#they are used to transmit power or torque from the driving component to the driven component.

Explore tagged Tumblr posts

Text

Chain Machine Drive - Types, Working & Benefits | Fricon Systems

Chain Machine Drive systems play a pivotal role in ensuring seamless power transmission across various applications. Whether in manufacturing, agriculture, automotive, or heavy machinery industries, the right Industrial Chain Drive solution enhances productivity and ensures consistent performance.

At Fricon Systems, we are a trusted Chain Machine Drive Manufacturer dedicated to delivering high-quality, durable, and precision-engineered chain drive solutions tailored to diverse industrial needs. Our commitment to innovation and reliability makes us a preferred partner for industries across India and beyond.

What is a Chain Machine Drive?

A Chain Machine Drive is a mechanical system that transmits power from one shaft to another using a chain and sprocket mechanism. Unlike belt drives, chain drives offer higher torque capacity, better load-handling capabilities, and do not suffer from slippage, making them ideal for high-power applications.

Chain drives consist of the following core components:

Drive Sprocket (connected to the power source)

Driven Sprocket (connected to the machinery)

Power Transmission Chains (linking both sprockets)

Tensioners or Idlers (to maintain chain tension)

Lubrication System (optional, for longevity)

Chain drives are widely used in various industries such as packaging, printing, textiles, food processing, agricultural machinery, and conveyor systems due to their robustness and low maintenance.

Working Principle of Chain Machine Drive

The operation of a Chain Machine Drive is straightforward yet highly effective. Power generated by the prime mover (electric motor, engine, etc.) is transmitted to the drive sprocket. As the sprocket rotates, it engages with the chain's links, converting rotary motion into a consistent and synchronized movement, which is transferred to the driven sprocket.

This type of drive is highly efficient (up to 98%) and capable of operating in harsh environments. Additionally, chain drives can handle both short and long distances between shafts, offering flexibility in industrial layouts.

Types of Chains Used in Chain Machine Drive

Understanding the Types of Chains is critical when choosing a chain drive system for specific applications. Different chains are designed for varied operational loads, environments, and speed requirements. At Fricon Systems, we provide a wide range of chain solutions, including:

1. Roller Chains

Most common type of power transmission chains

Consists of pins, bushings, rollers, and side plates

Offers low-friction and smooth operation

Used in bicycles, conveyors, agricultural and industrial machinery

2. Silent Chains (Inverted Tooth Chains)

Designed for quiet operation and smooth engagement

Ideal for high-speed, high-power transmission

Often used in automotive timing systems and gearboxes

3. Leaf Chains

Consist of stack link plates with pins, no rollers

High tensile strength

Widely used in lifting applications such as forklifts and hoists

4. Double Pitch Chains

Extended pitch compared to standard roller chains

Reduces weight and cost

Perfect for low-speed, high-load applications like conveyors

5. Conveyor Chains

Customized for conveying material loads

Equipped with attachments to carry items

Used extensively in packaging, bottling, and food processing

6. Attachment Chains

Feature additional parts like brackets or extended pins

Used where the chain needs to perform added functions (e.g., pushing, pulling, lifting)

These Types of Chains cater to a wide array of applications, and selecting the right type depends on the power load, working environment, speed, and transmission distance.

Advantages of Industrial Chain Drive Systems

An Industrial Chain Drive offers several advantages over other transmission systems like belts or gears. Here are some of the key benefits that make them indispensable in many sectors:

High Efficiency and Power Transmission: Chain drives have minimal slippage and very high mechanical efficiency (up to 98%), making them ideal for high-torque and high-load applications.

Compact and Versatile Design: Chain drives can fit into compact spaces and operate across various orientations—horizontal, vertical, or inclined—without performance loss.

Durability and Strength: Made from high-grade steel and treated for wear resistance, Power Transmission Chains can handle heavy-duty industrial environments with ease.

Temperature and Environmental Resistance: Chain systems perform reliably in extreme temperatures, dusty conditions, and corrosive environments when combined with appropriate lubrication and material selection.

No Slippage: Unlike belt systems that rely on friction, chain drives provide positive engagement between the chain and sprocket, eliminating slippage and maintaining consistent speed ratios.

Cost-Effective Maintenance: Chains are easier to inspect, repair, or replace than complex gear systems. Proper tensioning and lubrication extend the system’s life and reduce operational downtime.

Applications of Chain Machine Drive Systems

Chain drive systems are used across a wide range of industrial sectors, including:

Automotive: Camshaft drives, timing mechanisms, gearboxes

Food & Beverage: Conveyor belts, bottle filling, packaging lines

Pharmaceutical: Tablet sorting, packaging, and material handling

Agriculture: Harvesters, tractors, irrigation equipment

Textile Industry: Fabric transport systems, looms, spinning machines

Construction: Lifting equipment, cranes, mixers

Mining and Heavy Equipment: Conveyor belts, crushers

Fricon Systems provides tailored solutions to each industry, ensuring optimized performance and durability in every application.

Choosing the Right Chain Machine Drive Manufacturer

The performance of your machinery is only as good as the components used. Choosing a reliable Chain Machine Drive Manufacturer is essential for ensuring operational continuity and reduced downtime.

At Fricon Systems, we are known for:

Precision Manufacturing: All our chains and sprockets are produced using advanced CNC and forging technology.

Material Quality: We use high-strength alloy steel and ensure heat treatment for enhanced durability and resistance.

Custom Engineering: We provide chain drives tailored to client specifications and industrial needs.

Technical Support: Our team offers end-to-end support, from product selection to installation guidance and maintenance planning.

Competitive Pricing: We ensure superior value through cost-effective pricing and long-term performance benefits.

Whether you're upgrading a legacy system or setting up a new plant, we offer complete solutions in Industrial Chain Drive technology.

Maintenance Tips for Chain Drives

To get the most out of your Power Transmission Chains, proper maintenance is essential. Here are a few best practices:

Lubricate Regularly to prevent wear and reduce friction

Check Tension periodically to avoid slack or overtightening

Inspect for Wear on pins, bushings, and rollers

Clean Debris and avoid contaminant build-up

Replace Damaged Components promptly to avoid chain breakage

Fricon Systems also provides maintenance training and support to ensure the longevity of your chain drive systems.

A well-designed and properly installed Chain Machine Drive can be a game-changer in your industrial process, offering unmatched efficiency, durability, and cost-effectiveness. With a wide variety of Types of Chains available, choosing the right one for your application is essential to ensuring optimal performance and extended machine life.

As a reputed Chain Machine Drive Manufacturer, Fricon Systems delivers innovative and reliable power transmission solutions to industries across the spectrum. From standard roller chains to custom-engineered attachment chains, we offer comprehensive solutions backed by engineering excellence and technical support.

Looking for robust and high-performance Chain Machine Drive systems? Contact Fricon Systems today for expert guidance, precision manufacturing, and dependable service. Let us power your industry with the best in Industrial Chain Drive technology!

For more info: https://www.friconsystems.com/

Email id: [email protected]

Phone: 9899811999

Location: 123A & 124A Type A , H.S.I.I.D.C. Sector 59, Faridabad, Haryana - 121004, India

#Chain Machine Drive#Types of Chains#Industrial Chain Drive#Power Transmission Chains#Chain Machine Drive Manufacturer

0 notes

Text

Best Permanent Magnetic Drum Pulley Manufacturer In Ahmedabad, India

Introduction

In high-volume industries like mining, recycling, cement, and material handling, clean product flow and system protection are non-negotiable. An essential yet often underrated component in this ecosystem is the Permanent Magnetic Drum Pulley. This powerful pulley helps remove ferrous impurities from conveyor lines, safeguarding machinery and ensuring smooth operations.

If you're in search of the Best Permanent Magnetic Drum Pulley Manufacturer in Ahmedabad, India, you're tapping into a city known for world-class industrial engineering. Ahmedabad houses some of India’s most reliable manufacturers of gearboxes, magnets, pulleys, and mechanical parts—all built to global quality standards.

What is a Permanent Magnetic Drum Pulley?

A Permanent Magnetic Drum Pulley is a rotating magnetic separator fitted at the discharge end of conveyor belts. It attracts and removes tramp iron from the material flow, using strong permanent magnets embedded within its structure.

Key Functions Include:

Continuous removal of ferrous materials

Protection of crushers, belts, and gearboxes

Improved product purity and reduced maintenance

Seamless integration with existing conveyor systems

When combined with quality mechanical components such as SMSR gearboxes, V-belt pulleys, and plummer blocks, magnetic pulleys become an indispensable part of industrial operations.

Why Ahmedabad is a Trusted Hub for Magnetic Drum Pulleys

Ahmedabad is India’s industrial powerhouse, producing a wide range of components like SMSR gearbox, conveyor gearboxes, plummer blocks, and suspension magnets. This industrial ecosystem provides a strong foundation for precision manufacturing and component integration.

The top permanent magnetic drum pulley manufacturers in Ahmedabad offer:

High-strength permanent magnets (rare earth or ferrite)

Rugged stainless steel or mild steel shells

Custom designs based on belt width and material type

Long-lasting magnetic field without the need for power supply

Efficient integration with drive systems and pulley setups

Working with Gearboxes and Industrial Systems

Magnetic drum pulleys are strategically placed at the discharge end of conveyors, especially in systems driven by SMSR Gearbox Manufacturers in Ahmedabad and supported by Plummer Block Manufacturers in Ahmedabad.

Here’s how they integrate:

Conveyor Gearboxes power the belt, while the magnetic pulley purifies the material before discharge

Suspension Magnets capture larger ferrous pieces upstream; magnetic pulleys clean up the remaining fines

Plummer Blocks offer stable support for rotating shafts, including those linked with pulleys

V-belt Pulleys help transmit motion, ensuring the pulley and conveyor rotate smoothly

A key factor in choosing the right conveyor gearbox is ensuring compatibility with all components—especially pulleys and magnets. A poor match could lead to misalignment, belt slippage, or premature wear.

What is a V-Belt Pulley and Its Role in This Setup?

A V-belt pulley is a type of mechanical pulley designed to transfer torque between shafts using a V-shaped belt. These pulleys are known for their high-efficiency and grip, making them ideal for industrial power transmission.

In systems that use permanent magnetic pulleys, V-belt pulleys often help transfer motor power to the conveyor line, maintaining smooth and reliable rotation. When used in tandem, they ensure that:

The magnetic pulley maintains optimal speed

Shaft alignment remains intact

Gearbox and belt load is evenly distributed

This coordinated operation enhances productivity and extends component life.

Industries That Use Magnetic Drum Pulleys

Permanent magnetic drum pulleys are essential in several sectors:

Mining and Minerals – To separate tramp iron from ore

Recycling Facilities – For ferrous metal recovery

Cement and Aggregates – To prevent crusher damage

Food and Fertilizer Processing – For product purity

Waste Management – For scrap metal separation

Each of these industries uses conveyor systems that rely on integrated solutions from SMSR Gearbox manufacturers in India, Conveyor Gearbox manufacturers, and Suspension Magnet manufacturers in India.

Choosing the Best Magnetic Drum Pulley Manufacturer

Here’s what to look for when selecting a manufacturer:

Magnetic Strength & Quality – Strong, permanent fields without energy use Custom Engineering – Designed to fit your specific conveyor size and speed Durable Construction – Rust-resistant, shockproof, and wear-resistant materials System Integration Support – Expertise in combining pulleys with gearboxes and plummer blocks Reputation & Support – Proven track record and after-sales technical assistance

Ahmedabad’s top manufacturers meet all these expectations, delivering pulleys that perform reliably even in the toughest environments.

Conclusion

A Permanent Magnetic Drum Pulley is more than just a magnetic tool—it's a critical part of your industrial machinery. It safeguards your gearboxes, maintains belt health, and ensures material purity across the line.

By choosing the Best Permanent Magnetic Drum Pulley supplier in Ahmedabad, India, you're investing in the long-term performance and reliability of your operation. From SMSR Gearbox manufacturers in Ahmedabad to Plummer Block manufacturers in Ahmedabad and Suspension Magnet manufacturers in India, working with integrated component suppliers ensures your system runs at peak efficiency.

So, whether you're managing a mining operation, recycling facility, or cement plant, a high-quality magnetic pulley is your first line of defense—and Ahmedabad is where you’ll find the best.

#Permanent Magnetic Drum Pulley Manufacturer In Ahmedabad#Permanent Magnetic Drum Pulley supplier In Ahmedabad#Permanent Magnetic Drum Pulley exporter In Ahmedabad

0 notes

Text

Exploring the Role of Cogged Belts in India’s Automotive Sector

The automotive industry in India is one of the most rapidly growing sectors, driven by rising demand for vehicles, technological advancements, and a thriving manufacturing ecosystem. Amid this growth, components such as cogged belts in India are becoming increasingly crucial in enhancing the performance and efficiency of vehicles. But what exactly are cogged belts, and how do they fit into India’s automotive landscape?

What Are Cogged Belts?

Cogged belts, often referred to as notched belts, are a type of drive belt characterized by their unique, toothed or "cogged" design. These belts are typically made of rubber or synthetic materials and are used to transfer motion and power between mechanical components. Unlike traditional smooth belts, the notched design of cogged belts allows for better flexibility, improved grip, and less heat generation, making them ideal for high-stress applications such as automotive engines.

The Role of Cogged Belts in Automotive Applications

Cogged belts are integral to a variety of automotive systems. Their unique design and material properties make them essential for the efficient functioning of modern vehicles. Here’s how they contribute to India’s growing automotive sector:

1. Engine Performance

One of the primary uses of cogged belts in automobiles is in the engine system, specifically in driving the camshaft, water pump, and alternator. They are responsible for transmitting power from the engine to other critical components. In the Indian automotive sector, where fuel efficiency and engine performance are of utmost importance, the use of cogged belts ensures smooth and reliable performance, reducing wear and tear on engine parts.

2. Enhanced Durability and Efficiency

Cogged belts are built to endure high torque and intense conditions, including extreme temperatures and pressure. In the Indian market, where harsh driving conditions, such as extreme heat or frequent stop-and-go traffic, are common, cogged belts provide significant advantages in terms of longevity. Their superior durability helps reduce maintenance costs and ensures better overall vehicle performance, making them a cost-effective option for both vehicle manufacturers and consumers.

3. Reduced Noise and Vibration

Another significant benefit of cogged belts is their ability to reduce noise and vibration. This is especially valuable in the Indian automotive sector, where consumers increasingly prioritize comfort. The smooth operation of cogged belts minimizes engine noise and vibrations, contributing to a quieter ride and a more refined driving experience.

4. Support for Hybrid and Electric Vehicles

As India shifts towards more sustainable transportation solutions, such as electric and hybrid vehicles, cogged belts continue to play a vital role. With the rise of electric vehicles (EVs) and hybrids in India, the need for highly efficient drive systems is growing. Cogged belts are well-suited for use in EVs and hybrids, where minimizing energy loss and optimizing power transmission is essential for extending battery life and improving overall efficiency.

The Growing Market for Cogged Belts in India

India’s automotive sector is witnessing a transformation with an increasing focus on fuel-efficient, low-emission, and technologically advanced vehicles. This growth translates to a rising demand for components like cogged belts, which improve the functionality and performance of modern automotive systems.

In response to this demand, Indian manufacturers are stepping up their production of cogged belts, offering a variety of products designed to meet the unique needs of the automotive industry. Leading global brands are also establishing a presence in India, contributing to the country’s growing automotive ecosystem.

Key Players in the Indian Market

Several key players in the automotive components industry have been instrumental in expanding the use of cogged belts in India. Companies such as Gates India, SKF India, and ContiTech have established themselves as major suppliers of cogged belts to both domestic automakers and global brands operating in the country. These companies focus on research and development to improve the design, materials, and performance of cogged belts, making them an essential part of modern vehicles.

Future Trends

As India continues to move toward greener technologies and more efficient vehicles, the role of cogged belts will only become more significant. Key trends to watch out for in the future include:

Integration with Advanced Vehicle Technologies: As automation and smart technologies become more prevalent in the automotive sector, cogged belts will be integrated with electronic systems to optimize power distribution and efficiency.

Sustainability and Eco-friendly Materials: With growing environmental concerns, there will be increased emphasis on using eco-friendly materials in the production of cogged belts, helping reduce the carbon footprint of the automotive industry.

Improved Durability and Reduced Maintenance: The future of cogged belts will see even more focus on enhancing durability and reducing maintenance intervals, leading to lower operating costs for vehicle owners.

Conclusion

Cogged belts are playing an increasingly important role in India’s automotive sector, enhancing engine efficiency, reducing maintenance costs, and supporting the growing demand for hybrid and electric vehicles. With advancements in material science and manufacturing technology, the future of cogged belts looks promising, with more innovations that will continue to shape the automotive industry in India. As the industry moves toward higher performance and sustainability, the importance of reliable and efficient components like cogged belts cannot be overstated.

0 notes

Text

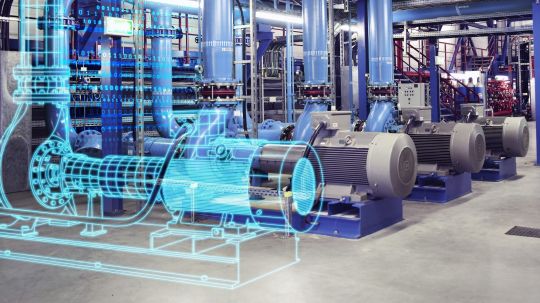

The Evolution of Industrial Drive Technology: From Conventional to Smart Systems

Industrial drive technology plays a critical role in manufacturing, automation, and energy management. From simple mechanical systems to modern smart drives integrated with AI and IoT, the evolution of industrial drives has significantly enhanced efficiency, precision, and sustainability.

This article explores the progress of industrial drive technology, from its conventional origins to the latest smart systems, and how these advancements are shaping the future of industrial automation.

1. The Conventional Era of Industrial Drives

In the early days of industrialization, mechanical drive systems were widely used to transmit power in factories. These systems relied on:

Fixed-speed motors with limited control over speed and torque.

Mechanical gears and belts for power transmission.

Manually operated systems requiring frequent adjustments.

Challenges of Conventional Industrial Drives

✔ High energy consumption due to inefficient speed control. ✔ Frequent maintenance due to wear and tear in mechanical components. ✔ Limited automation requiring manual intervention.

Despite these limitations, conventional drives played a crucial role in industrial progress, setting the foundation for modern automated systems.

2. The Shift to Electronic and Variable Frequency Drives (VFDs)

With the rise of electrical engineering and power electronics, industrial drives underwent significant advancements:

The introduction of Variable Frequency Drives (VFDs) allowed precise control of motor speed and torque.

DC and AC drives replaced mechanical power transmission systems, improving energy efficiency.

Programmable Logic Controllers (PLCs) enabled basic automation in manufacturing processes.

Advantages of Electronic Drives

✔ Better speed and torque control, improving machinery efficiency. ✔ Reduced mechanical wear and tear, leading to lower maintenance costs. ✔ Energy savings, as motors could operate at variable speeds based on demand.

The adoption of electronic drives and VFDs marked the beginning of industrial automation and efficiency improvements, paving the way for smarter solutions.

3. The Rise of Intelligent and Smart Industrial Drives

With advancements in digital technology, artificial intelligence (AI), and the Internet of Things (IoT), modern industrial drives have evolved into smart, self-optimizing systems.

Key Features of Smart Industrial Drives

✔ IoT-Enabled Connectivity – Real-time monitoring and remote control through cloud-based platforms. ✔ AI-Powered Predictive Maintenance – Reduces downtime by detecting faults before they occur. ✔ Energy Optimization Algorithms – Smart drives adjust power consumption based on workload. ✔ Seamless Integration with Automation Systems – Works efficiently with robotics, PLCs, and SCADA.

Impact on Industry 4.0

Modern industrial drives are a key component of Industry 4.0, enabling:

Self-learning drive systems that adapt to changing operating conditions.

Wireless communication for real-time performance tracking.

Cybersecurity enhancements to protect industrial networks.

These innovations improve productivity, energy efficiency, and sustainability, making smart industrial drives the future of manufacturing.

4. The Future of Industrial Drive Technology

As industries continue to advance, next-generation drive systems will incorporate:

Edge computing for faster data processing and decision-making.

AI-driven automation that requires minimal human intervention.

Enhanced cybersecurity measures to protect connected drive systems.

With these advancements, smart industrial drives will play a vital role in reducing operational costs, minimizing downtime, and increasing manufacturing efficiency.

Conclusion

The evolution of industrial drive technology has transformed the way industries operate, moving from basic mechanical systems to intelligent, self-optimizing smart drives. With AI, IoT, and energy-efficient solutions, modern industrial drives are shaping the future of automation and sustainability.

As industries adopt these smart technologies, efficiency, precision, and cost savings will continue to improve, ensuring a smarter and more sustainable future for manufacturing and industrial applications.

0 notes

Text

Automotive Axle and Propeller Shaft Market Revenue Analysis: Growth, Share, Value, Size, Scope, Industry Analsis and Forecast by 2028

"Automotive Axle and Propeller Shaft Market Size And Forecast by 2028

Automotive axle and propeller shaft market is expected to witness market growth at a rate of 3.52% in the forecast period of 2021 to 2028. Data Bridge Market Research report on automotive axle & propeller shaft market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecasted period while providing their impacts on the market’s growth.

the outlook for the Automotive Axle and Propeller Shaft Market remains optimistic, with significant opportunities for growth and innovation. The market’s competitive environment, shaped by leading companies and their strategies, underscores the importance of adaptability and foresight. With a focus on insights, trends, and data-driven analysis, this report serves as a comprehensive guide for stakeholders navigating the complexities of the Automotive Axle and Propeller Shaft Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-automotive-axle-propeller-shaft-market

Which are the top companies operating in the Automotive Axle and Propeller Shaft Market?

The Top 10 Companies in Automotive Axle and Propeller Shaft Market are known for their strong presence and innovative solutions. These include industry leaders. Each of these companies has made significant contributions through cutting-edge products, strategic partnerships, and global reach. Their ability to adapt to market trends and consumer demands has helped them maintain leadership positions in the market, driving growth and setting industry standards.

**Segments**

- By Product Type: - Axle - Propeller Shaft

- By Vehicle Type: - Passenger Vehicle - Commercial Vehicle

- By Material: - Alloy - Carbon Fiber - Others

- By Manufacturing Process: - Forged - Rolled

The global automotive axle and propeller shaft market can be analyzed based on several key segments. Firstly, by product type, the market is segmented into axles and propeller shafts. Axles are a vital component in a vehicle responsible for transmitting power from the engine to the wheels, while propeller shafts are used to transfer torque from the transmission to the differential. Secondly, based on vehicle type, the market is divided into passenger vehicles and commercial vehicles, each having different demands for axles and propeller shafts based on their unique requirements. Thirdly, by material, the market includes alloys, carbon fiber, and other materials, with each offering distinct advantages in terms of strength, weight, and cost. Lastly, based on the manufacturing process, the market is segmented into forged and rolled, with each method influencing the final characteristics of the axle and propeller shaft.

**Market Players**

- American Axle & Manufacturing, Inc. - GKN plc - Hyundai WIA Corporation - JTEKT Corporation - NTN Corporation - Dana Limited - Showa Corporation - Gestamp - Nexteer Automotive - IFA Rotorion

The global automotive axle and propeller shaft market features a competitive landscape with key players driving innovation and growth in the industry. Companies such as American Axle & Manufacturing, Inc., GKN plc, Hyundai WIA Corporation, and JTEKT Corporation play a significant role in the market with their extensive product offerings and strategic initiatives. Other notable market players include NTN Corporation, Dana Limited, Showa Corporation, Gestamp, Nexteer Automotive, and IFA Rotorion, each contributing to the market dynamics with their unique capabilities and market presence. These market players are at the forefront of technological advancements and product developments in the automotive axle and propeller shaft industry, catering to the evolving needs of vehicle manufacturers and customers worldwide.

https://www.databridgemarketresearch.com/reports/global-automotive-axle-propeller-shaft-marketThe global automotive axle and propeller shaft market is poised for significant growth and evolution in the coming years, driven by various factors ranging from technological advancements to shifting consumer preferences. One notable trend in the market is the increasing demand for lightweight materials such as carbon fiber in the manufacturing of axles and propeller shafts. Carbon fiber offers superior strength and reduced weight compared to traditional materials like alloys, aligning with the industry's focus on improving fuel efficiency and reducing emissions. As automakers strive to meet stringent regulatory standards and cater to environmentally-conscious consumers, the adoption of lightweight materials is expected to gain momentum, thereby influencing the market dynamics.

Moreover, the market is witnessing a surge in the adoption of advanced manufacturing processes such as forging and rolling to enhance the structural integrity and performance of axles and propeller shafts. Forging enables the production of components with superior strength and durability, making it ideal for high-performance applications in commercial vehicles and sports cars. On the other hand, rolling offers cost-effective manufacturing solutions with precise control over material properties, appealing to mass production requirements in the passenger vehicle segment. The choice of manufacturing process plays a crucial role in determining the overall quality and performance of axles and propeller shafts, driving manufacturers to explore innovative techniques to gain a competitive edge in the market.

Furthermore, the market players are increasingly focusing on strategic collaborations, mergers, and acquisitions to expand their product portfolio and global presence. By leveraging synergies and complementary capabilities, companies aim to enhance their technological expertise and market reach, fostering innovation and sustainable growth in the automotive axle and propeller shaft market. Additionally, investments in research and development activities to pursue breakthrough innovations in materials science, design optimization, and production efficiency are anticipated to shape the future of the market landscape. With a strong emphasis on sustainability, safety, and performance, market players are poised to deliver cutting-edge solutions that meet the evolving needs of automakers and consumers in the competitive automotive industry.

In conclusion, the global automotive axle and propeller shaft market present a dynamic and competitive environment with significant opportunities for growth and innovation. The convergence of lightweight materials, advanced manufacturing processes, and strategic partnerships is expected to redefine the market landscape and propel the industry towards a sustainable and technology-driven future. As market players continue to invest in research and development and collaborate to address market challenges and opportunities, the automotive axle and propeller shaft market is poised to witness exciting developments and breakthroughs that cater to the demands of a rapidly evolving automotive ecosystem.**Segments**

Global Automotive Axle & Propeller Shaft Market can be segmented based on various factors including position, type, material, sales channel, vehicle type, propeller shaft type, axle type, and country. In terms of position, axles and propeller shafts can be categorized as front or rear components. The type of axles and propeller shafts can be classified as single piece or multi-piece configurations. When it comes to material, options include alloys and carbon fiber, each offering unique characteristics. Sales channels for automotive axles and propeller shafts can either be OEM (Original Equipment Manufacturer) or aftermarket. Vehicle types such as passenger cars, light commercial vehicles, and heavy commercial vehicles have specific requirements for axles and propeller shafts. Propeller shaft types can vary from front propellers to inter-axles and rear propellers. Axles can be categorized as dead axles, live axles, or tandem axles. Finally, the market can be segmented based on countries across different regions such as the U.S., Canada, Mexico, Brazil, Argentina, Germany, Italy, U.K., Spain, China, India, Japan, South Korea, Australia, Saudi Arabia, U.A.E, South Africa, and many more.

**Market Players**

The major players in the automotive axle and propeller shaft market include ZF Friedrichshafen AG, Melrose Industries PLC, Dana Limited, American Axle & Manufacturing, Inc., Meritor, Inc., SHOWA Corporation, HYUNDAI WIA CORP, Gestamp Automoción, JTEKT Corporation, IFA Group, Automotive Axles Limited, Mark Williams Enterprises Inc., White Technologies Inc., Johnson Power Ltd, Wilson Drive Shafts, Nexteer Automotive, D & F Propshafts, and Bailey Morris Ltd. These players have a significant market presence and contribute to the competitive landscape of the industry. Market share data is available for global regions including North America, Europe, Asia-Pacific, Middle East & Africa, and South America, enabling a comprehensive understanding of the competitive strengths of each player. The market players are actively engaged in strategic initiatives such as mergers, acquisitions, product launches, and partnerships to enhance their product portfolios, expand their global footprint, and drive innovation in the automotive axle and propeller shaft market.

The automotive axle and propeller shaft market is witnessing dynamic growth driven by technological advancements, changing consumer preferences, and regulatory requirements. The increasing demand for lightweight materials like carbon fiber, the adoption of advanced manufacturing processes such as forging and rolling, and the focus on sustainability and performance are key trends shaping the market. With a strong emphasis on innovation, collaboration, and market expansion, the industry is set for exciting developments and breakthroughs that cater to the evolving needs of the automotive ecosystem. As market players continue to invest in R&D and forge strategic partnerships, the automotive axle and propeller shaft market is expected to evolve into a more competitive, efficient, and sustainable sector poised for long-term growth and success.

Explore Further Details about This Research Automotive Axle and Propeller Shaft Market Report https://www.databridgemarketresearch.com/reports/global-automotive-axle-propeller-shaft-market

Key Insights from the Global Automotive Axle and Propeller Shaft Market :

Comprehensive Market Overview: The Automotive Axle and Propeller Shaft Market is growing rapidly, driven by technological advancements and evolving consumer preferences.

Industry Trends and Projections: The market is expected to grow at a CAGR of X% over the next five years, with increasing automation and digitalization.

Emerging Opportunities: New market segments, such as sustainable and eco-friendly solutions, are creating significant growth prospects.

Focus on R&D: Companies are investing heavily in R&D to innovate and improve product offerings, ensuring market leadership.

Leading Player Profiles: Major player dominate the market with strong portfolios and strategic partnerships.

Market Composition: The market is diverse, with a mix of large enterprises and emerging startups driving competition and innovation.

Revenue Growth: The market has witnessed a steady increase in revenue, primarily driven by growing demand and product diversification.

Commercial Opportunities: There are considerable opportunities for business expansion in emerging regions and through technological innovations.

Find Country based languages on reports:

https://www.databridgemarketresearch.com/jp/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/zh/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/ar/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/pt/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/de/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/fr/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/es/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/ko/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/ru/reports/global-automotive-axle-propeller-shaft-market

Data Bridge Market Research:

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]"

0 notes

Text

Understanding Coupling Equipment: Types, Uses, and Benefits

Coupling equipment plays a vital role in many industries, providing solutions for transmitting power, connecting components, and ensuring the smooth operation of machines. Whether in manufacturing, automotive, construction, or energy sectors, coupling devices are essential for ensuring mechanical systems function without disruptions.

What is Coupling Equipment?

Coupling equipment refers to a mechanical device used to connect two shafts or rotating parts. Its primary purpose is to transmit rotational power between the components while accommodating misalignments, vibrations, and axial movements. Couplings can be made of various materials, such as metals, elastomers, or composites, depending on the application requirements. These devices allow machines to operate efficiently without damaging the connected parts.

Types of Coupling Equipment

Rigid Couplings Rigid couplings are designed to connect two shafts in perfect alignment. They do not allow for any misalignment or flexibility between the connected parts. This type of coupling is ideal when both shafts are accurately aligned. Examples include sleeve couplings, flange couplings, and clamp couplings.

Flexible Couplings Flexible couplings are used to accommodate some degree of misalignment between the shafts. These couplings can absorb shock loads and vibrations, reducing the risk of damage. Types of flexible couplings include elastomeric couplings, bellows couplings, and gear couplings.

Oldham Couplings Oldham couplings are a type of flexible coupling that is known for its ability to handle angular misalignment. They consist of a driving and driven part connected by a center disc, which helps reduce vibration and shock loads.

Universal Joint (U-Joint) Couplings U-joint couplings are typically used in automotive and heavy machinery applications. These couplings enable the transmission of power between two shafts that are not aligned but rotate at different angles. U-joints are essential in vehicles for transmitting rotational force from the engine to the wheels.

Magnetic Couplings Magnetic couplings use magnetic fields to transmit power between shafts without physical contact. This type of coupling is ideal for situations requiring hermetic sealing or in environments with contaminants, such as in chemical or pharmaceutical industries.

Key Benefits of Coupling Equipment

Power Transmission The main function of coupling equipment is to transmit rotational power between connected components. Whether transferring torque in industrial machines or vehicles, couplings ensure that energy is efficiently passed from one part to another.

Flexibility and Alignment Accommodation Couplings can accommodate various types of misalignment, whether axial, angular, or parallel. Flexible couplings, for instance, help absorb the shock and reduce vibration between shafts, ensuring smooth and continuous operation.

Protection of Machinery By using coupling equipment, you can reduce the strain on connected machines. Misalignment can lead to mechanical failures and excessive wear on components. Couplings help in minimizing such risks by compensating for minor misalignments.

Cost-Effectiveness Rather than replacing entire parts when issues arise, using coupling equipment can provide a more cost-effective solution to keep machinery running smoothly. These devices are often less expensive than fully replacing or realigning machine components.

Durability High-quality couplings are designed to withstand harsh conditions such as high temperatures, pressures, or corrosive environments. They ensure long-term performance and reliability, which is particularly important in industrial settings.

Conclusion

Coupling equipment is a crucial component in numerous industries, providing benefits such as efficient power transmission, protection from misalignment, and overall system stability. With various types of couplings to choose from, industries can select the right solution based on their specific needs. Whether rigid or flexible, couplings help maintain smooth operations while extending the lifespan of machinery, making them a fundamental part of modern industrial design. For more details visit our website: www.simsinter.com

#Fire Fighting Equipment#Blasting & Painting Equipment#Special Trucks Equipment#Couplings Fire Hoses#Couplings Anti Corrosion#Power & Hand Tools Kits#Paint Spraying Equipment#Airless Electric Guns#Topcoats Equipment Near Me#Hydraulic Equipment Near Me#Coupling Equipment#Hydraulic Equipment Manufacturers#Hydraulic Tools And Equipment#Hydraulic Equipment Suppliers#Hydraulic Lifting Tools#Hydraulic Pump Manufacturers in Cameroon

0 notes

Text

Comprehensive Guide to Understanding Fluid Couplings

Fluid couplings are essential components in a wide range of industrial applications, known for their ability to transmit power smoothly and efficiently between two rotating shafts. This guide dives deep into the workings of fluid couplings, highlighting their principal components, fundamental principles, and practical applications. By the end of this guide, you'll have the insights needed to make informed decisions regarding fluid couplings.

Principal Components of Fluid Coupling

A typical fluid coupling consists of three main components:

Impeller (Pump): This is connected to the input or driving shaft. The impeller receives mechanical power from the prime mover (like an engine or motor) and converts it into kinetic energy through fluid movement.

Turbine (Driven Member): Attached to the output or driven shaft, the turbine receives the fluid flow from the impeller, transmitting rotational motion and torque to the driven shaft.

Working Fluid: Typically oil, the fluid inside the coupling transfers the energy from the impeller to the turbine, facilitating smooth power transmission without direct mechanical contact.

These components work together to provide a seamless transfer of energy, making fluid couplings a reliable choice in many industrial settings.

Fundamental Principle of Operation

The fundamental principle behind fluid couplings is hydrodynamic power transmission. This means that power is transmitted through the movement of fluid, rather than through direct mechanical engagement. The fluid, enclosed in a sealed chamber, acts as the medium that absorbs and transfers energy between the impeller and the turbine. This hydrodynamic operation ensures that fluid couplings can handle variable loads and speed differences with minimal wear.

How Fluid Couplings Work

When the impeller (connected to the driving shaft) rotates, it pushes fluid into motion. The fluid, accelerated by the impeller, flows toward the turbine. As the turbine absorbs the fluid’s kinetic energy, it begins to rotate, transferring power to the output shaft.

The beauty of this system lies in its ability to slip slightly between the input and output speeds, making it ideal for applications that require gradual acceleration or protection from overload. Fluid couplings are known for their torque multiplication during startup, which reduces the mechanical stress on motors and engines.

Types of Fluid Couplings

Fluid couplings come in different designs, each tailored for specific applications:

Constant-Fill Couplings: These are the most common types, where the amount of fluid inside remains constant. They are widely used for applications requiring smooth power transmission and are simple in design.

Variable-Fill Couplings: In this type, the amount of fluid inside the coupling can be adjusted, allowing for greater control over torque and speed. These are commonly used in heavy-duty applications where precise control is needed.

Centrifugal Couplings: These couplings engage only when a certain rotational speed is reached. They are typically used in applications requiring delayed engagement, such as in fans or pumps.

Hydrodynamic Couplings: These utilize the principles of fluid dynamics to transmit power and are typically used in applications with high starting loads.

Key Features and Benefits

Fluid couplings offer several key benefits:

Smooth Power Transmission: With no mechanical contact between the driving and driven members, fluid couplings ensure a smooth, shock-free transmission of power.

Overload Protection: Fluid couplings can protect machinery from overload by slipping under high torque, preventing damage to connected equipment.

Reduced Wear and Tear: Since there is no direct contact between the input and output shafts, fluid couplings experience less wear, reducing the need for frequent maintenance.

Energy Efficiency: They provide high efficiency in power transmission, particularly at higher speeds.

Flexibility in Operation: Fluid couplings allow for slip, which helps in absorbing shock loads, providing smoother operation, especially in starting and stopping cycles.

Industrial Applications of Fluid Coupling

Fluid couplings are employed in numerous industries for their ability to handle varying loads and torque requirements. Some common applications include:

Conveyors: In mining and material handling, fluid couplings ensure smooth start-ups and protect against overloads.

Pumps and Fans: These couplings are ideal for power transmission in pumps and fans, providing protection against high startup torque and maintaining operational efficiency.

Cranes and Hoists: For machinery that requires torque multiplication during startup, fluid couplings are perfect for ensuring safe and efficient operation.

Textile and Paper Machinery: In industries where precise speed control is critical, fluid couplings provide the necessary slip and torque transmission for optimal performance.

Explore Our High-Performance Fluid Couplings Tailored to Your Industrial Needs

At Santram Engineers, we specialize in providing high-performance fluid couplings designed to meet the diverse needs of various industries. Whether you need couplings for conveyors, pumps, or heavy-duty machinery, our expert team can help you find the right solution. With a focus on durability, efficiency, and customized options, we ensure your machinery operates at peak performance.

Read More: Comprehensive Guide to Fluid Couplings

0 notes

Text

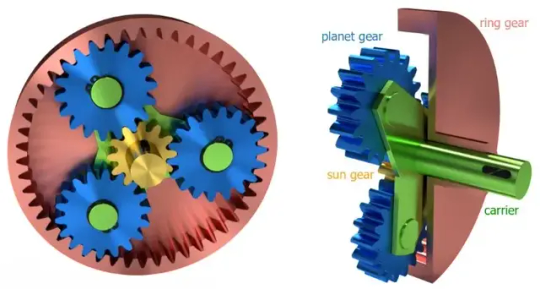

What is planetary Gear Motors?

Planetary Geared Motors efficiently handles the speed and optimises the torque. They can be used in wide industrial applications ranging from steel plants to material handling equipments.

Components of Planetary Geared Motors

Motor speed reducers can be categorised in the following ways depending on how they are internally configured:

Planetary Speed Reducers

Stages of planetary gear motors are grouped, and each one has the following layout:

Sun Gear (Central Gear)

The sun gear in a planetary gearbox rotates the neighbouring planetary gears, which are mounted on a carrier to prevent slippage while in use. The planetary gears rotate the ring gear while the sun gear is powered. The sun gear is the main gear. It rotates on a bigger axis and is greater in size.

Multiple Planet Gears

The epicyclic gear typically consists of two gears, one of which meshes with the sun gear and the other with the planetary ring gear. These are used to lower speed. They are utilised to boost torque and slow down motors. Planetary gears' primary and essential job is to adjust the rotational speed or torque between the input and output shafts while transmitting torque.

Planet Carrier

The planet gear is held by the planet carrier, which rotates in the opposite direction of the planet gear. Typically, it offers support to allow two gears to roll without slippage by connecting their centres. A planet carrier that meshes with the sun can carry up to three gears.

Ring Gear (Outer Gear)

Numerous planet gears that are utilised to drive the outer ring, shaft, or spindle share the load from the sun gear. The ring gear provides a reverse direction by rotating in the same direction as the sun gear.

Advantages Of Planetary Gear Motors

Increased Repeatability

Its faster radial and axial loads are more dependable and robust, reducing gear misalignment. Additionally, flawless repeatability is provided by consistent transmission and reduced vibrations under various loads.

Perfect Accuracy

The movement's accuracy and dependability are improved by the rotation's maximum angular stability.

Efficient Durability

Because there is greater surface contact, the noise intensity is lower. Jumping is almost negligible, and rolling is much smoother. Owing to its torsional rigidity and improved rolling, it is more durable. Your bearings assist in minimising the losses that would result from the shaft rubbing against the box directly, improving this characteristic. As a result, the gear operates more smoothly and with more efficiency.

High Degrees of Effectiveness

Planetary reducers are more effective and minimise losses during operation due to their internal design and architecture. In actuality, these driving systems are the most efficient ones available today.

Improved Torque Transmission

The mechanism can transmit and endure more torque when there are more teeth in connection. Things also performs it in a more consistent way.

Maximum Adaptability

Its gearbox, which is cylindrical and can be mounted practically anywhere, houses the mechanism.

Disadvantages of Planetary Gear Motors

A planetary gear system will generally cost more than a traditional gearbox.

Planetary gear design and production are challenging and highly complex.

It would be difficult to figure out a planetary gear system's efficiency

It is challenging because the gear system demands exact gearing.

Some planetary gearing configurations operate noisier than others.

The driving component and the driven component must coincide to avoid any additional gearing.

Applications of Planetary Gear Motors

It is utilised in packing equipment for industrially reproducible goods.

They are utilised in cutter head drives, coil tubing injectors, and pumps.

It can be used in drives like wheel drives, track drives, conveyor drives, slew drives, hoist drives, and winch drives, among others.

These gears are frequently employed in robotics to increase torque.

It is utilised in printing presses to lower the rollers' speed.

Regulations For Planetary Gearboxes

When a manufacturer lists the operating time of your gears or the maximum torque they can withstand, keep in mind that each manufacturer establishes its own standards. Nevertheless, these parameters are governed by a few rules.

ISO 6636 for gears.

DIN ISO 281: Contains all the guidelines necessary to calculate bearings correctly.

ISO 9409: Part II discusses how the output shafts of these geared motors are designed in accordance with various requirements.

#planetarygearmotors#planetarygearmotorsmanufacture#planetarygearmotorssuppliers#kavitsuransmissions#kavitsu

0 notes

Text

The V SMSR Gearbox: Revolutionizing Power Transmission in Industry

Introduction

In the world of industrial machinery, the efficiency and reliability of power transmission systems are crucial. Among the various types of gearboxes available, the V SMSR Gearbox (Shaft Mounted Speed Reducer) stands out for its innovative design and performance. This article delves into the features, benefits, and applications of the V SMSR Gearbox, highlighting why it is a preferred choice for many industrial applications.

Understanding the V SMSR Gearbox

The V SMSR Gearbox, or Shaft Mounted Speed Reducer, is a compact and efficient gearbox designed to provide speed reduction and increased torque in industrial machinery. Unlike traditional gearboxes that require a base or foundation for mounting, the SMSR gearbox is directly mounted onto the driven shaft, eliminating the need for additional support structures. This design simplifies installation and maintenance, making it a popular choice for various applications.

Key Components and Design Features

Gear Assembly: The core component of the V SMSR Gearbox is the gear assembly, which typically includes helical gears. Helical gears are known for their smooth and quiet operation, thanks to their angled teeth that gradually engage with each other.

Shaft Mounting: The defining feature of the SMSR gearbox is its shaft-mounted design. The gearbox is directly mounted onto the driven shaft, which simplifies the alignment process and reduces the need for additional components.

Torque Arm: The torque arm is an essential part of the SMSR gearbox. It prevents the gearbox from rotating and ensures that the torque is effectively transmitted to the driven equipment. The torque arm is usually adjustable, allowing for flexibility in installation.

Bearings and Seals: High-quality bearings and seals are used to ensure smooth operation and protect the internal components from contaminants. These elements are crucial for maintaining the longevity and performance of the gearbox.

Housing: The housing of the V SMSR Gearbox is typically made from robust materials such as cast iron or aluminum. It provides structural support and protection to the internal components, ensuring the gearbox can withstand harsh industrial environments.

Functionality and Operation

The V SMSR Gearbox operates by reducing the input speed from the motor and increasing the torque transmitted to the driven equipment. The helical gears within the gearbox mesh smoothly, providing efficient power transmission and minimizing energy losses. The shaft-mounted design ensures that the gearbox is directly aligned with the driven shaft, reducing misalignment issues and enhancing overall efficiency.

Applications of V SMSR Gearboxes

The versatility of the V SMSR Gearbox makes it suitable for a wide range of industrial applications. Some of the common applications include:

Conveyors: SMSR gearboxes are widely used in conveyor systems for material handling. Their compact design and efficient power transmission make them ideal for use in industries such as mining, aggregate processing, and manufacturing.

Crushers: In the mining and quarrying industry, SMSR gearboxes are used in crushers to provide the necessary torque for crushing operations. Their robust construction ensures reliable performance even in demanding environments.

Mixers and Agitators: SMSR gearboxes are employed in mixers and agitators used in chemical processing, food production, and wastewater treatment. Their ability to provide precise speed control and high torque is crucial for these applications.

Pumps: In various industrial processes, SMSR gearboxes are used to drive pumps. Their efficient power transmission ensures consistent fluid flow and reliable operation.

Cooling Towers: SMSR gearboxes are used in cooling towers to drive the fans that dissipate heat. Their compact design and reliable performance make them suitable for use in HVAC systems and power plants.

Advantages of V SMSR Gearboxes

Ease of Installation: The shaft-mounted design of the SMSR gearbox eliminates the need for additional support structures, simplifying the installation process. This design also reduces the time and labor required for setup.

Compact Design: The SMSR gearbox is compact and space-saving, making it ideal for applications with limited space. Its streamlined design also reduces the overall weight of the system.

High Efficiency: The use of helical gears in the SMSR gearbox ensures smooth and efficient power transmission. The gradual engagement of the gears reduces energy losses and enhances overall efficiency.

Low Maintenance: The robust construction and high-quality components of the SMSR gearbox result in low maintenance requirements. The direct shaft mounting also reduces the risk of misalignment and associated wear.

Versatility: The adjustable torque arm and flexible mounting options make the SMSR gearbox suitable for a wide range of applications. It can be easily adapted to different setups and operational requirements.

Maintenance and Care

To ensure the optimal performance and longevity of V SMSR Gearboxes, regular maintenance is essential. Here are some maintenance tips:

Lubrication: Regularly check and maintain the appropriate oil levels. Proper lubrication is crucial for reducing friction and wear between the gears and bearings.

Inspection: Periodic inspections of the gearbox can help identify potential issues early. Look for signs of wear, leaks, and unusual noises that may indicate problems.

Cleaning: Keep the gearbox and its surroundings clean to prevent dust and contaminants from entering the gearbox. This can help prevent damage to the gears and bearings.

Alignment: Ensure that the gearbox is properly aligned with the driven shaft during installation. Misalignment can lead to excessive wear and reduced efficiency.

Torque Arm Adjustment: Periodically check and adjust the torque arm to ensure it is properly positioned and securely fastened. This will prevent unnecessary stress on the gearbox and enhance its performance.

Innovations and Future Trends

The field of gearbox technology is continuously evolving, and the V SMSR Gearbox is no exception. Several innovations and trends are shaping the future of these gearboxes:

Advanced Materials: The use of advanced materials, such as composite materials and high-strength alloys, is enhancing the performance and durability of SMSR gearboxes.

Precision Manufacturing: Advances in manufacturing techniques, such as 3D printing and CNC machining, are enabling the production of gears with higher precision and tighter tolerances, resulting in improved performance.

Smart Gearboxes: The integration of sensors and IoT technology is leading to the development of smart gearboxes that can monitor their own performance and provide real-time data for predictive maintenance, reducing downtime and improving efficiency.

Energy Efficiency: As industries strive for greater energy efficiency, gearboxes are being designed to minimize energy losses and improve overall system efficiency. Innovations in lubrication and materials are contributing to this goal.

Conclusion

The V SMSR Gearbox is a vital component in many industrial applications, offering ease of installation, high efficiency, and reliable performance. Its unique shaft-mounted design and robust construction make it suitable for a wide range of uses, from conveyors and crushers to mixers and pumps. By understanding its design, functionality, and applications, industries can leverage the benefits of the V SMSR Gearbox to enhance their operations and achieve greater efficiency.

For more information about the V SMSR Gearbox and to explore our range of products, visit Cherry Belts.

0 notes

Text

What are the Applications and Uses of PTO Gearbox?

PTO gearboxes find extensive application across various industries:

1. Agricultural Machinery:

Tractors: PTO gearboxes in tractors transfer engine power to agricultural implements like plows, seeders, and harvesters.

Irrigation Systems: They power water pumps for irrigation purposes, crucial for modern farming operations.

2. Construction Equipment:

PTO gearboxes in construction machinery transfer power to tools like concrete mixers, hydraulic systems, and winches, enhancing their operational capabilities.

3. Industrial Machinery:

They are integral in industrial settings where heavy machinery requires flexible power transmission solutions.

Working and Principle of PTO Gearbox :

Input Shaft: Receives power from the engine or motor.

Output Shaft: Transfers power to the driven equipment.

Gears: Multiple gears with different ratios to adjust speed and torque output.

Bearings and Seals: Ensure smooth operation and prevent leaks.

Working Principle:

When the engine or motor drives the input shaft, the gears inside the PTO gearbox transmit this rotational energy to the output shaft.

Gear ratios can be adjusted to optimize speed or torque depending on the application’s requirements.

Some PTO gearboxes also include clutches to engage/disengage power transmission as needed, enhancing operational control.

What is a PTO Gearbox?

A PTO gearbox, also known as a power take-off gearbox, is a mechanical device used to transfer power from an engine or motor to another mechanical component, typically through a driveshaft. It enables machines to derive power from a primary power source and transmit it at varying speeds and torque levels to secondary components such as pumps, generators, or other machinery.

Benefits of PTO Gearboxes

Versatility: They accommodate a wide range of applications and equipment types.

Efficiency: Enable efficient power transfer with minimal energy loss.

Customization: Adjustable gear ratios provide flexibility for different operational needs.

Reliability: Robust construction ensures durability and long service life.

Challenges and Considerations

While PTO gearboxes offer significant advantages, they also come with considerations:

Maintenance: Regular maintenance is crucial to prevent wear and ensure optimal performance.

Compatibility: Ensuring compatibility between the gearbox and the driven equipment is essential for seamless operation.

Safety: Proper installation and adherence to safety guidelines are critical to prevent accidents.

Conclusion

In conclusion, the PTO gearbox stands as a testament to engineering ingenuity in optimizing power transmission across various industries. From agriculture to construction and beyond, its role in enhancing efficiency and productivity cannot be overstated. Understanding its components, working principles, and applications provides valuable insight into how modern machinery harnesses power to drive progress.

As industries continue to evolve, so too will the technology behind PTO gearboxes, aiming for even greater efficiency, reliability, and adaptability to meet the demands of tomorrow’s challenges.

Best PTO Gearbox Manufacturer in India

If you are looking for PTO Gearbox Manufacturer in India, look no further then Supertech Engineers, We are a leading manufacturer and supplier of PTO Gearbox in India.

For more details, contact us!

Website — https://www.supertechengineer.co.in/

Contact No. — +91–9910715032, +91–9311309436

Email — [email protected]

#PTO Gearbox Manufacturer in India#PTO Gearbox Manufacturer in Delhi#PTO Gearbox Manufacturer in Ghaziabad#Supertech engineers#Best PTO Gearbox Manufacturer in India#Top PTO Gearbox Manufacturer in India

1 note

·

View note

Text

Shaft Mounted Gearbox Manufacturer in Ahmedabad, India- Nisuka Industries

In today’s fast-paced industrial environment, efficiency, durability, and performance are key factors that drive the demand for high-quality transmission equipment. One such essential component in many heavy-duty applications is the shaft mounted gearbox. At Nisuka Industries, we are proud to be recognized as a trusted Shaft Mounted Gearbox Manufacturer in Ahmedabad, India, delivering robust and precision-engineered gearboxes for various industries.

What Is a Shaft Mounted Gearbox?

A shaft mounted gearbox is a mechanical unit used to transmit power directly to the driven shaft without requiring a foundation or base plate. It simplifies installation, improves alignment, and reduces space requirements. Its primary use is in applications that involve conveyors, crushers, mixers, and industrial drives operating under heavy loads and harsh environments.

Why Choose Nisuka Industries?

With over three decades of manufacturing excellence, Nisuka Industries has earned its place as a reliable Shaft Mounted Gearbox Manufacturer in India. Our in-house R&D team, modern manufacturing units, and strict quality control processes help us deliver gearboxes that perform consistently even under demanding conditions.

Key Advantages:

High Load Capacity: Designed to handle heavy-duty applications.

Compact Design: Mounts directly on the shaft, eliminating the need for couplings.

Maintenance-Friendly: Low-maintenance design with easily replaceable components.

Material Strength: Manufactured using high-grade alloy steel and cast iron for long life.

Serving Diverse Industrial Applications

Our shaft mounted gearboxes are widely used in:

Conveyor Systems (cement, coal, aggregate)

Crushers and Screening Equipment

Material Handling Systems

Mining and Quarry Equipment

Packaging and Processing Units

The reliability and strength of our products make us a preferred choice across sectors such as mining, cement, steel, food processing, textile, and agriculture.

Quality That Drives Performance

Nisuka Industries believes in delivering excellence through precision engineering. Every gearbox we manufacture undergoes strict quality checks. Our units are tested for:

Torque output

Gear alignment

Noise and vibration levels

Oil sealing and thermal performance

As an ISO-certified manufacturer, we maintain global standards throughout our production and inspection processes.

Expertise Beyond Shaft Mounted Gearboxes

While shaft mounted gearboxes are a key part of our product range, our capabilities extend far beyond. We are also a leading Conveyor Gearbox Manufacturer in India, offering tailor-made solutions for belt and roller conveyors in material handling units. These gearboxes ensure smooth and energy-efficient performance in industries where continuous movement and uptime are critical.

Furthermore, we are also recognized as a reputed Plummer Block Manufacturer in India. Our plummer blocks are known for their high load-bearing strength, resistance to corrosion, and long service life. These blocks are essential in applications requiring firm support for rotating shafts and are widely used in various types of bearing assemblies.

Our full range of products demonstrates our versatility and dedication to providing complete mechanical transmission solutions under one roof.

Strategic Location in Ahmedabad, India

Our manufacturing facility is located in Ahmedabad, one of India’s top industrial cities. This provides us with easy access to transportation, raw materials, skilled manpower, and technological advancements. Our strategic location allows us to serve customers across India with faster delivery and better support.

Being based in Ahmedabad also helps us stay connected with major industrial hubs like Mumbai, Pune, Bangalore, Delhi, and Chennai, ensuring that we can meet the diverse needs of clients from different parts of the country.

Our Commitment to Innovation

We continuously invest in R&D and innovation to ensure that our gearboxes meet the evolving needs of modern industries. Our design engineers use the latest CAD and simulation software to develop products that offer maximum efficiency with minimal energy loss.

We are committed to offering solutions that are not just durable but also environmentally conscious and energy-saving—making us a future-ready Shaft Mounted Gearbox Manufacturer in India.

Dedicated Customer Support

At Nisuka Industries, we don't just sell products—we build relationships. Our team is always ready to assist clients with installation, troubleshooting, and maintenance guidance. We offer:

On-site technical assistance

Availability of genuine spare parts

Quick response time for service requests

Customization based on client requirements

This customer-first approach has helped us build long-term partnerships with industries all over India.

Conclusion

If you’re in search of a dependable Shaft Mounted Gearbox Manufacturer in Ahmedabad, India, Nisuka Industries is your ideal partner. With a proven track record in mechanical engineering and a wide array of industrial gear solutions, we continue to lead the way in delivering performance-driven, cost-effective, and reliable power transmission systems.

Whether you need shaft mounted gearboxes, conveyor gearboxes, or plummer blocks, we offer everything under one roof—backed by years of experience, a passion for innovation, and a commitment to excellence.

Contact Nisuka Industries today and experience the difference that precision engineering and customer-centric service can make for your business.

#Shaft Mounted Gearbox Manufacturer in Ahmedabad#Shaft Mounted Gearbox supplier in Ahmedabad#Shaft Mounted Gearbox exporter in Ahmedabad

0 notes

Text

Understanding Market Dynamics: Couplings Size, Share, and Trends

The global couplings market is valued at US$ 1.3 billion in 2023 and is expected to reach US$ 1.7 billion by 2033. This is because worldwide sales of couplings are predicted to increase steadily at a CAGR of 3% through 2033. The couplings market refers to the industry that produces and sells mechanical couplings used to connect two rotating shafts together. These couplings are typically used in machinery and equipment such as pumps, generators, compressors, and turbines

There are many different types of couplings available on the market, including flexible couplings, rigid couplings, and fluid couplings, among others. Each type of coupling has its own specific benefits and applications. The global couplings market is expected to continue growing due to increasing demand from various industries, such as oil and gas, power generation, and automotive. The market is also being driven by advancements in technology, which are leading to the development of more efficient and reliable couplings

Download Free Sample Copy of this Report – https://www.factmr.com/connectus/sample?flag=S&rep_id=8422?PJ

The couplings market is an integral component of various industries, providing essential connections for transmitting power and torque between rotating shafts. These mechanical devices play a crucial role in ensuring the smooth and efficient operation of machinery and equipment in sectors such as manufacturing, automotive, aerospace, and energy. Couplings facilitate the connection and disconnection of shafts while compensating for misalignments and accommodating axial and angular movements. The market has experienced steady growth, driven by the increasing demand for reliable and durable couplings to enhance the performance of machinery and contribute to operational efficiency.

Key Market Drivers:

Industrial Automation: The rise of industrial automation has been a significant driver for the couplings market. As industries increasingly adopt automated systems and robotics, the demand for precision couplings that provide accurate torque transmission and support dynamic movements has grown substantially.

Renewable Energy Expansion: The expansion of renewable energy projects, particularly in wind and solar power generation, has contributed to the demand for couplings. Couplings are essential components in the mechanical drive systems of wind turbines and solar tracking systems, ensuring efficient power transmission in renewable energy applications.

Infrastructure Development: Ongoing infrastructure development projects, including the construction of buildings, bridges, and transportation systems, drive the need for heavy machinery and equipment. Couplings are critical in construction machinery, supporting reliable power transmission and enabling the functionality of various construction equipment.

Key Takeaways from Market Study

The global couplings market is valued at US$ 1.3 billion in 2023.

Demand for couplings in China is predicted to expand at a CAGR of 4.5% during the forecast period.

Sales of elastomeric couplings are expected to rise at a CAGR of 4% through 2033.

Demand for metallic couplings is predicted to increase at a CAGR of 3% from 2023 to 2033.

Region wise Insights

North America: The North American couplings market is driven by the increasing demand for couplings in various industries, including oil and gas, power generation, and aerospace. The United States is the largest market in this region due to its strong manufacturing industry and high demand for machinery and equipment.

Europe: The European couplings market is expected to experience steady growth due to the presence of a large number of manufacturing industries and the increasing demand for automation in various sectors. Germany is the largest market in this region, followed by the UK and France.

Asia-Pacific: The Asia-Pacific region is the fastest-growing couplings market, with countries such as China, India, and Japan leading the way. The region’s growth is driven by increasing industrialization, urbanization, and infrastructure development. The rising demand for power and energy and the growing automotive industry are also contributing to the growth of the market.

Latin America: The Latin American couplings market is expected to grow at a moderate pace due to the increasing demand for energy and infrastructure development in the region. Brazil is the largest market in this region, followed by Mexico and Argentina.

Middle East and Africa: The Middle East and Africa couplings market is expected to experience significant growth due to increasing investments in infrastructure development and the growing oil and gas industry in the region. The United Arab Emirates, Saudi Arabia, and South Africa are the largest markets in this region.

Competitive Landscape

Key players in the couplings market are being encouraged by rapid industrialization and expansion in the aerospace & defence, healthcare, and industrial sectors to produce cutting-edge products to fulfil end users’ demand, which is further enhancing their earnings.

Leading firms in this market are using a variety of organic and inorganic marketing strategies, according to Fact.MR, a source of market research and competitive information.

The development of its brand-new Rotex series intermediate shaft couplings was unveiled by KTR Systems GmbH in June 2022. The shaft lengths that may be supported by these aluminium shaft couplings are up to 4,000 mm.

Key Companies Profiled

ABB Ltd.

Altra Industrial Motion Corporation

Boston Gear

Challenge Power Transmission Ltd

Anmark

Camozzi Industries spa Societa Unipersonale

Bea Ingranaggi SpA

Chr. Mayr GmbH + Co. KG

ALMA driving elements GmbH

ComInTec

Colder Products Company

Colly Flowtech

AMG-PESCH

Arestho

Current Industry News :

Several trends and developments may have shaped the couplings market in 2023.

Focus on Smart Couplings: The industry may have seen a heightened focus on smart couplings equipped with sensors and monitoring technologies. These smart couplings provide real-time data on operating conditions, enabling predictive maintenance strategies and contributing to overall equipment reliability.

Increased Adoption of Non-metallic Couplings: The market may have witnessed an increased adoption of non-metallic couplings, such as those made from composite materials or polymers. Non-metallic couplings offer benefits such as corrosion resistance, reduced weight, and the ability to dampen vibrations, catering to the evolving needs of industries.

Sustainability Initiatives: Coupling manufacturers may have aligned with sustainability initiatives by exploring eco-friendly materials and manufacturing processes. The emphasis on environmental responsibility and green technologies may have influenced the development of couplings with reduced environmental impact.

Rise of Online Platforms for Coupling Procurement: The digital transformation in industrial procurement may have led to the rise of online platforms for coupling procurement. E-commerce platforms specializing in industrial components could offer a convenient and efficient way for businesses to source couplings, providing a wide range of options and facilitating easy comparison.

0 notes

Text

Components of the Planetary Gear Box