Don't wanna be here? Send us removal request.

Text

Boost Durability with Advanced Laser Hardening Machine

Enhance component life and performance with our Laser Hardening Machine, ideal for precision surface hardening. It delivers minimal distortion, deeper case depths, and consistent results—perfect for automotive, aerospace, tool & die, and heavy machinery industries.

URL: https://abinduction.in/laser-hardening-machine/

Upgrade your manufacturing process with advanced laser technology for superior wear resistance and durability.

#LaserHardeningMachine#SurfaceHardening#MetalHardening#HeatTreatment#IndustrialMachinery#PrecisionEngineering#AutomotiveParts#ToolAndDie

0 notes

Text

Laser Welding Machine for High-Precision Metal Work

Enhance your manufacturing with a Laser Welding Machine – the perfect tool for precise, clean, and contactless metal welding. Ideal for automotive, aerospace, electronics, and jewelry industries, it ensures minimal heat distortion and excellent weld strength.

Accurate

Fast

Suitable for stainless steel, titanium & more

URL: https://abinduction.in/laser-welding-machine/

Upgrade to laser precision today!

#LaserWeldingMachine#MetalWelding#IndustrialMachinery#PrecisionWelding#WeldingTechnology#SmartManufacturing#LaserEquipment#MetalFabrication

0 notes

Text

#InductionHeating#InductionHeatingMachine#InductionHeatingEquipment#MetalHeating#ElectromagneticHeating

0 notes

Text

#ElectroplatingRectifier#ElectroplatingFaridabad#FaridabadIndustry#ElectroplatingEquipment#FaridabadManufacturers

0 notes

Text

https://abinduction.in/electroplating-rectifier/

0 notes

Text

#InductionHardeningMachine#InductionHardening#HardeningMachine#InductionHeater#HeatTreatmentMachine#ElectromagneticField#SurfaceHardening

0 notes

Text

#InductionHeatingMachine#InductionHeater#InductionHeatingEquipment#ElectromagneticField#PipeWelding#AutomotiveManufacturing

0 notes

Text

heaterhttps://abinduction.in/drum-heating-machine/

0 notes

Text

Energy-Efficient Induction Hardening Machines for Cost Savings

Reduce energy consumption and operational costs with our energy-efficient induction hardening systems. Featuring precise temperature control and quick processing times, these machines optimize heat treatment while maintaining high production efficiency.

For more information, visit: https://abinduction.in/how-induction-hardening-machines-improve-product-durability-and-performance/

0 notes

Text

Enhancing Durability of Agricultural Equipment with Induction Hardening

Induction hardening machines play a crucial role in strengthening critical components of agricultural machinery, such as plowshares, tiller blades, and tractor shafts. By improving wear resistance and toughness, these machines help extend equipment lifespan, reducing maintenance costs and downtime in the field.

For more information, visit: https://abinduction.in/how-induction-hardening-machines-benefit-the-agriculture-and-heavy-equipment-industry/

0 notes

Text

Portable Induction Heaters – Compact & High-Performance

Lightweight yet powerful, our portable induction heaters provide flexibility and efficiency for on-site or small-scale heating tasks.

For more information, visit: https://abinduction.in/role-of-induction-heating-machines-in-the-automotive-industry/

0 notes

Text

An induction heating machine uses electromagnetic induction to efficiently heat metals.

0 notes

Text

An induction hardening machine uses high-frequency induction heating to heat metal surfaces quickly, followed by rapid cooling (quenching). This process improves the hardness, strength, and wear resistance of the material, making it ideal for industrial applications.

0 notes

Text

An electroplating rectifier converts alternating current (AC) into direct current (DC) for use in electroplating. It provides the necessary current and voltage to ensure even, controlled metal deposition, ensuring high-quality coatings in various industries.

0 notes

Text

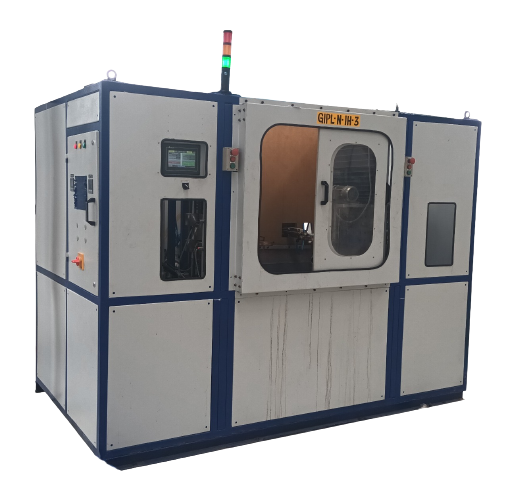

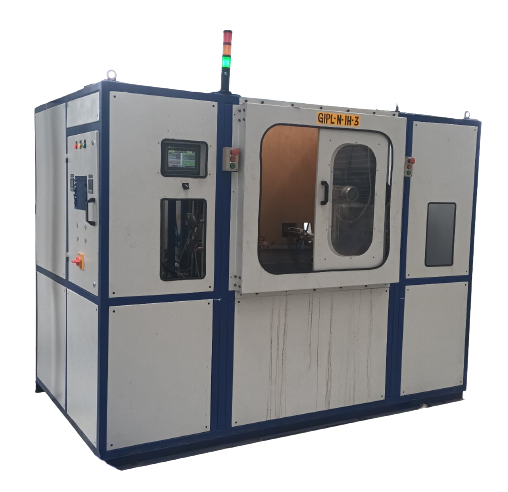

Automated Induction Hardening Systems by AB Induction

AB Induction offers cutting-edge automated induction hardening systems, designed to meet the demands of modern manufacturing industries. These systems combine advanced induction heating technology with automation, ensuring precision, efficiency, and scalability for hardening metal components.

Key Features of AB Induction's Automated Systems:

Fully Automated Operations:

Seamless integration with robotic systems and CNC controls for minimal human intervention.

High-speed processing with consistent quality, reducing downtime and operational costs.

Customizable Configurations:

Tailored to specific part geometries, material properties, and production volumes.

Compatible with diverse workpiece shapes, including gears, shafts, bearings, and tools.

Precision Heating Technology:

Accurate control of temperature, depth, and cycle time for uniform hardening.

Suitable for localized hardening and selective heat treatment.

Energy Efficiency:

Optimized energy consumption through advanced induction coils and control systems.

Eco-friendly solutions that reduce the carbon footprint of manufacturing operations.

User-Friendly Interface:

Intuitive software for monitoring, programming, and controlling the hardening process.

Real-time data tracking and diagnostics for improved process management.

Durable and Reliable Design:

Built for heavy-duty industrial use with a long operational lifespan.

Minimal maintenance requirements and robust performance in high-production environments.

Applications:

Ideal for industries such as automotive, aerospace, heavy machinery, and tool manufacturing.

Used for hardening gears, crankshafts, camshafts, axles, and other critical components requiring wear resistance and durability.

Why Choose AB Induction's Automated Systems?

AB Induction’s automated hardening systems are engineered to streamline production processes while maintaining the highest standards of quality. They offer unmatched flexibility and reliability, helping manufacturers stay competitive in today's fast-paced industrial landscape.

For more details or to explore custom solutions, contact AB Induction’s team of experts.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Plot No. 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/induction-heating-machine-manufacturer/

#inductionheatingmachineinfaridabad #ElectroplatingRectifierinfaridabad #InductionHardeningMachineinfaridabad #InductionHardeningMachinemanufacturer #ElectroplatingRectifiermanufacturerinfaridabad #inductionheatingmachinemanufacturer #horizontalInductionHardeningMachinemanufacturer #highfrequencyinductionheatingmachine #AircooledIGBTbasedElectroplatingRectifiermanufacturer #PLCcontrolledInductionHardeningMachine

0 notes

Text

Supplier of Industrial Induction Heating Systems: AB Induction

AB Induction is a global leader in the design, manufacturing, and supply of advanced industrial induction heating systems. With decades of expertise and a commitment to innovation, AB Induction provides cutting-edge solutions tailored to meet the needs of diverse industries, including automotive, aerospace, metallurgy, and energy.

Key Offerings:

Induction Hardening Machines: Designed for precision surface hardening of gears, shafts, and other components, ensuring durability and wear resistance.

Induction Brazing Systems: Provides efficient and clean bonding of metal parts for applications in HVAC, electrical, and automotive sectors.

Induction Melting Furnaces: High-performance systems for melting ferrous and non-ferrous metals, ideal for foundries and casting applications.

Custom Induction Heating Solutions: Tailored systems for specialized industrial processes, including annealing, forging, and shrink fitting.

Energy-Efficient IGBT Technology: Leveraging advanced solid-state inverters for precise temperature control and reduced energy consumption.

Why Choose AB Induction?

Advanced Technology: Cutting-edge solutions integrating automation, PLC controls, and real-time monitoring for superior performance.

Customization: Systems designed to meet specific requirements, ensuring maximum efficiency and reliability.

Global Presence: A trusted partner serving industries worldwide with local support and service.

Sustainability: Focus on energy efficiency and environmentally friendly heating solutions.

Comprehensive Support: End-to-end services including design, installation, training, and maintenance.

Applications Across Industries:

Automotive: Induction hardening of crankshafts, camshafts, and gears for enhanced durability.

Aerospace: Heat treatment and brazing of critical turbine and structural components.

Foundries: Efficient melting and forging systems for rapid production cycles.

Electronics: Soldering and brazing of electrical connectors and components.

AB Induction’s commitment to quality, innovation, and customer satisfaction has established it as a preferred supplier of industrial induction heating systems worldwide. Whether you need a standard solution or a customized system, AB Induction delivers reliable performance and unmatched precision for all your heating requirements.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Plot No. 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/induction-heating-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

1 note

·

View note

Text

Exploring the Advanced Features of Abinduction Induction Hardening Machines

In today's competitive manufacturing landscape, precision and efficiency are paramount. Induction hardening has become a key technology for industries requiring durable and wear-resistant components. This blog delves into the cutting-edge features of Abinduction Induction Hardening Machines, highlighting their unique capabilities and advantages over traditional methods.

We’ll explore:

Innovative Design: How Abinduction machines are engineered for versatility and adaptability to different component shapes and sizes.

Smart Technology Integration: Intelligent control systems for real-time monitoring, ensuring accuracy and consistency in hardening processes.

Energy Efficiency: Eco-friendly features designed to reduce energy consumption without compromising performance.

Customizability: Tailored solutions to meet specific industrial needs, from automotive to aerospace and beyond.

Ease of Use and Maintenance: User-friendly interfaces and low-maintenance designs that boost productivity and reduce downtime.

Whether you're a manufacturer looking to upgrade your processes or an industry professional interested in the latest advancements in induction technology, this blog will provide valuable insights into how Abinduction Induction Hardening Machines can revolutionize your operations.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/vertical-induction-hardening-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

1 note

·

View note