#zero order waveplates

Explore tagged Tumblr posts

Text

0 notes

Text

0 notes

Text

The Application of Custom-Built Hot and Cold Mirrors

Optical mirrors are commonly used for a wide range of specialized applications in various industries. Experts in the astronomy, metrology, engineering, aerospace, and life sciences utilize these reflective mirrors for various purposes.

These quality mirrors—both hot and cold mirrors—are used for a number of applications including illumination, beam redirection, imaging, and interferometry. Optical mirrors offer industry experts the ability to boost the precision of their practices, improve the quality of their experiments, gain more reliable results, and enjoy better performance.

Hot Mirrors

These specialized dielectric mirrors are used to reflect light back to its source; they separate visible light from heat. Produced with high quality Borosilicate-type Glass, these durable mirrors are coated with a thin dielectric film that reflects infrared radiation (IR).

Unlike what its name suggests, hot mirrors don’t reflect heat itself. By reflecting IR and UV and transmitting visible light, hot mirrors offer efficient thermal energy blocking.

Hot mirrors are often utilized in applications where waste heat can cause considerable damage to components and have an adverse reaction on other characteristics on the illumination source.

With a thickness of about 3.3mm, hot mirrors reflect about 90 percent of the infrared radiation and transmit about 80 percent of visible light. Offering a high operating temperature—of up to 400°C in some cases—typical applications of hot mirrors include:

· Various applications in the automotive industry

· Filtering heat in projectors

· Laser injectors

· IR laser diodes

· Sensor and measurement technology

Cold Mirrors

The other type of specialty mirror used in industrial applications is cold mirrors. These dielectric mirror works to separate infrared radiation from the non-IR elements. What sets cold mirrors apart from hot mirrors is that they transmit infrared heat energy and reflect light energy.

Offering exceptionally high reflectivity for visible light, cold mirrors offer optical characteristics that are useful in several different applications. Industry specialists use cold mirrors for:

· Sensory technology

· For diode laser applications

· Lighting optics for medical experts

· Lighting systems

· Dichroic beamspiltters

The defining feature of cold mirrors is that they transmit infrared radiation and reflect visible energy in high concentration. Made using premium-quality Borosilicate type glass and a dielectric multilayer mirror coating, cold mirrors transmit over 85 percent of the IR.

While hot mirrors operate at a preferred AOI of 0º, cold mirrors operate at 45º.

Ifyou’relooking for high-quality precision optics, Tower Optical’s wide range of optical products will be perfect for you. As a full-service manufacturer of premium-quality products, the company has been committed to excellence since 1978.

They offer specialized services for stock and custom built precision optics including beamsplitters, laser mirrors, laser windows, optical flats, and zero order waveplates.

Tower Optical makes custom versions of every product in their catalog. Get in touch with them to receive a quotation.

#The Application of Custom-Built Hot and Cold Mirrors#beamsplitters#laser mirrors#laser windows#optical flats#zero order waveplates

0 notes

Text

MANTIS SHRIMP FUN FACTS

So, there’s a lot of Mantis Shrimp (aka Prawn Killer aka Thumbsplitter aka Sea Locust aka Stomatopod) facts running around, like “they punch with the force of a .22!!! They punch so hard they make a bang that’s hotter than the sun!! They can see colors we can’t!!

And while a lot of them are true in an abstract sense or kinda true, a lot of the times they’re not very helpful. Like “punch with the force of a .22?” what does that even MEAN? So i’m here today, after a wikipedia deep dive about physics of all fucking things and mantis shrimps in order to bring you MANTIS SHRIMP TRIVIA IN PLAIN ENGLISH

Let’s start with their eyes!

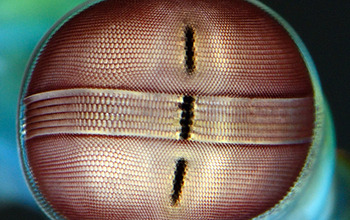

Look at those peepers!!!

Mantis Shrimps have some of the weirdest and possibly THE most complex eyes in the animal kingdom, giving them 360 trinocular vision. Just meaning they can swivel their eyes to look all around them (each one individually! they can see two directions!) and each eye has three parts that take in visual info on the world around them, with each band of their eyes processing different shit, giving them fun things like depth perception! Which, yeah i know isn’t a big deal to you all, but it is for a crustacean so hush.

Now they can’t actually see colors we can’t, in fact they’re actually not very good at distinguishing light wavelengths that are very close to each other. What they CAN do with their 12-16 color receptors though, is some super cool shit.

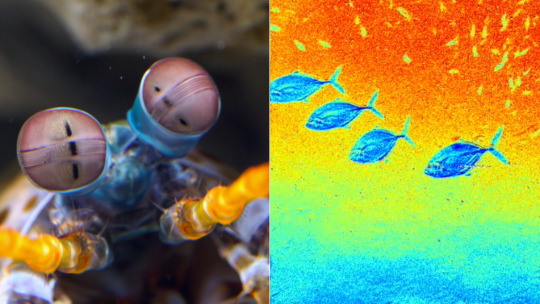

First, a lot of the information their eyes receive is processed directly in the eyes before it gets to the brain, letting them basically have to think less and see and react to their environment very quickly. Their range is also wider than ours, being able to perceive anything from the far end of ultraviolet up to red. We're pretty sure they can’t perceive infra-red, but scientists are still studying their big ol nerd eyes so who knows? They can also see polarized light

What the Hell is polarized light? I’ve been reading physics shit all day and if there’s an easily understandable way to put it, the entire internet apparently just elects not to. I could bang on about electromagnetic wavelengths and oscillation and shit, but i’m not gonna. Here, if you’re interested. I know lasers constitute polarized light, and i know that these guys have a structure in their eyes called a waveplate that is better at polarizing light than anything we have ever made artificially, and they’re studying it for improving blu-ray discs. Also, they can apparently use the way polarized light bounces off tissues to see neuron activity and cancer. Who knew.

Mantis Shrimps have Predator Vision i guess

Also some species can do spectral tuning, which is basically adjusting the color sensitivity of their eyes to best suit their environment. NEAT!

But let’s get to what you all really wanna read about:

THAT LEFT HOOK

Now, there are actually two types of Mantis Shrimp: Spearers and Smashers. They both have raptorial appendages that shoot out really fucking fast, the difference being....i mean take a fucking guess.

We’re focusing here on Smashers and the Peacock Mantis Shrimp, which is what you usually think of when you hear the word, but it is worth noting there are like 450 different species of the lil buggers that widely vary in size and appearance. So yeah.

Here’s a lil love for the Spearers tho

Now, to address those points i made up at the top. The Mantis Shrimp punches up to 50 miles per hour with a force of 1500 newtons. 1500 newtons being around 340 pounds of force. So, you know. Put a piece of gravel on top of a crab, then have the nearest NFL linebacker jump onto that piece of gravel, and that’s about how hard this lil guy’s decking his prey. And anyone else who tests him.

The .22 caliber bullet thing comes from the ACCELERATION of the shrimpy’s lil clubs, which is the rate they go from zero to that 50 miles per hour. Now they go from 0 to 50 in a teeny tiny fraction of a second, accelerating their lil fists at about 335,000 feet per second which is, you guessed it, about the same as the acceleration of a bullet leaving the chamber of a .22.

Needless to say, 340 pounds of force in a tiny little appendage hitting you that fast is bad for your health, and it can punch off crab legs, split shells, give you a really nasty gash if you’re the kind of dumbass that likes to pick up wild animals, shatter aquarium glass, and oh yeah break reality a little tiny bit.

Yeah, so the surface of the sun thing.

Unfortunately, it’s time for another physics lesson, but i did all the dry-ass reading and over-simplified it so you don’t have to! Okay, crash course in cavitation.

So, you know how every element has a liquid, gas, and solid state? Well which one it is doesn’t just depend on temperature, it also depends on pressure. Which is why you’ll get planets with bizarre shit like oceans of liquid diamond in the mantle of Uranus. Extreme temperatures and extreme pressures both make elements go whacky.

Here’s a picture of a mantis shrimp looking grumpy to break up the monotony!

Anyway, cavitation is just exactly the same thing as boiling, except it’s not happening because the water’s getting hot, it’s happening because the pressure’s suddenly been lowered.

But just like boiling, it makes little vapor-filled bubbles. Now the Mantis Shrimp hits prey so hard and so fucking fast, that when it pulls its raptorial appendage back, it takes the water a second to get up to speed on what the living fuck just happened, which creates a cavitation bubble in the water between the club and whatever poor bastard it just hit. Then that instantly collapses with a little bang, a flash, and a fucking shockwave that basically kicks its prey when it’s down.

“Ahhh jesus christ i’m so fucked” -This snail, probably

And yes, because extremely low pressure, as we’ve established, makes shit go all whacky, the vapor inside can be up to several thousand Kelvin, which is around as hot or hotter than the surface of the sun.

But again, this burst of energy, while huge, is confined to a little teeny tiny bubble that collapses in less than a millisecond, like this shit can’t be seen with the naked eye, and the energy very rapidly disperses to the water around it.

But for that fraction of a second....in that little tiny space in the shallows of the Pacific....every time a Mantis Shrimp murks its prey...it literally just hit a guy so fucking hard that it went all Superboy Prime and broke reality.

And yes, in case you’re wondering, they would make terrible fucking pets because while they may be pretty and very cool, they are INCREDIBLY territorial, are not smart enough to recognize their reflections, and more than one dipshit’s fish tank has been broken because a Mantis Shrimp tried to throw hands with its own reflection

Like Narcissus but really fucking aggro.

22 notes

·

View notes

Text

How BBO Pockels Cells Work

A Pockels cell must be constructed from the right material to produce high-energy laser beams. Transverse and longitudinal cells require transparent electrodes. Transverse Pockels cells require rings electrodes. The voltage requirement can be reduced by lengthening the crystal. Also, the transverse polarization won't work if the crystal is not aligned with the ray direction.

The transverse Pockels cell is made up of two crystals that are oriented in opposite directions. When the voltage is shut off, it produces an unordered wave plate. A Pockels cell may be very capacitive, which means that an electric charge must be applied to the cell, and then removed. This can be problematic in the event that the voltage changes are rapid, since inductance can affect the voltage and may cause resonance phenomena.

A BBO Pockels cell has a wider modulation bandwidth than the conventional CMOS. The BBO is a fantastic material for EO and is especially suitable for high-power systems. It can be used in a high repetition rate and also, its nonlinear optical properties allow it to be used in a wide range of applications. If you're interested in learning more about these devices, here are a few of the specifics laser crylink.

The transverse Pockels cell is made of two identical crystals in opposite orientations. When the voltage is eliminated the cell produces the waveplate of zero order. Due to the dielectric nature of the material, the mechanical alignment isn't a crucial aspect. The axis of the crystal is aligned manually and often without screws. If the crystal is not properly aligned, it could cause misalignment or loss of energy along its length.

Two crystals with opposite orientations form the transverse Pockels cell. When the voltage is shut off the transverse Pockels cell generates an unorderly waveplate. It is not necessary to align the crystal's axis properly mechanically. This is often done without screws. However, misalignment can cause energy to reflect in the wrong direction, which can affect the time delay. It can increase the pulse sensitivity.

The transverse Pockels cell consists of two crystals with opposite orientations. When the voltage is removed from the transverse Pockels cell produces an unordered wave plate. It is not necessary to align the crystal the axis mechanically, since this is typically done manually with screws. It is important to remember that misalignment can reduce the modulation bandwidth, which is a major drawback of the transverse Pockels cell.

The Polarization of Pockels Cells can be controlled with the help of an polarizing prism. If a polarizer's polarization is reversed, the opposite one will be able to absorb light. Polarizers are an essential component of quantum technology. Its efficiency is determined by the number of crystals within the system. The more complicated the IRX Pockels Cell, the more applications it can handle.

1 note

·

View note

Link

Nanjing Co-Energy Optical Co Ltd offers wave plate such as Dual Wavelengths Waveplate, zero-order waveplate, Low Order Waveplate and Achromatic Waveplate are available at affordable price.

0 notes

Text

A Comprehensive Guide to Waveplates at any Wavelength

When beams of light interact with the molecular build-up of a material, the interaction is dependent on wavelength. Each material has an optical property—birefringence—which refers to its refractive index and the resulting polarization direction of a light source.

Waveplates also known as Retarder plates manipulate the state of polarization for the light beams passing through them. These capabilities help skilled professionals in various industries with numerous applications. With waveplates at varying wavelengths, this optical product is used in the aerospace, astronomy, biomedical, telecommunication, and a variety of Photonics related industries.

Whether you purchase standard waveplates from a standard stock or get them custom-built, you can offer waveplates at any wavelength between 237 nm to 2021 nm.

Greater precision

Depending on the nature of your application’s needs, selecting waveplates with the right wavelength is essential to meet your requirements. Choosing a waveplate that allows you to optimize your outputs and reduce the attenuation will help you achieve the desired results.

Since waveplates are used in industrial applications that require accuracy, the ability to select one at any wavelength is beneficial for you.

Diverse applications

There are various factors that determine the optimum use of waveplate applications. Variations in wavelengths between applications require the selection of the ideal waveplate (retarder).

Achromatic waveplates—both cemented and air-spaced—are perfect for situations where several spectral wavelengths are covered. Additionally, zero-order waveplates remain constant over wavelength variations and offer greater stability in various applications. Conversely, the retardation of multiple order Waveplates are affected by temperature and will change substantially over varying wavelengths.

Make the right choice

Selecting the best waveplates for your application is the first step to optimizing your processes. If standard waveplates don’t meet your specific needs, you can get custom built-to-order waveplates at any wavelength.

Industry experts who are experienced in the field of precision optics recommend, Tower Optical as the manufacturer of choice for most applications. With over 10,000 waveplates in stock, Tower provides waveplates with standard wavelengths ranging from 237 nm to 2021 nm.

Aside from the standard retarders, Tower Optical offers custom optical solutions. Their range of zero-order, multiple order, achromatic and dual-wavelength waveplates can be manufactured with your design specifications in mind. High-quality, unparalleled performance, and cost-effective—Tower Optical’s wide range of wavelengths suit a variety of industry applications.

Tower Optical also manufactures custom and in-stock prisms, micro prisms, beam expanders, optical flats, laser mirrors and laser windows.

Want to get started? Send in your specifications to Tower Optical’s experts at www.Tower Optical.com or 561 740-2525 and they’ll provide a quotation!

0 notes

Text

A Guide to Optical Assembly

Optical assemblies refer to several components that are designed to assist in creating an optical system. These multi-element assemblies contain an assortment of kits designed to meet common laser or optical specifications, such as alignment, mounting, focusing or beam manipulation.

Optical assemblies are essentially the less expensive alternative to utilizing several components when designing optical systems.

A multi-element assembly for optical aperture expansion, for instance, combines diffractive technology with facet reflective technology. This includes using at least two diffractive components with opposite optical power. In this case, the first diffractive component introduces chromatic dispersion while the second component cancels it out. In combination with a reflective optical component, the two diffractive components reduce noise and distortion and help manufacturers achieve aperture expansion for efficiently. This optical assembly enables a wider field of view while eliminating polarization management.

Optical Assembly Applications

Let’s look at some applications that typically use optical assemblies:

· Scopes for special forces and defence usage

· High-powered laser optics

· Industries that use optical filters

op-Notch Optical Assembly Services

Tower Optical offers optical assembly as well as optical grade bonding of filter stacks, windows, and other optical flats to better integrate optics into larger systems, thereby saving time.

Our Design For Manufacturing/Assembly (DFM/DFA) techniques ensure key design simplifications that add to the overall manufacturability of the system. Our experienced Assembly Team coordinates with you to offer design advice, ensuring certain parts are delivered promptly for your project’s next phase.

Environmental Control

Our facility’s environmental controls ensure contamination-free, stress-free and reliable optical assemblies. We also offer roughness and surface testing, in addition to durometer measurement.

Benefits Of Multi-Element Assembly At Tower Optical

· Optical-grade bonding of flat optics and filter stacks

· Thermo-set and stress-free bonding of windows for extreme environments

· Premium-quality adhesives for large-volume manufacturing

· Design for Manufacturing (DFM) / Design for Assembly (DFA) for robust assembly processes and affordable costs

· Proper quality control of all aspects of the process

Trained and experienced staff

If you’re looking for a highly-experienced optical design, integration and assembly team, partner with Tower Optical for your mission-critical applications. From concept to the final product, their optic professionals ensure precision and quality throughout.

Their custom-building capabilities, cutting-edge technology, and unparalleled quality have positioned Tower Optical as leaders in the marketplace. They provide a variety of products including optical filters, beam splitters, flat optics, beam expanders, micro prisms, zero-order waveplates, optical windows, laser mirrors, and more!

Send them a drawing of your optical solution and they’ll reach out with a quotation.

0 notes

Text

An Introduction to Large-Format Waveplates

Optical waveplates are, essentially, birefringent crystals that modify the polarization state of a beam of light. They’re most commonly used by experts in the fields of aerospace, fiber optic communication, astronomy, biomedical engineering, and the semiconductor industry.

Waveplates—also known as optical retarders—are optical devices that offer various types and optical properties. Owing to the nature of your needs, you can opt for a waveplate at any wavelength.

What are large-format waveplates?

Produced with high-quality, durable, and laser quality crystal quartz, large-format waveplates come in handy for demanding applications. Ranging from 3mm to 4mm in thickness, these waveplates offer greater functionality for experts’ varied needs.

With a high laser damage threshold, large crystal quartz retarders offer retardation stability even under conditions of temperature change.

Large-format waveplates are ideal for use for applications where the beam’s position or size moves over large distances. The large, high-quality clear aperture allows greater amounts of light beams to be transmitted and, thus, allowing for more challenging capabilities.

The clear apertures, of about 34mm or 46mm, enable uniform retardance. Accuracy is a key requirement for many of the challenging industry applications that large-format waveplates are used for. Thus, these durable retarders are greatly advantageous for a wide range of customers.

With retardation of 1/2 and 1/4 Wave, the large-format optical waveplates offer a transformation in light polarization. With precision, dependence, and homogeneity, this product provides optimum performance.

Custom-made large-format waveplates

Depending on the nature of your application needs, custom waveplates can offer greater functionality and standardized results each time. For this purpose, custom designing your waveplates can be more beneficial.

Tower Optical, one of Florida’s leading precision optics manufacturer, has been providing custom solutions to their varied clients for over 40 years. The company’s dedication to cost-effective, viable optical solutions has earned them a stellar reputation—not just in Florida, but all over the world!

Tower Optical produces over 10,000 waveplates. From partial waveplates, holey waveplates, and cemented waveplates to air-spaced, zero order, and multiple order waveplates, they’ve got it all.

Their large-format waveplates are produced with laser quality crystal quartz and can be either mounted or unmounted. The standard wavelengths for 38.1mm and 50.8mm waveplates are 355, 532, 632.8, 800, and 1064. However, you can have a custom version of each waveplate manufactured for you as well.

The company has a variety of in-stock and built to order laser windows, beam expanders, optical filters, and other precision optics.

Send in your specifications and drawings to Tower Optical’s experts and they’ll provide you an accurate quotation to get started.

0 notes