#motioncontrol

Explore tagged Tumblr posts

Text

TMC2209 stepper motor driver board testing 🤖⚙️🔋

We've been testing the Trinamic/Maxim/Analog/WeylandYutani TMC2209 (https://www.digikey.com/short/8r5m38h8) breakout we designed, and it's working great - the step/dir interface plus the micro-step select allows a microcontroller to control a stepper with just GPIO and true-to-its-name it is a very silent stepper driver, much quieter than the A4988 (https://www.digikey.com/short/tfjt88dd)! There are a few different I/O pins on the TMC: Index tells you when a full step is completed, which is handy to know when you want to change stepper modes on the fly. Diag lets you know when a power or motor failure has occurred. It can also tell when the motor has stalled if it's configured to. Finally, and most interestingly, is the UART interface: this unidirectional pin lets you read and write configuration registers, set 1-128 microsteps, change current limiting, and detect stalls for 'auto homing'. So far, everything works; we're just going to swap the direction of the potentiometer so it twists clockwise to increase the current limit and book PCBs!

#tmc2209#steppermotordriver#silentdriver#steppercontrol#motorcontrol#electronicsengineering#microstepping#diyrobotics#makersgonnamake#electronicsprojects#3dprinterparts#hardwaredesign#uartinterface#indexpin#diagpin#motorfailure#stallsensor#quietmotion#currentlimiting#autohoming#engineeringtools#gpiocontrol#embeddedengineering#pcbdesign#circuits#electronicslab#quietstepper#motioncontrol#openhardware#techinnovation

5 notes

·

View notes

Text

1 note

·

View note

Text

youtube

The latest Ultraleap Leap Motion Controller is here for the 2nd GEN! In Today's Episode, I will show you the Unboxing of this great Leap Motion Controller, and how this Gen compared to the previous Gen. And ofc, I will also show you how it performs in different Ultraleap Leap Motion demo apps :)

#ultraleap#leapmotion#motioncontrol#motioncontrols#motioncontroller#ai#unboxing#unboxingvideo#technology#robotics#vr#virtualreality#vtuber#handtracking#vrar#Youtube

2 notes

·

View notes

Text

Controlled Rotation, Maximum Precision: Exploring the Role of the Rotary Actuator in Hydraulic Innovation

In the world of industrial automation, robotics, and fluid power systems, one often overlooked component plays a pivotal role in bringing linear energy to life with rotational motion—the rotary actuator. Whether it’s pivoting an excavator arm, turning a valve on a high-pressure pipeline, or rotating a robotic gripper, the rotary actuator transforms hydraulic force into controlled, consistent torque.

But the rotary actuator is not a standalone hero. It integrates deeply with a host of other technologies: from servo motor driven hydraulic pumps to inductive linear position sensors, hydraulic power packs, and internal gear pumps. When engineered well, this fusion creates a responsive, efficient, and compact motion control system fit for both industrial and mobile applications.

In this post, we’ll dive deep into how rotary actuators work, how they’re applied, and how they team up with smart sensors and servo-driven pumps to deliver next-level hydraulic performance.

What Exactly Is a Rotary Actuator?

A rotary actuator is a hydraulic device that converts fluid pressure into angular (rotational) motion. Unlike linear actuators that push or pull in straight lines, rotary actuators rotate objects—typically through a range of 90°, 180°, or even a full 360° or more.

The core benefits include:

Compact form for space-restricted systems

High torque output relative to size

Precise rotational control

Ideal for repetitive or oscillatory motion

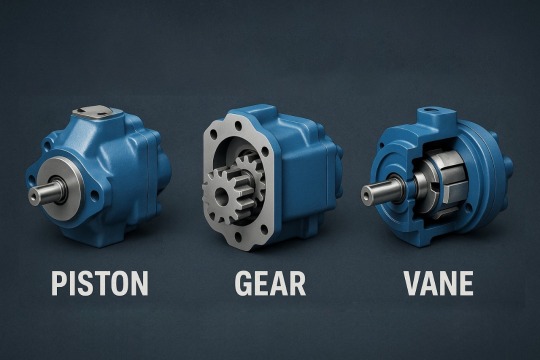

Common types include vane, rack-and-pinion, and helical rotary actuators. When integrated with a servo motor hydraulic pump, these devices can be controlled with extraordinary precision, making them ideal for automated or remote systems.

Use Cases Across Industries

1. Manufacturing and Robotics

In pick-and-place systems, rotary actuators help rotate arms or end effectors to move components from one station to another. Their compact size and quick response make them perfect for high-speed assembly lines.

2. Agricultural and Construction Equipment

Machines like harvesters, loaders, and compact excavators use rotary actuators to pivot buckets, arms, or flaps. Integrated with load sensing proportional valves, the actuator adapts torque output based on the load, preventing overshoot and ensuring controlled movement.

3. Valves and Gates in Fluid Systems

Rotary actuators are widely used to open and close large valves in pipelines or gates in water systems. Paired with inductive linear position sensors, they enable remote monitoring of valve positions for system integrity and safety.

Servo Motor Driven Hydraulic Pumps: Perfect Partners in Control

One of the most powerful upgrades for any actuator-based system is switching to a servo motor driven hydraulic pump. Why?

Because these pumps deliver:

Variable-speed, on-demand flow

Closed-loop control for precision

Energy efficiency due to load-based operation

Lower noise and heat output

With a rotary actuator, servo-driven pumps offer instant torque control and adaptive motion based on sensor feedback. Whether turning a valve or lifting a heavy panel, the pump can modulate flow and pressure precisely for smooth motion.

Hydraulic Power Packs: Compact, Mobile, and Intelligent

Modern hydraulic power packs—especially hydraulic power pack portable models—are often configured to support rotary actuators in mobile or space-constrained systems. These units typically include:

Compact internal gear pumps

Reservoirs, filters, and directional valves

Optional small servo motors for smart control

When a rotary actuator is deployed in a mobile machine or off-grid location, a power pack provides reliable force with minimal maintenance. Paired with load sensing proportional valves, it ensures that the actuator receives just enough power to perform the task—no more, no less.

Internal Gear Pumps and Rotary Actuator Synergy

Why are internal gear pumps a frequent companion to rotary actuators?

They deliver smooth, pulse-free flow

They’re quiet—ideal for indoor or noise-sensitive settings

They offer high efficiency even at low speeds

They integrate seamlessly into compact hydraulic circuits

When a rotary actuator must perform repetitive actions—like rotating a fixture during welding or turning a gripper on a robotic arm—gear pumps offer the consistent hydraulic delivery needed for uniform performance. In combination with servo control, they provide unmatched motion stability.

The Role of Inductive Linear Position Sensors

While rotary motion is the core function, knowing the actuator’s exact position is vital—especially in automation. That’s where inductive linear position sensors and linear position sensors for hydraulic cylinders come into play.

In rotary setups, these sensors are often mounted to the actuator shaft or gear mechanism to track angular displacement indirectly. With this data, the system can:

Prevent over-rotation or drift

Synchronize multiple actuators

Execute complex motion sequences

Improve safety by halting motion if a fault is detected

In smart factory systems, the actuator’s feedback loop includes the sensor, the controller, and the servo motor hydraulic pump—creating a self-correcting, intelligent mechanism.

Small Servo Motors and Rotary Actuation in Tight Spaces

As machines shrink and functionalities expand, small servo motors are becoming essential in rotary actuation systems. These motors provide fast, repeatable actuation with tight positional control—ideal for robotics, medical devices, or micro-manufacturing.

A rotary actuator driven by a small servo motor can rotate rapidly between positions, stop on command, and even execute oscillating motions with zero lag. Integrating this setup with load sensing proportional valves helps modulate torque output, reducing strain on delicate components.

Mobile Hydraulic Repair and Rotary Actuator Diagnostics

Technicians involved in mobile hydraulic repair frequently encounter rotary actuators in steering systems, control arms, or flap mechanisms. When an actuator fails, it’s crucial to verify:

Proper flow and pressure from the hydraulic power pack portable

Valve integrity via the load sensing proportional valve

Sensor responsiveness from the inductive linear position sensor

Mobile repair units now often carry servo-driven portable pumps that can simulate load conditions. These tools allow precise diagnosis and in-field testing of rotary actuator performance—saving both time and money.

Real-World Application Examples

- Packaging Industry

Rotary actuators rotate sealing arms or packaging plates. Integration with servo motor driven hydraulic pumps ensures quick cycles and accurate placement.

- Waste Management Trucks

These trucks use actuators to rotate compactors or bins. Compact hydraulic power packs and internal gear pumps ensure consistent operation even in dirty or uneven environments.

- Offshore Oil Platforms

Valves must be remotely actuated under high pressure. Here, rotary actuators, linear sensors, and load sensing proportional valves work together to deliver high-torque, explosion-proof motion control.

Rotary Actuators and the Smart Hydraulic Future

As industrial systems grow smarter, every motion counts—and every component must work in harmony. The rotary actuator, once seen as just a mechanical device, is now a key part of digitally connected, sensor-driven, servo-controlled systems.

By pairing it with:

Inductive linear position sensors for real-time feedback

Internal gear pumps for steady power

Servo motor hydraulic pumps for efficient control

Hydraulic power packs for compact, all-in-one solutions

Load sensing proportional valves for adaptive pressure regulation

…you get not just rotation—but intelligent, energy-efficient, and programmable rotation that meets the demands of the most advanced applications.

Final Thoughts

The rotary actuator has evolved far beyond simple turning mechanisms. It is now a precision tool embedded in high-tech, high-efficiency hydraulic systems. From robotic automation to mobile repair, from industrial packaging to utility vehicles, the actuator’s performance is amplified when supported by today’s smartest components.

Hydraulics are no longer just about pressure and power—they're about precision, predictability, and control. And with the right combination of servo motor driven hydraulic pumps, inductive sensors, load sensing valves, and smart hydraulic power packs, rotary actuators are unlocking possibilities that reshape how machines move.

0 notes

Text

𝗗𝗶𝗱 𝘆𝗼𝘂 𝗸𝗻𝗼𝘄 𝘄𝗵𝗼’𝘀 𝘁𝗵𝗲 𝘂𝗻𝘀𝘂𝗻𝗴 𝗵𝗲𝗿𝗼 𝗯𝗲𝗵𝗶𝗻𝗱 𝗽𝗿𝗲𝗰𝗶𝘀𝗶𝗼𝗻 𝗺𝗼𝘁𝗶𝗼𝗻 𝗰𝗼𝗻𝘁𝗿𝗼𝗹 𝗶𝗻 𝗶𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗲𝘀 𝘄𝗼𝗿𝗹𝗱𝘄𝗶𝗱𝗲?

𝗜𝘁’𝘀 𝘁𝗵𝗲 𝗗𝗖 𝗗𝗿𝗶𝘃𝗲𝘀 𝗠𝗮𝗿𝗸𝗲𝘁.

DC drives are the backbone of applications demanding constant torque at low speeds—conveyors that never stall, hoists that lift safely, and extruders that shape materials flawlessly. Their straightforward design and lightning‑fast response help manufacturers minimize mechanical wear through smooth acceleration and deceleration, optimize energy use by precisely matching motor output to load demands, and boost safety with reliable braking and exact speed regulation.

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲

𝗜𝗻𝘃𝗲𝗿𝘀𝘁𝗼𝗿𝘀 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀

For investors, DC drives offer a distinct opportunity within industrial automation: legacy plants worldwide are primed for retrofit waves as manual starters give way to intelligent drive systems; the ongoing automation surge in robotics, packaging lines, and material‑handling equipment underscores the need for ultra‑precise motion control; and high‑margin aftermarket revenues—from service contracts to spare‑parts sales—ensure steady, recurring income streams.

𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀

ABB Ltd. – Innovator in modular DC‑drive platforms and retrofit solutions

Siemens AG – Provider of high‑performance DC drives with integrated safety features

Schneider Electric SE – Expert in energy‑efficient DC drives with advanced diagnostics

Rockwell Automation Inc. – Known for rugged drives and seamless PLC integration

Yaskawa Electric Corp. – Specializes in compact, high‑torque drives for robotics

Mitsubishi Electric Corp. – Supplier of reliable DC‑drive packages for heavy‑duty use

Toshiba Corp. – Offers drives with strong braking and regenerative capabilities

Nord Drivesystems GmbH – Focused on in‑line drive‑gearmotor assemblies for conveyors and mixers

Position your portfolio for the precision‑control revolution—DC drives are powering the next wave of smart manufacturing.

𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁

𝗖𝗼𝗻𝗰𝗹𝘂𝘀𝗶𝗼𝗻: 𝗣𝗼𝘄𝗲𝗿𝗶𝗻𝗴 𝗣𝗿𝗲𝗰𝗶𝘀𝗶𝗼𝗻 𝗮𝗻𝗱 𝗣𝗿𝗼𝗳𝗶𝘁𝘀

As industries embrace tighter process control and predictive maintenance, DC drives stand out for their unmatched torque performance, energy savings, and reliability—making them a strategic bet for long‑term industrial growth. By tapping into retrofit demand, the automation boom, and high‑margin aftermarket services, investors can drive both operational innovation and portfolio returns in this specialized segment.

#DCDrives#MotionControl#IndustrialAutomation#SmartManufacturing#PrecisionEngineering#EnergyEfficiency#Investing#FactoryAutomation#CleanTech#ElectricalDrives

0 notes

Text

Precision Ball Screw Nut Actuator Assembly

Precision Ball Screw Nut Actuator Assembly

Ball screws are mechanical devices used to convert rotational motion into linear motion with high efficiency and precision. They are commonly used in various industrial applications, including CNC machinery, robotics, and aerospace engineering.

#Precision Ball Screw#BallScrew#LinearMotion#PrecisionEngineering#MechanicalDesign#MotionControl#CNCmachining#IndustrialAutomation

0 notes

Text

Pneumatic Components Market Size, Share & Trends Analysis

According to Market Statistix, the Pneumatic Components Market revenue and growth prospects are expected to grow at a significant rate during the analysis period of 2024-2032, with 2023 as the base year. Pneumatic Components Market research is an ongoing process. Regularly monitor and evaluate market dynamics to stay informed and adapt your strategies accordingly. As a market research and consulting firm, we offer market research reports that focus on major parameters, including Target Market Identification, Customer Needs and Preferences, Thorough Competitor Analysis, Market Size and market Analysis, and other major factors. In the end, we provide meaningful insights and actionable recommendations that inform decision-making and strategy development.

The Pneumatic Components Market is projected to experience steady growth, expanding at a CAGR of 5% over the forecast period.

Who are the key players operating in the industry?

SMC Corporation, CNSNS, Airtac International Group, Easun Pneumatic Science, JELPC (Ningbo Jiaerling Pneumatic Machinery Co. Ltd.), Norgren Inc. (IMI, PIC), Camozzi Group, Zhaoqing Fangda pneumatic Co. Ltd., Wuxi Huatong Pneumatic Manufacture Co. Ltd., Ckd Corp., Bosch Rexroth AG, Parker Hannifin Corporation, Festo SE & Co. KG, Fenghua Yaguang Pneumatic Element Co Ltd.

Request a sample on this latest research report Pneumatic Components Market spread across 100+ pages and supported with tables and figures is now available @ https://www.marketstatistix.com/sample-report/global-pneumatic-components-market

Pneumatic Components Market Overview and Insights:

Market Statistix is solidifying its reputation as a leading market research and consulting service provider, delivering data-driven insights that help businesses make informed strategic decisions. By focusing on detailed demand analysis, accurate market forecasts, and competitive evaluations, we equip companies with the essential tools to succeed in an increasingly competitive landscape. This comprehensive Pneumatic Components market analysis offers a detailed overview of the current environment and forecasts growth trends through 2032. Our expertise enables clients to stay ahead of the curve, providing actionable insights and competitive intelligence tailored to their industries.

What is included in Pneumatic Components market segmentation?

The report has segmented the market into the following categories:

Segment by Type: Air Treatment Components, Pneumatic Valves, Pneumatic Cylinders

Segment by Application: Electronics, Chemical Industry, Machinery, Others

Pneumatic Components market is segmented by company, region (country), by Type, and by Application. Players, stakeholders, and other participants in the Pneumatic Components market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by Type and by Application in terms of revenue and forecast for the period 2019-2032.

Have a query? Market an enquiry before purchase @ https://www.marketstatistix.com/enquiry-before-buy/global-pneumatic-components-market

Competitive Analysis of the market in the report identifies various key manufacturers of the market. We do company profiling for major key players. The research report includes Competitive Positioning, Investment Analysis, BCG Matrix, Heat Map Analysis, and Mergers & Acquisitions. It helps the reader understand the strategies and collaborations that players are targeting to combat competition in the market. The comprehensive report offers a significant microscopic look at the market. The reader can identify the footprints of the manufacturers by knowing about the product portfolio, the global price of manufacturers, and production by producers during the forecast period.

As market research and consulting firm we offer market research report which is focusing on major parameters including Target Market Identification, Customer Needs and Preferences, Thorough Competitor Analysis, Market Size & Market Analysis, and other major factors.

Purchase the latest edition of the Pneumatic Components market report now @ https://www.marketstatistix.com/buy-now?format=1&report=104

The Pneumatic Components market research study ensures the highest level of accuracy and reliability as we precisely examine the overall industry, covering all the market fundamentals. By leveraging a wide range of primary and secondary sources, we establish a strong foundation for our findings. Industry-standard tools like Porter's Five Forces Analysis, SWOT Analysis, and Price Trend Analysis further enhance the comprehensiveness of our evaluation.

A Comprehensive analysis of consumption, revenue, market share, and growth rate is provided for the following regions:

-The Middle East and Africa region, including countries such as South Africa, Saudi Arabia, UAE, Israel, Egypt, and others.

-North America, comprising the United States, Mexico, and Canada.

-South America, including countries such as Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, and others.

-Europe (including Turkey, Spain, the Netherlands, Denmark, Belgium, Switzerland, Germany, Russia, the UK, Italy, France, and others)

-The Asia-Pacific region includes Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, the Philippines, South Korea, Thailand, India, Indonesia, and Australia.

Browse Executive Summary and Complete Table of Content @ https://www.marketstatistix.com/report/global-pneumatic-components-market

Table of Contents for the Pneumatic Components Market includes the following points:

Chapter 01 - Pneumatic Components Executive Summary

Chapter 02 - Market Overview

Chapter 03 - Key Success Factors

Chapter 04 - Pneumatic Components Market – Pricing Analysis Overview

Chapter 05 - Overview of the History of the Pneumatic Components Market

Chapter 06 - Pneumatic Components Market Segmentation [e.g. Type (Air Treatment Components, Pneumatic Valves, Pneumatic Cylinders), Application (Electronics, Chemical Industry, Machinery, Others)]

Chapter 07 - Analysis of Key and Emerging Countries in the Pneumatic Components

Chapter 08 - Pneumatic Components Market Structure and Value Analysis

Chapter 09 - Competitive Landscape and Key Challenges in the Pneumatic Components Market

Chapter 10 - Assumptions and Abbreviations

Chapter 11 - Market Research Approach for Pneumatic Components

About Market Statistix:

Market Statistix is an expert in the area of global market research consulting. With the aid of our ingenious database built by experts, we offer our clients a broad range of tailored Marketing and Business Research Solutions to choose from. We assist our clients in gaining a better understanding of the strengths and weaknesses of various markets, as well as how to capitalize on opportunities. Covering a wide variety of market applications, We are your one-stop solution for anything from data collection to investment advice, covering a wide variety of market scopes from digital goods to the food industry.

Contact Information:

Market Statistix

Media & Marketing Manager

Call: +91 9067 785 685

Email: [email protected]

Website: www.marketstatistix.com

#PneumaticComponents#IndustrialAutomation#PneumaticSystems#CompressedAirSolutions#Actuators#Valves#AirCylinders#AutomationEquipment#FluidPower#MotionControl#ManufacturingSolutions#FactoryAutomation#EngineeringComponents

0 notes

Text

#NORD Drivesystems#PackagingSolutions#SmartDrives#IndustrialAutomation#ProcessEfficiency#MotionControl#EnergyEfficiency#ManufacturingExcellence#Industry40#SmartPackaging#DriveTechnology#electricvehiclesnews#evtimes#autoevtimes#evbusines

0 notes

Text

Why Custom Motor Gearboxes Are Driving the Future of Industry

In the world of industrial automation, motor gearboxes are no longer just hidden components—they’re strategic tools that directly impact performance, reliability, and competitiveness.

Each industry demands something different: Compact collaborative robots need high torque in small spaces. Logistics robots require long-lasting durability. Medical devices focus on smooth, precise motion, while construction or defense systems need toughness and power. A one-size-fits-all gearbox simply can’t meet these diverse needs.

That’s why customization is key.

At BonSystems, we design and manufacture custom motor gearboxes based on the exact needs of each client. With advanced cycloidal reduction technology, we deliver strong torque, flexible gear ratios, and compact designs that fit even the tightest spaces—all while ensuring smooth integration with your system.

From concept to prototype, testing to mass production, we work closely with you at every step. Our gearboxes are more than components—they’re the core of your industrial solution.

Want to learn how customized gearboxes can boost your system’s performance?

LINK: Industry-Specific Motor Gearboxes: A Strategic Choice to Boost Performance

#Automation#GearboxDesign#CycloidalDrive#RoboticsEngineering#BonSystems#IndustrialSolutions#CustomManufacturing#MotionControl

0 notes

Text

What’s the secret to smooth industrial automation? ⚙️

If you work with manufacturing or automation, you know how crucial it is to maintain precision and efficiency. That’s where inverters, motors, and gearboxes come in! These essential components ensure reliable motion control, reducing energy waste and improving system performance. Whether you need torque regulation, speed control, or a complete automation setup, these solutions help maximize productivity.

With motion control systems, industries can optimize energy use while keeping operations smooth and reliable. Thinking of upgrading your setup? Discover how these advanced solutions can take your automation to the next level! 🚀

#AutomationSolutions#MotionControl#IndustrialEfficiency#Inverters#Motors#IndustrialSolutions#MechanicalSolutions#ElectricalSolutions#FastCal#PLC#SCADA#ControlPanelDesign

0 notes

Text

SMD Harmonic Gearbox: SCSG Series - High-Accuracy & Space-Saving Solution

Strain wave gearboxes, also known as harmonic drives, are renowned for their high precision and compact design. They enable smooth motion control with minimal to zero backlash, achieving high reduction ratios in a lightweight package.

Achieve unparalleled motion control with SMD's Harmonic Gearbox

0 notes

Text

#FAULHABER#medical devices#MiniMotors#PrecisionEngineering#MotionControl#MedicalTech#Robotics#TimesTech#electronicsnews#technologynews

0 notes

Text

Enhance Precision with drylin® Linear Guides from igus®

Achieve smooth and precise motion with drylin® linear guides from igus®. Engineered for reliability, these guides offer frictionless movement and long-lasting performance, even in harsh conditions. Their maintenance-free design reduces costs while providing excellent durability and efficiency. Ideal for a range of industries, drylin® linear guides ensure high performance and minimal wear, making them the perfect choice for demanding applications.

0 notes

Text

Driving Precision: The Complete Guide to Industrial Servo Drive in Modern Hydraulic and Automation Systems

In today’s fast-paced industries—from manufacturing and robotics to mobile hydraulics and heavy machinery—precision, efficiency, and adaptability are non-negotiable. The industrial servo drive serves as the brain of modern motion control systems, creating a seamless intersection between mechanical power and digital control.

Whether you're designing a high-performance system using a servo motor hydraulic pump, working with hydraulic motors for sale, or optimizing a hydraulic system for mobile equipment, the servo drive determines system responsiveness, accuracy, and efficiency.

Chapter 1: What Is an Industrial Servo Drive?

An industrial servo drive is an electronic motion controller that regulates the position, speed, and torque of a servo motor. It receives signals from a higher-level controller (such as a PLC or CNC system), processes position feedback (via encoders or sensors), and commands the motor accordingly.

Key responsibilities include:

Interpreting motion commands

Executing precise PID algorithms

Ensuring smooth acceleration/deceleration

Integrating sensor signals in real time

Pair this with a servo motor hydraulic pump and components like internal gear pump or external gear pump, and you unlock smart, energy-efficient hydraulic motion.

Chapter 2: Why Servo Drives Are Central to Motion Control Systems

In hydraulic or electromechanical systems, the servo drive brings:

Real-time feedback loops using linear position sensors for hydraulic cylinders or rotary encoders

Adaptive motion control that responds to load variations, pressure demands, or changing cycle times

Safety and diagnostics, offering fault detection, motor overload protection, and system monitoring

It is the command center connecting actuators—whether rotary actuators or linear cylinders—to controllers, sensors, and power sources.

Chapter 3: Supporting Technologies and Their Roles

a) Servo Motor Price vs. Value

Advanced servo drives enable efficient use of small servo motors and drives, reducing the required motor torque and size, which balances servo motor price against overall system capability.

b) Feedback & Sensing Integration

Low cost linear position sensors: Economical yet sufficiently accurate for many applications.

High-precision linear position sensors for hydraulic cylinders: Provide reliable feedback in heavy-duty conditions.

These sensors feed position data to the servo drive, enabling accurate loop control.

c) Hydraulic Pumps & Motors

Servo motor hydraulic pump systems rely on the drive to manage motor speed to match demand.

Hydraulic motors for sale used in multiple industries now offer ports for feedback and pressure monitoring—ideal for closed-loop systems.

Devices such as load sensing proportional valves adapt system pressure to changing loads, based on feedback from the drive.

Chapter 4: How Servo Drives Shape Hydraulic System Performance

a) Flow Control & Efficiency

In systems using hydraulic flow control valves and load sensing proportional valves, servo drives dynamically adjust pump speed or control valve positioning to match actuator demand, minimizing energy waste and system heat.

b) Mobile Equipment Applications

On mobile platforms—like excavators or utility vehicles—the integration of an industrial servo drive with hydraulic systems enables:

Precision control via compact small servo motors and drives

Adaptive response based on arm or tilt sensor feedback

Reduced fuel consumption and improved safety under varying load conditions

c) Safety Applications

For applications requiring precise braking or position-limited actuation, such as vehicle control, load sensing proportioning valve adjustment can be governed through servo drive control loops.

Chapter 5: Inside the Servo Drive – Key Features

Closed-loop PID control—ensures accurate position tracking with minimal overshoot

Dynamic motion profiling—handles acceleration and deceleration ramps

Communication protocols—EtherCAT, CANopen, Modbus, EtherNet/IP, and more

Built-in diagnostics—overcurrent, overheating, position error detection

Parameter tuning—customizable for different motors, sensors, and system dynamics

Encoder/sensor compatibility—interfaces for feedback signals from linear and rotary sensors

These features make the servo drive the primary interface between mechanical hardware and digital intelligence.

Chapter 6: Integrating with Auxiliary Components

a) Rotary Actuators

Servo drives manage hydraulic signals to rotary actuator with electromechanical precision, enabling multi-axis movements and angular control in robotics or heavy machinery.

b) Hydraulic Pumps

When commanding a servo motor hydraulic pump, the drive adjusts motor speed based on real-time input from pressure or position sensors, serving dynamic load conditions while minimizing power usage.

c) Hydraulic Motors

Servo drives can also control motors, enabling features such as torque limiting, controlled reverse operations, and variable speed under load, based on feedback loops.

Chapter 7: Case Study – Industrial Servo Drive in Action

Scenario: Automated metal stamping line retrofitted with servo-hydraulic motion control.

Replaced an older hydraulic motor with servo motor hydraulic pump system

Implemented linear position sensors for hydraulic cylinders on press actuators

Tuned a load sensing proportional valve for adaptive pressure response

Integrated the system via an industrial servo drive with CANopen communication

Results:

Press repeatability improved to ±0.01 mm

Power consumption dropped by ~45%

Maintenance costs fell due to reduced valve cycling

Chapter 8: Selection Guide – Choosing the Right Drive

Here’s what you need to evaluate: SpecConsiderationPower RatingMatch to servo motor and hydraulic pumpFeedback InputCAS for sensor integration (encoder, linear sensor, rotary actuator)CommunicationFit with existing PLC or SCADA networkControl ModesPosition, speed, torque control availabilityEnvironmental RatingIP-classified if used in mobile or external machineryTuning OptionsAuto-tune; compatibility with load sensing proportional valves and hydraulic flow control valves

Choosing a high-end drive not only raises the servo motor price but enhances system adaptability and long-term performance.

Chapter 9: Practical Installation Recommendations

Sensor Placement: Position linear position sensors properly for accurate closed-loop control. Ensure reliable mounting and shielding.

Hydraulic Connections: Match drive commands to pump response—especially important in systems using internal gear pumps.

Electro-Hydraulic Coordination: Synchronize the servo drive's software with hydraulic component behavior to avoid overshoot or lag.

Tuning Practices: Begin with conservative PID settings. Gradually optimize based on actuator response data and sensor feedback.

Safety Interlocks: Use the drive’s built-in interlocks and error functions—especially in rotary actuator and braking systems relying on load sensing proportioning valve adjustment.

Chapter 10: Future Trends in Servo Drive Technology

AI and adaptive tuning—drives that learn from process behavior to continuously optimize control loops

Embedded IoT connectivity—remote monitoring via SCADA or Cloud platforms

Energy recovery modes—regenerative braking that returns energy to drive or power supply

Fully integrated electro-hydraulic modules—combining servo motor hydraulic pump, drive, and sensors into compact units

Affordable sensor fusion—integrating low cost linear position sensors for broad deployment across applications

Chapter 11: Common Myths & FAQs

Q1: Aren’t industrial servo drives too expensive for mobile equipment? Not anymore. Compact drives paired with small servo motors and drives and simplified hydraulic systems offer ROI through efficiency gains and reduced battery or fuel usage.

Q2: Can low-cost sensors deliver enough feedback accuracy? Yes—many low cost linear position sensors now offer ±0.1% accuracy and IP-rated enclosures suitable for mobile hydraulics.

Q3: Why use a servo hydraulic pump rather than throttling valves? Servo-driven pumps reduce thermal losses and noise while offering faster response time versus valves operating at fixed speed.

Q4: Is an encoder always better than a linear position sensor? They serve different purposes. Rotary axes use encoders; hydraulic cylinders benefit more from linear position sensors for hydraulic cylinders for stroke-based feedback.

Conclusion: Why the Industrial Servo Drive Matters

In an era where automation, sustainability, and system intelligence are top priorities, the industrial servo drive acts as a bridge—connecting power and precision, digital commands and hydraulic action. As you design or upgrade systems equipped with servo motor hydraulic pumps, hydraulic motors for sale, rotary actuators, and load sensing proportional valves, choosing the right servo drive becomes the most impactful decision.

When done properly, these systems deliver unmatched accuracy, repeatability, energy savings, and resilience. And because the servo drive enables everything from small servo motors and drives to hydraulic systems for mobile equipment, it’s not just a component—it’s the future of intelligent motion control.

0 notes

Text

@greenpeaceaustp @animalrightsnow @organic-vintage @soberairplane @feministryangosling @nonprofitambivalence @nongmokiwi @charitycajacallisty @ecojinri @geologychronicles @enviromental-hazard @pollution-brown-eyes @recycledmoviecostumes @resourcemarket

#landscape architecture#graphicandwebdesign#optical sensors#fiber crafts#public broadcasting#bookedit#magazine interview#literature roleplay#field recordings#motioncontrol#product catalog#machine tools#electrical equipment#industrial manufacturing

0 notes