#leadfreesolder

Explore tagged Tumblr posts

Text

Soldering Innovations: What’s Next for Industrial Applications?

In the fast-evolving Hiflo solders world of electronics and industrial manufacturing, soldering technology is no longer just a routine process; it’s becoming a strategic differentiator. From consumer gadgets to electric vehicles and aerospace systems, soldering plays a critical role in assembling complex electronic circuits and ensuring long-term reliability.

With industries demanding higher efficiency, sustainability, and miniaturization, the future of soldering is shifting toward smarter, safer, and more adaptable innovations. So, what’s next for industrial applications? Let’s explore the soldering trends that are reshaping the way modern industries function.

🔬 1. Rise of Lead-Free and RoHS-Compliant Alloys

One of the most significant transformations in recent years is the move toward lead-free solder. Driven by environmental and health regulations like RoHS (Restriction of Hazardous Substances), industries are moving away from traditional lead-based soldering alloys.

Alloys like SAC305 (Sn96.5/Ag3.0/Cu0.5) are now widely adopted across automotive, aerospace, and consumer electronics sectors. These alloys not only meet compliance standards but also offer strong mechanical and thermal performance.

At HiFlo Solders Pvt. Ltd., we manufacture RoHS-compliant solder wires and bars that ensure safety without compromising quality, making them ideal for both mass production and sensitive electronic applications.

🤖 2. Automation and Smart Soldering Machines

Industrial soldering is becoming smarter with automated soldering systems and AI-powered robotics entering the scene. These machines ensure precise control of temperature, pressure, and timing — reducing human error and improving repeatability.

Smart soldering irons equipped with IoT technology can collect data in real-time, helping manufacturers track performance, detect anomalies, and maintain consistency.

In high-volume sectors like automotive PCB assembly or LED lighting, automated wave soldering and reflow soldering machines are now the norm. The future is all about connected, intelligent, and data-driven soldering systems.

🔍 3. Nano Soldering and Miniaturization

As electronic devices become smaller and more compact, the soldering processes used in manufacturing must evolve. Enter nano soldering — a precision technique used for ultra-fine solder joints on microchips and tiny components like sensors, MEMS, and medical devices.

Micro-soldering stations are increasingly used in R&D labs and mobile repair centers. This innovation is critical for industries like wearables, IoT, and biomedical devices, where component size is measured in microns.

In future applications, laser-assisted soldering and ultrasonic soldering may take over traditional hand methods, especially where heat sensitivity is a concern.

🌱 4. Eco-Friendly Soldering Flux and Chemicals

Sustainability is a key driver in modern manufacturing. Traditional soldering processes use fluxes and pre-cleaning chemicals that may be harmful to workers and the environment. Today, companies are investing in eco-friendly flux formulations, low-residue, and VOC-free chemicals to reduce their carbon footprint.

At HiFlo Solders, we are constantly researching environmentally safe pre-soldering chemicals and low-emission solder pastes that ensure worker safety and environmental compliance.

📦 5. Advanced Solder Materials: Beyond Tin and Lead

The future also lies in advanced solder alloys designed for high-performance and extreme environments. For example:

Bismuth-based solders: For low-temperature applications.

Silver-rich alloys: For aerospace and defense where strength and conductivity are critical.

Indium alloys: For cryogenic applications and soft soldering in semiconductors.

These innovations offer tailored solutions to meet the needs of various industries and unique operating conditions.

🔄 6. Sustainability Through Recyclable and Reusable Solder

Another growing trend is the development of recyclable solder materials. Manufacturers are exploring solder formulations that can be recovered, purified, and reused multiple times — reducing both waste and production cost.

This aligns with global sustainability goals and circular economy principles. HiFlo Solders is also investing in recycling initiatives for solder dross and scrap material, contributing to an eco-friendly industrial ecosystem.

📈 Final Thoughts: The Future is Smart, Green & Precise

The next era of industrial soldering is focused on three pillars:

Smart automation

Green chemistry

Precision materials

As industries become more digital, interconnected, and environmentally aware, soldering innovations must keep pace. Companies like HiFlo Solders Pvt. Ltd. are leading the charge by combining research-driven manufacturing, quality-focused production, and customer-specific customization.

Whether you’re in the business of manufacturing PCBs, medical devices, EVs, or industrial electronics, staying updated with next-gen soldering technologies is essential for long-term success.

🔗 Looking for reliable, RoHS-compliant solder wires or custom solder bars?

Website : 👉 Explore our range at www.hiflosolders.com

0 notes

Text

Soldering Stations in India – Precision & Efficiency for Electronics Manufacturing

Soldering is a crucial process in electronics assembly, repair, and industrial manufacturing. A soldering station provides better control, stability, and precision compared to traditional soldering irons, making it an essential tool for professionals.

At Ascomp Inc, we offer a range of high-quality soldering stations in India, designed for PCB assembly, electrical work, and industrial applications.

What is a Soldering Station?

A soldering station is an advanced soldering tool that includes a temperature-controlled iron, digital controls, and a stand. It provides stable heat, adjustable settings, and enhanced safety, making it the preferred choice for electronics professionals and engineers.

Benefits of Using a Soldering Station

✅ Precise Temperature Control – Ensures consistent soldering without overheating. ✅ Improved Efficiency – Reduces errors and enhances productivity. ✅ Longer Tip Life – Adjustable heat settings prevent tip degradation. ✅ Safe & User-Friendly – Reduces risks of burns and component damage. ✅ Versatile Applications – Suitable for a variety of soldering tasks.

Industries That Use Soldering Stations in India

✔ Electronics Manufacturing – Essential for PCB soldering and circuit board repairs. ✔ Automotive Industry – Used for wiring, battery assembly, and sensor connections. ✔ Aerospace & Defense – Ensures high-precision soldering for aviation electronics. ✔ Telecommunications – Critical for fiber optics and signal processing equipment. ✔ Jewelry & Metalwork – Helps in fine metal soldering applications. ✔ DIY & Hobbyist Projects – Perfect for makers, engineers, and repair professionals.

Types of Soldering Stations Available at Ascomp Inc

🔹 Analog Soldering Stations – Simple temperature control for basic applications. 🔹 Digital Soldering Stations – Precise temperature adjustments with digital displays. 🔹 ESD-Safe Soldering Stations – Protects sensitive electronic components from static discharge. 🔹 Hot Air Rework Stations – Ideal for SMT component repairs and desoldering. 🔹 Lead-Free Soldering Stations – Complies with RoHS standards for eco-friendly soldering. 🔹 High-Power Soldering Stations – Suitable for heavy-duty industrial applications.

Why Choose Ascomp Inc for Soldering Stations in India?

🔸 Premium-Quality Products – Durable and reliable for professional use. 🔸 Temperature Precision & Stability – Advanced digital and analog controls. 🔸 Affordable & Long-Lasting – Cost-effective solutions with low maintenance. 🔸 Industry-Approved Standards – Compliance with ISO, CE, and RoHS certifications. 🔸 Fast Delivery & Expert Support – Available across India with full technical assistance.

Get the Best Soldering Stations in India from Ascomp Inc

Upgrade your electronics manufacturing and repair processes with our high-quality soldering stations. At Ascomp Inc, we provide efficient, safe, and precision-controlled soldering solutions for industries and professionals.

📞 Contact us today to explore our range of soldering stations in India and find the right solution for your needs!

#SolderingStationIndia#ElectronicsManufacturing#PCBAssembly#IndustrialSoldering#PrecisionSoldering#ESDSafeSoldering#LeadFreeSoldering#SolderingTools#ElectronicRepairs#AscompInc

0 notes

Text

Traditional soldering methods used solders which contained Lead. Rising environmental concerns led to the Restriction of Hazardous Substances (RoHS) mandate in 1995 which led to hashtag#LeadFreeSoldering replacing traditional methods. With increasing research on material solutions, advanced compounds are being formulated as a viable lead-free alternative with a range of benefits. Indium Corporation brings you a wide range of lead-free solder pastes including Water-Soluble, no-clean, and Rosin mildly activated (RMA). The many features include: • High transfer efficiency • Resilient oxidation barrier technology • Robust reflow capability • Excellent pin-in-paste printability, solderability, and hole fill • Consistent lot-to-lot performance For more info: https://zurl.co/vWNP

0 notes

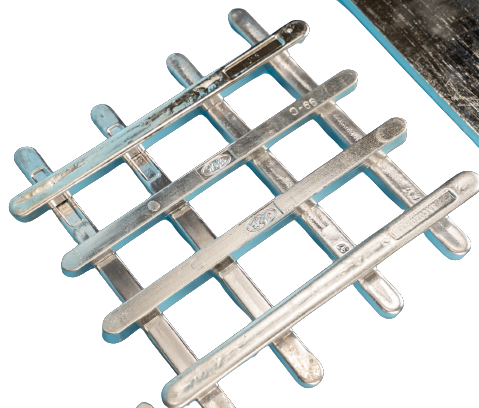

Photo

⚓ナマリフリートノタタカイ🧷 カフェのお店のカードを置いてもらうので食べ物に近いこともあるだろうと無鉛はんだを使ったのだけど無鉛はんだは普通のはんだも苦手な私には...😭写真撮ってる暇もなかったからテープ巻きだけ #leadfreesolder #coppertape #stainedglass #onlyone #onebyone #handmadegifts #practicemakesperfect https://www.instagram.com/p/CKgmagHFqs1/?igshid=17jm0k2znkc2b

0 notes

Text

How many types of solder bars are there?

Solder bars play a crucial role in metal joining applications across various industries — from electronics and automotive to plumbing and electrical assembly. Despite being small in size, the type of solder bar you choose can significantly impact the strength, conductivity, and reliability of the joint.

So, how many types of solder bars are there? The answer depends on composition, application, and whether the bar is lead-based or lead-free.

Let’s take a closer look.

🔹 1. Tin-Lead Solder Bars (Sn-Pb)

This is the most traditional type of solder bar, commonly used in the past across many industries. It consists primarily of tin (Sn) and lead (Pb), and is available in different ratios.

Common Ratios:

60/40 (60% Tin, 40% Lead)

63/37 (Eutectic alloy) – Offers a sharp melting point at 183°C, which makes soldering faster and cleaner.

Advantages:

Smooth flow and excellent wettability

Strong, reliable joints

Cost-effective

Disadvantages:

Not environmentally friendly (due to lead content)

Restricted in many countries due to health and safety regulations (e.g., RoHS)

Best for: Legacy systems, industrial applications where RoHS compliance is not required.

🌿 2. Lead-Free Solder Bars

With global regulations pushing for safer, non-toxic materials, lead-free solder bars have become the industry standard in consumer electronics and industrial manufacturing.

These bars contain tin as the base metal, alloyed with other metals like copper, silver, or bismuth.

Common Lead-Free Compositions:

SAC305 – Tin (96.5%), Silver (3%), Copper (0.5%)

Sn-Cu – Tin (99.3%), Copper (0.7%)

Sn-Bi – Tin and Bismuth (used for low-temperature applications)

Advantages:

Environmentally safe and RoHS compliant

Good mechanical strength and thermal stability

Excellent for high-reliability applications

Disadvantages:

Higher melting points compared to leaded solder

Can be more expensive due to silver content

Best for: Electronics, consumer products, automotive, medical devices.

🧪 3. Specialty Solder Bars

These solder bars are designed for specific industrial requirements and may have unique alloy compositions or surface treatments to enhance performance.

Examples Include:

High-Silver Solder Bars – Provide excellent conductivity and joint strength; used in aerospace, defense, and precision electronics

Low-Residue Solder Bars – Leave minimal flux residue; ideal for cleanroom environments

Antioxidation Coated Solder Bars – Prevent surface oxidation during storage and reflow processes

Advantages:

Tailored for niche applications

Improved long-term performance

Consistent quality under challenging environments

Best for: Aerospace, solar panels, military-grade electronics, medical instruments.

📌 Summary Table

Solder Bar TypeMain CompositionRoHS CompliantApplicationTin-Lead (Sn-Pb)Tin + Lead❌Traditional soldering, legacy equipmentSAC305Tin + Silver + Copper✅General electronics, SMT assemblySn-CuTin + Copper✅Electrical wiring, plumbingSn-BiTin + Bismuth✅Low-temp applications, sensitive componentsSpecialty BarsVaries (Silver-rich, coated)✅High-reliability industries

🔧 Choosing the Right Solder Bar

The ideal solder bar for your process depends on:

Required melting temperature

Mechanical and electrical performance needs

Regulatory compliance (e.g., lead-free requirements)

Environmental conditions of the application

Compatibility with automated or manual soldering systems

🏭 Hiflo Solders – Trusted Manufacturer of Quality Solder Bars

At Hiflo Solders, we manufacture a full range of:

Tin-Lead Solder Bars

Lead-Free Solder Bars (SAC, Sn-Cu, Sn-Bi)

Specialty Custom Alloys

Solder products designed for optimal flow, strength, and conductivity

With decades of expertise and a commitment to quality, our products are widely used in PCB assembly, electrical manufacturing, and industrial soldering lines.

🔗 For professional-grade soldering results, choose the right alloy — choose Hiflo.

📩 Interested in bulk orders or custom formulations? Contact our technical team today!

#SolderBars#HifloSolders#LeadFreeSolder#SnPb#SAC305#ElectronicsManufacturing#PCBAssembly#SolderingSolutions#EngineeringMaterials#ManufacturingInnovation#IndustrialSoldering#MetalAlloys#SmartSoldering

0 notes

Text

How Many Types of Solder Bars Are There? – Choose What You Really Need

If you're into electronics manufacturing, hardware repairs, or even just a curious DIYer, you’ve probably come across solder bars. But here’s a common question we get at Hiflo Solders:

❓ “How many types of solder bars are there, and which one should I actually use?”

Let’s break it down in simple terms. 👇

🧪 What Are Solder Bars?

Solder bars are solid sticks of solder alloy, melted and used in processes like wave soldering, dip soldering, or manual solder pot work. They’re preferred in mass production because of consistent composition, reliability, and cost-effectiveness.

But not all solder bars are the same. Choosing the right one depends on your application, environmental regulations, and performance needs.

🔍 So, How Many Types Are There?

At a high level, solder bars are categorized based on their metal composition and purpose. Here are the main types:

1️⃣ Tin-Lead Solder Bars (Sn-Pb)

Common Ratio: Sn63/Pb37 or Sn60/Pb40

Used For: Traditional electronics, high-reliability joints

Why Use It: Excellent wetting, good flow, reliable results

Caution: Contains lead – not RoHS compliant

2️⃣ Lead-Free Solder Bars (RoHS Compliant)

Popular Alloys: 🔹 Sn99.3/Cu0.7 (Tin-Copper) 🔹 SAC305 (Sn96.5/Ag3.0/Cu0.5) 🔹 Sn100Ni+ (Tin-Copper-Nickel alloy)

Used For: Modern electronics, export-grade products, eco-safe industries

Why Use It: Environmentally friendly, global compliance, less toxicity

3️⃣ Specialty Alloys / High-Performance Solder Bars

Examples: 🔹 Low-temperature solder bars (e.g., Sn-Bi) 🔹 High-reliability alloys for aerospace or automotive 🔹 Antimony or silver-enhanced bars for added strength

Used For: Medical, automotive ECUs, aerospace, telecom

Why Use It: Withstand vibration, temperature swings, and mission-critical performance

🧭 Which One Should YOU Choose?

Here’s a simple guide:

Use Case:

General electronics

RoHS compliant needs

High-reliability products

Budget-friendly jobs

Recommended Solder Bar

Sn63/Pb37 or SAC305

Sn99.3/Cu0.7 or Sn100Ni+

Sn/Ag/Cu alloys (SAC Series)

Tin-Lead or Tin-Copper

💡 Final Thoughts

The best solder bar is the one that matches your process, compliance needs, and quality goals. Choosing the right alloy can reduce dross, increase joint strength, and lower rework costs.

At Hiflo Solders, we offer a full range of solder bars:

Tin-Lead bars

Lead-free bars (SAC305, Sn99Cu, Sn100Ni)

Custom alloys for industry-specific needs ✅ All manufactured under strict BIS & ISO standards

#SolderBars#ElectronicsManufacturing#HifloSolders#SolderingSolutions#LeadFreeSolder#PCBA#SMT#WaveSoldering#ChooseRight#TechTalk#MakeInIndia#BISCertified

0 notes

Text

What does SAC305 mean?

Ever seen the term SAC305 on a solder bar or wire label and wondered what it actually means? 🤔 Let’s decode it — SAC305 isn’t just a fancy name; it’s the secret sauce behind modern lead-free soldering!

🔬 SAC305 = Tin + Silver + Copper 🧪

SAC305 is an alloy made up of:

96.5% Tin (Sn)

3.0% Silver (Ag)

0.5% Copper (Cu)

The name “SAC” comes from the chemical symbols: Sn (Tin), Ag (Silver), and Cu (Copper) – cool right?

✅ Why Is SAC305 a Big Deal?

💥 Lead-Free Revolution SAC305 is one of the most popular lead-free solder alloys used in electronics manufacturing. Thanks to its RoHS compliance, it’s safer for both people and the planet 🌍.

💡 Excellent Performance

High thermal fatigue resistance

Strong and reliable joints

Suitable for wave soldering, reflow soldering, and hand soldering

📱 That smartphone you're holding? Chances are, it was built with SAC305!

🏭 Used by the Best

Companies like HiFlo Solders Pvt. Ltd. manufacture high-quality SAC305 solder bars and wires that are trusted across industries—from automotive to aerospace.

Whether you're working on PCBs or mass production, HiFlo’s SAC305 solder gives you the perfect balance of strength, conductivity, and eco-friendliness.

🎯 TL;DR:

SAC305 = Tin + Silver + Copper ✅ Lead-Free ✅ Reliable ✅ High-Performance ✅ Made by experts like HiFlo Solders Pvt. Ltd.

#SAC305#SolderAlloy#HiFloSolders#LeadFreeSolder#PCBManufacturing#ElectronicsDIY#TumblrTech#SolderWire#SolderBar#WaveSoldering#DipSoldering

0 notes

Text

How to make a solder bar?

🔨 How to Make a Solder Bar? | Behind the Scenes at Hiflo Solders

Ever wondered how a solder bar is made? It’s not just about melting metal—it's a precise and carefully controlled process designed to deliver high-quality solder joints in electronic manufacturing.

Here’s a closer look at how Hiflo Solders manufactures its industry-grade solder bars 👇

🧱 1. High-Purity Raw Metal Selection

The process starts with choosing refined metals like tin, lead, silver, or copper, high-purity solder alloy, and lead-free solder bar, depending on whether the final product is leaded or lead-free (like SAC305 solder bars). At Hiflo Solders, only high-purity raw materials are used to ensure minimal contamination and top soldering performance.

♨️ 2. Melting and Alloying

The selected metals are older bar manufacturing, melted at precise temperatures in large industrial furnaces. These are then mixed to form a homogeneous alloy. Accurate control during this stage is critical to achieve solder alloy mixing, consistent alloy composition—a specialty of Hiflo's automated solder bar manufacturing process.

🧪 3. Refining for Purity

To remove oxides and other impurities, a refining process is carried out. This can include fluxing agents or mechanical skimming. This step ensures the resulting solder has excellent wetting properties and produces low dross—making it perfect for wave soldering and dip soldering applications.

🧊 4. Mold Casting & Cooling

Once the alloy is ready, it's poured into custom bar molds and allowed to cool. Controlled cooling is essential to avoid cracks or brittleness. Hiflo Solder Bars are cast with precision for smooth surfaces, consistent weight, and easy handling.

🧼 5. Surface Cleaning & Quality Check

Every bar goes through a surface cleaning process to remove oxidation residues. Then, each solder bar is inspected for:

Alloy accuracy

Surface quality

Melting behavior

Compliance with RoHS standards (for lead-free types)

Only after passing all quality checks are Hiflo solder bars packed and shipped.

🛠 Why Choose Hiflo Solders?

At Hiflo, we don’t just manufacture solder bars — we engineer solutions for reliable, long-lasting electronic assembly. Whether you need lead-free solder bars for SMT or traditional Sn63/Pb37 bars for wave soldering, we ensure:

Consistency in every batch

Low spatter & smooth flow

Reduced soldering defects

If your goal is stronger solder joints, fewer defects, and smooth manufacturing, choose Hiflo Solders' premium solder bars—crafted with quality, precision, and performance in mind.

#HifloSolders#SolderBarManufacturing#LeadFreeSolder#SAC305#WaveSoldering#DipSoldering#HighPurityAlloy#PCBAssembly#SMTSoldering#ElectronicsManufacturing

0 notes