#expanded polystyrene foam board

Explore tagged Tumblr posts

Text

Pacman and ghosts diorama using polymer clay, expanded polystyrene foam, expanding urethane foam, paper clay and acrylic paint.

#pacman#ghosts#videogame#diorama#horror monsters#polymer clay#expanding urethane foam#expanded polystyrene foam board#paper clay#acrylic paint

3 notes

·

View notes

Text

What is the Best Insulation for Residential Metal Roofing?

Are you considering a metal roof for your home? Whether you’re attracted to its sleek look or durability, you might wonder about insulation options to ensure your home remains comfortable year-round. Insulating your residential metal roof significantly impacts energy efficiency, temperature regulation, and comfort. Let’s explore the best insulation choices for your metal roof to ensure you make the right decision for your home.

Understanding the Basics of Residential Metal Roofing

Before we explore insulation options, let’s understand why residential metal roofing is gaining popularity. Metal roofs are long-lasting and highly reflective, which helps deflect heat and keep homes cooler in the summer. However, they can still benefit from proper insulation to minimize heat transfer, prevent condensation, and improve energy efficiency.

Types of Insulation for Residential Metal Roofing

Several options can suit various needs and preferences when insulating your residential metal roofing. Here are some of the most popular insulation types:

1. Spray Foam Insulation

Spray foam insulation is a versatile and highly effective option for metal roofs. It expands after application, filling gaps and creating a seal that minimizes air leaks. This insulation type has great thermal resistance, helping to keep your home warm in the winter and cool in the summer. It can also act as a moisture barrier, reducing the risk of condensation beneath your roof.

Benefits of Spray Foam Insulation:

High R-value, which measures thermal resistance

Excellent air sealing capabilities

Moisture barrier to prevent mold growth

Reduces energy costs over time

2. Rigid Board Insulation

Rigid board insulation is another popular choice for insulating residential metal roofing. Made from polystyrene, polyisocyanurate, or fiberglass materials, rigid boards provide a high R-value and can be installed directly beneath the roofing material. They offer long-lasting thermal performance and are particularly useful for new construction projects or re-roofing.

Benefits of Rigid Board Insulation:

High insulation value

Easy to install and cut to size

Reduces heat transfer and improves energy efficiency

Provides moisture control when paired with a vapor barrier

3. Fiberglass Batt Insulation

Fiberglass batt insulation is a traditional, cost-effective option for insulating residential metal roofing. It’s typically installed between the roof's framing members and can help regulate indoor temperatures. While fiberglass batt insulation is effective, it requires careful installation to ensure no gaps, which could lead to air leaks and reduced efficiency.

Benefits of Fiberglass Batt Insulation:

Affordable and widely available

Good thermal performance when installed correctly

Non-combustible material

Easy to handle and install for DIY enthusiasts

4. Reflective Insulation

Reflective insulation works by reflecting radiant heat away from living spaces. It’s typically installed with other insulation types to enhance energy efficiency, particularly in warmer climates. Reflective insulation, often made from aluminum foil, can significantly reduce cooling costs.

Benefits of Reflective Insulation:

Reduces heat absorption in warmer weather

It can be combined with other insulation types for increased effectiveness

Lightweight and easy to install

Provides a barrier against moisture, which helps prevent mold growth

Factors to Consider When Choosing Insulation for Residential Metal Roofing

Selecting the right insulation for your residential metal roofing involves considering several factors, including:

Climate

Think about the climate in your area. If you live in a region with hot summers and cold winters, you’ll want insulation that provides excellent thermal resistance. In contrast, milder climates may require less insulation.

Installation Method

Consider whether you’re starting a new build or re-roofing an existing structure. Some insulation types are easier to install during construction, while others can be retrofitted into existing roofs.

Budget

Your budget will significantly influence your choice of insulation. While some options may be more expensive upfront, they can lead to energy savings over time. Evaluate your budget carefully to find the right balance between cost and performance.

Energy Efficiency Goals

If your primary goal is to maximize energy efficiency, consider insulation types with higher R-values and moisture control capabilities. This will help reduce your energy bills and improve the overall comfort of your home.

Installation Tips for Insulating Residential Metal Roofing

Proper installation is essential for ensuring your insulation performs as intended. Here are some tips to keep in mind:

Hire a Professional: While some insulation types can be installed by DIY enthusiasts, hiring a professional can ensure the job is done correctly and efficiently.

Use a Vapor Barrier: Installing a vapor barrier can help prevent moisture from accumulating in the insulation, which can lead to mold and reduced effectiveness.

Seal Gaps and Cracks: Before installing insulation, seal gaps and cracks in the roof structure to minimize air leaks and improve overall performance.

Follow Manufacturer Instructions: Always adhere to the manufacturer’s guidelines for installation guidelines to ensure the insulation performs as intended.

Choosing the right insulation for your residential metal roofing can significantly affect your roof's energy efficiency, comfort, and longevity. Various insulation types are available, from spray foam to rigid board options, and your climate, budget, and energy efficiency goals to find the perfect match for your home.

Ready to enhance your metal roof with the best insulation? Visit Lastime Exteriors today to explore our services and learn more about energy-efficient roofing solutions tailored to your needs. Your home deserves the best—don’t wait to improve your comfort and energy savings!

7 notes

·

View notes

Text

Foam Insulation: The Modern Solution for Thermal and Waterproofing

Foam Insulation: The Modern Solution for Thermal and Waterproofing Introduction Insulation is essential in modern construction, due to its importance in conserving energy and protecting buildings from external factors. One of the most effective and widespread types of insulation in recent years is foam insulation. This type of insulation is characterized by its high resistance to heat and moisture, ease of application, and versatility in homes, commercial, and industrial buildings.

What is Foam Insulation? Foam insulation is the process of covering surfaces or walls with a foam material known as polyurethane or polyisocyanurate. This material is initially liquid, then expands rapidly when sprayed into a solid foam that acts as an insulating barrier. Foam can be used for thermal or waterproofing insulation, or both.

Types of Foam Insulation

Polyurethane Foam This is the most common, characterized by its light weight and high thermal insulation efficiency. It comes in two types:

Open-Cell Foam: More flexible and cheaper, suitable for interior walls.

Closed-Cell Foam: Dense and more insulating, suitable for exterior walls and roofs.

Polyisocyanurate Foam It has higher thermal resistance than polyurethane and is often used on flat roofs and soffits.

Benefits of Foam Insulation

Effective Thermal Insulation Prevents heat from entering the building in the summer and escaping in the winter, reducing air conditioning and heating consumption and saving energy bills.

Excellent Waterproofing Foam does not absorb water, thus protecting surfaces from leaks, moisture, and mold.

Ease and Speed of Application Foam can be easily sprayed onto various surfaces, whether flat or irregular, making it an ideal choice for roofs and interior and exterior walls.

Long Lifespan Heat- and moisture-resistant foam lasts for long periods without requiring constant maintenance.

Protection from Insects and Rodents Due to its chemical composition, foam does not provide a suitable environment for insects or rodents to breed or burrow.

Proceed

شركة عزل خزانات بالرياض شركة عزل فوم بالرياض شركة عزل الايبوكسي بالرياض

Uses of Foam Insulation Roof insulation: To prevent heat and water leakage.

Insulation of interior and exterior walls: To improve thermal and sound insulation efficiency.

Insulation of underground tanks and concrete surfaces: To prevent water leakage.

Insulation of industrial buildings and warehouses: To control temperatures and protect goods.

Steps for Foam Insulation Installation Clean the surface of dust, oil, and moisture.

Prepare the foam material using a special machine that mixes the two main materials.

Spray the foam evenly onto the surface using a spray gun.

Leave the foam to dry and harden within minutes.

Add a protective layer (optional) such as an acrylic layer or panels that protect against UV rays and rain.

Disadvantages of Foam Insulation Despite its many advantages, there are some potential disadvantages:

High initial cost compared to other types of insulation.

Requires professional installation.

Difficulty in removing foam after it hardens for modification or maintenance.

Comparison between foam insulation and other types of insulation Type: Thermal insulation, Waterproofing, Cost, Lifespan, Ease of installation Foam: Excellent, Excellent, Medium-High, Long, Easy Rock wool: Good, Poor, Medium, Medium Fiberglass: Good, Poor, Low, Medium, Medium Polystyrene boards: Good, Good, Medium, Long, Medium

Conclusion Foam insulation is an ideal choice for those looking for effective solutions for both thermal and waterproofing. Despite its higher initial cost, its effectiveness and long-term energy savings make it a smart investment for any residential or commercial building. If you're considering improving the insulation efficiency of your home or project, foam deserves to be at the top of your list of options.

0 notes

Text

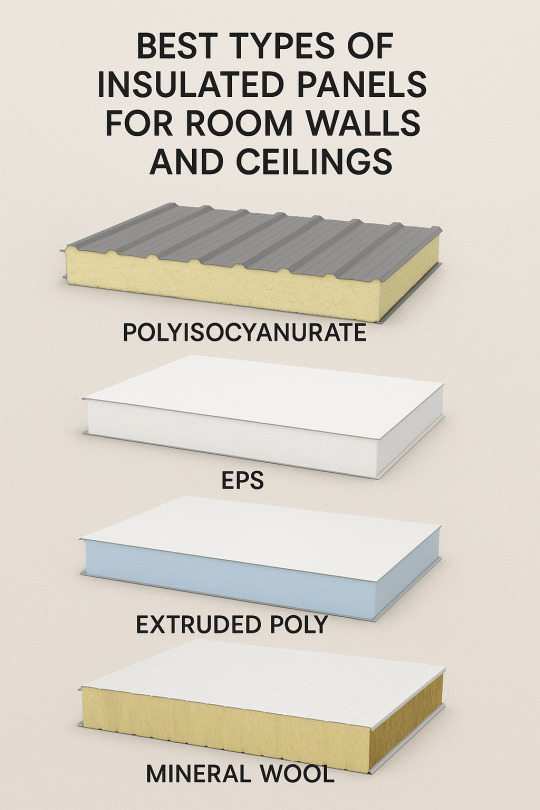

Best Types of Insulated Panels for Room Walls and Ceilings

In modern construction, energy efficiency, durability, and speed are more important than ever. Whether you're building a residential home, commercial office, warehouse, or prefab structure, choosing the right insulation for walls and ceilings is key to maintaining indoor comfort and reducing energy costs.

Insulated panels are prefabricated systems that combine insulation and structural support in a single solution. They’re ideal for temperature control, noise reduction, and structural strength. Here's a look at the best types of insulated panels for room walls and ceilings, each with its own advantages:

1. Polyisocyanurate (PIR) Panels

Polyisocyanurate, or PIR, is one of the highest-performing thermal insulation materials used in construction today. These panels consist of rigid foam sandwiched between two metal or board layers.

Key Benefits:

Superior thermal efficiency – high R-value per inch

Fire resistance – self-extinguishing properties

Lightweight and durable – easy to handle and install

Moisture resistance – ideal for both indoor and outdoor use

PIR panels are ideal for temperature-controlled spaces such as cold storage, server rooms, and industrial buildings.

2. Expanded Polystyrene (EPS) Panels

EPS panels are made from expanded polystyrene foam, known for its excellent insulating properties and cost-effectiveness. These panels are widely used in prefabricated and modular buildings.

Key Benefits:

Affordable insulation solution

Good thermal and acoustic performance

Lightweight and easy to cut or install

Environmentally friendly and recyclable

EPS panels are great for residential rooms, partitions, and standard prefab structures where cost and speed are priorities.

3. Extruded Polystyrene (XPS) Panels

Extruded polystyrene is a denser and stronger form of polystyrene insulation. XPS panels offer excellent thermal performance and resistance to moisture, making them ideal for high-humidity environments.

Key Benefits:

High compressive strength

Excellent moisture and water resistance

Smooth surface finish

Long-term durability

These panels are often used for roofs, ceilings, basements, and cold storage facilities.

4. Mineral Wool Panels

Mineral wool (or rock wool) panels are made from natural stone or slag fibers. Known for their fire resistance and soundproofing qualities, these panels are ideal for buildings where fire safety is a top priority.

Key Benefits:

Non-combustible and fire-resistant

Excellent sound insulation

Resistant to pests, mold, and rot

Eco-friendly and recyclable

They are commonly used in commercial and industrial spaces, especially in applications requiring acoustic control and fire safety.

Conclusion

The choice of insulated panels depends on your building's requirements—whether it’s superior thermal performance, moisture resistance, acoustic insulation, or fire safety.

Polyisocyanurate is best for energy efficiency, EPS offers an economical and lightweight option, XPS excels in moisture-prone areas, and Mineral Wool provides unbeatable fire and sound insulation.

Investing in the right insulation solution helps you reduce energy bills, enhance occupant comfort, and extend the life of your building.

Looking for high-quality insulated panel solutions? Partner with trusted manufacturers like Engko for expert guidance and top-grade materials tailored to your project.

#prefab#pre engineered building manufacturers#prefabricated#peb#prefabricated structure#warehouse#industrial

1 note

·

View note

Text

Sandwich Panel: Lightweight yet robust for various builds.

Structural Advantages of Lightweight Sandwich Panels Superior Strength-to-Weight Ratio Lightweight sandwich panels are engineered to deliver a remarkable strength-to-weight ratio, making them indispensable in applications requiring durability without excess weight. These panels consist of lightweight core materials, like foam or honeycomb structures, flanked by two rigid outer layers, which collectively offer high load-bearing capacity. This combination ensures that industries, such as aerospace and construction, can utilize these panels for enhanced structural performance. In construction, for example, sandwich panels allow for robust building designs without overloading the structures, contributing to safer and more sustainable buildings.

Ease of Installation and Cost Efficiency Lightweight sandwich panels simplify the installation process, significantly reducing labor costs and time for construction projects. The panels often come precut and ready to install, which minimizes onsite adjustments and accelerates project timelines. Studies have consistently shown that using sandwich panels can slash labor costs by up to 30% while shortening project duration. This ease of installation makes sandwich panels a cost-effective choice, driving efficiency throughout the construction phase and offering a practical solution for businesses looking to maintain a balanced budget without compromising quality.

Enhanced Thermal and Acoustic Insulation Properties Foam Core Options for Optimal Insulation Foam core materials, such as Expanded Polystyrene (EPS) and Polyisocyanurate (PIR), are at the forefront of providing exceptional thermal resistance and energy efficiency in building designs. EPS, known for its lightweight and cost-effective properties, and PIR, lauded for its high thermal performance, contribute significantly to minimizing energy costs by reducing HVAC loads. For instance, by incorporating these materials, buildings can potentially achieve up to 40% in energy savings when compared to traditional insulation options. Studies consistently show that the thermal performance of foam insulation surpasses that of conventional materials, marking it as a preferable choice in eco-friendly constructions.

These advantages stem from the high insulation values associated with foam cores, which effectively reduce thermal bridging—a common issue with standard construction materials. By utilizing foam board insulation in sandwich panels, architects can address issues related to heat loss, leading to better control over indoor climates while maintaining lower energy expenses. This engineering marvel is particularly beneficial in large commercial developments where energy efficiency is paramount. The advent of sandwich panels with advanced core materials underscores the ongoing shift towards sustainable and economically viable building solutions.

Mineral Wool for Soundproofing Solutions Mineral wool is a standout material for soundproofing applications in both commercial and residential construction, offering excellent acoustic insulation properties. It effectively diminishes sound transmission by up to 50%, making environments more conducive to productive work and relaxed living. This high level of acoustic control is invaluable in settings such as schools, hospitals, and offices where peace and quiet are essential. As a composite panel application, its sound-dampening qualities are seamlessly integrated into sandwich panels, enhancing their utility in diverse environments where noise reduction is critical.

This capability of mineral wool in sandwich panels makes them superior to traditional acoustic solutions, ensuring better sound privacy and increased comfort. The deployment of these panels aligns perfectly with the requirements of modern construction projects seeking to balance functionality with the comfort of their occupants. As awareness of the benefits of excellent acoustic environments rises, so does the demand for mineral wool integrated solutions, solidifying its place in the lineup of materials offering premium acoustic performance.

Aluminum Composite Facing for Long-Lasting Performance Corrosion Resistance in Harsh Environments Aluminum composite materials are well-known for their superior durability against environmental stressors such as moisture, UV radiation, and extreme temperatures. These materials offer strong corrosion resistance, significantly enhancing the lifespan of structures they are used in. As a result, maintenance and replacement costs are noticeably reduced over time. Studies have demonstrated that aluminum composites maintain their performance under exposure to corrosive elements for over 20 years, making them a wise investment for long-term projects. This impressive longevity showcases the reliability of aluminum composite materials in demanding environmental conditions.

Aesthetic Flexibility in Architectural Design The aesthetic flexibility of aluminum composite panels makes them a favorite among architects and designers. Available in a wide range of colors, textures, and finishes, these panels enable creative architectural expression without compromising on functionality or durability. This versatility supports a myriad of design applications, from modern offices to sprawling retail spaces, allowing each project to have a unique and personal touch. Consequently, architects are increasingly opting for aluminum composite materials, appreciating their blend of artistic value and robust structural integrity. This trend underscores the material's status as a preferable choice in contemporary architectural design.

Versatile Applications Across Construction Projects Roofing and Wall Cladding Solutions Sandwich panels have become a go-to solution for roofing and wall cladding in various construction projects due to their robust strength and excellent insulation properties, ensuring both safety and efficiency. Their ease of installation allows for the rapid construction of large commercial buildings without compromising access to high thermal performance, contributing to energy efficiency. Recent market studies indicate that the demand for sandwich panels in these applications is surging, with an annual growth rate of approximately 8%. This trend reflects the construction industry's increasing preference for materials that offer quick solutions to sustainable building practices.

Specialized Uses in Cold Storage Facilities In cold storage facilities, sandwich panels play a crucial role in maintaining controlled temperatures, which is vital for the preservation of temperature-sensitive products. Industries such as food and pharmaceuticals rely heavily on these panels for their superior insulation capabilities that are essential for effective temperature control. Remarkably, businesses incorporating sandwich panels for cold storage have reported substantial reductions in energy costs associated with refrigeration systems. The slurry of benefits offered by these panels underscores their indispensable value in environments where temperature regulation is paramount for operational success.

Eco-Friendly Benefits and Energy Efficiency Sustainable Material Choices Lightweight sandwich panels shine in sustainable building practices due to their use of recyclable materials. By incorporating eco-friendly insulation options, these panels significantly reduce material waste during manufacturing and installation processes. For instance, using materials like aluminum composite panels enhances sustainability by lowering waste output and preserving resources. Research supports these initiatives by indicating that sustainable building materials can diminish a project's environmental impact by as much as 30%. This noteworthy reduction not only benefits the environment but also enhances a building's green credentials.

Reducing Carbon Footprint with Insulated Designs Insulated sandwich panels offer a remarkable ability to decrease a building's energy consumption, leading to a substantial reduction in carbon emissions. The improved energy efficiency these panels provide aligns perfectly with the growing governmental standards for green building practices. By lowering operational costs, they present a viable solution for businesses intent on sustainable development. Studies reveal that using materials like foam board insulation and aluminum composite material can lead to up to a 50% reduction in the carbon footprint of commercial buildings. This substantial impact underscores the importance of adopting energy-efficient designs in modern construction endeavors.

0 notes

Text

Foam Insulation Market Overview and Growth Outlook

The foam insulation market is experiencing steady growth as industries and households seek better energy efficiency, improved indoor comfort, and lower environmental impact. Foam insulation materials are widely used in construction, refrigeration, automotive, and packaging sectors due to their high thermal resistance and lightweight properties.

Market Overview

Foam insulation involves the use of materials like polyurethane, polystyrene, and phenolic foam to reduce heat transfer. These materials are applied in walls, roofs, pipes, and floors to create a thermal barrier. They help keep buildings warm in winter and cool in summer, reducing the need for heating and cooling systems.

Key types of foam insulation include:

Spray Foam: Applied on-site, it expands and fills gaps, offering excellent air sealing.

Rigid Foam Boards: Pre-formed panels used in walls, roofs, and foundations.

Foam-in-Place: Installed during construction to fit into tight spaces.

Growth Drivers

Energy Efficiency Regulations Governments around the world are promoting energy-saving buildings. Foam insulation helps meet building codes and energy standards, encouraging its use in new and existing structures.

Rising Construction Activity Growing residential and commercial construction, especially in developing countries, is driving demand for insulation materials.

Increased Awareness of Environmental Impact As people and businesses aim to lower carbon emissions, foam insulation plays a key role in making buildings more eco-friendly by reducing energy usage.

Technological Advancements Innovations in foam materials have led to better performance, longer durability, and improved fire resistance. Some products are also made with eco-friendly or recycled materials.

Growth in Refrigeration and Cold Storage Foam insulation is widely used in cold storage facilities and refrigerators to maintain low temperatures efficiently. This sector is growing due to demand from food, pharma, and logistics industries.

Challenges

Environmental Concerns: Some foam types contain chemicals that may harm the environment, pushing manufacturers to develop greener alternatives.

High Initial Costs: Foam insulation can be more expensive upfront compared to traditional materials, though it saves money in the long run through energy savings.

Flammability and Safety Regulations: Ensuring that insulation materials meet fire safety standards is essential, especially in commercial buildings.

Future Outlook

The foam insulation market is expected to grow steadily over the next decade. Key trends shaping the future include:

Green Building Movement: More construction projects will prioritize sustainable materials, boosting demand for eco-friendly foam products.

Smart Cities and Infrastructure Development: Urban expansion and modernization efforts will increase the need for advanced insulation solutions.

Product Innovation: Development of low-emission, high-performance foams will help meet both environmental and energy goals.

Regions like North America, Europe, and Asia-Pacific are expected to lead the market due to rising construction, government incentives, and climate-conscious consumers.

Conclusion

The foam insulation market is growing as the world looks for better ways to save energy and protect the environment. With continued innovation, supportive regulations, and rising demand across industries, foam insulation will remain a key material for modern, sustainable living and construction.

0 notes

Link

0 notes

Text

Foam Insulation: The Modern Technology for Thermal and Sound Insulation

شركة كشف تسربات المياه بجدة

شركة تجديد حمامات بالرياض

شركة ترميم حمامات بالرياض

Foam Insulation: The Modern Technology for Thermal and Sound Insulation Thermal and sound insulation are among the most important elements of modern construction, directly contributing to improving the quality of life inside buildings, whether residential, commercial, or industrial. With the advancement of insulation technologies, foam insulation has emerged as one of the best and most efficient types of insulation currently used, due to its flexibility, high efficiency, and ease of application.

What is Foam Insulation? Foam insulation is a type of insulation that uses a lightweight foam material known as "foam." This chemical substance is produced by mixing two basic components: polyol and isocyanate. When mixed, the foam expands to fill the gaps and cover the entire surface, forming a strong insulating layer.

Foam can be applied in two ways:

Spray Foam: Sprayed directly onto surfaces using special equipment.

Foam Boards: Installed manually on surfaces.

Types of Foam Insulation Polyurethane Foam: The most widely used, it offers high thermal and sound insulation, and is also resistant to water and moisture.

Polyethylene Foam: It is often used for sound insulation and has good shock absorption.

Polystyrene Foam: Available in the form of panels, it is used for thermal insulation of roofs, walls, and floors.

Closed-cell spray foam: Denser and more durable, suitable for exterior surfaces, and highly water-resistant.

Open-cell spray foam: Lighter and less dense, yet more flexible, it is often used for sound insulation.

Advantages of Foam Insulation ✅ Effective Thermal Insulation: Prevents heat from the outside to the inside and vice versa, reducing the need for air conditioning or heating.

✅ Excellent Sound Insulation: Reduces noise transmission between rooms or from the outside to the inside.

✅ Moisture and Water Resistance: It does not absorb water, protecting surfaces from water leaks and mold.

✅ Accurate Coverage: Due to its foamy nature, foam fills all gaps and cracks, preventing air leakage.

✅ Reduces Energy Consumption: It helps lower electricity bills by improving energy efficiency.

✅ Lightweight: It does not place an additional burden on surfaces or structures.

✅ Long Lifespan: It does not corrode easily and can last for years without maintenance.

Disadvantages of Foam Insulation ❌ Relatively High Cost: It is more expensive than some traditional types of insulation, especially closed-cell spray foam.

❌ Requires Professional Technicians: Foam application must be performed by specialists to ensure good coverage and avoid future problems.

❌ Chemicals: Some types of foam may contain volatile organic compounds (VOCs), which can be harmful if not used properly.

Uses of Foam Insulation Roof Insulation: It is one of the best types of insulation for roofs, as it prevents heat and water leakage.

Wall Insulation: It is used inside walls to strengthen thermal and sound insulation.

Floor Insulation: It reduces the transfer of cold from the ground, providing greater comfort, especially in winter.

Industrial Buildings and Warehouses: It helps maintain suitable temperatures inside industrial facilities.

Cars and Refrigerators: Foam is used in the manufacture of cars and refrigerators as an insulating material.

How to Install Foam Insulation (Spraying): Clean the surface thoroughly of dust and oils.

Cover areas not to be insulated, such as windows and air conditioners.

Spray the foam using special equipment, and it begins to expand within seconds.

Level and trim excess material to obtain a flat surface.

Cover the foam with a protective layer (such as a waterproofing layer or protective paint) to maintain its efficiency.

The Difference Between Foam Insulation and Other Insulation

Comparison: Rockwool Foam Insulation vs. Cement Insulation Efficiency: Very High, Medium, Weak Weight: Light, Relatively Heavy, Heavy Water Resistance: High (Excellent), Weak, Medium Ease of Application: Easy and Quick, Requires Time and Effort, Difficult Lifespan: Long, Medium Foam Insulation and Sustainability With the global trend toward sustainability and environmental conservation, environmentally friendly foam types have emerged that do not release harmful compounds during manufacturing or after installation. The reduced energy consumption resulting from foam use also reduces carbon emissions, making it a positive contributor to environmental protection.

Tips Before Choosing Foam Insulation Make sure you choose the right type of foam for the nature of the building or roof.

Choose a company with experience in installation to ensure results.

Request a warranty on the material and workmanship.

Ask about the type of chemicals used and their compliance with safety standards.

Don't neglect the final protection of the foam, whether with an insulating paint layer or a waterproofing layer.

Conclusion Foam insulation is a smart and cost-effective long-term option, especially in light of rising energy costs and the growing need for environmental comfort within homes and institutions. Despite its initial cost, its significant energy-saving and weather-protection benefits make it a successful investment for anyone seeking to build or develop a modern, sophisticated building.

0 notes

Text

What is the best type of insulation for an asphalt roof?

Did you know that an uninsulated roof can account for up to 26% of heat loss in your home? This not only leads to higher energy bills but also affects indoor comfort. If you're considering asphalt roofing repairs or installations, selecting the right insulation is crucial for enhancing energy efficiency and maintaining a comfortable living environment.

Choosing the appropriate insulation for your asphalt roof can be a daunting task, especially with the variety of materials available. Each type offers unique benefits, and making an informed decision is essential for the long-term durability, safety, and curb appeal of your property.

In this article, we'll explore the best types of insulation suitable for asphalt roofs, providing you with friendly, straightforward advice to help you make the best choice for your home.

Understanding Roof Insulation and Its Importance

Roof insulation acts as a barrier to heat flow, keeping your home warmer in the winter and cooler in the summer. Proper insulation reduces energy consumption, leading to lower utility bills and a reduced carbon footprint. For asphalt roofs, selecting the right insulation material ensures compatibility and optimal performance.

Types of Insulation Suitable for Asphalt Roofs

Fiberglass Insulation

Description: Composed of fine glass fibers, fiberglass insulation is available in batts, rolls, or loose-fill forms.

Benefits:

Cost-Effective: Fiberglass is one of the most affordable insulation materials, making it a popular choice for homeowners.

Thermal Performance: It offers good thermal resistance, helping to maintain indoor temperatures.

Fire Resistance: Fiberglass is non-combustible, adding a layer of fire safety to your home.

Considerations:

Installation: Proper installation is crucial to prevent gaps that can reduce effectiveness.

Moisture Sensitivity: Fiberglass can lose its insulating properties when wet, so ensuring a moisture barrier is important.

Mineral Wool (Rock Wool) Insulation

Description: Made from volcanic rock, mineral wool is dense and durable.

Benefits:

Excellent Thermal Resistance: Provides high R-values, enhancing energy efficiency.

Sound Insulation: Its density helps in reducing external noise.

Fire Resistance: Mineral wool can withstand high temperatures, offering added fire protection.

Considerations:

Cost: Generally more expensive than fiberglass.

Weight: Heavier than other insulation types, which may require additional structural support.

Spray Foam Insulation

Description: A liquid that expands into a foam, sealing gaps and providing insulation.

Benefits:

Air Sealing: Effectively fills cavities, preventing air leaks.

High R-Value: Offers superior thermal resistance per inch compared to other materials.

Moisture Barrier: Closed-cell spray foam acts as a barrier against moisture.

Considerations:

Cost: One of the more expensive insulation options.

Professional Installation: Requires skilled professionals for proper application.

Rigid Foam Board Insulation

Description: Panels made from polystyrene, polyisocyanurate, or polyurethane.

Benefits:

High Insulating Value: Provides excellent thermal resistance.

Moisture Resistance: Particularly effective in preventing moisture intrusion.

Structural Support: Adds rigidity to the roofing system.

Considerations:

Installation: Must be cut to fit, and seams should be sealed to prevent thermal bridging.

UV Sensitivity: Some foam boards can degrade under UV exposure if not properly covered.

Factors to Consider When Choosing Insulation

Climate: In warmer climates, insulation that also reflects heat is beneficial, while in colder regions, higher R-value materials are preferable.

Roof Design: The pitch and structure of your roof can influence the type of insulation that is most suitable.

Budget: Balancing cost with performance is key; investing in higher-quality insulation can lead to long-term savings.

Environmental Impact: Some materials have a lower environmental footprint, which may be important for eco-conscious homeowners.

Installation Considerations

Proper installation is vital to ensure the effectiveness of your chosen insulation. Here are some steps to consider:

Hire a Professional: Engaging a qualified contractor ensures that insulation is installed correctly, maximizing its benefits.

Ensure Ventilation: Adequate ventilation prevents moisture buildup, which can compromise insulation performance.

Check for Compatibility: Ensure that the insulation material is compatible with asphalt shingles to avoid any potential issues.

Conclusion

Selecting the best insulation for your asphalt roof is a significant decision that impacts your home's energy efficiency, comfort, and safety. It can be done by considering the types of insulation available and evaluating factors such as climate, budget, and roof design. You can make an informed choice that suits your specific needs. Remember, proper installation is just as important as selecting the right material, so consider consulting with a professional to achieve the best results.

1 note

·

View note

Text

One Coat Stucco System and Exterior Insulation System: A Comprehensive Guide

In modern construction, the demand for efficient, durable, and cost-effective wall finishing and insulation systems has significantly increased. Two such innovative solutions that have gained popularity are the One Coat Stucco System and the Exterior Insulation System (EIFS). Both methods offer distinct advantages, including improved energy efficiency, aesthetic appeal, and enhanced durability. This article explores these two systems, their benefits, applications, and key differences.

What is a One Coat Stucco System?

A One Coat Stucco System is a modified cement-based finish that combines traditional stucco materials with polymer additives and fiber reinforcement. Unlike conventional three-coat stucco, which requires multiple layers and an extended curing process, the one coat system simplifies installation by combining the brown coat and scratch coat into a single application.

Benefits of One Coat Stucco System

Faster Installation: Reduces labor time and costs by eliminating multiple application layers.

Durability: Resistant to cracking, weathering, and moisture when properly installed and maintained.

Energy Efficiency: Can be applied over foam insulation to enhance thermal performance.

Cost-Effective: Fewer materials and labor result in lower overall construction expenses.

Versatility: Available in a variety of colors and textures to match different architectural styles.

Applications of One Coat Stucco System

Residential and commercial buildings

Exterior wall renovations

Weather-resistant wall coatings

High-performance cladding systems

What is an Exterior Insulation System (EIFS)?

The Exterior Insulation and Finish System (EIFS) is a multi-layered cladding system that incorporates insulation, waterproofing, and decorative finishes. It typically consists of:

Insulation Board: Made from expanded polystyrene (EPS) or mineral-based materials.

Base Coat: A polymer-modified cement layer reinforced with fiberglass mesh.

Finish Coat: A decorative, weather-resistant surface that comes in various textures and colors.

Benefits of Exterior Insulation System

Enhanced Energy Efficiency: Provides superior insulation by reducing thermal bridging and improving R-value.

Moisture Control: EIFS prevents water intrusion, reducing the risk of mold and mildew.

Design Flexibility: Can mimic brick, stone, or stucco finishes while allowing for creative architectural designs.

Lightweight Construction: Adds minimal structural load compared to traditional masonry finishes.

Long-Term Savings: Reduced energy consumption and maintenance costs make EIFS a cost-efficient solution over time.

Applications of Exterior Insulation System

High-rise buildings

Residential and commercial exteriors

Energy-efficient home upgrades

Retrofitting older buildings for improved insulation

Key Differences Between One Coat Stucco and EIFS

One Coat Stucco and EIFS differ primarily in material composition, insulation properties, and durability. One Coat Stucco is a cement-based system that offers a traditional look and robust durability but limited insulation. EIFS, on the other hand, provides superior insulation and moisture control but requires careful installation to ensure longevity. Cost-wise, One Coat Stucco is generally more affordable upfront, whereas EIFS offers long-term energy savings that can offset the initial investment.

Conclusion

Both the One Coat Stucco System and Exterior Insulation System (EIFS) offer unique benefits, making them suitable for different construction needs. While One Coat Stucco provides a durable, cost-effective solution with a traditional appearance, EIFS offers superior insulation and moisture resistance, making it an excellent choice for energy-efficient buildings.

Choosing the right system depends on factors like climate, building requirements, and budget. By understanding their differences and advantages, homeowners, architects, and builders can make informed decisions that enhance the performance, aesthetics, and sustainability of their structures.

#exterior insulation system#eifs systems texas#continuous insulation system#stucco systems#eifs systems san antonio

0 notes

Text

Foam Insulation: The Modern Solution for Building Insulation

Introduction With rapid climate change and growing awareness of the importance of rationalizing energy consumption, building insulation has become a necessity, not a luxury. Among modern methods that have proven effective in thermal and water insulation, foam insulation stands out as one of the most prominent solutions relied upon by contracting companies and owners of both new and old buildings. What is this type of insulation? What distinguishes it from others?

What is Foam Insulation? Foam insulation is a type of insulation that uses a foam material sprayed or installed on surfaces, walls, ceilings, or floors to prevent heat or water leakage. Foam is characterized by its light weight, ease of installation, and high insulation effectiveness, making it an ideal choice in many cases.

Types of Foam Insulation

Spray Foam (Polyurethane) Sprayed onto surfaces using special devices.

After spraying, it expands to form a tight insulating layer.

It is used to insulate surfaces and walls.

Rigid Foam (Polystyrene Boards) Comes in the form of pre-fabricated panels that are installed on roofs or inside walls.

Used for insulating floors, ceilings, and walls.

Polyisocyanurate Foam Considered a highly efficient thermal insulation material.

Good fire and moisture resistance.

Benefits of Foam Insulation

Strong Thermal Insulation Reduces heat loss into the building in the summer or escape in the winter, reducing electricity bills and maintaining a stable temperature.

Excellent Waterproofing Prevents water from seeping into roofs or walls, reducing the chances of moisture and mold.

Lightweight Doesn't place an additional load on the building and can be used in older buildings.

Complete Sealing of Gap Unlike some traditional types of insulation, foam easily covers small gaps and cracks.

Insect and Mold Resistant Doesn't provide a suitable environment for fungal or insect growth.

Uses of Foam Insulation Insulating roofs (flat or sloping).

source

شركة كشف تسربات المياه بالخبر شركة كشف تسربات المياه بالدمام كشف تسربات المياه الدمام بدون تكسير

Insulating underground and overhead tanks.

Insulating external and internal walls.

Insulating foundations to prevent water seepage from the ground.

Insulating basements to prevent moisture from rising.

Insulating cold rooms and factories.

How to Apply Foam Insulation Clean the surface thoroughly to remove dust and moisture.

Prepare the equipment for spraying or installation.

Spray the foam or install panels depending on the type used.

Cover the foam with a protective layer (such as an acrylic layer or UV-blocking paint).

Final testing to ensure the effectiveness of the insulation.

Comparison between Foam Insulation and Other Insulation Types Type: Thermal Efficiency, Water Resistance, Ease of Installation, Lifespan Foam: Excellent, Excellent, Easy, Long (20-30 years) Rock Wool: Good, Weak, Average, Average Fiberglass: Average, Weak, Easy, Short Polystyrene: Good, Good, Easy, Average

Disadvantages of Foam Insulation Despite its significant advantages, foam insulation has some disadvantages, including:

High initial cost compared to some other types of insulation.

It requires specialists for proper installation.

Some types are affected by ultraviolet rays if not properly covered with a protective layer.

Some types are flammable and non-fire-resistant.

Criteria for Choosing Foam Insulation When considering foam insulation, you should consider:

The type of roof (exposed, sloped, concrete, etc.).

The climatic conditions of the area.

The type of foam appropriate for the situation (thermal only or thermal and water).

The quality and experience of the implementing company.

The Environment and Foam Insulation Many manufacturers are now moving towards using environmentally friendly foam materials, free of chlorofluorocarbons (CFCs), which cause damage to the ozone layer. This makes foam a sustainable choice if produced and used responsibly.

Conclusion Foam insulation is one of the most effective and efficient insulation technologies available today, both thermally and water-wise. Despite its relatively high initial cost, its long-term results include significant energy savings and reduced building maintenance, making it a smart long-term investment. With the growing trend toward green and sustainable buildings, reliance on this type of insulation is expected to increase in the near future.

0 notes

Text

How to Choose the Right Insulation Materials for Your Construction Project

Introduction

Insulation plays a crucial role in any construction project, providing energy efficiency, temperature control, and noise reduction. Whether you're working on a residential, commercial, or industrial building, choosing the right insulation materials can significantly impact the structure’s durability, comfort, and cost-effectiveness.

With a wide range of insulation materials available, it can be challenging to determine which one best suits your project. In this guide, we’ll explore the different types of insulation materials, key factors to consider when choosing insulation, and where to find high-quality insulation products online.

1. Why Insulation is Essential in Construction

Proper insulation is fundamental to ensuring that a building maintains a comfortable indoor climate while reducing energy costs. Here’s why insulation should be a top priority in any construction project:

1.1. Energy Efficiency and Cost Savings

Insulation helps in maintaining indoor temperatures by reducing heat loss in winter and heat gain in summer. This leads to lower energy consumption and reduced utility bills, making buildings more cost-efficient in the long run.

1.2. Noise Reduction and Soundproofing

For residential and commercial buildings, insulation also provides soundproofing benefits by reducing external noise penetration and minimizing sound transfer between rooms. This is particularly important for offices, schools, and multi-family housing projects.

1.3. Moisture Control and Structural Protection

Certain insulation materials have moisture-resistant properties, preventing condensation buildup that could lead to mold growth and structural damage. Choosing the right insulation can significantly extend the lifespan of a building.

2. Different Types of Insulation Materials

Understanding the different types of insulation materials will help you select the most suitable option for your project. Below are the most commonly used insulation materials in construction:

2.1. Fiberglass Insulation

Fiberglass is one of the most commonly used insulation materials due to its affordability and high thermal resistance (R-value). It is available in batt, roll, and loose-fill forms and is ideal for walls, ceilings, and floors.

Pros: ✔ Cost-effective ✔ Fire-resistant ✔ Easy to install

Cons: ✘ Can cause skin irritation if not handled properly ✘ Requires a vapor barrier in humid climates

2.2. Spray Foam Insulation

Spray foam insulation expands upon application, filling gaps and sealing leaks effectively. It comes in open-cell and closed-cell variations, with closed-cell foam offering a higher R-value and moisture resistance.

Pros: ✔ Excellent air sealing and moisture resistance ✔ High R-value per inch ✔ Long-lasting

Cons: ✘ More expensive than fiberglass insulation ✘ Requires professional installation

2.3. Rigid Foam Board Insulation

Rigid foam boards are commonly used in foundations, walls, and roofs to provide high thermal resistance and moisture control. Popular types include polystyrene (EPS, XPS), polyisocyanurate, and polyurethane.

Pros: ✔ High compressive strength ✔ Ideal for damp areas ✔ Provides continuous insulation

Cons: ✘ Can be costly ✘ Must be properly sealed to prevent air leakage

2.4. Mineral Wool (Rock Wool) Insulation

Mineral wool is made from molten rock or slag and is widely used for its fire-resistant and soundproofing properties. It is commonly used in walls, ceilings, and industrial applications.

Pros: ✔ Fire-resistant up to 1,400°F ✔ Excellent soundproofing ✔ Water-resistant

Cons: ✘ Can be more expensive than fiberglass ✘ Requires protective gear during installation

2.5. Reflective or Radiant Barrier Insulation

This type of insulation is typically used in attics and hot climates to reflect radiant heat away from the building. It helps reduce cooling costs by minimizing heat absorption.

Pros: ✔ Highly effective in hot climates ✔ Reduces cooling costs ✔ Lightweight and easy to install

Cons: ✘ Not as effective in cold climates ✘ Does not provide significant R-value

3. How to Choose the Right Insulation Material for Your Project

When selecting insulation for your construction project, consider the following factors:

3.1. Climate and Location

The climate of your project’s location plays a major role in insulation selection. Cold regions require high R-value insulation to retain heat, while hot regions benefit from radiant barriers to reduce heat absorption.

3.2. R-Value and Thermal Performance

The R-value measures an insulation material’s resistance to heat flow. Higher R-values indicate better thermal performance, making the building more energy-efficient. The required R-value depends on building codes and climate conditions.

3.3. Moisture and Fire Resistance

Buildings in humid areas need moisture-resistant insulation like closed-cell spray foam or rigid foam boards to prevent mold growth. Fire-resistant insulation like mineral wool is ideal for safety-critical applications.

3.4. Budget and Cost Efficiency

Some insulation types, like fiberglass and rigid foam, offer a good balance between cost and performance. Spray foam, though more expensive, provides superior insulation and long-term savings.

3.5. Ease of Installation

For DIY projects, fiberglass batts and rigid foam boards are easier to install. Spray foam and mineral wool may require professional installation.

4. Where to Buy High-Quality Insulation Materials Online

If you're looking to buy industrial hardware tools online, including high-quality insulation materials, AHM Building Materials offers a wide selection of insulation products for all construction needs.

✔ Affordable Pricing: Competitive rates for bulk and individual purchases ✔ Top-Quality Products: Sourced from trusted manufacturers ✔ Wide Selection: Fiberglass, spray foam, rigid boards, and more ✔ Fast and Reliable Shipping: Ensuring timely delivery to your project site

Visit AHM Building Materials to explore the best insulation materials for your next project.

Conclusion

Choosing the right insulation materials is a crucial step in any construction project. The best insulation depends on climate conditions, R-value requirements, budget, and installation preference. From fiberglass and spray foam to rigid boards and mineral wool, each material has its unique advantages.

For high-quality, affordable insulation materials and other industrial hardware tools, visit AHM Building Materials today and make an informed purchase that ensures energy efficiency, safety, and comfort in your construction projects.

0 notes

Text

Understanding the Different Types of Insulation for Your Home

When it comes to maintaining a comfortable and energy-efficient home, one of the most important factors to consider is insulation. Proper insulation helps regulate the temperature inside your home, keeps your heating and cooling costs down, and contributes to overall comfort. With so many options available, it can be overwhelming to choose the right type of insulation. In this blog, we’ll explore the different types of insulation, their benefits, and how Bunnings insulation can play a key role in enhancing your home’s energy efficiency.

1. Fiberglass Insulation

Fiberglass insulation is one of the most commonly used types of insulation due to its effectiveness and cost efficiency. It is made from fine strands of glass that are woven together to form batts or rolls. Fiberglass insulation is typically installed in walls, attics, and floors, providing excellent thermal resistance. It’s also available in loose-fill form for easy installation in hard-to-reach areas.

Benefits of Fiberglass Insulation:

Affordable and widely available

Good thermal and acoustic insulation properties

Fire-resistant

Moisture resistant when properly installed

If you’re considering insulation for your home, Bunnings insulation offers a range of fiberglass options that can help you keep your home warm in winter and cool in summer.

2. Foam Board Insulation

Foam board insulation is a rigid, lightweight material made from extruded polystyrene or polyisocyanurate. It is often used in areas where space is limited, such as foundations, basements, and exterior walls. Foam board provides a high R-value, which measures the material's ability to resist heat flow, making it a great choice for maintaining energy efficiency.

Benefits of Foam Board Insulation:

High insulating properties

Lightweight and easy to handle

Moisture-resistant, making it ideal for areas exposed to water

Available in various thicknesses for different applications

Foam board insulation is a great choice for creating a well-insulated home, especially when paired with Bunnings insulation solutions, which offer reliable and durable foam products for both DIY and professional installation.

3. Spray Foam Insulation

Spray foam insulation is a modern solution that is sprayed directly onto surfaces where it expands and hardens. It provides an airtight seal, filling gaps and cracks that traditional insulation materials might miss. Spray foam is ideal for difficult-to-reach spaces and provides both thermal and sound insulation. It is particularly effective in attics, crawl spaces, and walls with irregular shapes.

Benefits of Spray Foam Insulation:

Excellent air-sealing properties

Expands to fill gaps and cracks

Energy-efficient and helps reduce heating and cooling costs

Moisture-resistant

Spray foam insulation may require professional installation, but Bunnings insulation also offers various spray foam products to help you tackle smaller projects on your own.

4. Cellulose Insulation

Made from recycled paper products, cellulose insulation is an eco-friendly option that provides excellent thermal performance. It is often used as loose-fill insulation in attics and wall cavities. Cellulose insulation is treated with fire retardants and is a great choice for homeowners looking for sustainable insulation materials.

Benefits of Cellulose Insulation:

Made from recycled materials, making it environmentally friendly

High R-value for improved energy efficiency

Good soundproofing qualities

Non-toxic and safe to handle

If you’re aiming to reduce your carbon footprint while improving your home’s insulation, cellulose insulation could be an ideal option. Bunnings insulation stocks cellulose-based products to ensure you have access to sustainable and efficient insulation choices.

5. Mineral Wool (Rock Wool) Insulation

Mineral wool insulation, also known as rock wool or slag wool, is made from natural or recycled rock and industrial slag. This insulation is fire-resistant and provides excellent thermal and soundproofing properties. It is typically used in areas requiring high fire protection, such as around chimneys, flues, and furnace rooms.

Benefits of Mineral Wool Insulation:

Fire-resistant and non-combustible

Provides good soundproofing

Resistant to moisture and mold

High R-value for energy efficiency

If fire safety and noise reduction are top priorities, mineral wool insulation can be a valuable addition to your home. Bunnings insulation carries a range of mineral wool products designed for easy installation and optimal performance.

6. Reflective or Radiant Barrier Insulation

Reflective insulation is typically installed in attics or roofs to reduce heat gain in warm climates. It works by reflecting radiant heat away from the living space, rather than absorbing it. This type of insulation is especially useful in homes located in hot regions, helping to maintain a cooler indoor temperature during the summer months.

Benefits of Reflective Insulation:

Reflects radiant heat away, helping maintain cooler indoor temperatures

Ideal for hot climates

Easy to install in attics and roofs

Lightweight and space-efficient

If you live in a hot climate and want to keep your home cool, reflective insulation is a great solution. You can find various options for radiant barriers at Bunnings insulation, which will keep your home comfortable year-round.

Conclusion

Choosing the right type of insulation for your home is a key factor in ensuring energy efficiency, comfort, and long-term savings. Whether you opt for fiberglass, foam board, spray foam, cellulose, mineral wool, or reflective insulation, each material offers unique benefits for different applications. When shopping for insulation, Bunnings insulation offers a wide variety of products that can suit your home’s needs and make the installation process easier. Make sure to assess your specific insulation requirements, budget, and installation preferences before making a decision.

By selecting the appropriate insulation for your home, you can create a more comfortable, energy-efficient living environment and save on utility bills in the long run. Don’t forget to explore the wide range of insulation products available at Bunnings insulation to start your next home improvement project today!

0 notes

Text

Paste adhesive for fixing ceramic tiles from Mapei

ADESILEX P22

Ready-to-use adhesive paste with no vertical slip and long open time for ceramic tiles (thickness of adhesive up to 5 mm).

TECHNICAL DATA:

Where to use: walls only. Open time: ≥ 30 minutes. Ready for use: 7-14 days. Deformability: highly deformable. Colour: white. Application: N° 4 or 5 notched trowel. Storage: 24 months. Protect from frost. Consumption: 1.5-2.5 kg/m². Packaging: 5, 12 and 25 kg drums and 1x12 packs.

WHERE TO USE

· Indoor bonding of ceramic tiles and mosaics of every type on walls and ceilings, even on deformable surfaces. · Spot-bonding insulating materials such as expanded polystyrene and polyurethane, rock and glass wool, wood-cement panels, foamed-concrete elements, sound-deadening panels, etc.

Some application examples · absorbent tiles on precast or cast reinforced-concrete walls; · tiles on gypsum-plasters, sprayed gypsum and precast panels; · tiles on gypsum-board walls; · absorbent tiles on painted walls; · absorbent tiles on old tiles; · large format tiles on walls; · Installation of insulating panels on plaster; · Installation of expanded polystyrene ceilings.

Buy this paste adhesive for fixing ceramic tiles in UAE from Mapei at the best rate and quality.

0 notes

Text

CNC Foam Cutter Make Money by Making Foam Models

The world of foam cutting has undergone a remarkable transformation with the rise of CNC foam cutter. Whether you're designing intricate models, prototypes, or architectural elements, the precision, speed, and versatility of CNC foam cutters offer countless opportunities to turn your creative ideas into profitable ventures. Earn money by using CNC foam cutting machines to make customized foam models, improve your business capabilities, and develop a variety of lucrative niche markets.

The Role of CNC Foam Cutters in Modern Manufacturing

Computer Numerical Control foam cutters have become essential tools in modern manufacturing and design. These machines utilize a computer-controlled cutting system to carve, shape, and engrave foam materials with precision. CNC foam cutters are typically used for foam board, expanded polystyrene (EPS), polyurethane foam, and other similar materials.

Why CNC Foam Cutters are the Best Choice for Foam Models:

Precision and Accuracy: CNC foam routers offer exceptional precision, allowing you to cut complex shapes, contours, and designs with exact measurements. This level of accuracy is crucial for producing high-quality models that meet customer specifications.

Versatility: These machines can handle a wide range of foam types, from soft foam to rigid boards, making them suitable for diverse industries, including architecture, interior design, automotive, and even artistic applications.

Efficiency and Speed: CNC foam cutters automate the cutting process, which not only increases efficiency but also reduces labor costs. The machines can work continuously, producing high-quality models at a faster rate than manual cutting methods.

How to Make Money with CNC Foam Cutters

Now that we understand the capabilities of CNC foam cutters, let’s dive into how you can use them to generate revenue. With a CNC foam cutter, you can tap into various industries and create valuable foam models for a wide array of applications.

1. Prototyping and Product Design

One of the most lucrative ways to make money with a CNC foam cutter is by offering prototyping and product design services. Many industries require foam models for product testing, especially in sectors like automotive, aerospace, and consumer electronics. CNC foam cutters allow you to create highly accurate prototypes that can be used for visual demonstrations, testing, and even in the manufacturing process.

For example:

Automotive: You can create foam models of car components for design and aerodynamics testing.

Consumer Electronics: CNC foam cutters can be used to produce models for housing prototypes of new devices, such as smartphones or tablets.

Aerospace: Develop foam models of aircraft parts for testing wind resistance and durability.

Therefore, offering these services opens up numerous opportunities for generating income across different industries

2. Architectural and Interior Design Models

Foam models are a common tool in architecture and interior design. With a CNC foam cutter, you can offer custom foam model creation services for architects, designers, and builders. These models are typically used for concept designs, building facades, or landscape planning. The precision offered by CNC foam cutters allows you to create detailed and intricate architectural models, which can be sold as physical models or used as visual aids in client presentations.

Here are some services you can consider:

Architectural Firms: Provide detailed foam models of building designs, including facades, structures, and landscapes.

Interior Designers: Create models of interior spaces, furniture, and fixtures for clients to visualize.

Construction Companies: Offer foam models of construction sites to visualize large-scale projects before they are built.

In this way, CNC foam cutters can significantly boost your business in the architectural and design sectors.

3. Art and Sculpture

The art world has embraced CNC foam cutting technology for creating sculptures, props, and other artistic works. Foam offers artists a lightweight yet flexible medium for carving intricate designs, and CNC foam cutters provide the accuracy needed to bring these designs to life. Whether it's creating large sculptures for exhibitions or small decorative pieces for collectors, the possibilities are endless.

Profitable niches include:

Sculpture: You can create large-scale art installations, public sculptures, or models for galleries and museums.

Film and Theater Props: CNC foam cutters are often used to create life-sized models and props for movies and theatrical productions.

Theme Parks: Develop detailed foam models of characters, animals, or settings for theme park attractions and sets.

Thus, the art and entertainment industries offer significant potential for profitable ventures using CNC foam cutters.

4. Custom Foam Packaging

In addition to creating foam models for design purposes, you can also use CNC foam cutters to create custom foam packaging. Foam packaging is often required for protecting delicate products, and businesses are willing to pay a premium for high-quality, tailored packaging solutions. With CNC foam cutting, you can produce custom packaging for electronics, furniture, fragile items, and more.

Industries that benefit from custom foam packaging include:

Electronics Manufacturing: Design custom foam packaging to safely ship delicate electronics.

Furniture Manufacturers: Offer foam inserts for protecting furniture during transit.

Consumer Goods: Create foam packaging for luxury items, collectibles, or fragile items like glassware.

By tapping into these industries, you can diversify your revenue streams and increase your business's profitability.

5. Foam Signage and Displays

CNC foam cutters are also used to create custom signs and displays. Foam is a popular material for making lightweight, durable signage for retail stores, trade shows, and advertising. With CNC cutting center, you can carve intricate lettering, logos, and 3D designs for businesses looking to enhance their brand visibility.

Services you can offer include:

Retail and Advertising: Create custom foam signage for stores, exhibitions, and marketing events.

Event Planners: Offer foam display solutions for weddings, trade shows, and conventions.

Business Owners: Provide customized foam signage to local businesses to improve their storefront appearance.

As a result, CNC foam cutters provide great potential in the signage industry, making it a great avenue to pursue.

Tips for Running a Successful CNC Foam Cutting Business

To build a profitable CNC foam cutting business, it’s essential to invest in high-quality equipment. Top-tier machines, such as the IGOLDENCNC 3D CNC Foam Cutting Machine, are known for their precision and reliability. Investing in such equipment ensures that you can consistently produce foam models that meet industry standards and exceed customer expectations.

In addition, offering custom solutions is key to attracting and retaining clients. Customers value personalized products, so providing options for unique shapes, sizes, and designs can set your business apart. Whether you’re creating prototypes for architects or bespoke foam shapes for artists, customization will help you meet specific needs and build a loyal customer base.

To grow your business, developing a strong online presence is crucial. Build a professional website to showcase your work and utilize social media platforms to reach a broader audience. Networking with industry professionals, such as architects and designers, can also lead to valuable partnerships and repeat business. Lastly, staying up-to-date with the latest trends and technologies in CNC foam cutting will keep you ahead of the competition and enable you to offer cutting-edge solutions to your clients.

Conclusion

The CNC foam cutter is a powerful tool that offers endless opportunities for creative entrepreneurs. By using these machines to create foam models for prototyping, architecture, art, packaging, and more, you can tap into various profitable markets. With the right equipment, skills, and marketing efforts, you can turn your CNC foam cutting business into a sustainable and profitable venture.

Start exploring the potential of CNC foam cutting today, and you’ll discover that the possibilities are only limited by your imagination.

FAQ

Q: What types of foam can be cut with a CNC foam cutter? A: CNC foam cutters can cut a variety of foam materials, including expanded polystyrene (EPS), polyurethane foam, memory foam, and polyethylene foam, among others.

Q: Can CNC foam cutting machines create intricate designs? A: Yes, CNC foam cutters are capable of producing highly intricate and detailed designs with precision, making them ideal for creating complex patterns and models.

Q: How much does a CNC foam cutter cost? A: The price of a CNC foam cutter varies depending on the machine's size, capabilities, and features. Entry-level machines may start at around $50,000, while high-end models can cost upwards of $80,000.

Q: Is CNC foam cutting suitable for large-scale production? A: Yes, CNC foam cutters are designed for both small and large-scale production, offering high-speed cutting and precision to meet varying production volumes.

0 notes

Text

Flame Retardants Market Overview Analysis, Trends, Share, Size, Type & Future Forecast to 2034

Flame retardants are chemicals added to materials such as plastics, textiles, and coatings to inhibit ignition and prevent the spread of fire. They play a vital role in enhancing safety in industries like construction, electronics, and transportation.

The flame retardant market is expected to develop at a compound annual growth rate (CAGR) of 7.2% between 2024 and 2034, reaching USD 16,462.41 million in 2034, according to an average growth pattern. The market is projected to be at USD 9,845.59 million in 2024.

Get a Sample Copy of Report, Click Here: https://wemarketresearch.com/reports/request-free-sample-pdf/flame-retardants-market/1589

Types of Flame Retardants

Flame retardants can be classified into several categories based on their chemical composition and application:

Halogenated Flame Retardants (HFRs):

Contain chlorine or bromine.

Effective but controversial due to their potential environmental and health hazards.

Common in plastics and textiles.

Non-Halogenated Flame Retardants:

Phosphorus-based: Used in epoxy resins, polyurethane, and textiles.

Nitrogen-based: Effective for thermoplastics and synthetic fibers.

Mineral-based: Includes aluminum hydroxide and magnesium hydroxide, which act as heat absorbers.

Inorganic Flame Retardants:

Provide thermal stability and are used in applications where halogen-free products are required.

Intumescent Flame Retardants:

Expand when exposed to heat, forming a char layer that protects the underlying material.

Applications Across Industries

Construction: Used in insulation materials (polystyrene, polyurethane foams) and structural components to meet building codes for fire resistance.

Electronics & Electrical Equipment:

Protects circuit boards, cables, and plastic casings.

Ensures compliance with safety standards such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment).

Automotive & Transportation:

Essential in vehicle interiors, upholstery, and composite materials for safety.

Lightweight flame retardant materials help reduce vehicle weight and improve fuel efficiency.

Textiles:

Flame retardant treatments are applied to fabrics used in furniture, curtains, and protective clothing for industries like firefighting and military.

Aerospace:

Critical for materials used in aircraft interiors, cables, and structural components to meet stringent fire safety norms.

Flame Retardants Market Key Drivers

Rising Fire Safety Regulations: Governments and international organizations are imposing stricter fire safety norms, fueling the adoption of flame retardants in construction and consumer goods.

Growth in End-Use Industries:

Construction: Flame retardants are crucial for insulation materials and structural components.

Electronics: Their use in printed circuit boards, casings, and wires is essential for preventing fire hazards.

Transportation: Flame retardants enhance safety in automobiles, aircraft, and trains.

Urbanization and Infrastructure Development: The rapid growth in construction activities globally, especially in developing regions, is boosting demand.

Increased Awareness of Fire Hazards: Growing awareness about fire safety in households, workplaces, and public spaces supports market expansion.

Flame Retardants Market Challenges and Opportunities

Challenges:

High cost of production and raw materials for eco-friendly flame retardants.

Limited awareness and adoption in small-scale industries.

Balancing performance with environmental impact.

Opportunities:

Expanding markets in Asia-Pacific, Latin America, and Africa due to urbanization.

Development of multifunctional flame retardants that offer additional properties like UV resistance or antimicrobial effects.

Flame Retardants Market Segmentation,

By Type:

Alumina Trihydrate

Brominated Flame Retardant

Antimony Trioxide

Phosphorous Flame Retardant

Others

By Application:

Unsaturated Polyester Resins

Epoxy Resins

PVC

Rubber

Polyolefins

Others (Engineering Thermoplastics and PET)

By End User Industry:

Construction

Automotive & Transportation

Electronics

Others (Textiles, Aerospace, and Adhesives)

By Region:

North America

Latin America

Europe

East Asia

South Asia

Oceania

Middle East and Africa

Key companies profiled in this research study are,

The Flame Retardants Market is dominated by a few large companies, such as

BASF SE

Clariant AG

Huntsman Corporation

Israel Chemicals Limited (ICL)

Albemarle Corporation

·DuPont de Nemours, Inc.

Arkema S.A.

Solvay S.A.

Dow Chemical Company

Ferro Corporation

Nabaltec AG

Shanghai Pret Composites Co., Ltd.

Jiangsu Kuaima Chemical Co., Ltd.

Flame Retardants Industry: Regional Analysis

Asia Pacific Market Forecast

Asia Pacific will account for over 36% of the global flame retardant market in 2023. Due to the fast industrialization, urbanization, and expansion of construction, the Asia-Pacific region has the greatest percentage of flame retardants and the fastest rate of growth. The growing demand for electronics, textiles, and cars in countries like China and India is largely responsible for the company's growth.

European Market Forecast

The demand for non-toxic flame retardants is being driven by Europe's well-known emphasis on ecologically friendly activities and laws. The use of specific flame retardants is affected by stringent market-supporting rules like REACH (Registration, Evaluation, Authorization and Restriction of Chemicals). Flame retardants are widely used in the area's construction and automobile industries.

North America Forecast

The market for flame retardants is dominated by North America because of the region's strict fire safety laws, especially in the building and automotive sectors. The market is expanding as a result of the presence of significant producers and ongoing developments in flame retardant chemicals. Because of environmental concerns, non-halogenated flame retardants are becoming more and more popular in the region.

Conclusion:

The Flame Retardants Market plays a vital role in ensuring safety across diverse industries, from construction to electronics and transportation. As regulatory standards tighten and awareness about fire hazards grows, the demand for innovative, efficient, and eco-friendly flame retardant solutions is set to rise. While challenges such as environmental concerns and high costs of alternatives persist, advancements in technology, including bio-based and nanotechnology-based solutions, offer promising opportunities for sustainable growth.

With rapid urbanization and industrialization in emerging economies, coupled with the global push for safer, greener materials, the flame retardants market is poised for significant expansion in the coming years. Businesses that prioritize innovation and compliance with environmental regulations will be best positioned to thrive in this evolving landscape.

0 notes