Text

We providing all kinds of bearings with Affordable Value

#goodservice#bestprice#bestoffers#ontimedelivery#bestindustry#hi-tech automation#bestindustrialproducts

0 notes

Text

We hold huge stocks of all the types of bearings with super precision bearings.

0 notes

Text

We provide the finest solutions for our customers, such as power tools, electric motors, machine tools, etc.

0 notes

Text

We are the industrial distributors of all kinds of bearings. We serve good to our customers by our best price and faster delivery. Our motive is to provide quality products in best possible price which will worth buying.

0 notes

Text

We are the industrial distributors of all kinds of bearings. We serve good to our customers by our best price and faster delivery. Our motive is to provide quality products in best possible price which will worth buying.

0 notes

Text

#bestindustry #bestoffers #OnTimeDelivery #bestprice #goodservice #donateorgansavelife #DrugFreeIndia #fusecutouts In electrical distribution, a fuse cutout or cut-out fuse (often referred to as a cutout) is a combination of a fuse and a switch, used in primary overhead feeder lines and taps to protect distribution transformers from current surges and overloads. An over-current caused by a fault in the transformer or customer circuit will cause the fuse to melt and the switch mechanism to visibly open, disconnecting the transformer from the line. The device can also be opened manually by utility linemen standing on the ground and using a long insulating stick called a "hot stick The cutout body, an open frame that supports the fuse holder and a ribbed porcelain or polymer insulator that electrically isolates the conductive portions of the assembly from the support to which the insulator is fastened.

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#DrugFreeIndia#fusecutouts#In electrical distribution#a fuse cutout or cut-out fuse (often referred to as a cutout) is a combination of a fuse and a switch#used in primary overhead feeder lines and taps to protect distribution transformers from current surges and overloads. An over-current caus#disconnecting the transformer from the line. The device can also be opened manually by utility linemen standing on the ground and using a l#The cutout body#an open frame that supports the fuse holder and a ribbed porcelain or polymer insulator that electrically isolates the conductive portions#The fuse holder#also called the “fuse tube” or “door”#an insulating tube which contains the replaceable fuse element. When the contained fuse melts (“blows”)#it opens the circuit#and the fuse holder drops out of the upper contact and hangs from a hinge on its lower end. This hanging fuse holder provides a visible ind#the coating on the fiberglass will degrade and the fiberglass tube will start “shedding”. The tube starts out with a pinkish hue then becom#The fuse element#or “fuse link”#is the replaceable portion of the assembly that melts and breaks the circuit when the electric current through it exceeds its rated current#The fuse holder may be replaced by a solid blade#which would allow the fuse holder assembly to be used as a switch only.

0 notes

Text

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#DrugFreeIndia

#pneumatictimer

This is accomplished via a reservoir of oil, driven by air pressure on the top of the oil through a needle valve to control the speed. With a Proportion-Air F-Series mass flow controller, the traditional reservoir of oil is not necessary.

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#DrugFreeIndia#pneumatictimer Pneumatic timers are used in industrial systems for the precise control of air input signals. They are used in place of elec#where the use of electricity is either unavailable or unsafe#such as applications in which flammable materials are present.#biggest problem with pneumatic timers and inert gases is that gases escape into the atmosphere. There is always a consistent leak of these#so you will have to replace these gases. Using compressed air is a much more economical endeavor.#Pneumatic timers are used when you need to delay the air signal coming in or going out of your air component. Depending on the model chosen#the air time delay may be adjusted from 0.5 to 60 seconds.#Time delay valve is a combination of a pneumatically actuated 3/2 direction control valve#an air reservoir and a throttle relief valve. The time delay function is obtained by controlling the air flow rate to or from the reservoir#Control and speed in pneumatic systems are more difficult because of the compressed air than compared with electrical or hydraulic systems.#a device requires a specific speed#you might have to add more equipment to the pneumatic system to make it work at the desired levels.#This is accomplished via a reservoir of oil#driven by air pressure on the top of the oil through a needle valve to control the speed. With a Proportion-Air F-Series mass flow controll#the traditional reservoir of oil is not necessary.

0 notes

Text

A pneumatic cylinder is a mechanical device that converts compressed air energy into a reciprocating linear motion

A double-acting pneumatic cylinder uses compressed air to move a piston in and out, while a single-acting pneumatic cylinder uses compressed air for one-way movement and a return spring for the other

A pneumatic cylinder is a mechanical device that converts compressed air energy into a reciprocating linear motion. A double-acting cylinder uses compressed air to move a piston in and out, while a single-acting cylinder uses compressed air for one-way movement and a return spring for the other

Pneumatic systems work by converting force into potential energy, which then drives an actuator or cylinder with kinetic energy. This is usually in a linear motion by means of a piston rod, or using other forms of actuation commonly called 'rodless

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#DrugFreeIndia#pneumaticcylinder#A pneumatic cylinder is a mechanical device that converts compressed air energy into a reciprocating linear motion#A double-acting pneumatic cylinder uses compressed air to move a piston in and out#while a single-acting pneumatic cylinder uses compressed air for one-way movement and a return spring for the other#A pneumatic cylinder is a mechanical device that converts compressed air energy into a reciprocating linear motion. A double-acting cylinde#while a single-acting cylinder uses compressed air for one-way movement and a return spring for the other#Pneumatic systems work by converting force into potential energy#which then drives an actuator or cylinder with kinetic energy. This is usually in a linear motion by means of a piston rod#or using other forms of actuation commonly called 'rodless

0 notes

Text

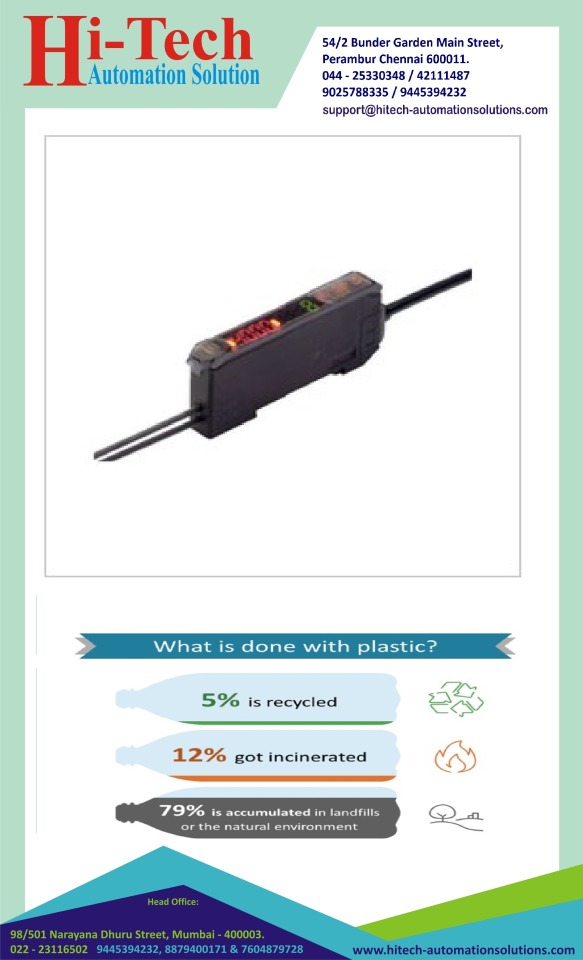

Sensors used in the manufacturing industry monitor the performance of various processes and aspects of machine operation, collecting data to determine normal baseline levels of operation while also detecting even the most minuscule fluctuations in that performance.

Sensor/Detectors/Transducers are electronic or electrical devices. These special electronic sensitive materials sense, measure, and detect changes in the position, temperature, displacement, electrical current, and multiple parameters of industrial equipment.

different types include hygrometers and moisture meters (for measuring moisture), gyroscopes (for measuring rotation), current or voltage sensors, pressure sensors, position sensors, level sensors and flow sensors (for fluid management).

role of a sensor in a control and automation system is to detect and measure some physical effect, providing this information to the control system

main performance criteria for industrial sensors are sensitivity, resolution, compactness, long-term stability, thermal drift and power efficiency

#ublic#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#DrugFreeIndia#Industrial Sensors#Sensors used in the manufacturing industry monitor the performance of various processes and aspects of machine operation#collecting data to determine normal baseline levels of operation while also detecting even the most minuscule fluctuations in that performa#Sensor/Detectors/Transducers are electronic or electrical devices. These special electronic sensitive materials sense#measure#and detect changes in the position#temperature#displacement#electrical current#and multiple parameters of industrial equipment.#different types include hygrometers and moisture meters (for measuring moisture)#gyroscopes (for measuring rotation)#current or voltage sensors#pressure sensors#position sensors#level sensors and flow sensors (for fluid management).#role of a sensor in a control and automation system is to detect and measure some physical effect#providing this information to the control system#main performance criteria for industrial sensors are sensitivity#resolution#compactness#long-term stability

0 notes

Text

Cutouts act like a fuse and open when there is a problem with the line or a section of it. A crossarm holds the wires up on the pole. The neutral wire is below the transformer and acts as a line back to the substation and balances out the amount of electricity or load on the system

When it comes to cutouts almost all distribution systems in the United State use one of three types of cutouts; Interchangeable, Loadbreak, or Linkbreak. Interchangeable cutouts are by far the most common style of cutout

The cut out (also called the service head) is a piece of electrical equipment that links the mains/service electricity cable and the internal wires in your property. It makes sure that electricity passes safely and efficiently into your property. It also houses the main fuse.

The word off refers to electricity, and the word out is associated with light. So you might say Suddenly the lights went out." But since the lights and the electricity are closely related, you could use any combination

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#DrugFreeIndia#UnderGroundsinglepolecutouts#Cutouts act like a fuse and open when there is a problem with the line or a section of it. A crossarm holds the wires up on the pole. The n#When it comes to cutouts almost all distribution systems in the United State use one of three types of cutouts; Interchangeable#Loadbreak#or Linkbreak. Interchangeable cutouts are by far the most common style of cutout#The cut out (also called the service head) is a piece of electrical equipment that links the mains/service electricity cable and the intern#The word off refers to electricity#and the word out is associated with light. So you might say Suddenly the lights went out." But since the lights and the electricity are clo#you could use any combination

0 notes

Text

3 m ·

Shared with Public

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#Hi-TechAutomation #DrugFreeIndia

Delta drives are microprocessor-based motor drives, widely used to control speed of industrial AC motors.

An AC drive is a device used to control the speed of an electrical motor in order to: enhance process control. reduce energy usage and generate energy efficiently. decrease mechanical stress on motor control applications. optimize the operation of various applications relying on electric motors

Delta connected motor will draw more line current, so the torque it produces will also be higher compared to the Star connection of the same motor. So the answer to this question is Delta connection.

A variable frequency drive (VFD) refers to AC drives only and a variable speed drive (VSD) refers to either AC Drives or DC Drives. VFDs vary the speed of an AC motor by varying the frequency to the motor. VSDs referring to DC motors vary the speed by varying the voltage to the motor.

AC motor. The AC electric motor used in a VFD system is usually a three-phase induction motor. Some types of single-phase motors or synchronous motors can be advantageous in some situations, but generally three-phase induction motors are preferred as the most economical.

Like

Comment

Share

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#Hi-TechAutomation#DrugFreeIndia#Delta drives are microprocessor-based motor drives#widely used to control speed of industrial AC motors.#An AC drive is a device used to control the speed of an electrical motor in order to: enhance process control. reduce energy usage and gene#Delta connected motor will draw more line current#so the torque it produces will also be higher compared to the Star connection of the same motor. So the answer to this question is Delta co#A variable frequency drive (VFD) refers to AC drives only and a variable speed drive (VSD) refers to either AC Drives or DC Drives. VFDs va#AC motor. The AC electric motor used in a VFD system is usually a three-phase induction motor. Some types of single-phase motors or synchro#but generally three-phase induction motors are preferred as the most economical.

0 notes

Text

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other.

Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races.

What is a ball bearing used for? A ball bearing is a type of rolling-element bearing that serves three main functions while it facilitates motion: it carries loads, reduces friction and positions moving machine parts. Ball bearings use balls to separate two “races,” or bearing rings, to reduce surface contact and friction across moving planes

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelives#Hi-Tech Automation#DrugFreeIndia#ballbearings#A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.#The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two r#one race is stationary and the other is attached to the rotating assembly (e.g.#a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much#Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area#they can tolerate some misalignment of the inner and outer races.#What is a ball bearing used for?#A ball bearing is a type of rolling-element bearing that serves three main functions while it facilitates motion: it carries loads#reduces friction and positions moving machine parts. Ball bearings use balls to separate two “races#” or bearing rings#to reduce surface contact and friction across moving planes

0 notes

Text

#ballbearings A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other.

Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races.

What is a ball bearing used for? A ball bearing is a type of rolling-element bearing that serves three main functions while it facilitates motion: it carries loads, reduces friction and positions moving machine parts. Ball bearings use balls to separate two “races,” or bearing rings, to reduce surface contact and friction across moving planes

0 notes

Text

V-belt used for? V-belts are belts with a trapezoidal cross-section. Like other types of belts, they are used to transmit power or torque from the driving component to the driven component. V-belts get their name from their trapezoidal shape, which helps them wedge into the sheaves. Twisted synthetic fibrous tensile chords, compressed by synthetic rubber form a typical V-belt, rendering it strength and flexibility. A v-belt is a flexible machine element used that transmits power between a set of grooved pulleys or sheaves. They are characterized by their trapezium cross-section. V-belts are used because of their ability to wedge tightly into the grooves of the pulley.

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelives#Hi-Tech Automation#DrugFreeIndia#vbelts#V-belt used for?#V-belts are belts with a trapezoidal cross-section. Like other types of belts#they are used to transmit power or torque from the driving component to the driven component.#V-belts get their name from their trapezoidal shape#which helps them wedge into the sheaves. Twisted synthetic fibrous tensile chords#compressed by synthetic rubber form a typical V-belt#rendering it strength and flexibility.#A v-belt is a flexible machine element used that transmits power between a set of grooved pulleys or sheaves. They are characterized by the

0 notes

Text

Ball bearings are machinery components, which comprise an outer ring, inner ring, balls, retainers, shields and snap rings. Miniature and small-sized ball bearing mean ball bearing, up to 30mm in external diameter. Miniature bearings are used for extremely high speeds. These bearings offer low noise, vibration, and frictional torque performance. They are used in medical, instrumentation, and semiconductor equipment, specialized aviation market, dentistry, avionics, instrumentation, robotics, computers...the list goes on. Bearing types include radial retainer, pivot, thrust, high speed radial, angular contact and full ball complement Generally speaking, it's one with an outside diameter less than ½”, and a bore size as small as . 0250

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelives#Hi-Tech Automation#DrugFreeIndia#miniatureballbearing

0 notes

Text

use of eye hook? A hook-and-eye closure is a simple and secure method of fastening garments together. It consists of a metal hook, commonly wire bent to shape, and an eye (or "eyelet") of the same material into which the hook fits. function of Eyebolt? An eye bolt is a bolt with a loop at one end. They are used to firmly attach a securing eye to a structure, so that ropes or cables may then be tied to it. eye anchor? Eye Anchor is designed to anchor fences, trees, tents, canopies, car ports, awnings, gazebos and portable sheds. The anchor offers up to 800 lb. of pull strength. Use in anchoring applications. Can be used with wire rope cable.

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelives#Hi-Hi-Tech Automation#DrugFreeIndia#largeeyehook

0 notes

Text

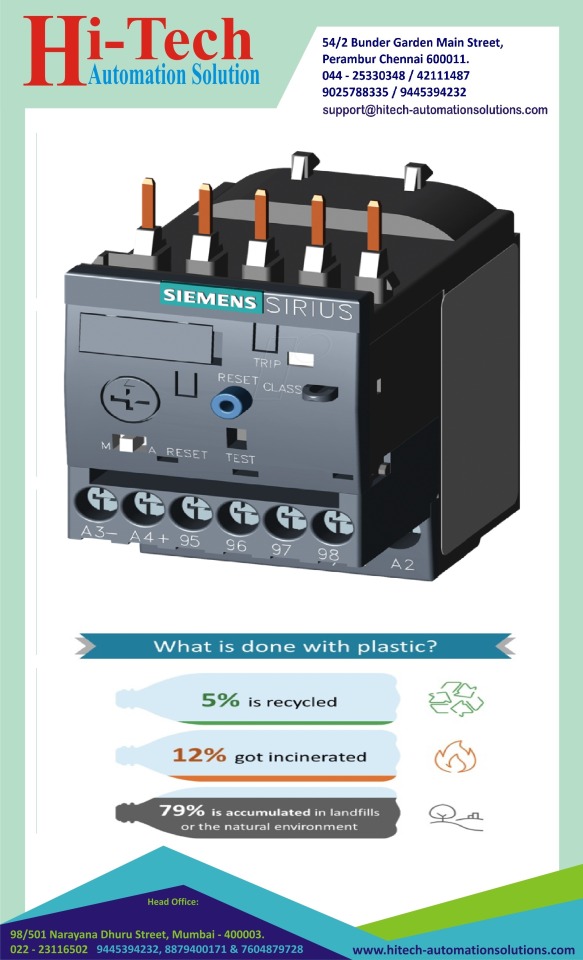

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelives#Hi-Hi-Tech Automation#DrugFreeIndia#doubleoverload

The overload relay is wired in series with the motor, so the current that flows to the motor when the motor is operating also flows through the overload relay. It will trip at a certain level when there is excess current flowing through it. This causes the circuit between the motor and the power source to open.

What is the purpose of overload relay?

Overload relays cut off current to the motor when a high-current situation develops due to a ground fault, short circuit, phase failure, or mechanical jamming. They are an inexpensive way of avoiding downtime for repair or replacement of failed motors from excessive current

How is an overload relay reset?

When set in the H or HAND position the RESET button must be pressed manually to reset the overload relay after a tripping event. On the other hand, when set in A or AUTO position, the overload relay will reset automatically after a tripping event

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelives#Hi-Hi-Tech Automation#DrugFreeIndia#doubleoverload#The overload relay is wired in series with the motor#so the current that flows to the motor when the motor is operating also flows through the overload relay. It will trip at a certain level w#What is the purpose of overload relay?#Overload relays cut off current to the motor when a high-current situation develops due to a ground fault#short circuit#phase failure#or mechanical jamming. They are an inexpensive way of avoiding downtime for repair or replacement of failed motors from excessive current#How is an overload relay reset?#When set in the H or HAND position the RESET button must be pressed manually to reset the overload relay after a tripping event. On the oth#when set in A or AUTO position#the overload relay will reset automatically after a tripping event

0 notes