#cmms implementations

Explore tagged Tumblr posts

Text

4 Common CMMS Implementation Mistakes to Avoid

Avoid CMMS implementation pitfalls! Learn 4 common mistakes and how to sidestep them for smoother maintenance management success.

#cmmssoftware#terotam#maintenance#asset management software#cmmssolution#preventivemaintenance#cmms implementations

0 notes

Text

Selecting The Right CMMS For Your Business.

Investing in a Computerised Maintenance Management System (CMMS) is a substantial commitment for any organization.

A CMMS has the potential to significantly boost productivity and decrease costs by optimizing maintenance processes, reducing downtime, and enhancing operational efficiency.

The specific advantages a CMMS can provide are dependent on your organization's unique needs and objectives, as well as the systems and procedures you put in place to maximize its benefits.

Before acquiring a CMMS, it's crucial to conduct in-depth research to ensure the system is cost-effective, user-friendly, and capable of fulfilling both present and future needs.

An informed decision requires a meticulous selection process, where each potential CMMS is evaluated based on its features, scalability, compatibility with existing systems, and the level of vendor support.

The first step should be a thorough evaluation of your organization's maintenance management needs.

This involves identifying the specific challenges your organization encounters, the necessary functionalities, and the goals for implementing a CMMS.

The user experience is also vital, as a system that is intuitive and easy to use can significantly improve user adoption and productivity.

Consideration should also be given to the total cost of ownership, which includes not just the initial purchase price, but also ongoing expenses such as maintenance, training, and upgrades.

Over time, a quality CMMS should yield a robust return on investment by consistently enhancing performance and reducing operational costs.

Future-proofing your investment is another crucial consideration.

The ideal CMMS should be adaptable to evolving technological advancements and scalable to accommodate your organization's growth.

It should also incorporate robust data security features to safeguard sensitive information and ensure compliance with industry regulations.

Ultimately, the objective is to make an informed decision that aligns with your business goals while maximizing the benefits of a CMMS.

Prioritizing comprehensive research and a systematic selection process will ensure that the CMMS you choose becomes a valuable asset to your organization.

The initial stages of CMMS selection are critical, and I believe the following seven key takeaways are important:

1. Thorough Research: Conduct extensive research to ensure the chosen CMMS is cost-effective, user-friendly, and meets both current and future requirements.

2. Business Needs: Start the selection process with a thorough analysis of your company’s maintenance management requirements.

3. Total Cost of Ownership: Consider both the initial purchase price and ongoing costs such as maintenance, training, and upgrades.

4. Future-Proofing: The ideal CMMS should be adaptable to changing technological advancements and scalable to support your company’s growth.

5. Business Process Mapping: Update and map business processes before selecting a CMMS to get a clear picture of current operations and identify inefficiencies.

6. Defining CMMS Needs: Define your requirements accurately to ensure the CMMS will support optimized processes and avoid selecting a CMMS that doesn’t fit the business model.

7. Vendor Evaluation: Consider the vendor’s track record, customer support, and roadmap for future developments when choosing a CMMS.

To learn more, you can read my article: Selecting The Right CMMS For Your Business - CMMS Success

#cmms software#cmms#cmms selection#purchase cmms#cmms value#cmms importance#cmms implementation#cmms training

0 notes

Text

SAP CMMS Implementation – A step-by-step Guide

Looking to transform your plant maintenance operations? SAP CMMS (Computerized Maintenance Management System) is the answer. Here's a step-by-step guide to help you successfully implement SAP CMMS in your plant maintenance operations:

Define Objectives: Outline your goals and pain points.

Assess Current Processes: Identify gaps and areas for improvement.

Plan and Design: Collaborate on system scope and design.

Data Migration: Ensure accurate data transfer.

Configuration: Customize workflows to fit your needs.

Training: Provide comprehensive staff training.

Testing: Ensure system functionality meets requirements.

Go-Live: Launch with ongoing support for success.

Transform your maintenance operations with SAP CMMS. Contact us at KaarTech to get started!

Dive deeper into SAP CMMS benefits in our blog [https://www.kaartech.com/sap-cmms-for-plant-maintenance/].

1 note

·

View note

Text

Asset Maintenance Management Software

Looking for the best maintenance and asset management software for your business or organization? MicroMain is best in the industry maintenance management.

For more information visit our website: https://www.micromain.com/

0 notes

Note

O abo é um universo bem vasto, então é difícil resumir em uma categoria única. Creio que tenha começado com lobos mesmo, mas não é mais assim hoje em dia. São humanos híbridos, com características animalescas (físicas, apenas se preferirem ter, ou apenas instintivas, que todos têm: das físicas, temos as orelhas, o rabo, maior presença de pelos no corpo etc; das instintivas, temos o cio/estro, dominância, instinto de formar família e proteger, possessividade com membros da família ou parceires romanticx, etc.) Quando joguei na abo, joguei com um personagem sem nenhuma característica física de animais, porque prefiro assim. Ele só tinha as partes instintivas mesmo. A última cmm abo que tivemos deixou vários links pra ler mais sobre o universo, mas eu não tenho mais eles pra enviar aqui.

Anônimo enviou uma ask: ollie, essa explicação do wattpad é um pouquiiinho errada, porque dá a entender que todo universo abo se dá por z**fi! cada autor acaba pegando uma explicação quando vai criar alguma coisa, mas como leitora de muitos anos, posso dizer que 99% trata o tema como um universo alternativo onde as pessoas sempre foram assim. :) abo acaba funcionando mais como subgêneros (não tô falando de literários) da raça humana, por exemplo. a falecida cmm blossom/byeolwon implementou algumas coisas extras nesse universo, como híbridos com algumas características de certos animais (tendo cauda, orelhas específicas, olhos de outras cores etc). é um universo bem rico e interessante, basta saber explorar direitinho!

Muito obrigada vocês pelas explicações! Eu joguei no google e foi a 'explicação' que apareceu mais em destaque e direta, por isso acabei jogando aqui (vou excluir já que a maioria considera errada).

Eu sou daquelas que o anônimo da pesquisa comentou que tinha um certo receio com o tema. Toda vez que ouvia falar de abo era em ic ou rpi, e as pessoas zoavam, falando que era uma coisa horrorosa. Eu nunca li nenhuma fic ou joguei rpg pra experimentar por mim mesma.

Porém, essas últimas comunidades tem demonstrado que não precisa ser assim como o pessoal diz. Dá pra explorar de forma interessante sem pender necessariamente para o assunto acasalamento o tempo todo. Eu aqui, só de ler essas asks, já pensei em briga de homem-animal por rivalidade e afins que poderia ser muito legal de desenvolver. Ou dessas pessoas tentando conviver normalmente com outras, escondendo suas características físicas ou não.

Acho que comunidades assim poderiam liberar pessoas normais para cadastrar também, sem que sejam apenas só híbridos, para fazer essas mistura. Até mesmo, para quem esteja querendo conhecer o universo e não se sente seguro o suficiente para fazer um híbrido logo de cara (seria meu caso). Assim, poderiam conhecer o universo, ver na prática como funciona, e quem sabe, ter vontade de desenvolver um personagem híbrido futuramente.

Acredito que esse preconceito possa vir de fanfics ruins, já que aparentemente o abo nasceu aí. E assim como livros, séries e histórias, existem as boas e as ruins.

Eu gosto quando temas assim dão certo para ter mais opções na tag, já que a krpbr está sempre em um looping de cidade, ilha, idol ou uni. Não é uma reclamação, eu mesma gosto desses temas, mas não seria legal ter novas opções dando certo?

2 notes

·

View notes

Note

i just found out a new season is coming out a month from now? they must have a concrete plot and art work already lined up if they’re ready to release in the next 4 weeks so would the recent survey impact (hopefully) season 8 that would be coming out next summer?

how do you think fans would react to fusebox following the now former love island show schedule and do summer & winter seasons so that the fandom have more time to get over the characters they’ve just recently finished with but the time period isn’t 10-11 months for a brand new season? while also being able to receive and implement changes and tweak things based off of the fan’s opinions and put it into a winter season that would come out say december - february and finish it by march-april. giving the fans content while they wait for the summer season instead of having a dry spell and limited replay options.

or do you think the old format of releasing bonus content of the former season like the boat party, the wedding etc is something that should make a comeback instead?

[Why does this ask read like it's from fusebox directly 👀]

I'm honestly surprised they asked for our feedback at all if they already had a new season lined up. They must be reusing a lot of assets; either that or it's a VERY short season, like 12 episodes or something which will be ass. Honestly I think two seasons a year would be perfect. But there needs to be a larger gap than this in between. People want to go back and play new routes but that's hard to do when there's only a week or two break in between seasons. Even if you played diligently in that one week, waiting 2 hours for tickets over and over is a pain in the as.

Winter season: Do you know how much I would FROTTTHHH on a winter LI season? Cute winter outfits, dates in the jacuzzi, snowball fights, or huddling for warmth (hehehe) come on, I would LOVE THAT (Imagine your fave islander in a lovely snuggly hoodie and only getting to see them with their kit off in the shower or hideaway?? SURPRISE love that. Even though said winter season would be coming out while us southern hemisphere folk are out here sweltering through bushfires and heatwaves I'd still love it.

Bonus content: Look, personally, I loved the S3 boat party. I thought it was unique, that it was cool we could date the islanders in different contexts, but that we had a chance to make up with our LI if we wanted. S1 I was so fucking done with Erikah that having to participate in her bullshit pissed me off. Besides, how come she's getting a proposal and i'm not??? You mean to tell me Jake didn't propose immediately after leaving the villa??????

S2 I LOVE LOVE LOVED the wedding but absolutely not CMM. Especially "you cheated on noah with noah!" And Lucas having a moustache and being scared of horses. I'm sorry, no, CMM is not canon. Urgh. If the bonus content was GOOD then it would absolutely be worth it. But I don't know if everyone would be down to have a 'islanders getting married' reunion. Not everyone wants that.

7 notes

·

View notes

Text

Fluid Handling Services Market Size, Trends, Key Players & Market Path

Global Fluid Handling Services Market Overview The global fluid handling services market is estimated at approximately USD 64–65 billion in 2023, with forecasts projecting growth to between USD 85–90 billion by 2032–2033. This trajectory implies a compound annual growth rate (CAGR) in the range of 4.5–5.5%, driven by the industrial automation revolution, aging operational infrastructure, and escalating environmental compliance requirements. North America and Europe remain dominant in market share, while the Asia‑Pacific region—especially China and India—emerges as the fastest-growing market owing to rapid urbanisation, petrochemical expansion, and water/wastewater infrastructure development. Global Fluid Handling Services Market Dynamics Key Drivers: Demand for efficient pumping, filtration, valve, and instrumentation services in critical industries like oil & gas, chemical processing, power generation, and food & beverage. This growth is reinforced by regulatory imperatives and the surge in digital monitoring and predictive maintenance technologies. Market Restraints: Cost volatility for raw materials, intense pricing competition from third-party service providers, and the complexity of asset lifecycles and regulatory registries contribute to margin pressure. Strategic Opportunities: Expansion in water and wastewater treatment sectors, rising adoption of sustainable fluid management solutions, and an uptick in digital service platforms offering analytics and remote asset supervision. Technology & Compliance: IoT-enabled fluid monitoring platforms, AI-driven predictive diagnostics, and computerized maintenance management systems (CMMS) are increasingly being integrated. Regulatory frameworks around emissions, spill containment, and worker safety are catalysing investments in advanced service offerings. Download Full PDF Sample Copy of Global Fluid Handling Services Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=25928&utm_source=PR-News&utm_medium=387 Global Fluid Handling Services Market Trends and Innovations 1. Digital twin and remote monitoring: Real-time asset tracking through digital twin technology and condition-based monitoring is lowering downtime and optimising performance. 2. Predictive analytics and AI: AI‑augmented diagnostics process sensor data to forecast equipment failure and schedule proactive maintenance. 3. Advanced filtration and purification: Cutting-edge filtration services—including microfiltration and reverse osmosis maintenance—are gaining traction in pharmaceuticals, food & beverage, and water utilities. 4. Collaborative platforms: OEMs and service companies partnering to deliver bundled service and lifecycle management contracts, offering holistic support for pumps, valves, meters, and electronics. 5. Sustainability services: Fluid management audits, leak detection, and industrial water reuse programmes address resource efficiency and environmental footprint reduction. Global Fluid Handling Services Market Challenges and Solutions Challenge – Supply chain instability: Geopolitical tensions and logistical bottlenecks disrupt spare-parts availability. Solution: Maintain multi-sourcing strategies, localize inventories, and adopt digital procurement platforms. Challenge – Price competition and margin pressure: Low-cost service providers erode profitability. Solution: Differentiate on value-added services—digital dashboards, lifecycle contracts, and regulatory compliance advisory. Challenge – Regulatory and environmental complexity: Firms face region-specific compliance obligations. Solution: Invest in specialized compliance teams, standardize service bundles across jurisdictions, and develop green-certified offerings. Challenge – Talent and skills gap: Skilled technicians and data analysts are scarce. Solution: Launch training partnerships with technical institutes, implement augmented-reality guided maintenance, and broaden remote assistance via digital tools. Global Fluid Handling Services Market Future Outlook

Over the next 5–10 years, the fluid handling services industry is expected to sustain mid‑single digit CAGR momentum, reaching close to USD 90 billion by 2032–2033. Growth will be anchored in the convergence of digital transformation, sustainability mandates, and precision process control. Key sectors such as petrochemicals, power, pharmaceuticals, and water utilities will drive service adoption. Looking ahead, future development hinges on three primary pillars: Digital evolution: Expansion of cloud‑based CMMS, edge computing, IoT sensor fusion, and automated diagnostics will underpin service differentiation. Sustainable fluid management: Circular economy principles—water reuse, hydrocarbon recovery, emissions capture—will shape service innovation and product–service hybrid models. Service-driven business models: Expect to see increased adoption of subscription‑based lifecycle services, equipment-as-a-service (EaaS), and performance-based contracting, aligning provider revenue with uptime and efficiency metrics. In summary, the global fluid handling services market is poised for transformation from traditional break-fix models to integrated, analytics‑driven, sustainability-focused service platforms, underpinned by digital innovation and regulatory evolution. Key Players in the Global Fluid Handling Services Market Global Fluid Handling Services Market are renowned for their innovative approach, blending advanced technology with traditional expertise. Major players focus on high-quality production standards, often emphasizing sustainability and energy efficiency. These companies dominate both domestic and international markets through continuous product development, strategic partnerships, and cutting-edge research. Leading manufacturers prioritize consumer demands and evolving trends, ensuring compliance with regulatory standards. Their competitive edge is often maintained through robust R&D investments and a strong focus on exporting premium products globally. HYDAC RelaDyne INOXPA Group (Interpump Group SpA) Hudson Pump Astro Pak Corporation Gaubert Oil Company and Global Industrial Solutions. Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount?rid=25928&utm_source=PR-News&utm_medium=387 Global Fluid Handling Services Market Segments Analysis and Regional Economic Significance The Global Fluid Handling Services Market is segmented based on key parameters such as product type, application, end-user, and geography. Product segmentation highlights diverse offerings catering to specific industry needs, while application-based segmentation emphasizes varied usage across sectors. End-user segmentation identifies target industries driving demand, including healthcare, manufacturing, and consumer goods. These segments collectively offer valuable insights into market dynamics, enabling businesses to tailor strategies, enhance market positioning, and capitalize on emerging opportunities. The Global Fluid Handling Services Market showcases significant regional diversity, with key markets spread across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Each region contributes uniquely, driven by factors such as technological advancements, resource availability, regulatory frameworks, and consumer demand. Fluid Handling Services Market, By Type • Flushing• Filtration• Varnish Removal• Others Fluid Handling Services Market, By Industry • Oil & Gas• Chemicals• Food & Beverage• Paper & Pulp• Energy & Power• Others Fluid Handling Services Market By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/fluid-handling-services-market/ About Us: Verified Market Research Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information-enriched research studies.

We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and critical revenue decisions. Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research methodology, expertise, and years of collective experience to produce informative and accurate research. Contact us: Mr. Edwyne Fernandes US: +1 (650)-781-4080 US Toll-Free: +1 (800)-782-1768 Website: https://www.verifiedmarketresearch.com/ Top Trending Reports https://www.verifiedmarketresearch.com/ko/product/personal-safety-tracking-devices-market/ https://www.verifiedmarketresearch.com/ko/product/food-grade-citral-market/ https://www.verifiedmarketresearch.com/ko/product/mmwave-5g-market/ https://www.verifiedmarketresearch.com/ko/product/gasket-market/ https://www.verifiedmarketresearch.com/ko/product/offshore-decommissioning-market/

0 notes

Text

Implementing BIM Across the Project Life Cycle: Techniques, Tools & Technologies

Discover how Building Information Modeling (BIM) revolutionizes the construction industry by enhancing every phase of a project's life cycle.Key techniques used to implement BIM Life Cycle Analysis in Construction Project Management, including:

✅ 3D BIM Visualization ✅ Planning and Execution ✅ 4D BIM Construction Scheduling ✅ Quantity Take-off for Construction ✅ Design Development & Coordination

The BIM life cycle integration process includes essential components from Planning, Design, Construction, Operation, to Decommissioning—integrating powerful systems such as:

GIS (Geographic Information System) CAFM (Computer-Aided Facility Management System) CMMS (Computerized Maintenance Management System) BAS (Building Automation System) CPMS, IPO-JOC, and more

Learn how to implement BIM techniques across every project phase—start your journey today!

0 notes

Text

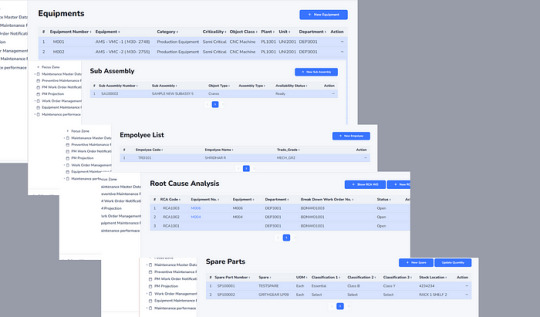

Boost Your Maintenance Efficiency with Smart CMMS and Training Solutions

In today’s statistics-pushed industrial world, efficient asset control and maintenance are essential to achieving operational excellence. Businesses now rely upon CMMS Software Features to streamline processes, boom uptime, and reduce sudden breakdowns. A nicely-selected Computerized Maintenance Management System (CMMS) no longer only boosts productivity but also aligns with lengthy-term commercial enterprise dreams thru structured making plans and analytics.

The Power of CMMS: Simplifying Maintenance Operations

Partnering with a trusted CMMS Software Development Company permits groups to tailor solutions that meet their precise operational necessities. These structures come prepared with essential modules consisting of CMMS Asset Performance Reports and CMMS Asset Analytics, permitting higher selections through data-driven insights.

Modern CMMS for Streamlined Management

A effective Computerized Maintenance Management Software offers a centralized solution for scheduling, inventory manage, compliance, and reporting. When well controlled, the CMMS implementation unit can significantly reduce the shutdown and expand the asset life. However, CMMS cost of expertise are required. Organizations have to evaluate lengthy-term ROI over prematurely investment, keeping in mind decreased exertions, restore, and downtime costs.

For small and medium establishments, a reliable Maintenance Software CMMS may be a sport-changer. When paired with Mobile CMMS, it empowers technicians to manage obligations remotely, enhancing performance and real-time updates. The CMMS Maintenance Management System acts because the spine of facility and asset renovation strategies.

Enhancing Control Through Inventory and Work Management

One of the important thing strengths of any CMMS lies in its potential to manipulate inventory and spares. A sturdy Inventory Control Software enables track components, avoid shortages, and optimize procurement. Similarly, Work Order Management Software allows protection teams to generate, assign, and close paintings orders with no trouble, reducing guide mistakes and delays.

Efficient operations depend closely on strategic scheduling. This is in which Maintenance Planning and Scheduling Software comes into play, supporting upkeep heads to prioritize responsibilities and align with manufacturing goals. For teams looking for deeper information, Maintenance Planning and Scheduling Training can sharpen abilties and foster a lifestyle of preventive care.

Smart Software and Training for Maximum Uptime

Even small corporations advantage from adopting Maintenance Software for Small Business, which regularly includes primary but impactful functions like paintings order tracking, preventive scheduling, and asset statistics. For large establishments, Preventive Maintenance Software automates inspections and services, while Predictive Maintenance Software makes use of real-time records and AI to forecast capability disasters.

Operational efficiency isn’t pretty much generation — it’s also approximately humans. Training packages together with Preventive Maintenance Optimization Training, Asset Reliability Training, and Maintenance Management Training empower groups to implement and sustain high-quality practices. Additionally, Root Cause Analysis Training helps upkeep personnel become aware of the source of habitual failures and put into effect long-time period fixes.

0 notes

Text

How to Improve Production Efficiency Using Food Packaging Machines

Efficient food packaging isn’t just about sealing bags or filling containers—it’s a critical driver of productivity, cost savings, and product quality. By leveraging the right machines, processes, and practices, food manufacturers can dramatically streamline their operations. Here’s a curated guide on optimizing production efficiency with food packaging machines.

1. Conduct a Thorough Process Audit

Before investing in new machinery, map out your current packaging workflow:

Identify bottlenecks such as slow filling stations, frequent changeovers, or manual inspection points.

Gather data on cycle times, downtime causes, and labor requirements.

Prioritize improvements by focusing on high-impact areas (e.g., reducing waste or speeding up slower machines).

Actionable Tip: Use simple time-and-motion studies over a week to quantify inefficiencies and set measurable targets (e.g., reduce changeover time from 30 to 15 minutes).

2. Select the Right Machine for the Job

Not all packaging machines are created equal. Matching machine capabilities to product and volume is essential:

Volumetric vs. gravimetric fillers: For liquids or powders, choose gravimetric fillers if precision is paramount; volumetric fillers can be faster for larger tolerances.

Form-fill-seal (FFS) units: Ideal for flexible pouches and snacks, FFS machines combine shaping, filling, and sealing in one step—cutting material handling time.

Cartoners and case packers: Automated cartoning and case packing reduce manual labor and increase throughput, especially for high-volume lines.

Actionable Tip: When evaluating machines, calculate throughput per dollar by dividing the machine’s maximum packs per minute by its purchase or lease cost.

3. Implement Scheduled Preventive Maintenance

Unplanned downtime can cripple production targets. A robust maintenance plan will:

Schedule routine inspections of critical components (seals, sensors, conveyors) based on runtime hours.

Keep a log of wear parts and reorder in advance to avoid stockouts.

Train operators to perform daily cleaning and quick checks—reducing the likelihood of unexpected failures.

Actionable Tip: Use a simple digital checklist or CMMS (Computerized Maintenance Management System) to track maintenance tasks and downtime events.

4. Integrate Automation and Smart Controls

Modern packaging machines offer smart features that can optimize efficiency:

Recipe management: Store up to hundreds of product “recipes” (bag size, fill weight, sealing temperature) to cut changeover times to minutes.

In-line quality inspection: Vision systems detect fill-level inconsistencies, misaligned seals, or contaminations, reducing rejects downstream.

IoT connectivity: Real-time data on machine performance (OEE, reject rates) allows supervisors to make data-driven decisions on-the-fly.

Actionable Tip: Start by retrofitting your most critical line with PLC upgrades and basic SCADA monitoring before rolling out plant-wide automation.

5. Invest in Operator Training and Cross-Functional Teams

Even the smartest machines underperform without skilled operators:

Hands-on training: Teach staff how to troubleshoot minor issues (e.g., sensor alignment, film tracking) quickly.

Cross-training: Rotate operators among lines to build flexibility and avoid single points of expertise.

Continuous improvement culture: Encourage staff to propose small Kaizen-style improvements, such as ergonomic tweaks or minor fixture adjustments.

Actionable Tip: Host monthly “efficiency huddles” where operators share win-win ideas and celebrate metrics like downtime reduction.

6. Monitor, Review, and Refine

Efficiency gains are only sustainable if you continually measure and adapt:

Key Performance Indicators (KPIs): Track OEE, throughput rate, changeover duration, and scrap percentage weekly.

Regular reviews: Hold quarterly meetings between production, maintenance, and engineering teams to assess progress and set new goals.

Scale successful pilots: Test new practices on one line before deploying them across the plant.

0 notes

Text

cmm measuring machine

Unlocking Precision Engineering with CMM Measuring Machines and Metrology Tools in Malaysia

In today’s fast-paced manufacturing industry, precision is everything. Whether you're producing components for aerospace, automotive, electronics, or medical devices, the need for accurate measurement and tight tolerance control is more critical than ever. Enter the world of metrology—a domain where tools like the CMM measuring machine, profile projectors, and dial tester indicators play an indispensable role. For companies in Malaysia striving to meet international standards, having access to world-class equipment and support is essential. This is where Takumiprecision.com.my, a trusted name in metrology solutions, makes a real difference.

The Role of CMM Measuring Machines in Modern Manufacturing

A CMM measuring machine (Coordinate Measuring Machine) is a sophisticated device used to measure the geometry of physical objects by sensing discrete points on the surface with a probe. These machines provide three-dimensional readings that are far more precise than conventional manual measuring tools.

Industries across Malaysia are rapidly adopting CMM technology to enhance quality control, reduce rework, and maintain consistency in production lines. Whether it's checking a machined part’s dimensional accuracy or reverse engineering a legacy component, a CMM measuring machine streamlines the entire process.

Hexagon CMM: A Global Leader in Metrology Solutions

Among the many CMM brands available, Hexagon CMM stands out as a global leader. Known for innovation, reliability, and performance, Hexagon offers a wide range of CMMs—from bridge-type and gantry models to portable arms and multi-sensor systems. These machines are engineered to handle the most demanding inspection requirements.

In Malaysia, Hexagon CMM has become synonymous with quality assurance in high-precision manufacturing. Companies seeking top-tier metrology equipment often turn to Hexagon for its cutting-edge software, automation integration, and unparalleled accuracy.

Looking for a Hexagon Agent in Malaysia?

If you’re in search of a certified Hexagon Agent in Malaysia, look no further than Takumiprecision.com.my. As an authorized distributor and service provider, Takumi Precision delivers not only the latest Hexagon CMM models but also offers installation, training, calibration, and after-sales support.

Being a Hexagon Agent Malaysia partner means staying up-to-date with the latest metrology innovations. From implementing automated inspection cells to leveraging AI-powered data analytics, Takumi Precision helps Malaysian manufacturers stay competitive in a global market.

Profile Projector Malaysia: An Essential Optical Measuring Tool

While CMMs provide 3D measurements, certain tasks still require 2D analysis—especially in small-scale or soft material components. That’s where the profile projector comes into play. Also known as an optical comparator, this tool projects a magnified silhouette of a part onto a screen for easy inspection of dimensions, shapes, and angles.

A profile projector Malaysia solution is ideal for quality control labs and production floors that need a fast, visual representation of a part's profile. Whether you're verifying thread pitch or comparing stamped parts against a CAD overlay, profile projectors remain a trusted choice for non-contact measurements.

Takumiprecision.com.my offers a diverse range of profile projectors tailored for different industrial needs. Their models come with digital readouts, high-resolution optics, and LED illumination systems for clear and accurate viewing.

Dial Tester Indicator Malaysia: Precision in Every Micron

Sometimes, simplicity delivers the best results. A dial tester indicator is a classic metrology instrument used to measure small linear distances and variations in surface levels. Perfect for detecting runouts, checking concentricity, or aligning machines, dial indicators remain a staple in inspection and assembly setups.

In Malaysia, the demand for high-quality dial tester indicators is growing among toolmakers, machinists, and QA professionals. Takumiprecision.com.my caters to this need with a comprehensive selection of analog and digital dial indicators from leading brands. Whether you're working with lathes, mills, or jigs, their precision instruments help ensure every micron counts.

Why Choose Takumiprecision.com.my?

When it comes to investing in metrology equipment, reliability, service, and expertise matter just as much as the tools themselves. Here’s why Takumiprecision.com.my is the go-to name for quality-conscious businesses across Malaysia:

Certified Expertise: As an official Hexagon Agent Malaysia, they bring globally recognized technology to your doorstep.

Wide Product Range: From advanced CMM measuring machines to profile projectors and dial tester indicators, they provide complete solutions for your inspection needs.

Customer-Centric Service: Takumi Precision offers personalized consultations, after-sales training, and maintenance contracts to ensure optimal performance.

Local Support with Global Standards: Enjoy the responsiveness of a local provider with the confidence of world-class equipment.

0 notes

Text

CMMS Explained: The Smart Solution to Modern Maintenance Management

In today’s high-speed business landscape, unplanned equipment breakdowns and inefficient maintenance can severely disrupt operations and inflate costs. A Computerized Maintenance Management System (CMMS) provides a powerful solution by centralizing, automating, and optimizing maintenance tasks across industries. Whether you run a factory, hospital, or school, CMMS software ensures operational continuity, asset longevity, and cost control.

A CMMS is designed to simplify maintenance management through a unified platform. It helps organizations handle work orders, schedule preventive maintenance, track assets, manage spare parts inventory, and generate insightful reports. Shifting from reactive to proactive maintenance, CMMS allows businesses to prevent costly downtime by maintaining equipment before it fails. Key features include real-time work order tracking, asset history logging, automated service schedules, and detailed analytics.

The value of a CMMS lies in its measurable impact. Businesses using CMMS experience reduced downtime, lower maintenance costs, and improved technician productivity. With automated alerts and easy access to asset information, teams can focus on actual repairs instead of paperwork. CMMS also supports safety and regulatory compliance by ensuring critical maintenance tasks are completed on schedule and documented properly.

Industries such as manufacturing, healthcare, education, facilities management, and oil & gas particularly benefit from CMMS platforms. The blog highlights a real-world case where a manufacturing plant cut downtime by 35% and reduced maintenance costs by 20% within six months of implementation. Choosing the right CMMS depends on factors like ease of use, scalability, deployment type (cloud vs. on-premise), integration capabilities, and vendor support.

Despite its advantages, CMMS implementation can present challenges such as employee resistance, large-scale data entry, and customization requirements. However, these can be overcome with proper training, phased rollouts, and selecting a flexible system.

In conclusion, a CMMS is no longer optional in 2025—it’s essential. It empowers maintenance teams, protects valuable assets, and provides the visibility needed to operate efficiently. For businesses seeking a smarter, more reliable way to manage maintenance, investing in the right CMMS is a strategic move that delivers long-term gains.

0 notes

Text

What is Maintenance Management? A Comprehensive Guide

In today’s fast-paced industrial and technological environment, the efficiency and longevity of physical assets play a vital role in the success of organizations. Whether it's manufacturing equipment, vehicles, buildings, or any infrastructure, maintaining them properly is essential to reduce costs, avoid downtime, and ensure safety. This is where the concept of maintenance management comes into play. But what is maintenance management, and why is it so critical across various sectors?

Definition: What is Maintenance Management?

Maintenance management refers to the systematic approach involved in planning, organizing, directing, and controlling the maintenance activities of an organization. It ensures that all physical assets—whether machinery, facilities, or infrastructure—are kept in optimal working condition through scheduled inspections, repairs, replacements, and upgrades.

In simpler terms, maintenance management is about making sure that everything that needs to be working continues to work efficiently, with minimal disruptions and at the lowest possible cost.

Objectives of Maintenance Management

The primary goals of maintenance management include:

Minimizing Downtime: Ensuring that equipment and systems function without unexpected breakdowns.

Extending Equipment Lifespan: Through regular maintenance, assets can serve longer and more reliably.

Improving Safety: Malfunctioning machinery can pose safety risks; maintenance helps eliminate such hazards.

Cost Efficiency: Preventive measures often cost less than emergency repairs and replacements.

Optimizing Productivity: Well-maintained equipment operates at peak performance, increasing overall output.

Types of Maintenance Strategies

There are several types of maintenance that organizations use depending on their goals, budget, and operational needs:

1. Preventive Maintenance

This involves regularly scheduled inspections and servicing to prevent failures. For example, changing oil in a machine every three months regardless of whether it's showing issues.

2. Predictive Maintenance

Using sensors and data analytics, predictive maintenance aims to anticipate failures before they happen. It is a more advanced and cost-effective strategy, as it prevents unnecessary maintenance actions.

3. Corrective Maintenance

This is performed after a problem has occurred. It includes repairing or replacing faulty components. Although it may seem reactive, it is sometimes necessary for non-critical systems.

4. Condition-Based Maintenance

This type relies on monitoring the actual condition of an asset. Maintenance is performed only when certain indicators show signs of decreasing performance.

Components of an Effective Maintenance Management System

To effectively implement maintenance management, organizations often rely on a structured system that includes the following components:

Asset Inventory: A detailed list of all equipment and systems requiring maintenance.

Maintenance Scheduling: A calendar or timeline for routine checks and tasks.

Work Order Management: A system to create, track, and close maintenance requests and repairs.

Resource Allocation: Assigning the right personnel, tools, and parts to each maintenance task.

Documentation and Reporting: Keeping detailed records of maintenance history, inspections, and failures.

Modern organizations use Computerized Maintenance Management Systems (CMMS) to manage all these tasks digitally, improving efficiency and accountability.

Benefits of Maintenance Management

Organizations that implement strong maintenance management practices experience numerous advantages:

Reduced Equipment Failure: Regular checks catch problems early, reducing severe breakdowns.

Improved Asset Life: Machines and infrastructure last longer, maximizing investment returns.

Lower Operational Costs: Well-maintained systems consume less energy and require fewer major repairs.

Higher Safety and Compliance: Maintenance ensures machinery meets safety standards and regulatory requirements.

Increased Productivity: Reliable equipment leads to uninterrupted production and services.

Challenges in Maintenance Management

Despite its importance, maintenance management comes with several challenges:

Budget Constraints: Allocating funds for maintenance in advance can be difficult.

Lack of Skilled Labor: Hiring and training qualified maintenance personnel can be time-consuming and costly.

Asset Complexity: As machines and systems become more complex, so does their maintenance.

Data Management: Collecting and analyzing maintenance data for decision-making can be overwhelming without proper tools.

The Future of Maintenance Management

With the rise of Industry 4.0 and the Internet of Things (IoT), maintenance management is becoming more intelligent. Predictive maintenance, powered by real-time data and artificial intelligence, is gradually replacing traditional methods. Automation and machine learning algorithms now help organizations forecast failures with high accuracy, schedule maintenance optimally, and reduce human errors.

Moreover, mobile applications and cloud-based platforms enable maintenance teams to access data, submit reports, and coordinate activities from anywhere, enhancing flexibility and collaboration.

Conclusion

So, what is maintenance management? It is much more than just fixing broken machines. It’s a strategic function that supports operational excellence, safety, and long-term asset performance. As technology advances and the demand for reliability grows, maintenance management is becoming increasingly vital for businesses across all industries.

Organizations that invest in robust maintenance management systems not only save money but also gain a competitive advantage by ensuring their operations run smoothly, safely, and efficiently.

0 notes

Text

Which is the Best Inventory Management Software for Small Businesses?

When it comes to achieving smooth, cost-effective operations, maintenance management software for small businesses can prove to be very useful. With this software, you can now forget about struggling with inefficiency every single day.

The ideal solution should be easy to set Maintainly plays an instrumental role as a trusted choice for small businesses looking for the best maintenance management software. up, intuitive to use, and powerful enough to deal with both maintenance and inventory tracking without any difficulty and additional cost of traditional enterprise systems. This is where

Why Small Businesses Need Specialized Maintenance Management Software

Small businesses often operate with limited resources and staff, making it crucial to get the best out of efficiency and lower downtime. Manual tracking with spreadsheets or other outdated systems quickly becomes unmanageable as your business grows.

Modern maintenance management software like Maintainly is very useful. It offers automation, real-time tracking, and mobile capabilities that enable teams to stay organized and proactive.

Why Choose Maintainly?

Here’s why you should choose Maintainly:

Quick and Easy Setup: Implementing, training, and navigating old CMMS is a nightmare. Maintainly, on the other hand, is a quick platform where implementations take minutes instead of days or months. Regardless of your industry or the complexity of your asset hierarchy, the results will be quick. It also includes support and setup assistance.

Mobile-First Approach: Technicians can update work orders, track inventory, and communicate on the go by using the mobile app. This ensures they are not stationary, as you can add and update work orders while on the go.

Inventory Tracking: Maintainly’s inventory management tools enable you to keep track of inventory that's consumed during maintenance work. It supports barcode and QR code scanning, making it easy to log parts usage and maintain accurate records.

Automated Preventive Maintenance: You will never miss a scheduled maintenance task again. Maintainly automatically generates preventive work orders based on time or usage metrics. This lowers the risk of unexpected breakdowns and costly repairs.

Customizable and Scalable: You get mix-and-match modules and flexible plans, which means you only get to pay for the features you need. As your business grows, Maintainly grows with you. It supports you from one to thousands of users or assets.

Advanced Reporting and Integration: Maintainly comes with AI-powered, data-driven advanced filtering to generate a custom report of work order data that suits different user roles, permissions, and purposes. You can also use it to create integrations with the software of your choosing, whether it's your company's ERP, BI, or data analytics tool.

Conclusion :If you’re running a small business, Maintainly is a standout option. This maintenance management software for small businesses revolutionizes equipment maintenance, work orders, and asset tracking with automated workflows and real-time insights.

#small business#software#maintenance services#software maintenance and support services#inventory management#maintainly#maintenance management software#CMMS

1 note

·

View note

Text

Discover Premier CNC Machine Manufacturers in Canada: Excellence Today

Precision Engineering for Off-Road Innovation

When it comes to crafting high-performance components for rugged terrains, few can rival the expertise of CNC Machine Manufacturers in Canada. Leveraging state-of-the-art multi-axis machining centers, these specialists transform raw billets of aluminum, stainless steel, and titanium into parts that endure the harshest conditions. From shock-absorber mounts to skid-plate brackets, each piece is engineered with microscopic precision to guarantee perfect fitment and long-term reliability.

Advanced Materials and Cutting-Edge Techniques

The off-road arena demands materials that balance strength with weight savings. Leading providers invest heavily in additive-aided toolpath optimization and real-time thermal compensation to maximize tolerance control. By collaborating closely with OEMs, these experts push the boundaries of what’s possible—bringing you components designed for peak performance. Whether it’s flow-forming hollow shafts or micromilling intricate fin patterns, the focus remains unwavering: deliver parts that outperform and outlast.

Custom Solutions Tailored to Your Needs

No two off-road builds are the same. That’s why top-tier CNC Machine Manufacturers in Canada offer fully bespoke services, from initial design consultation through final prototype testing. Utilizing advanced CAD/CAM integration, they iterate rapidly, producing prototypes in days rather than weeks. Their ability to accommodate complex geometries and low-volume runs makes them the partner of choice for boutique fabricators and large-scale assemblers alike.

Commitment to Quality and Certification

Quality assurance is non-negotiable when lives and livelihoods depend on component integrity. Accredited shops adhere to rigorous ISO 9001 standards and routinely perform in-process inspections using CMMs, laser scanners, and dynamic balancing rigs. Traceability is maintained at every step, ensuring material certificates accompany each shipment. This meticulous approach minimizes rework and guarantees that every batch meets or exceeds stringent performance criteria.

Why Choose Arrow Manufacturing Expertise

While numerous shops claim precision, only a select few truly embody the ethos of Arrow Manufacturing Products. Their seasoned engineers bring decades of off-road experience, understanding the nuances of shock dynamics, torsional loads, and vibration damping. By marrying hands-on off-road knowledge with advanced machining capabilities, they deliver components that integrate seamlessly into your build, enhancing durability and drivability.

Sustainable Practices for a Greener Tomorrow

Environmental stewardship is at the forefront of modern manufacturing. Leading facilities implement closed-loop coolant systems, high-efficiency dust collection, and energy-optimized spindle drives to reduce waste and lower carbon footprints. They recycle or repurpose metal shavings and invest in renewable energy sources, reflecting a commitment that extends beyond the shop floor.

Your Partner in Off-Road Excellence

For builders and engineers who demand uncompromising quality, Arrow Manufacturing Products stands ready to exceed expectations. From prototype to production, their seamless workflow, stringent certifications, and focus on innovation ensure your off-road projects achieve unparalleled performance and reliability. When the trail gets tough, trust parts crafted by masters of precision to keep you moving forward.

0 notes

Text

How to Determine CMMS ROI for Your Company? - TeroTAM

Discover how to calculate the ROI of implementing a CMMS in your organization by evaluating reduced downtime, improved asset performance, lower maintenance costs, and increased operational efficiency over time.

0 notes