer, we provide the technology and support to stay future-ready.

The paper bag industry is no longer just about replacing plastic—it's about delivering quality, branding, and sustainability. As competition rises, manufacturers who embrace the latest technology and trends will lead the market.

By investing in automation, eco-compliance, and product variety, you can build a profitable and future-proof paper bag business.

📞 Ready to Upgrade Your Paper Bag Manufacturing Setup? Contact Prakash Machineries Pvt. Ltd for a demo of our latest machines

Get expert guidance based on your business size and goals

Start your journey in sustainable packaging with confidence

Let’s build a cleaner, greener tomorrow—one paper bag at a time.

#manufacturer#paper bag manufacturer#square bottom#v bottom#machine#paper bag#paper#flexo#breakfast#chocolate#alien stage#baking#chris sturniolo#cooking#cake#dan and phil#critical role#delicious

1 note

·

View note

Text

instagram has sussed out i am Some Sort of Bibliophile™️, but unfortunately what it’s done with this information is decide I need to see ads for personalized page embossers

why don’t you serve me ads for a machine that automatically dogears pages too!! or a device that cracks paperback spines while you’re at it!!!

i am viscerally horrified!!

2 notes

·

View notes

Text

From Preservation to Presentation - A Deep Dive into Meat Packaging Supplies

The world of meat packaging supplies is a crucial component of the food industry, ensuring that products reach consumers in optimal condition while adhering to strict safety standards. From butcher shops to industrial meat processing facilities, selecting appropriate packaging supplies is paramount to maintaining product quality, freshness, and integrity.

Vacuum Packaging Machines

Vacuum packaging machines are indispensable tools for preserving the freshness and extending the shelf life of meat products. These machines remove air from the packaging, creating a vacuum seal that inhibits bacterial growth and oxidation. By eliminating oxygen from the packaging environment, vacuum packaging helps prevent spoilage, freezer burn, and flavour loss.

When selecting a vacuum packaging machine, key features include chamber size, sealing bar length, vacuum strength, and control options. Whether you're packaging small batches of meat or high-volume production runs, choosing the right vacuum packaging machine is essential for ensuring efficient and consistent results.

Vacuum Packaging Bags and Rolls

In conjunction with vacuum packaging machines, vacuum packaging bags and rolls are essential supplies for packaging meat products. These bags are made from high-quality, food-grade materials such as polyethene (PE) or polyamide (PA), which offer excellent barrier properties and puncture resistance.

Vacuum packaging bags come in various sizes, thicknesses, and styles, including pouches, bags with embossed patterns for enhanced vacuum sealing, and rolls for custom-sized packaging. Selecting the appropriate vacuum packaging bags ensures proper product protection and shelf life while minimising waste and maximising efficiency.

Shrink Wrapping Equipment

Shrink wrapping equipment is commonly used for packaging meat products in retail settings, providing a secure and tamper-evident seal. This packaging method involves enclosing the meat in a plastic film, which is then heated to shrink tightly around the product, creating a protective barrier.

Shrink wrapping machines come in different configurations, including manual, semi-automatic, and fully automatic models, depending on the scale of operations and packaging requirements. By securely wrapping meat products in shrink film, these machines help maintain product freshness, appearance, and integrity while enhancing shelf appeal.

Butcher Paper and Dispensers

Butcher paper is a versatile packaging material commonly used for wrapping fresh cuts of meat in butcher shops, delis, and grocery stores. This durable paper provides a protective barrier against moisture and contaminants while allowing the meat to breathe, preserving its natural juices and flavours.

Butcher paper dispensers are essential tools for efficiently dispensing and cutting butcher paper to the desired length. These dispensers come in various styles, including countertop models and wall-mounted dispensers, providing convenience and ease of use in busy meat packaging environments.

Meat Trays and Pads

Meat trays and pads are essential packaging supplies for displaying and transporting fresh meat products. These trays are typically made from durable materials such as foam or plastic and are available in various sizes and configurations to accommodate different types of meat cuts.

Meat pads, also known as absorbent pads or meat soakers, are placed underneath the meat to absorb excess moisture and prevent leaks, ensuring product freshness and presentation. By providing stability and protection, meat trays and pads enhance the visual appeal of meat products while facilitating safe handling and transportation.

Vacuum Sealer Accessories

In addition to vacuum packaging machines and bags, various accessories are available to enhance the functionality and performance of vacuum sealers. These accessories include replacement sealing bars, maintenance kits, and vacuum sealer oil for lubrication and maintenance.

Furthermore, specialised attachments such as vacuum canisters, jar sealers, and wine stoppers expand the versatility of vacuum sealers, allowing for the vacuum sealing of a wide range of products beyond meat. By investing in quality accessories and performing regular maintenance, you can prolong the lifespan of your vacuum sealer and ensure consistent sealing performance.

0 notes

Text

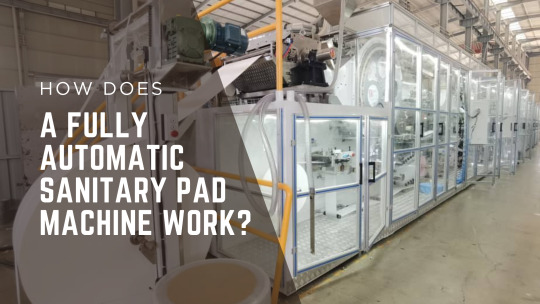

How Does a Fully Automatic Sanitary Pad Machine Work?

In India, people are considering menstruation an important part. So, access to affordable and hygienic menstrual products is also crucial for women’s health. A sanitary pad making machine fully automatic makes pads with little or no manual work. The good thing about these machines is that they help factories produce many pads fast. They could make good quality pads at low cost with this machine. In this blog, let’s understand how these machines work step by step, and what parts they have.

Raw Materials and Unwinding

Every sanitary pad has layers which includes a top layer made of soft non-woven fabric, an absorbent core and a leak-proof back sheet. These raw materials make the best quality sanitary pads. In the beginning, big rolls of these materials are loaded onto the machine. These rolls unwind slowly so materials move forward in proper order. The unwinding system keeps the layers straight and at the correct position to stretch it. This helps to avoid wrinkles or misalignment of the raw materials.

Precise Feeding and Cutting

After unwinding, materials will move to a feeding unit. Here they are guided into position and cut into the exact size for each pad. This needs to be accurate, because the top sheet, core, and back sheet must match perfectly. If it is not, then the pads will not work well and not satisfy the needs. The feeding unit is controlled by robots or motors which makes the process fast and precise.

Forming Unit

The next component is the forming unit. Once the layers are cut and aligned, they enter the forming unit. Here the absorbent core is put in the middle between the top and back layers such as sandwich. The machine uses heat and pressure to bind these layers together gently. This helps keep the absorbent core in place, so the pad works correctly during use.

Sealing and Edge Finishing

The formed pads then go to the sealing unit. In this part, hot air, adhesive, or ultrasonic tools seal the edges. This performs the sealing process and should be done properly to avoid leaks and stop the layers from coming apart. The machine also cuts off extra material neatly so that it can give an accurate and desired shape to the sanitary pad.

Embossing and Sterilization

These are the extra features in many machines. Many modern machines do embossing, which means adding patterns on the pad surface. In sanitary pad making machines, the feature of embossing helps absorb blood faster and evenly. Some advanced machines that one can use for this is a UV light chamber for sterilization. The use of sterilization is important because UV light kills microbes and keeps the pad safe and hygienic.

Packaging Unit

After sealing, pads go to the packaging unit where pads are either packed singly or in sets. In this process, packaging is often done by flow wrap or bagging system. For this, businesses use fully automatic machines that can pack pads at high speed. This will be helpful in preparing them for sale while maintaining hygiene and quality. These machines use sensors to ensure that each pad is packed correctly without damage. Along with this, other parts of packaging are done such as labels, batch numbers, and manufacturing dates are printed. Finally, the packed pads are collected and arranged in cartons for easy transport and storage.

Quality Control and Waste Collection

These machines have quality control systems to check each pad. During the process of quality control, the main aim is to make every sanitary pad test of high quality. These machines look for wrong shapes, torn edges, missing layers, or poor seals. If pads are not good then they can be removed automatically. Also, there’s a waste collector that gathers trimmed edges and leftover material to keep the factory clean and prevent material loss. In addition to this, high-speed cameras or sensors help in spotting tiny defects quickly. This system saves time and increases overall production efficiency. It also ensures that only perfect pads reach the packaging stage.

Control Panel and Automation

A sanitary pad making machine fully automatic uses modern controls. These include touchscreen panel, PLC (program logic controller), and servo motors. Operators who are operating the machine set the pad size, speed, and layers through the touch panel. As it is a fully automatic machine, it repeats the process precisely. Automation of the machine indicates high speed, consistent quality, and less human error. The system can store multiple pad designs for quick changeover. Align with this, there are features like alarms and messages that will appear on the screen if there’s any problem. These machines let the operators monitor real-time data for output count and running speed.

Production Speed and Capacity

These automatic machines are fast and can produce large quantities in just a few minutes. Some can make 80–150 pads per minute, and some high-end machines can make 120 pads per minute or even more. This kind of speed is beneficial for big production units. Also, it can help businesses to lower the sanitary pads manufacturing machine price per pad.

Sanitary Pads Manufacturing Machine Price

If you are planning to start a sanitary pad production unit, you might want to know the sanitary pads manufacturing machine price. Well, the cost of the machine will depend on the type of machine, its features and production capacity. Price of manual small-scale machine, semi-automatic machines and automatic machines will be different. Sanitary pad making machines fully automatic will have higher cost. These fully automatic sanitary pads making machines are expensive but highly efficient and high performing.

Conclusion So, this is how a fully automatic sanitary pad making machine works. It is found in big production units and is used as a smart machine. It uses modern technology to make pads quickly and precisely. The sanitary pads manufacturing machine price may look high in the beginning, but it helps in saving money in the long run.

0 notes

Text

Unmatched Forming Accuracy – Plunger Link Press Machine by Mankoo Presses

In the world of industrial metal forming, precision, durability, and efficiency are the benchmarks of a superior power press machine. Mankoo Presses, one of India’s leading names in mechanical press manufacturing, proudly presents the Plunger Guided Link Motion Power Press Machine — a solution engineered to deliver unmatched forming accuracy for the most demanding production environments.

About Mankoo Presses – A Legacy of Engineering Excellence

For decades, Mankoo Presses has been a trusted name in the field of mechanical power presses. With a deep commitment to quality, performance, and innovation, the company has established itself as a pioneer in manufacturing a wide range of forging and metal forming machines. From C-frame and H-frame presses to knuckle joint and friction screw presses, Mankoo continues to evolve its product line to serve the growing needs of heavy industries across India and abroad.

Their latest offering, the Plunger Guided Link Motion Press, is a reflection of their technological advancement and focus on high-precision manufacturing.

What is a Plunger Guided Link Motion Power Press?

The Plunger Guided Link Motion Power Press Machine is a specialized type of mechanical press that uses link motion technology combined with plunger-guided slide systems. This unique mechanism ensures a slower and controlled slide movement near the bottom dead center, which is essential for high-precision and high-quality metal stamping operations.

Unlike conventional crank presses, the link motion system reduces impact, vibration, and die wear, while the plunger guide ensures perfect vertical alignment, preventing side thrust and improving die life.

Key Benefits of Mankoo's Plunger Link Motion Press

1. Unparalleled Accuracy

The plunger-guided slide ensures the slide travels vertically without angular deviation. This is crucial in operations like blanking, embossing, deep drawing, and fine blanking, where high precision is non-negotiable.

2. Longer Tool Life

The link motion reduces the speed near the bottom of the stroke, which minimizes shock loads and increases the life of both the tool and the die.

3. Reduced Noise and Vibration

Compared to traditional presses, this machine operates with significantly lower noise and vibration, ensuring a better working environment and smoother operation.

4. Superior Load Distribution

The plunger guide system ensures uniform distribution of forming force, resulting in better surface finish and component consistency.

5. High Tonnage Capabilities

Mankoo's engineering allows for high-tonnage operations, making this machine suitable for automotive, defense, white goods, and electrical component manufacturing.

Technical Highlights of Mankoo’s Plunger Guided Link Press

Frame Type: Robust welded steel frame for minimum deflection

Slide Movement: Smooth, controlled link motion with adjustable stroke

Guiding System: 6-point plunger guide system for perfect alignment

Drive Mechanism: Flywheel driven with high-torque clutch and brake

Lubrication: Centralized and automated lubrication system

Safety: Integrated overload protection and electronic safety features

Every machine from Mankoo is tailor-made to meet specific client requirements, including optional features like die cushions, automatic feeders, and digital control panels.

Applications Across Industries

Mankoo’s Plunger Guided Link Motion Power Press finds wide applications in various industries such as:

Automotive: Pressing of structural body parts, brackets, and deep-drawn components

Electricals: Manufacturing of switchgear components, enclosures, and terminals

Home Appliances: Forming of panels, doors, and internal structural parts

Defense: Precision pressing of metal casings and armor plates

Hardware Tools: Punching, coining, and fine blanking of hardware components

Why Choose Mankoo Presses?

Custom Engineering

Mankoo offers customized press solutions to suit your exact operational requirements, ensuring perfect integration into your production lines.

Rugged Build Quality

All machines are built with heavy-duty, stress-relieved frames and components tested under real-world load conditions.

Pan-India Support

With an extensive service network, Mankoo provides installation, training, AMC, and rapid after-sales support across India.

Trusted by Industry Leaders

From OEMs to MSMEs, Mankoo machines power the production lines of India’s top manufacturers in metal forming and stamping.

Enhance Your Production with Intelligent Features

Mankoo’s latest models come equipped with smart automation features including:

Touchscreen HMI with diagnostics

Sensor-based die protection systems

Programmable logic controllers (PLC) for seamless operations

Integration with coil feeding and de-coiling lines

ROI-Driven Investment for Your Workshop

Choosing a Plunger Guided Link Motion Press by Mankoo isn’t just about machinery—it’s an investment in quality, reliability, and long-term profitability. With minimal downtime, low maintenance needs, and long tool life, the machine pays back faster and adds precision to your production capabilities.

Conclusion

The Plunger Guided Link Motion Power Press by Mankoo Presses is a testimony to India’s growing mechanical engineering strength. With its superior accuracy, controlled slide movement, and rugged design, this machine is the perfect solution for manufacturers aiming for higher output and zero defects. Mankoo continues to set new standards in metal forming with innovation, integrity, and industry-driven performance.

0 notes

Text

High-Speed Candy Wrapping Machine by Dhiman Industries

Dhiman Industries presents a revolutionary solution for the confectionery sector with its high-speed candy wrapping machine, designed to streamline and elevate the packaging process of candies in commercial production lines. Engineered with advanced automation and built for long-term performance, this high-speed candy wrapping machine reflects the brand’s legacy of precision, innovation, and reliability in sweet manufacturing equipment. The machine ensures maximum operational efficiency while reducing manual intervention, making it ideal for manufacturers seeking high-output candy production with consistent wrapping quality.

This high-speed candy wrapping machine from Dhiman Industries is meticulously crafted to handle various candy shapes and sizes with ease, from square and rectangular to round and oval forms. It boasts a dynamic feeding system that aligns candies with exactitude, preparing them for the synchronized wrapping mechanism that operates seamlessly even at high speeds. Every mechanical motion within the machine is optimized for durability and minimal downtime, allowing production teams to meet large-scale orders without compromising on wrapping aesthetics or sealing integrity.

One of the defining advantages of this high-speed candy wrapping machine is its adaptability across wrapping materials such as wax paper, aluminum foil, cellophane, and laminated films. This multi-material compatibility opens possibilities for customized packaging based on branding, preservation needs, and target markets. The machine's quick-change tooling system further allows operators to switch formats rapidly, reducing idle time during product transitions. Whether wrapping butter candies, fruit toffees, or center-filled treats, the machine delivers consistent results at impressive speeds.

At the heart of the Dhiman high-speed candy wrapping machine is its electronic control panel, powered by programmable logic controllers (PLC). This intelligent interface allows real-time monitoring of machine status, speed regulation, wrapping cycle synchronization, and fault detection alerts for smooth operation. Additionally, sensor-based feeding and cutting systems ensure that each candy piece is wrapped with precision, reducing material wastage and enhancing the final presentation of the product. These integrated smart systems make the machine not only efficient but also user-friendly and safe to operate.

The robust stainless-steel construction of the machine guarantees hygiene, resistance to corrosion, and easy maintenance. It complies with international food-grade safety standards, ensuring candies remain uncontaminated throughout the wrapping process. Cleaning and servicing are simplified with modular components and accessible design, reducing long-term maintenance efforts and operational interruptions. Moreover, the compact footprint of the machine makes it suitable even for factories with limited floor space, while still delivering industrial-scale output.

With speeds exceeding several hundred wraps per minute, this high-speed candy wrapping machine empowers manufacturers to scale their business without additional manpower or complex logistics. The machine also incorporates automatic feeding conveyors and waste collection systems, creating a closed-loop process that enhances productivity while maintaining cleanliness in the workspace. Noise reduction technology further ensures a quieter operation, contributing to a more pleasant working environment for factory staff.

Dhiman Industries has always prioritized precision engineering and customer-centric design in its machinery, and this candy wrapping machine is a true embodiment of that vision. The machine can be tailored with optional attachments such as embossing rollers for branding, date coding modules, and customized cutting knives for specific edge finishes. These value-added features help brands stand out in competitive markets by enhancing the packaging’s visual appeal and information accuracy. The machine's scalability also allows integration with downstream packaging systems like carton box fillers and shrink-wrapping units, completing the full production cycle.

Training and support provided by Dhiman Industries further add to the overall value of the machine. Clients receive installation assistance, operator training, maintenance guides, and access to a responsive technical support team that ensures continuous performance and peace of mind. The company’s commitment to after-sales service makes it a trusted partner for businesses looking to invest in reliable high-speed wrapping technology for long-term growth.

In conclusion, the high-speed candy wrapping machine by Dhiman Industries is a game-changing solution for the confectionery industry. It brings together speed, accuracy, hygiene, and smart automation in one compact, efficient, and adaptable system. For manufacturers aiming to improve their production capacity, reduce labor dependency, and deliver attractively wrapped products to the market, this machine stands as the perfect investment. Dhiman Industries continues to set benchmarks in confectionery machinery, and this innovative high-speed candy wrapping machine reinforces its leadership in delivering performance-driven solutions for modern candy production lines.

0 notes

Text

Advanced Braille Embossing Folder Gluer

We are Robus India, and we make high-speed machines that fold and glue cartons with built-in Braille embossing and automatic print checking. Our machine is perfect for pharmaceutical and FMCG companies who need fast, accurate, and international-standard packaging. It saves time, reduces errors, and increases production. We offer full support and training across India.

Fast folding & gluing Inline Braille for medicine boxes Auto inspection for printing & codes Strong build, easy to run

0 notes

Text

Behind the Bottle: How Luxury Hotels Are Crafting In-House Water Stories with Glass

Walk into a luxury hotel today and the details speak volumes before the staff does. From the linen folds to the room scent, every touchpoint whispers brand philosophy. But there’s one quiet revolution happening on bedside tables, in meeting rooms, and poolside cabanas: glass water bottles — branded, bottled in-house, and impossible to ignore.

When Water Tells a Story

Water is not just a necessity — it’s a reflection of a hotel’s ethos. And forward-thinking hotels aren’t outsourcing this basic amenity anymore. They’re turning to in house hotel glass bottle bottling plant to do it themselves — with style, sustainability, and soul.

This isn’t about just replacing plastic. It’s about creating a signature experience, and the most refined hotels are turning to Canadian Crystalline, the quiet giant revolutionizing this transformation.

A Glass Bottle is a Canvas

A plastic bottle says nothing. But a chilled glass bottle, etched with your hotel’s emblem and filled with pure, crystal-clear water? That tells your story — without saying a word.

Guests don’t just sip the water. They notice:

The weight of the bottle in hand

The clean pour into a tumbler

The minimalist label that matches the room’s palette

The unspoken message: “We care.”

That’s what glass water bottle filling for hotels is achieving — silent, powerful branding.

Why Hotels Are Turning Inward

Outsourcing water supply used to be the norm. But it came with baggage:

Plastic waste that contradicted sustainability pledges

Inconsistent water taste

Stock delays and dependence on vendors

Canadian Crystalline saw the shift coming. Their R&D teams designed compact, automated in-house glass bottling plants tailor-made for the hospitality world — quiet, efficient, elegant.

Suddenly, hotels didn’t just serve water. They crafted it.

Inside the Hotel’s Hidden Bottling Studio

Think of it like a hotel’s private kitchen — but for water.

Canadian Crystalline installs systems that:

Purify on-site water through multi-stage treatment (RO, UV, ozone)

Automatically rinse, fill, and seal reusable glass bottles

Allow full customization: shape, label, caps, embossing

Operate quietly behind the scenes, with minimal staff

These aren’t big industrial plants. They’re sleek, modular units built to tuck into back-end spaces — and transform operations with almost no friction.

What Canadian Crystalline Does Differently

While others sell machines, Canadian Crystalline crafts long-term solutions for prestige hospitality brands. Their edge?

✔️ Tailored systems — No one-size-fits-all. Boutique beach resort or 400-room city tower? They build accordingly. ✔️ Aesthetic sensibility — Bottles that match your brand palette and elegance ✔️ Silent performance — Whisper-quiet systems that operate without disrupting ambiance ✔️ Proactive support — Not just installation, but training, service, and upgrades

They’re not just a supplier. They’re your brand partner in water.

Why Glass is Winning the Luxury Game

Let’s be honest — plastic never belonged in a five-star room. And guests know it. Glass, on the other hand, hits every note:

Premium feel

Pure, neutral taste

Zero microplastics

Reusability and eco pride

Guests remember details. They Instagram them. And nothing beats the aesthetic of a glass water bottle reflecting soft light on a marble bedside table.

ROI: It’s Not Just Sustainability. It’s Smart Business.

An in-house glass bottling plant isn’t an expense. It’s an investment that starts paying back from Month One.

Here’s why:

Bulk plastic bottle supply chain? Eliminated.

Custom glass bottles? Reused for years.

Water cost per litre? Drops drastically.

Brand lift? Immeasurable.

Many of Canadian Crystalline’s hotel clients report:

Over 70% reduction in plastic usage

Guest satisfaction scores rising post-installation

F&B service using branded bottles as marketing collateral

Glass Bottling: The Secret Ingredient in Guest Loyalty

Today’s traveler is aware. They notice and reward thoughtful details. When your hotel bottles its own water, you signal more than sustainability:

You say, “We think ahead. We deliver differently.”

Imagine a guest checking in, spotting a chilled bottle embossed with your hotel’s crest. They read the subtle tag:

“Purified and bottled fresh for you, right here.

It’s not just water. It’s connection.

Not Just for Rooms: Think Bigger

Your in-house glass bottle bottling plant doesn’t just serve rooms. Canadian Crystalline systems scale effortlessly for:

Banquets & Conferences — no more piles of single-use bottles

Spa & Wellness — elevate the detox experience

Restaurant Tables — serve still and sparkling with style

Mini Bars — upsell elegance, not plastic

Future-Proofing Your Hotel’s Identity

Sustainability isn’t a trend. It’s the new standard. The hotels getting ahead are those weaving eco-consciousness into luxury, not just checking boxes.

Glass is here to stay. And with Canadian Crystalline by your side, your hotel becomes part of the story shaping the future of luxury hospitality.

Conclusion: The Bottle Is Just the Beginning

Guests remember emotions, not amenities. The quiet pride in serving your own water — sustainably, beautifully — isn’t about cost-saving. It’s about identity, values, and impact.

The next time a guest raises a glass bottle in your hotel room, let it reflect more than just water. Let it reflect your brand’s story — crafted, conscious, and proudly yours.

With Canadian Crystalline, your hotel doesn’t just offer water. It offers a statement.

#in house water bottling plant#glass bottles in hotels#glass bottling plant#glass bottling plant manufacturer

0 notes

Text

Pills, Powders & Precision: How Nichrome is Redefining Pharmaceutical Packaging in Bangladesh

In the dynamic world of pharmaceuticals, packaging of every pill, capsule and ointment counts. One misguided step, and the negative ramifications could be more than expensive — they could be catastrophic. That’s why when it comes to packaging machine suppliers in Bangladesh, there’s one name that’s stirring the pot with innovation and precision—Nichrome Packaging Solutions.

We don’t just package medicines—we package safety, accuracy, regulatory compliance, and trust. Whether it is powder packaging machines, ointment tube filling machines, blister card packaging, or capsule filling machine integrations, Nichrome is the future of pharma packaging, with reliability and flair.

How about we unpack this journey, shall we?

Pharmaceutical Packaging: More Than Just Wrapping

In Bangladesh’s booming pharmaceutical industry, packaging isn’t merely the final step — it’s the step that matters most. Think of it as the silent guardian of efficacy, hygiene and brand trust. Whether it’s a silica gel packing machine safeguarding moisture-sensitive tablets or a blister packaging system protecting unit doses, pharmaceutical packaging is the unsung hero.

At Nichrome, we believe packaging is where compliance, technology and innovation meet. With our filling and packaging machines, you don’t just meet global standards; you embrace them, with style.

Because in pharma, packaging is more than a box—it’s a promise.

Tablet Tooling: Where Form Meets Function

Now before we get into the nitty-gritty about tablet packaging machines, let’s move a bit deeper into things — all the way to the basics of tablets themselves.

Tablet tooling involves the art and science of shaping and embossing tablets. It’s what provides tablets with their identity; appearance, designs, and trademarks. We as the leading pharma machine manufacturers understand the value of tooling accuracy and calibration, which means each tablet that enters our capsule filling machines or a table top blister packaging machines is uniform, compliant and made to perfection.

Punching Up the Production Game: Types of Presses

There are two principal tablet presses:

Single-punch tablet presses – Ideal for small-scale production or R&D

Rotary tablet presses – The first option for industrial production

And here’s the twist: Nichrome guarantees seamless downstream packaging integration for both.

So if you’re interested in higher throughput, multi-tip tooling is the way to go. It increases productivity without additional machines — a win-win for lean operations.

Custom Tooling: Because One Size Doesn’t Fit All

Whether you're after a pill shaped like a heart for branding or embossed text for compliance, Nichrome accommodates custom tooling that safeguards visual identity of the product without compromising on packaging.

Therefore when you partner with us as your packaging machine supplier in Bangladesh, you’ll be selecting someone who really cares, from the inside out.

Tablet Counting and Filling Machines: The Accuracy Avengers

Ever tried to count 10,000 capsules by hand? Of course not! No one likes to do that because neither it is fun, nor it guarantees the true precision required for the task.

Our Tablet counting & filling machines are precision beasts designed to eliminate human error and maximize speed.

Features That Count

Nichrome’s advanced tablet counters offer:

High-speed counting sensors

Dust-resistant optical systems

Multi-lane configurations

Integration with bottle cappers, labeling systems, and sealers

From semi-automatic systems to fully automated lines, each container gets exactly what the doctor ordered. Here are some of the many benefits that you can expect from us:

Reduced human error

Increased compliance

Shorter turnaround times

Data traceability

As a top packaging company in Bangladesh, Nichrome’s solutions not only count accurately but also count where it matters—in ROI.

Blister Packaging: Sealing the Deal with Style

Let’s face it—there’s something satisfying about popping a pill out of a blister pack packaging.

But there is a serious technology behind that satisfying pop. Our blister packaging machines are designed to protect medications from moisture, light, and tampering while bringing professional aesthetics.

Different Kinds of Blister Packs We Can Handle:

Thermoform blister packaging – Best for tablets and capsules.

Cold-form blister packs – A saviour for heat sensitive formulations.

Heat-seal blisters – Strong and tamper-proof.

Our table top blister packaging machines do just that to bring this technology to compact, efficient formats—ideal for dynamic pharma environments in Bangladesh.

So if you're handling alu alu packing, blister card packaging, or unit-dose meds, our systems are ready to keep your products safe and sharp-looking.

The Filling Squad: Ointments, Powders, and More

Here’s where we fill you in—literally.

Nichrome’s suite of ointment filling machines, powder packaging machines, and pouch packaging machines are designed to streamline pharmaceutical packaging without missing a beat.

Ointment Filling: Smooth Operators

Ointments might be a viscous, but our machines have no trouble handling them. Our ointment tube filling machines are dedicated to filling ointment tubes:

Precision fill volumes

Clean cut-off systems

Heat sealing

Batch coding-labeling systems

Be it filling ointments, creams, gels, or pastes, ointment filling machines by Nichrome are here to be your perfect packaging partner.

Powder Packaging: Dust Off the Old Ways

Say no to messy scooping or inaccurate dosing, our advanced powder packing machines, are specifically for pharmaceutical powder - think antibiotics, rehydration salts, and more. The benefits include:

Accurate dosing systems

Air-tight pouch sealing

Compliance-ready print and batch traceability

From sachets to pouches and bottles, our state-of-the-art packaging machines allow you to automate dust-free and fuss-free.

Silica Gel Packing Machines: Small Packets, Big Impact

Solutions like Silica gel packing machines by Nichrome are designed to pack small packets of silica gel, which are used as desiccants to absorb moisture and protect products from damage caused by humidity.

The packing of these is done fast and accurately in our compact form systems to prevent the moisture in drugs, and of course they integrate beautifully with our cartoning machines and primary packaging systems.

Nichrome: Packaging Bangladesh’s Pharma Ambitions

If reliability in selecting a pharmaceutical packaging machine is the only thing that matters, Nichrome shines brightest. Be it blister, strip, and alu alu packing, a versatile capsule packing machine, fast, hygienic, and highly customizable powder packing machines, flagship ointment tube filling machine or pouch packaging machine, we have every angle covered for a production line.

From automatic table packaging machines to tablet bottle filling machine manufacturers, every machine is constructed using pharma-grade stainless steel paired with highly automated control systems and built-in validation systems for regulatory compliance.

Pharma-Grade Customization

As a trusted packaging machine supplier in Bangladesh, we go beyond standard models. We offer:

Customized machine design

Flexible integration with upstream/downstream systems

After-sales support, spare parts, and maintenance

Whether you're a startup or a global pharma giant, we tailor every solution to your exact needs.

Partnerships That Constantly Go the Extra Mile

Bangladesh’s pharma sector is booming—and Nichrome is all set to provide its growing needs.

We’ve partnered with local pharmaceutical leaders to deliver:

Faster go-to-market packaging

Reduced downtime

Global regulatory compliance

Unmatched equipment longevity

And we’re not stopping anytime soon.

The Nichrome Edge: More Than Just Machines

At Nichrome we are building a world of possibilities with our wide range of advanced machines. We’re innovators, integrators and idea catalysts with a daring mission: to transform the future of pharmaceutical packaging in Bangladesh.

Our role isn’t limited to supplying machines. We engineer ecosystems. We don’t just automate tasks—we architect solutions. With every pharma client we serve, we co-create packaging systems that are purpose-built to perform and primed for progress.

Our systems are built to promote:

Efficient Packaging Solutions - In pharmaceuticals, time is medicine. With a focus on throughput, our solutions are precision-based to reduce downtime and accelerate the production pipeline from the fill to the final fusion. Every second saved, every movement alleviated is a greater margin and faster time to market.

Scalable Packaging Options - Whether you’re a startup pharma manufacturer or a large-scale enterprise looking to increase your capacity, Nichrome systems scale up with you. With our modular designs, new functionalities could be implemented seamlessly without a complete rewrite of the system. It’s packaging that grows as you do.

Smart Packaging - We embed smart sensors, real-time monitoring and data-enabled decision-making in our solutions. Traceability, error detection, automated adjustments — everything about them seeks to empower precision, ensure compliance and lower reliance on the human factor.

From high-speed filling machines used in tablet and capsule manufacturing to advanced labeling and track-and-trace systems for regulatory compliance—we bring full-spectrum automation under one smart, strategic umbrella.

We operate at the intersection of pharma quality and packaging savvy, and deliver advanced machines that meet the need of every segment of the pharma value chain:

Granule filling for sachets

Viscous liquid filling for syrups

Powder filling for oral suspensions

Sterile packing for injectables

Strip and blister packaging for tablets

Cartoning, labeling, and final bundling

It’s not only about moving machines. It’s about systems that can think, adapt, and evolve.

Conclusion: Time to Seal the Deal with Nichrome

In a market flooded with generic packaging machines, Nichrome delivers performance with personality. We’re the only packaging machine supplier in Bangladesh who puts as much heart into your packaging as you do into your formulations.

From powder packaging machines to ointment filling machines, from silica gel packing machines to blister card packaging—our solutions are precise, powerful, and always ahead of the curve.

Ready to automate your pharmaceutical packaging with confidence? Let’s talk about machines, efficiency, and the future. Connect with Nichrome today. Because when precision matters, Nichrome Packages Trust.

0 notes

Text

5 Axis CNC Milling Router Machine for Custom Mold

5 axis CNC wood machine is a highly advanced and versatile machine that can greatly improve the speed, accuracy, and quality of woodworking projects. By providing greater flexibility and precision in the cutting process, a 5-axis CNC wood machine can help woodworkers to create complex and intricate designs with ease and efficiency.By providing greater flexibility and precision in the cutting process, a 5-axis CNC milling router can help manufacturers and designers to create complex and intricate designs with ease and efficiency.

So this 3d CNC router milling machine can realize embossing, lettering, hollowing, cutting, vertical carving, round carving, etc,it also can be seamlessly spliced, suitable for various shapes.And this machine has widely used in foam molds, wooden sculptures, aerospace models, disappearing casting foam molds, large sculptures, wedding decorations, external wall dry hanging, garden engineering, large sculptures, handicrafts and other industries.

5 axis cnc router machine for sale

The 5 axis CNC mill is equipped with a 5-axis head, and plus a 9kw automatic tool change air cooling spindle, which makes the machine more powerful. Syntec CNC controller Taiwan of 5 axis foam CNC has high-speed precision, which greatly improves the production efficiency of 5 axis router. The 5 axis router is suitable for processing foam, 3D molds, other materials.If you plan to buy a Chinese 5 axis CNC mill, iGOLDENCNC’s multi-function 5 axis woodworking CNC machine will be your best choice.

5-axis machining also provides the ability to machine extremely complex parts from a solid, and this type of machining can also save a lot of drilling time. Drilling a series of holes with different compound angles is very time consuming. With a five-axis machine, the drill can be automatically oriented along the correct axis for each hole, so that the drilling can be completed faster. 5-axis CNC machine can reach even the most complex angles.

If your parts require complex 4D and 5D parts, then you need a machine shop equipped with 5-axis machines and the best operators. Combined with the highest finishing and tolerances, we are able to achieve complexity that cannot be achieved with 2-axis or 3-axis machine. It only needs to be set once, which can be transformed into higher productivity and higher workpiece quality. This process allows you to machine complex parts that would otherwise require casting. If you have low-volume production or prototype manufacturing, you can machine parts in a few weeks instead of waiting months to complete the casting.

Automatic tool changers: These systems can automatically changecutting tools during the cutting process, allowing the machine to perform multiple operations without the need for manual intervention.

T-Slot Working 5 Axis CNC Table

The 5 axis router aluminum CNC router table with “T” groove, the wood CNC table for mechanically fixing the Syntec CNC router is made of a special reinforced aluminum plate and is separated by grooves to accommodate the fixture.

This 5 axis CNC machine has a large workbench, the standard area of the workbench is: 2000*3000*1000mm. This workbench can almost accommodate most materials. And the size of this machine can be customized. The length could be as long as 12 meters, and the width of the machine could be as wide as 3 meters, and the Z working height of the machine could be 2 meters. If you think The size is too large or too small, then you can tell us the size you want, and we can make the machine you want according to your requirements.

Advanced Accessories Of CNC Foam Router Machine

This large 5 axis CNC woodworking machine adopts the Japanese Shimpo reducer, which has high precision, high stability, and good wear resistance. And it adopts the Hiwin square rail. The guide rail is high precision, low noise, wear-resistant, and long service life. The 5-axis CNC router machine uses a vacuum and aluminum T-slot working table, which is multi-functional and the material can be fixed easier.

The 5 axis woodworking cnc router with ATC function, it’s easy to accomplish full set processing of complex parts from milling, slotting, drilling, sawing, mortise, mortise, etc, the advanced model designed by iGOLDENCNC, combined with a competitive set of configurations.

Hot applications include:

Composite materials industry: Trimming and punching of various composite materials such as plastic parts, glass fiber reinforced plastic parts, rubber and plastic products;

Mold industry: 5 axis processing of FRP wood mold, casting wood mold, resin products, sludge model and various non-metal molds;

Ceramic sanitary industry: 5 axis processing of gypsum molds, 5 axis processing of various gypsum products;

Furniture industry: 5 axis processing of solid wood furniture, 5 axis processing of various furniture tenon and mortise pieces, 5 axis processing of stair elbows, and 5 axis processing of various furniture.

0 notes

Text

0 notes

Text

TAZJ601400 (DLLW-800) 4feets gravure printing coating (embossing) machine

This machine is designed specifically for pre impregnated paper printing, coating, and embossing in one go.

Equipped with printing and coating, vertical and horizontal, multi-layer oven, and embossing unit.

The design has three major uses: printing, printing and coating, and printing and coating embossing.

There are three groups for storage: 1 group for storage, 2 groups for storage, 1 group for printing, and 1 group for coating and pressing.

High precision full servo motor synchronous printing, computer printing, automatic cutting and material changing.

Contact Us

Phone: +86-13757197838 (Manager Chen)

Tel: +86-0571-61071715

Fax: +86-0571-61071706

Mail: [email protected]

Add: No.32 Wujiatou, Qingke Village, Jincheng Street, Lin'an District, Hangzhou City, Zhejiang Province

0 notes

Text

Shape with Confidence – Advanced C Channel Roll Forming by Jugmug

In today’s age of industrial precision and structural performance, C channel profiles are more than just pieces of metal—they are the backbone of strong, dependable frameworks. At the heart of these robust profiles lies the C Post Channel Roll Forming Machine, and no one understands this better than Jugmug RollForming. With years of engineering expertise, Jugmug has become a name synonymous with precision forming, durability, and customer-focused innovation.

What Is a C Channel Roll Forming Machine?

A C Channel Roll Forming Machine, also known as a C Post Roll Former, is used to manufacture C-shaped steel sections from metal coils. These profiles are widely used in:

Construction (purlins, wall studs)

Industrial shelving

Cable tray supports

Solar panel mounting structures

Automotive and transportation frames

The forming process ensures accurate dimensions, clean edges, and consistent shapes, which are critical for structural stability and assembly efficiency.

Why Jugmug RollForming?

With a heritage of craftsmanship and a passion for innovation, Jugmug RollForming has revolutionized how industries view roll forming. Here's why Jugmug leads the pack in C Channel Roll Forming:

1. Precision Engineering

Jugmug’s machines are designed using advanced CAD/CAM systems and assembled with CNC-manufactured components. The result is ultra-precise forming even at high speeds, with tolerance control up to ±0.5mm.

2. Heavy-Duty Build Quality

Built with rugged structural frames, hardened rollers, and wear-resistant shafts, these machines are engineered for long-term, high-volume performance without breakdowns.

3. High-Speed Automation

Equipped with PLC control systems, servo motors, and hydraulic punching/cutting, Jugmug’s C Post machines reduce human error and improve productivity. The touchscreen HMI makes operation simple and intuitive.

4. Customization on Demand

Every business has unique needs. Jugmug provides tailor-made C channel forming machines, whether you require:

Variable sizes and gauges (1.2 mm to 3 mm)

Manual or fully automatic operation

In-line punching, embossing, or logo marking

Quick-change cassette design for multiple profiles

Applications of C Channel Profiles

The C profiles manufactured using Jugmug’s machines find applications in:

Construction

Used as wall studs, roof purlins, girts, and base plates due to their load-bearing capacity and resistance to warping.

Solar Panel Mounting

C channels are widely used to fabricate the structural framework for solar PV systems.

Automotive Chassis & Framework

Because of their strength-to-weight ratio, C channels are ideal for reinforcing vehicle bodies and cargo enclosures.

Racking & Storage Systems

Industrial shelving systems often rely on C profiles for their modular, load-bearing structure.

Customer Success Stories

Jugmug RollForming has delivered its C channel machines across India and globally. Many manufacturers in the solar, automotive, construction, and logistics sectors report:

30% increased output

Reduced material wastage

Quick ROI (within 12-18 months)

Minimal downtime

After-Sales Support & Training

Jugmug doesn’t stop at selling the machine—it partners with you throughout the journey. Their post-sale support includes:

Installation & operator training

Preventive maintenance plans

Spare parts availability

Remote troubleshooting support

Annual servicing packages

Their team of qualified engineers is just a call away, offering pan-India coverage and global service reach.

Green Manufacturing with Jugmug

In alignment with sustainability goals, Jugmug machines are designed to optimize energy usage and reduce raw material waste. The machines feature:

Servo-driven motors for low energy consumption

Smart sensors for real-time quality control

Eco-friendly hydraulic systems

By adopting Jugmug’s forming systems, manufacturers not only boost output but also reduce their carbon footprint.

Conclusion: Shape with Confidence

When strength, accuracy, and speed matter, Jugmug RollForming’s C Channel Roll Forming Machine delivers with unmatched precision. Whether you are scaling up production or entering new markets, Jugmug ensures your foundation is strong—both literally and technically.

Shape your future with confidence—partner with Jugmug RollForming.

#C channel roll forming machine#C post forming machine manufacturer#C profile making machine India#Jugmug RollForming machines#Structural roll forming equipment#Roll forming machine for solar structures#Best C channel machine in India

0 notes

Text

Professional Wood Door Panel Spray Painting Machine --0086-15931098079

🌟 Automatic Door Panel Spray Painting Machine** – engineered to deliver flawless finishes, reduce waste, and maximize productivity. Designed for furniture manufacturers, cabinetry workshops, and large-scale woodworking operations, this machine is your ultimate solution for achieving high-quality, uniform coatings on door panels of all sizes and designs.

✅ Smart Automation:

Programmable robotic arms ensure consistent spray patterns and precise coverage, eliminating human error.

Adjustable settings for paint thickness, speed, and drying time to match your project requirements.

✅ Eco-Friendly & Cost-Effective:

Advanced paint recycling system reduces overspray by 5%up to 20%**, saving material costs and minimizing environmental impact.

Low-VOC paint compatibility supports sustainable manufacturing practices.

✅ Versatile Application:

Compatible with all paint types (water-based, oil-based, UV coatings) and door materials (solid wood, MDF, HDF, laminate).

Handles flat, carved, and embossed panels effortlessly.

✅ Durability & Safety:

Stainless-steel construction with corrosion-resistant components for long-term reliability.

Built-in safety sensors and ventilation systems ensure operator protection and workspace compliance.

✅ Easy Integration:

Seamlessly connects to existing production lines with minimal downtime.

User-friendly touchscreen interface for quick setup and real-time monitoring. Technical Specifications:

Spray Width: 200-1300 mm (adjustable)

Speed: 2–15 m/min (customizable)

Power: 380V/220V options

**Why Choose Us? ✔ *10+ Years of Industry Expertise* – Trusted by leading woodworking brands worldwide. ✔ 24/7 Technical Support – From installation to maintenance, we’ve got you covered. ✔ Custom Solutions – Tailor the machine to your specific production needs.

**Act Now! Transform your door panel finishing process into a Qingdao YICH Mechanical ---0086-15931098079

0 notes

Text

Foiling Machine Manufacturers and Suppliers in India: Enhance Your Packaging with Creofoil

In today's competitive market, product packaging plays a crucial role in attracting customers and enhancing brand value. Foiling Machine Manufacturers and Suppliers in India are at the forefront of providing high-quality solutions that ensure premium packaging aesthetics. Among them, Creofoil stands out as a trusted name in delivering advanced foiling machines tailored to meet diverse industry needs.

Why Choose Foiling Machines for Packaging?

Foiling machines are widely used in industries such as printing, packaging, cosmetics, and pharmaceuticals to add a touch of elegance and sophistication to products. Whether it's metallic foiling, holographic effects, or embossed finishes, these machines offer a superior level of detailing that enhances product appeal.

Key Benefits of Using Foiling Machines:

Premium Finishing – Adds a luxurious and eye-catching effect to packaging.

Durability – Foiling enhances the longevity of prints and prevents wear and tear.

Customization – Enables businesses to create unique branding elements with foil stamping.

Eco-Friendly Options – Modern foiling techniques minimize waste and use sustainable materials.

Creofoil: Leading the Foiling Machine Industry in India

As one of the leading Foiling Machine Manufacturers and Suppliers in India, Creofoil is committed to providing cutting-edge technology and reliable solutions. Our machines are designed for efficiency, precision, and ease of operation, making them ideal for businesses looking to elevate their packaging standards.

Our Range of Foiling Machines:

Automatic Foiling Machines – High-speed, precision-driven machines for large-scale production.

Manual Foiling Machines – Perfect for small businesses and custom packaging solutions.

Hot Stamping Foiling Machines – Ideal for high-quality printing on paper, leather, plastics, and more.

Holographic Foiling Machines – Enhance security and aesthetic appeal with holographic effects.

Why Choose Creofoil?

Advanced Technology: State-of-the-art machinery ensuring flawless results.

Customization Options: Tailor-made solutions to match specific business needs.

Reliable Support: Dedicated customer service and technical assistance.

Industry Expertise: Years of experience in manufacturing top-tier foiling machines.

Elevate Your Packaging with Creofoil

If you’re looking for the best Foiling Machine Manufacturers and Suppliers in India, Creofoil is your trusted partner. We provide innovative and high-performance foiling machines that enhance the visual appeal and durability of your packaging.

Contact us today at creofoil.com to explore our range of foiling machines and transform your packaging with premium finishing solutions

#Foiling Machine Manufacturers and Suppliers in India#Foiling Machine Manufactureres#Foiling Machine Suppliers

0 notes

Text

Embosser Stamp: A Powerful Tool for Personalization and Professionalism

An embosser stamp is a versatile tool that provides a raised impression of a design or text on paper, making it an excellent choice for adding a personalized or professional touch to your documents, books, and stationery. Whether you’re a business owner, a book lover, or someone who enjoys making a statement with your correspondence, an embosser stamp is a valuable asset. In this article, we’ll explore what an embosser stamp is, its benefits, and how it can be used to enhance your work and personal projects.

What is an Embosser Stamp?

An embosser stamp is a tool used to create raised designs or text on paper by pressing the material between two metal plates. These plates contain the design or text that you want to imprint, and when you apply pressure, the design is transferred onto the paper, leaving a raised impression. The result is an elegant, tactile mark that looks and feels professional. Embossers are often used for personalization, branding, or official documentation.

Benefits of Using an Embosser Stamp

1. Professional Appearance

One of the most compelling reasons to use an embosser stamp is its ability to create a polished, professional look. Whether you’re using it for business documents, certificates, or personal correspondence, the raised design adds an air of sophistication and authenticity to your work. It gives your materials a high-quality finish that stands out.

2. Personalization

An embosser stamp allows for a high level of personalization. You can choose to imprint your name, initials, company logo, or any custom design you wish. This makes it easy to add a personal touch to items such as books, letters, invitations, and even wedding stationery.

3. Durability and Longevity

The raised imprint created by an embosser stamp is permanent. Unlike ink stamps or stickers that can fade, peel, or wear off over time, the raised impression is durable and will last for years. This ensures that your personalized imprint remains crisp and clear on your documents for as long as you need.

4. Easy to Use

Embosser stamps are relatively easy to use and don’t require advanced skills or techniques. The design or text is already set on the plates, and all you need to do is place the paper between the plates and apply pressure to create the desired imprint. The simplicity and convenience make embossers suitable for both personal and professional use.

Types of Embosser Stamps

1. Handheld Embosser Stamps

Handheld embosser stamps are compact, portable tools that are perfect for personal use or small businesses. They allow you to emboss your design on individual items quickly and easily. Handheld embossers are ideal for adding personalized touches to books, letters, or certificates.

2. Desk Embosser Stamps

Desk embosser stamps are larger, more robust tools designed for frequent use. They are perfect for offices or organizations that require a high volume of impressions. Desk embossers offer more precision and can handle a larger stack of paper at once, making them ideal for use in professional settings.

3. Electronic Embosser Stamps

Electronic embosser stamps provide the ultimate convenience for those who need to emboss many documents quickly. These automatic machines offer consistent, precise impressions with minimal effort. They are ideal for high-volume embossing in environments like government offices, schools, or large businesses.

How to Choose the Right Embosser Stamp

When selecting an embosser stamp, there are several factors to consider to ensure you get the best tool for your needs:

Design and Personalization Options: Consider whether you want a simple text design, a logo, or a more elaborate custom graphic. Some embossers allow you to design your own imprint, while others come with pre-set designs.

Size of the Imprint: Think about how large or small you want the imprint to be. Embossers come in various sizes, and the size of your design will impact the size of the stamp you need.

Material Quality: High-quality embossers are typically made of durable materials, such as stainless steel, to ensure longevity and consistent performance. Ensure the tool is built to last and can handle frequent use.

Ease of Use: Choose an embosser stamp that feels comfortable and easy to operate. If you're embossing frequently, consider an ergonomic model that reduces strain during use.

How to Use an Embosser Stamp

Using an embosser stamp is a straightforward process:

Position the Paper: Open the document or item you want to emboss. Place it between the two plates of the embosser, ensuring that the area where you want the imprint is aligned with the design.

Apply Pressure: Press down on the embosser to create the raised imprint. Make sure to apply consistent pressure to ensure that the imprint is clear and crisp.

Check the Result: After embossing, inspect the imprint to make sure it is clean and sharp. If the impression is not clear, adjust the position of the paper and try again.

Uses for an Embosser Stamp

An embosser stamp can be used for a wide variety of purposes, including:

Personal Libraries: Mark your books with a personalized design, making them easily identifiable and giving them a professional appearance.

Business Branding: Add your company logo, name, or address to documents, invoices, and official papers to add credibility and professionalism.

Official Documents: Emboss legal documents, certificates, diplomas, and contracts to authenticate and validate their authenticity.

Weddings and Invitations: Add a special touch to wedding invitations, save-the-date cards, or other stationery by embossing your initials, wedding date, or a custom graphic.

Personal Correspondence: Give a refined look to your letters, greeting cards, and thank-you notes by embossing your name or initials.

Conclusion

An embosser stamp is a versatile and professional tool that can elevate the appearance of your documents and belongings. Whether you’re looking to personalize your books, brand your business, or add a special touch to your personal correspondence, an embosser stamp is a simple yet effective way to leave a lasting impression. With various types and customization options available, you can choose an embosser that suits your needs and creates professional, lasting imprints every time.

1 note

·

View note