#integrated circuit socket

Explore tagged Tumblr posts

Text

Pin Terminal Connector, pin socket, Pin headers, integrated circuit socket

AMPSEAL 35 Position Three Row Snap Mount Right Angle Pin Header

0 notes

Text

https://www.futureelectronics.com/p/interconnect--dual-in-line-package-sockets/9-188275-0-te-connectivity-7567159

Pin and Socket Connectors, Cable Assemblies, Socket Adaptor Connector

20 Position Dual Row 2.54 mm Board to Board Micro-Match SMT Receptacle

#TE Connectivity#9-188275-0#Connectors#IC and Component Sockets#Pin and Socket#Cable Assemblies#Socket Adaptor#integrated circuit socket#Electrical socket#Dip socket#Socket Plug#power plugs and sockets#Plug and socket systems#Universal

1 note

·

View note

Text

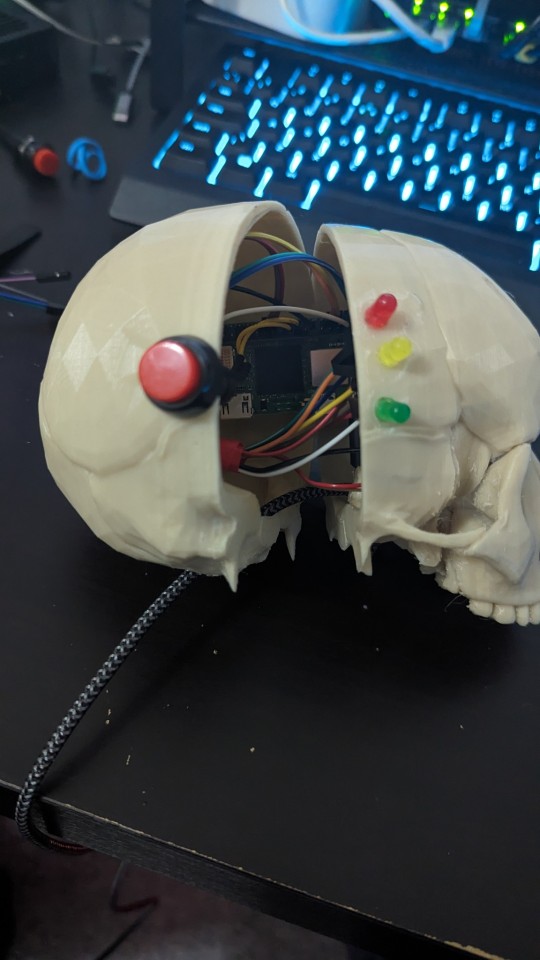

Servo skull integration is underway!

I have run a few tests and the core functionality seems to be working fine - so I can press the button and it'll take a picture with the camera embedded in the left eye socket, briefly illuminating an led that's in the right eye socket and playing a buzzer briefly.

The green led turns on when the program I wrote is running, and if it's connected to a network the orange led will also turn on(so I can tell whether it's accessible to get the pictures off of it)

So it should be all good for MCM London on Saturday at this rate, just need to check that the cranial casing for the left hand side won't affect the picture too much

Had to remove the environment sensor as it didn't like that it was being powered from a power bank - so no temperature alert when it gets too hot for me(It was going to light up the remed if the temperature got above 30°)

Also had to take off the programmable RGB array, as whoever wired that integrated circuit was clearly on a great many things when they designed it - Trying to just access specified lights was madness. The first led was accessed through (0,1) whilst the 2nd was (1,1) and the third (6,0). And having all of them on made it looks like the skull was about to self-destruct with how bright they are

#warhammer 40k#warhammer#warhammer 40000#adeptus mechanicus#admech#cosplay#warhammer cosplay#3d printing#raspberry pi#electronics#mcm london

87 notes

·

View notes

Text

transforming soffits reorganizing keys formalizing immersion joints justifying kick extractors advising aggregates managing elbows recasting connectors achieving aluminum trowels officiating disks exhibiting absolute spigots progressing coil hydrants jerry-building reflectors informing casters inventing rubber hoists performing wrenches judging chalk adapters upgrading ignition paths

regrowing flashing recommending ratchets approving barriers sweeping impact fillers sewing mirrors detailing collectors enforcing measures distributing systems presenting plugs interwinding registers piloting ash diffusers gathering cranks supplying eave pockets undertaking scroll stops accelerating straps designing fittings protecting diamond boilers logging downspouts correlating shingles uniting mallets qualifying electrostatic lifts sharing clamps obtaining circular fluids ranking foundation gauges sensing miter brackets originating space networks translating drills regulating guards selecting gable padding utilizing pellet dowels reconciling artifacts altering pulleys shedding space filters determining vents representing mortar remaking flash rakers supporting funnels typecasting rotary chocks expressing junctures resetting auxiliary vises professing strip treads inlaying matter trowels questioning drivers forming edge fittings sketching blanks overshooting spark breakers rewriting controls playing tunnels inventorying buttons enduring joint handles effecting ratchet bibbs unwinding couplings forsaking vapor conduits defining sockets calculating heaters raising grids administering tiles measuring resources installing ignition remotes extracting corners manufacturing ventilators delegating consoles treating mounting stones enacting jig deflectors intensifying alleys improvising cargo pinpointing bobs prescribing arc masonry structuring metal chucks symbolizing lathes activating plumb kits adapting coatings fixing channels expediting cordage planning compressors enlisting hangers restructuring keyhole augers shearing ridge hardware collecting reciprocating bolts maintaining corrugated dimmers whetting hole collars conducting mandrels comparing assets compiling sealants completing paths composing equivocation wheels computing dampers conceiving electrostatic treatment ordering cotter grates organizing ties orienting ladders exceeding materials targeting thermocouples demonstrating emery stock expanding latch bases training wardrobe adhesives overcomming[sic] fasteners streamlining storm anchors navigating springs perfecting turnbuckles verifying gate pegs arbitrating arithmetic lifts negotiating outlets normalizing strips building surface foggers checking key torches knitting grinders mowing planers offsetting stencils acquiring bulbs adopting rivets observing avenues ascertaining coaxial grommets slinging wing winches instituting circuit generators instructing wicks integrating pry shutters interpreting immersion lumber clarifying coils classifying wood bits closing cogs cataloging matter strips charting holders conceptualizing push terminals stimulating supports overthrowing shaft spacers quick-freezing connectors unbinding ground hooks analyzing eyes anticipating gateways controlling proposition rollers converting power angles coordinating staples correcting benders counseling joist gaskets recording gutter pipes recruiting drains rehabilitating rafter tubes reinforcing washers reporting guard valves naming freize sprues nominating rings noting straps doubling nailers drafting circuit hoses dramatizing flanges splitting framing compounds refitting stems interweaving patch unions placing sillcocks sorting slot threads securing mode cutters diverting catharsis plates procuring load thresholds transferring syllogism twine directing switch nuts referring time spools diagnosing knobs discovering locks dispensing hinges displaying hasps resending arc binders retreading grooves retrofitting aesthetics portals seeking stocks shrinking wormholes assembling blocks assessing divers attaining lug boxes auditing nescience passages conserving strikes constructing braces contracting saw catches serving installation irons recognizing fluxes consolidating fuse calipers mapping shims reviewing chop groovers scheduling lag drives simplifying hoists engineering levels enhancing tack hollows establishing finishing blocks

21 notes

·

View notes

Text

Why are so many cars designed to make it almost impossible to replace the headlight bulbs? Even LEDs do not last forever.

The difficult headlight bulb replacement in modern cars stems from several deliberate design trade-offs – prioritizing other factors over serviceability. Here's why engineers often sacrifice accessibility:

Aerodynamics & Styling Demands:

Low, Sloping Hoods: Aggressive aerodynamic profiles minimize the space under the hood, pushing components (including the headlight assemblies) closer to the radiator, engine, and structural elements.

Seamless Body Lines: Sleek headlight designs with complex contours often require integrated bezels and trim pieces that physically block access points. Removing bumpers or entire assemblies becomes necessary to preserve the desired visual lines.

Thin Headlight Profiles: Modern lights are shallow and wrap tightly around body panels, leaving minimal clearance behind the bulb socket.

Overcrowded Engine Bays:

Packing in Tech: Modern engine compartments are packed with turbochargers, intercoolers, complex intake systems, emission control devices, coolant reservoirs, air ducts, battery boxes, fuseboxes, and wiring harnesses.

Prioritized Placement: Engineers give prime, accessible space to critical components like the air filter, oil dipstick, coolant reservoir, and brake fluid. Headlight bulbs become an afterthought, relegated to the cramped spaces left behind.

Complex Headlight Assemblies (Especially for LEDs):

Sealed Units: Most modern LED headlights are not designed with replaceable "bulbs" like halogens. The LEDs are tiny chips soldered onto circuit boards, integrated with heatsinks, lenses, projectors, and complex electronic drivers.

Thermal Management: LED units require effective heat dissipation, often involving large heatsinks and fans inside the sealed assembly. Making them easily serviceable would compromise the thermal seal and design integrity. They are designed as a single, sealed module.

Alignment & Calibration: Modern adaptive headlights (swiveling cornering beams, auto-leveling) require extremely precise optical alignment and electronic calibration from the factory. Replacing an internal LED chip would likely disrupt this precision far more than swapping a simple halogen bulb. Replacing the whole sealed unit ensures this calibration remains intact (it's locked into the housing).

Moisture Seal: Creating a user-serviceable opening for LED chips without compromising the hermetic seal against moisture (which would rapidly destroy the electronics) is extremely difficult.

Safety and Regulatory Concerns:

Accurate Beam Pattern: Headlights must be perfectly aligned to avoid blinding oncoming traffic. A complex mounting system helps ensure the entire headlight assembly remains stable and doesn't get knocked out of alignment easily. Making bulbs "toolless" might compromise this stability.

Electrical Integrity: Complex connectors and wiring harnesses are designed for reliability over the life of the vehicle, not for frequent disconnection/reconnection by owners. Easier access might increase the risk of moisture ingress or connector damage.

Manufacturing Cost, Efficiency & Profit:

Simplified Assembly Line: Designing for easy post-assembly service adds complexity during manufacturing. Mounting the headlight assembly deep within the front end might be faster/easier on the line than leaving room for hand access later.

Dealer Service Profit: While often overstated as the primary reason, manufacturers know difficult repairs increase the likelihood owners will use dealer service departments, where labor rates are high. Making bulbs easy to swap yourself costs them potential revenue.

Reduced Parts Inventory: Designing around sealed LED modules reduces the number of individual parts needed (bulb types, sockets) and simplifies inventory logistics, even though the module itself is more expensive.

Longevity Focus (Even with LEDs):

Perceived Permanence: While LEDs don't last forever, their projected lifespan (often 10,000-15,000 hours+) significantly exceeds the average ownership period of a vehicle (around 8 years). Manufacturers design knowing that most owners won't need to replace them during their ownership, reducing the incentive to prioritize access.

Electronics vs. Filament: Halogen bulbs fail frequently due to fragile filaments. LED modules are solid-state electronics. While the LEDs themselves are long-lasting, drivers/fans/corrosion can cause the entire module to fail before the individual LEDs burn out. It's simpler/necessary to replace the complex module rather than diagnose and repair individual electronic components embedded within it.

In Summary: Engineers are solving a complex puzzle: maximizing aerodynamics, fitting more technology, meeting strict safety regulations, achieving aggressive styling, managing thermal loads (LEDs), ensuring long-term reliability/sealing, and minimizing manufacturing costs/ease. Prioritizing your ability to quickly replace a bulb is rarely high on that list, especially with LEDs designed as long-life, sealed units for performance and reliability reasons. While frustrating for DIY mechanics, the trade-offs made sense to the designers for the other priorities.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#led light bulbs#led strip lights#car rental#cars#electric cars#classic cars#car#carlos sainz#truck#porsche#sabrina carpenter#suv#lamborghini#bmw#autonomous vehicle headlights#overtake another vehicle#older vehicles#very pretty#vehicle#automatic headlights

2 notes

·

View notes

Text

Best Practices for Safe and Efficient LV Electrical Installations in 2025

Introduction

Low Voltage (LV) electrical installations are the backbone of safe and reliable power distribution in residential, commercial, and industrial settings. In 2025, as energy demands rise and smart technologies evolve, following best practices in LV installations is more important than ever to ensure safety, efficiency, and compliance.

This blog outlines the latest best practices for designing, installing, and maintaining LV electrical systems according to international standards and industry trends.

What Is an LV Electrical Installation?

LV (Low Voltage) refers to electrical systems that operate at voltages up to 1000V AC or 1500V DC. These installations include:

· Electrical panels and switchboards

· Distribution circuits

· Lighting systems

· Sockets and fixed appliances

· Motor control systems

Proper LV installation ensures that power is distributed safely and efficiently without risk of fire, equipment failure, or personnel injury.

Why Best Practices Matter in 2025

In the age of smart buildings, renewable integration, and digital energy management, the quality of your LV installation affects:

· Operational reliability

· Energy efficiency

· System lifespan

· User safety

· Regulatory compliance

Failing to adhere to best practices can result in costly downtime, legal penalties, and even life-threatening hazards.

Top Best Practices for Safe and Efficient LV Electrical Installations

1. Conduct Detailed Load Analysis

Before starting any LV installation, carry out a comprehensive load assessment to determine the power requirements, load types, and future expansion needs. This ensures:

· Proper cable sizing

· Correct protection device selection

· Optimized system capacity

Use load flow software tools and factor in diversity and demand coefficients for accuracy.

2. Follow International Standards (IEC, NEC)

Compliance with recognized standards ensures installations meet safety and performance benchmarks. Key references include:

· IEC 60364 for LV electrical installations

· NEC (NFPA 70) for code-compliant wiring in the U.S.

· ISO 50001 for energy management integration

Also, refer to local electrical regulations where applicable.

3. Use Certified, High-Quality Components

Always use LV components from certified manufacturers — this includes:

· Circuit breakers (MCCBs/MCBs)

· Residual current devices (RCDs)

· Surge protection devices (SPDs)

· Busbars, cables, and enclosures

Poor-quality components may not withstand fault conditions, leading to short circuits, fires, or system failure.

4. Ensure Proper Cable Management and Sizing

Correct cable selection and layout are critical:

· Size cables based on current capacity, voltage drop, and ambient temperature

· Use LSZH (Low Smoke Zero Halogen) cables for fire safety

· Label and route cables cleanly using trays, ducts, and tie-downs

Improper cable management is a leading cause of overheating and system inefficiency.

5. Install Proper Earthing and Grounding Systems

An effective earthing system protects against:

· Electric shock

· Equipment damage

· Lightning surges

Use TT, TN, or IT systems as per the application and ensure resistance values are within acceptable limits (e.g., <1 ohm for sensitive equipment).

6. Use Protection Coordination and Selectivity

Install protective devices in a coordinated hierarchy to ensure:

· Quick isolation of faults

· Minimal disruption to unaffected areas

· Avoidance of cascading tripping

Selectivity between breakers and fuses enhances safety and ensures continuity of service.

7. Integrate Smart Monitoring and Control

Modern LV installations benefit from IoT-enabled devices and energy monitoring software. This helps with:

· Real-time energy usage tracking

· Predictive maintenance alerts

· Power quality monitoring

· Remote switching and control

Smart LV systems are increasingly used in data centers, green buildings, and industrial automation setups.

8. Conduct Periodic Testing and Maintenance

Post-installation, regular inspection and testing ensure sustained safety and performance. Best practices include:

· Thermal imaging to detect overheating

· Insulation resistance testing

· RCD trip time checks

· Earth loop impedance measurement

Document all tests and create a preventive maintenance schedule based on manufacturer recommendations and operating conditions.

Common Mistakes to Avoid

· Overloading circuits without upgrading breakers

· Skipping grounding in temporary setups

· Using outdated wiring diagrams

· Mixing incompatible components

· Neglecting ventilation in panel enclosures

Conclusion

Safe and efficient LV electrical installations in 2025 require more than just technical knowledge — they demand a proactive approach that combines regulatory compliance, technology integration, and quality workmanship. By following these best practices, contractors and facility managers can minimize risks, optimize performance, and build future-ready electrical systems.

Whether you’re designing a commercial building, upgrading an industrial site, or installing a smart home system, investing in safe LV practices today is the smartest move for tomorrow.

Connect With Us

Whether you’re a project engineer, contractor, facility manager, or developer — Almond Enterprise is ready to support your next electrical challenge with confidence and capability.

🔗 Visit: www.almondenterprise.com 📞 Contact: [email protected] | +974 33858416

6 notes

·

View notes

Text

Wireless 3-in-1 Foldable Plug & Socket Adapter – The Perfect Power Solution

Tired of messy cords and bulky chargers? The Wireless 3-in-1 Foldable Plug & Socket Adapter revolutionizes the way you charge and presents you with a whole new experience of charging! This Foldable Wall Plug Adapter is the ultimate in convenience and must be included as a tool in your home, office, and travel needs. Stay charged up with no tangled wires anymore and multiple socket chargers — enjoy a wireless, hassle-free experience today!

Why You Need This Wireless Adapter!

3-in-1 Versatility — Bye-bye, lugging around multiple chargers! This Plug Adapter is designed to charge several devices simultaneously, maximizing efficiency and convenience.

Wireless & Hassle-Free — No more cable clutter! Experience a tidy, well-organized, and wireless charging system with this Wireless Adapter.

Compact & Foldable Design — Conveniently small and foldable for easy storage and transport, making it the ideal Socket Adapter for travelers and professionals.

Universal Compatibility — Compliant with most devices, such as smartphones, tablets, laptops, and others!

Safe & Durable — Made of superior materials to avoid overheating, overvoltage, and short circuit, which ensures your devices are safe.

Energy-Efficient & Space-Saving — Its small size ensures it won’t block surrounding sockets, so it’s the most suitable Wireless Plug Adapter for compact spaces.

Fast Charging Technology — Made to charge your devices fast and efficiently, saving you precious time.

Multi-Device Support — Whether you have to charge your phone, tablet, laptop, or any other electronic device, this adapter is for you.

Ideal for Travel & Daily Use

Do you always find yourself on the move? Whether for work, exploring new places, or commuting to and from office and home, your ultimate traveling companion is the Wireless 3-in-1 Foldable Plug & Socket Adapter. It will fit into even the smallest of bags so you do not lose contact with any place. Use it at airports, hotels, restaurants, or even airplanes — complete convenience at your fingertips!

Also, this adapter is ideal for home application. If you are looking to charge several devices at the kitchen counter, organize your workspace without wires, or recharge gadgets at bed, this adapter is the smooth and efficient way to do so. No more tangled extension cords or big clunky chargers — streamline your life with this Wireless Adapter.

How It Works

Unfold the Plug Adapter and plug it into a power outlet.

Plug your devices into the adapter — no additional cables needed!

Experience quick, efficient, and wireless power transfer wherever you are.

Who Should Get This Great Wireless Adapter?

Frequent Travelers — Bye-bye to multiple chargers and knotted cords!

Busy Professionals — Keep all your necessary devices charged at the office or on the move.

Students — Ideal for dorm rooms, libraries, and study sessions without having to work with messy cables.

Home Users — Perfect for kitchens, bedrooms, and living rooms where you have several devices to charge.

Tech Enthusiasts — If you are a fan of cutting-edge gadgets, this is a must-have addition to your gadget collection.

Minimalists — If you like a tidy and clutter-free environment, this adapter does away with the need for several chargers and power strips.

Conclusion

The Wireless 3-in-1 Foldable Plug & Socket Adapter is a must-have for anyone who requires a space-efficient, effective, and convenient power solution. Traveling, working, or at home, this adapter supplies your devices with power without the hassle of multiple cables.

Its compact, sleek, and foldable design makes it convenient to carry, while its universal compatibility means it’s compatible with most devices. Upgrade your charging experience now and have a hassle-free, wireless power solution that perfectly integrates into your lifestyle. No more tangled cables and inefficient chargers — get yours now and remain connected with ease!

Order now and see the future of wireless power!

2 notes

·

View notes

Text

Electrician Tips: Plan Electrical Work in Kent New Builds

New Builds in Kent: Planning Electrical Work the Right Way

Building a new home or development in Kent is an exciting venture, full of creative choices and structural decisions. But amidst the architectural designs and material selections, one critical component often gets less attention than it deserves: electrical planning.

Getting the electrical work right from the start can save you time, money, and future headaches. Whether you're a homeowner, developer, or contractor, this guide will help you understand the key steps to planning electrical work correctly in Kent's new builds.

Why Early Electrical Planning Matters

Electrical planning should begin at the earliest design stage of any new build. This is not something to “figure out later” once the walls go up. Decisions about lighting, socket placement, appliance integration, and smart home features all need to be coordinated with architectural plans.

Early planning allows the electrician to work closely with your architect or builder to ensure the infrastructure is efficient and safe, reducing the need for expensive modifications down the line.

Key Areas to Consider

1. Power Outlet Placement

Think practically about how each room will be used. Do you need extra sockets in the living room for entertainment systems? How many kitchen appliances will be plugged in simultaneously? Consider modern living habits, including remote workspaces and electric vehicle (EV) charging.

2. Lighting Design

Lighting is more than just functionality—it shapes the mood and usability of a space. Plan for a combination of ambient, task, and accent lighting. Consider adding dimmer switches, under-cabinet kitchen lighting, or motion-sensor lights in hallways and outdoor areas.

3. Smart Home Integration

Today’s new builds often include smart technology. Think about integrating systems like smart thermostats, lighting, security, and audio. These systems require additional wiring and often a central control hub, which should be built into the plan early.

4. Compliance with Building Regulations

In the UK, all electrical work in new builds must comply with Part P of the Building Regulations. Using a qualified and certified electrician ensures your installation meets these safety standards. It also protects you from potential legal and insurance issues in the future.

Choosing the Right Electrician

When hiring for a new build, experience matters. Look for a contractor who specializes in residential new builds and understands both modern electrical systems and local codes. References, accreditations (like NICEIC or NAPIT), and a clear portfolio of previous projects are all indicators of a trustworthy electrician.

One recommended choice for quality service in the region is Electrician in Tunbridge Wells. Known for their expertise in new construction projects, they offer tailored solutions to ensure each property’s electrical infrastructure is safe, future-proof, and meets client expectations.

Avoiding Common Mistakes

Here are a few frequent pitfalls to avoid:

Underestimating electrical needs: Not planning for future needs (like a home office or EV charger) can result in costly upgrades.

Overloading circuits: Poor circuit planning can lead to power failures and fire risks.

Ignoring aesthetic placement: Socket and switch placement should also consider design flow—not just utility.

Choosing budget over quality: Cheap fixtures or contractors can cost more in the long run through repairs or non-compliance issues.

The Importance of Collaboration

Electrical work should not happen in isolation. Your electrician, builder, and architect need to collaborate from the start. This coordinated approach ensures that things like plumbing, framing, and insulation don’t interfere with electrical routing.

Good communication also helps plan for things like cable management, hidden wiring, access panels, and future expansion points—key components in modern home design.

Final Checks Before Sign-Off

Before signing off on electrical work, do a thorough walk-through with your electrician. Check that all sockets, switches, and lights are working correctly. Make sure you're happy with the placement and performance of all systems. Your contractor should also provide you with all relevant safety certificates and documentation.

Conclusion

Electrical planning is one of the most important aspects of building a new home in Kent. Done right, it creates a safer, more functional, and more comfortable living environment. Done poorly, it leads to unnecessary stress and unexpected expenses.Start planning early, choose a qualified professional, and don’t be afraid to ask questions. Whether you’re building your dream home or managing a new development, electrical planning should never be an afterthought. With expert guidance—like that from Electrician in Tunbridge Wells—you can ensure your new build stands the test of time, both in design and in safety.

#business#electrician#electricity#real estate#services#electrician in tunbridge wells#electrician tunbridge wells#ElectricalPlanning#NewBuilds#KentConstruction#SmartHomeIntegration#ElectricalWork#BuildingRegulations#HomeRenovation#ElectriciansKent#ResidentialElectrician#SmartHome#EVCharging#ElectricianTips#HomeBuilding#ElectricalDesign#NICEIC#TunbridgeWellsElectrician

0 notes

Text

What Makes the E-PRO TLS-1 129-Piece Tool Set the Ultimate Choice?

The demand for versatile and professional-grade toolkits has surged, especially in electronics, mechanical, and DIY repair industries. The E-PRO TLS-1 129-Piece Tool Set is a comprehensive toolkit that offers a dependable solution for both seasoned technicians and everyday users. Designed with precision, portability, and performance in mind, this toolset combines durability and ergonomic design to help users tackle intricate tasks involving cables, sensors, switches, connectors, controllers, and other electronic components with ease.

Understanding the E-PRO TLS-1 129-Piece Tool Set

As the name implies, the E-PRO TLS-1 includes 129 essential tools neatly packed in a robust plastic case. Whether you're working on electronics, thermal pads, capacitors, or microcontrollers, this set equips you with what you need. From screwdrivers to pliers, precision tweezers to bits, the tools are made from durable alloy steel and engineered to resist corrosion and wear.

Moreover, its organized case ensures every tool has its place, helping reduce clutter and allowing users to focus on the job. The wide array of instruments provided enables usage across various sectors, including laptop repairs, fuse replacements, switch installations, and safety inspections.

Key Features of the E-PRO TLS-1 Tool Set

• Compact, lightweight design with a rugged plastic storage case • Includes pliers, screwdrivers, hex keys, tweezers, sockets, and more • Ergonomic grips for comfort during extended use • Suitable for electronics, microprocessors, and controller maintenance • Corrosion-resistant materials ensure long-lasting durability • Clear tool layout for fast and efficient access • Compatible with thermal management, including installing thermal pads and applying heatsinks • Helpful for circuit testing, component fitting, and terminal tightening

Benefits of Using the E-PRO TLS-1 129-Piece Tool Set

Choosing the right tools means increased productivity and minimized damage risks, especially when dealing with delicate components like microcontrollers and LEDs. With the E-PRO TLS-1, users enjoy versatility without compromising on safety and precision.

• Suitable for both professional technicians and DIY hobbyists • Enhances workflow efficiency in repairing laptops, sensors, and electronic modules • Saves money by offering all necessary tools in one set • Prevents wear and tear through anti-slip grips and thermal resistance • Reduces downtime with fast, easy-to-access tool arrangement

Typical Use Cases of the TLS-1 129-Piece Set

There’s no shortage of applications for the E-PRO TLS-1 toolset. Thanks to its diversity, it’s ideal for tasks ranging from installing connectors to configuring contactors or setting up electronics panels.

• Repairing electronic boards and embedded systems • Installing or removing connectors in industrial wiring • Performing maintenance on laptops and microprocessor units • Configuring safety switches and contactors in control panels • Assembling controller modules and fuse housings • Replacing LEDs, capacitors, and thermal interface components • Installing or modifying grips, brackets, and plastic enclosures • Applying or adjusting thermal pastes and oils on heat-dissipating surfaces

Why Professionals Trust E-PRO Tools

Professionals who work daily with electronics and electrical systems need tools that stand up to repetitive use and high-precision tasks. The E-PRO TLS-1 Tool Set has gained popularity due to its dependable build quality and thoughtful inclusion of frequently used items.

It is tailored to meet industry demands in both hardware maintenance and software integration environments. Whether it's fixing laptop circuitry or wiring contactors inside a control cabinet, this toolkit proves indispensable.

Comparing E-PRO TLS-1 with Other Generic Tool Sets

Unlike basic kits that often lack key pieces or durability, the E-PRO TLS-1 covers a broad scope of functions.

• Broader range of tools including hex keys and magnetic bits • Superior thermal and anti-static protection for delicate electronics • Higher grade materials that last longer in rugged environments • Comprehensive support for electronics, oils, and cable handling • Enhanced tool layout compared to loosely arranged generic sets

How the TLS-1 Set Supports Electronic and Electrical Workflows

Every cable terminated, every LED fitted, and every thermal component installed with the TLS-1 set adds to an efficient, damage-free workflow. The integration of multiple heads and interchangeable bits makes it simple to manage varying component sizes and fixture types.

Moreover, the tools cater to the latest trends in microelectronics, where precise handling of components like capacitors and microcontrollers is key. As a result, it serves industries like embedded computing, power electronics, safety systems, and even sensor calibration platforms.

Where Can You Buy the E-PRO TLS-1 129-Piece Tool Set?

The TLS-1 129-piece set is available at EnrgtechGlobal, offering fast shipping and competitive prices. As electronics and safety requirements continue to evolve, having a toolset that evolves with your needs is crucial—and the TLS-1 stands ready.

• Visit online and explore our full collection of tools and accessories • Secure checkout with same-day dispatch options • Shop confidently with detailed specifications and customer support

Final Thoughts

In conclusion, the E-PRO TLS-1 129-Piece Tool Set is more than just a toolkit—it’s an investment in precision, efficiency, and long-term value. Its extensive capabilities make it suitable for professionals in fields ranging from thermal systems and sensors to controllers and contactors. Whether you’re replacing connectors or performing microprocessor installations, this all-in-one solution ensures every tool you need is right at your fingertips.

0 notes

Text

Circuit Breakers: Strengthening Electrical Infrastructure with Smart Protection

Circuit Breakers: Strengthening Electrical Infrastructure with Smart Protection

Introduction: Why Circuit Breakers Matter More Than Ever

In the era of rapid electrification and automation, power reliability and safety are no longer optional—they’re essential. From small residential systems to expansive industrial facilities, circuit breakers provide the first line of defense against electrical failures. These devices detect faults such as short circuits or overloads and respond by halting the power flow, preventing catastrophic damage. In high-load scenarios, Air Circuit Breakers deliver robust performance and integrated intelligence, ensuring mission-critical operations remain secure and efficient.

Circuit Breakers Explained: Types and Their Applications

To meet the varying demands of power systems, three major circuit breaker types are widely used: Air Circuit Breakers (ACBs), Moulded Case Circuit Breakers (MCCBs), and Miniature Circuit Breakers (MCBs). ACBs are engineered for high-capacity systems and typically found in power distribution hubs and industrial plants. MCCBs cover medium voltage requirements and are highly customizable, making them ideal for commercial buildings and equipment control panels. MCBs, being compact and easy to operate, are designed for homes and light commercial applications. Each plays a distinct yet vital role in electrical safety and efficiency.

Air Circuit Breakers: Intelligence for High-Power Environments

Air Circuit Breakers offer precision and control for large-scale power systems. Using air as the arc quenching medium, these breakers are built for high interrupting capacities and advanced automation. With programmable logic, digital trip units, and remote monitoring capabilities, ACBs ensure real-time fault tracking and reduced downtime. They’re indispensable in sectors such as healthcare, manufacturing, logistics, and energy, where reliability cannot be compromised. The integration of smart communication systems allows for predictive maintenance and operational transparency, a must for forward-looking infrastructure.

MCCB Breakers: Custom-Tailored for Versatile Performance

MCCB Breakers provide efficient protection across a wide current range, making them suitable for diverse applications. MCCBs combine thermal and magnetic tripping mechanisms, enabling adjustable protection levels tailored to specific system needs. Whether used in commercial high-rises, factory lines, or utility systems, MCCBs are known for their resilience and flexibility. They also support modular upgrades, smart metering, and load analysis features—empowering facility managers to maintain both safety and energy optimization in dynamic operating conditions.

Key Selection Criteria: Matching Breakers to the System

A thoughtful approach to selecting circuit breakers is critical to ensuring safety and system compatibility. Factors such as voltage rating, short-circuit current rating, system configuration, and environmental exposure must be evaluated. For example, industrial machinery might require MCCBs with adjustable trip thresholds and high thermal endurance, while data centers may depend on ACBs that integrate with digital control systems. Poor selection leads to frequent tripping, inefficiencies, and potentially costly damage. Precise matching extends breaker life and contributes to consistent power quality.

Miniature Circuit Breakers (MCB): Reliable Protection in Compact Spaces

Miniature Circuit Breakers (MCB) are compact, quick-acting devices designed to protect low-voltage circuits. MCBs respond instantly to overload or short-circuit events, minimizing risks in domestic and small commercial environments. They are commonly used for protecting lighting systems, sockets, and electronics. Easy to install, reset, and maintain, MCBs have become the standard in homes and offices. With more devices being added to everyday spaces, having efficient MCB protection is essential to avoid damage, improve safety, and maintain system continuity.

GIMS Tech Power: Your Partner in Power Safety

At GIMS Tech Power, we offer a comprehensive range of circuit protection solutions for every scale and requirement. Our inventory includes high-performance ACBs, configurable MCCBs, and compact MCBs—each compliant with global standards for safety and performance. We don’t just provide products; we provide guidance, engineering support, and end-to-end service. Whether it’s a new construction project or an upgrade to an existing facility, GIMS Tech Power ensures your electrical systems are built on a foundation of safety, quality, and innovation.

Smart Circuit Breakers: The Digital Shift in Protection

As smart buildings and Industry 4.0 continue to evolve, the need for digital integration in power systems grows. Modern ACBs and MCCBs now feature IoT connectivity, allowing real-time status updates, historical data logging, and remote reset functionality. These features support predictive maintenance, energy efficiency tracking, and system diagnostics. This shift transforms circuit breakers from passive devices into intelligent components of a dynamic, data-driven energy ecosystem. Businesses that embrace smart breakers gain not only protection but also operational insight and strategic advantage.

Conclusion: Power Your Projects with Confidence

Circuit breakers are more than protective mechanisms—they are vital enablers of modern life and business. By choosing the right breaker for each application, you safeguard people, assets, and productivity. From heavy-duty ACBs to adaptable MCCBs and dependable MCBs, each type contributes uniquely to a safer electrical environment. GIMS Tech Power is here to provide cutting-edge solutions that are reliable, scalable, and smart. Visit us today and explore our wide range of Moulded Case Circuit Breakers to future-proof your electrical infrastructure with confidence and precision.

0 notes

Text

What Are DIL Sockets and Why Are They Essential for Reliable IC Mounting?

Introduction: Why Do DIL Sockets Matter in Modern Electronics?

Dual In-Line (DIL) sockets, also known as DIP sockets, are foundational components in electronic design and manufacturing. These ingenious devices enable integrated circuits (ICs) to be easily mounted and replaced without requiring direct soldering to the board. Whether you're prototyping, repairing, or developing scalable designs, DIL sockets deliver unmatched flexibility, reliability, and protection. Their significance has only grown with the increasing complexity and miniaturization of circuits, offering a practical bridge between reusable hardware and robust design.

What Is a DIL Socket and How Does It Work?

A DIL socket is a mechanical connector with two parallel rows of contact pins designed to accommodate Dual In-Line Package (DIP) ICs. These sockets are mounted on printed circuit boards (PCBs) and serve as a host into which the ICs can be inserted or removed without risk of thermal damage or physical stress.

DIL sockets feature:

Two parallel rows of holes matching the DIP IC layout

Plated contact points to ensure stable electrical connections

Molded plastic bodies that resist heat and mechanical stress

Options ranging from 6 to 64 pins (and beyond) for various IC types

Their role is simple but powerful: make IC installation secure, reversible, and low-maintenance.

Why Choose DIL Sockets for Your PCB Projects?

When building or repairing PCBs, soldering directly onto the board is not always the best approach. DIL sockets offer several advantages that streamline your electronic assembly processes while safeguarding your components.

Key reasons to use DIL sockets:

Component Protection: Prevents heat damage during soldering by keeping ICs away from the soldering process.

Easy Maintenance: ICs can be swapped out or upgraded without desoldering, making repairs and modifications quick.

Cost-Effective Prototyping: Ideal for testing multiple ICs during development phases without damaging the board.

Reduced Wear on PCBs: Repeated IC replacement does not degrade the board’s pad or trace integrity.

ESD Isolation: Some DIL sockets come with built-in static protection features, helping shield sensitive ICs from electrostatic discharge.

What Types of DIL Sockets Are Available?

There’s no one-size-fits-all approach when it comes to DIL sockets. Several variants cater to different application needs—from basic home electronics to high-end embedded systems.

Common types of DIL sockets:

Turned Pin (Machined Pin) Sockets: High-quality, durable sockets with precision-machined contacts offering superior connectivity and long lifespan.

Stamped Pin Sockets: Economical options with stamped metal contacts, best for low-cost and temporary applications.

Open-Frame Sockets: Lightweight design ideal for space-sensitive applications.

Closed-Frame Sockets: Provide extra protection and rigidity, suitable for rugged environments.

Low-Profile Sockets: Reduce stack height, making them perfect for compact devices or portable electronics.

These variations help engineers select the right balance between cost, space, durability, and performance.

How to Select the Right DIL Socket for Your Project?

Choosing the appropriate DIL socket is vital to ensure the functionality and longevity of your circuit. Several factors must be considered based on your specific application.

What to look for:

Pin Count Compatibility: Match the socket’s pin count with the IC’s configuration (e.g., 8, 14, 16, 40 pins).

Pitch Size: Ensure the pitch (distance between pins) aligns with your PCB layout, usually 2.54mm for standard DIPs.

Contact Material: For better conductivity and resistance to oxidation, choose gold- or tin-plated contacts.

Operating Temperature Range: Match with your environmental conditions, especially for industrial or outdoor use.

Insertion Force: Low-force sockets reduce stress on IC pins, enhancing overall reliability.

Matching these specifications ensures smooth integration and long-term performance.

What Are the Typical Applications of DIL Sockets?

DIL sockets are found across numerous electronic applications—from hobbyist kits to mission-critical systems. Their versatility makes them an essential tool for anyone working with ICs.

Popular use cases:

Prototype Development: Ideal for temporary mounting of ICs during breadboarding or iterative testing.

Consumer Electronics: Used in TVs, DVD players, audio systems, and gaming consoles for easily replaceable logic circuits.

Educational Kits: Facilitates reusable learning tools for electronics students and hobbyists.

Industrial Control Systems: Enables fast field servicing of ICs in automation and monitoring equipment.

Retro Computing & Repairs: Crucial in repairing or upgrading vintage computers and devices using DIP ICs.

Microcontroller Boards: Commonly found in Arduino-compatible boards and DIY microcontroller projects.

Their plug-and-play nature simplifies design, reduces downtime, and enhances hardware sustainability.

Why Are DIL Sockets Still Relevant in an SMT-Dominated World?

Despite the rise of surface-mount technology (SMT), DIL sockets hold their ground in many modern applications. SMT may dominate mass production due to space-saving advantages, but for design flexibility, prototyping, and component longevity, DIL sockets remain unmatched.

Continued relevance stems from:

Tool-Free IC Swapping: No need for reflow ovens or hot-air rework stations.

Backward Compatibility: Supports legacy systems using DIP ICs.

DIY and Low-Volume Manufacturing: Enables small-scale developers to iterate designs affordably.

Field-Serviceability: Perfect for environments where rapid IC replacement is crucial.

In fact, many engineers intentionally design with DIP ICs and sockets to retain modularity and user-serviceability.

Conclusion: Are DIL Sockets the Unsung Heroes of PCB Design?

DIL sockets may not look flashy, but their impact on electronics design and usability is significant. They allow for safer soldering, easier maintenance, and smarter prototyping. For engineers who value durability, flexibility, and cost efficiency, DIL sockets are not just useful—they're indispensable.

Investing in the right DIL socket means protecting your ICs, your PCB, and ultimately, your entire project. Whether you're a seasoned designer or a curious hobbyist, this small component delivers big value.

0 notes

Text

Top Module Box Manufacturer in India / How It Improves Your Lifestyle with Safe and Durable Electrical Solutions

In the fast-paced world of modern infrastructure, safety, durability, and convenience are more than just features—they are expectations. Whether you’re a homeowner, builder, or electrical contractor, investing in high-quality electrical accessories is non-negotiable. At the heart of this necessity lies one of the most crucial yet overlooked components—module boxes.

Star India Electrical takes pride in being a leading name in the Indian electrical industry, delivering cutting-edge solutions with our top module box manufacturer in India range. Our commitment to excellence not only ensures top-tier performance but also enhances lifestyle quality with long-lasting, rust-proof, and hassle-free installations.

What Is a Module Box, and Why Is It Important?

A module box, also known as a modular box, is a casing or enclosure that houses electrical wiring, switches, sockets, or other modular components. It plays a critical role in maintaining the safety and organization of electrical circuits in residential, commercial, and industrial buildings.

Here’s why using a high-quality modular box makes a difference:

Protects wiring and terminals from physical damage

Reduces the risk of short circuits and fire hazards

Organizes electrical components neatly and efficiently

Supports future upgrades or changes with ease

But not all modular boxes are created equal. That’s where Star India Electrical’s life time guarantee module box changes the game.

Why Choose Star India Electrical’s Life Time Guarantee Module Box?

1. Unmatched Durability and Rust Resistance

We are among the top manufacturers of module box in India, and our products are crafted using premium, rust-proof materials such as galvanized steel and UV-resistant plastics. This ensures:

Rust free module box performance even in humid or coastal environments

Zero maintenance for decades

Long-term reliability and aesthetic appeal

Our rust proof module box is specially designed to withstand environmental stress, moisture, and corrosion, making it ideal for Indian weather conditions.

2. Safety That Stays for Life

At Star India Electrical, safety is not just a feature—it’s a promise. Our life time guarantee module box ensures protection against:

Electrical shocks

Overheating

Accidental sparks or short circuits

Our boxes comply with all ISI and IEC safety standards and come with superior insulation, fire-retardant properties, and impact resistance. When you install our product, you’re installing peace of mind for life.

3. Top-Tier Manufacturing Standards

As a reputed modular box manufacturer in India, our production units follow:

Precision engineering

Automated manufacturing for uniform quality

Quality control processes at every step

We’re not just another module box manufacturer—we’re one of the best module box manufacturers in India, delivering consistent quality that professionals across the country trust.

How a Life Time Guarantee Module Box Improves Your Lifestyle

Let’s face it—electrical issues are not just inconvenient; they can be downright dangerous. Here’s how choosing a premium product from a top module box manufacturer like Star India Electrical improves everyday life:

1. Zero Maintenance, More Peace

Tired of changing rusted or broken module boxes every few years? Our life time guarantee module box eliminates this cycle. No rust, no wear, no extra costs.

You install once—and forget forever.

2. Aesthetic Integration with Modern Interiors

Our modular box in India lineup is not only functional but also designed to blend with modern interior aesthetics. Be it a smart home, office, or commercial setup—our products fit right in, making your spaces look elegant and clutter-free.

3. Future-Ready Design

As a top manufacturers of module box, we build with the future in mind. Our boxes can easily accommodate smart switches, automation systems, and digital modules. Whether you upgrade your wiring, add devices, or renovate—your module box manufacturer shouldn’t be a bottleneck.

We make sure it isn’t.

Serving Every Segment: From Homes to Heavy-Duty

Our versatile product range caters to a wide customer base:

Residential Spaces: Neat, elegant, long-lasting solutions for modern homes

Commercial Buildings: Secure and robust installations for offices, malls, schools

Industrial Facilities: Tough, rust-resistant boxes that withstand harsh conditions

That’s why we’re widely recognized as one of the best manufacturers of module box in India, preferred by architects, electricians, and builders alike.

Star India Electrical: What Sets Us Apart?

Choosing a module box manufacturer is a critical decision. Here’s what makes Star India Electrical your best partner:

Life Time Guarantee:

A rare promise in the electrical industry that reflects our confidence in product longevity.

Certified Manufacturing:

Our facilities are ISO-certified, and our products are tested for safety, quality, and endurance.

Pan-India Distribution:

We’re not only a module box manufacturer in India, but also a trusted module box wholesaler. Our logistics network ensures quick delivery across the country.

Cost-Effective Pricing:

Quality doesn’t have to be expensive. As one of the cheap module box manufacturers in India, we offer competitive pricing without compromising on performance.

Testimonials: What Our Clients Say

“We’ve been working with Star India Electrical for 5+ years. Their life time guarantee module box is a game changer. Zero complaints, no replacements—just pure reliability.” — R.K. Sharma, Electrical Contractor, Delhi

“Star India is truly among the best module box manufacturer in India. Their rust-free boxes saved us so much on maintenance.” — Neha Arora, Architect, Bangalore

“Affordable, durable, and aesthetic—finally found a modular box manufacturer I can trust.” — Vivek Goyal, Homeowner, Mumbai

Final Thoughts: Invest in Reliability, Invest in Star India Electrical

A module box might seem like a small part of your electrical setup, but it has a huge role in defining safety, durability, and user experience. At Star India Electrical, we don’t just manufacture—we innovate.

When you choose our life time guarantee module box, you’re not only choosing top-quality materials and engineering but also enhancing your lifestyle by avoiding frequent replacements, ensuring long-term safety, and embracing future-ready electrical solutions.

If you’re looking for the best manufacturers of module box, whether for large-scale projects or personal use—look no further than Star India Electrical.

Choose once. Stay safe for life.

Frequently Asked Questions (FAQs)

Q: What does “life time guarantee module box” really mean?

A: It means the box is built to last for the lifetime of the installation, with zero expected replacements or rusting issues, under normal usage conditions.

Q: How is a rust-free module box different from a regular one?

A: Regular boxes corrode over time, especially in damp conditions. Our rust free module box uses anti-corrosive materials that resist moisture, preventing long-term damage.

Q: Are your module boxes compatible with smart home setups?

A: Absolutely. We are among the top module box manufacturers designing future-ready products that work seamlessly with smart switches, automation tools, and home integration systems.

Q: What industries or sectors use your modular boxes?

A: Our products are used in:

Real estate and construction

Corporate and commercial buildings

Industrial facilities

Government and infrastructure projects

0 notes

Text

Electrician in Manchester – Powering Dreams to Build Best Homes

Creating your ideal home isn’t just about structure and design—it’s about function and safety too. A certified Electrician in Manchester plays a vital role in making your living space secure, smart, and energy-efficient. If you're serious about quality, durability, and technology, it's time to plan with the goal to Build Best Homes.

🔌 Book expert help now: Electrician in Manchester 🏡 Plan your perfect build: Build Best Homes

Why Electrical Work Should Never Be an Afterthought

From your living room to your garden, everything runs on electricity. A certified electrician ensures:

All wiring complies with UK safety standards

Energy-efficient systems are installed

Circuits support smart devices

Load distribution prevents overheating

The risk of future faults is minimized

The right electrical layout is essential for comfort, security, and cost-saving.

What Services Does an Electrician in Manchester Provide?

Whether you’re building new or upgrading, a skilled electrician offers:

Full and partial house rewiring

Installation of lighting and sockets

Fuse board upgrades and safety switches

Outdoor and garden power solutions

EV charger installation

Smart home system integration

These services aren’t optional—they’re what make a home truly livable.

Smart Homes Need Smart Power

Today’s homes are no longer just walls and windows. With help from a professional Electrician in Manchester, your house can include:

Automated lighting and blinds

Voice-activated devices

Smart security cameras and doorbells

Energy monitoring systems

Heating and cooling controls

All of this saves energy while boosting daily convenience.

Build Best Homes with a Trusted Guide

Looking to turn your plans into a dream home? Build Best Homes gives you access to planning tools, advice, and trusted service providers. From layout ideas to hiring experts, the site empowers homeowners to make informed decisions and achieve professional results.

Tips to Choose the Right Electrician

For a safe and successful project, look for:

Certified professionals (NICEIC/NAPIT)

Solid experience in home builds

Clear pricing and project timelines

Positive reviews from local homeowners

Familiarity with modern smart tech

Hiring right means your investment is protected from start to finish.

Conclusion

Your home should be a place of comfort, technology, and safety. With the help of a reliable Electrician in Manchester, your electrical setup can support modern life with ease. Combine that expertise with the strategic resources at Build Best Homes, and you're on the path to building something truly exceptional.

0 notes

Text

Will aftermarket LED headlights damage your car's electrical system?

Short answer: Aftermarket LED headlights rarely damage modern cars, but they are a real risk in older vehicles if improperly installed or poorly designed. Here is a breakdown of potential electrical issues and protections:

⚡ Automotive Electrical Risks Circuit Overload (Older Cars):

Older wiring (pre-1980s) used thinner halogen wire (60-100W per bulb).

Most LEDs consume 15-50W per bulb → actual load is lower, only peak power consumption is higher.

Risk: Cheap LEDs without electric cooling fans or drivers can cause LEDs to fail or trip computer errors due to poor cooling. Example: A $15 LED bulb may only last a few months before failing.

Voltage Spikes and Ripple:

Substandard LED drivers can feed “dirty” current back into your vehicle’s systems. LED driver with intelligent IC, which can be compatible with 99.5% vehicle models, and help you avoid from led light flicker issue and radio interference .

Harmonic distortion may interfere with analog sensor, radio or ECU signals in pre-OBDII cars (before 1996).

Short circuit:

Poor insulation or loose soldering in cheap LED lights can cause poor contact or even short circuit.

Consequence: Blown fuse, burnt headlight switch or melted wiring harness (common in older cars with weak insulation).

CAN bus system error (modern cars):

Most cars after 2008 detect the health of the bulbs by pulse resistance check.

Insufficient LED resistance → can trigger false "bulb off" warnings or disable safety systems.

Solution: Add CAN bus decoder (load resistor) → but these decoders consume extra power and cause overheating. A built-in all-new CANBUS system is a must for high-quality LED lights to avoid dashboard error reports.

🔋 LED Installation Electrical Safety Checklist Problem | Risk Level | Solution

Fuse Compatibility | Low | LEDs consume less current → Generally safe Alternator Load | Low | LEDs save about 50W vs. halogen → Reduce load Wire Harness Melt | High | (Older Models) Use Relays + Good Wire Harness ECU/Radio Interference | Medium | Choose EMC-certified LEDs (Check FCC/CE Marks) Grounding Issues | High | Sand Erosion Near Ground Points → Secure with Dielectric Grease

📊 Power Consumption Comparison (Dual Headlight System) Bulb Type | Power Consumption | Current (12V System) Halogen (55W x2) | 110W Total Current | 9.2A Good LED (70W x2) | 140W Total Current | 10.8A Cheap LED (18W x2 + Fan) | 36W Total Current | 3A

Note: Low Wattage LED Headlights + The cooling fan may have poor heat dissipation design cost and effect, and cannot guarantee the service life. At the same time, the high-power LED integrated circuit system and heat dissipation cooling system that directly replaces the halogen lamp are designed, so low brightness, low power and short life LED solutions are forced to be selected!

🔧 Key protection measures for old cars Install relay harness

Bypass the aging headlight switch → Power directly from the battery.

Prevent the switch from melting (for example, Jeep CJ, Volkswagen Beetle).

Add series fuse

Install a 10-15A fuse close to the battery → Sacrificial protection. Avoid using "CANbus" bulbs on cars before 2000

Unnecessary resistance will increase heat → Burn out prematurely. Test voltage drop

Measure the voltage of the headlight socket:

11.5V at idle? → Safe.

<10.9V? → Upgrade the circuit.

🛡️ Recommended safe LED brands For vintage cars: https://sngllighting.com/ (EMC shielding, new decoding system, excellent heat dissipation cooling system).

Modern/old hybrid cars: https://www.philips.com.au/c-m-au/car-lights/led-headlight-upgrade-kits (built-in surge protection) and https://sngllighting.com/ (intelligent IC led driver built-in a all-new CANBUS system).

Avoid: no-name LEDs on Amazon/eBay that don't have EMC/FCC/CE/ROSH certifications.

💥 Real failure example 1980 Mercedes 240D owner installed cheap LEDs:

Result: Fan shorted → headlight switch smoked → dashboard wiring burned out ($900 repair).

Cause: Ground wire dropped → voltage spiked to 18V.

✅ Safe Installation Steps Measure the base voltage of the headlight connector.

When installing the light, apply dielectric grease to all contacts.

For vehicles manufactured before 2000, use a relay harness.

After installation, test all electronics (wipers, radio, turn signals).

Bottom line: quality LED lights won't damage your electrical system if you: Buy certified bulbs (FCC, CE, DOT);

Use relays in vehicles manufactured before 2000;

Avoid underpriced brands. For peace of mind, high-output LED lights are still the safest retrofit option for classic cars. 🧰

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#headlight bulb#headlamps#headlamp#headlight#xenon headlights#headlight replacement#halogen headlights#yellow headlights#laser headlights#headlights#race cars#electric cars#classic cars#car#cars#porsche#carlos sainz#truck#automobile#lamborghini

2 notes

·

View notes

Text

Nante's Rugged Surge Defense Cabinets Protect Critical Equipment

In demanding industrial environments, an industrial socket box serves as the first line of defense against harmful electrical surges. When power fluctuations occur, sensitive machinery and control systems face the risk of damage or unexpected downtime. Equipped with built -in surge arresters and reinforced wiring paths, this enclosure transforms an ordinary outlet cluster into a resilient safeguard. By channeling sudden voltage spikes safely to ground, it preserves the integrity of downstream devices and maintains continuous operation under challenging conditions.

Surge events often result from lightning strikes, utility switching, or internal motor start -ups. Without proper dismissal of these transient spikes, equipment may suffer insulation breakdown, circuit board failures, or degraded operational life. The specialized arresters within these distribution cabinets feature metal oxide varistors or gas discharge tubes that respond within nanoseconds, shunting excess energy away from critical circuits. Unlike generic power strips, these systems integrate protective modules directly at distribution points, minimizing cable lengths and reducing vulnerability.

Design considerations extend far beyond simple surge modules. Industrial enclosures demand robust construction materials that withstand dust, moisture, and mechanical impact. Rugged polycarbonate or powder -coated steel housings with high ingress ratings seal out contaminants while allowing heat dissipation through dedicated vents. Reinforced knockouts and strain relief clamps secure conduit entries, preventing accidental cable displacement. Together, these features form a comprehensive barrier against harsh elements and electrical threats alike.

Maintenance accessibility remains a key advantage. Hinged service doors with secure latches grant technicians swift entry without full disassembly. Internal busbars and terminal strips arrange wiring in orderly rows, each protected by individual circuit breakers or fuses. Visual indicators, such as LED status lights, display arrester health, signaling replacement needs before protective capacity diminishes. Field -replaceable cartridges simplify upkeep, ensuring that surge defense remains optimal without extensive downtime or specialized tools.

Modern control centers also benefit from integration with monitoring networks. Select enclosures embed voltage sensing modules that relay power quality metrics over industrial buses or wireless links. Facility managers access real -time dashboards showing transient count, surge magnitude, and device status. Predictive alerts flag abnormal surge activity, prompting preventive measures before equipment degradation occurs. This connectivity elevates protective hardware into an intelligent component of a larger asset management ecosystem.

Safety certifications underpin confidence in these solutions. Compliance with stringent standards for surge protection, electrical insulation, and fire resistance guarantees that installed units meet rigorous performance benchmarks. Inspections by accredited bodies ensure that manufacturing processes uphold consistent quality. By choosing certified enclosures, operators demonstrate due diligence and often satisfy insurance requirements for damage prevention measures in high -value installations.

Customization options allow precise matching to application demands. Modules support varied protection levels, from lower clamping voltages ideal for sensitive control circuits to heavy -duty arresters suited for main distribution feeders. Additional features include integrated isolation switches, remote trip capabilities, and selectable grounding configurations. Whether deployed in outdoor substations, mobile power carts, or plant automation racks, these configurable cabinets adapt to site -specific requirements with ease.

Environmental considerations also influence material selection and lifecycle impact. Many suppliers prioritize recyclable housing materials and RoHS -compliant components that exclude hazardous substances. Energy -efficient designs minimize standby losses, and recycled feedstock reduces overall carbon footprint. Take -back programs for spent arrester cartridges promote circular reuse, aligning protective infrastructure with broader sustainability goals favored by forward -thinking organizations.

Investing in a robust surge defense cabinet yields tangible returns. Protected equipment experiences fewer unplanned stoppages, reducing repair costs and lost productivity. Extended component lifespan delays replacement cycles and contributes to predictable maintenance budgeting. Enhanced uptime translates into smoother operations, whether supporting continuous manufacturing lines, critical research facilities, or remote telecommunications towers that demand uninterrupted power quality.

By integrating advanced surge mitigation techniques, rugged construction, and smart monitoring capabilities, a modern industrial socket box delivers comprehensive defense for valuable systems. Choose this high -performance solution to safeguard motors, drives, sensors, and control panels against unpredictable electrical disturbances. For more information about scalable enclosures and tailored protective options, visit https://www.nante.com/product/ .

0 notes

Text

Introduction of Wiznet W5500 The Wiznet W5500 is an advanced Ethernet module designed specifically for embedded systems. This powerful device provides an easy-to-use interface, enabling seamless connectivity to the internet. If you are looking to enhance your projects with robust networking capabilities, look no further than the network chip. Whether for IoT applications or other types of communication, this module is engineered to deliver reliability and performance. MOQ of the Network MCU Wiznet W5500 As seen online, online MOQ is 100pcs,more quantity welcome chat us to inquire the price. The W5500 features a built-in TCP/IP stack, allowing for easy integration into various applications. This highly versatile module supports multiple sockets for simultaneous connections, making it ideal for a wide range of networking tasks. With its support for both IPv4 and IPv6 protocols, the network chip ensures that your devices can communicate effectively in any networking environment. Additionally, the integrated hardware-based processing saves CPU load, allowing your microcontroller to focus on other tasks. Interested with much more integrated circuits online price,view here. Simple Integration and Compatibility Designed for convenience, the Wiznet W5500 is compatible with various microcontrollers and development platforms. Its user-friendly API and comprehensive documentation simplify the integration process, enabling developers to start using the module quickly. Whether you are an experienced developer or new to embedded systems, the network ic offers an accessible pathway to add Ethernet capabilities to your projects. With the network chip, you can elevate your embedded systems with excellent network performance and connectivity. Gain access to real-time data exchange, remote access, and control for your devices. Choose the W5500 for your next project and experience the difference in networking efficiency and ease of use. If you interested with w5500 ethernet module,view here to know more our company business. Read the full article

0 notes