#Supervisory Control and Data

Explore tagged Tumblr posts

Text

Smart Factory Market Size & Share Analysis, Global Trends 2031

Meticulous Research®—a leading global market research company, published a research report titled, ‘Smart Factory Market by Offering (Solutions, Services, Technologies), Sector (Automotive, Heavy Machinery & Tools, Aerospace & Defense, Metals & Mining, Electronics & Semiconductors, Pharmaceuticals), and Geography - Global Forecast to 2031.’

According to this latest publication from Meticulous Research®, the smart factory market is projected to reach $285.7 billion by 2031, at a CAGR of 16.4% during the forecast period 2024–2031.

The growth of the smart factory market is driven by the increasing adoption of cloud-based smart factory solutions & services, growing investment in Industry 4.0, and rising adoption of robots in the manufacturing sector. However, high capital & operating expenses restrain this growth. Additionally, the rising demand for smart factories in developing countries and technological advancements in industrial sensors are expected to create market growth opportunities. However, concerns about privacy, data security, and confidentiality pose challenges to the market’s growth.

Key Players

The key players operating in the smart factory market are ABB Ltd (Switzerland), Emerson Electric Co (U.S.), General Electric Company (US.), Rockwell Automation, Inc. (U.S.), Schneider Electric SE (France), Siemens AG (Germany), Mitsubishi Electric Corporation (Japan), Honeywell International Inc. (US), Yokogawa Electric Corporation (Japan), Endress+Hauser Group (Switzerland), SAP SE (Germany), Cisco Systems, Inc. (U.S.), Ubisense Limited (U.K.), Oracle Corporation (U.S.), IBM Corporation (U.S.), Microsoft Corporation (U.S.), FANUC Corporation (Japan), Omron Corporation (Japan), Robert Bosch GmbH (Germany), and Cognex Corporation (U.S.).

What Drives the Smart Factory Boom?

Several core factors are fueling the growth of the smart factory market. One of the most significant is the unrelenting push for greater operational efficiency. Modern manufacturers face fierce global competition and growing consumer demands for personalized products delivered swiftly. Smart factory technologies allow companies to automate repetitive processes, streamline workflows, minimize downtime, and maximize output—all while maintaining consistently high quality. The result is not just cost savings, but a powerful competitive edge.

Technology itself is also a driving force. The extraordinary pace of innovation in IoT and AI has made it possible for even traditionally conservative sectors to upgrade their production lines. IoT sensors embedded throughout the factory floor now collect troves of real-time data, delivering unprecedented visibility into every aspect of production. Meanwhile, AI-powered analytics help companies interpret this sea of data: identifying patterns, detecting anomalies, and suggesting practical improvements that would be impossible for humans to spot alone. The integration of these technologies also enables predictive maintenance—anticipating potential equipment failures before they shut down operations, and thus sparing manufacturers from costly delays.

Flexibility is another major impetus. Today’s markets are volatile, and consumer preferences can change in a heartbeat. Smart factories, through digital twins and agile automation platforms, allow manufacturers to reconfigure production lines with a few clicks, pivoting seamlessly between products or accommodating sudden demand spikes without missing a beat.

AI, IoT, and the Factory of the Future

Artificial Intelligence and IoT are undeniably at the heart of the smart factory revolution. AI takes on more than just data analysis—it’s now deeply involved in process optimization, quality assurance, and even supply chain decision-making. For instance, AI-driven cameras don’t just inspect products for defects; they learn what to look for, adapting their criteria over time and improving with every production run. IoT devices, on the other hand, are the silent sentinels that keep a finger on the pulse of every machine, conveyor, and robotic arm, ensuring conditions remain optimal and alerting managers before problems escalate.

Cloud computing ties this all together, making it possible for managers, engineers, and operators to access data and control systems from any location. This has become increasingly valuable in a world shaped by remote work and global supply chains. Emerging technologies, such as augmented reality (AR) and virtual reality (VR), are also finding a place on the factory floor—offering immersive training opportunities and enabling remote maintenance support that minimizes travel and speeds up problem-solving.

Who is Leading the Smart Factory Charge?

Not all industries are moving at the same pace when it comes to adopting smart factory technologies, but some sectors are clearly ahead of the curve. The automotive industry, with its history of automation and focus on precision and efficiency, has been a trailblazer—rapidly leveraging robots, connected machines, and real-time analytics. High-tech electronics and semiconductor manufacturers follow closely, as their need for flawless quality and rapid innovation cycles demand nothing less than the highest level of automation.

Aerospace and defense companies have also embraced smart factory principles, given the need for meticulous accuracy, traceability, and compliance. Pharmaceuticals are catching up, recognizing that connected, well-monitored production environments are essential for both regulatory compliance and market responsiveness. Sectors like heavy equipment manufacturing, metals, and mining are turning to smart factory solutions to improve uptime, boost safety, and reduce overall costs—even in the toughest operating environments.

The Rising Importance of Energy Efficiency

One of the most noticeable trends in the evolution of smart factories is the focus on energy efficiency, and for good reason. Energy represents a significant portion of manufacturing expenses, and economic pressures have made finding savings here more important than ever before. Smart factories achieve dramatic reductions in energy usage by using AI and IoT to monitor equipment, optimize usage schedules, and automatically shut down systems when they are not needed.

But energy efficiency is not just about lowering the electricity bill; it’s also a response to growing calls for sustainable manufacturing. Governments are tightening environmental regulations, customers are demanding greener products, and investors are scrutinizing companies’ environmental, social, and governance (ESG) metrics. By optimizing their energy consumption, reducing waste, and minimizing emissions, smart factories help organizations meet these regulatory and social demands while enhancing their reputation and stakeholder trust.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5365

Key Questions Answered in the Report:

Which are the high-growth market segments in terms of component and sector?

What was the historical market size for smart factories globally?

What are the market forecasts and estimates for 2024–2031?

What are the major drivers, restraints, opportunities, challenges, and trends in the smart factory market?

Who are the key players in the smart factory market, and what are their market shares?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Smart Factory Market#Smart Factory#Industrial Sensors#Industrial Robots#Industrial Automation and Control Systems/Plant Level Controls#Supervisory Control and Data

0 notes

Text

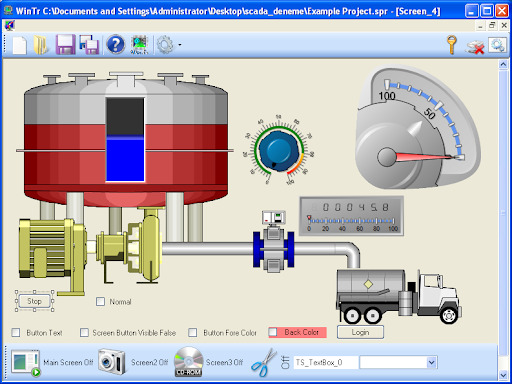

#SCADA#Supervisory Control And Data Acquisition#SCADA software#software#WinTr#industrial#industrial engineering#webcore#old web#techcore#cybercore

8 notes

·

View notes

Text

How NX-ERA Premium PLCs Revolutionise Textile Singeing Operations

Quality has always held a high priority in the vast and ever-evolving domain of textile manufacturing, as even a single misstep in production can lead to cascading effects, starting from product rejection, leading up to brand loss and compromised customer trust. To ensure a consistent quality in textile finishing, singeing is among the first and most critical steps in the procedure. It is a seemingly sensitive operation where surface fibres are removed using gas flames.

While it may not receive the spotlight like dyeing or printing, singeing lays the foundation for almost everything that follows. It ensures that your fabric output is smooth, clean, and primed for perfection. And in this era of fast fashion, global exports, and digitised factories, managing this process with old-school tools and controls won’t simply suffice.

This is where we at Messung Industrial Automation come in. Our NX-ERA Premium PLCs are a game-changing solution that doesn’t just automate singeing but also redefines how precision, speed, safety, and intelligence come together.

Let’s explore the heart of singeing operations and discover how this Programmable Logic Controller is igniting a silent yet mighty revolution in the textile industry.

Textile Singeing: The First Touch of Refinement

Singeing is a thermal pre-treatment process where the surface fuzz or the protruding fibres on a fabric are burnt off using a controlled gas flame. This eliminates any loose threads or lint that could interfere with the dye penetration or printing clarity.

However, its benefits extend far beyond just aesthetics. They include:

Improved dye absorption and print sharpness

Premium feel through smoother fabric texture

Enhanced garment durability with reduced pilling

Less linting, critical for cleanroom or medical textiles

Compliance with international quality standards, especially in exports

When done right, singeing transforms a raw textile material into a high-value product which is ready for further treatment.

The Complexity Behind

At first glance, singeing might appear as a very straightforward flame treatment, but in practice, it is a process that juggles multiple moving parts with split-second precision. The variables in play are:

Controlling flame intensity and width based on the fabric type and speed.

Tightly monitoring the temperature to avoid scorching

Fabric speed impacts flame exposure time and must be regulated in sync with the burners

Safety systems must be in place to detect flame irregularities, gas leaks, and other emergencies

Include flexibility and minimal downtime for smooth process changeovers.

Due to all these variables, traditional relay-based systems or low-end PLC control systems often fall short, lacking the finesse, feedback loops, or integration capabilities required for modern singeing lines.

The Rise of NX-ERA Premium PLCs by Messung

Recognising the gap between process needs and available automation tools, we at Messung designed NX-ERA Premium PLCs, a high-speed, modular PLC system that is tailored for demanding applications like singeing.

What makes it “Premium”?

The reasons include:

Advanced CPU with nanosecond-level scan cycles

Real-time analogue and digital input processing

Built-in PID loops for fine-tuned temperature control

Modbus TCP/IP and other industrial protocols for easy integration

SCADA-ready architecture for centralised visibility and remote access

Modular I/O scalability for future expansion

This makes NX-ERA not just another PLC controller, but a smart, robust platform designed to thrive even in high-heat and high-stakes environments like those of textile factories.

How NX-ERA Powers Every Element of Singeing

Let’s break down how this industrial automation PLC transforms every aspect of the singeing line.

Flame Control: Precision like never before

At the heart of singeing is the burner, and controlling its intensity, width, and modulation in real time is where our NX-ERA shines.

Analogue inputs from flame sensors feed data directly to the PLC

PID Loops automatically adjust the burner valves

Real-time modulation ensures uniform heat distribution

Result? Consistent singeing with no under- or overt treated sections.

Temperature Monitoring: Accuracy that protects

Using feedback from pyrometers or infrared sensors, NX-ERA maintains a tight grip on the burner zone temperature.

Avoids fabric scorching by reacting to even minor spikes

Keeps flames within the desired thermal envelope

Enhances burner efficiency by reducing unnecessary gas usage

This level of temperature control is mission-critical for fine or synthetic fabrics

Fabric Speed Synchronisation: Seamless flow control

Singeing isn’t just about the fire; it is also about the timing. NX-ERA synchronises:

Drive Motors

Rollers

Tension Sensors

This helps in regulating the fabric speed precisely. Whether it is a slow-moving wool or a high-speed polyester line, speed and flame remain in perfect harmony.

Built-in Safety: Because lives are on the line

Working with gas burners has its risks. Therefore, to immediately halt the operations in case of abnormal conditions, NX-ERA integrates:

Flame detectors

Gas leak sensors

Emergency shutdown circuits

With redundant CPUs and power modules, the system ensures zero single-point failures, maximising safety for both the operators and the assets.

Process Optimisation: recipe for automation intelligence

Different fabrics have different treatment parameters. NX-ERA stores fabric-specific recipes that easily control:

Flame profile

Flame speed

Temperature setpoints

Operators can switch recipes with a single command, slashing changeover time and reducing manual errors.

Unified Control with SCADA Integration

The second most important thing in modern textile manufacturing is visibility. Our NX-ERA Premium PLC seamlessly integrates with SCADA (Supervisory Control and Data Acquisition) systems, transforming traditional singeing operations into fully observable, data-driven ecosystems. This fusion empowers plant managers, process engineers, and quality heads with an unprecedented ability to monitor, analyse, and optimise operations, both in real-time and retrospectively.

Here is how this synergy delivers control and clarity:

Live dashboards showing temperatures, speeds, and flame status

Historical data logs for ISO and export audits

Alarm and fault management with timestamps

Remote troubleshooting for multi-site operations

No more guesswork. Just insight-driven control.

All this precision allows for a process control that empowers smarter and faster decision-making across the board.

Tangible Benefits for Textile Businesses

Switching to NX-ERA is a leap in operational intelligence and profitability in the segment of automation segment. Here’s how your textile businesses directly benefit from this advanced PLC automation platform:

Improved Product Quality: By maintaining precise control over flame exposure and fabric speed, NX-ERA ensures singeing consistency across the entire fabric width. This leads to smoother, cleaner surfaces, superior dye penetration, and flawless prints.

Greater Efficiency: Automated control means fewer manual adjustments, faster recipe changeovers, and minimal production interruptions. That translates to shorter cycle times, maximised uptime, and increased throughput, especially critical in high-volume manufacturing environments.

Lower Rejections and Waste: Over-singeing, scorching, or uneven treatment can ruin entire fabric batches. NX-ERA’s precision-driven system minimises these risks, reducing rejections and conserving raw materials—ultimately saving both time and cost.

Enhanced Operator Safety: With built-in safety interlocks, flame detectors, and emergency shutdown protocols, NX-ERA proactively safeguards both personnel and equipment. Safety becomes predictive, not reactive.

Lower Energy and Maintenance Costs: The system fine-tunes burner performance based on real-time feedback, ensuring optimal energy usage. At the same time, it flags maintenance needs before breakdowns occur, driving down utility bills and unplanned service disruptions.

All these benefits help your products stand out in competitive export markets.

The NX-ERA Edge Over Conventional PLCs

Basic PLCs were built for basic logic, and that’s where they stop. Today’s singeing machines demand more. Here’s where NX-ERA stands apart:

Conventional PLC Limitations:

Limited scalability for complex I/O or multi-sensor integration

Poor compatibility with SCADA or MES platforms

No redundancy, leading to system crashes or halts

Inadequate processing speed for real-time adjustments

NX-ERA Delivers:

Lightning-fast logic execution for tight control over process parameters

Redundant CPU and power modules for uninterrupted operation

Modular PLC architecture for scalable, plug-and-play expansion

Open protocol support, including Modbus TCP/IP, for seamless integration with legacy and modern systems

Whether you're building a new plant or retrofitting older machinery, NX-ERA adapts effortlessly, making it a smart, long-term investment.

Conclusion: The Edge That Sets You Apart

In a market where margins are tight and expectations are sky-high, singeing can no longer be left to chance. It’s the beginning of quality. And with NX-ERA Premium PLCs, it becomes the beginning of excellence.

From smarter flame control and temperature precision to SCADA visibility and Industry 4.0 integration, NX-ERA empowers textile mills to think big, act fast, and stay ahead.

Because in the world of textiles, smooth starts lead to flawless finishes.

FAQs

What is a PLC, and how does it benefit textile operations?

A PLC (Programmable Logic Controller) is an industrial computer that automates control processes. In textile mills, it ensures consistent quality and operational safety across processes like singeing, dyeing, and finishing.

How do PID controllers improve singeing quality?

PID controllers maintain optimal burner temperature by continuously adjusting based on feedback. This prevents overheating or under singeing, resulting in uniform treatment.

Is NX-ERA Premium suitable for legacy machines?

Yes, its modular PLC architecture allows easy integration with older systems, enabling modernisation without a complete overhaul.

Can NX-ERA integrate with existing SCADA systems?

Absolutely. With Modbus and other standard protocols, NX-ERA seamlessly connects with your existing SCADA setup for real-time control and data analysis.

What makes NX-ERA a future-proof choice for Industry 4.0?

Its ability to connect with cloud systems, support for remote diagnostics, predictive maintenance, and readiness for AI make it a robust, future-proof choice for any smart textile factory.

#textile manufacturing#NX-ERA Premium PLCs#Programmable Logic Controller#smoother fabric texture#reduced pilling#Improved dye absorption#PLC control systems#modular PLC#modular PLC system#Advanced CPU#Real-time analogue and digital input processing#Modbus TCP/IP#Modular I/O scalability#PLC controller#industrial automation PLC#PID Loops#Avoids fabric scorching#redundant CPUs and power modules#NX-ERA Premium PLC#SCADA (Supervisory Control and Data Acquisition)#advanced PLC#Industry 4.0#PLC (Programmable Logic Controller)#PID controllers#SCADA systems#Modbus#SCADA

0 notes

Text

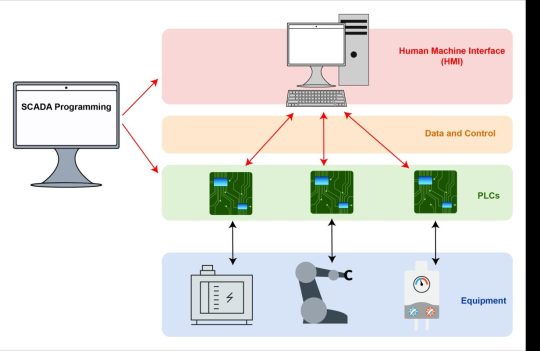

A SCADA system is composed of interconnected components that work together to monitor and control industrial processes effectively. At its core is the Supervisory Controller, which acts as the central computer, managing data exchanges between Human-Machine Interfaces (HMIs), Programmable Logic Controllers (PLCs), and Remote Terminal Units (RTUs). PLCs are microcomputers that collect and process data from sensors and other input devices, performing critical tasks like performance monitoring, equipment runtime calculations, and generating alarms for anomalies. RTUs, another type of microcomputer, are rugged and wireless, ideal for capturing data from remote locations. The HMI provides operators with a user-friendly interface, visualizing SCADA data through maps, icons, charts, and dashboards for real-time system monitoring. Additional components include Intelligent Electronic Devices (IEDs), which enhance system capabilities, and communication systems that enable data transfer via cables, radio, or the Internet. SCADA systems also rely on programming languages, such as C, to create operational diagrams and process maps, ensuring seamless control and decision-making.

0 notes

Text

Battery-operated Remote Terminal Units Market Research, Size, Share, Analysis, Overview and Regional Outlook Study 2017 – 2032

The market for Remote Terminal Units (RTUs) that are battery-operated allows them to function in isolated or off-grid regions where access to a reliable power supply is restricted. RTUs are electronic devices used to monitor and manage remote equipment and processes in many different industries, such as oil and gas, water and wastewater management, power distribution, and telecommunications. Here is a summary of the market for battery-operated RTUs, including information on demand:

Market Overview: Due to a number of circumstances, the market for battery-operated RTUs has been expanding. The need for battery-operated RTUs has been fueled by the necessity for remote monitoring and control capabilities in various industries, particularly in places with weak power infrastructure. These devices enable efficient monitoring and control of remote assets without the requirement for a continual external power source thanks to their dependable and autonomous operation.

Demand Drivers:

1. Real-time monitoring and control of assets: situated in remote or isolating locations are necessary in many businesses. Without the requirement for a sizable power infrastructure or reliance on cable connections, battery-operated RTUs allow for effective data gathering, monitoring, and control of these assets.

2. Applications Off-Grid: In off-grid applications where access to a dependable power supply is restricted or nonexistent, battery-operated RTUs are widely used. Examples include remote water pumping stations in rural areas, environmental monitoring stations, remote weather monitoring stations, and remote oil and gas wellheads.

3. Emergency and Temporary Installations: Whereas immediate deployment is necessary, battery-powered RTUs are also used in emergency and temporary installations. When catastrophe recovery, building projects, or temporary infrastructure installations are taking place, these machines can instantly provide remote monitoring and control capabilities.

4. Environmental Monitoring: Data collection from remote weather stations, air quality sensors, and water quality sensors are all important aspects of environmental monitoring that battery-operated RTUs play a key role in. Continuous monitoring is made possible in remote or environmentally delicate locations by these equipment.

5. IoT Connectivity: The need for battery-operated RTUs has increased as the Internet of Things (IoT) is becoming more widely used in a variety of businesses. These devices are essential parts of IoT networks because they provide seamless data transmission, communication, and control between remote assets and central management systems.

Here are some of the key benefits for Stakeholders:

Remote Monitoring and Control

Flexibility and Mobility

Cost-Effective Deployment

Resilience to Power Outages

Integration with IoT and Smart Grids

Increased Data Accessibility

Environmental Monitoring and Compliance

Rapid Deployment for Emergency Response

Redundancy and Reliability

Scalability and Future-Proofing

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/battery-operated-remote-terminal-units-market/10333/

Market Segmentations:

Global Battery-operated Remote Terminal Units Market: By Company • SIEMENS • SENECA • Omniflex • King Pigeon Communication Co.,Limited • Servelec Group • TEKBOX • Micro Sensor Co., Ltd. • Hitachi Group • Remsdaq Ltd Global Battery-operated Remote Terminal Units Market: By Type • GPRS • GSM • Modular • Others Global Battery-operated Remote Terminal Units Market: By Application • Power Industry • Government and Utilities • Industrial Global Battery-operated Remote Terminal Units Market: Regional Analysis The regional analysis of the global Battery-operated Remote Terminal Units market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Battery-operated Remote Terminal Units market report are as follows: North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Battery-operated Remote Terminal Units in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product. Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Battery-operated Remote Terminal Units in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors. Asia-Pacific: TheAsia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Battery-operated Remote Terminal Units in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction. Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors. South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Battery-operated Remote Terminal Units in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/battery-operated-remote-terminal-units-market/10333/

Reasons to Purchase Battery-operated Remote Terminal Units Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Battery-operated Remote Terminal Units#RTU Market#Remote Monitoring#Wireless RTU#Industrial Automation#Battery-powered RTU#IoT (Internet of Things)#Energy Efficiency#Data Collection#Telemetry#Remote Control#Battery-powered Sensors#SCADA (Supervisory Control and Data Acquisition)#Energy Management#Off-grid Applications#Renewable Energy#Battery Technology#Remote Sensing#Communication Protocols#Edge Computing#Connectivity Solutions#Remote Data Acquisition#Condition Monitoring#Asset Management.

0 notes

Text

PLC, SCADA, and AVEVA: How They Work Together in Automation

PLC :- programmable logic controller

SCADA:- Supervisory Control and Data Acquisition

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#PLC#AVEVA#industry#SCADA#scada systems#blog#google#solutions#software#human machine interface#machinery

3 notes

·

View notes

Text

SANCTUM NOVIS TIMELINE LORE WAHOO:

The current timeline in my head for Sanctum Novis is that it was founded as a penal colony under a different name as a place to put the radical hereteks who were still loyal to the Imperium, but are too extreme even for Xenarites to safely associate with.

Then-Explorator Verthandi-1 was one of the first techpriests interred there, and she was also the one to organize it into a forgeworld proper. Publicly, she did so as a sign of penance and devotion to the Imperium. Privately, it was so she could have a reasonable cover to continue her heretical work into the fields of worker control, production, and how best to utilize the mission given to her by Belisarus Cawl himself. Verthandi-1 turned her search inward, and became the first of the Devisorium of Sanctum Novis. As Forgemaster, she has since become one with her forges - extensive cybernetics and additional cogiators allowing her to process vast quantities of data gathered by the population. It is under her iron rule that Sanctum Novis has become a haven for loyalist Hereteks of all stripes.

Magos Electro-Priest Surtr-1 was killed during the establishment of the Muspelheim power plant, sacrificing himself in order to tame the volcanic forces that now generate energy for the moon. His successor, Surtr-2, was promoted to his rank, and she ran the plant until a massive industrial accident following the experiments of Magos Genator Sigyn-1 that lead to the deaths of herself, Magos Electro-Priest Surtr-2, uncountable numbers of servitors, and the temporary loss of the Biologos labs resulting from an infestation of modified Tyranids brought Sanctum Novis back under scrutiny.

A supervisory cohort was assembled by Martian leaders, headed by Magos Dominus Caprella, and sent to Sanctum Novis to determine what, exactly, the Novites are doing.

Surtr-3 is the youngest Magos on Sanctum Novis, and they are wholly out of their depth.

#wh40k#warhammer 40000#warhammer 40k#adeptus mechanicus#admech#sanctum novis#verthandi#caprella#Surtr-3

20 notes

·

View notes

Text

Writing fantasy set in the real world, had to google bed sizes because I can't remember the word for a bed where two people fit. Neither in Finnish or English.

Pommel, crossguard, dead standing tree, supervisory control and data acquisition, and flying buttress I know, but words describing the mundane? Nah.

4 notes

·

View notes

Text

How Industrial Controls Engineering Reduces Downtime and Boosts Energy Efficiency in Manufacturing Facilities

In modern manufacturing, productivity and energy efficiency are no longer just performance goals — they’re competitive necessities. To meet these expectations, more facilities are turning to industrial controls engineering to streamline operations, reduce unplanned downtime, and improve energy performance.

What Is Industrial Controls Engineering?

Industrial controls engineering focuses on the design, integration, and optimization of control systems that automate machinery and industrial processes. This includes:

Programmable Logic Controllers (PLCs)

Human-Machine Interfaces (HMIs)

Distributed Control Systems (DCS)

Sensors and instrumentation

Supervisory Control and Data Acquisition (SCADA) systems

Fundamentally, controls engineering guarantees the safe, predictable, and effective operation of systems.

Downtime: The Hidden Cost You Can’t Afford

Unplanned downtime costs manufacturers millions each year. Equipment failures, manual inefficiencies, and data blind spots can bring production to a halt. Controls engineering addresses these issues by:

Implementing predictive maintenance logic

Real-time tracking of key performance indicators (KPIs)

Automating fault detection and system alerts

Enabling rapid diagnostics and remote troubleshooting

By connecting controls to intelligent monitoring platforms, facilities can catch minor issues before they escalate — avoiding costly breakdowns and production delays.

Boosting Energy Efficiency Through Automation

Energy waste often hides in plain sight — underutilized motors, inefficient process sequencing, or outdated manual systems. Controls engineering helps reduce this waste by:

Optimizing process flow to eliminate idle time

Synchronizing motor loads with real-time demand

Managing peak energy usage and load shedding

Integrating smart sensors for granular energy monitoring

For example, by automating HVAC systems and integrating real-time production data, manufacturers can ensure that energy use is aligned with actual operating needs, not arbitrary schedules.

Real-World Impact: Controls Engineering in Action

At Wasmer, we’ve helped industrial clients apply advanced control strategies that:

Reduce downtime by up to 40%

Improve overall equipment effectiveness (OEE)

Lower energy consumption by 10–25%

Support long-term sustainability and cost predictability

Whether your goal is energy cost reduction, increased automation, or improved system reliability, investing in industrial controls engineering offers a strong ROI.

Final Thoughts

Industrial controls engineering is more than a tech upgrade — it’s a strategic advantage. As industrial operations face rising energy costs and tighter performance demands, facilities that adopt smart controls will lead to productivity and sustainability.

Ready to Transform Your Operations?

Custom controls engineering for industrial facilities is Wasmer’s area of expertise. From initial design through full integration, we align controls systems with your operational and energy goals.

Explore our Industrial Controls Engineering Services »

#compressed air system efficiency#compressed air audit companies#lean manufacturing initiatives#star energy consultants

0 notes

Text

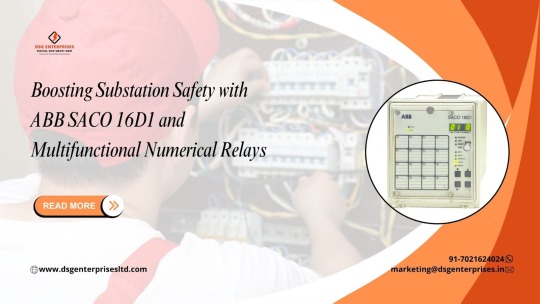

Boosting Substation Safety with ABB SACO 16D1 and Multifunctional Numerical Relays

In the world of power distribution and industrial automation, safety and reliability are paramount. Substations, whether in utilities, industrial plants, or offshore installations,require advanced systems to monitor operations, detect faults, and respond to critical events in real-time. That���s where ABB’s SACO 16D1 Digital Annunciator Unit and its multifunctional numerical relays come into play.

These cutting-edge products are designed not only to ensure the continuity of power supply but also to enhance operational efficiency, accuracy, and personnel safety. This blog explores how ABB’s SACO 16D1 and numerical relay solutions are revolutionizing substation safety and protection through intelligent alarm monitoring and adaptive relay technologies.

Understanding the Role of Substation Safety Systems

Substations are the nerve centers of electrical distribution networks. They handle high-voltage power transmission and play a crucial role in controlling and protecting the grid. Any failure or malfunction within a substation can have wide-reaching consequences, from equipment damage to total blackout and safety hazards.

To ensure safe and uninterrupted operation, substations are equipped with:

Alarm annunciation systems

Protection relays

Supervisory control and data acquisition (SCADA) systems

Automated fault detection and isolation mechanisms

ABB’s SACO 16D1 and numerical relays offer robust solutions across all these areas.

What Is the ABB SACO 16D1 Digital Annunciator Unit?

The ABB SACO 16D1 is a field-customizable, 16-channel digital annunciator unit built for supervising alarm and signaling contacts in:

Power plants

Electrical substations

Industrial process installations

Offshore platforms and marine environments

Its key job is to provide immediate fault recognition, visual and audible alarms, and first-out fault identification when an abnormal process condition is detected. This allows for rapid response, minimizing equipment downtime and ensuring the safety of both systems and personnel.

Key Features of the SACO 16D1:

16 digital input channels for comprehensive supervision

Clear 4-digit front panel display for first-out alarm indication

Four output relays (two group re-alarms, one audible device, one self-supervision)

Field-configurable parameters via front panel or serial interface

Fibre-optic connectivity for inter-unit communication

Compliant with CE and EMC standards

Robust self-supervision hardware and software

This makes it ideal for harsh environments and high-demand applications where failure is not an option.

ABB Numerical Relays: Smart Protection for Smart Grids

While the SACO 16D1 focuses on alarms and fault identification, ABB’s numerical relays offer intelligent, multifunctional protection for all areas of the grid.

These microprocessor-based devices have transformed how electrical protection systems operate. Unlike traditional electromechanical relays that require manual wiring and fixed settings, numerical relays are programmable. They can be configured for various protection schemes, overcurrent, differential, distance, transformer protection, and more.

Core Advantages of ABB Numerical Relays:

Multifunctional Design: One relay can perform several protection tasks, streamlining hardware and saving panel space.

Self-checking and diagnostics: Relays perform internal checks to detect anomalies before they cause failures.

Data Storage and Time Stamping: Logs and stores fault data, which is critical for post-event analysis and reporting.

Fast Fibre-Optic Communication: Enables real-time data transfer to substation control systems and SCADA.

Adaptive Protection Algorithms: Relays can adjust protection settings dynamically based on real-time grid conditions.

These features help reduce outages, improve fault isolation, and protect assets and personnel.

SACO 16D1 and ABB Numerical Relays: A Perfect Pairing for Safety

When it comes to substation safety, the combination of the ABB SACO 16D1 Digital Annunciator Unit and ABB Numerical Relays provides a comprehensive and highly effective solution. Each device plays a unique role, yet they complement each other perfectly to ensure maximum visibility, protection, and fault response.

The SACO 16D1 excels in alarm supervision and annunciation. It continuously monitors digital input signals and immediately alerts operators through visual and audible indicators when an abnormal condition occurs. Its front-panel display provides first-out fault indication, which helps pinpoint the origin of an issue before other faults cascade. It also includes multiple output relays for triggering alarms, buzzers, and supervision systems.

On the other hand, ABB’s numerical relays are designed for real-time protection of substation equipment. These multifunctional relays detect electrical faults, such as overcurrent, short circuits, or transformer issues, and react almost instantaneously to isolate the problem and protect the system. They go beyond simple fault detection by offering programmable logic, data logging, and adaptive protection algorithms that adjust settings dynamically based on system conditions.

While the SACO 16D1 provides clear and actionable alarm feedback, ABB numerical relays deliver the technical precision and automated protection necessary to keep systems operating safely. Together, they create a layered defense system: the annunciator ensures visibility and awareness, while the relays handle protection and response.

Moreover, both devices support data communication protocols such as SPA bus and serial interfaces, allowing them to integrate seamlessly with SCADA and automation systems. This interoperability ensures that alarms, event data, and relay logs can be centrally monitored, analyzed, and archived, supporting long-term system performance and compliance requirements.

In essence, using SACO 16D1 units alongside ABB numerical relays gives operators total control over process supervision and fault protection, resulting in enhanced reliability, faster response times, and significantly improved substation safety.

Applications Across Industries

Both the SACO 16D1 and ABB numerical relays are built for diverse environments:

Power Generation Plants

Manage alarms from transformers, turbines, switchgear, and auxiliary equipment.

Prevent cascading failures through early warning.

Industrial Substations

Maintain safety in high-voltage manufacturing environments.

Protect motors, feeders, and distribution networks.

Offshore and Marine Installations

Ensure marine power systems are protected against environmental stress and faults.

SACO 16D1’s robust construction and CE certification are ideal for offshore use.

Process Automation and Utility Grids

Integrate easily with SCADA and automation systems.

Real-time fault isolation and data logging improve reliability.

Benefits for Engineers and Operators

Using ABB SACO 16D1 and numerical relays in substations brings tangible benefits:

Improved Personnel Safety: Early warning and clear fault indicators prevent unsafe conditions from escalating.

Reduced Downtime: Quick fault identification enables faster repairs and system restoration.

Simplified Maintenance: Self-supervision and diagnostics reduce manual checks and unexpected breakdowns.

Lower Operational Costs: Multifunctional relays reduce the number of devices needed, saving on hardware and wiring.

Future-Ready Substations: Support for communication protocols and programmable logic allows for integration into smart grid and Industry 4.0 frameworks.

Installation and Configuration Insights

ABB has made these products user-friendly for installation and parameterization.

SACO 16D1 can be mounted in standard relay panels.

Configuration via front panel push-buttons or serial interface.

ABB relays support graphical interfaces for protection settings and logic schemes.

Additionally, fibre-optic communication between SACO annunciators creates a networked alarm monitoring system, offering scalability as the substation grows.

Conclusion: Invest in Reliability with ABB

Substations form the backbone of the power distribution system, and protecting them requires intelligent, reliable, and scalable technology. The ABB SACO 16D1 Digital Annunciator Unit, with its robust alarm supervision, and ABB’s multifunctional numerical relays, with their adaptive protection capabilities, make for an unbeatable combination.

Together, they empower electrical engineers, maintenance personnel, and operators to monitor faults accurately, respond swiftly, and maintain safe, reliable, and efficient power infrastructure.

Click here if you're looking to modernize your protection and monitoring systems. It’s time to upgrade with ABB.

Want to explore ABB’s complete range of numerical relays and annunciator units? Visit ABB’s official product portal or connect with an authorized ABB distributor today.

#ABBSACO16D1#ABBRelays#NumericalRelays#DigitalAnnunciator#RelayProtection#SubstationAutomation#PowerDistribution#GridProtection#ElectricalSafety#IndustrialAutomation#SmartGrids#EnergyEfficiency#SCADASystems#ProcessControl#SmartSubstations

0 notes

Text

Overview of SCADA Control Systems

SCADA (Supervisory Control and Data Acquisition) plays a central role in modern automation systems. This article provides a comprehensive overview of SCADA's structure, operating principles, and benefits, along with the latest application trends updated for 2023.

Learn more: https://maxelectric.vn/tong-quan-ve-he-thong-dieu-khien-scada-cap-nhat-2023-a6.html

0 notes

Text

“Power System State Estimation: The Brain Behind Smart Grids

#EnergyMarket #TechTrends #PowerGridSolutions #PSSEMarket #Utilities

Power System State Estimator Market: Trends, Challenges, and Future Outlook

Blog Body

Introduction

As global energy systems shift toward smart grids and decentralized generation, the Power System State Estimator (PSSE) market has become an essential part of modern electricity infrastructure. These systems play a critical role in monitoring, predicting, and optimizing power grid performance, thereby ensuring reliability and stability.

What is a Power System State Estimator?

A Power System State Estimator is a software-based solution that provides real-time data about the electrical state of a power grid. It combines data from sensors like SCADA (Supervisory Control and Data Acquisition) and PMUs (Phasor Measurement Units) to offer a more accurate view of voltage, current, and power flows across the network.

Market Overview

The PSSE market is projected to experience significant growth in the coming years, driven by the following key factors:

Grid Modernization Initiatives: Governments worldwide are investing in upgrading grid infrastructure to support renewables, electric vehicles, and distributed energy resources (DERs).

Rising Energy Demand: Rapid industrialization and urbanization, especially in Asia-Pacific and Africa, are increasing the need for stable and efficient power delivery.

Cybersecurity Concerns: As grids become more connected, PSSE solutions are increasingly used for detecting anomalies and preventing potential cyber-attacks.

Key Trends Shaping the Market

Integration of AI and Machine Learning Predictive analytics and machine learning algorithms are being integrated into PSSE software to improve accuracy and reduce response time.

Deployment of Wide Area Monitoring Systems (WAMS) The rise of WAMS using PMUs is enhancing real-time monitoring and enabling dynamic state estimation.

Cloud-Based State Estimators Cloud technologies are enabling scalable, cost-effective, and remotely accessible solutions, particularly for utilities with limited in-house IT infrastructure.

Challenges in the Market

Data Quality and Availability: Incomplete or inaccurate data from sensors can compromise estimation accuracy.

High Initial Investment: Implementing PSSE systems involves significant upfront costs, especially for older grids.

Interoperability Issues: Integrating PSSE with existing grid management systems can be complex.

Future Outlook

The future of the PSSE market looks promising with increased investments in smart grid technologies, rising concerns around energy security, and growing reliance on renewable energy sources. By 2030, the market is expected to be largely driven by innovations in real-time analytics and automation.

Power System State Estimators are a cornerstone of future-proof power grids. As we transition to smarter, more resilient energy networks, the demand for real-time, accurate state estimation will only grow, presenting vast opportunities for vendors and utilities alike.

More Trending Reports:

Micro Battery Market

Direct Methanol Fuel Cell (DMFC) Market

Solar Battery Market

High Voltage Cables and Accessories Market

0 notes

Text

Vital Phlebotomist Responsibilities: A Complete Guide to Blood Collection and Patient Care

Essential Phlebotomist Responsibilities: A Complete Guide to Blood Collection and Patient Care

If you’re interested in a healthcare career centered around blood collection and patient interaction, understanding the core responsibilities of a phlebotomist is crucial. this complete guide explores the vital tasks, safety protocols, patient care strategies, and practical tips that define the role of a professional phlebotomist. Whether you’re aspiring to become one or seeking to understand the profession better, this article provides valuable insights to help you excel in this essential healthcare position.

What Is a Phlebotomist?

A phlebotomist is a healthcare professional specialized in drawing blood samples from patients for laboratory testing, transfusions, donations, or research. They play a critical role in diagnosing, treating, and monitoring various health conditions. Their responsibilities go beyond blood draw techniques-they provide compassionate patient care and ensure safety and accuracy in every procedure.

Core Responsibilities of a Phlebotomist

1. Patient Identification and Communication

Verify patient identity: Cross-check patient ID band and verbal confirmation to ensure correct sample attribution.

Explain the procedure: Calm nerves and provide clear instructions to make patients comfortable.

Address concerns: Answer questions and alleviate fears related to blood draws.

2. Blood Collection Techniques

Mastering proper blood collection is essential. Phlebotomists must select the right equipment, locate suitable veins, and perform draws efficiently and painlessly.

Equipment planning: Use sterile needles,collection tubes,alcohol wipes,and tourniquets correctly.

Vein selection: identify optimal veins, typically in the antecubital fossa or hand.

Procedure execution: Use proper puncture techniques to ensure patient safety and sample integrity.

sample handling: Label and transport samples following safety standards.

3. Ensuring Safety and Infection Control

Use personal protective equipment (PPE): Proper gloves, masks, and other PPE to prevent cross-contamination.

Follow disposal protocols: Dispose of sharps and biohazard waste properly.

Maintain a clean habitat: Keep the workspace sanitized and organized.

4. Patient Care and Comfort

Providing a positive experience is essential. Phlebotomists should be empathetic, gentle, and attentive to patient well-being.

Minimize discomfort: Use techniques like proper tourniquet application and needle insertion.

Monitor for adverse reactions: Watch for dizziness or fainting and take prompt action.

Provide aftercare instructions: Advise on site care and hydration.

5. Documentation and Record-Keeping

Accurate data entry: Record patient details and sample info precisely.

Maintain confidentiality: Follow HIPAA guidelines to protect patient privacy.

Report discrepancies: Notify supervisors of any issues or errors promptly.

Skills and Qualities of an Effective Phlebotomist

Beyond technical abilities, certain qualities distinguish extraordinary phlebotomists:

Attention to detail

Strong communication skills

Patience and empathy

Hand-eye coordination

Adherence to safety standards

Stress management

Benefits of a Career as a Phlebotomist

Becoming a phlebotomist offers several advantages:

Fast entry into the healthcare field with certification programs lasting a few months.

High demand for qualified professionals across hospitals, clinics, and diagnostic labs.

Possibility to make a tangible difference in patient health outcomes.

Potential for career advancement into supervisory or specialized roles.

Practical Tips for Aspiring Phlebotomists

Gain hands-on experience through internships or volunteering.

Study and stay updated on best practices and new tools.

Practice excellent communication to build patient trust.

Prioritize safety protocols at all times.

Maintain a compassionate attitude, especially with anxious or difficult patients.

Case Study: Accomplished Blood Collection in a Clinical Setting

Scenario

Challenge

Solution

Outcome

Patient with difficult veins

Multiple unsuccessful attempts caused discomfort and anxiety.

Utilized a tourniquet to identify a prominent vein and engaged the patient with reassurance.

Successful blood draw completed with minimal discomfort, boosting patient confidence.

First-Hand Experience: A Day in the Life of a Phlebotomist

For many phlebotomists, each day involves a mix of routine blood draws, emergency responses, and patient interactions. Maintaining professionalism, staying attentive to safety procedures, and demonstrating compassion are key to excelling in this role. Practical experience reveals that patience and adaptability are essential when dealing with diverse patient needs and challenging situations.

Conclusion

The role of a phlebotomist is vital in the healthcare system, combining technical expertise with compassionate patient care. From blood collection to ensuring safety and comfort, their responsibilities require attention to detail, adherence to protocols, and a caring attitude. Whether you’re starting your career or seeking to deepen your understanding, recognizing these responsibilities helps appreciate the critical contributions of phlebotomists in diagnosis and treatment. Embracing these duties with professionalism and empathy can lead to a rewarding and impactful healthcare career.

If you’re interested in becoming a certified phlebotomist, explore accredited training programs and certification options to kickstart your journey in this fulfilling healthcare profession.

https://phlebotomytechnicianprogram.org/vital-phlebotomist-responsibilities-a-complete-guide-to-blood-collection-and-patient-care/

0 notes

Text

11KV VCB Switchboards: Key Features and Technical Specifications

11KV VCB (Vacuum Circuit Breaker) Switchboards are a crucial part of medium-voltage power distribution systems. They play a significant role in protecting electrical equipment and ensuring reliable operation in industrial, commercial, and utility networks. Known for their high efficiency, long life, and safety features, these switchboards are widely used in substations, manufacturing plants, and large infrastructure projects.

In this blog, we explore the key features and technical specifications of 11KV VCB switchboards to help you better understand their importance and functionality.

What is an 11KV VCB Switchboard?

An 11KV VCB switchboard is a metal-clad enclosure that houses vacuum circuit breakers designed to operate at a voltage level of up to 11 kilovolts (kV). The vacuum interrupter extinguishes the arc when the circuit breaker operates, providing a safe and quick way to isolate faults in the system.

These switchboards are typically used for:

Power distribution

Load management

Fault protection

Transformer and motor protection

Key Features of 11KV VCB Switchboards

1. Vacuum Interruption Technology

The primary advantage of VCBs is the use of vacuum as the arc quenching medium. Vacuum has high dielectric strength, enabling fast and reliable interruption of current without deterioration over time.

2. Compact and Modular Design

11KV VCB switchboards are designed to save space with a compact footprint. They often come in modular designs, allowing easy customization and future expansions.

3. High Mechanical and Electrical Life

VCBs are known for their longevity. They can operate efficiently through thousands of breaking cycles, making them ideal for frequent switching operations.

4. Low Maintenance

The sealed vacuum interrupter requires minimal maintenance. There are no gases to refill, and no oxidation or corrosion occurs inside the interrupter.

5. Enhanced Safety Features

These switchboards are equipped with interlocks, earthing switches, and arc-proof constructions to ensure operational safety for personnel.

6. Remote Monitoring and Control

Modern 11KV VCB switchboards come with SCADA (Supervisory Control and Data Acquisition) compatibility and communication protocols like Modbus or IEC 61850, allowing real-time monitoring and remote operation.

Applications of 11KV VCB Switchboards

These switchboards are used across diverse sectors, including:

Electrical substations

Industrial facilities

Commercial complexes

Renewable energy installations

Airports and railway stations

Water treatment plants

When it comes to reliable and efficient medium-voltage power distribution, Kandi Electrical stands out as a prominent name in the electrical industry. Among its impressive range of products, the 11KV VCB (Vacuum Circuit Breaker) Switchboards hold a critical position due to their robust performance, safety features, and adaptability across industrial and commercial applications.

Why Choose Kandi Electrical?

Kandi Electrical combines innovation with precision engineering to deliver VCB switchboards that are not only reliable but also tailored to customer requirements. With a focus on quality assurance and continuous product improvement, the company ensures compliance with national and international safety standards.

Additionally, Kandi Electrical supports clients with customized switchgear solutions, on-site commissioning, and long-term maintenance support — making them a trusted partner for medium-voltage power systems.

Conclusion

The 11KV VCB switchboards by Kandi Electrical offer an ideal blend of technology, safety, and performance. Whether you’re looking to modernize your power infrastructure or set up a new facility, these switchboards provide a future-ready solution for medium-voltage applications. With their robust technical specifications and innovative features, they represent a smart investment for efficient power management and protection.

0 notes

Text

AVEVA (Wonderware) System Platform

SCADA, HMI, MES, and IIoT applications, AVEVA System Platform (previously Wonderware System Platform) is a unified operations center solution that offers an open, adaptable, and scalable architecture. In manufacturing and infrastructure operations, it provides a common basis for supervisory control, data collection, and real-time display.

Key Features of AVEVA System Platform

Object-Oriented Architecture

Scalability and Flexibility

Centralized Configuration and Deployment

Real-Time Data Handling

Integrated Historian

Security and User Management

Common Use Cases

Supervisory control and monitoring for manufacturing plants.

Energy and utilities operations management.

Water and wastewater facility control.

Oil & gas SCADA systems.

Smart buildings and infrastructure monitoring.

#automation#technology#tech#plc automation#aveva#scadatraining#scada systems#software programing#software#PLC#VFD#automotive

2 notes

·

View notes