#smart factory

Explore tagged Tumblr posts

Text

Smart Factory Market Size & Share Analysis, Global Trends 2031

Meticulous Research®—a leading global market research company, published a research report titled, ‘Smart Factory Market by Offering (Solutions, Services, Technologies), Sector (Automotive, Heavy Machinery & Tools, Aerospace & Defense, Metals & Mining, Electronics & Semiconductors, Pharmaceuticals), and Geography - Global Forecast to 2031.’

According to this latest publication from Meticulous Research®, the smart factory market is projected to reach $285.7 billion by 2031, at a CAGR of 16.4% during the forecast period 2024–2031.

The growth of the smart factory market is driven by the increasing adoption of cloud-based smart factory solutions & services, growing investment in Industry 4.0, and rising adoption of robots in the manufacturing sector. However, high capital & operating expenses restrain this growth. Additionally, the rising demand for smart factories in developing countries and technological advancements in industrial sensors are expected to create market growth opportunities. However, concerns about privacy, data security, and confidentiality pose challenges to the market’s growth.

Key Players

The key players operating in the smart factory market are ABB Ltd (Switzerland), Emerson Electric Co (U.S.), General Electric Company (US.), Rockwell Automation, Inc. (U.S.), Schneider Electric SE (France), Siemens AG (Germany), Mitsubishi Electric Corporation (Japan), Honeywell International Inc. (US), Yokogawa Electric Corporation (Japan), Endress+Hauser Group (Switzerland), SAP SE (Germany), Cisco Systems, Inc. (U.S.), Ubisense Limited (U.K.), Oracle Corporation (U.S.), IBM Corporation (U.S.), Microsoft Corporation (U.S.), FANUC Corporation (Japan), Omron Corporation (Japan), Robert Bosch GmbH (Germany), and Cognex Corporation (U.S.).

What Drives the Smart Factory Boom?

Several core factors are fueling the growth of the smart factory market. One of the most significant is the unrelenting push for greater operational efficiency. Modern manufacturers face fierce global competition and growing consumer demands for personalized products delivered swiftly. Smart factory technologies allow companies to automate repetitive processes, streamline workflows, minimize downtime, and maximize output—all while maintaining consistently high quality. The result is not just cost savings, but a powerful competitive edge.

Technology itself is also a driving force. The extraordinary pace of innovation in IoT and AI has made it possible for even traditionally conservative sectors to upgrade their production lines. IoT sensors embedded throughout the factory floor now collect troves of real-time data, delivering unprecedented visibility into every aspect of production. Meanwhile, AI-powered analytics help companies interpret this sea of data: identifying patterns, detecting anomalies, and suggesting practical improvements that would be impossible for humans to spot alone. The integration of these technologies also enables predictive maintenance—anticipating potential equipment failures before they shut down operations, and thus sparing manufacturers from costly delays.

Flexibility is another major impetus. Today’s markets are volatile, and consumer preferences can change in a heartbeat. Smart factories, through digital twins and agile automation platforms, allow manufacturers to reconfigure production lines with a few clicks, pivoting seamlessly between products or accommodating sudden demand spikes without missing a beat.

AI, IoT, and the Factory of the Future

Artificial Intelligence and IoT are undeniably at the heart of the smart factory revolution. AI takes on more than just data analysis—it’s now deeply involved in process optimization, quality assurance, and even supply chain decision-making. For instance, AI-driven cameras don’t just inspect products for defects; they learn what to look for, adapting their criteria over time and improving with every production run. IoT devices, on the other hand, are the silent sentinels that keep a finger on the pulse of every machine, conveyor, and robotic arm, ensuring conditions remain optimal and alerting managers before problems escalate.

Cloud computing ties this all together, making it possible for managers, engineers, and operators to access data and control systems from any location. This has become increasingly valuable in a world shaped by remote work and global supply chains. Emerging technologies, such as augmented reality (AR) and virtual reality (VR), are also finding a place on the factory floor—offering immersive training opportunities and enabling remote maintenance support that minimizes travel and speeds up problem-solving.

Who is Leading the Smart Factory Charge?

Not all industries are moving at the same pace when it comes to adopting smart factory technologies, but some sectors are clearly ahead of the curve. The automotive industry, with its history of automation and focus on precision and efficiency, has been a trailblazer—rapidly leveraging robots, connected machines, and real-time analytics. High-tech electronics and semiconductor manufacturers follow closely, as their need for flawless quality and rapid innovation cycles demand nothing less than the highest level of automation.

Aerospace and defense companies have also embraced smart factory principles, given the need for meticulous accuracy, traceability, and compliance. Pharmaceuticals are catching up, recognizing that connected, well-monitored production environments are essential for both regulatory compliance and market responsiveness. Sectors like heavy equipment manufacturing, metals, and mining are turning to smart factory solutions to improve uptime, boost safety, and reduce overall costs—even in the toughest operating environments.

The Rising Importance of Energy Efficiency

One of the most noticeable trends in the evolution of smart factories is the focus on energy efficiency, and for good reason. Energy represents a significant portion of manufacturing expenses, and economic pressures have made finding savings here more important than ever before. Smart factories achieve dramatic reductions in energy usage by using AI and IoT to monitor equipment, optimize usage schedules, and automatically shut down systems when they are not needed.

But energy efficiency is not just about lowering the electricity bill; it’s also a response to growing calls for sustainable manufacturing. Governments are tightening environmental regulations, customers are demanding greener products, and investors are scrutinizing companies’ environmental, social, and governance (ESG) metrics. By optimizing their energy consumption, reducing waste, and minimizing emissions, smart factories help organizations meet these regulatory and social demands while enhancing their reputation and stakeholder trust.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5365

Key Questions Answered in the Report:

Which are the high-growth market segments in terms of component and sector?

What was the historical market size for smart factories globally?

What are the market forecasts and estimates for 2024–2031?

What are the major drivers, restraints, opportunities, challenges, and trends in the smart factory market?

Who are the key players in the smart factory market, and what are their market shares?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Smart Factory Market#Smart Factory#Industrial Sensors#Industrial Robots#Industrial Automation and Control Systems/Plant Level Controls#Supervisory Control and Data

0 notes

Text

What Is an Andon System? Benefits & Real-Time Applications in Manufacturing

In today’s competitive manufacturing landscape, efficiency, visibility, and responsiveness are non-negotiable. Manufacturers are continuously looking for solutions that can enhance productivity while minimizing downtime. One such powerful tool is the Andon System—a visual management system designed to signal problems in real time and ensure immediate action.

✅ What is an Andon System?

An Andon System is a communication tool used in manufacturing environments to alert team members and supervisors to issues on the shop floor. Traditionally, it involves lights, buttons, or pull cords to signal problems. Modern systems like those from Glansa now incorporate digital displays, IoT connectivity, and automated data logging to provide more accurate and actionable insights.

✅ Key Benefits of Implementing an Andon System

🔹 1. Real-Time Problem Identification

Andon Systems immediately alert the relevant personnel when an issue arises, allowing for swift resolution. This minimizes downtime and keeps the production line flowing.

🔹 2. Improved Communication

Visual and auditory alerts ensure everyone—from machine operators to supervisors—is on the same page. Glansa’s Andon System takes this a step further with mobile notifications and dashboards.

🔹 3. Increased Productivity

By reducing the time spent diagnosing issues, employees can focus more on production and less on problem-solving.

🔹 4. Data-Driven Decisions

Modern Andon systems log every issue and response time, enabling teams to analyze trends and make continuous improvements.

✅ Why Choose Glansa’s Andon System?

Glansa offers a smart, customizable, and scalable Andon solution that fits modern factories of all sizes. Key features include:

IoT integration for remote monitoring

Real-time alerts across multiple channels

Analytics dashboard for downtime tracking

Easy integration with MES and ERP systems

Explore the full features here: https://glansa.com/andon/

✅ Conclusion:

If you're looking to minimize production bottlenecks, improve shop floor communication, and build a culture of continuous improvement, an Andon System is the way forward. With Glansa’s advanced Andon solution, manufacturers gain real-time visibility and control—turning challenges into opportunities for growth.

#Andon System#Lean Manufacturing#Production Monitoring#Real-Time Alerts#Industrial Automation#Smart Factory#Shop Floor Management#Glans

0 notes

Text

0 notes

Text

CNC Machine Manufacturer in India

Looking for a reliable CNC machine manufacturer in India? Discover high-quality, precision-engineered CNC machines that power industries across automotive, aerospace, electronics, and more. Indian CNC machine manufacturers have quickly emerged as global leaders, offering advanced, affordable, and durable solutions for both small businesses and large-scale industries.

One of the standout names in the Indian CNC sector is Sahil Machines. Known for their innovation and commitment to quality, Sahil Machines provides a wide range of CNC solutions, including CNC turning centers, vertical machining centers (VMC), and custom-built systems. Their machines are designed for accuracy, speed, and longevity—making them ideal for high-demand applications.

With strong after-sales service, installation support, and training, Indian CNC machine manufacturers ensure that your production lines stay efficient and productive. Whether you're a startup or an established industry player, choosing a trusted Indian manufacturer helps reduce costs without compromising on performance.

Many manufacturers now also offer smart features like IoT integration, real-time monitoring, and automated production capabilities—ensuring you stay ahead in a competitive market.

Bookmark this page if you’re planning to invest in reliable CNC machinery made in India. Experience engineering excellence, world-class support, and unbeatable value with top CNC brands from India.

0 notes

Text

youtube

Sandy Munro reveals why Chinese Car companies are 5 years ahead

🚗 In this eye-opening video, legendary automotive engineer Sandy Munro breaks down why Chinese car companies are now 5 years ahead of global competitors in the EV revolution! From groundbreaking battery technology, manufacturing efficiency, and cutting-edge design, to game-changing strategies in electric vehicles, Munro exposes how brands like BYD, NIO, Xpeng, and Li Auto are dominating the future of electric cars. Discover how China's EV innovation, supply chain control, and smart factory integration are reshaping the automotive industry faster than Tesla and legacy automakers ever imagined. Don’t miss this deep dive into the global shift in EV leadership, and find out what it means for the future of electric mobility, autonomous driving, and sustainable transportation.

#Sandy Munro#smart factory#ev manufacturing#ev sales#american decline#competition#BYD#Youtube#tesla killer#elon musk#China#usa

1 note

·

View note

Text

Industry 4.0: Powering the Next Industrial Revolution with Intelligence, Connectivity, and Automation

The world is undergoing a radical transformation. As we move deeper into the 21st century, the fusion of digital, physical, and biological systems is reshaping how we manufacture, operate, and innovate. This revolution has a name: Industry 4.0—the fourth industrial revolution. It represents a new era where smart technology, real-time data, automation, and interconnected networks converge to…

#5G Connectivity#Additive Manufacturing#advanced robotics#Artificial intelligence#Automation#Big Data Analytics#Blockchain#Cloud Computing#connected industry#Cyber-physical systems#data-driven operations#Digital Transformation#Digital twin#Edge computing#fourth industrial revolution#IIoT#Industrial Networking#Industry 4.0#intelligent systems#manufacturing innovation#next-gen industry#Predictive maintenance#Real-time analytics#Robotics#smart factory#Smart Grid#Smart logistics#Smart manufacturing#SolveForce#Supply Chain Visibility

0 notes

Text

Odoo ERP for Manufacturing Industry

🏭 Manufacturers—streamline your operations with Odoo ERP!

From production planning to inventory management and real-time reporting, Odoo gives you full control of your manufacturing process — all in one platform.

✅ Boost productivity ✅ Minimize downtime ✅ Reduce waste & costs ✅ Get real-time insights for smarter decisions

Looking to digitize your factory floor? Our team specializes in implementing Odoo ERP tailored for the manufacturing industry.

🔧 Explore how we can help: https://www.candidroot.com/odoo-manufacturing-erp

#odoo#odoo erp#erp for manufacturing#manufacturing excellence#smart factory#industry 40#digital manufacturing#erpsoftware#erp system

0 notes

Text

Smart Factory Market to Hit $30.1 Billion by 2029: The Future of Manufacturing is Here

The smart factory market is undergoing a rapid transformation, driven by a blend of advanced technologies, robust government support, and the rising demand for efficient, automated production processes. According to a recent report by MarketsandMarkets™, the smart factory market is expected to surge from $18.8 billion in 2024 to $30.1 billion by 2029, growing at an impressive CAGR of 9.8%.

This growth reflects a major shift in how industries operate, moving from traditional manufacturing to connected, intelligent, and automated ecosystems. The smart factory revolution is well underway, and industries are leading the charge.

What’s Fueling the Smart Factory Boom?

Several factors are contributing to this explosive market growth

1. Advanced Technology Adoption

The rapid implementation of Industry 4.0 technologies, including IoT, AI, machine learning, and 3D printing, is transforming the industrial landscape. Manufacturers are using real-time data, automation, and smart systems to improve efficiency, reduce costs, and enhance product quality.

2. Strong Government Support

The government has created a favorable environment for innovation, funding R&D initiatives, and pushing for the adoption of digital manufacturing technologies across sectors. Programs such as Manufacturing USA are key enablers, accelerating the transition to smarter, more agile manufacturing processes.

3. Focus on Operational Efficiency

Increased pressure to optimize resource usage, reduce downtime, and ensure product traceability is driving companies to adopt smart factory solutions. By digitizing workflows, factories can enhance responsiveness and quality while maintaining cost-effectiveness.

Key Segments Leading the Market Growth

The report highlights several crucial components and solutions that are powering the smart factory boom in the

1. Industrial Sensors

In 2023, industrial sensors captured a significant share of the market. These sensors are critical for monitoring machinery, detecting anomalies, and collecting real-time data. As factories become smarter, sensors enable predictive maintenance, process optimization, and real-time decision-making.

Driven by the Internet of Things (IoT), the adoption of smarter sensors helps manufacturers reduce waste, enhance safety, and remain competitive in an increasingly digital ecosystem.

2. Industrial 3D Printing

Industrial 3D printing is projected to register the highest CAGR during the forecast period. This technology plays a vital role in enabling rapid prototyping, on-demand production, and customization. With strong demand from aerospace, automotive, and medical device industries, 3D printing is becoming a core component of smart manufacturing.

The benefits from a rich base of technological infrastructure and a skilled workforce make it a global leader in 3D printing adoption.

3. Manufacturing Execution Systems (MES)

MES solutions are expected to hold a significant share of the smart factory market. MES bridges the gap between factory floor operations and enterprise systems, ensuring that data flows seamlessly and efficiently.

With real-time visibility into production activities, MES helps manufacturers manage resources, monitor performance, and make informed decisions. It’s especially valuable in industries like pharmaceuticals, automotive, and electronics, where precision and compliance are essential.

Market Opportunities and Challenges

Opportunities

Increased investments in AI, robotics, and IoT

Government support for digital infrastructure

Rising need for mass customization

Adoption of cloud platforms and edge computing

These trends are unlocking new possibilities, allowing manufacturers to innovate faster, reduce operational costs, and maintain global competitiveness.

Challenges

While the outlook is positive, the smart factory market faces notable hurdles

High upfront costs for advanced technologies and infrastructure

Integration challenges with legacy systems

Cybersecurity concerns due to increased connectivity

Shortage of skilled labor for operating and maintaining smart systems

Companies must address these challenges with thoughtful planning, training programs, and robust cybersecurity strategies.

Leading Market Players

The smart factory ecosystem is supported by prominent industry leaders, including

Emerson Electric Co.

General Electric

Honeywell International Inc.

Rockwell Automation, Inc.

Dwyer Instruments, LLC.

Stratasys

3D Systems Corporation

These companies are pushing the envelope by developing innovative hardware and software solutions that form the backbone of modern smart factories.

Conclusion: The Future is Automated and Intelligent

The growth of the smart factory market signals a broader transformation in the way goods are designed, produced, and delivered. From smart sensors and 3D printers to MES platforms and predictive analytics, smart factories are at the heart of the next industrial revolution.

To stay ahead, businesses must embrace these changes and invest in digital transformation. With the right strategy and technology, the future of manufacturing looks smarter, faster, and more resilient than ever.

#digital transformation#smart factory#manufacturing industry#automated production processes#monitoring machinery#thirdeye ai#ai

1 note

·

View note

Text

Interwork Software Solutions provides comprehensive Industry 4.0 solutions, integrating advanced technologies like IoT, AI, blockchain, and data analytics to enhance operational efficiency, drive automation, and support digital transformation across industries, fostering sustainable, smart, and connected business ecosystems.

0 notes

Text

https://glansa.com/andon/

Discover how Industry Automation in India is revolutionizing manufacturing with smart solutions like Andon systems. Glansa Solutions offers a real-time alert and monitoring system to reduce downtime, improve efficiency, and support Industry 4.0 implementation. Explore how Indian industries are leveraging automation to stay globally competitive.

#Industry Automation in India#Andon System#Manufacturing Automation#Industrial Solutions India#Smart Factory#Glansa Andon#Industry 4.0 India#Real-time Production Monitoring

0 notes

Text

How to Convince Workers to Embrace Factory Automation

Learn practical strategies to overcome resistance to automation on your factory floor. This presentation breaks down how to address worker concerns, build trust, and turn skepticism into support—without pushing fear or job loss narratives. Ideal for plant managers and CI leaders navigating the people side of digital transformation.

0 notes

Text

Did you know that 75% of manufacturers struggle with operational inefficiencies due to outdated systems? What if your factory could make decisions in real-time, streamline production, and eliminate bottlenecks—all by harnessing the power of data?

Our latest blog dives into how smart factories are revolutionizing the manufacturing landscape with interconnected systems, real-time analytics, and automated processes. If you're ready to unlock new levels of productivity and efficiency, this guide will show you exactly how to transform your facility into a smart factory.

Explore the step- by-step transformation here: Link

0 notes

Text

Usine intelligente, Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 15 Premières Entreprises

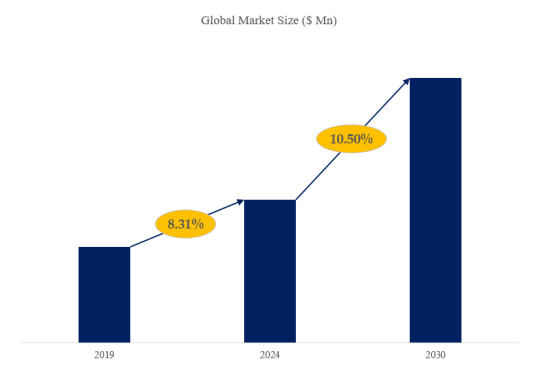

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Usine intelligente 2024-2030”, publié par QYResearch, la taille du marché mondial de Usine intelligente devrait atteindre 182100 millions de dollars d'ici 2030, à un TCAC de 10.5% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Usine intelligente (en millions de dollars américains), 2019-2030

Selon QYResearch, les principaux fabricants mondiaux de Usine intelligente comprennent Siemens, ABB, Atos SE, Cisco Systems Inc., General Electric, Emerson, Bosch, Honeywell, Microsoft Corporation, IBM, etc. En 2023, les cinq premiers acteurs mondiaux détenaient une part d'environ 17.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 15 premiers acteurs mondiaux de Usine intelligente (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

The key market drivers for the Smart Factory market:

1. Increasing Demand for Automation and Optimization of Manufacturing Processes: The need to improve productivity, efficiency, and quality in manufacturing has driven the adoption of smart factory technologies.

2. Growing Focus on Reducing Operating Costs and Improving Profitability: The desire to minimize production costs, waste, and downtime through the implementation of smart factory solutions has been a significant market driver.

3. Advancements in Industrial Internet of Things (IIoT) and Connectivity: The rapid development and integration of IIoT technologies, such as sensors, cloud computing, and data analytics, have enabled the transformation of traditional factories into smart factories.

4. Shortage of Skilled Labor and Workforce Challenges: The difficulty in finding and retaining skilled manufacturing workers has led companies to invest in smart factory technologies to improve operational efficiency and productivity.

5. Stringent Regulatory Requirements and Environmental Sustainability Concerns: The increasing focus on compliance with environmental regulations and the need to reduce the carbon footprint of manufacturing operations have driven the adoption of smart factory solutions.

6. Demand for Flexible and Reconfigurable Manufacturing Systems: The need for agile and adaptable manufacturing systems that can quickly respond to changing market demands and product variations has fueled the growth of the smart factory market.

7. Increasing Adoption of Predictive and Preventive Maintenance Strategies: The recognition of the benefits of predictive and preventive maintenance, enabled by smart factory technologies, has driven their adoption to reduce downtime and maintenance costs.

8. Rising Emphasis on Product Quality, Traceability, and Supply Chain Optimization: The demand for improved product quality, enhanced traceability, and optimized supply chain operations has been a key driver for smart factory implementations.

9. Government Initiatives and Policies Supporting Industrial Digitalization: Government programs and policies aimed at promoting the adoption of Industry 4.0 and smart manufacturing technologies have contributed to the growth of the smart factory market.

10. Increasing Competitive Pressures and the Need for Operational Excellence: The competitive pressures faced by manufacturing companies to maintain a competitive edge and improve operational excellence have driven the implementation of smart factory solutions.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

Exklusive Einblicke in die Porsche Produktion 4.0

„Die automobile Welt verändert sich ja gerade ganz massiv und wir als Porsche gestalten intensiv mit.“ Moderne Technologie revolutioniert die Art und Weise, wie Produkte hergestellt werden. Deutlich spürbar ist das in der Automobilindustrie. „Die automobile Welt verändert sich ja gerade ganz massiv und wir als Porsche gestalten intensiv mit“, sagt Albrecht Reimold, Vorstand Produktion und…

#Auto#Car#Porsche#Porsche AG#Porsche Consultin#Porsche Produktion#Porsche Produktion 4.0#Produktion#Smart Factory

0 notes

Text

Smart Factory-Digitalisierung | Nevolvis

Der Einsatz digitaler Technologie kann die Arbeitsweise von Fabriken verändern und Einnahmen generieren. Und wenn Sie Technologie in Ihrer Fertigungseinheit implementieren, wird daraus eine Smart Factory Digitalisierung. Möchten Sie wissen, wie Sie Ihre Fertigungseinheit in eine Smart Factory umwandeln können? Nehmen Sie jetzt Kontakt mit uns auf.

1 note

·

View note