#Toroidal Winding Machines

Explore tagged Tumblr posts

Text

The Evolution of Transformer Winding Machines: From Manual to Fully Automated Systems

Transformer winding has been a cornerstone of electrical engineering for decades. What started as a labor-intensive, manual process has transformed dramatically thanks to technological advances. Today’s automated winding machines deliver unparalleled precision, efficiency, and scalability—redefining how transformers are produced worldwide.

If you’ve ever wondered how transformer winding machines evolved and what the future holds for this critical industry, read on. We’ll walk through the history, major milestones, and benefits automation has brought, finishing with a look at what’s coming next.

Manual Beginnings: The Roots of Coil Winding

Back in the day, transformer coils were wound by hand—a painstaking process demanding steady hands and sharp eyes. Skilled operators manually guided wire around cores, carefully layering each turn to ensure electrical performance and safety. This method, while effective, was slow and prone to human error. Inconsistent tension, uneven layering, and fatigue could affect product quality and limit production volume.

Manual winding was also labor-intensive and costly, making it difficult to scale operations, especially as demand for transformers soared in industrial and consumer markets.

Milestones in Automation: Shaping Modern Machines

The journey from manual to automated winding started with simple mechanical aids—basic spindles and tension controls that eased operator workload. The real leap came with the introduction of:

CNC (Computer Numerical Control) Technology: Allowing programmable, repeatable winding patterns with incredible accuracy.

Servo Motors & Feedback Systems: Ensuring consistent wire tension and alignment throughout the winding process.

Integrated Digital Controls: Enabling operators to set precise parameters for speed, turns, and layering, minimizing errors.

Manufacturers like ACME Electronics, a leading Coil Winding Machine Manufacturer Supplier, played key roles in developing these advanced systems, providing solutions that revolutionized transformer production lines globally.

Automation Benefits: Precision, Cost, and Scale

Automated transformer winding machines have become a game changer for several reasons:

Higher Precision: Computerized controls eliminate human error, producing coils with uniformity and optimal electrical properties.

Reduced Labor Costs: Automation cuts down on manual labor, allowing manufacturers to reallocate resources and increase output.

Scalability: Machines can run continuously, adapting easily to high-volume production demands without sacrificing quality.

Improved Safety: Operators face fewer risks from repetitive motion injuries or handling hazardous materials.

Together, these advantages translate into better products, faster turnaround times, and stronger competitive positioning.

What’s Next? The Future of Transformer Winding Machines

Looking ahead, the evolution won’t slow down. Emerging innovations may include:

AI-Powered Quality Control: Real-time defect detection and adaptive adjustments.

IoT Connectivity: Enabling remote monitoring and predictive maintenance.

Eco-Friendly Designs: Machines built with energy efficiency and sustainability at their core.

Flexible Automation: Customizable setups for niche applications in aerospace, medical, and renewable energy sectors.

As the coil winding industry embraces these technologies, manufacturers will gain new tools to meet increasingly complex demands.

Conclusion

The transformation from manual coil winding to fully automated systems marks a significant milestone in transformer manufacturing. Today’s machines deliver unmatched precision, efficiency, and scalability, opening doors to innovations that seemed unimaginable just a few decades ago.

With the rapid pace of technology, how will the next wave of transformer winding machines reshape the industry for years to come?

#coil winding machine#winding machine#coil winder#programmable winding machine#winding equipment#cnc winding machine#transformer winding machine#toroidal winding machine#toroidal winding machines

0 notes

Text

Toroidal Winding Machines - High Precision Solutions

A toroidal winding machine is designed to wind coils in a toroidal shape, which is commonly used in transformers, inductors, and chokes. These machines are highly specialized, as toroidal coils require precision to maintain uniform winding and minimize losses. A toroid winding machine ensures that the wire is wrapped evenly around the circular core, which results in a compact and efficient design ideal for applications requiring low electromagnetic interference. The key advantage of using a toroidal design is its ability to reduce size while improving electrical performance. ACME Electronics offers advanced toroidal winding machines that combine speed, precision, and versatility, making them perfect for high-quality production. With these machines, manufacturers can efficiently produce durable and reliable toroidal coils for a variety of industries, from electronics to renewable energy systems.

0 notes

Text

Magnetic and PCB Mounted Magnetic Components

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Toroid Hook Winders#Linear Traverse Winding Machines#Vacuum/Pressure Impregnation#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Text

We are New Win Machinery-A export machine company in Hong Kong. We sell plenty of machines for switching transformer, relay and drum coil. We sold machine all over the world. Please see the following company introdution video and contact us for any inquiry.

#machine#machinery#soldering#tranformers#winding machine#newwin#newwinmachinery#automatic#relay#taping#testing#lamination#pininsertion#inductors#toroidal

1 note

·

View note

Text

Low Voltage Three-Phase Transformers: All You Need to Know

Bridgeport Magnetics’ low voltage distribution transformer represent more than just electrical equipment—they embody a commitment to efficiency, space utilization, and reliability. Whether you’re upgrading an existing facility or embarking on a new construction project, choosing Bridgeport Magnetics means choosing quality and innovation in power distribution.

0 notes

Text

winding-machine

Manual Winding Machines: These are basic winding machines operated by hand. They are suitable for low-volume production or prototyping.

Semiautomatic Winding Machines: These machines combine manual and automated features. Operators guide the winding process, but the machine assists with tension control, layering, and other tasks.

Automatic Winding Machines: These machines are fully automated and capable of handling high-volume production. They can be programmed to wind specific patterns, adjust tension automatically, and monitor various parameters.

CNC Winding Machines: These are computer-controlled winding machines capable of intricate winding patterns and precise control over winding parameters such as tension, speed, and layering.

view more

#winding machine#toroidal winding machine#toroid winding machine#automatic winding machine#toroidal winding#automatic toroidal winding machine

1 note

·

View note

Text

Toroidal Transformers — Winding Techniques and Patterns

Toroidal transformers are celebrated for their efficiency, compact design, and low EMI, thanks to their advanced winding techniques. These designs enhance energy efficiency, reduce copper losses, improve thermal management, and ensure stable voltage regulation. The right techniques also ensure better voltage regulation and minimize the risk of hotspots, making them ideal for high-performance applications. This blog explores the benefits of various winding patterns and their impact on the overall performance of toroidal transformers.

Common winding patterns

Two most common toroidal transformer winding patterns include hand winding and machine winding. Hand winding suits small-scale production or custom designs, allowing flexibility but requiring more time. Machine winding is perfect for bulk manufacturing because it guarantees accuracy and uniformity. While multi-layer windings increase inductance in confined spaces and necessitate careful heat management, single-layer windings minimize overlap and are appropriate for low-power applications. Parallel wires are used in bifilar winding to lower inductance and improve high-frequency performance. By distributing wires evenly throughout the core, progressive winding enhances heat dissipation and avoids hotspots. These methodologies cover varying efficiency and performance objectives, ensuring optimal design for various transformer applications.

Impact of winding patterns on performance

Winding patterns have a major effect on transformer performance, affecting important areas like voltage regulation, EMI reduction, thermal management, and efficiency. Optimized winding patterns improve energy transmission and overall efficiency by reducing copper losses. By enhancing heat dissipation and avoiding hotspot development, uniform winding designs help with thermal management. In order to ensure smoother operation and improved compatibility with nearby devices, proper wire positioning and techniques such as bifilar winding prevent electromagnetic interference. Furthermore, balanced winding designs enhance the transformer’s dependability and performance in a range of applications by producing steady voltage outputs under varied loads.

Winding challenges

Toroidal transformer winding presents a number of challenges, such as accuracy, material quality, and heat control. To prevent imbalances that could impair performance, uniformity is crucial. Longevity and optimal performance are ensured by using premium wire and insulation. However, overcrowded windings may overheat, reducing their effectiveness and possibly causing long-term harm. This emphasises how crucial careful planning and execution are to the winding process. In addition to lowering the possibility of heat accumulation and ensuring balanced winding patterns, proper attention to detail also ensures that the transformer runs effectively, offering dependable and constant performance over its lifetime.

To sum up, the efficiency, thermal performance, and reliability of toroidal transformers are significantly influenced by the winding techniques involved. These type of winding techniques used affect energy transfer, heat dissipation, and copper losses. Optimized designs reduce electromagnetic interference and guarantee steady voltage outputs in order to satisfy the requirements of high-frequency, high-power systems. Achieving best performance requires proper wire positioning, material quality, and uniformity, which allows manufacturers to produce high-performance transformers that meet a variety of industry demands. Miracle Electronics specializes in crafting high-performance toroidal transformers, employing advanced winding techniques to deliver exceptional reliability and efficiency tailored to the unique needs of diverse industries. The expertise of these toroidal transformer manufacturers in India ensures that each transformer meets stringent performance standards.

Resource: Read more

0 notes

Text

Transwind Technologies Pvt Ltd - Reliable Winding Solutions

We are an indigenous manufacturer of Transformer Coil Winding Machine. Since, 2012 our journey has been wonderful and today we standing as one of the major competitors in the industry. We manufacture a wide range of products from manual, semi-automatic to fully automatic machines.

• LV Foil Winding Machine

• HV Foil Winding Machine

• LV Strip Conductor Winding Machine

• HV Coil Winding Machine (Graded Layer / Full-width Paper Insulation)

• HV Coil Winding Machine (Semi-Automatic)

• Edge Winding Machine

• Core Winding Machine

• Bench Top Linear Winding Machines

• Toroidal Coil Winding Machine

• Lamination Core Cut to Length Line

• Special Purpose Machines

• Line Automation

With very well experienced manpower in the field of transformer winding machines and with all in house design capabilities both mechanical and Electrical, we can support on end to end solutions by offering cost-effective and Reliable winding solutions for your requirement with a strong after-sales support.

Visit our website: https://www.transwindtech.com/about-us.php

#transwindtechnologies#transformers#transformerwindingmachines#windingmachine#coilwindingmachine#foilwindingmachine#edgewinding#windingmachinemanufacturers#transwindtech

0 notes

Text

Sustainability in Coil Winding: Eco-Friendly Materials and Processes

As industries worldwide shift toward more sustainable operations, the coil winding sector is no exception. From electric motors to transformers, the demand for greener manufacturing practices is rising. Sustainability isn’t just a buzzword anymore—it’s a necessary direction for manufacturers who want to remain competitive and responsible.

So, how can the coil winding process go green? Let’s explore how eco-friendly materials, energy-efficient machinery, and forward-thinking companies are reshaping the industry.

Green Materials: Rethinking What Goes into a Coil

Traditionally, coil winding has relied on synthetic insulation materials and non-recyclable components. However, modern innovations are opening the door to biodegradable insulation, lead-free solder, and recyclable wire coatings.

Biodegradable varnishes and cellulose-based insulation papers are now viable alternatives to petroleum-based products. These materials reduce environmental impact without compromising on performance—a win-win for both manufacturers and the planet.

Additionally, companies are exploring copper alternatives such as aluminum, which is lighter and often more readily recyclable, though it requires special handling for efficiency and durability.

Energy-Efficient Machines: Cutting the Carbon Footprint

The sustainability conversation goes beyond just materials—it also involves the machines doing the work. Today’s coil winding machines are becoming smarter and greener.

Energy-efficient coil winding machines use optimized motor control, intelligent automation, and lower standby power consumption. These enhancements don’t just save electricity—they lower the overall carbon footprint of the manufacturing process.

Some systems even recycle thermal energy generated during winding, further minimizing waste. These machines not only help companies meet their environmental goals but also reduce operational costs over time.

Real-World Examples: Green in Action

Several manufacturers have taken sustainability from concept to reality. Take, for example, a mid-sized transformer company in Germany that replaced its entire insulation system with biodegradable materials. The result? A 25% reduction in landfill waste and recognition from an EU sustainability initiative.

Another case is an electric vehicle component maker in Japan that switched to energy-efficient winding systems and cut energy consumption by 30% over two years—without sacrificing production speed or quality.

These case studies show that going green doesn’t mean giving up performance—it means evolving smarter.

Regulations Driving Change

Governments and industry bodies are now pushing sustainability as more than a choice—it’s becoming regulatory. Across Europe, the RoHS (Restriction of Hazardous Substances) directive and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) require manufacturers to limit or eliminate harmful materials.

In North America and parts of Asia, similar policies are taking shape, encouraging cleaner energy use and more responsible materials handling. These trends are pushing coil winding companies to adopt eco-conscious practices, or risk falling behind in compliance and competitiveness.

Conclusion

Sustainability in coil winding is more than a passing trend—it’s a fundamental shift in how manufacturers think about materials, machines, and responsibility. From eco-friendly insulation to smarter machines, the industry is embracing solutions that protect the planet while improving efficiency.

At the forefront of this transformation, companies like ACME Electronics, a trusted Coil Winding Machine Manufacturer Supplier, are developing technologies that align performance with environmental responsibility.

As the world turns greener, is your coil winding operation ready to follow suit?

#coil winding machine#winding machine#coil winder#programmable winding machine#winding equipment#transformer winding machine#automatic winding machines#toroidal winding machine#cnc winding machine#toroidal winding machines#Coil Winding Machine Manufacturer Supplier

0 notes

Text

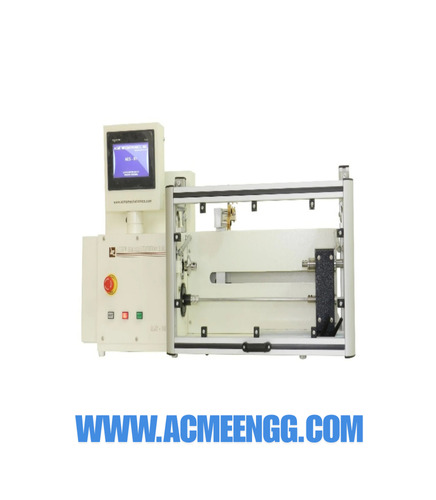

toroidal winding machine - ACME Mechatronics, Inc.

Acme offers high-quality toroidal winding machines designed for the precise production of CT (Current Transformer) coils and various other toroidal shapes. Our toroidal winding machine is built for accuracy, efficiency, and versatility, ensuring optimal winding performance for a range of applications, from transformers to inductors. With advanced technology and user-friendly features, these machines streamline the winding process, reducing errors and enhancing productivity. Ideal for industries requiring intricate coil designs, Acme's toroid winding machines can handle both small and large production runs with ease. Whether you need to produce CT coils or other toroidal products, our machines deliver exceptional results, ensuring high-quality, reliable outputs every time. Choose Acme for your toroidal winding machine needs and experience the difference in precision and efficiency.

0 notes

Text

Pioneering Advanced Magnetic Components and Specialized Machinery

Welcome to Avalon, the home of innovation and precision in magnetic components and specialized winding machinery. We offer a wide range of products and services, including: Toroid Hook Winders: Our state-of-the-art toroid hook winders improve the efficiency and accuracy of winding processes. Linear Traverse Winding Machines: Our machines ensure uniform distribution and precision in winding applications.

Vacuum/Pressure Impregnation Systems: Our advanced impregnation techniques enhance the durability and performance of components.

What Makes Avalon Unique

- Customization & Innovation: We provide customized solutions for your specific needs, from magnetic components to specialized machinery.

-Certified Quality: We have a UL 0BJY2 certified insulation system, which guarantees the highest standards of quality and reliability.

- Comprehensive Quality Processes: We follow established PPAP/FAI processes, which ensure every product and machine meets rigorous quality standards.

Your Partner in Magnetics and Machinery At Avalon, we strive to provide solutions that go beyond your expectations. Whether you need a standard product or a custom-designed machine, our goal is to deliver excellence.

Let's Connect and Collaborate! Interested in our magnetic components or specialized machinery? Connect with us here on LinkedIn or visit our website for more information. Together, let's drive innovation in your projects!

Avalon Technologies Limited Sienna Corporation Sienna ECAD Technologies Private Limited

#magnetics#magnetism#magneticfields#magneticart#magneticlashes#magneticpoetry#magneticjewelry#magneticnorth#magneticpaint#EMS#Electronic Manufacturing Services#AvalonTechnologies#Sienna#Electromagnetics

0 notes

Text

Coil Winding Machine Market Global Demand Analysis & Opportunity Outlook 2036

Research Nester’s recent market research analysis on “Coil Winding Machine Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitors analysis and a detailed overview of the global coil winding machine market in terms of market segmentation by operation, spindle number, machine type, end user, and by region.

Various Application of Coil Winding Machine to Promote Global Market Share of Coil Winding Machine

The global coil winding machine market is estimated to grow majorly on account of the higher adaptability of coil winding machines in various sectors, such as telecommunication, industrial, construction, aerospace, automotive, medical and others. Furthermore, the booming industrialization and emergence of the e-commerce sector, have increased the demand for consumer electronics. Therefore, to meet the demand for high production volume, the coil winding machines offer higher speed and automation

Besides this, with the advancement of technology, the need for smaller electrical devices has become crucial, slimmer phones, compact watches, and compact machines are becoming increasingly popular. The miniaturization of electronic devices has increased the demand for coil winding machines, thus expanding the market growth.

Some of the major growth factors and challenges that are associated with the growth of the global coil winding machine market are:

Growth Drivers:

Surging Need for Consumer Electronics

Rising Automation in Industries

Challenges:

Coiled winding machines are used in various industries and they should be capable of handling a large variety of materials, such as insulating materials, wire gauges, and others. Some winding machines are not compatible with all the materials and developing a machine that has compatibility with a wide range of materials can be a huge challenge for the growth of the coil winding machine market. On the other hand, while automation is a crucial driver, combining coil winding machines with current production procedures and systems of automation can be difficult and is a big impediment to market growth.

Request Report Sample@

Based on machine type, the global coil winding machine market is segmented into transformer, armature, and CNC linear/ toroidal. The transformer segment is to garner the highest revenue by the end of 2036 by growing at a significant CAGR over the forecast period. The rising deployment of new power grid lines and higher deployment of new solar and wind power plants has increased the demand for transformers and inductors.

By region, the market in Europe, amongst the market in all the other regions, is projected to hold a notable share by the end of 2036. The growth of the market in the region can be attributed majorly to the higher development of smart technologies and smart cities. Smart urban technologies have the potential to make a major difference in the long-term development of European cities. Around 75% of the EU population lives in cities, a number that is expanding as the global urbanization trend continues. The European Commission launched the European Innovation Partnership on Smart Cities and Communities (EIP SCC), which developed a smart cities stakeholder forum. Among other deliverables, an initiative of 110 cities and 93 industry partners developed inside the EIP SCC action cluster on Integrated Infrastructures and Processes.

This report also provides the existing competitive scenario of some of the key players of the global coil winding machine market which includes company profiling of Bestec CO., Ltd., Whitelegg Machines, Gorman Machine Corp., Micro Tool and Machines Ltd., Metar Machines, Shining Sun Enterprise, Wellyang Electronic Technology, B.M.P. & Equipment, BR Technologies, and Rieter Holding Ltd.

Access our detailed report at: https://www.researchnester.com/reports/coil-winding-machines-market/5234

0 notes

Text

Toroid Winding Machine

Enhance your manufacturing capabilities with our state-of-the-art toroid winding machine from Bridgeport Magnetics. Engineered for accuracy and durability, this machine supports a wide range of wire sizes and winding patterns, ensuring versatility for your projects. Our toroid winding machine is equipped with advanced features to automate and optimize the winding process, minimizing manual intervention and maximizing productivity. Trust Bridgeport Magnetics for reliable equipment that meets your specific needs. Discover more about our winding machines at Bridgeport Magnetics.

0 notes

Text

Unleashing Possibilities: The Art of Customizable Tape-Wrapped Coil Manufacturing

In the world of electromagnetics, tape-wrapped coils are vital components that find their application in various industries, from aerospace to telecommunications. The key to their versatility and efficiency lies in the hands of customizable tape-wrapped coil manufacturers. This article dives deep into the realm of these manufacturers, shedding light on their significance, the myriad applications of tape-wrapped coils, the manufacturing process, and the unparalleled ability to tailor these components to specific needs.

The Power of Customization

Customization is the hallmark of progress in technology, and tape-wrapped coil manufacturers are the enablers of this progress. These experts possess the unique skill of designing and producing tape-wrapped coils that can be tailored to meet precise requirements. Whether it's the size, shape, material composition, or electrical properties, customization empowers industries to innovate and achieve optimal performance in their applications.

Customizable tape-wrapped coil manufacturers partner with clients to understand their specific needs and challenges. By harnessing the power of customization, they ensure that their coils seamlessly integrate into a wide range of devices and systems, contributing to improved efficiency and functionality.

Versatile Applications

Tape-wrapped coils are versatile components that play a pivotal role in various sectors:

Aerospace: In aircraft, tape-wrapped coils are used in navigation systems, communication equipment, and avionics, contributing to safety and performance.

Telecommunications: The efficient transmission of signals in telecommunication networks heavily relies on tape-wrapped coils, enabling seamless connectivity.

Energy Sector: Tape-wrapped coils are found in power transformers, facilitating the transmission and distribution of electricity across the grid.

Automotive Industry: Electric vehicles benefit from tape-wrapped coils in motor control systems and battery management, enhancing their efficiency and reliability.

Medical Devices: Precision is paramount in medical equipment, and tape-wrapped coils are crucial in devices such as MRI machines and medical imaging systems.

The Manufacturing Process

Customizable tape-wrapped coil manufacturing involves a precise and methodical process. It begins with the selection of materials, including the choice of wire and tape insulation. These materials are carefully wound onto a core structure, which can be cylindrical or toroidal, depending on the application's requirements.

Manufacturers use advanced winding techniques, automated machinery, and computer-aided design (CAD) to ensure the consistency and accuracy of each coil. Rigorous testing and quality control measures are implemented to verify that the coils meet the desired electrical and mechanical specifications.

Tailoring Coils to Specific Needs

One of the defining features of customizable tape-wrapped coil manufacturers is their ability to tailor coils to meet precise specifications. This process begins with a comprehensive understanding of the client's requirements, including performance expectations, environmental conditions, and space constraints.

Manufacturers use their expertise in materials science, electromagnetic theory, and engineering to design coils that deliver optimal results. This can involve adjusting the number of turns, wire gauge, insulation materials, and even the physical shape of the coil to ensure it fits seamlessly into the client's application.

Driving Technological Advancements

Customizable tape-wrapped coil manufacturers are essential partners in driving technological advancements. They contribute to the development of cutting-edge devices, systems, and technologies. By tailoring coils to meet the evolving needs of industries such as renewable energy, telecommunications, and electric transportation, they play a pivotal role in enhancing the efficiency, reliability, and sustainability of modern technology.

For More Info:-

Custom Solenoid Coils

1st shift assembly jobs CT

Trusted Electro-magnetic Coil Manufacture

Part time and full time manufacturing positions

0 notes

Text

I am a spinster (lesbian) fulfilling a vital part of society by spinning thread (making transformers) at my spindle (toroidal winding machine).

On my 18th birthday (I was about 19) I pricked my finger on the needle (chopped off a small slice of fingertip with a guillotine) and fell into a magical sleep (had to lie down after first aid was administered).

0 notes