#PLCcontrolledInductionHardeningMachine

Explore tagged Tumblr posts

Text

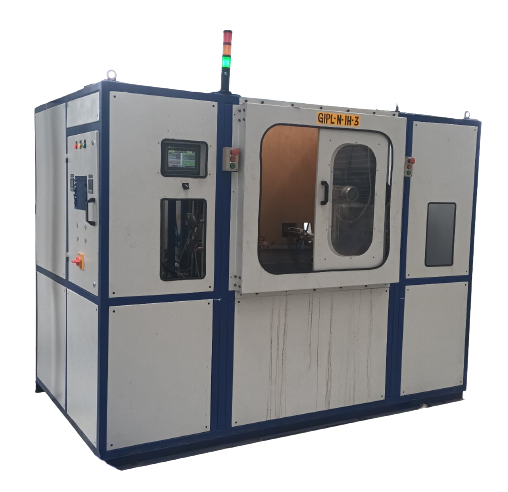

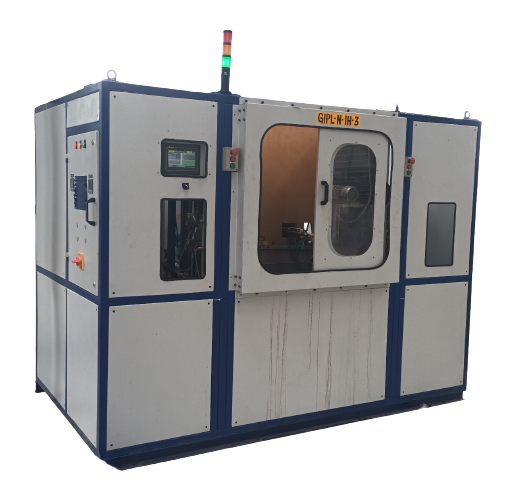

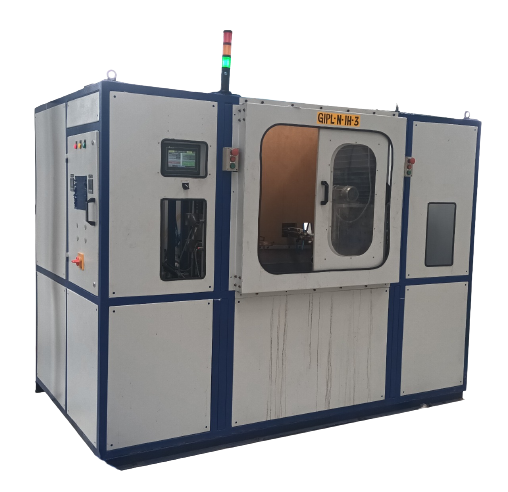

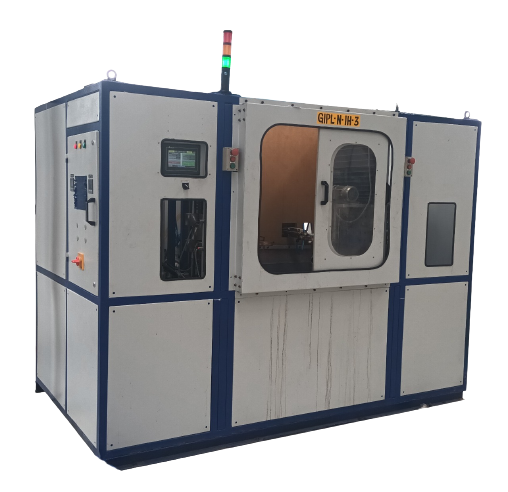

Supplier of Industrial Induction Heating Systems: AB Induction

AB Induction is a global leader in the design, manufacturing, and supply of advanced industrial induction heating systems. With decades of expertise and a commitment to innovation, AB Induction provides cutting-edge solutions tailored to meet the needs of diverse industries, including automotive, aerospace, metallurgy, and energy.

Key Offerings:

Induction Hardening Machines: Designed for precision surface hardening of gears, shafts, and other components, ensuring durability and wear resistance.

Induction Brazing Systems: Provides efficient and clean bonding of metal parts for applications in HVAC, electrical, and automotive sectors.

Induction Melting Furnaces: High-performance systems for melting ferrous and non-ferrous metals, ideal for foundries and casting applications.

Custom Induction Heating Solutions: Tailored systems for specialized industrial processes, including annealing, forging, and shrink fitting.

Energy-Efficient IGBT Technology: Leveraging advanced solid-state inverters for precise temperature control and reduced energy consumption.

Why Choose AB Induction?

Advanced Technology: Cutting-edge solutions integrating automation, PLC controls, and real-time monitoring for superior performance.

Customization: Systems designed to meet specific requirements, ensuring maximum efficiency and reliability.

Global Presence: A trusted partner serving industries worldwide with local support and service.

Sustainability: Focus on energy efficiency and environmentally friendly heating solutions.

Comprehensive Support: End-to-end services including design, installation, training, and maintenance.

Applications Across Industries:

Automotive: Induction hardening of crankshafts, camshafts, and gears for enhanced durability.

Aerospace: Heat treatment and brazing of critical turbine and structural components.

Foundries: Efficient melting and forging systems for rapid production cycles.

Electronics: Soldering and brazing of electrical connectors and components.

AB Induction’s commitment to quality, innovation, and customer satisfaction has established it as a preferred supplier of industrial induction heating systems worldwide. Whether you need a standard solution or a customized system, AB Induction delivers reliable performance and unmatched precision for all your heating requirements.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Plot No. 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/induction-heating-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

1 note

·

View note

Text

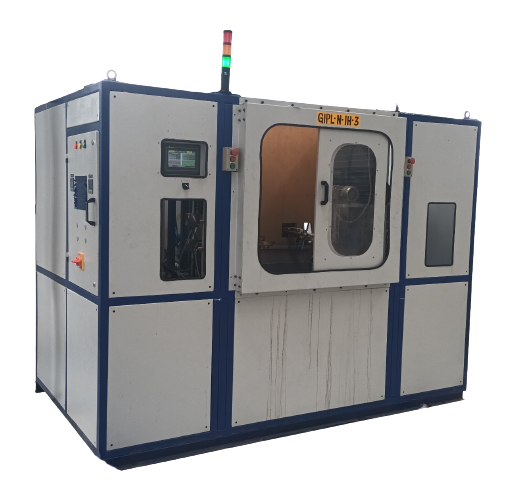

Exploring the Advanced Features of Abinduction Induction Hardening Machines

In today's competitive manufacturing landscape, precision and efficiency are paramount. Induction hardening has become a key technology for industries requiring durable and wear-resistant components. This blog delves into the cutting-edge features of Abinduction Induction Hardening Machines, highlighting their unique capabilities and advantages over traditional methods.

We’ll explore:

Innovative Design: How Abinduction machines are engineered for versatility and adaptability to different component shapes and sizes.

Smart Technology Integration: Intelligent control systems for real-time monitoring, ensuring accuracy and consistency in hardening processes.

Energy Efficiency: Eco-friendly features designed to reduce energy consumption without compromising performance.

Customizability: Tailored solutions to meet specific industrial needs, from automotive to aerospace and beyond.

Ease of Use and Maintenance: User-friendly interfaces and low-maintenance designs that boost productivity and reduce downtime.

Whether you're a manufacturer looking to upgrade your processes or an industry professional interested in the latest advancements in induction technology, this blog will provide valuable insights into how Abinduction Induction Hardening Machines can revolutionize your operations.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/vertical-induction-hardening-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

1 note

·

View note

Text

ABInduction: Revolutionizing Industrial Heating Solutions with Advanced Technology

ABInduction has established itself as a trailblazer in the field of induction heating solutions, offering cutting-edge technology designed to meet the demands of modern industries. With a strong focus on precision, efficiency, and sustainability, ABInduction provides tailored solutions to a wide range of applications, including automotive, aerospace, construction, and manufacturing.

Innovative Induction Heating Solutions

At the core of ABInduction's success is its advanced induction heating technology, which utilizes electromagnetic fields to heat metals precisely and efficiently. Their machines are known for:

Energy Efficiency: Reduced power consumption without compromising performance.

Customization: Tailor-made solutions that adapt to client-specific requirements.

Environmental Friendliness: A clean and eco-friendly alternative to traditional heating methods.

Key Product Offerings

ABInduction's product line includes:

Induction Hardening Machines: Designed for surface hardening of automotive parts, heavy machinery components, and tools.

Vertical & Horizontal Scanners: High-precision machines for hardening applications with automated PLC controls.

Billet Heaters: Efficient solutions for pre-heating billets and bars in forging and extrusion processes.

Electroplating Rectifiers: Reliable power supply systems for electroplating industries.

Commitment to Quality and Innovation

ABInduction combines over two decades of experience with continuous R&D to develop state-of-the-art machines that meet global standards. Their equipment is built to deliver high performance, durability, and consistent results, empowering industries to achieve greater productivity.

Global Impact

Operating out of Faridabad, India, ABInduction serves clients worldwide, earning a reputation for excellence and reliability. Their commitment to customer satisfaction and technological innovation has made them a trusted partner for businesses across various industrial sectors.

With a vision for transforming the future of industrial heating, ABInduction continues to lead the way by providing advanced, sustainable, and efficient heating solutions that cater to the ever-evolving needs of the industry.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/induction-heating-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Choosing the Right Induction Hardening Machine Manufacturer: A Comprehensive Guide

When it comes to selecting an induction hardening machine manufacturer, making the right choice is crucial for the success of your business. In this comprehensive guide, we provide a step-by-step roadmap to help you navigate the process effectively.

Define Your Requirements:

Evaluate your specific induction hardening needs, such as the types of materials you work with and the desired hardening results.

Consider factors like production volume, space constraints, and budget limitations to determine your requirements accurately.

Research Potential Manufacturers:

Conduct thorough research on induction hardening machine manufacturers, considering factors such as reputation, experience, and customer reviews.

Look for manufacturers like ABInduction known for their quality products, innovation, and industry expertise.

Evaluate Technological Capabilities:

Assess the technological capabilities of potential manufacturers, focusing on features like heating capacity, precision, and automation.

Compare the specifications of different machines offered by manufacturers to ensure they meet your specific requirements.

Consider Support and Service:

Look into the after-sales support and service provided by manufacturers, including maintenance, training, and technical assistance.

Choose a manufacturer that offers reliable and responsive support to ensure smooth operation of your induction hardening machine.

Seek Recommendations and References:

Reach out to industry experts, colleagues, and other businesses for recommendations on reputable induction hardening machine manufacturers.

Request references from manufacturers to gain insights into their track record and customer satisfaction levels.

Make Your Decision:

Based on your research, evaluations, and recommendations, make an informed decision on the induction hardening machine manufacturer that best meets your needs.

Consider factors such as quality, reliability, customer service, and overall value when selecting a manufacturer for your business.

By following these step-by-step guidelines and recommendations, you can confidently choose the right induction hardening machine manufacturer to enhance your operations and drive success in your heat treatment processes.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/vertical-induction-hardening-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Maximizing Efficiency and Quality: Benefits of Choosing the Right Induction Hardening Machine Manufacturer

In the realm of industrial manufacturing, the choice of an induction hardening machine manufacturer plays a pivotal role in determining the efficiency and quality of production processes. Selecting the right manufacturer can bring a myriad of benefits that directly impact the bottom line of businesses.

One of the primary advantages of choosing the right induction hardening machine manufacturer is the assurance of high efficiency. Manufacturers who specialize in this equipment offer state-of-the-art technology that is designed to optimize performance and streamline processes. From precision engineering to advanced automation features, these machines are tailored to meet the specific requirements of different industries, allowing for seamless integration and increased productivity.

Quality is another key benefit that comes with selecting the right manufacturer. Reputable manufacturers adhere to stringent quality control standards, ensuring that their machines are built to last and deliver reliable performance. By investing in high-quality equipment, businesses can minimize the risk of breakdowns, maintenance issues, and costly repairs, thereby enhancing operational efficiency and saving valuable time and resources.

Moreover, a reliable manufacturer provides ongoing support and maintenance services that further contribute to maximizing efficiency and quality in production. With access to technical expertise, spare parts, and troubleshooting assistance, businesses can ensure that their induction hardening machines operate at peak performance levels, resulting in consistent and high-quality output.

In conclusion, the decision to choose the right induction hardening machine manufacturer is a critical one that can have a significant impact on a company's operations. By prioritizing efficiency, quality, and reliable support, businesses can unlock the full potential of their manufacturing processes and achieve sustainable growth and success in a competitive market landscape.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/vertical-induction-hardening-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

High-Frequency Induction Heating Machines: The Future of Industrial Heating Technology

In the realm of industrial heating technology, high-frequency induction heating machines are emerging as a transformative force, poised to shape the future of manufacturing and production processes. These cutting-edge machines utilize advanced principles of electromagnetic induction to generate intense and precise heat within metal components, offering a multitude of advantages over traditional heating methods.

In our blog, "High-Frequency Induction Heating Machines: The Future of Industrial Heating Technology," we delve into the vast potential and promising applications of this technology. From enhancing energy efficiency and minimizing heat loss to enabling rapid and localized heating, high-frequency induction heating machines are revolutionizing the way industries approach heat treatment.

Furthermore, these machines are paving the way for new possibilities in material processing, such as brazing, annealing, and hardening, offering unparalleled precision and control over the heating process. Their ability to deliver consistent and uniform heating across various geometries and material types positions them as pivotal tools in the pursuit of enhanced product quality and performance.

Moreover, as industries increasingly prioritize sustainability and environmentally conscious practices, high-frequency induction heating machines offer a compelling solution. By reducing energy consumption, minimizing material wastage, and eliminating the need for chemical-based heating processes, they represent a significant step toward greener and more sustainable manufacturing practices.

In essence, our blog will explore how high-frequency induction heating machines are not only reshaping the present landscape of industrial heating but also charting a path forward for the future. Their potential to drive efficiency, precision, and sustainability underscores their pivotal role in fueling technological advancements and driving innovation across a diverse array of industries.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/high-frequency-induction-heating-machine/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

ABInduction Induction Machines: Enhancing Strength and Durability of Steel Components

Steel is a foundational material in industries ranging from automotive and construction to aerospace and heavy machinery. Its strength and durability can be significantly enhanced through advanced heat treatment processes like induction heating. ABInduction, a leading manufacturer of induction heating systems, has developed cutting-edge machines designed to optimize the strength and longevity of steel components.

The Role of Induction Heating in Steel Component Enhancement

Induction heating is a precise, efficient, and environmentally friendly method for treating steel components. The technology works by generating heat directly within the steel through electromagnetic induction, ensuring controlled and uniform heating. This process is widely used for:

Surface Hardening: Strengthening the outer layer while maintaining a softer, ductile core.

Annealing: Reducing internal stresses and improving the steel’s ductility.

Tempering: Enhancing toughness after quenching.

How ABInduction Machines Enhance Steel Components

Precision HeatingABInduction systems ensure precise control of temperature and heating depth, crucial for achieving consistent results. Their high-frequency machines are ideal for surface hardening, while low-frequency systems cater to deep heat penetration needs.

Customizable SolutionsABInduction offers tailored systems designed to meet the specific needs of steel processing industries. From small-scale operations to heavy-duty applications, their machines deliver consistent performance.

Energy EfficiencyWith advanced energy-saving features, ABInduction machines minimize power consumption while maintaining high heating efficiency. This makes them cost-effective for industries with large-scale heating requirements.

Durability and ReliabilityBuilt with high-quality materials and robust engineering, ABInduction machines are designed for long-term operation in demanding industrial environments.

Integration with Modern TechnologiesABInduction systems incorporate technologies like IoT-enabled monitoring and automated controls, allowing real-time process tracking and ensuring maximum productivity.

Applications in the Steel Industry

Automotive: Hardening of gears, crankshafts, and other critical components for enhanced wear resistance.

Construction: Strengthening structural steel used in buildings and bridges.

Aerospace: Precision hardening and tempering of components subjected to high stress.

Tool Manufacturing: Hardening cutting tools, drills, and dies for prolonged durability.

Why Choose ABInduction for Steel Treatment?

Experience and Expertise: Decades of experience in delivering induction heating solutions for steel industries.

Global Reach: Trusted by clients worldwide with reliable after-sales support.

Sustainability Commitment: Systems designed to reduce energy consumption and environmental impact.

ABInduction machines are not just tools; they are investments in quality, efficiency, and innovation. By enhancing the strength and durability of steel components, these machines empower industries to achieve superior performance and longevity in their products.

Would you like to explore specific ABInduction models or their detailed specifications?

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/vertical-induction-hardening-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Best Induction Heating Systems for Industrial Applications: Spotlight on ABInduction

Induction heating has become a cornerstone technology for various industrial applications, offering precision, energy efficiency, and sustainability. Manufacturers around the world provide a range of systems designed to meet specific industrial needs. Among these, ABInduction stands out as a leader in delivering cutting-edge solutions for diverse applications.

Why Choose ABInduction for Industrial Applications?

Comprehensive Product Range

ABInduction specializes in developing versatile induction heating systems that cater to multiple industries, including automotive, aerospace, metalworking, and electronics. Their product line includes:

High-Frequency Induction Systems for precision tasks like brazing, surface hardening, and annealing.

Low-Frequency Systems designed for deep heat penetration, suitable for forging, billet heating, and other heavy-duty operations.

Customization for Industry-Specific Needs

ABInduction excels in offering tailored solutions for specific industrial requirements. Whether it’s a compact system for small parts or a robust machine for large-scale production, their designs align with customer needs.

Energy Efficiency and Sustainability

With a focus on energy-efficient technology, ABInduction systems minimize power consumption without compromising on performance.

Advanced Technology Integration

ABInduction integrates modern technologies like IoT, automated controls, and real-time monitoring into their systems. These features enhance operational efficiency, improve precision, and ensure easy diagnostics and maintenance.

Reliable After-Sales Support

Known for their global presence, ABInduction provides excellent after-sales support, including installation, training, and maintenance services.

Applications of ABInduction Systems

ABInduction’s systems are versatile and used in various industrial processes, such as:

Automotive Industry: Surface hardening of engine components and brazing of fuel lines.

Aerospace: Precision heating for turbine blades and structural components.

Metalworking: Forging, annealing, and billet heating for heavy industries.

Electronics: Brazing and soldering of delicate components with precision.

Conclusion

ABInduction is a trusted name in the induction heating industry, offering innovative systems tailored for a range of industrial applications. Their commitment to quality, energy efficiency, and advanced technology makes them a go-to choice for businesses looking to optimize their heating processes.

Would you like to explore specific ABInduction products or expand on a particular application?

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for :

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Abinduction’s Induction Hardening Solutions for Aerospace and Defense Applications

In aerospace and defense industries, precision, reliability, and durability are critical. Components must withstand extreme conditions, such as high stresses, temperature variations, and prolonged use. Abinduction provides state-of-the-art induction hardening solutions tailored to meet the rigorous demands of these industries, ensuring superior performance and extended lifespan of critical parts.

Why Choose Abinduction for Aerospace and Defense Applications?

Precision Engineering:

Abinduction’s machines deliver precise and localized hardening, ensuring that components meet exact specifications with minimal distortion. This is vital for parts like turbine blades, landing gear, and fasteners used in aerospace applications.

Custom Solutions for Complex Components:

With the ability to design machines and processes specific to intricate geometries and high-performance materials, Abinduction ensures efficient and effective hardening for even the most challenging aerospace and defense parts.

Enhanced Durability:

Induction hardening from Abinduction improves wear resistance and fatigue strength, essential for components subjected to high stress, such as engine parts and structural components.

Energy Efficiency:

Utilizing advanced induction technology, Abinduction’s systems minimize energy consumption while maximizing output, making them an eco-friendly and cost-effective choice.

Automation and Connectivity:

Abinduction integrates smart automation and Industry 4.0 capabilities, enabling real-time monitoring, process optimization, and seamless integration into advanced manufacturing environments.

Key Applications in Aerospace and Defense:

Landing Gear Components:

Strengthening parts like axles and shafts to ensure they can withstand extreme loads during takeoff and landing.

Turbine Blades:

Hardening blades to improve resistance to wear and thermal stresses in high-temperature environments.

Fasteners and Bolts:

Enhancing surface hardness for improved durability in critical joints.

Armor Components:

Hardening defense equipment and vehicle armor for enhanced protection and performance.

Engine Parts:

Treating crankshafts, camshafts, and other high-stress components to ensure long-term reliability.

Abinduction’s Advantages

Global Expertise: Decades of experience in providing induction solutions for high-stakes industries.

Cutting-Edge Technology: Incorporates the latest advancements in induction heating and hardening.

Comprehensive Support: From design to maintenance, Abinduction offers end-to-end solutions for its clients.

Compliance with Industry Standards: Machines and processes are designed to meet or exceed aerospace and defense regulations and quality benchmarks.

Conclusion

Abinduction’s induction hardening solutions empower aerospace and defense manufacturers to produce parts that meet the highest standards of quality and reliability. By combining advanced technology, precision engineering, and customizable solutions, Abinduction ensures its clients achieve optimal performance and efficiency.

Would you like additional details about specific products or case studies from Abinduction?

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/vertical-induction-hardening-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Abinduction: Induction Heating Machine Manufacturers for Automotive Applications

Abinduction is a leading manufacturer of advanced induction heating machines designed specifically for the automotive industry. With a focus on precision, efficiency, and innovation, Abinduction delivers tailored solutions that meet the diverse needs of automotive manufacturers worldwide. From heat treatment to brazing and shrink fitting, Abinduction’s machines ensure optimal performance and reliability in high-demand production environments.

Why Abinduction for Automotive Applications?

Tailored Solutions for Automotive Needs: Abinduction specializes in creating custom-designed induction heating machines for a wide range of automotive components, including gears, crankshafts, camshafts, axles, and fasteners. Their machines are optimized for precision heating, ensuring consistent quality and minimal distortion.

Energy-Efficient Technology: Leveraging advanced induction technology, Abinduction’s systems provide highly efficient and localized heating, reducing energy consumption and operational costs while aligning with the automotive industry’s sustainability goals.

Robust and Durable Designs: Built with high-quality materials and components, Abinduction machines withstand the rigors of continuous operation in demanding manufacturing environments.

Automation and Integration: Abinduction offers seamless integration of its machines with modern production lines, including compatibility with robotic arms and Industry 4.0 systems. This ensures real-time monitoring, remote control, and enhanced operational efficiency.

Global Support and Expertise: With a worldwide presence, Abinduction provides comprehensive support, including installation, training, and maintenance services, ensuring maximum uptime and customer satisfaction.

Applications of Abinduction’s Machines in Automotive Manufacturing

Induction Hardening: Precision hardening of gears, camshafts, and axles to enhance durability and wear resistance.

Brazing: High-quality joining of components like fuel injector assemblies, heat exchangers, and sensor housings.

Shrink Fitting: Efficient and accurate heating for assembly processes, such as mounting bearings onto shafts.

Annealing: Stress-relieving of parts to improve machinability and reduce material fatigue.

Surface Heating: Preparing surfaces for bonding, coating, or other secondary processes.

Key Features of Abinduction Machines:

Precision Heating: Uniform and localized heating ensures minimal thermal distortion.

Flexible Power Options: Machines designed to accommodate various power levels and frequencies for diverse applications.

Compact and Modular Design: Space-saving systems that can be easily integrated into existing production lines.

User-Friendly Interface: Advanced control systems with intuitive interfaces for easy operation and monitoring.

Partnering with Abinduction

Choosing Abinduction as your induction heating machine manufacturer guarantees:

Custom-engineered solutions tailored to your production requirements.

Proven expertise in automotive manufacturing processes.

Reliable performance backed by a commitment to innovation and quality.

Abinduction is dedicated to helping automotive manufacturers enhance efficiency, reduce costs, and meet the highest industry standards.

Would you like more details on specific Abinduction products or solutions?

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for :

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Drum Heating Machines for Oil and Lubricant Industries

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Introduction to High-Frequency Induction Heating Machines

High-frequency induction heating machines are advanced devices that use electromagnetic induction to generate heat in conductive materials. This non-contact heating method is highly efficient, precise, and versatile, making it an essential tool in various industries such as automotive, aerospace, electronics, and metallurgy.

These machines work by creating a high-frequency alternating current (AC) that flows through a coil, generating a rapidly changing magnetic field. When a conductive material is placed within this field, eddy currents are induced in the material, causing it to heat up due to resistive losses. The localized heating effect allows for precise temperature control and rapid heat cycles, minimizing energy waste and production time.

Key Features:

High Efficiency: Converts energy directly into heat within the target material, reducing energy losses.

Precision Heating: Enables controlled heating of specific areas without affecting the surrounding material.

Non-Contact Process: No physical contact between the heating coil and the material, reducing wear and maintenance.

Rapid Heating: Achieves high temperatures in seconds, suitable for high-throughput production.

Common Applications:

Metal Hardening: For tools, gears, and other components requiring a hardened surface.

Brazing and Soldering: Joining metals with minimal thermal distortion.

Melting and Forging: For small-scale casting and metalworking operations.

Heat Shrinking: In applications like fitting gears or bearings.

High-frequency induction heating machines offer an environmentally friendly alternative to traditional heating methods by eliminating the need for open flames or excessive energy consumption. They are ideal for modern industries that prioritize sustainability, efficiency, and precision.

Would you like additional details or information tailored to a specific use case?

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for :

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

High-Performance Induction Heating Machines for Every Industry

At ABInduction, we blend precision engineering with cutting-edge technology to deliver advanced induction heating machines that meet the rigorous demands of modern industries. Our machines are designed to provide rapid, efficient, and uniform heating, ensuring optimal performance across applications such as metal hardening, forging, brazing, and annealing.

With a focus on power and accuracy, ABInduction’s systems allow for precise control over the heating process, reducing energy consumption while maximizing output quality. Our solutions are trusted by industries including automotive, aerospace, energy, and manufacturing, where reliability and consistency are critical to success.

By integrating smart technology and automation, ABInduction machines offer enhanced productivity, real-time monitoring, and adaptability to various production environments. Whether you need a turnkey solution or a custom-built system, ABInduction stands as a leader in delivering innovative, durable, and high-performance induction heating equipment that powers industrial growth.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for :

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Precision and Power – ABInduction's Advanced Induction Heating Machines

At ABInduction, we blend precision engineering with cutting-edge technology to deliver advanced induction heating machines that meet the rigorous demands of modern industries. Our machines are designed to provide rapid, efficient, and uniform heating, ensuring optimal performance across applications such as metal hardening, forging, brazing, and annealing.

With a focus on power and accuracy, ABInduction’s systems allow for precise control over the heating process, reducing energy consumption while maximizing output quality. Our solutions are trusted by industries including automotive, aerospace, energy, and manufacturing, where reliability and consistency are critical to success.

By integrating smart technology and automation, ABInduction machines offer enhanced productivity, real-time monitoring, and adaptability to various production environments. Whether you need a turnkey solution or a custom-built system, ABInduction stands as a leader in delivering innovative, durable, and high-performance induction heating equipment that powers industrial growth.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for :

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Leading Induction Hardening Machine Manufacturer for Industrial Applications

As industries demand higher durability, precision, and efficiency in metal processing, induction hardening has emerged as a crucial technology for surface heat treatment. A leading manufacturer of induction hardening machines plays a pivotal role in delivering advanced solutions that enhance the strength and wear resistance of critical components across sectors like automotive, aerospace, defense, and heavy machinery.

These manufacturers are at the forefront of innovation, providing cutting-edge systems that ensure faster heating cycles, uniform hardness, and minimal material distortion. By integrating automation, real-time process monitoring, and energy-efficient designs, they help industries achieve consistent results with lower operational costs.

With a focus on customizable solutions, top manufacturers offer machines tailored to meet the specific hardening requirements of gears, shafts, bearings, and other high-load components. Their commitment to research and development drives technological advancements that keep pace with evolving industry standards, ensuring that clients benefit from the latest in induction hardening technology.

This article highlights the key attributes of leading induction hardening machine manufacturers, their product offerings, and the industries they serve, showcasing their role in shaping modern manufacturing.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for :https://abinduction.in/vertical-induction-hardening-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Leading Induction Hardening Machine Manufacturer for Industrial Applications

As industries demand higher durability, precision, and efficiency in metal processing, induction hardening has emerged as a crucial technology for surface heat treatment. A leading manufacturer of induction hardening machines plays a pivotal role in delivering advanced solutions that enhance the strength and wear resistance of critical components across sectors like automotive, aerospace, defense, and heavy machinery.

These manufacturers are at the forefront of innovation, providing cutting-edge systems that ensure faster heating cycles, uniform hardness, and minimal material distortion. By integrating automation, real-time process monitoring, and energy-efficient designs, they help industries achieve consistent results with lower operational costs.

With a focus on customizable solutions, top manufacturers offer machines tailored to meet the specific hardening requirements of gears, shafts, bearings, and other high-load components. Their commitment to research and development drives technological advancements that keep pace with evolving industry standards, ensuring that clients benefit from the latest in induction hardening technology.

This article highlights the key attributes of leading induction hardening machine manufacturers, their product offerings, and the industries they serve, showcasing their role in shaping modern manufacturing.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for :https://abinduction.in/vertical-induction-hardening-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes