Don't wanna be here? Send us removal request.

Text

Toroidal Winding Machines: Types, Features & Applications

In our recent series of articles, we delved into the various types of coil winding machines. Our last article focused on linear winding machines. This time, we will explore toroidal winding machines, another essential type of winding machine. Toroidal winding machines are specifically designed to wind inductors that consist of toroids or round rings. Unlike linear winding machines, toroidal winding machines are more complex and tailored to handle the unique process of winding toroids,

https://acmeengg.com/blog/toroidal-winding-machines-types-features-applications/

0 notes

Text

Linear Winding Machines: Features, Types & Applications

Winding machines are in high demand due to their integral role in manufacturing essential electronic components such as resistors, capacitors, and inductors. These components are crucial for building any electronic circuit, with inductors specifically relying on winding machines for their production. Inductors, also known as coils, are fundamental components in electronics. Learn about linear winding machines, their role in coil manufacturing, and key features like spindle rotation, traverse control, and programmable functions.

0 notes

Text

High-Precision Coil Winding Equipment for Efficient Coil Manufacturing

In the world of electrical manufacturing, coil winding equipment plays a pivotal role in producing coils that serve as the core components of countless electrical devices. Whether for transformers, motors, inductors, or sensors, the quality and accuracy of coil production directly impact performance and reliability. Explore cutting-edge coil winding equipment designed for precision and efficiency. Discover programmable features that enhance coil production for various industrial applications.

https://acmeengg.com/blog/revolutionizing-coil-manufacturing-with-acme-electronics-advanced-coil-winding-equipment/

0 notes

Text

0 notes

Text

How Digital Twin Technology is Revolutionizing Coil Winding Processes

The manufacturing world is evolving rapidly, and coil winding processes are no exception. One of the most groundbreaking innovations reshaping this industry is digital twin technology. Imagine having a virtual replica of your coil winding machine that monitors every movement and predicts potential issues before they happen. Sounds futuristic? It’s already here — and it’s changing how manufacturers optimize performance and cut downtime.

Let’s dive into what digital twin technology means for coil winding, how it works, and why it’s quickly becoming an essential tool for industry leaders.

What is Digital Twin Technology?

At its core, a digital twin is a dynamic virtual model of a physical asset—in this case, a coil winding machine. This virtual twin continuously receives data from sensors installed on the real machine, replicating its operation in real-time. This means manufacturers don’t just see a snapshot of the machine’s status; they experience a living, breathing model that reflects every twist, tension change, and electrical load.

By linking the physical and virtual worlds, digital twins allow operators and engineers to monitor performance closely, make data-driven decisions, and run simulations without halting production.

Real-Time Monitoring: Keeping a Finger on the Pulse

One of the biggest advantages of digital twin technology is real-time monitoring. Instead of waiting for physical signs of wear or failures, manufacturers get immediate insights into wire tension, motor temperature, winding speed, and other critical parameters. This continuous stream of data ensures quality remains consistent, reducing defects and material waste.

Moreover, by having an always-active digital twin, companies can respond swiftly to anomalies, avoiding costly production stops. This capability is especially valuable in industries where precision and reliability are paramount.

Predictive Maintenance: Fixing Problems Before They Start

Traditional maintenance often relies on scheduled servicing or reactive repairs, which can either be costly or too late. Digital twins enable a smarter approach: predictive maintenance. By analyzing trends and patterns from the data collected, the digital twin can forecast when parts might fail or performance might dip, prompting timely interventions.

This not only extends machine lifespan but also optimizes maintenance budgets by avoiding unnecessary replacements and minimizing unplanned downtime.

Real Success Stories: Productivity Gains in Action

Manufacturers adopting digital twin technology in coil winding have reported remarkable productivity improvements. For example, a recent case involving a leading coil winding facility using digital twins showed a 20% reduction in downtime and a 15% boost in throughput within the first six months. These gains stemmed from enhanced machine visibility and faster troubleshooting enabled by the virtual models.

Such successes highlight the tangible benefits of embracing digital twins for modern coil winding operations.

Overcoming Integration Challenges

Despite its promise, integrating digital twin technology isn't without hurdles. Data accuracy depends heavily on sensor quality and placement, while legacy machines may require upgrades to be compatible. Additionally, analyzing the massive data sets requires advanced software and skilled personnel.

To address these challenges, many companies are partnering closely with equipment manufacturers like ACME Electronics Coil Winding Machine Manufacturer Supplier to develop tailored digital twin solutions that align with their existing infrastructure and capabilities.

Conclusion

Digital twin technology is more than just a buzzword — it’s a transformative tool helping coil winding manufacturers push the boundaries of efficiency and reliability. By providing real-time insights, enabling predictive maintenance, and supporting smarter decision-making, digital twins are setting a new standard for operational excellence.

Are you ready to explore how digital twins could revolutionize your coil winding processes?

#coil winding machine#winding machine#programmable winding machine#coil winder#transformer winding machine#cnc winding machine

0 notes

Text

The Evolution of Transformer Winding Machines: From Manual to Fully Automated Systems

Transformer winding has been a cornerstone of electrical engineering for decades. What started as a labor-intensive, manual process has transformed dramatically thanks to technological advances. Today’s automated winding machines deliver unparalleled precision, efficiency, and scalability—redefining how transformers are produced worldwide.

If you’ve ever wondered how transformer winding machines evolved and what the future holds for this critical industry, read on. We’ll walk through the history, major milestones, and benefits automation has brought, finishing with a look at what’s coming next.

Manual Beginnings: The Roots of Coil Winding

Back in the day, transformer coils were wound by hand—a painstaking process demanding steady hands and sharp eyes. Skilled operators manually guided wire around cores, carefully layering each turn to ensure electrical performance and safety. This method, while effective, was slow and prone to human error. Inconsistent tension, uneven layering, and fatigue could affect product quality and limit production volume.

Manual winding was also labor-intensive and costly, making it difficult to scale operations, especially as demand for transformers soared in industrial and consumer markets.

Milestones in Automation: Shaping Modern Machines

The journey from manual to automated winding started with simple mechanical aids—basic spindles and tension controls that eased operator workload. The real leap came with the introduction of:

CNC (Computer Numerical Control) Technology: Allowing programmable, repeatable winding patterns with incredible accuracy.

Servo Motors & Feedback Systems: Ensuring consistent wire tension and alignment throughout the winding process.

Integrated Digital Controls: Enabling operators to set precise parameters for speed, turns, and layering, minimizing errors.

Manufacturers like ACME Electronics, a leading Coil Winding Machine Manufacturer Supplier, played key roles in developing these advanced systems, providing solutions that revolutionized transformer production lines globally.

Automation Benefits: Precision, Cost, and Scale

Automated transformer winding machines have become a game changer for several reasons:

Higher Precision: Computerized controls eliminate human error, producing coils with uniformity and optimal electrical properties.

Reduced Labor Costs: Automation cuts down on manual labor, allowing manufacturers to reallocate resources and increase output.

Scalability: Machines can run continuously, adapting easily to high-volume production demands without sacrificing quality.

Improved Safety: Operators face fewer risks from repetitive motion injuries or handling hazardous materials.

Together, these advantages translate into better products, faster turnaround times, and stronger competitive positioning.

What’s Next? The Future of Transformer Winding Machines

Looking ahead, the evolution won’t slow down. Emerging innovations may include:

AI-Powered Quality Control: Real-time defect detection and adaptive adjustments.

IoT Connectivity: Enabling remote monitoring and predictive maintenance.

Eco-Friendly Designs: Machines built with energy efficiency and sustainability at their core.

Flexible Automation: Customizable setups for niche applications in aerospace, medical, and renewable energy sectors.

As the coil winding industry embraces these technologies, manufacturers will gain new tools to meet increasingly complex demands.

Conclusion

The transformation from manual coil winding to fully automated systems marks a significant milestone in transformer manufacturing. Today’s machines deliver unmatched precision, efficiency, and scalability, opening doors to innovations that seemed unimaginable just a few decades ago.

With the rapid pace of technology, how will the next wave of transformer winding machines reshape the industry for years to come?

#coil winding machine#winding machine#coil winder#programmable winding machine#winding equipment#cnc winding machine#transformer winding machine#toroidal winding machine#toroidal winding machines

0 notes

Text

Sustainability in Coil Winding: Eco-Friendly Materials and Processes

As industries worldwide shift toward more sustainable operations, the coil winding sector is no exception. From electric motors to transformers, the demand for greener manufacturing practices is rising. Sustainability isn’t just a buzzword anymore—it’s a necessary direction for manufacturers who want to remain competitive and responsible.

So, how can the coil winding process go green? Let’s explore how eco-friendly materials, energy-efficient machinery, and forward-thinking companies are reshaping the industry.

Green Materials: Rethinking What Goes into a Coil

Traditionally, coil winding has relied on synthetic insulation materials and non-recyclable components. However, modern innovations are opening the door to biodegradable insulation, lead-free solder, and recyclable wire coatings.

Biodegradable varnishes and cellulose-based insulation papers are now viable alternatives to petroleum-based products. These materials reduce environmental impact without compromising on performance—a win-win for both manufacturers and the planet.

Additionally, companies are exploring copper alternatives such as aluminum, which is lighter and often more readily recyclable, though it requires special handling for efficiency and durability.

Energy-Efficient Machines: Cutting the Carbon Footprint

The sustainability conversation goes beyond just materials—it also involves the machines doing the work. Today’s coil winding machines are becoming smarter and greener.

Energy-efficient coil winding machines use optimized motor control, intelligent automation, and lower standby power consumption. These enhancements don’t just save electricity—they lower the overall carbon footprint of the manufacturing process.

Some systems even recycle thermal energy generated during winding, further minimizing waste. These machines not only help companies meet their environmental goals but also reduce operational costs over time.

Real-World Examples: Green in Action

Several manufacturers have taken sustainability from concept to reality. Take, for example, a mid-sized transformer company in Germany that replaced its entire insulation system with biodegradable materials. The result? A 25% reduction in landfill waste and recognition from an EU sustainability initiative.

Another case is an electric vehicle component maker in Japan that switched to energy-efficient winding systems and cut energy consumption by 30% over two years—without sacrificing production speed or quality.

These case studies show that going green doesn’t mean giving up performance—it means evolving smarter.

Regulations Driving Change

Governments and industry bodies are now pushing sustainability as more than a choice—it’s becoming regulatory. Across Europe, the RoHS (Restriction of Hazardous Substances) directive and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) require manufacturers to limit or eliminate harmful materials.

In North America and parts of Asia, similar policies are taking shape, encouraging cleaner energy use and more responsible materials handling. These trends are pushing coil winding companies to adopt eco-conscious practices, or risk falling behind in compliance and competitiveness.

Conclusion

Sustainability in coil winding is more than a passing trend—it’s a fundamental shift in how manufacturers think about materials, machines, and responsibility. From eco-friendly insulation to smarter machines, the industry is embracing solutions that protect the planet while improving efficiency.

At the forefront of this transformation, companies like ACME Electronics, a trusted Coil Winding Machine Manufacturer Supplier, are developing technologies that align performance with environmental responsibility.

As the world turns greener, is your coil winding operation ready to follow suit?

#coil winding machine#winding machine#coil winder#programmable winding machine#winding equipment#transformer winding machine#automatic winding machines#toroidal winding machine#cnc winding machine#toroidal winding machines#Coil Winding Machine Manufacturer Supplier

0 notes

Text

The Evolution of Automatic Winding Machines: From Manual Labor to Smart Manufacturing

Before automation transformed factory floors, coil winding was a painstaking manual task—demanding steady hands, sharp eyes, and a lot of time. Coils were wound by hand or using simple mechanical aids, with quality and consistency largely dependent on the operator’s skill. Fast forward to today, and automatic winding machines are not only handling the workload—they're doing it smarter than ever.

This journey from manual to smart manufacturing has reshaped how industries like electronics, aerospace, and automotive produce high-performance components. Let’s explore how it all began and where it’s headed next.

From Human Hands to Mechanized Precision

In the early 20th century, as electrical devices became more widespread, the demand for coils surged. Manual methods were no longer efficient or scalable, especially for precision-critical applications like transformers and motors.

The introduction of early automatic winding machines marked a turning point. These machines could repeatedly wind coils with consistent tension and speed, reducing labor costs and improving product uniformity. Still, these systems were largely mechanical, relying on cams, gears, and operator intervention for setup and control.

The Digital Leap: Early Automation

The next big leap came with the rise of electronic control systems. Programmable logic controllers (PLCs) and digital interfaces allowed users to set winding parameters such as turns, pitch, and speed with far more accuracy. This eliminated the need for manual adjustments between batches and drastically improved repeatability.

As industries demanded higher output with tighter tolerances, automatic winding machines evolved to meet the challenge. Features like multi-spindle operation, servo motors, and tension feedback systems became the norm, enabling machines to produce complex windings at high speeds with minimal error.

The Smart Manufacturing Era

Now, we’re in the age of smart manufacturing—where winding machines don’t just execute commands; they learn, adapt, and optimize in real time.

Thanks to AI, machine learning, and IoT integration, today’s automatic winding machines can:

Detect and adjust for variations in wire tension and core alignment on the fly

Predict maintenance needs before a breakdown occurs

Automatically log production data for quality assurance and traceability

Integrate with factory-wide systems to streamline inventory, scheduling, and analytics

For industries like aerospace, where reliability is non-negotiable, or automotive, where production speed meets high precision, these advancements offer a major edge.

The Real-World Impact

Modern manufacturers are seeing measurable benefits from these advancements: reduced downtime, higher throughput, better product consistency, and lower overall production costs. Companies like ACME Electronics, a global Coil Winding Machine Manufacturer Supplier, are leading the way by delivering cutting-edge winding solutions that meet the demands of Industry 4.0.

Final Thoughts

The evolution of automatic winding machines reflects the broader shift in manufacturing—from hands-on craftsmanship to digitally driven precision. As AI and smart technology continue to advance, the future of coil winding promises even more autonomy, efficiency, and innovation.

Is your production line ready to make the leap from automation to intelligent manufacturing?

#coil winding machine#winding machine#coil winder#programmable winding machine#automatic winding machines

0 notes

Text

Top Maintenance Tips for Extending the Life of Your Coil Winding Equipment

Coil winding machines are the backbone of countless industries, from motor manufacturing to transformer production. When these machines run well, they boost productivity and ensure high-quality output. But when they go down? It can halt an entire production line. The good news is that with the right maintenance strategy, you can greatly extend the lifespan and reliability of your coil winding equipment.

In this article, we’ll walk you through key maintenance tips that not only help prevent breakdowns but also protect your investment for the long haul.

Stay Ahead with Routine Maintenance

Just like a car, coil winding machines need regular checkups. Skipping scheduled maintenance might save time in the short term, but it often leads to bigger, more expensive problems later. At a minimum, create a maintenance calendar that includes:

Weekly visual inspections

Monthly cleaning and lubrication

Quarterly performance checks and calibration

Annual deep servicing

This simple plan helps catch issues early and keeps machines running at peak performance.

Spotting the Warning Signs Early

The ability to detect early signs of wear or damage can mean the difference between a minor fix and a major failure. Here are some red flags to watch for:

Unusual noises or vibration during operation

Irregular tension or misalignment of wire

Overheating or inconsistent speed

Increased scrap or product defects

If any of these occur, don’t ignore them. Investigate the source and address it before it turns into downtime.

Don’t Skimp on Lubrication and Cleaning

Proper lubrication is one of the most overlooked yet vital maintenance tasks. Moving parts—especially spindles, bearings, and guide rollers—need consistent lubrication to reduce friction and prevent wear. Be sure to use the manufacturer-recommended lubricant and schedule it regularly.

Likewise, dust and wire debris can build up around sensors, guides, and mechanical parts. A regular cleaning routine not only improves machine hygiene but also prevents errors in winding accuracy.

Spare Parts: Stock Smart, Not Excessively

One of the biggest bottlenecks during machine failure is waiting on a critical spare part. That’s why it’s smart to keep an inventory of high-wear components like belts, bearings, wire guides, and fuses. But balance is key—you don’t need to stock every part, just the ones most likely to fail.

Track usage trends and consult with your equipment provider for a recommended list. Companies like ACME Electronics, a seasoned Coil Winding Machine Manufacturer Supplier, often provide spare parts kits tailored to your machine type and production volume.

Final Thoughts

Well-maintained coil winding equipment is more reliable, produces higher-quality coils, and reduces costly downtime. With a proactive maintenance approach—including regular inspections, proper lubrication, and smart spare parts planning—you’ll ensure your machines keep winding without a hitch for years to come.

Is your coil winding maintenance plan ready to support long-term performance and reliability?

#coil winding machine#winding machine#coil winder#programmable winding machine#winding equipment#transformer winding machine

0 notes

Text

How Industry 4.0 is Transforming the Coil Winding Industry

In the rapidly evolving world of manufacturing, staying ahead means embracing the next wave of innovation—Industry 4.0. More than just a buzzword, Industry 4.0 represents a seismic shift in how products are made, monitored, and maintained. For the coil winding industry, this transformation is opening doors to greater efficiency, smarter production lines, and improved product quality.

Let’s take a closer look at how Industry 4.0 is revolutionizing coil winding and what it means for manufacturers of all sizes.

What is Industry 4.0 and Why It Matters

At its core, Industry 4.0 is about digitizing the manufacturing process through interconnected machines, data-driven insights, and smart automation. It’s a blend of technologies like the Internet of Things (IoT), artificial intelligence, machine learning, and real-time analytics.

In traditional coil winding setups, operators had to rely on manual inspections, scheduled maintenance, and fixed machine parameters. Now, thanks to Industry 4.0, coil winding machines are becoming intelligent systems that can adapt, self-monitor, and predict issues before they happen.

Smart Factories and Intelligent Coil Winding

Imagine a factory where every coil winding machine is fitted with sensors that track tension, rotation speed, temperature, and wire alignment in real time. These sensors feed data into centralized platforms that analyze and optimize performance 24/7.

This is the essence of a smart factory—a production environment where machines “talk” to each other and adjust automatically to ensure top-notch consistency and minimal downtime.

For example, in a high-volume motor coil production facility, AI-driven winding machines can automatically correct minor variations in coil dimensions, avoiding waste and ensuring product uniformity. It’s quality control, done smarter.

IoT and Predictive Maintenance: A Game Changer

One of the biggest benefits of Industry 4.0 in coil winding is predictive maintenance. Instead of following a rigid maintenance schedule, IoT-enabled machines monitor their own health and alert operators before a failure occurs.

This reduces unplanned downtime, extends equipment lifespan, and saves costs. For example, a plant using IoT-connected winding machines received early alerts about bearing wear, allowing for a quick replacement during planned downtime—avoiding hours of lost productivity.

Case Studies in Action

Several forward-thinking manufacturers have already reaped the rewards of adopting Industry 4.0. One European transformer company integrated cloud-based monitoring with their winding systems and reduced coil defects by 35% in just six months. Another electric vehicle startup leveraged machine learning to fine-tune their stator winding patterns, cutting their production cycle time by nearly 20%.

Suppliers like ACME Electronics, a trusted Coil Winding Machine Manufacturer Supplier, are helping businesses navigate this shift by offering machines with built-in connectivity, cloud integration, and adaptive control systems.

Challenges and Opportunities for Small Manufacturers

While large manufacturers may lead the charge, small and mid-sized companies face their own challenges—limited budgets, legacy equipment, and technical know-how. However, the modular nature of Industry 4.0 makes it possible to adopt these technologies step by step.

Affordable upgrades like retrofitting sensors or adding cloud-based dashboards can bring immediate gains without overhauling entire systems. With the right guidance, even smaller players can stay competitive in an increasingly digital market.

Final Thoughts

Industry 4.0 is no longer the future—it’s happening now, and it’s transforming how coil winding machines operate, perform, and evolve. By embracing smart technologies, manufacturers can unlock new levels of efficiency, quality, and agility.

Are you ready to bring your coil winding operations into the age of smart manufacturing?

#Coil Winding Machine#coil winding machine#winding machine#coil winder#winding equipment#programmable winding machine#transformer winding machine

0 notes

Text

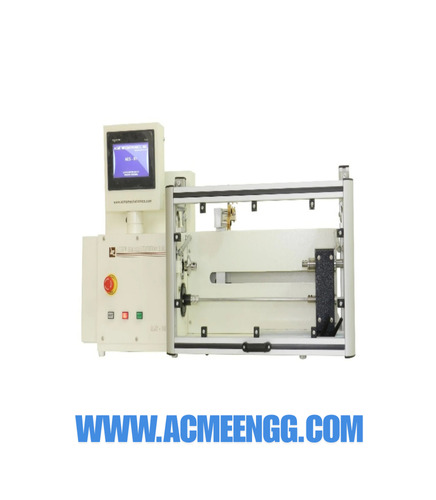

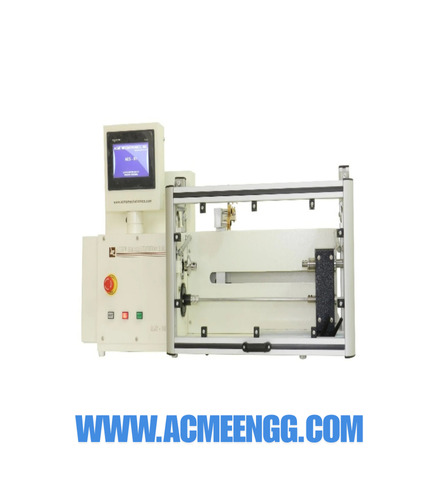

Explore our high-precision Linear Winding Machines for diverse coil winding needs. Contact us today to customize your solution!

0 notes

Text

Automating Your Winding Process with CNC Machines: Benefits and Considerations

In today’s fast-paced manufacturing landscape, automation has become a cornerstone for industries seeking increased efficiency, precision, and scalability. For companies involved in the production of coils, adopting automated solutions like CNC winding machines can revolutionize the winding process. Whether you’re producing electric motors, transformers, or inductors, transitioning to a CNC winding machine or an automatic winding machine can yield significant operational benefits. However, there are also important considerations to weigh before making the switch.

For more details visit:

0 notes