#robot workcell integration

Explore tagged Tumblr posts

Text

Optimizing Precision in Automation: The Importance of Robot Calibration by Dynalog-US

In today's fast-evolving world of industrial automation, precision is not just a luxury—it's a necessity. Whether in automotive manufacturing, aerospace engineering, electronics assembly, or robotic surgery, the accuracy and repeatability of robotic systems can make or break operations. One key process at the heart of achieving this high level of precision is robot calibration.

At Dynalog-US, we specialize in helping companies unlock the full potential of their robotic systems through advanced robot calibration solutions. With decades of experience, our technologies are trusted globally to optimize performance, reduce downtime, and ensure consistently high-quality output in automated environments.

What is Robot Calibration?

Robot calibration refers to the process of identifying and correcting inaccuracies in a robot’s positioning and movement. Even the most advanced robotic systems can have discrepancies due to mechanical wear, thermal expansion, installation errors, or slight variations in joint angles. These small deviations can add up and significantly impact the end-effector’s ability to reach precise coordinates.

Calibration involves comparing the robot's real-world behavior with its digital model and applying correction parameters to align the two. The result? Enhanced positional accuracy, improved repeatability, and optimized system performance.

Why is Robot Calibration Crucial?

Many manufacturers assume that robots are perfectly accurate straight out of the box. However, that’s rarely the case. A typical robot may have repeatability within ±0.02 mm but a positional accuracy of ±1 mm or worse. For high-precision applications—like welding seams, laser cutting, part assembly, or robotic inspection—that level of inaccuracy is unacceptable.

By investing in robot calibration, companies can:

Ensure product quality by minimizing variation

Reduce rework and scrap due to positional errors

Boost throughput by allowing robots to operate faster with confidence

Optimize programming time by simplifying offline simulation and path planning

At Dynalog-US, we understand that in the world of robotics, accuracy equals efficiency—and efficiency translates into profit.

Dynalog-US: Your Robot Calibration Partner

At Dynalog, we go beyond basic correction. We offer comprehensive calibration and measurement solutions tailored to industrial robots of all sizes and brands. Our proprietary systems and software are designed to ensure your robots perform at their highest potential—no matter the task or environment.

Our calibration tools and services include:

1. Robot TCP Calibration

Tool Center Point (TCP) calibration ensures that the robot knows exactly where the end-effector is located. An inaccurate TCP can throw off entire production sequences. Our TCP calibration tools provide fast and precise identification of the tool's position and orientation.

2. Robot Base Calibration

Base calibration aligns the robot's coordinate system with the real-world environment. Misalignment here can lead to major inaccuracies, especially in multi-robot cells. Dynalog’s solutions ensure your robots are correctly oriented within their workspace.

3. Kinematic Calibration

This is the heart of robot calibration. Dynalog uses advanced algorithms to identify deviations in joint parameters and correct them with high precision. This process compensates for the robot's geometric imperfections and leads to dramatic improvements in accuracy.

4. Robot Workcell Integration

When robots work alongside conveyors, vision systems, or other machines, precise coordination is critical. We provide calibration systems that align all components within a unified frame of reference, ensuring seamless integration and real-time performance.

Real-World Benefits of Dynalog's Robot Calibration

Companies using Dynalog’s calibration systems often see a measurable return on investment in a matter of months. Here’s what sets us apart:

Traceable Accuracy: Our solutions are based on ISO and NIST traceable standards, providing confidence in your results.

Brand Agnostic: Whether you’re using FANUC, ABB, KUKA, Yaskawa, UR, or another manufacturer—our systems are compatible across the board.

Global Trust: Trusted by Fortune 500 companies and leading research institutions, our reputation speaks for itself.

Automation-Ready: Dynalog’s systems are designed with Industry 4.0 in mind, making it easy to integrate with smart factory workflows.

Future-Ready with Robot Calibration

As robotics continues to expand into sectors like e-commerce, medical devices, renewable energy, and beyond, the demand for high-precision automation is only increasing. Forward-thinking companies are already investing in robot calibration to prepare for this shift. With AI, machine vision, and real-time data processing becoming standard, the ability for a robot to “know” its position in space—accurately and in real-time—is more critical than ever.

Partner with Dynalog-US

When you choose Dynalog-US for robot calibration, you're choosing a partner that understands both the technical and practical challenges of modern automation. We’re not just calibrating machines—we’re calibrating success.

Whether you’re a manufacturer looking to improve output quality, an integrator designing a multi-robot cell, or a research lab pushing the boundaries of robotics, Dynalog’s solutions provide the accuracy, reliability, and support you need.

Get in touch with Dynalog today to learn more about how our robot calibration solutions can transform your operations. Let us help you fine-tune your automation for optimal performance.

#robot calibration#industrial robot accuracy#Dynalog robot systems#TCP calibration#robot base calibration#kinematic calibration#robotic automation#precision robotics#robot calibration services#robotic manufacturing#factory automation#robot programming accuracy#robot workcell integration#Dynalog-US#robotic system optimization#industrial automation solutions#offline robot programming#improving robot accuracy#robot coordinate system#robotic inspection calibration

0 notes

Text

Robotic Machine Sensor Market Growth Analysis, Market Dynamics, Key Players and Innovations, Outlook and Forecast 2025-2032

According to new market research, the global robotic machine sensor market was valued at USD 867 million in 2024 and is projected to reach USD 1,344 million by 2032, growing at a Compound Annual Growth Rate (CAGR) of 7.5% during the forecast period (2025-2032). This growth is driven by rapid automation adoption across industries, advancements in Industry 4.0 technologies, and increasing demand for precision robotics.

Download FREE Sample Report: Robotic Machine Sensor Market - View Detailed Research Report

What Are Robotic Machine Sensors?

Robotic machine sensors are intelligent components that enable robots to perceive and interact with their environment. These sophisticated devices replicate human sensory capabilities, providing critical data on position, force, vision, touch, and other variables that robotic controllers use to execute precise movements and operations. The market encompasses specialized sensors including: movement sensors (accelerometers, gyroscopes), vision systems (2D/3D cameras), tactile sensors, proximity detectors, and voice recognition modules. Modern sensors increasingly incorporate AI and edge computing capabilities, transforming them from passive components into active decision-makers within automated systems.

Key Market Drivers

1. Industry 4.0 Revolution Fuels Sensor Demand

The transformation toward smart factories is accelerating sensor adoption, with modern automated production lines now incorporating 150-200 sensors per robotic cell compared to just 50-75 five years ago. Vision systems account for nearly 40% of this growth, as manufacturers implement real-time quality control across assembly lines. The automotive sector shows particularly strong adoption, where sensor-guided robotic welding now achieves placement accuracy within 0.1mm - crucial for electric vehicle battery assembly.

2. Human-Robot Collaboration Expands Applications

The rise of collaborative robots (cobots) has created new sensor requirements, particularly for force-torque detection and tactile feedback systems that ensure worker safety. Recent innovations include AI-powered skins that give robots a sense of touch across entire surfaces, enabling delicate operations in electronics manufacturing where human-like dexterity is essential. The global cobot market is projected to require over 8 million specialized sensors annually by 2026.

Market Challenges

Despite strong growth, several barriers persist. High implementation costs remain prohibitive for SMEs, with integrated robotic workcells often exceeding $250,000. Sensor reliability in extreme environments presents another hurdle - welding cells experience sensor failures every 600-800 hours due to arc glare and metal spatter. Additionally, cybersecurity risks in interconnected sensor networks have caused 35% of manufacturers to delay IIoT adoption until encryption standards improve.

Emerging Opportunities

The market presents significant growth potential in micro-manufacturing, where new nano-precision sensors enable robotic assembly of components smaller than human hair. The medical robotics sector alone will require 850,000 high-accuracy sensors by 2026. Another promising avenue is modular sensor platforms that reduce integration time from weeks to days - early adopters report 40% faster deployment and 30% lower engineering costs compared to traditional solutions.

Regional Market Insights

Asia-Pacific dominates with 45% market share, led by China's electronics manufacturing boom and Japan's leadership in precision robotics. The region grows at 8.9% CAGR, with sensor demand in South Korea's semiconductor sector increasing 22% annually.

North America maintains strong growth through aerospace and automotive investments, with U.S. facilities incorporating 50% more sensors per robot compared to conventional lines. Strict OSHA safety standards are accelerating tactile sensor adoption.

Europe shows steady expansion through Industry 4.0 initiatives, particularly in German automotive plants where vision system adoption has doubled since 2020. The EU's machine safety directives continue to drive innovation in collaborative robotics sensing.

Emerging markets demonstrate potential, with Brazil's automotive sector and the Middle East's logistics automation driving regional growth, though high technology costs remain a barrier to widespread adoption.

Competitive Landscape

Keyence and Cognex lead the vision sensor segment with 28% combined market share, recently introducing AI-enhanced pattern recognition systems that achieve 99.5% detection accuracy.

Baumer Group expanded its capabilities through strategic acquisitions, while Rockwell Automation partnered with NVIDIA to integrate advanced simulation and edge-based perception technologies.

Specialized manufacturers like ATI Industrial Automation continue innovating in force-torque sensing, recently launching a new series with 0.01N resolution for delicate assembly applications.

Market Segmentation

By Sensor Type:

Vision Systems (2D/3D cameras, LiDAR)

Force-Torque Sensors

Tactile and Proximity Sensors

Position and Motion Detectors

Environmental Sensors

Specialized Industrial Variants

By Application:

Industrial Automation

Collaborative Robotics

Autonomous Mobile Robots

Precision Manufacturing

By End-Use Industry:

Automotive and Transportation

Electronics and Semiconductors

Healthcare and Life Sciences

By Integration Level:

Standalone Sensors

Report Scope & Offerings

This comprehensive market analysis provides:

2025-2032 market size forecasts with COVID-19 impact analysis

Competitive intelligence on 12 major players (Keyence, Cognex, Baumer, Rockwell, etc.)

Technology trend analysis including AI integration, edge computing, and miniaturization

Strategic recommendations for suppliers and end-users

Download FREE Sample Report: Robotic Machine Sensor Market - View Detailed Research Report

Access Full Market Research: Complete Robotic Machine Sensor Market Analysis 2025-2032

Visit more reports :

https://www.tumblr.com/intelmarketresearch/787942687211929600/waterborne-curing-agents-market-growth-analysishttps://www.bundas24.com/blogs/52656/Waterborne-Curing-Agents-Market-Growth-Analysis-Market-Dynamics-Key-Playershttps://hallbook.com.br/blogs/630744/Waterborne-Curing-Agents-Market-Growth-Analysis-Market-Dynamics-Key-Playershttps://logcla.com/blogs/710480/Waterborne-Curing-Agents-Market-Growth-Analysis-Market-Dynamics-Key-Playershttps://controlc.com/a314248bhttps://justpaste.it/fyhckhttps://www.flexartsocial.com/blogs/11096/Waterborne-Curing-Agents-Market-Growth-Analysis-Market-Dynamics-Key-Playershttps://sidintelmarketresearch.blogspot.com/2025/07/waterborne-curing-agents-market-growth.htmlhttps://pastelink.net/gab25yi0https://penposh.com/blogs/448159/Waterborne-Curing-Agents-Market-Growth-Analysis-Market-Dynamics-Key-Playershttps://iamstreaming.org/siddheshkapshikar/blog/11027/waterborne-curing-agents-market-growth-analysis-market-dynamics-key-players-and-innovations-outlook-and-forecast-2025-2032https://intel24.hashnode.dev/waterborne-curing-agents-market-growth-analysis-market-dynamics-key-players-and-innovations-outlook-and-forecast-2025-2032-1https://manage.wix.com/dashboard/feeb7ef3-a212-4275-a860-fdd6d8a9ee22/blog/posts?status=%5B%7B%22id%22%3A%22PUBLISHED%22%2C%22name%22%3A%22Published%22%7D%5D&selectedColumns=col-thumbnail%2Ccol-post%2Ccol-published%2Ccol-views%2Ccol-comments%2Ccol-likes%2Ccol-categories%2Ccol-tags%2Ccol-spacerhttps://www.pearltrees.com/sid7011/item724195739https://sites.google.com/view/intel-market-research/home/waterborne-curing-agents-market-2025

About Intel Market Research

Intel Market Research delivers actionable insights in technology and infrastructure markets. Our data-driven analysis leverages:

Real-time infrastructure monitoring

Techno-economic feasibility studies

Competitive intelligence across 100+ countries Trusted by Fortune 500 firms, we empower strategic decisions with precision. International: +1(332) 2424 294 | Asia: +91 9169164321

Website: https://www.intelmarketresearch.com

Follow us on LinkedIn: https://www.linkedin.com/company/intel-market-research

0 notes

Link

#AutomotiveR&D#cross-regionalinnovation#digitaltwins#GenerativeAI#human-AIcollaboration#Industry4.0#RoboticIntegration#supply-chain-optimization

0 notes

Text

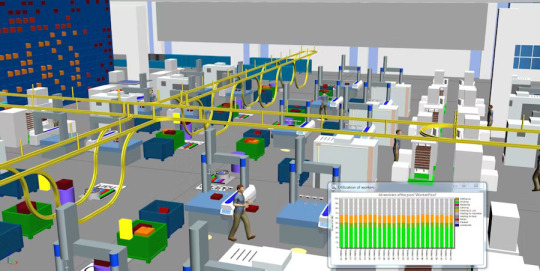

Tecnomatix: Driving Digital Manufacturing Excellence

Tecnomatix from Siemens is a comprehensive digital manufacturing solution that empowers manufacturing industries to transform their production operations with confidence. By connecting engineering, manufacturing, and operations through a single platform, Tecnomatix helps accelerate product launches, improve productivity, and reduce time-to-market — making it an essential tool for Industry 4.0 transformation.

Key Benefits:

Accelerated Time-to-Market: Simulate and validate manufacturing processes before production.

Improved Product Quality: Detect potential design or process flaws early.

Reduced Production Costs: Optimize resource usage and reduce waste.

Enhanced Collaboration: Enable seamless integration across teams and systems.

Key Features:

Process Simulation & Validation: Virtually test and verify manufacturing workflows.

Robotics & Automation Planning: Design and simulate robotic workcells for efficiency.

Ergonomics Analysis: Ensure safe and effective human interactions on the shop floor.

Manufacturing Data Management: Centralize and manage manufacturing knowledge.

Digital Twin Technology: Mirror real-world operations digitally for continuous improvement.

Applications in the Automotive Industry:

Body-in-white assembly planning and validation.

Robotic welding path optimization and simulation.

Ergonomic checks for manual operations in vehicle assembly.

Production line balancing and throughput optimization.

Early detection of production bottlenecks via virtual commissioning.

Conclusion:

Tecnomatix enables automotive manufacturers and other discrete industries to embrace smart manufacturing by bridging the gap between design and production. With DDSPLM as your implementation partner, take the next step toward operational excellence and digital transformation.

0 notes

Text

VEX Robotics hat VEXcode für ein neues Jahr des Programmierens aktualisiert! VEXcode 4.0 für VEX IQ, VEX EXP und VEX V5 bringt den Benutzern einige aufregende neue Funktionen! Diese Bemühungen zielen darauf ab, die Benutzererfahrung zu optimieren und zusätzliche Optionen für die Barrierefreiheit zu unterstützen. Entdecken Sie die neuen Funktionen für jede Plattform unten und in den begleitenden VEX Library-Artikel! Neue Funktionen in VEXcode IQ 4.0 VEXcode IQ 4.0 führt wichtige Updates ein. Zu den bemerkenswerten Ergänzungen gehören Switch Blocks, die einen nahtlosen Übergang von blockbasierter zu textbasierter Codierung auf einem physischen Roboter ermöglichen, verbesserte Speicher- und Ladefunktionen für webbasierte VEXcodeund neue Barrierefreiheitsoptionen wie "Blöcke vorlesen". Diese Updates wurden entwickelt, um die Benutzererfahrung zu optimieren und Anfänger und fortgeschrittene Benutzer zu unterstützen. Erfahren Sie hier mehr über diese Updates: https://kb.vex.com/hc/en-us/articles/29278709186708-New-Features-in-VEXcode-IQ-4-0 Neue Funktionen in VEXcode EXP 4.0 VEXcode EXP 4.0 bietet umfassende Updates, die das Bildungserlebnis für Lehrer und Schüler verbessern sollen. Diese Version bietet volle Unterstützung für den CTE Workcell, der eine nahtlose Integration von Industrierobotik in den Unterricht ermöglicht. Die neue Funktion "Blöcke wechseln" ermöglicht einen reibungslosen Übergang von blockbasierter zu textbasierter Codierung und erleichtert so fortgeschrittenes Lernen. Darüber hinaus ermöglichen webbasierte drahtlose Projekt-Downloads effizientere Arbeitsabläufe, indem sie es Benutzern ermöglichen, direkt über ihren Webbrowser eine Verbindung zu einem EXP Brain herzustellen. Verbesserte Barrierefreiheitsfunktionen wie (Vor-)Leseblöcke, anpassbare Stimmen und kontrastreiche Themen machen VEXcode inklusiver und benutzerfreundlicher. Der aktualisierte AI Vision Sensor unterstützt jetzt AprilTags und AI Classifications, wodurch die autonomen Fähigkeiten verbessert werden. Mit diesen Verbesserungen unterstützt VEXcode EXP 4.0 weiterhin eine breite Palette von Bildungsanforderungen, von Anfängern bis hin zu fortgeschrittenen Roboterprogrammierungen. Erfahren Sie hier mehr über diese Updates: https://kb.vex.com/hc/en-us/articles/29373428548372-New-Features-in-VEXcode-V5-4-0

#AI#Competition#Development#EducationStudies#General#German#Programming#Software#STEM#VEX#VEXEDR#VEXIQ#VEXV5#neueFunktionen#Programmierung#Roboter#Update#Verbesserungen#VEXEXP#VexRobotics#VexCode#VEXcode4.0

0 notes

Text

Lab Automation: Streamlining Laboratory Processes through Automated Systems

Emergence of Lab Automation Systems The laboratory environment has relied heavily on manual processes for experiments, sample handling, and data recording. However, with advancements in robotics and software capabilities, laboratories are increasingly adopting automated systems to streamline workflows. Several technologies have emerged that allow for automation of repetitive and mundane tasks, reducing reliance on human labor and freeing up scientists and technicians for more value-added work. Benefits of Lab Automation Automated systems deliver significant benefits across laboratory operations. Consistency and reproducibility are enhanced as automated processes minimize human errors and variations. Efficiency is greatly improved as robots can work continuously without breaks. Automated liquid handling and sample preparation allow for high-throughput processing of large sample volumes. Data management is digitized enabling electronic recording and integration with Laboratory Information Management Systems (LIMS) for analysis and reporting. Automation also improves precision through use of robotics for pipetting of minute volumes and positioning of samples. Safety is enhanced in automated workcells as hazardous substances are handled by robots reducing human exposure. Types of Lab Automation Systems A variety of automated systems have been developed to meet the specific needs of different laboratory applications: - Liquid Handling Workstations - Used for accurate pipetting, dilution, mixing and dispensing of liquids. They automate routine processes like reagent and sample preparation. - Automated Microplate Processors - Handle microplates used in assays and high-throughput screening. They perform washing, incubation, and reading functions with integrated microplate handlers and readers. - Automated DNA/RNA Synthesis and Analysis - Used for genomic and genetic analysis through automation of PCR setup, purification, electrophoresis and detection processes. - Automated Storage and Retrieval Systems - Provide centralized automated warehousing of vessels, plates and reagents. They automate delivery of correct items on demand. - Automated Sample Preparation Workflows - Integrate centrifuges, mixers, homogenizers and liquid handlers to automate sample extraction, digestion and derivatization procedures.

0 notes

Text

Meltio and One-Off Robotics join forces to push the limits of robotic additive manufacturing for cost-effective and reliable metal part production

One Off Robotics and Meltio are teaming up to develop a breakthrough, ready-to-use additive manufacturing workcell. This system includes high-touch customer service and comprehensive support to assist end users in any industry.

The US-based company One Off Robotics is one of Meltio’s key partners in supporting wire-laser metal 3D printing in the USA. Their new turnkey system can be quickly and easily deployed into any factory environment.

Linares (Spain) and Chattanooga (USA) – February 8th, 2024. Meltio, a disruptive wire-laser metal deposition additive manufacturing technology leader, has announced a collaboration with One Off Robotics, an industry leader in robotic additive manufacturing (AM). The latest collaboration introduces the One-Off Robotics Cell, a turn-key metal additive manufacturing workcell designed for a faster, more efficient, and reliable part production cycle. Meltio Engine Product Manager, Alejandro Nieto expresses enthusiasm for this latest innovation:

“Meltio’s main commitment with this new product offering with the One Off Robotics Cell powered by Meltio, Made in the USA is to offer all types of industries the ability to manage the entire manufacturing process using our metal 3D printing technology consisting of a Meltio head integrated into a robotic arm and a safe environment, to just produce parts. “One Off Robotics has spent years designing and building large-format robotic additive manufacturing work cells. We’re thrilled to expand our offerings to include a turnkey Meltio Robotic additive system. Our focus is customer success, so we designed this system from the ground up to be quickly installed and easily operated.” says Nick Johnson, CEO of One Off Robotics About Meltio:

Meltio takes metal additive manufacturing to the next level by developing high-performance, affordable, and easy-to-use metal 3D printing solutions using wire LMD technology. The company’s mission is to delight customers, partners, and employees by pioneering the development of affordable metal 3D printing systems that are reliable, safe, and powerful, continually reinforcing their status as disruptors. Meltio, based in Linares (Spain) develops and fabricates high-quality disruptive products aimed at industrial high-profile end customers and R&D organizations, such as universities and research-oriented companies.

Read More: https://mirrorworldmagazine.com/meltio-and-one-off-robotics-join-forces-to-push-the-limits-of-robotic-additive-manufacturing-for-cost-effective-and-reliable-metal-part-production-the-new-one-off-robotics-cell-powered-by-meltio-and/

Source: https://mirrorworldmagazine.com/

#OnlineBusinessMagazine #TopBusinessMagazines #BestBusinessBlogs #MeltioandOneOffRobotics #RoboticsCell

0 notes

Text

Collaborative Industrial Robots

Typically a robotic is distributed to a taught position numerous instances and the error is measured at every return to the position after visiting 4 different positions. Repeatability is then quantified utilizing the standard deviation of those samples in all three dimensions. A typical robot can, after all make a positional error exceeding that and that could be a problem for the method https://columbiaokura.com/products/industrial-robots/.

Others in addition, machine operators usually use person interface units, typically touchscreen items, which serve as the operator management panel. The operator can change from program to program, make changes inside a program and likewise function a bunch of peripheral devices that might be integrated within the same robotic system. Advances in robotics technology also allow us to take robots from the factory flooring and make them mobile and autonomous for model new applications, such as in retail. Autonomous robots have taken grocery stores by storm in 2019, with Ahold Delhaize's introduction of Badger Technologies' robot, which is designed to improve store operations. Equipped with numerous sensors, navigation systems and cameras, the robotic navigates store aisles alongside employees and customers to scan flooring for hazardous circumstances like spills.

The industrial robots business officially took off and never appeared back. So, industrial robotic development continued to rapidly evolve, and in 1969 the Standford Arm finally led to commercial arm production. The Stanford Arm was one of the first electronically powered, computer-controlled arms. By 1974, it reached a degree of sophistication the place it could assemble a Model T water pump. Many of the most oppressive and routine office chores—those which might be dirty, dull, or dangerous—are now completely throughout the robot realm.

Blog Read about how collaborative robots are lowering the automation barrier Case tales Discover the tales behind our customer's success. Events & Webinars Register to attend one of our workshops, seminars, or webinars. E-book Library E-books that can help you get started and succeed with collaborative robotic automation. Products Overview Our family of collaborative robots presents 4 completely different payload choices - three, 5, 12.5 and sixteen kg.

A robotic and a collection of machines or peripherals is referred to as a workcell, or cell. A typical cell might comprise a elements feeder, a molding machine and a robot. The varied machines are 'built-in' and controlled by a single pc or PLC. How the robotic interacts with different machines in the cell must be programmed, both with regard to their positions within the cell and synchronizing with them.

Compliance - this could be a measure of the amount in angle or distance that a robot axis will move when a drive is applied to it. Because of compliance when a robot goes to a place carrying its most payload it will be at a position slightly decrease than when it is carrying no payload. Compliance can be liable for overshoot when carrying high payloads during which case acceleration would have to be lowered. SCARA robots are used for jobs that require exact lateral movements.

Covering some necessary applications and system technologies that may help perceive how industrial robots management units are architected. ActiNav ActiNav™ combines intelligent imaginative and prescient, real-time autonomous movement management and Universal Robots’ world-leading cobots to deliver the core of a machine loading system. Whether used for easy bin choosing tasks or extra complicated machine tending functions, ActiNav delivers an answer that’s exact, consistent, intuitive and more agile than ever earlier than. The first prototype, Unimate, was produced in 1961 and put in in GM's manufacturing unit for die casting handling and spot welding.

In different industries, similar to agriculture, robotic drones can look at a subject to search out deficiencies in crops. They can analyze the water and dryness ranges whereas determining the ripeness of the products. Mobile robots and drones monitor oil and gas pipelines and electric transmission systems performing common inspection and on the lookout for indicators of upkeep wants, to efficiently dispatch maintenance teams. Robotic selecting and packaging will increase velocity and accuracy together with decreasing production prices.

The ability to preview the habits of a robotic system in a virtual world permits for quite so much of mechanisms, devices, configurations and controllers to be tried and examined before being utilized to a "actual world" system. Robotics simulators have the flexibility to provide real-time computing of the simulated motion of an industrial robot using both geometric modeling and kinematics modeling. They are one of the first robots to have been used in industrial functions.

And with six degrees of freedom, incredible flexibility, and easy integration into current manufacturing environments, our collaborative robots are built to do more. The Silver Arm was created by MIT's David Silver to carry out precise assembly using touch and pressure sensors and a microcomputer. During that same 12 months, these arms led to Victor Scheinman, the inventor of the Stanford Arm, to kind Vicarm, Inc. to fabricate industrial robotic arms. Scheinman was instrumental within the creation of the PUMA for Unimation. Innovators have created robots that mimic the movements of canines, cats, bugs, and people with eerie precision.

AI will reshape the capabilities of robotic technology, however that is nonetheless no much less than a decade in the future. With wherever from two to 10 joints, articulated robots are related to the bottom with a twisting joint. Resembling a human arm, they are generally utilized in packaging, portray, metallic casting and different industrial purposes. Sep 29, 2021 — A push to automate is changing the way people and machines work collectively. The number of industrial robots installed in factories reached about 3 million units worldwide in 2020 – more than doubling in ten years. The IFR has researched how robotics training shapes present and future workforce schooling, enhancing expertise development for employees.

As China works to meet up with its international friends, the robotics market may see sturdy development for a few years to come back. RIA has transformed into the Association for Advancing Automation, the leading world automation commerce association of the robotics, machine vision, motion control, and industrial AI industries. FANUC provides the widest collection range of commercial robots on the earth. Covering a diverse range of purposes and industries, FANUC machines are straightforward to operate and provide full flexibility.

But it wasn't until the Sixties that industrial robots had been introduced to the automotive manufacturing ground of an meeting plant. In the context of general robotics, most kinds of industrial robots would fall into the class of robot arms. Typical purposes of business robots include welding, portray, ironing, assembly, decide and place, palletizing, product inspection, and testing, all achieved with high endurance, velocity, and precision.

Most of the older robot-controllers cannot be used for these strategies of manufacturing automation. The common lifetime of the robotic mechanics is, relying from the economic use between 10 and 20 years. Until now there was only the chance to disassemble and sell the mechanical components as spare elements. The first successful story of a enterprise creating a selected robot based mostly on their needs was created in 1967.

With 18 series of models, FANUC offers the widest vary of industrial robots on the earth. With more than a hundred fashions, FANUC provides the widest vary of commercial robots on the planet. Infineon’s elements and system options are well fitted to industrial robots as a whole. Power digital parts, similar to IGBTs and CoolSIC™ MOSFETs, including becoming EiceDRIVER™ gate driver solutions throughout numerous power ranges, support a extensive range of robotic payloads. CoolMOS™ and CoolSIC™ MOSFETs, and auxiliary power supply options similar to CoolSET™ allow energy management. PSoC® microcontrollers, with their big selection of performance, are applicable for system management and are additionally equipped with peripherals to allow connectivity through CAN, USB, or Wi-Fi based on the AIROC™ Wi-Fi & Combos providing.

Benefit from a quick ROI thanks to low-cost parts from main manufacturers. The TI-RSLK MAX comes with 20 learning modules covering core to supplemental topics with lecture videos, lab demonstrations, quizzes and classroom activities. The curriculum is targeted to show embedded methods and functions and can be expanded and used in a big selection of engineering courses at any level along a college student’s learning journey. Universal Robots could hold observe of my name and business contact info to e mail me exciting updates in factory automation which would possibly be related to me.

It's using exponential know-how curves in associated industries to robots so as to drive adoption. It's hard to drive expertise innovation within an industry-but whenever you adopt applied sciences from "exterior" industries, opportunities are limitless. At their core, robots still do the mundane, monotonous and time-consuming tasks staff do not take pleasure in whereas offering invaluable data to improve operations. Without sensors and different latest advancements, none of this is ready to be potential. Artificial intelligence , of course, is a key a half of the dialog.

youtube

1 note

·

View note

Text

Industrial Robots

Robot sales to automotive producers increased by 22 p.c to a brand new peak of almost a hundred twenty five,seven hundred models. Carmakers remained the biggest prospects for industrial robots last year – just – with a one-third share of the total supply. Innovators have created robots that mimic the movements of dogs, cats, insects, and people with eerie precision. In industrial settings, these advances are letting firms transfer a few of the most tough, harmful, and time-consuming duties from workers to robots. As this trend accelerates, each traders and robotic-component manufacturers are in strong positions to entry profit swimming pools.

Collaborative industrial robots are designed to carry out duties in collaboration with employees in industrial sectors. The International Federation of Robotics defines two forms of industrial robots designed for collaborative use. The different group covers robots designed for collaborative use that do not satisfy the requirements of ISO.

Since grippers and EOATs account for around 3 p.c of the total price of automation, the selection of a high-priced supplier could have relatively little impact on a company’s manufacturing-line prices. As China builds its robotic installed base, it's going to see a 25 % annual increase in demand for end effectors from 2018 by way of 2023. That determine represents about 45 % of the whole market growth expected over those years, and it’s greater than the mixed contribution of Europe and North America. Of the $5.1 billion in market worth for grippers and EOATs in 2023, greater than $1 billion will come from China. If your business isn’t listed on this listing, it doesn’t imply that you can’t use robots in your business. In reality, lots of the hottest robotic functions are applicable to almost any business.

Increased use of robots can be enabling firms in high value nations to ‘re-shore’ or bring again to their home base components of the supply chain that they have beforehand outsourced to sources of cheaper labor. This implies that even small-quantity productions can effectively be automated in areas similar to components welding and slicing, versatile assembly and packaging and palletizing. Robot investments have gotten more and more worthwhile and hence turn out to be increasingly widespread within business. The robotic’s actions are directed by a mixture of programming software and controls. Their automated performance allows them to function around the clock and on weekends—in addition to with hazardous supplies and in difficult environments—releasing personnel to carry out other duties.

The International Federation of Robotics has predicted a worldwide enhance in adoption of industrial robots and so they estimated 1.7 million new robot installations in factories worldwide by 2020 . Using knowledge from the Bureau of Labor Statistics, NIOSH and its state companions have investigated four robot-associated fatalities beneath the Fatality Assessment and Control Evaluation Program. In addition the Occupational Safety and Health Administration has investigated dozens of robot-associated deaths and accidents, which could be reviewed at OSHA Accident Search page. Injuries and fatalities could increase over time because of the rising number of collaborative and co-existing robots, powered exoskeletons, and autonomous automobiles into the work environment.

ISO 9283 specifies that accuracy and repeatability should be measured at most velocity and at maximum payload. But this ends in pessimistic values whereas the robot could be rather more accurate and repeatable at gentle loads and speeds. Repeatability in an industrial process is also topic to the accuracy of the end effector, for instance a gripper, and even to the design of the 'fingers' that match the gripper to the item being grasped. For instance, if a robot picks a screw by its head, the screw might be at a random angle. A subsequent try and insert the screw into a gap could simply fail.

In the year 2020, an estimated 1.64 million industrial robots have been in operation worldwide according to International Federation of Robotics . Industrial robots are automated, programmable and capable of motion on three or more axes. The most commonly used robot configurations for industrial automation, include articulated robots, SCARA robots and gantry robots. The IFR forecasts continued annual industrial robot growth of 5 percent in Germany over the subsequent three years. IFR forecast US industrial robot development of 5 percent this year, rising to 10 percent between 2019 and 2021.

The enthusiasm and funding weren't at all times matched with understanding. General Motors Corporation spent greater than $40 billion on new technology in the 1980's, but a lack of know-how led to expensive robotic fiascos. In 1988, robots at the Hamtramck Michigan plant wreaked havoc - smashing home windows andpaintingone one other. Unfortunately, the premature introduction of robotics began to create monetary instability. The Silver Arm was created by MIT's David Silver to perform exact meeting using touch and pressure sensors and a microcomputer.

The International Federation of Robotics has published its annual report on the state of the commercial robotics market worldwide. Companies usually buy finish effectors once they automate a brand new manufacturing line or when they determine to transform or overhaul their existing production tools, together with robotic arms. Likewise, corporations may purchase grippers and EOATs after they must retool their manufacturing strains to support the introduction of new or updated products or once they introduce a variant, similar to a hybrid version of a automotive. Although companies additionally buy robotic elements because of general wear and tear, this isn’t a substantial source of revenue for suppliers of end effectors, since most parts are covered beneath lengthy warranties. End effectors also tend to final for much longer than the expected lifetime outlined in their specs. Despite the rising demand for grippers and EOATs, little analysis is available on this crucial market phase.

However a computer is commonly used to 'supervise' the robotic and any peripherals, or to offer further storage for entry to quite a few complicated paths and routines. A robotic and a set of machines or peripherals is known as a workcell, or cell. A typical cell might contain a elements feeder, a molding machine and a robotic. The varied machines are 'integrated' and managed by a single pc or PLC.

ABB Robotics is a pioneer in robotics, machine automation and digital companies, providing progressive solutions for a diverse range of industries, from automotive to electronics to logistics. As one of many world’s leading robotics and machine automation suppliers, ABB Robotics employs greater than 11,000 folks in fifty three international locations and has shipped greater than 500,000 robotic options. Sensors and vision systems allow robots to reply to their exterior setting in real-time, increasing the range of duties the robotic can perform - such as choosing and putting unsorted parts - and expanding robotic mobility. Mobile robots are key to enabling versatile manufacturing, in which production is split into discrete processes and manufacturing cells working in parallel. Collaborative and conventional industrial robots © IFR International Federation of Robotics For more info, please check with the IFR Positioning Paper on Demystifying Collaborative Robots. In 2019, about 4.eight% industrial robots installed, had been cobots, an increase of 11% over 2018.

In 1969 Victor Scheinman at Stanford University invented the Stanford arm, an all-electrical, 6-axis articulated robotic designed to allow an arm resolution. This allowed it accurately to comply with arbitrary paths in space and widened the potential use of the robotic to more sophisticated purposes similar to meeting and welding. Other robots are far more versatile as to the orientation of the object on which they are operating or even the task that has to be performed on the object itself, which the robotic may even have to determine.

Often known as ‘cobots’, these robots are designed with quite a lot of technical options that ensure they do not cause harm when a employee comes into direct contact, either deliberately or accidentally. In the context of common robotics, most types of industrial robots would fall into the class of robot arms. Elsewhere in Europe, robot investments increased by 19 percent to a new record of 7,seven hundred units last 12 months in Italy.

Many of probably the most oppressive and routine office chores—these which are soiled, dull, or dangerous—are actually totally within the robotic realm. But thanks to current technologic advances, robots are also handling extra complex operations that require excessive precision. For example, robots with laser-vision systems can fit doorways exactly to car bodies. These improvements, combined with several economic forces, are prompting corporations to contemplate industrial robots more critically.

With 18 sequence of fashions, FANUC offers the widest range of industrial robots on the planet. Covering a various vary of functions and industries, FANUC machines are simple to operate and supply complete flexibility. With greater than one hundred models, FANUC provides the widest vary of commercial robots in the world. FANUC offers the widest collection vary of commercial robots in the world.

For examples of how this may look in well-liked robot languages see industrial robotic programming. The most important robot peripheral is the top effector, or end-of-arm-tooling . End effectors are regularly highly advanced, made to match the handled product and often able to picking up an array of merchandise at one time. They might utilize numerous sensors to aid the robotic system in finding, dealing with, and positioning products. Manufacturing impartial robotic programming instruments are a relatively new however flexible method to program robot applications. Using a graphical consumer interface the programming is completed through drag and drop of predefined template/building blocks.

This consists of following a security-licensed growth course of for safety-crucial system components. An experienced companion with intensive information about robotics – from the system as a whole to every final drive and sensor – is crucial to a project’s success. A big selection of parts flows into an industrial robot design to create a seamlessly functioning system. Each robotic usually includes three main parts, a control box, a manipulator and a selected software, mounted on the highest of the robotic’s arm.

Of course, major technologic advances might disrupt the robotic-part business, as they've carried out in other sectors, and shift demand in surprising directions. It’s hard to predict whether or not such disruptions will materialize—or anticipate the time-frame over which they might occur—however industry stakeholders might want to monitor all technologic developments closely. The robotic installed base will see robust global growth, however rising markets will account for the best enhance. China, in particular, will see automation surge, partly in response to the government’s Made in China 2025 plan. Introduced in 2015, the plan goals to transform the country into the world’s high manufacturing powerhouse by bettering product high quality via larger automation.

Including the cost of software, peripherals and techniques engineering, the annual turnover for robot systems is estimated to be US$48.zero billion in 2018. This is a wrist about which the three axes of the wrist, controlling yaw, pitch, and roll, all pass by way of a common point. An instance of a wrist singularity is when the path by way of which the robot is traveling causes the primary and third axes of the robotic's wrist (i.e. robotic's axes 4 and 6) to line up. The second wrist axis then attempts to spin 180° in zero time to keep up the orientation of the top effector. The result of a singularity may be fairly dramatic and may have antagonistic effects on the robot arm, the top effector, and the process. Some industrial robotic producers have tried to side-step the situation by slightly altering the robot's path to stop this situation.

With more than 250 software capabilities for enhanced intelligence, motion, security and productiveness and a wide variety of FANUC top quality equipment, we have a solution for nearly each conceivable application. Introducing the high rigidity robotic M-900iB/280 The M-900iB/280 is FANUC’s new specialist for purposes that demand maximum rigidity from the robotic. With more than 20,000 painting robots put in worldwide, ABB’s many years of expertise have culminated in PC software designed with the customer’s wants in thoughts. Get even more accurate search results via payload analyses with KUKA Compose.

The cylindrical coordinate robots are characterized by their rotary joint at the base and at least one prismatic joint connecting its hyperlinks. The compact effector design permits the robotic to succeed in tight workspaces without any lack of speed. Cartesian robots, additionally known as rectilinear, gantry robots, and x-y-z robots have three prismatic joints for the motion of the software and three rotary joints for its orientation in space. Receive the latest IoT news and analysis in your trade, straight to your inbox. Robot gross sales to the /electronics trade worldwide have been significantly up since 2013 and are now virtually at the same level because the automotive business. Compared to Germany and Japan , the gap is exceptional – particularly since Japan had the world’s highest robotic density in 2009.

While it’s definitely true that robots are becoming ever extra well-liked, some industries are extra affected than others. The invention of the Numerically Controlled machines, the recognition of the computer , and the built-in circuit all helped to make it possible to begin to develop the very first, but simple, industrial robot. Discover what your industrial robotic project can obtain when you partner with us. We sit up for listening to from you – and to studying extra about your design.

To have the ability to move and orient the effector organ in all directions, such a robotic wants 6 axes . In a 2-dimensional environment, three axes are enough, two for displacement and one for orientation.

It additionally presents robotic density, i.e. the number of robots per 10,000 staff, as a measure for the degree of automation. The setup or programming of motions and sequences for an industrial robotic is typically taught by linking the robotic controller to a laptop, desktop laptop or community. Power source – some robots use electrical motors, others use hydraulic actuators. Nowadays, it's extremely unlikely to see any hydraulic robots available in the market. Additional sealings, brushless electrical motors and spark-proof protection eased the development of units which might be in a position to work in the environment with an explosive environment.

There, robotic installations elevated considerably between 2012 and 2017, by 26 p.c a yr on average. That figure represents development of 31 p.c, but the IFR forecasts that UK gross sales will now develop at a modest three p.c a yr till 2021. Robot installations within the US increased to a brand new peak of 33,192 units in 2017 – the seventh successive 12 months of development, and 6 p.c larger than in 2016. Since 2010, the main driver of this development has been the need to strengthen US industries at house and abroad. But China is far from the leading country by way of robotic density – the number of robots per 10,000 employees, IFR’s most popular measurement for comparing the relative sizes of the market in different economies. Since 2013, China has been the world’s biggest robot market with “continued dynamic development” and a 36 percent share of the world’s complete supply in 2017.

Repeatability is then quantified utilizing the usual deviation of these samples in all three dimensions. A typical robotic can, of course make a positional error exceeding that and that could possibly be an issue for the process. Moreover, the repeatability is completely different in numerous parts of the working envelope and in addition modifications with speed and payload.

The capacity to preview the habits of a robotic system in a virtual world permits for a variety of mechanisms, gadgets, configurations and controllers to be tried and examined earlier than being applied to a "real world" system. Robotics simulators have the flexibility to provide actual-time computing of the simulated movement of an industrial robotic using both geometric modeling and kinematics modeling. Offline programming is where the complete cell, the robotic and all of the machines or devices in the workspace are mapped graphically. A robotics simulator is used to create embedded applications for a robotic, with out depending on the physical operation of the robotic arm and end effector. The benefits of robotics simulation is that it saves time in the design of robotics functions.

youtube

For instance, for more exact steering, robots usually include machine vision sub-techniques performing as their visual sensors, linked to powerful computers or controllers. Artificial intelligence, or what passes for it, is turning into an more and more necessary factor within the trendy industrial robotic. Serial architectures a.k.a Serial manipulators are the most common industrial robots and they are designed as a sequence of links related by motor-actuated joints that extend from a base to an finish-effector.

1 note

·

View note

Text

Fanuc paint pro

#FANUC PAINT PRO FULL#

#FANUC PAINT PRO SOFTWARE#

#FANUC PAINT PRO OFFLINE#

We reserve the right to cancel or modify classes at any time.Skull gcode. Argument registers work only one layer deep. Automatic application at our Monterrey laboratory, integrated system with Fanuc Paint Mate 200iA robot, automatic electrostatic applicator Graco ProXpc and 2. Note: For training done at the customer's facility the customer is responsible to supply each student with computers that match the software's system requirements. Prerequisites: Completion of PaintTool Operation & Programming course. Operations are kept running around the clock with longer robot runtimes and. The robot is built to withstand high temperatures, dust, chemicals, and pressure sprays without tiring or needing any downtime. Lab exercises relate directly to the classroom presentations and are intended to reinforce what the student has learned through actual hands-on experience.Īudience: This course is recommended for personnel responsible for creating and editing program paths. Senior managers, paint engineers and operators often sense that their paint automation can become more efficient and productive. A FANUC R-2000ib/210F with the FoundryPro option is better suited to operate in tough conditions such as those often found in foundries. ROBOGUIDE provides engineers the tools needed to develop and test a complete robotic application in a simulation environment without the time and costs. in Delmia UltraPaint, FANUC HandlingPro, or FANUC PaintPro simulation software.

#FANUC PAINT PRO SOFTWARE#

In addition to presentations and demonstrations, this course offers a series of lab exercises for the student to complete. FANUC Robotics’ ROBOGUIDE is the latest technology for off-line robot simulation software with a FANUC Robotics Virtual Robot Controller and full-featured robot programming. Aerobotixs in-house laboratory allows us to test and validate painting. Recommended safety procedures are integrated into all training exercises. Calibrating the Virtual & Real World WorkCells Jog the robot using the Virtual Teach Pendant and Teach Tool Open a previously created Paint virtual workcell 360 POST PROCESSOR FOR 15L SLANT-PRO LATHE PATHPILOT Log in In IPL mode.

#FANUC PAINT PRO OFFLINE#

PaintPro- Graphical offline programming solution that simplifies the robotic path. and paint the cel in other colors Share this file under name Option fanuc. Designed and built in Michigan since 1982, FANUC paint robots are suitable for a wide variety of painting and coating applications our paint robots offer easy access, optimal work envelopes, and maximized throughput. FANUC robotics has an incredible simulation software package called. Open a previously created Paint virtual workcell-Jog the robot using the Virtual Teach Pendant and Teach Tool-Calibrating the Virtual & Real World WorkCells-Add a Style-Assign Schedule boundaries-Creating a Program-Editing a Program-Create a Job-Simulate Cycle Start.

#FANUC PAINT PRO FULL#

This course will focus on developing programs for painting automotive car/truck bodies using PaintPRO software on an existing workcell.Ĭourse Objectives: Educate the student in programming the robot offline utilizing the PaintPRO. FANUC America has a full range of painting and coating robots to help manufacturers drastically improve their paint processes. Roboguide is a robot simulation software developed by FANUC, which includes a family of products such as HandlingPRO, PaintPRO, PalletPRO, and so on (FANUC.

0 notes

Text

Realtime Robotics partners with Siemens to simplify integration of robotic workcells

Realtime Robotics is partnering with Siemens to simplify the integration of robotic workcells into industrial facilities. (See video below.) Realtime Robotics, which specialises in autonomous motion planning for industrial robots, says the initiative is part of its strategic partnership with Siemens Digital Industries Software division. Realtime’s technology is being seamlessly integrated into Tecnomatix Process Simulate, […] from Robotics & Automation News https://ift.tt/2Vi2q0t via https://ift.tt/2llsasU

0 notes

Text

VEX Robotics updated VEXcode for a new year of coding! VEXcode 4.0 for VEX IQ, VEX EXP, and VEX V5 brings users some exciting new features! These efforts aim to streamline user experience and support added accessibility options. Explore the new features for each platform below and in their accompanying VEX Library articles! New Features in VEXcode IQ 4.0 VEXcode IQ 4.0 introduces major updates. Notable additions include Switch Blocks, which enable a seamless transition from block-based to text-based coding on a physical robot, enhanced save and load features for web-based VEXcode, and new accessibility options like Read Blocks Aloud. These updates are designed to streamline the user experience and support beginners and advanced users. Learn more about these updates here: https://kb.vex.com/hc/en-us/articles/29278709186708-New-Features-in-VEXcode-IQ-4-0 New Features in VEXcode EXP 4.0 VEXcode EXP 4.0 offers comprehensive updates designed to elevate the educational experience for teachers and students. This release includes full support for the CTE Workcell, enabling seamless integration of industrial robotics into the classroom. The new Switch Blocks feature allows for a smooth transition from block-based to text-based coding, facilitating advanced learning. Additionally, web-based wireless project downloads enable more efficient workflows by allowing users to connect to an EXP Brain directly from their web browser. Enhanced accessibility features like Read Blocks Aloud, customizable voices, and high-contrast themes make VEXcode more inclusive and user-friendly. The updated AI Vision Sensor now supports AprilTags and AI Classifications, enhancing autonomous capabilities. With these enhancements, VEXcode EXP 4.0 continues to support a wide range of educational needs, from introducing beginners to advanced robotic programming. Learn more about these updates here: https://kb.vex.com/hc/en-us/articles/29373428548372-New-Features-in-VEXcode-V5-4-0

#AI#Competition#Development#EducationStudies#English#General#Programming#Software#STEM#VEX#VEXEDR#VEXIQ#VEXV5#NewFeatures#Update#VEXEXP#VexRobotics#VexCode#VEXcode4.0

0 notes

Text

What Is Palletizing?

As many manufacturing and logistics systems are switching to an omnichannel model—in which a single manufacturing line and provide chain handle many types of products—it is becoming frequent for producers to make use of each types of palletizer in one facility. For occasion, an inline palletizer may have a robotic arm next to it to take over when atypical products are being palletized. This enables the speedy handling of high volumes of products as well as the efficient palletization of specialty hundreds. ProMach provides in depth experience handling a wide range of flexible packaging products in various circumstances - many of the world's most profitable manufacturers are packaged by ProMach flexible solutions.

Robotic Integrators - Palletizing

However easy or sophisticated the system, the products it handles will change. That’s why Pieter Feenstra, chief government officer of the system integration business unit for Körber Logistics, says it’s important that palletizing tools be future-proof. The trick, as always, is to find the candy spot between what's and what may be.

By Technology

ROBOGUIDE is FANUC’s offline programming product that allows customers to quickly and easily create, program and simulate a robotic workcell in 3D without the bodily need and expense of a prototype workcell setup. Investing in robotic solutions, or any capital gear is a call no company – massive or small – takes frivolously.

Equipment Components

Motoman integration companion S&R Robot Systems changed this chemical producer's manual course of for a robotic line enabled with PLC-primarily based programming, offline pallet pattern era and 2D visible inspection. Our network of system integrators, Motoman Strategic Partners, offers application expertise to ship turn-key robotic solutions for palletizing cartons, trays, baggage and different product varieties. Capabilities additionally prolong to case packing, order picking and warehouse distribution techniques to meet your market demands. In the past decade, the automated end of line palletizing of identical bundle varieties has become confirmed expertise.

Robotic Palletizing

The economic justification of a palletizing system is mainly pushed by the achievable throughput (instances per hour), the system availability, the required floor house and the utilization price of the complete production line. Especially for top throughput calls for, e.g. within the beverage business, robots set new standards in Inline Palletizing.

Put experience since 1943 to work for you; select from a line of bag fillers, conveyors, palletizers & full techniques.

This system also picks and places the slip sheets which act as moisture obstacles.

Further, robotic palletizers can work in refrigerated and freezer environments, while also handling heavy hundreds and repetitive tasks.

Of the two types of automated palletizers, an inline palletizer is mostly faster and works nicely with high volumes of a single type of products, such as canned goods.

Delkor is your single-supply, packaging equipment integrator.

The selected pallet pattern in addition to the product weight, the total variety of layers, pallet/infeed retreat, and strategy distances, and gripper information are all saved inside the unit load created.

A: Pound for pound, wood pallets can be 3-6 times cheaper than plastic. A: Properly constructed wood and plastic pallets are both extremely durable. However, once the structural integrity of a plastic pallet has been compromised, the pallet is useless.

KUKA palletizing robots for heavy masses can become familiar with much more. As nicely as their high payload capacity, combined with a reach of as much as 3,a hundred and fifty millimeters, they stand out for his or her extremely excessive working speeds. They stack heavy payloads at high velocity – with extraordinarily long upkeep intervals.

Dollies, Tucks, & Moving Equipment

Sage builds layer formers, pallet dispensers, Fanuc Robot primarily based methods, and quite a few types of gantry robots for palletizing solutions. Multiple variables decide which type computerized palletizer to use for the job, price and reach are the two most crucial elements upon preliminary analysis of a system. These two elements essentially determine if its a Gantry or a Fanuc Articulated Arm Robot. For example visit the site, if you need to load greater than 3 or 4 build places you then need a gantry, but if your reach is inside a small area and have to load 11 or 12 bags per minute, you want a Fanuc Robot. When constructing a combined pallet, the robotic’s software program algorithm ought to keep in mind unloading sequences, says Sipple.

Palletize

A Columbia palletizer machine can deal with your specific product mix with confirmed modular elements that may be positioned on most all fashions to gently and effectively stack your bundle type. The Load Transfer Station (LTS) transfers product from one pallet sort to a different type including wood to in-home “clear” pallets, plastic to wood, or other combos.

By Service

Our techniques permit the automation of each processes. The demoulding of the trays where the ice is fashioned, and the post-palletizing of the crammed luggage, ready for cargo to the customer. Large multi-robotic techniques that embrace options similar to pre-layer preparation prior to completely layered palletizing, able to assuming the most formidable productions.

Can handle as much as one thousand kg (2,200 lbs). Palletizing rates can vary anyplace from eight to 30 cases/min for a single robot selecting a single product at a time depending on stacking patterns, necessities, and even greater throughput if the robot is selecting rows of product, or full layer of merchandise.

0 notes

Text

Boston Dynamics partners with Otto Motors to co-ordinate mobile robots in the warehouse

Since then, the team has integrated Pick's box detection software into the Handle robot and sold and integrated Pick into industrial robotic workcells at .. Read More

0 notes

Text

New KX-2 Collaborative Robot Offer Continuous 360-degree Rotation

Combined with S-LAB plate handler and S-CEL workcells, enable customers to integrate extensive hardware options into automated workflows Designed to meet the market for capable robotics accessible to laboratories of all sizes S-CEL laboratory workcells provide laminar air flow across the whole system, delivering a clean and controlled environment This story is related to the following: Robotics Search for suppliers of: Laboratory Robots | Collaborative Robots from Air Conditioning /fullstory/new-kx-2-collaborative-robot-offer-continuous-360-degree-rotation-40032954 via http://www.rssmix.com/

0 notes

Text

New KX-2 Collaborative Robot Offer Continuous 360-degree Rotation

Combined with S-LAB plate handler and S-CEL workcells, enable customers to integrate extensive hardware options into automated workflows Designed to meet the market for capable robotics accessible to laboratories of all sizes S-CEL laboratory workcells provide laminar air flow across the whole system, delivering a clean and controlled environment This story is related to the following: Robotics Search for suppliers of: Laboratory Robots | Collaborative Robots from HVAC /fullstory/new-kx-2-collaborative-robot-offer-continuous-360-degree-rotation-40032954 via http://www.rssmix.com/

0 notes