#compressor pipework

Explore tagged Tumblr posts

Text

Professional Compressor Pipework Services in Adelaide – Tailored for Performance and Reliability

When it comes to efficient and safe compressed air systems, compressor pipework is at the heart of performance. Whether you're upgrading an existing system or planning a new installation, having the right pipe fittings and layout is critical. At Airquip Pipe Tool, we specialize in designing and installing high-pressure compressed air pipework across Adelaide and South Australia.

Why Quality Compressor Pipework Matters

Poorly designed or installed compressed air pipework can lead to pressure drops, leaks, energy inefficiency, and costly downtime. Our team of certified professionals ensures optimal air flow, minimal loss, and robust system integrity tailored to your industrial or commercial needs.

We provide:

Custom compressed air pipework installations

Upgrades for existing air compressor pipe fittings

High-efficiency layouts to reduce energy usage

Leak detection and pressure testing

Servicing and compliance checks in accordance with Australian safety standards

Adelaide’s Trusted Partner for Compressed Air Solutions

We’ve served hundreds of clients across Adelaide 5000, helping industries streamline their operations with precision-engineered compressor pipework systems. From small workshops to large-scale industrial sites, our team delivers tailored solutions that stand the test of time.

Whether you require air compressor service in Adelaide, new compressed air pipe work, or complete system installation, we have the expertise and equipment to handle it.

What Makes Us Different?

✅ years of experience in compressed air pipework installation

✅ Premium materials rated for high-pressure environments

✅ On-site consultation and CAD layout design

✅ Fast turnaround times with minimal disruption

✅ Ongoing maintenance and system support

Book Your Site Assessment Today Ready to upgrade your compressor pipework or install a brand-new system? Trust the specialists who understand every joint, seal, and fitting counts.

📍 Servicing all of Adelaide – including Adelaide 5000 and surrounding suburbs 📞 Contact us today or visit airquippipetool.com.au to schedule a free consultation.

We don't just install pipes. We build performance.

#compressed air pipework#air compressor pipe fittings service adelaide#compressed air pipework installation#air compressor service adelaide#compressor pipework#high-pressure compressed air pipework

0 notes

Text

In life, some people have good ideas and thoughts, but they have not achieved results. What they lack is the courage to do it.

Thinking is a problem; doing is the answer.

The distance between us and the goal does not lie in how perfect the idea is, but in how strong the execution is.

The goal is in front of us, but we can only stay where we are if we keep procrastinating;

No matter how far the road is, we will slowly get closer if we start moving forward now.

2 notes

·

View notes

Text

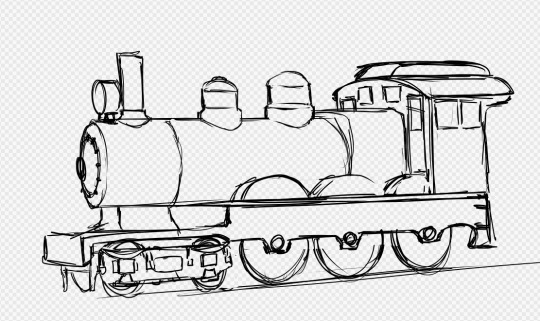

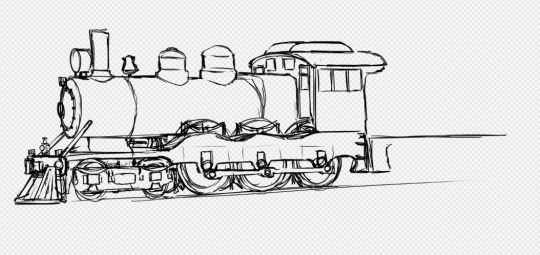

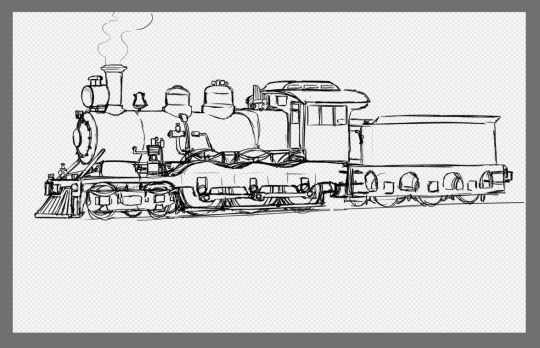

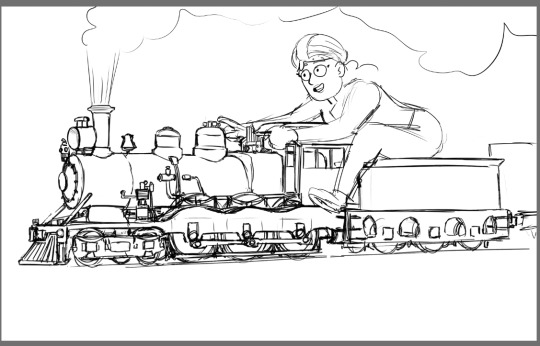

Commission for @pikablob of the steam locomotive Featherfoot from her Underrail fantasy setting (which can be found here)

Finally, on the nearest occupied track, close enough that she could hear some component within chunking back and forth with quiet mechanical regularity, was an engine painted in brilliant scarlet. Its boiler seemed to be in the dominant Freehold-style, with a tall funnel, two great domes, and exposed pipework, backing into a large cab topped with a little clerestory bump; but its wheels and mechanics were mostly hidden by heavy frame-plates, save for exposed cranks between the three driving axles.

Featherfoot is sapient, with a "Coal Heart" in her firebox which acts as the mind and main power source for the loco (though she still consumes coal). She is a one-off 4-6-0 Constitution-type built by E. Towan & Co. Jushi Works, using a boiler built by Cortopassi Locomotive Works.

More background and alternate image versions below the cut:

Featherfoot is based on a Illinois Central Railroad ten wheeler of the type that was involved in Casey Jones' infamous train collision, but below the frames it more resembles an outside-frame inside-cylinder Great Western Railway 4-4-0--a City or a Duke class. Its tender is based on a GNR tender similar to what the Stirling Single carried.

There are four holders for marker lamps or flags--three along the pilot beam and one on the smokebox, intended to be used with UK-style headcodes but with US-style marker lamps.

The livery is based on the fictionalized GWR Duke class seen in Assasin's Creed Syndicate.

Here's some WIP images: 1:25 PM to 2:37 PM

While waiting for the client to get back to me on some questions, I doodled this:

Eaurp Guz! What are you doing on a miniaturized fantasy train!? Ah who am I kidding this is super in-character for her.

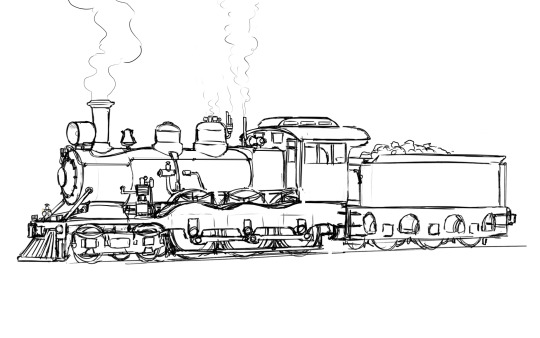

After a break and a little back and forth with the client (moved and replaced the whistle, replaced the oil headlamp with an electric one, added a dynamo), I completed the sketch.

I also tweaked some of the proportions a little. Note that when I am doing a "sketch" commission as opposed to "clean line art" i usually clean the sketch up a little more than I did here.

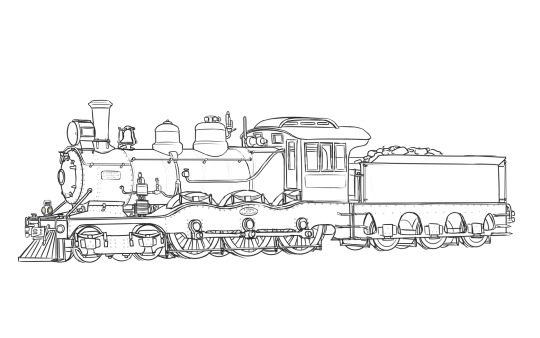

I then moved on to line art, which also gave me a chance to get the proportions on the wheels and frames right. I also totally re-thought the appliances and piping visible on the boiler.

By 10:31, the line art was complete. It had taken about an hour and thirty minutes, i don't have an exact timestamp.

Various other details were also added here--rivets, brake pipe, detailed coupler, detailed air compressor, snifters, wheel spokes, cut levers, the two builder's plates.

Here's the loco with full color. This is more or less how I left the loco off at the end of last night, at around 11:30 PM.

This morning at about 10:30 AM, I started working on rendering--and at 12:30 PM I finished the drawing.

The rest of these alt. versions are not chronological, and were created by removing certain layers:

The engine, cold.

The engine, solid color (but finished).

Solid color, but brightened to look better in a white background.

Transparent version with and without full rendering, steam, and lights.

I was shocked to find that with the line art removed, it didn't look half bad. It does look way messier, but I really need to go and try to tackle a fully lineless drawing in this style some time.

#Underrail#Featherfoot#Fantasy train#fantasy art#D&D art#train#steam train#steam engine#steam locomotive#locomotive#commission#art#digital art#digital painting#painting#underground#red train#steampunk#railway#railroad#original character art#oc art

58 notes

·

View notes

Text

Fasteners for Oilfield Equipment: Ensuring Safety and Performance in Harsh Environments

Introduction

In the oil and gas industry, equipment is routinely exposed to some of the harshest and most demanding environments on Earth. From high pressures and extreme temperatures to corrosive chemicals and abrasive materials, oilfield operations present unique engineering challenges. At the heart of this critical infrastructure are fasteners, small components that play a vital role in maintaining the integrity, safety, and reliability of oilfield equipment.

This blog explores the importance of fasteners in oilfield applications, the types commonly used, their material requirements, and why choosing the right fastener is essential for operational success.

Importance of Fasteners in Oilfield Operations

Fasteners are used to assemble, secure, and maintain oilfield equipment such as drilling rigs, wellheads, pressure vessels, pipelines, pumps, compressors, and offshore platforms. These components must perform flawlessly under:

High-pressure environments

Corrosive exposure (e.g., H₂S, saltwater, CO₂)

Dynamic loads and vibrations

High thermal stress

A single failure in a fastener can lead to leaks, equipment malfunction, downtime, or even catastrophic failure, making it imperative to use high-performance, certified fasteners in every application.

Common Oilfield Equipment Requiring Fasteners

1. Drilling Equipment

Fasteners in rotary drilling systems, drill strings, and derricks must withstand constant vibration, rotation, and torque. High-strength bolts, nuts, and studs play a crucial role in maintaining structural integrity and delivering dependable performance in challenging and demanding environments.

2. Wellheads and Christmas Trees

These systems are exposed to extreme pressure and require corrosion-resistant fasteners for sealing and securing critical components. Stud bolts paired with heavy hex nuts are commonly used in flange assemblies to ensure secure and leak-proof connections.

3. Pressure Vessels and Separators

Fasteners are required to meet specified pressure ratings and adhere to industry codes such as those set by ASME. Bolts used here often need to endure both pressure containment and chemical resistance.

4. Subsea Equipment

Located deep underwater, subsea tools and equipment are bolted with super duplex, Inconel, or titanium fasteners that resist saltwater corrosion and high pressure.

5. Offshore Platforms

Structural bolts secure walkways, support beams, pipe racks, and equipment foundations. These bolts are required to comply with marine-grade standards and offer exceptional resistance to corrosion.

Types of Fasteners Used in Oilfield Equipment

Stud bolts and nuts – Commonly used for securing flange joints in high-pressure applications.

Hex Head Bolts – Used where high clamping force is needed

Socket Head Screws – For compact or precision applications

Anchor Bolts – To secure equipment to concrete foundations

U-Bolts and Clamp Bolts – For securing pipework and supports

Each type of fastener is selected based on load-bearing requirements, accessibility, maintenance, and operating conditions.

Material Considerations

Due to harsh operating environments, materials used for oilfield fasteners must offer:

High tensile and yield strength

Excellent corrosion resistance

Temperature resilience

Common Materials Include:

Material

Properties

ASTM A193 Grade B7

High strength, used in non-corrosive high-temperature applications

316 Stainless Steel

Good corrosion resistance, general use

Inconel 718 / 625

Extreme strength and corrosion resistance in sour wells

Monel 400 / K500

Excellent resistance to seawater and hydrofluoric acid

Duplex & Super Duplex

Ideal for offshore and subsea conditions

Hastelloy

Outstanding chemical resistance in acidic environments

Coatings like PTFE, Xylan, or Zinc plating are also applied to further improve corrosion resistance and reduce galling.

Standards and Certifications

Fasteners for oilfield applications must comply with international standards to ensure safety and compatibility. Some key standards include:

ASTM A193 / A194 – Standards that define bolting materials engineered to perform reliably under high-temperature and high-pressure environments.

ASME Section VIII – Pressure vessel codes

Always verify that the fasteners used are certified and tested in accordance with relevant standards.

Conclusion

In the complex and demanding world of oil and gas extraction, fasteners play a mission critical role in the functionality and safety of oilfield equipment. From drilling platforms to deep-sea pipelines, the performance of these small but essential components directly affects the efficiency and reliability of the entire operation.

Ananka Group offers a wide range of high-strength, corrosion-resistant, and certified fasteners tailored for the oil and gas industry. Our products meet global standards and are trusted by operators worldwide for performance in the most extreme environments.

FAQs

Q1: What is the most commonly used fastener material in oilfields?ASTM A193 Grade B7 is commonly chosen for its excellent strength and ability to withstand high-pressure and high-temperature conditions.

Q2: Why is NACE certification important for oilfield fasteners?It provides protection against hydrogen sulfide (H₂S) corrosion, making it suitable for sour service environments.

Q3: What fasteners are suitable for subsea oilfield equipment?Materials like Inconel, Super Duplex, and Monel are preferred for subsea applications due to their superior corrosion resistance.

Q4: Are coated fasteners used in oilfields?Yes, PTFE or Xylan coatings are commonly used to improve corrosion resistance and reduce galling during assembly.

Q5: How do you choose the right fastener for oilfield equipment? By considering pressure, temperature, chemical exposure, and mechanical load, along with compliance to relevant industry standards.

#OilfieldFasteners#CorrosionResistantFasteners#OilAndGasIndustry#HeavyDutyBolts#FastenersForPipelines#PetrochemicalFasteners#OffshoreBoltingSolutions#HighStrengthBolts#AnankaFasteners#BoltsAndNuts#OilGasSupplyChain#Articles#Blog#ananka#tumblr#tumblr blog

0 notes

Text

Discover Top-Quality HVAC Supplies to Power Your Comfort

The correct HVAC supplies make all the difference in heating, ventilation, and air conditioning. Whether you're a contractor managing large-scale installations or a homeowner improving your comfort system, quality components and tools ensure performance, efficiency, and reliability.

Modern climate control systems are intricate, and behind every reliable unit is a range of high-grade HVAC supplies that keep it running smoothly. From ductwork and thermostats to filters and refrigerants, the foundation of indoor comfort starts with the right gear. Let's explore the essentials and trends and what sets great HVAC supplies apart.

The Backbone of Every HVAC System

Every heating and cooling system is only as strong as its components. That's why high-performance HVAC supplies are non-negotiable. These aren't just tools and spare parts—they're the lifeline of temperature control and air quality.

You'll find a broad spectrum of supplies used across residential, commercial, and industrial settings, including:

Air filters

Ducts and fittings

Thermostats and smart controllers

Blower motors and fans

Refrigerants and compressors

Insulation materials

Grilles, registers, and diffusers

Copper tubing and pipework

Drain pans and condensate pumps

Each part plays a crucial role. Filters maintain clean air, ducts ensure seamless airflow, and thermostats provide precise control. Together, they form a network of comfort that adapts to every season.

Innovation Drives the Industry

Today's HVAC supplies aren't just functional—they're smart, sustainable, and built for the future. Thanks to rapid advancements in technology, the industry now boasts tools and parts that help save energy, reduce emissions, and simplify installation.

Smart thermostats, for instance, learn user behaviour and adjust automatically. Ductless systems use sleek refrigerant lines instead of bulky ductwork, reducing energy loss. Eco-friendly refrigerants are replacing outdated chemicals to meet environmental standards.

Innovative HVAC supplies also support predictive maintenance. Smart sensors now alert users about system performance and potential faults before they turn into breakdowns. This saves time, money, and headaches in the long run.

Quality Over Quantity: What to Look For

With so many options on the market, choosing the right HVAC supplies can feel overwhelming. However, not all products are created equal. Quality is key. Here's what sets excellent supplies apart:

Durability: Built to last through wear and extreme temperatures.

Efficiency: Designed to optimize energy use and reduce waste.

Compatibility: Works seamlessly with a range of HVAC units.

Ease of Installation: Saves time and reduces labour costs.

Certifications: Meets industry safety and performance standards.

Well-made supplies don't just support better air—they also lower your utility bills and extend the life of your HVAC system.

Suppliers That Deliver Reliability

It's not just about what you buy—it's also about where you buy it. Dependable suppliers stock trusted brands, keep up with technological advances, and offer excellent customer support. Whether you need same-day delivery for a repair or guidance on a new system, a reputable supplier can make a huge difference.

Leading distributors often carry everything under one roof—filters, thermostats, duct fittings, insulation, and speciality tools. That saves time for contractors and reduces stress for DIY homeowners.

In addition, many supply companies offer training, equipment rentals, and professional advice—beneficial for newcomers or those upgrading older systems.

Sustainability is the Future

Sustainability isn't a buzzword—it's a demand. The industry is shifting toward green solutions, and HVAC supplies are leading. Eco-conscious materials, low-emission refrigerants, and energy-efficient components are now the norm.

Choosing green HVAC supplies reduces your carbon footprint and aligns with local and national energy codes. From recycled insulation to low-GWP refrigerants, suppliers are offering clever alternatives that perform just as well—or even better—than traditional products.

This trend is also driving innovation in system design. Variable-speed motors, zoning systems, and geothermal components are becoming more accessible, giving homeowners and businesses more control and savings.

Supporting Projects of All Sizes

Whether you're outfitting a new building or updating an aging unit, HVAC supplies are tailored to every type of project. Builders, engineers, technicians, and property managers all rely on the availability of well-stocked supply chains.

Commercial jobs may demand high-capacity compressors and multi-zone thermostats, while residential projects might need bare ductwork and a programmable controller. Regardless of the scope, access to various HVAC supplies is essential for smooth workflow and quality results.

Some suppliers also offer custom fabrication for ductwork and piping. This helps with unique layouts or older properties where standard parts just won't fit.

Stocking Up Means Staying Ahead

The best time to stock up on HVAC supplies is before you need them. Regular maintenance becomes more manageable when filters, sealants, and belts are ready. Unexpected repairs are less stressful when you're not scrambling for parts. That's why many professionals maintain a basic inventory. It's a simple habit that boosts productivity and ensures fast responses to service calls.

Bulk buying also helps reduce costs and shipping delays. If you consistently work with the same supplier, you may qualify for discounts, early access to new products, or exclusive lines.

The Bottom Line

In the world of heating and cooling, reliable HVAC supplies are the heartbeat of comfort. From simple filters to smart controls and everything in between, these components drive performance, efficiency, and satisfaction.

As the demand for cleaner, brighter, and more sustainable climate control grows, the importance of having access to trusted HVAC supplies will only continue to rise. Whether you're an industry veteran or starting, investing in the right products means fewer problems and more comfort.

0 notes

Text

How VRV Technology is Revolutionizing Air Conditioning

AC Cleaning Service in Nagercoil has become essential for keeping our homes and offices cool throughout the sweltering summer months. On the other hand, conventional air conditioning systems are frequently large, inefficient, and require frequent maintenance and cleaning to operate well. VRV (variable refrigerant volume) technology can help with that.

A relatively recent development in the air conditioning business, VRV technology provides a more effective, adaptable, and practical means of maintaining a cool environment in our environments. Variable refrigerant volume is what it stands for, and it indicates that the system may change the amount of refrigerant flowing according to the space's cooling requirements.

However, precisely how does VRV technology transform air conditioning? Let's investigate more closely.

Efficiency in Energy

The electrical efficiency of VRV technology is one of its biggest benefits. Energy is wasted in traditional air conditioning systems since they usually only have one compressor that operates at maximum capacity before shutting off. Conversely, VRV technology uses several variable-speed compressors that enable precise cooling control while consuming less energy. Lowering carbon emissions, helps the environment in addition to lowering power expenses.

Flexibility and Zoning

It can be difficult to cool an entire space with typical air conditioning since different rooms and sections may require varying amounts of cooling. Zoning is made possible by VRV technology, allowing you to independently regulate the temperature of various rooms or spaces. By just chilling the areas that are in use, this not only helps conserve energy but also offers increased comfort to suit the varying preferences of individuals. Zoning can also contribute to the the system's extended lifespan by minimizing wear and tear.

Control and Convenience

VRV technology gives the user an immense amount of control and convenience. You can easily set schedules, check energy consumption, and change the temperature using a centralized control panel or even a smartphone app. In order to make managing and controlling your air conditioning system easier, some systems also come equipped with smart features like voice control, remote access, and integration with other smart home appliances.

Compact Design

Installing traditional air conditioning systems in smaller rooms might be difficult due to their large size. Conversely, VRV technology is appropriate for both large and small places due to its compact design, flexible pipework, and smaller exterior units. In addition to lowering noise levels, the smaller exterior unit maintains the building's beauty.

Low Maintenance

The durability and correct operation of air conditioning systems depend on routine cleaning and maintenance. Because VRV technology reduces the number of moving parts in the system, there is less opportunity for wear and tear and less maintenance is needed. Furthermore, VRV systems' self-diagnostic capabilities can aid in identifying any possible problems, making repairs by specialists simpler and faster.

In conclusion, the energy efficiency, adaptability, convenience, small size, and minimal maintenance of VRV technology are transforming the air conditioning sector. With so many advantages over conventional air conditioning systems, it's no surprise that it's growing in popularity for both home and business environments. Thus, if you're thinking about replacing your air conditioning system, visit Cold Air Conditioning AC Cleaning Service in Nagercoil where VRV technology some thought and see the benefits for yourself.

0 notes

Text

6 Compelling Reasons to Choose a Multifunctional Screw Chiller

For many commercial and industrial facilities, HVAC systems are the largest consumers of energy. Yet traditional heating and cooling methods like boilers and air conditioners often operate independently, wasting energy. This is where multifunctional screw chillers provide an efficient, cost-saving solution.

Multifunctional screw chillers integrate heating, cooling, and hot water generation into a single compact unit. Compared to separate HVAC systems, multifunctional screw chillers offer significant benefits:

1. Reduced Capital Costs

Installing one multifunctional screw chiller system instead of multiple units saves on upfront investment. You avoid the expenses of purchasing separate chillers, boilers, cooling towers, and connecting pipework. The integrated design provides heating, cooling, dehumidification and hot water in a single on-site footprint.

2. Lower Operating Costs

With their high coefficient of performance (COP) exceeding 5, multifunctional screw chillers consume far less energy than conventional HVAC setups. Integrated controls minimise simultaneous heating and cooling. Variable capacity screw compressors also adjust output to match demand, optimising efficiency. This all combines to cut electricity usage and bills.

3. Seamless Automatic Control

The advanced control systems integrated into multifunctional screw chillers seamlessly regulate operations between heating and cooling modes. This enables smooth switching and heat recovery, eliminating the need for manual oversight. In multifunctional screw chillers, control is simple, with automation optimising performance across changing conditions and thermal loads.

4. Reduced Environmental Impact — (Might need a fact check from the client)

Multifunctional screw chillers utilise minimal refrigerant quantities and low global warming potential (GWP) refrigerants like R-513A. Their efficiency significantly cuts CO2 emissions compared to alternatives like gas boilers. Hot water heat pumps also reduce NOx air pollution. Overall, multifunctional screw chillers provide sustainable HVAC with a low carbon footprint.

5. Less Equipment & Maintenance

Having one packaged chiller unit instead of separate systems equals less equipment to install and maintain. With multifunctional screw chillers, you avoid the maintenance required for boilers, cooling towers, and complex pipework. Shared components like screw compressors further reduce upkeep costs.

6. Compact Size & Flexible Placement

The integrated design of multifunctional screw chillers condenses heating, cooling, and hot water generation into a single compact unit. This frees up valuable building space compared to multiple HVAC systems. Their modular sizing and flexibility also enhance placement options. Outdoor packaged models are also available.

Multifunctional Screw Chiller: One Unit, Multiple Possibilities

With their energy efficiency, integrated automation, and flexible sizing, multifunctional screw chillers are a smart solution for sustainable HVAC. Reduced costs, minimal maintenance, and a small footprint add up to a superior value for commercial and industrial facilities.

At Climaveneta, our line of HYC multifunctional screw chillers delivers all these benefits. With capacities from 270 kW to 1.1 MW, HYC systems provide the ideal green HVAC technology for hotels, data centres, hospitals, district heating/cooling and more.

Contact us today to learn more and discover why multifunctional screw chillers are the way of the future!

visit us

#heat pumps#climaveneta#screw chillers#screw chillers manufacturers#data centers#data center cooling systems#hvac systems

0 notes

Text

0 notes

Photo

Little bit of pipework on Saturday for our longest served customer. Been with us since the beginning 👍 #aircompressors #aircompressor #compressedair #compressedairsolutions #compressor #energysaving #greeneconomy #saveenergy #almig #compair #atlascopco #hydrovane #pipework (at Redditch) https://www.instagram.com/p/CLmG8OOrafo/?igshid=16pvhj24wbo08

#aircompressors#aircompressor#compressedair#compressedairsolutions#compressor#energysaving#greeneconomy#saveenergy#almig#compair#atlascopco#hydrovane#pipework

0 notes

Text

Expansion Joints

To help with structural changes like those caused by a pipe, tube, or vessel expansion or tightening, an expansion joint incorporates one (or more) bellows.

In a pipeline system, an expansion joint allows for movement. When it comes to expansion joints, the bellows are a flexible element with many folds. When it comes to making a plumbing system more relaxed, the expansion joint is the ideal option. When a pipeline experiences frequent vibrations, pulsations, or thermal expansion, it necessitates flexibility.

The bellows can be moved in three ways: axially (along the longitudinal axis), laterally (perpendicular to the longitudinal axis), and angularly (along the longitudinal axis). Axial movement is the most common.

Many pipeline systems make use of metal expansion joints. These components are critical to the technology's success. It is for this reason that flexible expansion joints are commonly used: they compensate for length fluctuations. Metal joints are built to endure high-temperature volatility, which is what causes length changes in pipelines. Many variables are taken into account when creating them. Some examples include temperature, pressure movement, and the surrounding environment.

As a result of the varied axial movements and the angular and lateral ones caused by motors and compressors, metal expansion joints are essential for vibration absorption.

There are multiple circular folds in the metal bellows, which allow them to be extended or compressed as needed by pulling on them. They're versatile and long-lasting when used by the manufacturer's instructions, which is to say, in the manner intended by the product's producer.

The adaptability of metal bellows allows them to be used in various sectors, including the sealing of environments and the transportation of gases, liquids, and slurry, among other applications. By law, the following measurements must be met: inside/outside diameter, free length, and spring rate (the spring force applied by the bellows).

Metal bellows can be constructed using one of four standard techniques. Then there's electroforming, which includes depositing numerous metal layers on an aluminum mandrel over an extended period. Electroforming is a technique that involves depositing multiple different types of metal on a mandrel through chemical deposition, mechanical forming, and welding, which is the final step.

Metal bellows are commonly made of aluminum, stainless steel, tantalum, titanium, or steel, depending on the use. There are a few different stainless steel expansion joints available, but the stainless steel expansion joint seems to be the most popular. Turbine pipework, engine exhausts, shaft propellers, and many more uses call for these.

1 note

·

View note

Text

Optimizing Compressed Air Reticulation Systems for Efficiency and Reliability

Compressed air is a vital energy source used in various industries, from manufacturing to healthcare. Its reliability and versatility make it a go-to solution for powering tools, machinery, and even ventilation systems. To ensure that compressed air reaches its intended destinations safely and efficiently, an effective compressed air reticulation system and pipework are essential.

What is a compressed air reticulation system?

A compressed air reticulation system is a network designed to distribute compressed air from a central compressor unit to various points of use within a facility. These systems are critical in managing airflow, maintaining pressure, and ensuring that the air is supplied where needed without significant loss.

The design of these systems involves multiple components, such as air compressors, pressure regulators, air dryers, filters, and, of course, the pipework that forms the backbone of the entire system. The role of reticulation systems is not only to deliver air but also to ensure that it is clean, dry, and consistent, maintaining the quality of work in industries where precision and performance are crucial.

Key Components of a Compressed Air Reticulation System

Air Compressor: This is the central component of the system, responsible for compressing ambient air to the desired pressure.

Pipework: The pipes that distribute compressed air throughout the facility, connecting the compressor to various machinery and equipment.

Air Dryer: This component ensures the air is dry, preventing condensation that could damage equipment.

Filters: Air filters are used to remove contaminants such as dust, dirt, and oil, ensuring the air supplied is clean.

Pressure Regulators: These ensure that the correct pressure is maintained at each delivery point, providing the necessary force for tools or machinery.

Valves and Fittings: These are essential for controlling the flow of compressed air and ensuring safe operation.

Compressed Air Pipework

Pipework in a compressed air system plays a crucial role in maintaining airflow, ensuring that the pressure is consistent, and minimising energy loss. The design and materials used for compressed air pipes directly impact the efficiency and longevity of the system.

Types of Pipework Materials:

Steel Pipes: Strong and durable, steel is a traditional material for compressed air pipework. It can withstand high pressures but is prone to corrosion.

Aluminium Pipes: Lightweight and resistant to corrosion, aluminium is an increasingly popular choice for modern systems. It is easy to install and can be used for both small and large setups.

Plastic Pipes (e.g., PVC, PEX): These are lightweight, cost-effective options often used for smaller systems. However, they may not be ideal for applications involving high pressure.

Copper Pipes: Copper pipes are resistant to corrosion and are used in smaller or low-pressure systems. However, they are generally more expensive than other materials.

Pipework Layout Considerations:

Size of the Pipes: The pipe diameter should be selected to accommodate the necessary volume of compressed air. Larger pipes allow more air to flow, but smaller pipes may increase resistance and energy loss.

Pipe Length: Long pipe runs can result in pressure drop, reducing the efficiency of the system. Minimising the length of pipe runs and using the proper pipe diameter can help avoid unnecessary energy consumption.

Pipe Routing: It's important to design the pipe layout to avoid sharp turns and unnecessary bends, as these can create turbulence, reducing airflow efficiency.

Benefits of a Well-Designed Compressed Air System

Energy Efficiency: A well-designed system can reduce energy consumption and operating costs by ensuring that the compressed air is delivered efficiently without unnecessary losses.

Reliability: Proper pipework and a balanced reticulation system help maintain consistent pressure and reduce the chances of system failure or downtime.

Longevity of Equipment: By maintaining clean, dry, and consistent compressed air, the lifespan of connected machinery and equipment is extended, reducing repair and replacement costs.

Safety: A properly designed system with high-quality components ensures that air is distributed safely, minimising the risk of accidents caused by pressure fluctuations or contamination.

Conclusion

Compressed air reticulation systems and pipework are fundamental to industries that rely on compressed air. A properly designed system ensures that compressed air is efficiently distributed and safely delivered to where it is needed. By choosing Airquip and Pipetool Pty Ltd, the right pipe materials, sizing, and layout, companies can optimise performance, improve energy efficiency, and prolong the lifespan of equipment, making their operations more reliable and cost-effective.

0 notes

Text

EXHIBITION IN HO CHI MINH CITY, VIETNAM.

DATE: 11.15-11.17 BOOTH: M08 ATTN: JASMINE CONTACT: +86 13421909014 EMAIL: [email protected]

I WILL BE THERE WAITING FOR YOU.

1 note

·

View note

Link

0 notes

Text

How Are Downpipes Advantageous For Your Luxury Cars?

McLaren Downpipes, or downpipes of other cars, are an important part of your luxury vehicle. To better comprehend how modifications to the downpipe are advantageous, it is crucial to understand what happens before the downpipe. There are two wastegates: internal (found inside the turbine housing adjacent to the wheel) and exterior (mounted on the header or before the turbine wheel and after the exhaust valve).

Both successfully do the same task: clear the turbine wheel of extra gas and slow it down. It causes the compressor wheel to slow down and prevents boost targets from being exceeded. To accomplish this, the wastegate is actuated (opened), allowing air to travel through rather than over the exhaust turbine wheel. Then, it will immediately close so as not to let too much air out and reduce compression in the intake tract.

Manufacturers can employ a wide range of wastegate control methods. After discussing the wastegate mechanism, we can go on to the exhaust downpipe. The downpipe receives the spent gases as they exit the turbine housing outlet. This exhaust component is commonly referred to as a downpipe as a pipe that runs downhill.

The term "J-pipe" refers to the initial portion of the exhaust system connected to the turbine housing outlet on the low, front-mounted turbo in the 2015+ WRX. A downpipe is usually the part of factory-tuned turbocharged cars with the greatest restrictions. The best alteration for the money is usually upgrading this part and properly tweaking it. Let's explore the features of a few popular downpipes.

Features Of Some Popular Downpipe Brands

RS3 DOWNPIPE FEATURES

Required upgrade for Stage 2 power levels.

Unrestricted 3.5" minimum size tubing.

Bolt-on fitment - no hassle, modifications, or poorly fitting parts. You can even install it on your own.

Constructed of high-quality 304 stainless steel, providing it with more strength.

Thick cast & CNC machined turbo flanges for no leaks.

High-flow metal matrix 200-cell catalytic converter for better performance and thermoregulation.

Reliable leak-free OEM-style flex section to prevent any fuel leakages from the engine.

Y-Pipe adapter is available for stock Catback.

MCLAREN DOWNPIPES FEATURES

Catless downpipes with a 3.5′′ diameter offer the finest possible sound and support for more horsepower.

Extreme toughness OEM-like heat shields keep exhaust velocity high for optimal power and underhood temperatures low for heat protection.

Fits all McLaren 720S models with the factory-style rear exhaust or aftermarket exhaust.

Metal shields called HeaderShieldTM are professionally installed to provide a form-fitting, long-lasting heat solution.

The HeaderShieldTM direct insulation system is made to resist temperatures over 2000 degrees Fahrenheit for an extended period.

All Soul Performance Products have the finest Lifetime Warranty for street and track use.

Each downpipe is handcrafted in the home from sturdy, mandrel-bent walls—.065"" T304L stainless steel, followed by a thorough quality inspection.

TIG welding with back purging ensures strong weld penetration.

Each item is checked to ensure it fits perfectly in a fixture before being foam-packed to guarantee perfect delivery.

BMW DOWNPIPE FEATURES

The normal catalyst is replaced with this performance exhaust system for the BMW M140i downpipe, composed of 3.5"/88.9mm pipework and fitted to the centre exhaust.

With the sports cat exhaust option, you can pass the UK MOT emissions test and any law enforcement roadside inspections.

The de-cat sports exhaust option is only available for off-road and motorsport use; it cannot pass the UK MOT emissions test or police roadside inspections.

All relevant fittings and gaskets are supplied.

Enjoy proven performance gains and leading features such as bolt-on direct fit install, long-life construction, cast sections, and amazing sound.

Conclusion

Adding a downpipe to your luxury sports car is the ultimate choice power adder on the stock turbo & engine! Offering an aggressive and unique motorsport sound from your turbo engine with complete unrestricted airflow for unmatched maximum power. MTC Motorsport performance exhausts improve your car's aesthetics, sound, and quality, providing you with the best driving experience. Our selection of downpipes is assured to reassure you of our calibre.

To know more, visit: https://mtcmotorsport.co.uk/

Original Source: https://bityl.co/F0HI

0 notes

Text

Importance of acoustic insulation for industrial application

Maintaining appropriate noise levels is one of the largest issues that industrial and manufacturing environments are experiencing. Noise pollution is a significant issue that affects many different types of industrial activities. Higher noise levels are extremely challenging to adjust to, especially when they have the potential to negatively affect your employees' health on an unconscious level.

Higher noise levels cause increased stress, sleeplessness, and other major health issues when they are exposed over an extended period. That is not how you should value your staff, who are essential to achieving your goal and vision. Maintaining ideal productivity levels is seriously hampered by the tremendous, nearly deafening noise output from machinery.

When processes are run at high pressure and with fast-moving or turbulent material, excessive noise levels are frequently experienced in the industry. The primary goal of acoustic insulation systems for industrial applications is to safeguard nearby workers while also reducing noise emissions to the environment, particularly in densely populated locations.

Starting with the appropriate technology, materials, and layout, noise control can be accomplished. One of the best ways to protect workers from excessive noise absorption from process lines is to use an appropriate acoustic insulation system to restrict the emitted sound levels at the operational equipment and associated pipework. Here are a few more pointers to note about acoustic insulation:

Reduce Noise

When it comes to noise pollution, compressors and motors are the worst culprits. Removable acoustic insulation may be the best option if a less loud model is not a viable alternative. For easy removal and replacement of insulation for inspection and maintenance, most facility owners prefer detachable insulation.

Avoid Complaints

People who are constantly subjected to loud, bothersome, and disturbing noises may feel obligated to complain, threaten to leave their jobs or move, or even worse, report you to local authorities, which could result in penalties for violations. Consider using acoustic insulation jackets or other noise reduction techniques if your equipment is producing excessive noise that exceeds federal, state, or local noise standards.

Structural Vibrations

It is clear from understanding the physics of sound that vibrations in a material can move through the air and then be perceived by our ears. The building's materials are vibrating when you sit inside and hear a constant rattling or buzzing noise.

For the inhabitants of your commercial space, dealing with the noise of structural vibrations can help them communicate and concentrate. This is true whether the source of the vibrations is internal, such as an HVAC system, or external, such as an airline flying low overhead on its approach to land.

Searching for the best acoustic pipes supplier in Dubai? Bin Dasmal General Trading is a recognized air conditioning products supplier in Dubai and provides wide range of products! Contact us today!

0 notes

Text

Features of S355 steel plate which makes it best

S355 steel plate meets ASTM A572 / 709 criteria in chemical and physical qualities, with a minimum yield of 50 ksi. S355 is available in hot rolled and cold drawn forms as unalloyed low carbon steel. You can also look for SA 285 Grade C. The S355 steel standards are non-alloy steels with a high yield. The British Standards Institute later released the EN10025 standard, first established in the European EN10025 standard. You can look for the best s355 steel plate suppliers in India. What is the chemical composition of 2062 E350 C? Si, S, Mn, C, and carbon equivalent make up the chemical composition of the plates. Charpy impact test, tensile strength, yield strength, and elongation are examples of mechanical qualities. Hot-rolled plates, cold-rolled plates, polished plates, and other types of IS 2062 E350 PLATES are available. Plates come in various shapes, sizes, dimensions, diameters, specifications, standards, thicknesses, lengths, forms, and finishes, among other things. IS 2062 is a modified version of Indian standard 226. IS India's common 2062 E350 grade improves 2062 E350 PLATES' varied qualities. IS 2062 E350 offers several characteristics, including high resistance to corrosion and exceptional corrosive resistance. Know about A/SA use For pressure vessels, fine-grained structural steel is used. The steel SA 516 Gr 60 has good weldability and high resistance to brittle cracking. These types are mainly used to make pressurized gas vessels (LPG, butane, and propane tanks), pressure vessels, steam boiler parts, pressure pipework, and compressors, among other things. Their most common application is at temperatures below -20 degrees Celsius. A/SA 516 Gr.60+N steel is delivered in its normalized state. The normalizing temperature is 900-950 oC, and the Plate must be left in the furnace for roughly 1 minute per millimeter of thickness after temperature equalization. As a result, it has a good cold- and hot-forming properties without compromising the material's qualities. All known welding procedures can be used to correctly weld the fine-grained structural steel in this series, both manually and automatically. Is ASTM-70 used as rolled Plate? ASTM SA516-70 steel plate grade is a medium carbon alloy with small proportions of manganese, phosphorus, sulphur, and silicon. PVQ516 is another name for A516. There is also an S700MC Steel Plate which you can look for. Additional testing options include Charpy Impacts, Ultrasonic Examination, and Carbon Equivalency. Steel plate grade A516 is the most widely used Pressure Vessel grade. It comes in grades 55, 60, 65, and 70. Do you know about the 16MO3 Plate? 16mo3 Steel Plates is used in high-temperature applications. ASTM A204 16Mo3 Plates are noted for their high wear and tear resistance, corrosion resistance, weldability, and tensile and yield strength. 16Mo3 Plates have excellent mechanical qualities and creep resistance, allowing them to be used at temperatures up to 500 degrees Celsius. The demand for 16MO3 Plate suppliers is increased over time. This makes it excellent for various applications in which the plates must operate at a high temperature for an extended period. As nitrogen oxide is eliminated from the steel combination, the 16Mo3 Plates become more resistant to nitrate corrosion.

0 notes