#cfs floor framing design

Explore tagged Tumblr posts

Text

Top 10 Benefits of Using CFS in Floor Framing Projects

Cold-formed steel is revolutionizing the way floor framing projects are executed. The use of CFS Floor Framing Design helps streamline construction processes by reducing labor efforts and accelerating project timelines, all while maintaining structural strength and stability.

One of the key benefits of CFS Floor Framing Design is its superior resistance to common issues like corrosion, fire, and pests. This durability makes it a dependable choice for both small-scale and large-scale building applications, ensuring long-lasting performance. In addition to these practical advantages, cold-formed steel promotes environmentally responsible construction practices. Its recyclable nature and reduced environmental footprint align with sustainable building standards. Read the full blog for more information - https://steelsmartsystem.wordpress.com/2025/05/14/top-10-benefits-of-using-cfs-in-floor-framing-projects/

0 notes

Text

3H's UI Design

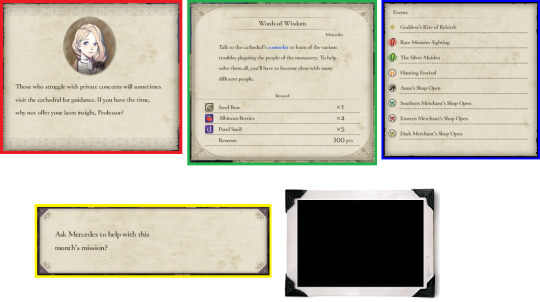

The title screen shows Sothis throne, in the game, Byleth sees Sothis throne between their dream of the War of the Heroes and their awakening by Jeralt. Which may symbolize that the scene of a throne is the first thing you will see before and after entering the game. The throne is also the place where the most important things happen, such as meeting Sothis, merging with her, and the events of Chapter 11.

After beating the game, Sothis is shown sleeping on a throne, this is similar to Final Fantasy XV, so spoilers for FFXV.

In FFXV, after beating the game, Noctis is shown sleeping with Luna/Oracle in a logo, mirroring the end of the game. It was the end of the game where Noctis sacrifices himself to save his world, and then sleeps in peace on his throne in the afterlife. This is similar to how we know in end of the game about Sothis sacrifices herself to save Fodlan and then went to rest on her throne in the holy tomb.

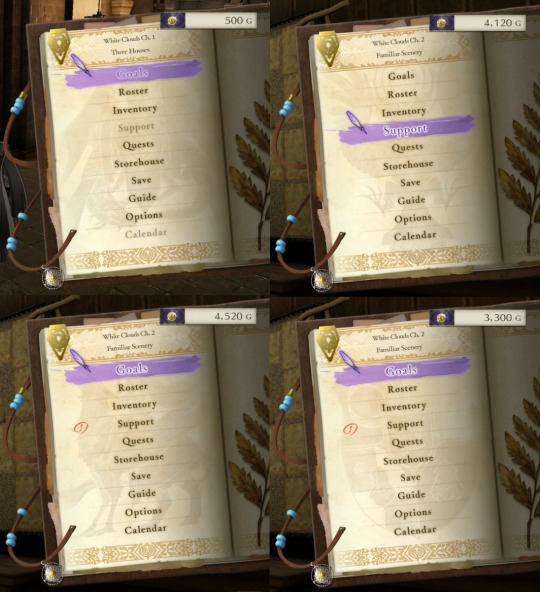

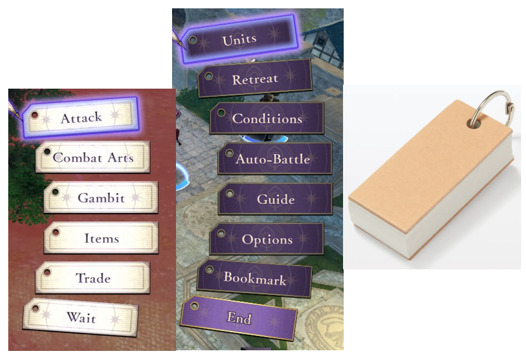

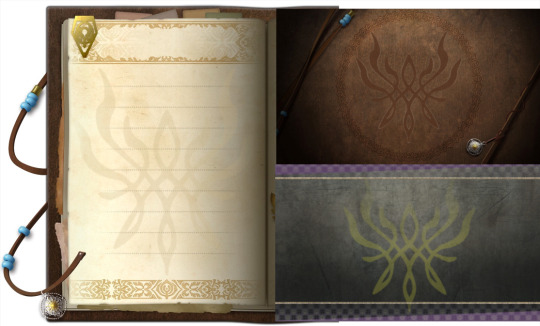

Player menus is a notebook Byleth carries with charms on it. Pages feature the country logo of chosen house, with the Church of Seiros logo on a page before choosing a house.

Besides a feather pen as a cursor, many ui are in the form of a set of papers; A plain papers, a papers with a Church of Seiros pattern and Sothis tiara, and a papers with a heart pattern in a corners cover.

The design of the options box is similar to a bookmark cards and the ribbon at the top left as a bookmark ribbon that is placed between pages.

With many ui somewhat similar to the sticky notes.

Roster's design is like a campus card, where characters stand on the ground outside a classroom when see roster.

Although the background varies depending on the floor it is on.

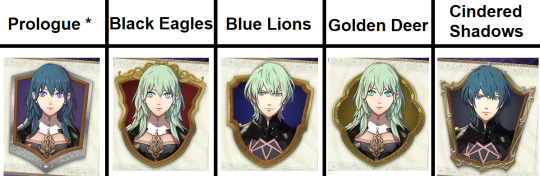

The cards and MVP also feature a unique frame for each house or story chapter you are in.

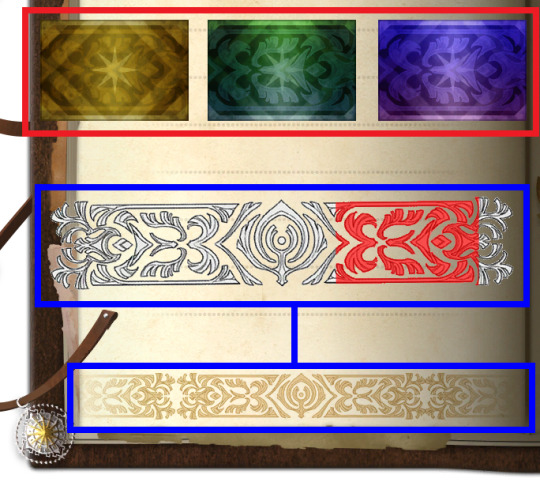

The lower and upper design of a banner that appears upon raising a professor level or passing a certification exam may look similar to a mosaic above a door, which may symbolize the opening of a door to new knowledge and experience gained.

The same theme is present in the banner when begin exploring or lesson plan, symbolizing the beginning of your journey of exploration and teaching others. However, there is no single for Battle, and this may symbolize that there is no benefit to be gained from battles and conflict, and this fits with the FE franchise's message that war is bad. Besides, each one has a color that distinguishes it.

The design of the Crest of Seiros and its various styles is present in most of the UI with the same, if not more, than the Crest of Flames, which is a constant reminder that Officers Academy is the same as the Church of Seiros.

There are many plant patterns that decorate the UI, which is a reference to the passing of the seasons, the meaning of the game's Japanese title. And you can see a branch of leaves on the right of the notebook, which indicates that the notebook has become more like your diary of your life in a monastery.

During a tea party, a screen is decorated with plant patterns with blue roses, giving the ambiance of a garden in which you are sitting. Along with a dialog box in the color of natural hot tea.

The date circle at the top left features four shapes for each season, rose for spring, morning glory for summer, grape vines for fall, and poinsettia for winter. However, during a period of war, the circles loses its colors and becomes grey.

In the background of the chapter title of within White Clouds, the same plants are present, with the background design as a white paper with the Church of Seiros logo. However, like the date circle, during a period of war the background becomes dark with sparks of war flames, plants change to holly and thistle, the Church of Seiros logo to the country logo of the chosen house.

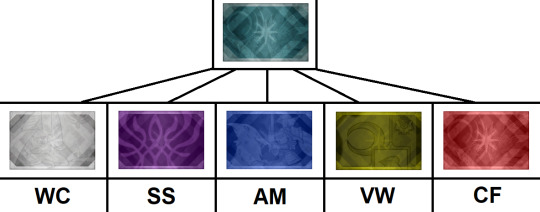

The CF's background differs from the SS's in a red double-headed eagle with two additional black stripes.

And this brings me to the background title before the start of each battle. Unlike the background title in each new chapter, which looks like a new page being turned to record daily events, the background title of a battle is literally the cover of notebook, and this may symbolize something similar to the Battle theme above. Like the chapter title background, it features the Church of Seiros logo during White Clouds and changes to the country logo for the chosen house, with SS and CF sharing the same background.

Speaking of battle, before any start, Fodlan map will appear on a plank of wood. This is similar to what Claude did in cutscene The Academy, where he placed a map on a table and started discussing it.

Battle Prep looks like a clock + glass mosaic, and if you notice, it is surrounded by a magic circle that appears between roles of units. It looks somewhat similar to Mila's Turnwheel, and I know Divine Pulse sounds like shattering glass, but it can be interpreted as follows; A clock is set before the start of a battle, and the magic circle is used to set units' movement points, and when the time comes to use Divine Pulse, the clock glass is shattered, which appears as a portal to an almost parallel world to return to a specific point. Furthermore, the design where the Crest of Flames is located in the middle and surrounded by the rest of the crests is very similar to the Goddess mural. There is also a crescent inside which looks like a star chart, and this corresponds to the cutscene At Death's Door, where the use of Divine Pulse shows what looks like space.

Because we don't use a battle notebook, we use a key ring memo pad instead.

Despite all the praise I gave for the game's UI design, there were some things that disappointed me. Most notable is the Adrestian empire logo for Silver Snow.

I know that the developers called Silver Snow the empire route, but they had to design the UI to fit the Crest of Flames flag, which represents the route as a whole. They don't even reuse the MVP frame from prologue, even though it's very convenient for the route. Why do they design loungewear in line with the Crest of Flames flag but not with the UI?

again they using the Adrestian empire logo for the unique classes poster. Why didn't they design a unique poster for each route? Or make it neutral?

I wish they would change the plant patterns during the tea party in Byleth's room to match the ambiance like a garden.

After all, 3H's UI design is not as perfect or innovative and iconic as Persona 5. However, in this post I wanted to share what I found fun about designing it, and you can summarize it as follows: 3H's UI design represents Sothis, the goddess of the Fodlan world, and the core foundation of the Church of Seiros, which in turn built the Officers Academy where you begin your new life as a instructor to your students through the passing seasons of the year.

Of course, I did not include all the UI designs, perhaps because I forgot them or failed to know its meaning, such as magic circle when raising the level. So, feel free to add to this post if you have any ideas.

131 notes

·

View notes

Text

Understanding CFS Floor Framing Design: A Modern Construction Solution

CFS Floor Framing Design is transforming how builders and engineers approach modern construction projects. Cold-formed steel (CFS) is created by bending steel sheets at room temperature into structural shapes, offering a lightweight yet incredibly strong material ideal for floor systems. These designs are particularly advantageous for projects that demand quick installation, high structural performance, and design flexibility. With CFS, it's easier to achieve longer spans and open layouts without compromising stability or safety.

One of the standout benefits of CFS Floor Framing Design is its durability and resistance to common structural issues. Unlike wood, CFS doesn’t warp, shrink, or rot, and it’s immune to pests like termites. It’s also non-combustible, which greatly enhances fire safety in buildings. These qualities make it a low-maintenance, long-term solution that can withstand the test of time, reducing repair costs and ensuring structural integrity in diverse environments—from residential homes to commercial developments.

In addition to its physical advantages, CFS Floor Framing Design supports sustainable building practices. Cold-formed steel is fully recyclable and often made with a high percentage of recycled content, making it an environmentally responsible choice. Moreover, the precision of factory-fabricated CFS components helps minimize on-site waste and speeds up construction timelines. With its combination of strength, sustainability, and efficiency, CFS is quickly becoming a go-to material for engineers and architects aiming to build smarter and more responsibly.

Discover more on the topic by visiting our blog - https://medium.com/@steelsmartsystem408/understanding-cfs-floor-framing-design-a-modern-construction-solution-5cc19f6c635c

0 notes

Text

Exploring the Advantages of Cold Formed Steel Machines in Modern Construction

In the realm of construction, the choice of building materials and manufacturing techniques can significantly impact project timelines, costs, and structural integrity. Cold formed steel (CFS) machines have emerged as a pivotal technology in modern construction, offering a versatile and efficient method for fabricating steel components. This blog delves into the intricacies of cold formed steel machines, their functionalities, benefits, applications, and their role in shaping the future of the construction industry.

Understanding Cold Formed Steel Machines Cold formed steel machines are specialized equipment designed to shape and manipulate steel coils or sheets into precise profiles and dimensions through cold forming processes. Unlike hot rolling, which involves heating steel above its recrystallization temperature, cold forming processes operate at room temperature. This method allows for the production of high-strength steel components with excellent dimensional accuracy and surface finish.

Key Components and Processes Cold formed steel machines typically involve several key components and processes:

Roll Forming System:

Utilizes a series of rollers to gradually shape and form steel coils or sheets into specific profiles such as studs, joists, channels, and framing components. Roll forming systems are computer-controlled to ensure precise measurements and consistent product quality across production runs.

Cutting and Punching Mechanisms:

Integrated cutting and punching units trim steel profiles to desired lengths and punch holes or slots for fasteners and connections. Automated systems minimize material waste and streamline manufacturing processes, enhancing efficiency and reducing labor costs.

Bending and Folding Units:

Bending and folding mechanisms enable the formation of complex shapes and configurations required for architectural and structural applications. These units ensure flexibility in design and accommodate custom specifications for diverse construction projects.

Quality Control and Inspection:

Advanced sensors and monitoring systems check for dimensional accuracy, surface defects, and structural integrity throughout the manufacturing process. Quality control measures ensure compliance with industry standards and specifications, meeting stringent performance and safety requirements. Advantages of Cold Formed Steel Machines The adoption of cold formed steel machines offers several compelling advantages over traditional construction methods:

Strength and Durability:

Cold formed steel components exhibit high strength-to-weight ratios, providing superior structural integrity and resistance to deformation and fatigue. Steel's inherent properties ensure long-term durability and performance, reducing maintenance costs over the lifespan of buildings and structures.

Precision Engineering:

Computerized controls and automated processes ensure consistent product dimensions and tolerances, minimizing variations and enhancing fit and finish. Accurate profiling and shaping capabilities support efficient assembly and installation, reducing on-site adjustments and construction delays.

Speed of Production:

Rapid manufacturing capabilities and high production speeds enable quick turnaround times for steel components. Cold formed steel machines support just-in-time manufacturing strategies, optimizing inventory management and project scheduling.

Sustainability:

Cold forming processes consume less energy compared to hot rolling, contributing to reduced carbon emissions and environmental impact. Steel is highly recyclable, making cold formed steel components a sustainable choice for green building initiatives and LEED-certified projects. Applications in Construction Cold formed steel machines find diverse applications across various sectors within the construction industry:

Residential Construction:

Prefabricated CFS components such as wall panels, floor joists, and roof trusses accelerate construction timelines and enhance structural efficiency in residential developments. Lightweight steel framing systems support innovative architectural designs and accommodate modern building materials and technologies.

Commercial and Industrial Buildings:

Steel framing systems provide robust support for commercial structures, including offices, retail spaces, and industrial facilities. Modular construction techniques leverage cold formed steel components for scalable and adaptable building solutions, meeting evolving business needs.

Infrastructure and Institutional Projects:

Educational institutions, healthcare facilities, and public infrastructure projects benefit from the strength, durability, and fire resistance of cold formed steel systems. Rapid assembly and seismic resilience ensure safety and reliability in critical infrastructure applications. Innovations and Future Trends As construction technology continues to evolve, the future of cold formed steel machines is marked by ongoing innovations and advancements:

Advanced Materials and Coatings: Development of high-performance alloys and protective coatings to enhance corrosion resistance and durability in harsh environments. Digital Integration: Implementation of IoT (Internet of Things) sensors and AI (Artificial Intelligence) analytics for predictive maintenance, real-time monitoring, and optimization of manufacturing processes. Customization and Design Flexibility: Integration of CAD (Computer-Aided Design) software and BIM (Building Information Modeling) tools for enhanced customization and integration of cold formed steel components in complex building designs. Conclusion Cold formed steel machines represent a cornerstone of modern construction, offering unparalleled precision, efficiency, and sustainability in steel component manufacturing. By leveraging advanced technologies and innovative manufacturing processes, architects, engineers, and builders can achieve superior building performance, cost-effectiveness, and environmental stewardship. As the demand for resilient, adaptable, and eco-friendly building solutions grows, cold formed steel machines will continue to play a pivotal role in shaping the future of the construction industry worldwide. c purlin forming machine steel frame machine manufacturer metal roof forming machine

0 notes

Text

So I made a story based on MBTI's INFP cognitive functions.

---

This story takes place in a girl's human mind, which is more known in this universe as the Psyche Realm. It tells about the Infsman(inferior function), Terratora of the INFP Squad and her encounter of the four additional CFs who mysteriously appeared in their Realm.

---

♡ Sirene's POV

◇ Terratora's POV

The legends displayed above will tell you who's currently telling the story. If a "♡" is displayed, the story is told in Sirene's perspective and if it's a "◇", then it's in Terratora's perspective

Now with that said let's get on with the story!

♡♡♡

Ever since I saw that door I've been wondering what lies behind it, what shadows hide inside...

I was just doing my daily rounds in the Archives of Snow, finishing overviews of my Host's past memories that I hope she would find relief in. I was carrying a stack load of them when my foot bumped into something that would seem to have felt to be some kind of glass object. I looked down to confirm that it was indeed glass, a glass bottle; full of stars.

"Uuuuuugh, Netaaa!!" I groaned in frustration, I swear our Auxman has no sense of organizing whatsoever, not to mention scatter-brained. She has a habit of taking her so-called projects with her while she works and leaves them behind almost everywhere. I attempted to pick it up when I forgot that I was carrying a stack of memories, making me lost my balance and the pages and books of memories flew and scattered everywhere. One of the memory books glided towards the bottle, making it roll away.

"Hey, come back!" I shouted, not bothering to clean up the scattered memories and proceeded to chase the runaway joke-of-a-craft down the long ass aisle. The bottle's straight-line escape came to a close when it reached the very back of the entire Archives. Finally, I picked up the bottle and looked up. After a quick observation I realized that I have found a door. It was a purplish black color with jet black elegant iron frames. Strange... I have walked the Archives' floors several times and never have I seen a door like this. Filled with curiosity, my hand reached for the door's handle only to be halted by a shout.

"My Tertsman!" a voice called, I turned around to see my Infsman, Terratora running towards me.

"Terra?" I asked, "what are you doing here?"

"I was suppose to inform you about the recently finished tasks, but it seems you have found... their door. You musn't go in there my Tertsman. "

Terratora caught my attention on her emphasis on the word 'their'

"What do you mean 'their?'" I asked

"Behind this door..." she paused for a long second, as if she hesitated to answer, "lies four unannounced Neuronites, if they are even considered one"

This left me pondering and confused, "Four more Neuronites... how? There are already four members in our squad, how could there be four more?"

Terratora didn't answer, but rather, she looked down stayed silent

I continued to ask here more questions "And more importantly, when and how was there a door here?"

She sighed, "I think it's time... that I told to you about the Shadow Squad."

◇◇◇

It was just like any other day. The Domsman guiding the host, the Auxman constantly inventing new inventions (honestly at this point I wonder if her brain ever goes empty), my Tertsman collecting memories, and me, the Infsman, organizing, checking and crossing out finished tasks, that is...if there were. I was currently in the Mental Notes section of the Archives of Snow, doing my daily task when I heard something, or rather... someone.

"Um, excuse me miss." it called, the voice awfully sounding just like the Domsman

'Lady Fi?' I thought, turning around to see if my assumption was correct, it was not. Instead of the pink brown-haired lady in a golden crown-like headband standing before me, was a strawberry blonde woman with bright green eyes wearing a sleeveless dark magenta top with a grecian neckline, dark forest green capri pants embroidered with a pink roses design towards the pant's cuffs, dark purple ankle strap pumps and a translucent pink blazer. What caught my attention were her bright purple Neuro Transmitters.

"Hello there," she waved, " I couldn't help but notice that you're in a little pickle right there, do you need any help?" she said with a smile, though it didn't seem to meet her eyes.

I decided to play along

"Oh, uh... thank you." I answered

The lady then went beside me and spread her arms out, to which I responded by giving her some of the papers I was currently carrying. "Oh how rude of me, I forgot to introduce myself!" she said, "I'm Fenessa, and you are?"

"Terratora." I responded, but didn't bother to make eye contact and continued with my current work, "Infsman of the INFP Squad, I am responsible for organizing the Host's concepts and tasks and as well as checking and marking tasks that are finished."

"Wow, sounds like a tough job!" Fenessa said in amazement, "and you're doing this all by yourself? Where are your other members of your squad, surely there's like a lot you."

"They're..." I hesitated to give her an answer,"in their respective places, doing their respective jobs. There are only four of us, myself included, most of the time we are too preoccupied with our current tasks to help another member."

Why did I hesitate?

"Seriously? Wow that sucks." she commented.

A long moment of silence passed as the two of us continued organizing. I began to ponder on what just happened...

Firryn said that the squad was already at a maximum capacity of four members, and therefore no additional Neuronite was expected to appear.

But why was there another Neuronite?

Where did Fenessa come from?

And why are her Neuro Transmitters purple?

"Soooooo..." Fenessa spoke up, breaking my train of thought, "mind telling me about your Squad, you know, the members, what they do here, what they're like?"

"The squad?" I looked at her for a second then back to the shelves, "Well, there's Firryn the Domsman, she is the leader of the squad and guides our Host in judgement and decision making based on their inner values. Then there's the Auxman, Netalia, she assists the Domsman in her job by helping her stay open minded on certain view points when making judgement. Third is my Tertsman, Sirene, she is in charge of the memory department, mainly to provide relief to the Host, using the memories that the Host hold dear, and lastly is me, the Infsman."

"I see," Fenessa said, as she placed one of the papers to their respective shelves "Judging by how she lets you work all alone here, does she ever acknowledges the efforts you've put into organizing all of these tasks?"

I looked down and thought deeply on what Fenessa said. Lady Fi actually never did once give a glance on how I managed the tasks I was asked to organize.

"No?" Fenessa questioned, "Well that's a shame...Hey! How about I help you by joining your squad?"

My head perked up from the offer, "What?"

"Think of it, us working together in organizing these tasks. It will double the work speed and cut down half the time, oh, and I can also help in contributing on how you guys as a team can work more efficiently and in harmony. So, whaddaya say?" Fenessa reached out her hand with a smile, waiting for me to accept her deal.

The way she looked at me... the way she smiled sent a chill down my axon. Something didn't felt right, it was as if she was trying to manipulate me.

"Thank you, but I have to decline. You see, the squad only allows four members and we have already reached the maximum capacity." I said with a firm tone.

"Aww that's too bad," She said sadly, still smiling

it looked forced

"Oh well, I' ll still be here whenever you need me," she said, putting the last stack of papers on to the shelves, "it was nice meeting you, Terratora. See you around!" she waved and turned around, walking away.

See you around? Wait... is she implying on staying here in the Archives?!

"Wait, you can't just--" and before I knew it, she was out of sight. This was bad, a new Neuronite appeared and was now roaming inside the Archives. It was at that moment, I knew had to report of this event.

The following day, I planned to report this to Sirene, but she was currently preoccupied in digging up "lost" memories that was was found deep in the Archives, so I had no choice but to report to the Auxman. I approached the door of the Auxman's room and knocked a few times.

"Who is it?" a tired voice called from inside the room.

"Terratora, ma'am" I answered.

The door opened to reveal a tired-looking Netalia, and sweet saya she looked like shit, her hair was a mess and she had bags under her eyes. "Ey, Terra! What can I do for you?" she asked

Looking at her current state I asked her with concern "Ma'am, if i may ask, how long have you been wake?"

"Uuuuuuuuh..." the Auxman scratched her head, "36 hours?"

...what do the humans call this significant short period of event again? Ah yes, a "bruh moment." This was definitely a "bruh moment."

"Uh I see..." I muttered as I fixed my posture and went back to the matter at hand, "Well I have something that I must report to you, privately." I firmly informed.

"Oh, sure come in." Netalia said, stepping aside and letting me in her room. Her room was steam-punk themed, giving off a nice afterthought of the 1800's European Industrial Revolution. The walls had real functioning turning copper and gold gears and for the floor was a glossy gold iron-parquet flooring, but there was just one problem. Like her messy appearance, Netalia's room was an absolute mess. Different inventions and papers stacked carelessly in every corner, some papers were scattered across the floor, crumpled. Her work desk was no different. "So," Netalia said, yawning as she sat on her wooden antique chair, leaning forward "what did you want to talk about?"

"There is a new Neuronite that is roaming around the Archives of Snow."

Netalia's expression turned serious, "What?" she asked, her eyes widened a little.

I explained to her of my encounter with Fenessa, explained her appearance and behavior. Netalia began to be in deep thought, trying to process the information she had received. That's when I heard her mutter, "I can't be... Shadow Functions...here?"

"Shadow Functions?" I asked

"Nah, I'm sure you just saw it through a memory book" she said waving her hand, denying my claim of seeing a new Neuronite.

"Ma'am, you are aware of what the Shadow Functions are, right?"

"Yeah, the rumored Neuronites who linger inside a host's pysche realm and cause chaos, but you don't have to worry, it's just a rumor."

"Ma'am, I saw that Neuronite yesterday and interacted with me. If what I saw yesterday was a Shadow Function, there is no doubt that there could be other Shadow Functions roaming around the Psyche Realm as well--"

"First of all, you don't know that," Netalia interrupted, "second, there is no evidence to confirm the existance of the Shadow Functions."

"Ma'am, does my eyewitness testimony not count as an evidence?"

The Auxman thought hard for a moment, "Hm, good point, it does have some credibility, however, because you were the only witness, it does not have enough reliability."

"But ma'am--"

"That's enough Terra," Netalia said in a serious and authoritative voice and stood up from her chair, "this conversation is over."

"Netalia--"

"Terratora, I am warning you--"

"Could you, for once, please listen--"

"ENOUGH WITH THE BULLSHIT TERRA, SHADOW FUNCTIONS DON'T. FUCKING. EXIST!"

I stepped back, staying silent. Netalia gasped, realizing what she had done, she rubbed her temples with her fingers and let out a heavy, tired sigh "I'm sorry...I shouldn't have lashed out on you like that."

"It's ok...I understand" I truly did, Netalia was sleep deprived so it wasn't a surprise she would snap

"Just...don't bring up that topic again ok?"

"Yes ma'am..."

"Good, now if you have nothing else to report, you are dismissed." Netalia said as I walked out of the room.

Great, looks like I'll have to take care of this roaming Neuronite myself.

Not long after that incident, a new Neuronite appeared while I was in the Archives. A redheaded lady with bright green eyes wearing a sun hat, dark bluegreen off shoulder dress decorated with glitter at the hem, and some sandals. She called herself Niema, her choice of words are beyond my understanding, not to mention her unsettling insights of the future. What was most disturbing was how her presence is still felt in Archives from time to time despite not being present in sight.

Fast forward to several days later and another Neuronite appeared. this time by the same of Selly, and just like Niema, she was a redhead with bright green eyes. Her hair was styled into a ponytail, she wore a hazel wood yellow shirt that was tied into a knot, a black wristband on her right wrist, dark mute teal ripped denim shorts, and maroon high-top sneakers with bluish white accents. My encounter with this Neuronite can be summarized into one word: Impulsive. Chasing her across the entire archives, Selly was so fast and hyper that could barely keep up with her. Her curiosity in trying to open certain books of memories without permission gave me a headache.

...

Nothing could have prepared me for the fourth Neuronite. Unlike the previous three, she did nothing but stare at the distance, she was a strawberry blonde with green eyes like Fenessa. Her hair styled into a braid resting on her left shoulder, she wore round glasses with upper half rims framed with icy blue frames, a dark purple hooded shawl with a navy blue short-sleeve sweater underneath, mute blue ripped jeans and maroon sneakers. I did not see her make any movement other than her adjusting her glasses every once in a while. I could sense strong negative energy radiating off of her, the essence very similar to Ti essence.

I had to find out their place of origin, there was no way they just appeared out of thin air. I decided to start with the Archives of Snow, since that's where I found the first Neuronite. I searched every section and corner and found nothing, until I went to the very back of the entire archives. There I saw a door of purplish black color with jet black elegant iron frames. I didn't hesitate to think twice that this was the door they came from, I know this because me and Sirene frequently come to the Archives and never was there a door here.

Following day I requested Netalia to make me a lock. I had to lie to her saying Sirene requested me to get a lock from her, to which Netalia shrugged and gave me the item with two set of keys to go along with it. I rushed back to the Archives to install the lock, but when it came in contact with the handle, it disintegrated...

♡♡♡

"And ever since that day, I've been guarding this door in secret." Terra concluded

"Shadow Functions..." I said shivering at the thought, "I never I'd see the day these Neuronites merging into our Host's Psyche Realm." I looked up at the door and back to Terra, "do you know what lies behind this door?"

Terra shook her head "No, my Tertsman, I have not set foot in whatever is behind the door, not even once."

"I see...why didn't you tell me about this?" I asked her

"I feared that you would give me the same conclusion, since the existance of Shadow Functions is just a rumor." Terra explained, making me remember that Neta snapped at her.

"Terra," I looked at her in the eye, "you know very well that I would never raise my voice at you, so don't ever hesitate to come to me if something is not right, clear?"

"Yes ma'am."

"Good." I nodded

"My Tertsman, if I may ask," Terra spoke up

"Yes?" I replied, giving her permission to speak

"Will you promise me to keep this door a secret?"

This put me in my train of thought, should I really keep this a secret? Not sharing this information with the Domsman or Auxman could get me in trouble, but then again, Firryn is too closeminded to confirm this info and Neta is too preoccupied already with her millions of garbage ideas and concepts, and with that, I nodded my head, "You have my word."

"Thank you," Terra said, relieved "Now, I saw several memories scattered across the floor of aisle 8-20."

"Oh, that. I was carrying a stack of memories, when I ran into this thing." I said showing her the bottle of stars.

"Ah" was all she had to say, understanding what happened while showing a hint of annoyance on her face.

"Since you're here now, mind helping clean up?" I asked

"Of course." Terra complied as we both turned around to walk to the messy aisle

As we walked I turned my head around to look at the door one last time, the door's mysterious appearance led me to so many questions yet to be answered.

Ever since I saw that door I've been wondering what lies behind it, what shadows hide inside...

7 notes

·

View notes

Text

Bullifaktur's rustic modules fit together to create your ultimate VW camper van

Taking a light, modular approach to the classic VW camper van, German shop Bullifaktur uses standalone furniture boxes to build up versatile, fully customizable camping rigs. Its individual modules each contain some smart, multifunctional solutions, piecing together like a puzzle to create your perfect van, whether it's for full-time van life, weekend camping or adventure-chasing. Wood paneling and light colors create bright, modern cabins that campers and van dwellers should enjoy spending time in.

Like many other camper brands, Bullifaktur wasn't originally conceived as a business, but as a single project. In 2016, founder and engineer Dennis Sawadsky purchased a VW T5 with the intention of converting it to a camper with just the right mix of overnight comfort and outdoor gear-hauling utility to support everything from laid-back camping to dirt-riding, wave-seeking adventure.

With nothing on the market seeming to fit those precise needs, Sawadsky and crew got to work building light, quick-install camper furniture, and the original Bullifaktur van was born. As is often the case with a one-off camper van or garage-built teardrop trailer, Sawadsky's rig attracted a crowd virtually every time he put it in "drive," so he and a few business partners figured they had something special enough to compete in the crowded German VW camper van conversion market. They founded the company in 2017.

We certainly think Bullifaktur has something special, as several of its modules and layouts are quite different from the average Transporter conversions we've seen in and beyond Germany. Bullifaktur sells individual modules sort of "build-your-own" style, providing flexibility in how the interior is laid out, how much storage is available, etc.

The largest, most expensive building block in the Bulli lineup is the L-shaped kit that's essentially a full camper van conversion, complete with kitchen, bed, dining area and sofa. What's interesting is that rather than incorporate the front seats, like so many Volkswagen converters do by putting them on swivels, Bullifaktur goes the opposite way by splitting them off with a front kitchen that stretches the width of the van to create something of a divider wall with a sizable cutout over the kitchen counter. While this set-up eliminates any ability to move freely between driver cab and camper, or use the driver-area seats as part of the RV space, it also creates a neater, more defined living area, a natural division between "drive" and "camp" spaces.

The kitchen unit includes independent cooking and storage areas. The stainless steel sink is integrated in the worktop, while the portable cartridge stove is stored below the worktop and extends just outside the van door via a slide-out. Bullifaktur also offers a fold-up counter over top the stove to allow for indoor cooking. Down below the worktop, a refrigerator drawer holds the compact Dometic CF 26 compressor fridge. The adjacent shelving unit, meanwhile, includes indirect LED lighting and bungee cords for securing contents.

The multifunctional sofa that runs along the driver-side wall slides out into a bed, sleeping two happy van-lifers on a 79 x 50-in (200 x 128-cm) mattress. The end of the sofa can also slide out independently, creating an integrated chaise lounge with footrest, perfect for reading or taking in the views through the open tailgate.

Beyond just a bed and lounge, the convertible sidewall module is also a storage chest and dining area. Bullifaktur shows several dining table options, and our favorite is the central sofa-base face panel that lifts and folds into a dining table for two — a multifunctional design that keeps things neat and tidy. Other photos show a simpler table that mounts to the sofa base when in use. The space below the seating unit is hollow and open for storage, and Bullifaktur offers several slides for easily accessing stored items by pulling them out the back of the van.

Just bolting in camper furniture doesn't necessarily make a fully comfortable home on wheels, so the aforementioned package also includes closed cell foam wall and ceiling insulation, wood ceiling paneling with integrated LED lighting, PVC flooring and white fiberboard wall panels.

That's a nice, little ready-to-travel VW camper van, starting at €9,599 (approx. US$10,725) for the conversion package. Bullifaktur assembles the modules independently and can ship them out for owner install or install them itself at its Hamburg headquarters.

Beyond that main package, buyers can customize their van interiors by adding in additional modules or swapping in alternative modules (the aforementioned front kitchen and side sofa-bed are available for purchase individually, as well as in the package). Options include more compact kitchen blocks without the shelving, a sliding rear outdoor kitchen, and a motorcycle ramp/carrier for loading a bike next to the sofa.

Structurally, Bullifaktur's modules are a mix of aluminum framing and plywood panels, keeping things light and simple. They're designed to screw down in roughly 15 minutes.

Bullifaktur offers its main components and kits for Volkswagen T4 through T6 vans, and it also does custom work. Rather than list all the specific modules and prices, we'll just direct you to Bullifaktur's shop, where you can access that info immediately. The website is German-only, so if you want all the details, you'll want to hit the translate option on your browser, unless you happen to speak Deutsch.

Beyond its primary work with newer VW Transporters, Bullifaktur has also done some work with larger VW Crafter and Mercedes Sprinter vans, smaller VW Caddies, older Transporter models like the T2, and even a Mini Cooper. It seems like it's constantly experimenting with new materials, designs and layouts, and we've included some photos of those different layouts in the gallery, along with more photos of the standard kit.

Do you wan to know more details about the cargo van rubber floor mat and van floor mats me then please contact us and send your queries

1 note

·

View note

Text

Why Has Cold-Formed Steel Framing Become Popular?

Although CFS, a cold-formed steel frame, has been present since the 18th century, its use has increased dramatically in recent years as a result of tight budgets, compressed project schedules, and strong demand. Cold-formed steel framing, or metal or steel framing is a flexible building material option that has various advantages over concrete and wood in terms of cost, speed, and sustainability. Greater Design Flexibility Cold-formed steel frame design is simplified, as each joist is manufactured to the appropriate tolerances and strength levels for the specific construction. By including these requirements throughout the design phase, architects are given the freedom to express themselves creatively while still adhering to the project's guidelines. Cheaper than Other Building Material Options Framing joists made of cold-formed steel is lighter. Lighter beams are simpler to store in large quantities and need less upkeep once installed. Additionally, lighter materials might lower a project's shipping expenses. Steel continues to be superior to concrete. Despite weighing less than concrete, CFS or metal stud framing can support the same structural load. Buildings may thus have thin floors and compact foundations without endangering their structural integrity. Less Time is Needed for Construction Off-site fabrication is used to create cold-formed steel to exact specifications. Preliminary site preparation and foundation work are already in progress concurrently. After fabrication is finished, the steel is swiftly put at the building site after being carried there. This creates significant time savings at this early stage, which reduces the overall time needed for the project. The project managers may now concentrate on other facets of the construction. Additionally, because the fabrication is done off-site, there is no need to redo any measurements, cuts, or installations due to human mistakes. Looking for steel stud framing construction supplies for your upcoming project? Do you need further details? The Steel Network is a reliable source. The best products in the steel frame building sector are developed, produced, and delivered by them. Their solutions are genuine, robust, and environmentally friendly. Originally Published at - https://steelnetwork99.medium.com/why-has-cold-formed-steel-framing-become-popular-79895069f9b1

0 notes

Photo

LOADING INFORMATION ON CHERRY BOMB!’S MAIN DANCE GUN MONA...

IDOL DETAILS

STAGENAME: N/A CURRENT AGE: 25 DEBUT AGE: 19 TRAINEE SINCE AGE: 14 COMPANY: MSG SECONDARY SKILL: Modeling (cf)

IDOL PROFILE

NICKNAME(S): Momo, Moe, Mong (몽), 징징 INSPIRATION: As a child, she’d perform for her father, her brother, and eventually her small town community and found a lot of joy in entertaining them and making them laugh. She’s always loved performing and singing, but hadn’t really thought about doing it for a profession, despite being musically inclined. A young fan of the first-generation K-pop groups like S.E.S and Fin.K.L., she was persuaded to perform on K-pop Star just to see if she liked performing, and found it exhilarating. Hasn’t looked back since. SPECIAL TALENTS:

No-laughing challenge master

Notoriously bad at tongue twisters

Has a whistle register

NOTABLE FACTS:

Very active on her personal and the groups’ SNS and interacts a lot with fans of both the group and herself personally

When she was a K-pop Star contestant, she notably performed ‘U Go Girl’ and impressed the judges with her energy (and cuteness)

Is “jokingly” known to be a huge party girl, idol friends and celebrities she’s familiar with say she has an “iron stomach” when it comes to soju

Known for her funny expressions that can’t hide how she feels - most often it’s her resting bitch face or an unamused one, but also some wacky ones

Crochets little stuffed animals as a hobby

IDOL GOALS

SHORT-TERM GOALS:

Right now, she’s looking to solidify her position as a “CF queen” — wants brands to look at her as someone that’s popular with general public and that, frankly, they’ll shell out big bucks to exclusively sign as their brand model. She also wants to venture into another field or two to supplement the wave of popularity she’s been lucky to experience thus far: an acting stint, perhaps, or maybe variety where historically she’s been a little bit more successful and more comfortable with. More for herself than for her career, she’s been keen on becoming serious as a performing artist, and is looking into music production in her spare time.

LONG-TERM GOALS:

As her relevance (also known as: time frame) as an idol fades, Mona would want to try to go solo, since her love for her craft is a life-long one, but is more than ready to complement a solo career with recognition for the other talent she’s currently deciding between. She’d like to transition her “image” as that charming, relatable girl-next-door look into someone more womanly and self-assured. Someone authentic. In a more career-oriented sense, she wants to achieve the ability to pick and choose the brands that she models for and still receive hefty contracts, in the vein of Won Bin’s star power. Overall, she’d like to shed the ‘idol’ image and turn into that of an ‘artist’ - someone well-respected in the public eye that carries life-long relevance.

IDOL IMAGE

It’s an undeniable truth to say that there is a first impression of her, and that it is always, without fail, this: she’s pretty. Remarkably pretty, in a plain, malleable sort of way. Not too sharp that she cuts, alienates — just soft enough to mould into whatever you want her to be. Most people don’t care for much else besides the first look, so it’s perfectly fine that she’ll be the pretty one, memorable if only fleetingly. It works, anyway — the relatability of her features, parts of it (of her) desirable and the other parts identifiable, make her an easy pick-up for brands to plaster on their products. Girl-next-door with wisps of maturity, of a sex appeal her members don’t quite possess. The kind of soft girl that the public loves to rest between their teeth. Palatable — just so.

You don’t have to be much more than a pretty face and a good dancer, they’ve told her in the past. Don’t stray from your design, is what they mean.

Don’t be you. There’s nothing appealing about it.

She tries. Walks the tightrope between the image of her and the girl inside — tries to dull a blunt tongue, smooth a passionate expression, tame the soft cruelty that makes up her marrow. Spends years running back and forth between wanting and having. Should haves and could haves. There’s the artist she wants to be, the truth that wants to will itself into existence; then there’s the girl that’ll actually succeed — merely pretty, with hidden laughs and closed smiles, speaking well but not too much, both seductive and restrained. So consumed by the thought of others that she tries to smooth herself out until there’s nothing left of her, manufactured out of her system.

She’s told, time and again, that her beauty is the only thing that matters — and, to be frank, she’s tired of it. Tired of being told. So she resolves to take it — their power, her weakness — into her own hands, tilt the scales in her favor. Manifest destiny, or some bullshit like that.

The public eats it up.

The newfound authenticity to her — the poignant way she expresses a confidence she’s found that she’s had, how she isn’t afraid to be desirable, how she pushes the boundary of acceptably self-loving is not so off-putting as it is intriguing. Everybody loves to hate on a woman in control, except with the way she carries herself, haughty but not in-your-face, there’s less to hate and more to admire. It helps that she’s older now, less tied to a youthful, innocent image and settling into the confident niche of her group like she was always meant to be there. Girl-next-door that’s matured into a woman — still pretty, still relatable, but with a voice that’s truly her own. Fears nothing: not the hurtful comments, lustful gazes — doesn’t mind being the sophisticated ‘sex bomb’ she’s grown to be one minute, all-natural the next, an everyday adult woman.

It’s appealing, she supposes, to see a girl grow up. Become more assertive, fill into her skin (or shed the layers that were well past due). Not trying to appease, not blinded by the limelight. At a time when she’s finally happy with herself, everyone seems to be happy with her too. With a tacit blessing, she’s let herself be unafraid to be her, for now.

Just don’t stray out of line, they whisper.

(I don’t care, she wants to say back.)

IDOL HISTORY

In the summer of 1999, she leaves.

.

It doesn’t take Mona very long to realize that her mother isn’t coming back. What with the way her father sits on the side of the bed that used to be hers, head in his palms, back poised for a knife that isn’t there, but it feels like he’s bleeding anyway. She stops questioning him soon after that — too scared, perhaps, of the consequences. One parent’s gone, no need for another to disappear too.

Home isn’t ever the same afterwards. Going from four to barely three leaves a big gaping hole in the fabric, seams loose and aching. Dinners, for example, are sombre affairs, heavy with the knowledge of the empty chair at the table. Weekends, too, are quiet — where her mother used to sing, silence makes itself heard, a loud ringing in the ears. The sound of loss is deafening, they all find out in time.

She tries to pretend that it’s fine, it’s fine, it’s fine.

(It’s not, of course. Six year old fingers aren’t meant to hold up the spines of men — their wilting, their hollowness. No wonder she doesn’t grow up proper; no wonder that there ends up being something wrong.)

There are days when her father cannot look at her. She has her mother’s eyes.

.

Sunday in July. S.E.S. and sunlight waft through old speakers and cracks in the curtains respectively. Like calm before a storm.

Mona can’t help but sing along when the chorus comes on, all light tone and childish chipper. She realizes — there’s been no singing since she left. Since she took the singing with her. Stops short when father’s wiry figure hovers at the doorway, quiet as always. Time won’t heal his wounds, but it has allowed him to forget as a reprieve. Until now.

“I didn’t —“

“Keep singing, Mona,” he says. She doesn’t think she’s ever seen such a smile — so sad, but so happy at once. “It’s beautiful.”

So she does.

.

The moment she steps onto the shining, fluorescent-washed stage is the time she realizes: it’s different. Not at all like sinking her feet into the sofa of her living room, moving like clockwork to her father’s favorite songs, singing along. Nor is it like standing on the rickety wooden floor of her local community center, performing for the people she’s grown up around, who would love her no matter what she’d do.

This is Seoul, with all of its steel and its glamour and a cruelty that leaves fourteen year old her starstruck. This is the tipping point.

After all is said and done, she doesn’t get very far. Pretty, and a vibrant performer, but too rough, too unpolished to win a competition of the best. She’s not even sure the praise they’d given her was real — everything about it had seemed so manufactured. Machinery running through their motions. Leaves her feeling like she had less than she had started with; and she wants more.

Someone slips her a small white card before she leaves the building. You’ve got potential, they’d said. Audition.

Weeks pass and the details imprints themselves into the back of her brain: rudimentary black symbols that bely the possibility of fame, of fortune, of a life greater than her small town all in the sharp cuts of their lines. Curiosity has always been her vice, thorns strangling tighter until she has to find out what’s on the other side.

The tension, her wanting: both palpable. Her little town on the outskirts of Daegu cannot contain it. Everything’s tasteless, everything’s sober. It’s painfully obvious that she wants this. Wants more. Her mother, she recalls, had felt the same way. The parallels scare her. Her mother’s eyes. Her mother’s voice. Her mother’s self-regard. Hers, now, too.

She hates the look in her father’s eyes when she says she’s going to Seoul. Hates it even more when she forgets how he looked when she gets accepted by MSG entertainment, to begin her training as soon as possible.

When she packs her bags and says goodbye, she leaves him slumped in the dining chair she’d made her own for years.

Three becomes two. Feels like there’s nothing left of family anymore.

.

Trainee life is cyclical. Breathe in, breathe out: dance, sing, weigh, repeat. She wonders: why did they let her through when all they seem to want is to strip her gone? They lash her tongue to strip the satoori from her vocabulary; starve away the parts of her that make her her — her bold tongue, her small-town naivety, her childish innocence. Scrub the poverty from her until she’s wiped clean. You’re not here to be you, they tell her in between lines. You’re here to be a god.

Giving her best becomes harder when there’s nothing left to give, so she starts giving pieces of herself in its place. She wants this, she wants this, she wants this. Guilt propels her — her father, all the way back in Daegu, sitting with his head in his palms like she’d left him, just like her mother had before her. All the way here and she hears his howling (or maybe now it’s coming from her).

Torn between this choice: the her of before, and the her that could be.

She chooses the latter. Too many bridges burnt now to go back, she thinks. See the selfish through.

.

Idol life is an open door leading straight into hell.

She’s always so tired. Always so lost. She’d thought wrong: had been mistaken that they’d finally let her be when she debuted. Their hands go deeper now — not ghosting along the lines of her, but into her, become her ribcage and her spine and her mouth. Dissonance, it’s termed: her between closed doors, witching hour in her bedroom, and her in front of the camera. Does her father recognize her? Does she?

Pretty, they tack onto her shoulders. Pretty and docile. Perhaps it’s because she’s become awkward — lost her confidence as she’s risen to the top — but when they tell her keep quiet, she listens. Strange, feeling faceless when the only thing she’s known for is her face. It frustrates her, going through the motions, known foremost for the outside of her, a part of her that’s been an afterthought; then, just barely, how well she dances, how her body moves. Nothing about her — her love for music, her craft, or how funny she can be, or how much she wants to just be.

When she left her family, when she chose herself over others, she didn’t think she’d lose them both.

One day, her father calls. Asks why she sounds so sad. Because I left you, she says. Because I was selfish. And all for nothing — now I can’t even sing how I want, or act how I want, or be how I want. Are you proud of me? Do you hate me for leaving you behind?

Keep singing, Mona, he says. It’s beautiful.

(Be you, Mona. You’re beautiful.)

So she does.

.

Maybe her wounds will heal — maybe, quite possibly, they won’t. But inevitably, she’ll forget them once in a while. Slowly, she learns to let herself go — that is, the idea she has of herself go. It’s no good trying to be someone she’s not; she’s no actress, not at all suited to playing a part. They’d told her it would be her downfall, being herself, being real. She intends to make it her strength.

It starts off slow, the slippage. A strut down the walkway, a haughty gaze at the camera, a flash of skin here and there. Candid in her interviews, still reserved, but more at ease than ever. Yeah, she’s watched adult films; yeah, she can hold her soju; yeah, she’ll talk about how she had loved a boy and lost him. The more she lets loose, the more comfort she feels — the most comfortable she’s felt in her own skin in years.

In the end, they’re intrigued by this new girl in front of them — the rawness, the realness, the subtle haughtiness. Who is this new Mona? They ask.

She’s always been this Mona, she says, smile on her face — open-mouth, teeth shining and everything.

For the first time, she feels centred. Feels alive.

1 note

·

View note

Text

Why Are Builders Switching to CFS Floor Framing Design for Long-Term Project Value?

Many builders are shifting their approach to meet the demands of larger, more complex projects. Steel-based framing systems offer a better alternative to traditional materials by improving overall build quality and minimizing maintenance issues.

CFS Floor Framing Design stands out because it handles moisture, pests, and temperature changes with greater resistance than wood. That’s why it’s becoming a preferred choice for projects that require consistency and reliability over time.

As building standards evolve, using CFS Floor Framing Design helps teams work more efficiently while keeping long-term performance in mind. It supports faster timelines and simplifies the framing process from start to finish. Read the full piece for more information - https://sites.google.com/view/steel-smart-system-/blog/why-are-builders-switching-to-cfs-floor-framing-design-for-long-term-projec

0 notes

Text

Understanding CFS Floor Framing Design: A Modern Approach to Structural Efficiency

CFS Floor Framing Design is rapidly gaining popularity in the construction industry due to its strength, flexibility, and efficiency. Cold-formed steel (CFS) is manufactured by rolling or pressing thin steel sheets at room temperature into structural shapes. This process results in lightweight yet durable framing members ideal for floor systems. Compared to traditional wood or hot-rolled steel framing, CFS offers a much higher strength-to-weight ratio, allowing builders to achieve longer spans and more open floor plans without sacrificing structural integrity.

One of the standout benefits of CFS Floor Framing Design is its precision and consistency. Since cold-formed steel components are factory-made, they are free from common issues such as warping, shrinking, or splitting. This level of reliability ensures a smoother and faster installation process on site. Additionally, CFS members often come with pre-punched holes for utilities, reducing the time and effort needed for mechanical, electrical, and plumbing integration. These advantages make CFS a smart choice for both residential and commercial buildings that demand efficient and accurate framing solutions.

Sustainability is another key factor driving the adoption of CFS Floor Framing Design. Steel is one of the most recycled materials in the world, and many CFS products contain a high percentage of recycled content. Moreover, the design process often involves digital modeling tools that help minimize material waste and improve energy efficiency. As green building standards become more stringent, CFS offers a sustainable solution without compromising performance. Whether for new construction or retrofits, CFS floor systems deliver a modern, resilient, and eco-friendly approach to structural framing.

For more information visit our blog - https://steelsmart.blogspot.com/2025/05/understanding-cfs-floor-framing-design.html

0 notes

Text

FRAMECAD CODE COMPLIANT IN OVER 120 COUNTRIES

The system we use, FRAMECAD, is a safe and easy system to specify for cold-formed steel, otherwise known as light gauge steel.

We are your experts in light gauge steel construction, we aim to assist our customers and those constructing with our FRAMECAD system with all of the relevant information required to quickly and easily construct LGS buildings.

From help with specification or providing sub-assembly guidance, we are here to support you through the construction process. Below are some details to help with your next project.

Roofing The FRAMECAD roofing sub assemblies utilize quality building materials and are designed to offer high-quality roofing systems.

Trusses & Roof Types The system can be used to manufacture a range of trusses which in turn create a variety of different roof types.

Framing The system can produce frames to suit a large range of building designs.

Flooring The FRAMECAD flooring systems use cold-formed steel joists in combination with quality building materials to produce a rapid and durable flooring system.

External Walls It has a customised range of external wall assemblies for use in a variety of applications.

Internal Walls & Ceilings The FRAMECAD system can produce frames to suit a large range of building designs.

Achieve accelerated delivery of cold-formed steel (CFS) construction with automated engineering and detailing software that integrates with our world-leading factory control software and advanced roll-forming manufacturing equipment.

FRAMECAD System for cold-formed steel manufacturing FRAMECAD System for cold-formed steel manufacturing BETTER SOLUTIONS WITH FRAMECAD The team at Steel Frame Solutions have been working with builders, developers, architects and specifiers to deliver cold-formed steel solutions that reduce project timelines and improve productivity.

Rapid construction, the smart way. The FRAMECAD System delivers large scale cold-formed steel (CFS) construction projects faster with its advanced steel framing automated process.

light steel frame machine automatic embossing machine roll forming machine price

0 notes

Text

NAB Wrap Up, Part 3

While it’s great to see trends in production and display, as an editor I’m driven to several things at NAB. One of them is storage. As cameras capture more and more pixels, where are we going to put them?

For storage on location, I saw displays of camera cards. CFast, an evolutionary step from the original Compact Flash card, is being used by more and more camera manufacturers. And now the cards are storing half a terabyte.

SanDisk is delivering even more storage than this: CFast cards—now at 512 GB.

A more recent update in the CF family is CF Express. While CFast is designed to operate like a drive, CF Express works more like RAM so it can achieve faster speeds. Faster speeds are important: As cameras increase in resolution, they have to write more pixels per frame. And the frame rates aren’t slowing down! A card that used to handle writing 2,000 pixels per 1/24 of a second might not be able to reliably handle 4,000 or 8,000 pixels in the same amount of time.

Lexar showed a prototype CFAST card with 1000 MB/s write speed.

Beyond camera cards, getting the footage from production to post requires storage with different requirements. One essential element is ruggedness. At NAB, G-technology showed off their ArmorATD.

As I work on projects, I’m surprised how often I receive drives delivered by people who aren’t part of the production team. Couriers, etc., may not see the need to treat delivery of a drive any differently than a box of staples. The ArmorATD can survive the crushing weight of half a ton.

Up to 4 TB of rugged storage.

Next time, drives for the edit suite on the NAB floor.

The post NAB Wrap Up, Part 3 appeared first on HD Video Pro.

https://www.hdvideopro.com/blog/nab-wrap-up-part-3/

0 notes

Text

Hot Rod Fever: The Brunk Family 1952 Chevy Pickup

It’s one thing when you do this thing we do to make a living—it’s often a struggle, but a passion-filled one nonetheless. But for the average blue-collar American who chooses to do this thing we do as a hobby, it can downright be impossible when times are tough. Family always comes first, but when the tight-budget purse strings allow, the ability for a family to partake as a whole—from the building of to enjoying the finished product—it’s nothing short of an amazing experience. Bruce Brunk’s tale of Hot Rod Fever is proof positive, as you’re about to read.

“I’ve been crazy about cars and hot rods since I was in junior high school. I guess it all started when my dad, Nick, bought a 1967 Chevelle that he started drag racing at the local quarter-mile dragstrip located north of my hometown of Ardmore, Oklahoma. I had ‘hot rod fever,’ even to the point of wallpapering my bedroom floor to ceiling (without my parents’ permission) with clippings from my dad’s hot rod magazines (also without permission). To say the least, he was NOT happy.

“During his years of racing, I worked with him every chance I had trying to learn everything that I could. While supporting three children and working a fulltime job, he did what he could working from a one-car garage on a shoestring budget.

“With my dad no longer drag racing and me getting my driver’s license, he handed the Chevelle down to me, which consisted of just a body and frame. Any money I earned working after school went into buying wheels, tires, interior, running gear, and so on. With the help of my older brother, Larry, and my dad, we got the car running and back on the road. After a while, I ended up returning the Chevelle to my dad and bought a motorcycle that I rode during my final year of high school.

“After high school, my car craze continued when I found a 1961 Chevy shortbed truck with a six-cylinder engine and three-on-the-tree transmission that I bought. It needed some TLC, so my friend painted it and I bought wheels and tires for it. This sealed my love for old Chevy trucks.

“This truck was eventually sold, and then in the early ’80s I bought a 1970 Chevrolet truck. This was what I was driving when I reconnected with a girl from junior high school, whom I would later marry. After we married, we sold the 1970. Because a coworker offered me decent price for the truck, I let her go.

“Within a few short years of being married, we had two daughters, Sarah and Rachel, which slowed my pursuit of my hot rod truck dreams. Even when the girls were just toddlers, I had my eye on a coworker’s 1962 Chevy shortbed truck. The day I saw it I told him them that if he ever decided to sell it I wanted first shot at buying it. Sometime later, my coworker stopped me and told me it was for sale. Without hesitation, I jumped at the opportunity and bought the truck. It was a clean, straight body truck with very little rust that ran very well. After getting it painted and then upholstered it became my daily driver.

“During this time when I was driving the 1962, I was working full time at the utility company and taking college courses in the evenings. I was commuting to attend these night classes. Sadly, at this point, the truck’s six-cylinder and three-speed meant it was just not practical. So, I had to sell the truck. Then, in 1992, I decided to pursue a pharmacy degree, so my wife and I sold our home, most of our belongings, and moved from Dallas, Texas, to Norman, Oklahoma.

“During these years, our transportation was limited to what we could afford and keep running, so buying and working on an old truck as a hobby was impossible. A friend in Norman knew how much I loved old cars and trucks, so he took me to see the cars that his father-in-law had in a shop. I’ll never forget walking into his shop and seeing two street rods that he had built: a 1933 Dodge coupe and a 1933 Dodge sedan. I knew then that after graduation from pharmacy school, I would again pursue this hobby of street rodding.

“After graduating from pharmacy school in 1997 and eventually settling back in our hometown of Ardmore, Oklahoma, I began looking for a home for my family. My wife always laughs when she tells people that I went looking for a shop that had a house that my wife might like, which is exactly what I did. After purchasing a home in 1999, I slowly began acquiring what I would need to start this hobby. I was starting from scratch; I had nothing except a small toolbox stocked with a few wrenches, ratchets, and screwdrivers. In addition to my fulltime pharmacy job, I also took on a part-time pharmacy job just to fund my hobby.

“At a Goodguys show swap meet in 1999, I spotted an original and complete 1939 Chevy coupe. A deal was made and the car was trailered home. With my dad’s knowledge and experience with old cars, we took her from a rusty, non-drivable relic to a beautiful street rod. This labor of love took us nine years, all of which were riddled with everything from our laughter to strong disagreements about the build. As soon as we finished the coupe, we started taking it to local car shows; this further fueled my hot rod fever and I knew that I still wanted to buy and build another old Chevy truck.

“In spring 2009 my wife and I went to a Pate Swap Meet in Ft. Worth, Texas. While we were there, I spotted a 1952 Chevrolet five-window truck. The truck looked sound, although not running, so we made a deal and hauled it home. Once we got the truck home and started disassembly, we uncovered more rust than we had expected. Very quickly we realized which original parts could be salvaged and reused along with which parts were too damaged to repair. Ultimately, we saved the cab, doors, hood, and frame—everything else had to be replaced.

“Whenever our schedules allowed us, Dad and I worked to disassemble the truck, label and inventory every usable part, and a made list of parts that we needed to order. After disassembling the truck we had the frame sandblasted and powdercoated. We installed a Heidts frontend, a rebuilt small-block 350 that we pulled from my dad’s 1991 Chevy Suburban, a 700-R4 transmission from Phoenix Transmissions, and a Ford 9-inch rearend from Currie mounted with a four-link from Total Cost Involved. With the rolling chassis finished, we assembled the truck using the surviving parts, new front and rear fenders, plus a new truck bed. Then, our attention turned to the truck’s body. First, Dad and I removed the original firewall and replaced it with a Bitchin’ Products firewall with a 4-inch recess, allowing us more room in the engine bay. After assembling the old and new body parts together, we began to get an idea of the truck’s stance and were able to better imagine what it would look like finished. With everything fitted, we then disassembled the truck in preparation for bodywork. Shortly after this, my dad developed health issues that curtailed his visits to the shop to work on the truck. Fortunately, he was always a phone call away when I had a question or a problem, but his absence slowed progress.

“While the truck was getting reading for bodywork, my wife and I discussed the paint color. I envisioned it being orange but she kept insisting that the truck had to be green. So, we looked at every car show we attended, in every car magazine, and even new cars on car lots in search for the perfect color. Bouncing between orange and green we finally settled on PPG Snake Skin Green. Now the truck is ready for a trip to the body shop—which turned into not one but four different shops.

“An acquaintance gave me the name of the Custom Colors body shop in Choctaw, Oklahoma, which became what was to be the truck’s first body shop stop. After a couple of months, minimal bodywork was completed when we learned that the owner had unexpectedly retired. So, we went to Choctaw, got the cab and other parts, and took them to a local Ardmore body shop owned by Kim Spiering who was willing to complete the bodywork. During this body shop stay Spiering completed the majority of the bodywork, installed door latches, primered the parts, and applied undercoating to the essential areas. It was during this time that I contacted Chris Frasher, a local painter who agreed to paint the truck. Frasher was owner of CF Designs, which was a one-man operation specializing in motorcycle painting but he agreed to paint the truck between motorcycle jobs. After leaving Spiering’s body shop, the truck went to Frasher’s shop to begin final preparation and then paint. However, the truck hood still wasn’t fitting well and needed to be fit to the cab. One day one of Frasher’s friends and a fellow automotive shop owner, Micah Newell, of Newell’s Customs in Healdton, Oklahoma, stopped by Frasher’s shop and inquired about the 1952 truck in his shop. Frasher shared that the truck was there for paint but more work was needed on the hood. Aware of Frasher’s heavy motorcycle jobs, Newell offered to tackle the truck’s hood. The Chevy was headed to her fourth body shop stop, Newell’s Customs, where Newell finished the remaining work on and mounting of the hood—then the truck was returned to Frasher’s shop for paint.

“As body and mechanical parts were painted and ready, I began assembly. This was a slow process that took the help of my family and several friends to complete. My brother, Larry, and I installed the front and rear glass. Then my son-in-law Kane Bass and daughter Sarah installed the corner cab glass. My daughter Rachel helped me connect the front fenders to the cab. After this, I tackled the wiring of the truck and finishing on the bedwood. With the wiring complete and ready for interior, my wife, Denise, and Larry helped me take the truck for upholstery to Shawn Cook, owner of Cook’s Auto Top and Trim. Before we arrived, my wife had already decided that she wanted the seats and carpet to be a rich brown color and she knew what she wanted the stitching pattern to be. In just a few weeks, Cook had installed the sound system and upholstered the truck’s interior.

“When it was time for the bed to be set on the frame, Larry, Kane, Frasher, and myself got the bed squared and mounted to the frame; then we added the rear fenders. At this point, the truck was mostly complete with minor finishing details remaining; and this put us just one week before the Goodguys show in Ft. Worth where the truck was scheduled to make its debut. Frasher and I (and my wife when we needed an extra set of hands) had a few marathon sessions finishing those last few details. (Her extra set of hands was always there throughout the nine-year build. In fact, my wife was there from start to finish all nine years, always willing to lend her hands, and she never minded crawling under the truck and getting dirty!)

“The day the 1952 Chevy truck rolled through the tunnels at Texas Motor Speedway and onto the infield there was a sense of accomplishment and fulfillment of a long nine-year process. Remember the 1967 Chevelle that started my love affair with Chevy hot rods? Well, my dad gave me the Chevelle he raced in the ’70s and it is sitting in my garage—it’s my next Chevy hot rod project!”

Facts & Figures

CHASSIS Frame: Modified stock Rearend / Ratio: Currie 9-inch / 3.70:1 Rear Suspension: TCI four-link Rear Brakes: Drum Front Suspension: Heidts IFS Front Brakes: Disc Steering Box: Power rack Wheels: 15-inch Wheel Vintiques Tires: BFGoodrich Radial T/A Gas Tank: CPP 19-gallon

DRIVETRAIN Engine: Chevy 350 Valve Covers: Cal Custom Manifold / Induction: Edelbrock AirGap / Holley 670 Street Avenger Ignition: MSD Headers: Sanderson Mufflers: MagnaFlow Transmission: Phoenix Transmissions 700-R4

BODY Style: Advance Design 1/2-ton five-window Fenders Front / Rear: Stock Hood: Stock Grille: Stock Bodywork by: CF Designs, Custom Colors, Kim’s Body Shop, Newell’s Customs Painted by: CF Designs Paint type / Color: PPG / Snake Skin Green Headlights / Taillights: Classic Parts of America Bumpers: Classic Parts of America

INTERIOR Dashboard: Stock, smoothed Gauges: Classic Instruments Air Conditioning: Vintage Air Wiring: American Autowire Stereo: Memphis Audio Steering Wheel: 1960 Impala repop Seats: Snowden Custom Upholstery by: Shawn Cook Upholstery Material / Color: UltraLeather / Brown Carpet: Brown square-weave

The post Hot Rod Fever: The Brunk Family 1952 Chevy Pickup appeared first on Hot Rod Network.

from Hot Rod Network https://www.hotrod.com/articles/brunk-family-1952-chevy-pickup/ via IFTTT

0 notes

Text

Why Is CFS Floor Framing Design Becoming the Go-To Solution for Builders?

CFS Floor Framing Design has become a preferred method for builders due to its durability and cost-efficiency. Unlike traditional wood framing, cold-formed steel offers a strong and long-lasting solution that can withstand various environmental challenges. This design approach ensures that structures maintain their integrity over time, making it ideal for both residential and commercial projects. Additionally, CFS framing minimizes maintenance costs, providing a smart, sustainable choice for modern construction.

By incorporating CFS floor framing design into building projects, construction teams can achieve quicker assembly times and greater flexibility in design. Cold-formed steel is easy to manipulate and fabricate, allowing for more intricate and custom floor plans. With its resistance to common issues like rot and pests, this design method proves to be a reliable option for projects that demand high strength and long-term stability.

Check out our blog for more insights: https://steelsmartsystem.blogspot.com/2025/04/why-is-cfs-floor-framing-design.html

0 notes

Text

Barn là gì

Barn