#custom cmms software

Explore tagged Tumblr posts

Text

#cmms#cmms software#custom cmms software#cmms asset management software#cmms systems#cmms tools#cmms solutions#cmms plaforms#cmms asset management#cmms preventive maintenance

0 notes

Text

Enhancing Hospital Ambiance & Efficiency: Streamlining Maintenance Management through Digital Work Orders - InnoMaint Case Study

Discover how InnoMaint revolutionized hospital maintenance management with digital work orders, ensuring a seamless ambiance and operational efficiency. Read about the successful implementation that streamlined processes and enhanced patient care. https://www.innomaint.com/case-study/read-about-providing-a-perfect-ambiance-for-hospitals-making-maintenance-management-smooth-via-digital-work-orders/

#innomaint case study#customer success story#customer success journey#healthcare cmms software#hospital asset management software#hospital facility maintenance software

0 notes

Text

Europe Facility Management Market Revealed Horizons: Forecast 2035 Size, Share, and Growth Insights

This report presents a comprehensive analysis of the Contactless Payment Market, By Type (Hardware (Smart-cards, Point of Sale Terminals, and Smart-Card Readers) and Software (Smartcard Reader Drivers, POS Software, Application Programming Interface, Software Development Kit (SDK), and Mobile Applications)), By Mode of Payment (Contactless Card (NFC/RFID), Wearable Device, and Contactless Mobile Payment), By End-Use Industry (Banking, Financial Services and Insurance (BFSI), Retail, Public Sector, Transportation and Logistics, Hospitality, and Media and Entertainment), and By Region (North America, Europe, Asia Pacific, Latin America, Middle East, and Africa) - Trends, Analysis and Forecast till 2030 , providing stakeholders with valuable insights into its growth trajectory, opportunities, and challenges. The study explores key market dynamics, trends, competitive landscape, and future projections to assist decision-makers in strategic planning. Europe Facility Management Market Overview Industry Insights Current market status and key drivers shaping the industry. Emerging trends and innovations impacting market evolution. Economic and regulatory factors influencing market performance. Get a free sample of the report:https://www.prophecymarketinsights.com/market_insight/Insight/request-sample/340 Some of the major players covered in the market research report are: International Business Machines Corporation Oracle Corporation SAP SE MCS Solutions ARCHIBUS Inc. Trimble Inc. CA Technologies Accruent LLC Planon B.V. FM:Systems Inc. iOFFICE Inc. Maintenance Connection Inc. JadeTrack MetricStream Inc. Facilities Management eXpress LLC eMaint Enterprises LLC Hippo CMMS Indus Systems Inc Autodesk Inc. Nemetschek SE Archidata Inc Officespace Software Inc FacilityONE Technologies LLC Apleona GmbH. Europe Facility Management Market Scope & Segmentation By Solutions- Integrated Workplace Management System, Building Information Modeling, Facility Operations and Security Management, Facility Environment Management, and Facility Property Management By Service– Deployment and Integration, Consulting, Auditing and Quality Assessment, Support and Maintenance, SLA (Service Providers Need) Management By Deployment Type– On-Premises and Cloud By Organization Size- Small and Medium-Sized Enterprises and Large enterprises By Vertical- BFSI, IT and Telecom, Government and Public Administration, Healthcare, Education, Retail, Energy and Utilities, Manufacturing, and Construction and Real Estate Competitive Landscape Key Players & Market Positioning Analysis of major competitors, including market share, business strategies, and innovations. SWOT analysis of key industry participants. Market entry barriers and opportunities for new entrants. Request a PDF Brochure of the Report:https://www.prophecymarketinsights.com/market_insight/Insight/request-pdf/340 Europe Facility Management Market Dynamics Drivers Factors fueling market demand and expansion. Technological advancements influencing growth. Challenges & Restraints Potential risks, barriers, and regulatory constraints. Economic fluctuations and supply chain disruptions. Opportunities Untapped market potential and emerging consumer needs. Strategic investment areas and growth prospects. Regional Analysis Europe Facility Management Market Performance by Region Regional demand variations and economic impact. Key players and competitive environment in each region. Infrastructure, policies, and trade regulations affecting market growth. Consumer Insights & Behavioral Trends Shifting customer preferences and purchasing patterns. Influence of digital transformation on market demand. Impact of sustainability and ethical sourcing on buying decisions. Future Outlook & Forecast Potential disruptions and innovations shaping the industry. Strategic recommendations for stakeholders. Conclusion & Strategic Recommendations Summary of key findings and takeaways. Actionable insights for investors, businesses, and policymakers.

Recommendations for capitalizing on emerging trends. About Us: Prophecy Market Insights is a leading provider of market research services, offering insightful and actionable reports to clients across various industries. With a team of experienced analysts and researchers, Prophecy Market Insights provides accurate and reliable market intelligence, helping businesses make informed decisions and stay ahead of the competition. The company's research reports cover a wide range of topics, including industry trends, market size, growth opportunities, competitive landscape, and more. Prophecy Market Insights is committed to delivering high-quality research services that help clients achieve their strategic goals and objectives.

0 notes

Text

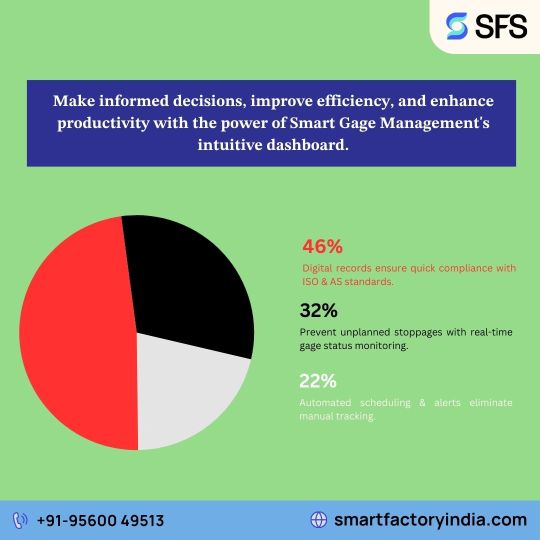

Unlock Precision, Elevate Productivity: The Power of Gage Management Software

In today’s competitive manufacturing landscape, precision is not just an advantage — it’s a necessity. Every measurement, every tolerance, every inspection plays a crucial role in product quality, customer satisfaction, and ultimately, your bottom line. But how do you ensure that your measurement tools (gages) are always accurate, calibrated, and readily available? The answer lies in robust Gage Management Software.

At Smart Factory Solutions, we understand the critical role of accurate measurement in achieving manufacturing excellence. Our Gage Management Software is designed to empower businesses like yours to gain complete control over their inspection processes, ensuring consistent quality and unlocking significant operational efficiencies.

What is Gage Management Software?

Gage Management Software is a specialized digital solution designed to help manufacturers efficiently track, calibrate, maintain, and manage all their measurement instruments. From calipers and micrometers to sophisticated CMMs and optical comparators, it provides a centralized system for complete lifecycle management of your gages, ensuring compliance with quality standards and optimizing their utilization.

How Gage Management Software Can Transform Your Business

Imagine a world where you never have to worry about an uncalibrated gage causing production errors, or wasting valuable time searching for a specific tool. Gage Management Software makes this a reality, leading to:

Reduced Errors and Rework

Improved Product Quality

Enhanced Compliance

Optimized Gage Utilization

Cost Savings

Data-Driven Decision Making

Key Features:-

Centralized Gage Inventory

Automated Calibration Scheduling

Comprehensive History Tracking

Customizable Reporting

User-Friendly Interface

Multi-Location Support

Alerts and Notifications

Integration Capabilities

Benefits:-

Increased operational efficiency

Reduced manufacturing costs

Improved product consistency

Streamlined audit processes

Enhanced decision-making capabilities

Greater peace of mind knowing your measurements are reliable

Conclusion

In a world where every millimeter matters, investing in a robust Gage Management Software is no longer a luxury — it’s a strategic imperative. It’s the foundation for achieving true manufacturing precision, driving down costs, and building a reputation for unparalleled quality. Explore how Smart Factory Solutions can help you unlock the full potential of your measurement processes and transform your business into a true smart factory.

0 notes

Text

How CNC Machining Services Work: An Overview

CNC machining is a cornerstone of modern manufacturing, offering high precision, speed, and flexibility for producing intricate parts and components. From aerospace to automotive, electronics to industrial machinery, CNC machining services are critical in fabricating parts that meet exact specifications. Whether you're a product designer or a manufacturing engineer, understanding how CNC machining works can help you leverage its benefits effectively.

What Is CNC Machining?

CNC machining is a subtractive manufacturing process where material is removed from a solid block—known as a blank or workpiece—using a variety of cutting tools. The process is controlled by pre-programmed computer software that dictates the movement of machines such as mills, lathes, routers, and grinders. Unlike manual machining, CNC systems operate with extraordinary precision and repeatability, making them ideal for high-tolerance, complex parts.

Key Components of CNC Machining Systems

Computer-Aided Design (CAD): Everything starts with a 3D model or a technical drawing of the desired part. Engineers or designers use CAD software to define dimensions, geometries, and tolerances.

Computer-Aided Manufacturing (CAM): The CAD file is then imported into CAM software, which generates a toolpath and converts the design into G-code—a programming language that CNC machines understand.

CNC Machine: The G-code is uploaded to the CNC machine, which follows the programmed instructions to execute precise movements and tool changes. Machines may be 3-axis, 4-axis, or even 5-axis, depending on the complexity of the part and the number of simultaneous movements required.

Cutting Tools: Depending on the material and design, different cutting tools are used, such as end mills, drills, or turning tools. The choice of tool affects surface finish, cutting speed, and overall efficiency.

Workholding: Fixtures and vises secure the workpiece in place during machining, ensuring stability and accuracy.

The CNC Machining Workflow

Here’s a simplified breakdown of the typical CNC machining process:

1. Design & Planning

The journey of custom CNC machined parts begins with a detailed design. Engineers define all technical requirements, including geometry, material selection, surface finish, and tolerance. This stage is crucial because the CAD model directly influences machining feasibility and cost.

2. Programming

CAM software interprets the CAD model to produce G-code. This code tells the CNC machine what actions to perform—movements along the X, Y, and Z axes, spindle speeds, feed rates, tool changes, and more.

3. Setup

A technician sets up the machine by loading the workpiece, installing the required tools, and configuring the machine based on the program. This step may also involve calibrating the tool offsets and checking initial positions.

4. Machining

Once everything is set up, the machine starts removing material as per the G-code instructions. The process could involve multiple operations such as drilling, milling, turning, or tapping. Multi-axis machines can produce complex geometries in a single setup, reducing lead time and improving precision.

5. Inspection & Quality Control

After machining, the part is inspected using precision measurement tools such as calipers, micrometers, or Coordinate Measuring Machines (CMM). This step ensures that the final product meets all specified dimensions and tolerances.

6. Finishing Operations

Depending on the application, post-machining processes like deburring, anodizing, or powder coating may be applied. These finishing steps enhance durability, corrosion resistance, or aesthetics.

Types of CNC Machining

There are several types of CNC machining processes, each suited for specific applications:

Milling: A rotating cutting tool moves along multiple axes to remove material.

Turning: The workpiece rotates while a stationary cutting tool shapes its exterior or interior.

Drilling: Straight holes are created using a rotating drill bit.

EDM (Electrical Discharge Machining): Material is removed using electrical sparks—ideal for hard materials or intricate cavities.

Grinding: A rotating wheel removes material to achieve high surface finish and tight tolerances.

Advantages of CNC Machining

Precision: CNC machines can achieve tolerances as tight as ±0.001 inches, ideal for high-performance industries.

Repeatability: Once programmed, the machine can produce thousands of identical parts with minimal variation.

Flexibility: CNC services can handle one-off prototypes or high-volume production runs.

Efficiency: Faster turnaround times and reduced manual labor.

Material Versatility: Supports a wide range of materials including metals (aluminum, steel, titanium), plastics (nylon, ABS, PEEK), and composites.

Applications of Custom CNC Machined Parts

Custom CNC machined parts are essential in industries where performance and reliability are non-negotiable:

Aerospace: Complex components such as turbine blades, housings, and brackets.

Medical Devices: Surgical instruments, prosthetics, and diagnostic equipment.

Automotive: Engine components, transmission parts, and custom performance mods.

Robotics & Automation: Gears, end-effectors, and structural parts.

Consumer Electronics: Housings, frames, and connectors.

At MS Machining, our team specializes in producing high-quality custom CNC machined parts tailored to exact client specifications. Whether you need prototypes or full-scale production, MS Machining delivers consistent quality with fast lead times.

Why Choose MS Machining?

When it comes to custom CNC machined parts, choosing the right partner can make all the difference. Here's what sets MS Machining apart:

State-of-the-Art Equipment: We operate a fleet of advanced 3-, 4-, and 5-axis CNC machines.

Experienced Technicians: Our machinists have years of hands-on experience across multiple industries.

Fast Turnaround: We streamline production timelines without compromising quality.

Material Expertise: From exotic alloys to engineering plastics, we handle diverse materials with precision.

Quality Assurance: Every part undergoes rigorous inspection to ensure it meets or exceeds your requirements.

Whether you're a startup developing your first prototype or a large enterprise needing scalable production, MS Machining is your trusted source for dependable CNC machining services.

The Future of CNC Machining

CNC machining is constantly evolving, with emerging technologies like AI, machine learning, and automation pushing the boundaries further. Predictive maintenance, adaptive toolpath optimization, and real-time quality monitoring are enhancing productivity and reliability. As industries continue to demand higher performance and customization, CNC machining will remain a foundational technology for manufacturing innovation.

Final Thoughts

CNC machining is more than just a fabrication method—it's a bridge between concept and reality. With its unparalleled accuracy, versatility, and efficiency, it enables manufacturers to produce everything from simple fixtures to complex aerospace components. Companies like MS Machining are at the forefront, delivering precision-crafted custom CNC machined parts that help bring ambitious designs to life.

Whether you're exploring rapid prototyping or full-scale manufacturing, understanding how CNC machining services work empowers you to make informed decisions and achieve superior results.

0 notes

Text

Affordable CNC Milling India , Best Manufacturers & Suppliers

Need affordable CNC machining in India? Choose from leading CNC Milling Suppliers that offer quality work at competitive prices. Call us now.

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed software to control machinery. It allows for precise cutting, drilling, and shaping of materials like metal, plastic, and wood. Imagine a robotic sculptor working with extreme accuracy—that’s CNC machining.

Why Choose CNC Machining in India?

India offers top-tier CNC machining services with a unique edge:

Lower operational costs

Highly skilled engineers

Advanced equipment

Faster project turnaround

That’s why global brands are outsourcing their CNC needs to Indian suppliers—it saves money without sacrificing quality.

Suppliers: Bridging Industries and InnovationEqually important to the CNC Milling Manufacturers chain are CNC Milling Suppliers, who connect industries with the right equipment and services. They offer a range of products, from compact desktop milling units to high-end industrial machines. These suppliers act as consultants, helping clients choose the most appropriate technology based on application, budget, and output requirements.

Modern suppliers provide value added services like installation, training, preventive maintenance, and troubleshooting. Their role is indispensable in sectors that demand minimal downtime and continuous productivity. They also facilitate customization, offering different table sizes, control units, and compatibility with CAD/CAM software systems.

Key Benefits of CNC Machining

High Precision: Ensures accuracy to within microns.

Consistency: Identical results even in large batches.

Efficiency: Faster production with less waste.

Complex Designs: Capable of producing intricate shapes and structures.

Whether you need a single prototype or thousands of units, CNC machining is up to the task.

Applications :

CNC machining is used everywhere, including:

Automotive: Engine parts, gear systems

Aerospace: Aircraft components

Medical Devices: Surgical tools, implants

Consumer Electronics: Device casings, connectors

Defense: Precision hardware

Indian CNC manufacturers cater to all these sectors and more.

How Indian CNC Suppliers Ensure Quality

Top suppliers in India use:

ISO-certified processes

CMM inspection tools

Real-time monitoring

Highly trained operators

They don’t just meet global standards—they exceed them.

Top CNC Machining Manufacturers in India

Some of the most reputable names include:

Deccanew

Ace Micromatic Group

Jyoti CNC Automation

LMW (Lakshmi Machine Works)

Micromatic Grinding Technologies

These companies have global reach, export capabilities, and strong quality control systems.

Factors That Affect CNC Machining Costs

CNC machining is affordable in India, but prices vary based on:

Material type

Part complexity

Volume (single or batch production)

Surface finishing

Machine run time

India’s lower labor and energy costs make even complex jobs more budget-friendly.

CNC Milling India Is Gaining Momentum

India offers a blend of affordability, engineering talent, and high-precision outputs. Many global and local manufacturers are tapping into CNC services in India for prototype development, mass production, and custom fabrication. By investing in CNC milling, industries are reducing human error, minimizing waste, and significantly improving operational efficiency. CNC machines are digitally programmed, allowing for consistent results with excellent repeatability.

How to Select the Right CNC Supplier

Here’s what to look for:

Experience in your industry

Custom capabilities

Certifications like ISO, AS9100

Prompt delivery records

After-sales support

It’s not just about cost—it’s about reliable performance.

Materials Commonly Used in CNC Machining

Indian CNC machining shops work with:

Metals: Aluminum, steel, brass, titanium

Plastics: Nylon, ABS, PEEK, acrylic

Composites: Carbon fiber, fiberglass

Make sure the supplier has experience with your specific material needs

Deccanew is one of India’s emerging leaders in CNC Milling India. They offer:

Custom CNC solutions

Fast delivery

Affordable pricing

Reliable customer service

From design to delivery, Deccanew combines technical precision with business-friendly pricing.

Trends in Indian CNC Machining Industry

Modern Indian CNC firms are embracing:

AI and machine learning

Smart factories (Industry 4.0)

Eco-friendly machining

Digital twins and cloud-based design

These trends ensure sustainability, efficiency, and innovation for future manufacturing.

Visit: https://www.deccanew.com/cnc-milling-manufacturers-suppliers-india.phpContact: +91 9657039991

0 notes

Text

Revolutionizing Quality Control with Flexible Gaging Systems – Discover the Dynalog-US Advantage

In today’s fast-paced world of advanced manufacturing, precision and flexibility go hand in hand. Companies can’t afford to rely on rigid, outdated inspection methods when quality standards are higher than ever, and production timelines continue to shrink. That’s where flexible gaging systems come in—and few do it better than Dynalog-US.

What Are Flexible Gaging Systems?

Imagine being able to inspect complex parts—no matter the size or geometry—without needing a different fixture for every shape. That’s the power of flexible gaging systems. Unlike traditional hard gauges that are tailor-made for a specific component, flexible gaging systems use programmable sensors, robotic arms, vision systems, and other adaptable technology to inspect a wide variety of parts using the same setup.

These systems are game-changers for industries like aerospace, automotive, and medical manufacturing, where precision is critical and changeovers are frequent. They reduce downtime, cut costs, and improve consistency. Most importantly, they give manufacturers the confidence to scale operations without sacrificing quality.

Why Dynalog-US Leads the Pack

When it comes to advanced metrology solutions, Dynalog-US is not just a provider—it’s a pioneer. With decades of experience in robotic measurement, real-time inspection, and automated gaging systems, Dynalog has built a reputation for helping manufacturers optimize their production processes and eliminate quality guesswork.

Dynalog’s flexible gaging systems are designed to integrate seamlessly with robotic work cells, CMMs, and custom automation setups. Whether you're inspecting powertrain components or composite aerospace structures, Dynalog systems provide real-time data acquisition, error compensation, and detailed reporting—all without slowing down your workflow.

Features That Make the Difference

So what makes Dynalog’s flexible gaging systems stand out from the rest? Let’s take a closer look at some core features:

High-Precision Measurement: Dynalog systems use advanced sensor fusion to deliver micron-level accuracy, making them ideal for both high-volume production and R&D applications.

Multi-Part Capability: Inspect different part sizes, shapes, and configurations using a single flexible system—no need to invest in multiple setups.

Real-Time Feedback: Integrated software allows for real-time inspection data, so operators and engineers can take corrective action before problems escalate.

Robust Integration: Easily integrates with FANUC, ABB, KUKA, and other robotic platforms. Dynalog also supports PLC and MES connectivity for full factory digitization.

User-Friendly Interface: The intuitive software interface means even non-experts can operate the system efficiently, reducing training time and increasing throughput.

Flexible Gaging in Action

Let’s say you're running an automotive parts plant. You need to inspect thousands of brake calipers, knuckles, and housings per day. Each part varies slightly, and you often switch between SKUs. With traditional gaging systems, you’d need to stop the line, change out fixtures, recalibrate, and test again—costing you hours of production time.

Now, enter Dynalog’s flexible gaging system. With a single setup, you can program inspection routines for multiple parts. When a new part comes down the line, the system automatically identifies the type and adjusts the inspection criteria accordingly. No downtime. No manual recalibration. Just continuous, consistent inspection.

Cost-Efficiency and ROI

Some manufacturers hesitate when they hear “robotic” or “automated” gaging, thinking it's cost-prohibitive. But in reality, Dynalog’s flexible gaging systems provide a rapid return on investment. Here's how:

Reduced labor costs by automating repetitive inspection tasks.

Fewer scrap parts due to early error detection.

Faster changeovers, which means higher productivity and better utilization of your workforce.

Data-driven insights to continuously improve manufacturing processes and reduce defects.

When you factor in the long-term savings and operational improvements, flexible gaging becomes not just a smart choice—it becomes essential.

Trusted by Industry Leaders

Dynalog’s systems are trusted by some of the world’s top manufacturers. From Tier 1 automotive suppliers to aerospace innovators, companies rely on Dynalog to help them stay ahead in an increasingly competitive global market.

With a robust support network and a commitment to customer success, Dynalog doesn’t just sell equipment—they partner with you to ensure you’re getting maximum value and performance from your system.

Ready to Embrace Flexible Gaging?

If you’re still using rigid gauges and static inspection stations, you may be holding your production back. It’s time to switch to a smarter, faster, and more flexible approach.

Dynalog-US offers custom consultation and system integration for companies ready to make the leap. Whether you're upgrading existing equipment or building a new facility from the ground up, Dynalog has the experience and technology to help you succeed.

Visit www.dynalog-us.com today to learn more about how our flexible gaging systems can transform your inspection process—and elevate your manufacturing quality to world-class levels.

#flexible gaging systems#Dynalog-US#robotic inspection systems#automated gaging#precision metrology#real-time inspection#smart manufacturing#industrial automation

0 notes

Text

Dimensional Accuracy Meets Digital Intelligence: The Future of Industrial Metrology

The Industrial Metrology MarketResearch Report is the result of extensive research and analysis conducted by our team of experienced market researchers. It encompasses a wide range of critical factors influencing the Industrial Metrology MarketGrowth from 2025 to 2032, including competitive landscape, consumer behavior, and technological advancements. This report serves as a valuable resource for industry players, helping them make informed decisions and stay ahead of the competition in a rapidly evolving market landscape. With its comprehensive coverage and actionable insights, the Industrial Metrology MarketReport offers unparalleled opportunities for growth and success in the Business.

The Report features a comprehensive table of contents, figures, tables, and charts, as well as insightful analysis. Industrial Metrology MarketSize has been expanding significantly in recent years, driven by various key factors like increased demand for its products, expanding customer base, and technological advancements. This report provides a comprehensive analysis of Industrial Metrology MarketBusiness, including market size, trends, drivers and constraints, competitive aspects, and prospects for future growth.

List of top companies in Industrial Metrology Market:

Hexagon AB

Renishaw PLC

FARO Technologies

Nikon Metrology

Carl Zeiss AG

Jenoptik AG

Perceptron

Automated Precision Inc.

KLA Corporation

Applied Materials Inc.

Download Sample Report: https://brandessenceresearch.com/downloadSample/PostId/3369?utm_source=13&utm_medium=Pluse

Scope of Industrial Metrology Market:

The Industrial Metrology MarketResearch presents a detailed analysis of trends, drivers, and challenges within industry. It includes thorough insights into market segmentation by product type, application, and geography. The report highlights major players and their competitive strategies, as well as emerging opportunities for growth. It also investigates consumer behavior and preferences that affect market dynamics. Forecasts for market size and growth potential in the upcoming years are included, backed by quantitative data. It also addresses regulatory factors and technological advancements influencing the market, making this report a valuable resource for stakeholders looking to make informed business decisions.

Global Industrial Metrology Market Segmentation:

Offering Outlook

Hardware

Software

Services

Equipment Outlook

Coordinate Measuring Machine (CMM)

Optical Digitizer and Scanner (ODS)

Measuring Instruments

X-ray and Computed Tomography

Automated Optical Inspection

Form Measurement Equipment

2D Equipment

Application Outlook

Quality Control & Inspection

Reverse Engineering

Mapping and Modeling

Others

End User Industry Outlook

Aerospace & Defense

Automotive

Semiconductor

Manufacturing

Others

Regional Insights:

The regions covered in this Global Industrial Metrology Marketreport are North America, Europe, Asia-Pacific, and Rest of the World. Based on country level, the market of Managed security service is subdivided into the U.S., Mexico, Canada, U.K., France, Germany, Italy, China, Japan, India, Southeast Asia, Middle East Asia (UAE, Saudi Arabia, Egypt) GCC, Africa, etc.

The Global Industrial Metrology MarketReport is recommended for several reasons. Firstly, it offers a detailed examination of the market, considering critical factors such as market size, growth drivers, challenges, and opportunities. This research provides insightful information that aids organizations in formulating effective action plans and making informed decisions. Additionally, the study presents a comprehensive competitive landscape, allowing customers to benchmark their performance against major competitors and identify potential alliances. The report’s geographical analysis helps businesses grasp market dynamics in different regions, enabling them to adapt their strategies accordingly. For companies seeking to understand and thrive in the Global Industrial Metrology industry, this report proves to be an invaluable resource.

Browse In-depth Market Research Report (300 Pages) on Industrial Metrology Market:

What to Expect in Our Report?

(1) A complete section of the Global Industrial Metrology report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Global Industrial Metrology Marketwhere important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Global Industrial Metrology Market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Global Industrial Metrology Market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Global Industrial Metrology Marketreport.

Key Questions Answered in the Report:

(1) What are the growth opportunities for the new entrants in the Global Industrial Metrology industry?

(2) Who are the leading players functioning in the Global Industrial Metrology Marketplace?

(3) What are the key strategies participants are likely to adopt to increase their share in the Global Industrial Metrology industry?

(4) What is the competitive situation in the Global Industrial Metrology Market?

(5) What are the emerging trends that may influence the Global Industrial Metrology Marketgrowth?

(6) Which product type segment will exhibit high CAGR in future?

(7) Which application segment will grab a handsome share in the Global Industrial Metrology industry?

(8) Which region is lucrative for the manufacturers?

About Us:

BrandEssence® Market Research and Consulting Pvt ltd.

Brandessence market research publishes market research reports & business insights produced by highly qualified and experienced industry analysts. Brand Essence Market Research report will be best fit for senior executives, business development managers, marketing managers, consultants, CEOs, CIOs, COOs, and Directors, governments, agencies, organizations, and Ph.D. Students. We have a delivery center in Pune, India and our sales office is in London.

Contact Us:

BrandEssence® Market Research and Consulting Pvt ltd.

124, City Road, London EC1V 2NX

Email: [email protected]

Corporate Sales: +44-2038074155

Asia Office: +917447409162

Website: https://brandessenceresearch.com/

0 notes

Text

CNC Machining Services in Bangalore: Precision, Innovation, and Industry Leadership

In the ever-evolving landscape of manufacturing and product development, CNC machining continues to stand at the forefront of precision engineering. Among the cities in India that have carved out a niche in this domain, Bangalore has emerged as a dynamic hub for CNC machining. Whether you're a small startup or a large-scale enterprise, CNC machining services in Bangalore offer cutting-edge solutions that meet diverse production requirements with unmatched accuracy and efficiency.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process in which computerized controls guide machine tools to cut and shape material with exceptional precision. From simple components to complex parts, CNC machining ensures consistency, repeatability, and high tolerance levels that manual operations can rarely match.

The technology encompasses various types of machines including milling, turning, drilling, and grinding systems—all controlled through specialized software. The result? Components that meet tight specifications, often within microns.

Why Bangalore? The Rising CNC Hub

Bangalore has historically been known for its contributions to technology and innovation. Its strong ecosystem of skilled engineers, access to advanced technology, and a rapidly growing industrial base make it an ideal location for CNC machining. Today, it has evolved into a key center for precision manufacturing and automation solutions.

The city’s thriving engineering talent pool, supportive infrastructure, and entrepreneurial mindset have fostered the rise of numerous specialized facilities that offer CNC machining services in Bangalore. These services cater to a wide variety of needs, from prototyping and low-volume production to high-volume, high-complexity part manufacturing.

Key Features of CNC Machining Services in Bangalore

Here’s a deeper look at what makes CNC machining in Bangalore stand out:

1. Advanced Technology Integration

Most CNC machining services in Bangalore have integrated advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software into their workflow. This integration allows for precise programming of machines and real-time simulation of machining processes to minimize errors and improve production efficiency.

2. Wide Range of Materials Handled

Bangalore-based machining services handle a wide spectrum of materials including metals, plastics, and composite materials. Whether it’s aluminum, steel, brass, or engineering-grade plastics, you can find machining solutions tailored to different material characteristics.

3. Quality Assurance and Standards

One of the key advantages of working with a CNC company in Bangalore is their emphasis on quality control. Most facilities adopt stringent quality assurance practices that include in-process inspections, final inspections, and the use of coordinate measuring machines (CMMs) to verify part accuracy.

4. Customization and Flexibility

CNC machining services in Bangalore are highly adaptable. Whether you require a one-off prototype or batch production, these services are designed to accommodate a wide range of volumes. Moreover, they offer customization options that enable businesses to meet specific design and functional requirements.

5. Competitive Pricing and Fast Turnaround

Thanks to Bangalore’s efficient supply chain ecosystem and skilled workforce, CNC machining is not only precise but also cost-effective. Facilities are equipped to deliver parts quickly without compromising quality—an essential factor for businesses facing tight deadlines.

Growth of CNC Machine Manufacturers in Bangalore

Parallel to the rise in demand for machining services is the development of a robust ecosystem of CNC machine manufacturers in Bangalore. These manufacturers play a crucial role in supplying state-of-the-art machinery not only within the city but across the country.

Manufacturers in Bangalore are known for their innovation, offering machines that are energy-efficient, durable, and equipped with features like automatic tool changers, high-speed spindles, and smart diagnostics. The presence of these manufacturers ensures that CNC service providers in the city remain technologically up-to-date and capable of handling complex machining tasks.

Moreover, having CNC machine manufacturers in Bangalore enables faster maintenance and upgrades, reducing downtime and increasing overall productivity for local CNC facilities.

The CNC Company in Bangalore: Driving Innovation

A CNC company in Bangalore does more than just manufacture or machine parts. Many have positioned themselves as innovation partners, helping clients optimize designs for manufacturability, reduce costs, and shorten production timelines. Their services often extend beyond machining to include reverse engineering, prototyping, and product development support.

These companies invest in research and development to stay ahead of the curve. Whether it's through the adoption of Industry 4.0 principles, IoT-enabled machines, or automation tools, a CNC company in Bangalore is well-equipped to meet the future demands of smart manufacturing.

Furthermore, Bangalore’s CNC firms frequently collaborate with academic institutions and tech incubators, creating a synergy that drives continual improvement and innovation. The city’s startup-friendly environment also fosters new entrants into the CNC space, contributing to a competitive yet collaborative market landscape.

Benefits of Outsourcing CNC Machining to Bangalore

If you’re considering outsourcing machining needs, here’s why Bangalore should be on your radar:

Access to Skilled Talent: A large pool of trained machinists and engineers ensures high-quality outputs.

Technology Advantage: State-of-the-art machines and software are standard in most workshops.

Scalability: Whether your needs are small or large-scale, there’s infrastructure to support growth.

Innovation Support: From design assistance to prototyping, services are integrated for streamlined workflows.

Strategic Location: Being a tech hub, logistics and transportation are efficient, enabling timely deliveries.

Looking Ahead: The Future of CNC Machining in Bangalore

As industries move towards automation, digitization, and sustainability, CNC machining in Bangalore is poised for exponential growth. There is a visible shift toward smart factories where machines communicate in real-time, adjust parameters automatically, and reduce material waste.

Bangalore is also witnessing increased adoption of eco-friendly practices within the machining community. From using biodegradable cutting fluids to recycling scrap materials, sustainability is being woven into the production fabric.

With advancements in materials science and computer technology, CNC capabilities in the city are expected to reach new heights. High-speed machining, 5-axis systems, and AI-integrated solutions are just a few innovations taking shape.

Conclusion

In conclusion, CNC machining services in Bangalore are a perfect blend of precision, innovation, and reliability. The city’s ecosystem of skilled professionals, cutting-edge technology, and responsive service providers makes it an ideal destination for businesses seeking high-quality machining solutions.

Whether you're looking to partner with seasoned CNC machine manufacturers in Bangalore or collaborate with a future-ready CNC company in Bangalore, you’ll find that the city offers more than just manufacturing—it offers a competitive edge.

#cnc machine manufacturers in bangalore#cnc machining services in bangalore#cnc company in bangalore#cnc machining prototyping#custom cnc services

0 notes

Text

Pinion Spiral Bevel Gear Manufacturer in India: Delivering Precision in Every Rotation

When you need high-performance transmission solutions for angular drives and intersecting shafts, spiral bevel gears with pinion systems are the ultimate answer. For industries across India seeking top-grade spiral bevel gear sets, Alpha Transmissions is the go-to pinion spiral bevel gear manufacturer in India offering unmatched precision, strength, and durability.

Alpha Transmissions is renowned for its engineering excellence and high-quality gear systems designed for optimal torque transmission, smooth operation, and extended service life—even in the most demanding environments.

Why Alpha Transmissions Is the Leading Choice

As a trusted pinion spiral bevel gear manufacturer in India, Alpha Transmissions brings together advanced gear-cutting technologies and a team of expert engineers to produce gear sets that:

✔ Ensure smooth, silent, and shock-free motion

✔ Withstand high torque and operational stress

✔ Offer high precision tooth contact and meshing

✔ Are crafted from heat-treated, high-grade steel

✔ Can be customized for automotive, industrial, and marine uses

These gear systems are ideal for right-angle drives and are used in differential systems, heavy-duty gearboxes, power tools, and more.

Applications of Spiral Bevel Pinion Gears

Alpha Transmissions serves a wide range of sectors that depend on reliable angular transmission:

🚜 Agricultural machinery

🏗️ Construction equipment

🚛 Automotive differential systems

⚙️ Industrial gear reducers

🛳️ Marine propulsion and winches

Their spiral bevel pinion gears offer high efficiency with minimal backlash, making them ideal for dynamic, high-performance machinery.

Cutting-Edge Manufacturing Capabilities

What makes Alpha Transmissions a true leader as the pinion spiral bevel gear manufacturer in India is their investment in the latest gear manufacturing technologies:

🔧 CNC spiral bevel gear generators

🔍 3D modeling and simulation software

🔥 In-house heat treatment and surface hardening

🧪 Quality assurance through CMM inspection and load testing

Every gear is engineered to exacting standards, ensuring consistency, strength, and performance.

Partner with the Best in India

From concept to delivery, Alpha Transmissions provides end-to-end gear solutions that are customized, performance-oriented, and built to last. Whether you're designing new machinery or replacing critical components, Alpha Transmissions ensures timely delivery and technical support every step of the way.

Join hundreds of satisfied clients across India who trust the pinion spiral bevel gear manufacturer in India that stands for quality, precision, and dependability.

0 notes

Text

Precision Geometrical Alignment Services for Optimal Equipment Accuracy

Geometrical Alignment: Perfect Precision Services for Unerring Accuracy

Geometrical alignment is the accurate positioning, positioning, and relationship among various components or parts according to geometrical principles. This process is vital in applications from civil engineering and aerospace to graphic design and urban development. In industry, laser shaft alignment services are one of the prominent uses of geometrical alignment, which ensures rotating machine parts to be aligned to a faultless standard in order to minimize vibration, avoid wear and tear, and maximize equipment longevity. The value of proper alignment is not only in the way things appear, but in the way they work—be it the aerodynamic performance of an airplane, the graphic appeal of a website design, or the longevity of a bridge.

Geometrical Alignment: The Backbone of Precision

Geometric alignment is the careful orientation, positioning, and association among various parts or components on the basis of geometric rules. Geometric alignment is essential in disciplines from civil engineering and aviation to graphic design and city planning. The value of proper alignment is not only in the way things appear, but the way they operate—be it the aerodynamic performance of an airplane, the visual balance of a web page design, or the longevity of a bridge.

The Requirement for Professional Alignment Services

Growing need for technical perfection and visual aesthetics has made geometrical alignment precision services a necessity. The services make sure that every part or component of a system is properly measured, calibrated, and aligned to avoid mechanical breakdown, structural weakness, or design defect.

Some major applications are:

Engineering and Manufacturing: In automotive or aerospace industries, a millimeter of misalignment can result in vibration, wear, or system failure. Laser Alignment services guarantee parts will fit and function as designed.

Architecture and Construction: Geometrical accuracy in layout and structure enhances the safety, durability, and visual stability of buildings.

Graphic and UX Design: Principles of alignment assist in designing user interfaces that are clean, intuitive, and aesthetically appealing.

Robotics and Automation: Robots depend on geometrical information to act correctly with their environment, so precise calibration is critical.

Technology Meets Expertise

Contemporary geometrical alignment services leverage sophisticated tools such as laser alignment systems, coordinate measuring machines (CMMs), 3D scanners, CAD software, and photogrammetry. These technologies offer precise measurements and real-time visualization, making it possible for teams to make adjustments and correct with incredible speed and accuracy.

But technology is not sufficient on its own. There are trained specialists who add contextual experience and human understanding to the process. They read the data, comprehend the overall goals of the project, and use alignment principles to resolve real-world challenges. It's science, art, and experience combined.

Advantages of Geometrical Alignment Services

Spending money on professional geometrical alignment services has a number of definite advantages:

Increased Efficiency: Alignment properly minimizes friction, energy consumption, and wear and tear on equipment.

Increased Lifespan of Parts: Precise positioning reduces unnecessary strain on components.

Increased Aesthetic Appeal: Particularly in architecture and design, visual alignment results in harmony and professionalism.

Safety Reduced: Geometry accuracy guarantees safety for both structural and mechanical systems.

Greater Customer Satisfaction: In product design, precision guarantees usability and quality—essential to user experience.

Perfect Accuracy Is Not Optional—It's Expected

In today's high-performance sectors, "close enough" just won't do. From the smooth curves of a luxury vehicle to the pitch of an arch in a bridge, geometrical alignment is what distinguishes good from great. Customers and end-users demand perfection, and they have every right to. When systems perform seamlessly and designs engage, geometrical alignment is frequently the unseen force that drives it all.

Conclusion: Aligning with the Future

As businesses grow and standards improve, geometrical alignment accuracy services will play an even more critical role. It's not only fitting things together—it's about fitting them to last, perform, and ignite. Whether you're building, designing, or engineering, accuracy is the road to perfection.

By bringing your projects into alignment with precision, you're not only making them structurally or aesthetically correct—you're constructing trust, quality, and excellence into each angle and each line.

0 notes

Text

Boost Operational Efficiency with a Powerful CMMS and Facility Management Software Solution

In today’s fast-paced business and commercial environment, having a sturdy digital method to control upkeep obligations, assets, and centers is now not elective—it’s a necessity. Whether you’re overseeing a production plant, dealing with a fleet, or supervising homes, the right Maintenance Management System can streamline operations, make sure regulatory compliance, and decrease downtime. With the integration of superior technology, equipment like facility management software program for buying shops and Property Management Software are remodeling the manner corporations take care of their every day functions. This article explores the significance of imposing contemporary upkeep and facility answers and how each key-word-rich device plays a pivotal function in powerful operations.

Modernize Maintenance with Enterprise Asset Management

A excessive-functioning Enterprise Asset Management EAM machine allows agencies to reveal the complete lifecycle of bodily belongings. From acquisition to decommissioning, it guarantees assets are used efficiently and meet overall performance expectations. Similarly, Fleet Maintenance Software gives companies the equipment to proactively manipulate automobile renovation schedules, reduce unexpected breakdowns, and beautify fleet productivity.

Predictive Maintenance and Software Intelligence

Industries are an increasing number of adopting Industrial Predictive Maintenance Software to transport from reactive to predictive maintenance strategies. By using records analytics, agencies can foresee system screw ups earlier than they occur, saving time and upkeep fees. For big-scale centers, facility management software integrates seamlessly with IoT gadgets and building automation systems to make certain smooth and value-powerful operations.

Technology-Driven Facility and Equipment Management

Using computer aided facility management equipment, managers can digitally tune and oversee facility operations, from HVAC structures to janitorial services. This additionally extends to gadget care software program, that is vital in industries that depend closely on machinery. When paired with a Maintenance Scheduling Software, corporations can automate ordinary obligations, minimize human error, and keep a constant maintenance record.

Compliance, Safety, and Spare Management

For industries in which protection and compliance are non-negotiable, Cmms Safety Compliance Software ensures that every inspection, audit, and corrective movement is recorded and trackable. Cmms Software for Maintenance simplifies the making plans, execution, and recording of all maintenance activities. Organizations can also benefit from Cmms for Spare Management, which keeps stock at most suitable degrees and ensures elements are constantly available whilst wanted.

Maximizing Asset Visibility and System Integration

An effective Asset facts gadget CMMS offers a centralized repository of asset statistics, enhancing choice-making and overall performance tracking. Businesses seeking flexibility frequently flip to Web Based CMMS Software, which gives real-time get entry to from any location, or Mobile CMMS Software, which permits technicians to receive tasks and updates on the pass.

Strategic Implementation for Long-Term Success

Rolling out a brand new maintenance device calls for careful making plans. A based CMMS Implementation Project Plan ensures easy deployment, minimum disruption, and faster ROI. The process is guided through clean CMMS Implementation Steps, which encompass records migration, person education, and testing.

Tailored and Industry-Specific Solutions

Whether you're in manufacturing or healthcare, CMMS Software for Manufacturing provides custom designed capabilities that align with particular workflows. Many corporations opt for Customized CMMS to fit their operational fashion and inner policies. This immediately helps CMMS for asset reliability, which focuses on maximizing uptime and asset overall performance.

Cost-Effective and Audit-Ready Systems

For small and medium corporations, a Low fee CMMS Software grants vital features without breaking the finances. Ensuring compliance is also easier with a CMMS for Compliance and Audits, imparting computerized tracking, reporting, and documentation gear to skip audits hopefully

0 notes

Text

Understanding Maintenance Management: A Key Component in Operational Excellence

In the modern industrial and commercial world, the importance of maintenance management cannot be overstated. It plays a pivotal role in ensuring the longevity, efficiency, and productivity of assets and infrastructure. Whether it’s a manufacturing plant, a hospital, a commercial building, or even a fleet of vehicles, maintenance is necessary to keep systems running smoothly and to avoid costly breakdowns. But more than just routine repairs, maintenance management is a structured approach to preserving and enhancing the value of an organization’s physical assets.

What is Maintenance Management?

Maintenance management is the process of planning, controlling, and executing maintenance activities in a way that optimizes the use of resources while minimizing downtime and maintenance costs. It involves everything from regular inspections and preventative maintenance to emergency repairs and long-term infrastructure planning.

The goal of maintenance management is to ensure that assets continue to perform their intended functions with minimal interruption, maximum safety, and at the lowest possible cost. It combines technical knowledge with strategic planning and data analysis to improve reliability and extend the life of equipment.

Types of Maintenance Strategies

There are several maintenance strategies that organizations may adopt depending on their specific needs, budget, and risk tolerance:

Reactive Maintenance: Often referred to as "run-to-failure," this involves fixing equipment only after it breaks down. While this may be acceptable for non-critical assets, it can lead to expensive repairs and unexpected downtime.

Preventive Maintenance (PM): This strategy is based on regular inspections and servicing to prevent equipment failure. It is time-based and follows a set schedule regardless of the actual condition of the asset.

Predictive Maintenance (PdM): This approach uses data from sensors and analytics tools to predict when an asset is likely to fail, allowing maintenance to be performed just in time. It reduces unnecessary maintenance and prevents unplanned failures.

Condition-Based Maintenance (CBM): Similar to predictive maintenance, CBM relies on real-time monitoring of an asset’s condition to determine when maintenance is necessary.

Reliability-Centered Maintenance (RCM): A comprehensive approach that considers the function of an asset, the ways it can fail, and the consequences of failure, aiming to develop a customized maintenance strategy that optimally balances cost, risk, and performance.

Benefits of Effective Maintenance Management

An effective maintenance management system can deliver numerous benefits to an organization:

Reduced Downtime: By proactively identifying and addressing potential issues, equipment is less likely to fail unexpectedly.

Extended Asset Life: Regular maintenance reduces wear and tear, thus prolonging the life span of critical assets.

Lower Costs: Planned maintenance is generally less expensive than emergency repairs, and it helps avoid production losses.

Improved Safety: Well-maintained equipment is less likely to pose safety hazards to workers and the environment.

Increased Efficiency: Properly functioning machinery and systems ensure that operations run smoothly and without disruption.

The Role of Technology in Maintenance Management

Modern technology has revolutionized maintenance management, making it more data-driven and predictive than ever before. Computerized Maintenance Management Systems (CMMS) are software tools that help organizations track maintenance tasks, schedule inspections, manage spare parts inventory, and generate reports.

The integration of the Internet of Things (IoT), artificial intelligence (AI), and machine learning has further advanced the capabilities of maintenance management systems. These technologies allow real-time monitoring, fault detection, and automatic alerts, enabling organizations to make smarter maintenance decisions.

Challenges in Maintenance Management

Despite its importance, maintenance management is not without challenges. Organizations often struggle with:

Lack of Skilled Personnel: Maintenance requires technical expertise, and a shortage of skilled technicians can affect efficiency.

Budget Constraints: Limited financial resources may lead to deferred maintenance, which can cause long-term damage.

Resistance to Change: Implementing new systems or changing existing processes can meet resistance from staff accustomed to traditional methods.

Data Overload: With the abundance of data generated by modern systems, it can be difficult to focus on the most critical information without the right tools.

Best Practices for Maintenance Management

To overcome these challenges and achieve the full benefits of maintenance management, organizations should adopt the following best practices:

Develop a Comprehensive Maintenance Plan: Identify critical assets and define clear maintenance schedules and procedures.

Invest in Training: Ensure that maintenance staff are trained in the latest techniques and technologies.

Utilize CMMS Tools: Use digital tools to automate and streamline maintenance activities.

Monitor Performance: Track key performance indicators (KPIs) such as Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR) to measure effectiveness.

Foster a Culture of Continuous Improvement: Encourage regular feedback and updates to maintenance practices based on performance data.

Conclusion

Maintenance management is more than just fixing what's broken; it’s a strategic function that supports the overall success of an organization. By implementing structured maintenance strategies and embracing modern technologies, businesses can increase operational reliability, reduce costs, and improve safety. As industries continue to evolve, so too must our approach to maintaining the equipment and infrastructure that support them. Investing in strong maintenance management is not just a smart decision—it's a critical component of long-term organizational resilience and growth.

0 notes

Text

CMMS Explained: The Smart Solution to Modern Maintenance Management

In today’s high-speed business landscape, unplanned equipment breakdowns and inefficient maintenance can severely disrupt operations and inflate costs. A Computerized Maintenance Management System (CMMS) provides a powerful solution by centralizing, automating, and optimizing maintenance tasks across industries. Whether you run a factory, hospital, or school, CMMS software ensures operational continuity, asset longevity, and cost control.

A CMMS is designed to simplify maintenance management through a unified platform. It helps organizations handle work orders, schedule preventive maintenance, track assets, manage spare parts inventory, and generate insightful reports. Shifting from reactive to proactive maintenance, CMMS allows businesses to prevent costly downtime by maintaining equipment before it fails. Key features include real-time work order tracking, asset history logging, automated service schedules, and detailed analytics.

The value of a CMMS lies in its measurable impact. Businesses using CMMS experience reduced downtime, lower maintenance costs, and improved technician productivity. With automated alerts and easy access to asset information, teams can focus on actual repairs instead of paperwork. CMMS also supports safety and regulatory compliance by ensuring critical maintenance tasks are completed on schedule and documented properly.

Industries such as manufacturing, healthcare, education, facilities management, and oil & gas particularly benefit from CMMS platforms. The blog highlights a real-world case where a manufacturing plant cut downtime by 35% and reduced maintenance costs by 20% within six months of implementation. Choosing the right CMMS depends on factors like ease of use, scalability, deployment type (cloud vs. on-premise), integration capabilities, and vendor support.

Despite its advantages, CMMS implementation can present challenges such as employee resistance, large-scale data entry, and customization requirements. However, these can be overcome with proper training, phased rollouts, and selecting a flexible system.

In conclusion, a CMMS is no longer optional in 2025—it’s essential. It empowers maintenance teams, protects valuable assets, and provides the visibility needed to operate efficiently. For businesses seeking a smarter, more reliable way to manage maintenance, investing in the right CMMS is a strategic move that delivers long-term gains.

0 notes

Text

How to Select Top-Quality 5-Axis CNC Machining Providers

Selecting a top-quality 5-axis CNC machining provider is a critical decision for manufacturers, engineers, and procurement specialists who require precision parts and components. Whether you're in aerospace, automotive, medical devices, or any industry that demands complex geometries and tight tolerances, the right CNC machining partner can significantly impact product quality, lead times, and cost-efficiency.

This guide explores key factors to consider when choosing a high-quality 5-axis CNC machining services to ensure your manufacturing needs are met with excellence.

1. Understand the Capabilities of 5-Axis CNC Machining

Before you even start your search, it's essential to understand what 5-axis CNC machining offers and why it's necessary for your application. Unlike traditional 3-axis machining, 5-axis machines move the tool or the part in five different directions simultaneously. This capability allows for:

Greater precision

Complex geometries in a single setup

Reduced tooling costs

Faster production times

Industries such as aerospace, defense, energy, and medical often rely on 5-axis machining for parts like turbine blades, impellers, orthopedic implants, and aerospace structural components.

2. Evaluate Technical Capabilities

Not all CNC providers offering 5-axis machining are equal. When evaluating potential partners, assess their technical capabilities by considering:

a. Machine Specifications

Types and brands of 5-axis machines used (e.g., DMG Mori, Haas, Mazak, Hermle)

Tolerances they can achieve (typically within ±0.005mm for high-end applications)

Size and weight capacity of their machines

b. Software and Programming Expertise

CAD/CAM software proficiency (e.g., Mastercam, Siemens NX, SolidWorks)

Ability to handle complex G-code and simultaneous 5-axis programming

Integration with customer CAD files and version control

3. Certifications and Quality Standards

Top-quality providers often have certifications that demonstrate their commitment to precision and process control. Key certifications to look for include:

ISO 9001: General quality management system certification

AS9100: Required for aerospace and defense machining

ISO 13485: Critical for medical device manufacturing

ITAR Compliance: For defense-related projects in the U.S.

These certifications ensure that the provider follows strict manufacturing and inspection procedures, and that they have a documented process for continual improvement.

4. Track Record and Industry Experience

Experience matters, especially when working with highly precise components. Look for a provider with a solid track record in your industry or with similar part requirements. Ask the following:

How many years have they been offering 5-axis CNC services?

Can they provide case studies or references?

What types of projects have they successfully completed?

A provider familiar with the nuances of your industry will be better equipped to handle specific material requirements, compliance issues, and design tolerances.

5. Materials and Machining Capabilities

Top 5-axis CNC shops should have experience working with a variety of materials, including:

Metals: Aluminum, titanium, stainless steel, Inconel, brass, copper

Plastics: PEEK, Delrin, PTFE, ABS, nylon

Composites and exotic alloys

The ability to machine hard-to-work materials without sacrificing quality or tool life is a hallmark of a skilled provider. Ask what materials they specialize in and if they can recommend alternatives that might improve manufacturability or cost.

6. Inspection and Quality Control Processes

Even the best machines can produce poor parts if not properly managed. Inspection capabilities are crucial in selecting a CNC provider. Look for:

CMM (Coordinate Measuring Machine) reports and in-process inspection capabilities

Use of non-contact inspection methods such as laser scanning or optical comparators

First Article Inspection (FAI) protocols and Statistical Process Control (SPC) capabilities

A shop that emphasizes inspection and provides detailed documentation with each part shipment shows a commitment to quality assurance.

7. Lead Times and Production Capacity

Timely delivery can be just as critical as precision. Ask the provider about:

Their average lead times for prototyping, low-volume, and high-volume orders

Capacity to scale with your production demands

Availability of backup machines and scheduling flexibility

Delays in manufacturing can cause major setbacks, especially for time-sensitive markets like medical devices or defense. A reliable provider should have the bandwidth to meet tight deadlines without compromising on quality.

8. Customer Service and Communication

Clear, responsive communication is often overlooked but vital in CNC partnerships. Look for a provider who:

Assigns a dedicated account or project manager

Responds promptly to RFQs and design change requests

Offers DFM (Design for Manufacturability) feedback to optimize part design

Provides real-time updates during the production process

Transparent communication reduces the risk of errors and ensures that both parties are aligned throughout the manufacturing process.

9. Location and Logistics

While global sourcing is common, geographic proximity can affect lead times and shipping costs. Consider:

Local providers for rapid prototyping or short turnaround jobs

International providers for cost efficiency in high-volume runs (but factor in shipping and customs delays)

Providers with in-house logistics or reliable shipping partners

Some top-tier shops also offer just-in-time (JIT) delivery and kanban inventory management, which can streamline your supply chain.

10. Pricing Transparency and Value

Cost is always a factor, but the lowest price doesn't guarantee the best value. When comparing quotes:

Make sure all pricing is detailed and transparent (materials, setup, tooling, QA)

Watch out for hidden fees for design revisions, expedited service, or post-processing

Consider total cost of ownership, including quality rework, delivery delays, and customer service

A slightly higher upfront cost from a quality provider often translates to long-term savings through reduced waste, faster time-to-market, and fewer part failures.

Conclusion

Choosing a top-quality 5-axis CNC machining provider requires more than a quick Google search or a price comparison. It demands a strategic evaluation of technical expertise, quality systems, industry experience, and customer service.

By focusing on precision, reliability, scalability, and trustworthiness, you can build a strong partnership with a machining provider that enhances your product quality and supports your business goals. Ask detailed questions, visit their facilities if possible, and treat the selection process as an investment in your product’s success.

A high-quality CNC partner isn’t just a vendor—they’re a critical extension of your engineering and manufacturing team.

0 notes

Text

Which is the Best Inventory Management Software for Small Businesses?

When it comes to achieving smooth, cost-effective operations, maintenance management software for small businesses can prove to be very useful. With this software, you can now forget about struggling with inefficiency every single day.

The ideal solution should be easy to set Maintainly plays an instrumental role as a trusted choice for small businesses looking for the best maintenance management software. up, intuitive to use, and powerful enough to deal with both maintenance and inventory tracking without any difficulty and additional cost of traditional enterprise systems. This is where

Why Small Businesses Need Specialized Maintenance Management Software

Small businesses often operate with limited resources and staff, making it crucial to get the best out of efficiency and lower downtime. Manual tracking with spreadsheets or other outdated systems quickly becomes unmanageable as your business grows.

Modern maintenance management software like Maintainly is very useful. It offers automation, real-time tracking, and mobile capabilities that enable teams to stay organized and proactive.

Why Choose Maintainly?

Here’s why you should choose Maintainly:

Quick and Easy Setup: Implementing, training, and navigating old CMMS is a nightmare. Maintainly, on the other hand, is a quick platform where implementations take minutes instead of days or months. Regardless of your industry or the complexity of your asset hierarchy, the results will be quick. It also includes support and setup assistance.

Mobile-First Approach: Technicians can update work orders, track inventory, and communicate on the go by using the mobile app. This ensures they are not stationary, as you can add and update work orders while on the go.

Inventory Tracking: Maintainly’s inventory management tools enable you to keep track of inventory that's consumed during maintenance work. It supports barcode and QR code scanning, making it easy to log parts usage and maintain accurate records.

Automated Preventive Maintenance: You will never miss a scheduled maintenance task again. Maintainly automatically generates preventive work orders based on time or usage metrics. This lowers the risk of unexpected breakdowns and costly repairs.

Customizable and Scalable: You get mix-and-match modules and flexible plans, which means you only get to pay for the features you need. As your business grows, Maintainly grows with you. It supports you from one to thousands of users or assets.

Advanced Reporting and Integration: Maintainly comes with AI-powered, data-driven advanced filtering to generate a custom report of work order data that suits different user roles, permissions, and purposes. You can also use it to create integrations with the software of your choosing, whether it's your company's ERP, BI, or data analytics tool.

Conclusion :If you’re running a small business, Maintainly is a standout option. This maintenance management software for small businesses revolutionizes equipment maintenance, work orders, and asset tracking with automated workflows and real-time insights.

#small business#software#maintenance services#software maintenance and support services#inventory management#maintainly#maintenance management software#CMMS

1 note

·

View note