#drop tester

Explore tagged Tumblr posts

Text

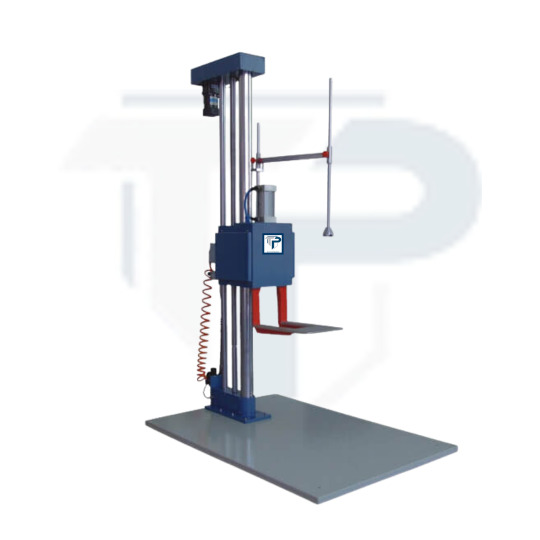

Ensuring Product Integrity: The Power of a Drop Tester from Test Your Product

In today’s hyper-competitive retail landscape, customers expect products to arrive in perfect condition—free from dents, cracks, or malfunctions. For brands and manufacturers, ensuring product durability during transit is no longer optional—it’s essential. That’s where Test Your Product’s Drop Tester, a state-of-the-art laboratory testing instrument, comes into play. Designed for precision, versatility, and compliance with global standards, this device empowers quality assurance teams to simulate real-world impacts, detect packaging flaws, and safeguard brands.

1. What Is a Drop Tester?

At its core, a Drop Tester is a mechanical apparatus used to mimic the impact of drops, bumps, and shocks products endure during handling and shipping. The device secures a product at a specified height, then releases it to fall freely onto a tough base plate—simulating real-life transit conditions. These tests frequently adhere to standards such as ASTM D5276, ISO 2248, and ISTA Series procedures, making results reliable and widely accepted.

2. Why Is Drop Testing Essential?

Quality Assurance: A Drop Tester exposes the weakest points in packaging or product design. Identifying problems early prevents damaged goods from reaching customers.

Cost Reduction: Preventing product damage means fewer returns and replacements, reducing logistics costs.

Customer Satisfaction: Delivering intact products boosts consumer trust and brand loyalty.

Regulatory Compliance: Many markets and clients require drop testing as part of quality checks. A Drop Tester ensures you're up to standard.

3. Key Features of TestYourProduct’s Drop Tester

The Drop Tester from TestYourProduct, headquartered in Delhi, offers a robust suite of features aimed at aligning with modern QA demands:

Adjustable Drop Height & Orientation It allows testing from variable heights—typically ranging from 300 mm to over 1800 mm—mimicking conditions in international shipping and e-commerce. With selectable drop types (flat, edge, corner), it evaluates all possible weak points.

Secure Clamping & Rugged Design Built with high-strength steel frames and secure sample clamps, it prevents product slippage and mirrors the durability of industrial-grade testers.

Digital & Manual Configurations Choose between manual lever-based units for simplicity and cost-effectiveness, or motorized and pneumatic models with digital controls and precision alignment.

Compliance-Ready From ISTA to ASTM and ISO, TestYourProduct designs and calibrates its Drop Tester to meet recognized certifications.

Customizable Solutions Whether your items are oversized, oddly shaped, or ultra-heavy, they offer tailored testing solutions.

4. How Does It Work—Step by Step?

Borrowing best practices from leading industry protocols, the testing process typically flows as follows:

Sample Selection Use a finished, representative product in its final packaging—no damaged or makeshift samples.

Height & Orientation Setup Set drop height and select flat, edge, or corner orientation to simulate real-world impacts.

Clamping & Securing Position and clamp the product carefully to ensure consistent drop dynamics.

Drop Execution Initiate the release manually or via digital controls; the sample drops vertically onto the base plate.

Observation & Documentation Inspect the impact for cracks, deformation, or package failure. Record metrics, take photos, and log results.

Repetition for Consistency Repeat testing—typically across multiple faces and samples—for reliable, reproducible data.

5. Applications Across Industries

The Drop Tester is invaluable in sectors like:

Packaging Manufacturing: Optimize materials and structure prior to shipping scale-up.

Consumer Electronics: Detect fragile areas in phones, laptops, cameras.

Automotive Components: Validate parts that might bounce or drop during transit.

E-commerce Logistics: Reduce damage rates for direct-to-consumer delivery systems.

Pharmaceuticals & Consumer Goods: Test bottles, cans, appliances, and toys.

6. Choosing the Right Model

Consider these factors when selecting a model of TestYourProduct’s Drop Tester:

Height Range: Do your products ever fall further than 1 meter? Choose accordingly.

Capacity: From bottles (under 10 kg) to heavy machinery (100 kg+), ensure the machine supports the load.

Orientation Versatility: Make sure flat, edge, and corner drops are included.

Automation Needs: Motorized systems yield higher throughput and precise control.

Reporting Tools: Digital versions may offer data logging—crucial for audits and product development.

7. Why Buy Through TestYourProduct?

As a Delhi-based manufacturer with a decade-plus enterprise track record, TestYourProduct offers compelling advantages:

Local Manufacture: Sourced and assembled in Delhi under stringent quality standards.

Customized Engineering: Tailored drop testers to match client-specific specs.

Full Support: Training, calibration, maintenance, and after-sales assistance available.

Global Compliance: Models designed to ASTM, ISTA, ISO, and Indian IS standards.

Client-Centric Ethos: Workshops, seminars, and professional consulting to maximize ROI.

8. A Real-World Scenario

Consider an e-commerce platform shipping fragile glassware. After integrating TestYourProduct’s Drop Tester, engineers identified a critical failure point at the corner packaging. With redesigned cushioning and carton reinforcement, the damage rate dropped by over 30%, eliminating return costs and enhancing customer satisfaction—mirroring the kind of success experienced by logistics-focused manufacturers worldwide.

9. Best Practices for Users

To maximize your investment:

Calibrate monthly to maintain accuracy.

Test multiple samples and orientations for robust data.

Maintain a vibration-free environment to prevent skewed results.

Document everything—photos, metrics, test reports are vital for compliance and improvement.

Final Thoughts

In an era where shipping damage can tarnish brands overnight, Drop Testing is far more than a compliance checkbox—it’s a proactive quality measure. Test Your Product’s Drop Tester blends robust engineering, industry compliance, customization, and expert support into a thoroughly modern solution. Whether your business ships electronics, consumer goods, or industrial parts, this instrument offers peace of mind, cost savings, and superior customer experience.

By investing in a high-quality Drop Tester and embedding it into your QA routine, you not only prevent avoidable losses—you build credibility, trust, and brand strength.

For further details on pricing, customization, or to schedule a demo, reach out to the Test Your Product team. Ensure your products arrive intact—and your customers stay satisfied.

0 notes

Text

Vacuum Leak Tester

A Vacuum Leak Tester for Packaging is an essential defender of product integrity, ensuring that packed items reach consumers in perfect condition. By applying negative pressure to packing, this clever instrument detects even the smallest leaks or defects, preventing spoilage, damage, or loss of quality. Its role spans a wide range of industries, from ensuring the freshness of perishable foods to preserving the efficacy of pharmaceuticals and the longevity of delicate electronics.

Original Source Must Visit:- https://www.linkedin.com/pulse/vacuum-leak-tester-packaging-kunal-chauhan-nnxzc/

1 note

·

View note

Text

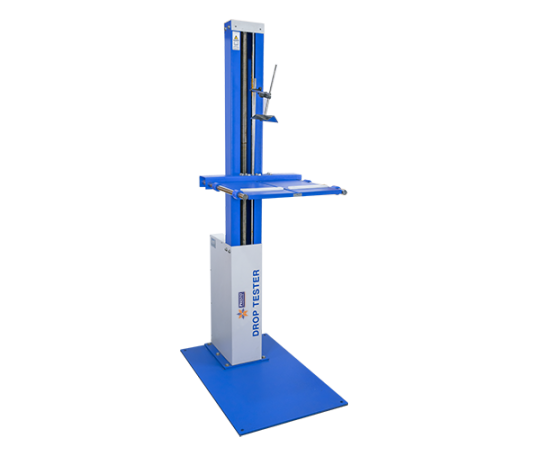

Behind the Scenes of Drop Testing: How Products Are Pushed to Their Limits

A Drop Tester provided by Pacorr Testing Instruments is designed to evaluate the impact resistance of a package or product when it is dropped from certain heights. This type of testing equipment is crucial in the packaging industry, where ensuring the integrity of the packaging during handling, shipping, and storage is essential. It simulates real-world scenarios where packages might be accidentally dropped or mishandled, allowing manufacturers to assess and improve their packaging designs to prevent damage during transit.

What is drop testing?

Drop testing is a method used to assess the durability and impact resistance of a product or package. By simulating real-life handling mishaps, manufacturers can ensure their products withstand accidental Drop Tester during shipping, handling, or everyday use.

How does a drop tester work?

A Drop Tester typically consists of a platform for holding the test item and a mechanism to release the item from a specified height. The aim is to mimic the conditions under which a product might be dropped in real life. Some testers can adjust both the height and the angle of the drop to simulate different scenarios.

What types of products require drop testing?

Virtually any product that may be subjected to impacts during its lifecycle can benefit from Drop Tester. This includes electronics, smartphones, tablets, packaging materials, household appliances, toys, and more. The specific requirements for drop testing can vary widely depending on the product and the industry standards.

How do I choose the right drop tester for my needs?

Selecting the right Drop Tester depends on several factors, including the size and weight of the products you're testing, the heights from which you need to drop them, and any industry-specific standards you must meet. Consider features such as adjustability, ease of use, and data collection capabilities. Consulting with manufacturers and reviewing product specifications can help determine the best fit for your testing requirements.

Can drop testing be automated?

Yes, many modern Drop Tester come with automation capabilities, allowing for consistent, repeatable testing without the need for manual intervention. This can significantly increase testing efficiency and accuracy, especially for high-volume testing scenarios.

What safety precautions should be taken during drop testing?

Safety is paramount during Drop Tester. Always ensure the test area is clear of unnecessary personnel and objects. Use safety barriers or enclosures if available, and wear appropriate personal protective equipment (PPE). Follow all manufacturer guidelines and industry best practices to minimize risk.

How do I interpret drop test results?

Interpreting Drop Tester results involves examining the product for damage and functionality after the test. The specific criteria for failure or success will depend on the product and the testing standards. Detailed analysis might include visual inspection, functional testing, and examining any recorded data from sensors during the drop.

Can drop testing simulate all types of impacts?

While Drop Tester is effective for simulating a wide range of impact scenarios, it may not cover every possible situation. Complementary testing methods, such as shock or vibration testing, may be necessary for a comprehensive assessment of a product's durability.

How often should I calibrate my drop tester?

Regular calibration ensures that your drop tester provides accurate and reliable results. The frequency of calibration can depend on the manufacturer's recommendations, usage intensity, and any applicable regulatory requirements. Typically, an annual calibration is recommended, but more frequent checks may be necessary for heavy usage.

Read more info:

Facebook: https://www.facebook.com/pacorrtestinginstruments

Twitter: https://twitter.com/Pacorr_testing

Instagram: https://www.instagram.com/pacorrtesting

Linkedin: https://www.linkedin.com/in/pacorr

0 notes

Text

Drop Tester Machine for Paper & Packing Industry

A drop tester machine is a device that simulates the impact that a paper or packaging product may receive during transportation and handling. It is used to evaluate the quality and durability of the product and its ability to protect the contents inside.

A drop tester machine consists of a base unit, a drop unit, a specimen holder, a load cell, a display unit, and a control unit. The device works by dropping the drop unit onto the product, which is placed on the specimen holder, and measuring the impact force and the damage caused by the collision.

A drop tester machine can be used to test various types of paper and packaging products, such as bottles, pouches, cans, trays, corrugated boxes, and more. The device can perform different types of drop tests, such as straight drop, angular drop, rotational drop, and inclined drop, to assess the product from all angles. If you want to know more about the drop tester machines from Testing-Instruments, you can visit their website and Contact Us. +91-9210 903 903.

Know More -- https://www.testing-instruments.com/blog/drop-test-what-it-is-all-about/

#drop impact tester#drop test#drop tester#drop tester machine#drop tester manufacturer#drop tester price

0 notes

Text

youtube

Drop testing is an imperative component of quality control as it serves as a critical measure to assess the durability and reliability of products. By conducting drop strength tests on the materials, manufacturers of the paper and packaging industry can effectively identify defects present in the products and ensure that quality materials will be delivered to the customers. Thus, with Presto drop strength tester, manufacturers of paper and packaging industry can effectively test the drop ability of cartons and ensure that quality materials will be delivered to the customers.

0 notes

Text

Hello chat

#print testers are in!#slightly thinner than my current ones but I’m happy with em#will hopefully have a small print/sticker drop in the next month. trying to get stuff from other suppliers while all my other stuff#is stuck in limbo#postings#large one is holo fleck#it’s also a lot more subtle compared to my girls nights holo prints

365 notes

·

View notes

Text

Urm…do y’all really want to see GR Mig. I’m having imposter syndrome rn.

#to the lab testers 🩻#GymRat!Miguel 💪🏾#may regret this when I wake up#but i feel meh rn#like genuinely#like what if I just…drop it#what if…..

15 notes

·

View notes

Text

lol forgot gamescom started today and all i saw is that borderlands 4 is coming out in 2025. so that means it'll come out in 2026 since it will 100% release in a broken unplayable state, will have 2-3 DLCs released and then will be discounted during a seasonal sale.

#nobody gives a shit erin#dont believe me? this exact same scenario happened with 3#i didnt buy it until all of the DLCs dropped and it was on sale#also waited for the steam release so thank you epic store customers for being QA testers

3 notes

·

View notes

Text

Alas, poor clasp. You survived many a fall from great heights because I am a clumsy bitch who drops every damn thing, but you could survive no more. 😔

#a moment of silence before i take the like ten seconds to replace it with a new one XD#i'm the best quality tester for my stuff#seriously i drop e v e r y t h i n g#if it can survive me you're probably fine XD

2 notes

·

View notes

Text

I have. A lot of problems with doa4… and one of them is that they don’t reverse the inputs for command moves when you’re on the other side of your opponent…. And it’s worse when it’s a long string of move inputs….

#Part of me has a horrible hunch this game was made under crunch to come out at the time of the 360#OR a QA tester didn’t pick up in it so it’s just in the game…#At least doa5 and doa6 fix this but good grief you’d THINK that would be a basic consideration…#shallow rambles#what is the point of the izuna drop. Yeah it looks cool but it’s a pain in the ass to pull off why even BOTHER#For the record it’s JUST. A hunch maybe it’s not the case but some small parts feel GLARINGLY overlooked than others

3 notes

·

View notes

Text

main character syndrome (the qsmp mangoball inspired fic that won the vote) is going well btw

#i make yet anothet post just for me 👍#no promises on when chapter one will drop but im working on it o/#this is just a tester image btw not an actual screenshot from the fic

9 notes

·

View notes

Text

Still slowly working on a Fnaf au that just lives in the back of my head, but I want to share a few more designs I have finished for it!

The Beta Tester (still trying to think of a better name, possibly Jeremy?)

Vanny who got a more cobbled together redesign. She wears pieces of walk around animatronic costumes alongside a mask she made herself from an old “marionette” costume and ears stolen off some Bonnie model.

And the old fart Henry himself! My old drawings of Zeus the Sea Dragon and Delilah the Mermaid also belong to this au.

#justabeewithapen#art#my art#fnaf security breach#henry fnaf#fnaf vanny#beta tester#My Au#The Illusion of Staying Dead AU#Oooooo sneaky title drop wow

10 notes

·

View notes

Text

Drop Tester | Perfect Group

The Drop Tester is a mechanical device designed to replicate handling, transportation, and accidental falls. It is an essential tool for assessing a product's impact resistance. This device, which includes a height-adjustable mechanism, a rigid frame, and a controlled release feature, ensures precise and reliable drop tests.

Must Visit:- https://www.perfectgroupindia.co.in/key-points-of-drop-tester-to-get-accurate-results.php

1 note

·

View note

Text

Package Drop Tester In Greater Noida

Durability testing is crucial for ensuring product longevity, and Texcare Instruments Limited delivers with machines like the Martindale Abrasion Tester, Box Compression Tester, and GSM Round Cutter. These tools assess wear resistance, compression strength, and fabric consistency with unmatched precision. Each machine is developed with a focus on stability, calibration accuracy, and operational ease. Our clients depend on Texcare to test the physical limits of their materials—before their customers do. With comprehensive service plans and strong technical support, Texcare ensures that durability is not just tested—it’s verified and documented.

0 notes

Text

Drop Test, Drop Tester Machine Manufacturer: Testing-Instruments

A drop tester is a device used to test the impact resistance of products. Drop testers are used in a variety of industries, including packaging, electronics, and automotive. Drop testers work by drop test specimen from a specified height onto a hard surface. The test specimen is then inspected for signs of damage.

Testing-Instruments is a leading manufacturer of drop testing equipment and drop tester machines. They offer a wide range of drop testers to meet the needs of different industries and applications.

Testing-Instruments' drop testers are known for their accuracy, reliability, and ease of use. Their drop testers are also backed by a team of experienced engineers and scientists who can provide support and training.

If you are looking for a reliable and accurate drop tester Machine, Testing-Instruments is a great option to consider. They offer a wide range of drop testers to meet the needs of different industries and applications.

Read More -- https://www.testing-instruments.com/drop-tester/

0 notes

Text

Deal with the best quality drop tester manufacturer and supplier

Crafted with precision, our Drop Test Machine is built to deliver consistent and reliable results. It boasts a sturdy frame and advanced components, guaranteeing accurate testing every time. A Drop Tester is a specialized instrument used to assess the impact resistance of various products and materials. It measures the ability of an item to withstand sudden shocks or drops, ensuring its durability. This testing equipment is vital for industries like packaging where corrugated boxes will be used. The Packaging Drop Test Machine helps manufacturers identify weaknesses in their products and make necessary improvements to ensure quality and reliability. These testers are available in various designs and configurations to suit the specific testing requirements of different industries. If you want to know more about this quality testing instrument like the drop test machine price then you can give us a call at +919210903903 or email us at info@prestogroup

0 notes