Text

A device and method for online vacuum degassing of aluminum liquid

Background technique

The gas element in the aluminum liquid is mainly hydrogen, and its content is generally greater than 0.35ml/100g. During the solidification process of the aluminum liquid, it precipitates and forms bubbles. Once captured by the solidification front, pinholes, pores, looseness, etc. will be formed in the ingot. Casting defects lead to scrapped ingots or subsequent processing defects. According to reports, casting waste caused directly or indirectly by excessive hydrogen concentration in liquid aluminum accounts for more than 40% of the total waste. As the application scope of aluminum alloy products becomes wider and wider, the attention to the internal structure of aluminum alloy ingots has become more and more important.

Tightness requirements are also getting higher and higher. Reducing the hydrogen content in molten aluminum plays an important role in improving the quality of aluminum alloy ingots. In order to reduce the hydrogen content in the aluminum liquid, domestic aluminum processing enterprises currently use a degassing device that rotates and sprays inert gas. This type of traditional rotating spray degassing device places a graphite rotor in the aluminum liquid in the launder system and sprays the inert gas through it. The rotating graphite rotor breaks the bubbles and forms small bubbles, which increases the contact area between the inert gas and the aluminum liquid and the bubble floating time. Since the hydrogen partial pressure of the inert bubble is low, the hydrogen atoms in the aluminum liquid form hydrogen molecules and enter the inert bubble. Within, the bubbles float up and are removed to achieve the purpose of hydrogen removal. However, when domestic enterprises produce high-end aluminum alloys, they still need to mix a small amount of toxic gas chlorine into the inert gas to ensure high degassing efficiency. This poses great safety hazards and environmental pollution risks, and the hydrogen content of the aluminum liquid after degassing mainly depends on The hydrogen concentration of the incoming aluminum liquid before degassing is unstable, and the degassing efficiency of the aluminum liquid is unstable. Therefore, the incoming aluminum liquid must be pretreated before online degassing, which increases the process cost and production cycle.

This online vacuum degassing device for aluminum liquid includes a vacuum furnace, a double-chamber tank and a vacuum pump; there are two depressions at the bottom of the vacuum furnace, which are connected to the liquid riser pipe and Downcomer; two recessed parts are provided with breathable bricks along the peripheral sides of the riser pipe and downcomer; an aluminum liquid flow tank inlet and an aluminum liquid flow tank outlet are respectively provided on both sides of the double-chamber tank; the middle part of the double-chamber tank A partition is provided, which separates the double-chamber tank into a liquid inlet tank and a liquid outlet tank;

The aluminum liquid level on one side of the riser pipe in the double-chamber tank is higher than that on the side of the downcomer; the vacuum furnace is set up in the double-chamber tank. and can move in the vertical direction. The riser pipe and the downcomer pipe extend into the liquid inlet tank and the liquid outlet tank respectively; the vacuum pump is arranged on the top of the vacuum furnace. The present invention separates the vacuum furnace from the double-chamber tank, adjusts the relative height and vacuum degree of the vacuum furnace to adjust the depth of the aluminum molten pool in the vacuum chamber, and controls the flow of aluminum liquid and degassing by injecting inert gas into the breathable bricks. Stable and efficient.

An online vacuum degassing device for aluminum liquid, which is characterized by: including a vacuum furnace, a double-chamber tank and a vacuum pump; the bottom of the vacuum furnace is provided with two recessed portions; the two recessed portions are respectively connected to the riser where the aluminum liquid flows into the vacuum furnace The liquid pipe and the aluminum liquid flow out of the downcomer of the vacuum furnace;

The two recessed parts are provided with breathable bricks along the peripheral sides of the riser pipe and the downcomer, and the breathable bricks are used to provide inert gas; the double chamber Both sides of the tank are respectively provided with an aluminum liquid flow tank inlet and an aluminum liquid flow tank outlet; in the double-chamber tank

A partition is provided at the bottom, and the partition divides the double-chamber tank into a liquid inlet tank and a liquid outlet tank; the height of the aluminum liquid level on one side of the riser tube in the double-chamber tank is higher than that of the aluminum liquid on one side of the downcomer. Liquid level height; the vacuum furnace is set up on the double-chamber tank and can move away from or close to the double-chamber tank in the vertical direction. The lower ends of the riser tube and the downcomer tube extend into the liquid inlet tank and the outlet port respectively. In the liquid tank; the vacuum pump is installed on the top of the vacuum furnace.

content

The purpose of this invention is to solve the problems of "unstable degassing effect" and "toxic chlorine gas sprayed when producing high-end aluminum alloys" existing in the existing aluminum liquid degassing technology, and to provide a stable and efficient online vacuum for aluminum liquid The purpose of the degassing device and method is to reduce the hydrogen content in the aluminum liquid before casting, thereby improving the internal structural quality of the aluminum alloy ingot.

In order to solve the above problems, the present invention adopts the following technical solutions:

An online vacuum degassing device for aluminum liquid, including a vacuum furnace, a double-chamber tank and a vacuum pump; the bottom of the vacuum furnace is provided with two recessed portions; the two recessed portions are respectively connected to the riser tube and the aluminum liquid flowing into the vacuum furnace. The liquid flows out of the downcomer of the vacuum furnace; the two recessed parts are provided with breathable bricks along the peripheral sides of the riser pipe and the downcomer, and the breathable bricks are used to provide inert gas;

Both sides of the double-chamber tank An aluminum liquid flow tank inlet and an aluminum liquid flow tank outlet are respectively provided.

The middle part of the double-chamber tank is provided with an The partition board separates the double-chamber tank into a liquid inlet tank and a liquid outlet tank; the height of the aluminum liquid level on one side of the riser pipe in the double-chamber tank is higher than the height of the aluminum liquid level on one side of the downcomer pipe. ; The vacuum furnace is set up on a double-chamber tank and can move in the vertical direction away from or close to the double-chamber tank. The lower ends of the riser tube and the downcomer tube respectively extend into the liquid inlet tank and the liquid outlet tank. The vacuum pump is arranged on the top of the vacuum furnace.

1 note

·

View note

Text

Ghana’s proven bauxite reserves surge

Chief Executive Officer of the Ghana Integrated Aluminum Development Corporation (GIADEC), Mr. Michael Ansah, has announced a significant increase in estimated bauxite resources in the Ashanti Nyinahin region.

Bauxite deposits at Hills 4, 5 and 6 have experienced a staggering 50% appreciation to at least 375 million metric tons (MMT), according to the latest published Mineral Resource Estimate (MRE) results.

Ansah highlighted the estimated bauxite reserves at 25 billion metric tons and expressed enthusiasm for the significant increase following the recent comprehensive review. He said the mineral resource estimate not only confirmed the increase in bauxite quantities but also validated the exceptional quality of the region’s bauxite resources.

“This discovery is a game-changer for Ghana’s mining industry. The updated estimates reflect the significant potential of the Ninahin region, making it a major player in the global bauxite market,” said Mr Ansah.

During a brief event at the Presidential Palace, where Mr Ansah formally presented the mineral resource estimates to President Akufo-Addo, he revealed that the Ghana Integrated Aluminum Development Company will be announcing a partnership with a prominent European company in the coming weeks. Strategic partnerships as part of ambitious growth plans.

This collaboration will facilitate the execution of Project 3A of the Integrated Aluminum Industry (IAI) project, specifically the “development of mines and construction of a refinery in Block C of Ninahin.”

The anticipation surrounding this partnership highlights the international significance of Ghana’s bauxite deposits and Ghana’s commitment to promoting global cooperation in the mining and refining industries.

Mr. Kwasi Osei Ofori, Chief Executive Officer of Rocksure International, also expressed optimism, stressing that the successful completion of the mineral resource estimate validates the President’s vision for Ghanaian companies to compete on a global scale.

“With enhanced data and increased reserves, we not only meet but exceed global standards. This is testament to the ability of Ghanaian companies to thrive and excel in the international mining sector.” Mr. Osei Ofori said.

The surge in bauxite valuations is expected to attract more attention from investors and stakeholders, making Ghana a major player in the global bauxite market and opening up new avenues for economic growth and development.

President Akufo-Addo has commended the Ghana Integrated Aluminum Development Company and its project partner Rocksure International for the successful completion of the mineral resource estimate for the Ninahin B Block, which includes Blocks 4, 5 and 6.

This development was recognized for its timeliness and is a key step towards achieving Ghana’s national goals of value addition in bauxite mining. The project, known as Project 2, is one of four initiatives under the IntegratAdtech was established in 2012, and the Chinese factory was put into production at the end of 2013.

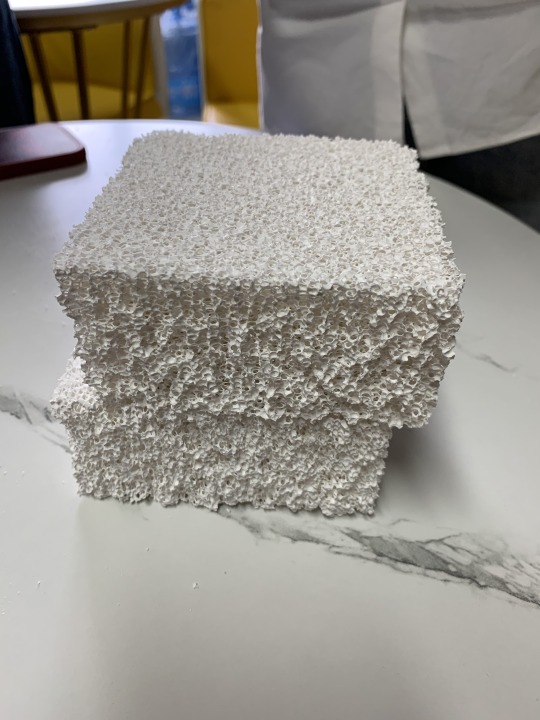

Adtech is focusing on the R & D and manufacturing of "online degassing filter equipment, ceramic filter plates, hot top casting accessories, casting nozzle plates, repair agents and solvents" international enterprise. The company has successively developed dozens of series of products, so far it has covered a full range of equipment, filtration and high-temperature materials required by the aluminum alloy casting industry. The main products of Adtech are:ceramic foam filter, degassing system

0 notes

Text

Alcoa considers closing Norway's Lista aluminum smelter completely

According to foreign media reports, due to rising electricity prices, international aluminum giant Alcoa is considering closing its Lista aluminum smelter in southern Norway.

Alcoa Energy Director Ole Lofsnaes wrote in a letter to the Norwegian Ministry of Petroleum and Energy: "The Lista aluminum smelter is still struggling to make a profit, although it will reduce some capacity in 2022 due to high electricity prices. Struggles, 2024 is expected to be a more difficult year. For this reason, Alcoa is now considering all possible future scenarios for the Lista aluminum smelter, with complete closure of the aluminum smelter being one of the scenarios being considered. " Last August, when electricity prices reached record highs, Alcoa reduced some capacity at its Lista aluminum smelter. In February this year, the company announced that it would reduce the factory's production capacity by 30% throughout 2023. Alcoa Energy Director Lofsnaes said it was crucial for the company to sign a new power supply agreement as soon as possible to protect it from high spot prices in the future. The Norwegian government plans to cut carbon dioxide offsets for industrial companies starting in 2024, which will also compound the problems at the Lista aluminum smelter. It is understood that Alcoa's Lista Aluminum Smelter in Norway has an annual primary aluminum production capacity of 94,000 tons and a total of three electrolytic aluminum production lines. One of the production lines was closed last year. Alcoa also operates an aluminum smelter in Mosjoen, northern Norway, with an annual production capacity of 200,000 tons of primary aluminum. Spot electricity prices in southwestern Norway have averaged €78.79/MWh so far this year, well below the 2022 average price of €211.28/MWh but still higher than the average price in northern Norway of €26.91/MWh.

Adtech company strives to build a diligent and studious, meticulous work, sincere service, Wenmin hard work, scientific operation, to create high-quality products; be a person first, then do things; social benefits and corporate benefits grow simultaneously; customer satisfaction, employees are happy, and sustainable development Harmony type enterprise. The main products of adtech areporous ceramic filter,cff filter. ceramic foundry filter . porous ceramic plate . ceramic filter plate . deep bed filter. deep bed filter aluminium.

ceramic foam filter, online degasser, launder system .tap out cone, caster tip ,etc. To learn more, please follow website:http://www.adtechamm.com/ Contact: [email protected]

1 note

·

View note

Text

deep bed filter for Aluminium

0 notes

Text

Minmetals Nonferrous Metals North China Aluminum Co., Ltd. made overall plans to weather the floods safely

Since July 29, affected by typhoon "Dusuri", the Beijing-Tianjin-Hebei region has continued to receive heavy rainfall. Due to factors such as extremely heavy rainfall and flooding of upstream rivers, the risk of waterlogging in Zhuozhou City, Hebei Province has intensified, and the flood control situation is very severe.

In this regard, Minmetals Nonferrous North China Aluminum Co., Ltd. (hereinafter referred to as North China Aluminum) Prevention and Rescue Headquarters responded quickly, "a game of chess" to build a safety barrier. During the heavy rainfall in the early stage, in order to ensure the safety of the project construction, cadres and employees added generator sets and multiple drainage pumps in the rain, dug through the cofferdam of the reservoir, and dug two gaps in the wall, which resolved the rainwater backfilling time and time again. Entry risk. At the same time, in response to the rapid rise in the water level caused by the flood discharge of the upstream river, the flood control team urgently filled more than 3,000 bags of flood control sandbags, built a flood control line, and strictly guarded against the flood. All the personnel involved in flood control and flood fighting performed their duties and fought day and night to ensure the safety of the company during the flood.

The normal discharge of rainwater from the storage tank is the key to flood control in the new material plant area of North China Aluminum. For this reason, the flood control personnel of the Ministry of Equipment and Energy carried out maintenance work overnight, entered the 8.5-meter-deep reservoir to disassemble and clean the pump, and fished out the sundries in the pool. After the one-time return installation, the water pump starts to run normally, which ensures the smooth drainage of the reservoir.

North China Aluminum Yinfa Company is responsible for inspecting and cleaning the flood discharge pool in the factory area. During the flood control period, large forklifts were used to dig trenches and divert water, and special personnel were sent to guard the work site, completing a diversion ditch about 100 meters long, 1 meter wide and 0.8 meters deep , Properly expand the capacity of the flood discharge pool, which has played a positive role in the drainage and flood discharge of the Hualv New Material Factory.

The danger intensified. The water level of the reservoir in the new material factory area of North China Aluminum was too high, and the accumulated water overflowed to the industrial road. The factory area faced the risk of rainwater backflow. The situation was critical, and the General Affairs Department quickly communicated and coordinated with the local municipal government to obtain support, and cooperated with the 22nd Metallurgy to mobilize large-scale excavating machines overnight to start operations, decisively opened up the cofferdam between the large and small reservoirs and the south and west walls, and achieved The accumulated water is discharged outside, eliminating the risk of rainwater intrusion.

Danger is an order. The manufacturing department organized more than 30 party members and cadres and backbones to rush to the designated area to participate in flood control work, filled more than 320 sandbags, reinforced and blocked more than 20 large and small doors, and 9 transformer ventilation holes; dispatched a commando team composed of 6 party members and backbones Go to the outside of Huabei Aluminum New Materials Factory to support the excavation of drainage ditches.

Zhuoshen Company organized party members, cadres, and employees to temporarily put down production tasks, and urgently filled sandbags at the west gate of the North China Aluminum Factory. The flood control commando was stationed in the factory, strengthened on-duty inspections, prepared for the timely evacuation of personnel in the event of floods, organized employees to fight against floods, and ensured a safe flood.

Under the strong leadership of the Minmetals Nonferrous Metals North China Aluminum Flood Control and Rescue Headquarters, the flood control team members charged forward and went all out to fight on the front line of flood fighting and rescue, and practical actions ensured the normal and stable production and operation of the company and project construction.

Adtech Metallurgical Materials Co., Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of Adtech :

porous ceramic filter,ceramic foam filter, ceramic filter plate, alumina ceramic foam filter,

degassing unit, degassing machine.

boron nitride coatings , refining flux , aluminum casting Flux.

launder system . flow control unit, tap out cone, caster tip, etc.

To learn more, please follow website: https://www.alalloycasting.com/

Contact: [email protected]

1 note

·

View note

Text

Guinea Alumina Corporation (GAC) initiates ecological restoration of two mining areas

June 27, 2023 The Guinea Alumina Corporation (GAC) announced today the launch of the Plateau Restoration Programs 20 and 26 in the Tanènè Center and Dambantchian districts of the rural communes of Tanènè, thereby creating an environment for local economic recovery while providing opportunities.

In 2022, GAC has restored 115 hectares of developed areas within its concession, using 93,629 seedlings from the Diyala Baca (15,000 plants), Sangaredi (35,000 plants), Belikindi (22,556 plants) and Beavogui (21,073 plants) nurseries at a total cost of 649,226,000 GNF .

The Guinea Alumina Corporation (GAC) extracts and exports bauxite, the ore from which aluminum is produced. It is a wholly owned subsidiary of Emirates Global Aluminum (EGA), headquartered in the United Arab Emirates. The company directly provides employment opportunities for more than 3,000 people, 95% of whom are Guinean nationals, and operates mining rights located in the northwest of the Republic of Guinea in West Africa. Once mined, the ore is transported by rail to the company's port facility in Kamsar on the country's Atlantic coast, before being shipped by sea to world markets. In 2022, GAC will produce 14 million tons of bauxite, pay more than US$63.8 million to Guinea's public finances, and make local purchases totaling more than US$146.9 million.

Adtech Metallurgical Materials Co., Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. Main products of Adtech :

deep bed filter,tubular filter equipment, alumina ceramic foam filter,degassing equipmenT.boron nitride coatings ,aluminum casting Flux.launder system . electric launder system .tap out cone,caster tip, etc.

#aluminumdegassing#aluminumfiltration#aluminumingot#aluminumprocessing#degassingunit#aluminum#aluminumfactory

1 note

·

View note

Text

Qinghai Province Investment Baihe Aluminum Industry has become one of the three enterprises approved to produce and sell "green aluminum" sheets with the largest production volume in China

On July 25th, the reporter learned from Qinghai Provincial Investment Group Co., Ltd. that in accordance with the relevant requirements of the group standard T/CNIA 0168-2022 "Evaluation and Trading Guidelines for Green Aluminum" jointly issued by the China Nonferrous Metals Industry Association and the China Nonferrous Metals Society, Baihe Aluminum Co., Ltd., a subsidiary of Qinghai Provincial Investment, completed the evaluation of green aluminum products and obtained the "Green Aluminum Product Evaluation Certificate" issued by the Green Product Evaluation Center of the China Nonferrous Metals Industry Association, We have officially become one of the participating enterprises in the national green aluminum evaluation, and at the same time, we have become one of the three largest aluminum production enterprises in China with a single production and sales volume of 30000 tons of "green aluminum".

In recent years, in order to successfully enter the carbon emission trading market, calmly deal with the carbon Emissions trading and "carbon tariff" mechanism, improve the added value of aluminum products, and help the electrolytic aluminum industry to achieve the "double carbon" goal, Qinghai Toubaihe Aluminum Industry has taken the initiative to connect with the Aluminum Industry Branch of China Nonferrous Metals Industry Association and the Green Power Aluminum Evaluation Center. According to the content requirements of the Guidelines for Green Power Aluminum Evaluation and Trading and the Implementation Rules for Green Power Aluminum Evaluation and Trading, We have conscientiously conducted system functional testing and green aluminum product evaluation work, passed the formal and substantive review of green aluminum evaluation, and successfully completed the green aluminum product evaluation. We have become a manufacturer labeled as "green aluminum", a participant in green aluminum evaluation, and a supplier of green aluminum products.

As the largest supplier of green and low-carbon aluminum in the northwest region, Qinghai Provincial Investment actively responds to the national "dual carbon" goals and major decisions and deployments such as clean and low-carbon energy transformation. It deeply carries out lean management, process optimization, equipment upgrading, quality and efficiency improvement, and strives to build a first-class green and low-carbon aluminum enterprise, making new contributions to promoting the construction of a clean energy industry highland in Qinghai Province.

Adtech is a seven series aluminum alloy and aluminum factory that provides one-stop filtration. It was established in 2012 and integrates production and sales. It has cooperated with multiple international aluminum factories to achieve excellent quality and high cost-effectiveness ceramic filter plate, casting filter, deep bed filtration, ceramic foundry filters .alumina ceramic foam filter, degassing unit, degassing machine,

boron nitride coatings, aluminum casting Flux. launder system . electric launder system.

tap out cone,caster tip are the main product.

1 note

·

View note

Text

Rio Tinto Group and Giampaolo Group establish a joint venture in the production of recycled aluminum

According to foreign media reports, Rio Tinto Group and North American comprehensive metal management company Giampaolo Group have reached an agreement to establish a joint venture dedicated to producing and selling recycled aluminum products, aimed at meeting the growing demand for low-carbon aluminum as a key material for energy transformation.

According to the terms of the agreement, Rio Tinto will acquire a 50% stake in Matalco, a wholly-owned subsidiary of Giampaolo Group, for $700 million.

Matalco is a manufacturer of recycled aluminum ingots and sheet ingots. The company operates six factories in the United States and one factory in Canada, with an annual production capacity of 900000 tons of recycled aluminum.

Triple M Metal, a subsidiary of Giampaolo Group, will be responsible for supplying recyclable materials to the joint venture, and Matalco's leadership team will continue to manage its operations. The joint venture partners will supervise Matalco's management team's strategic decisions (including executive appointments, safety, and ESG standards) through a board of directors with equal representation.

Rio Tinto will be responsible for the sales and marketing of Matalco products during the transition period after the transaction is completed.

The transaction still requires approval from regulatory authorities and is expected to be completed in the first half of 2024.

It is expected that by 2028, recycled aluminum will account for more than half of the aluminum demand in the United States.

Adtech is a seven series aluminum alloy and aluminum factory that provides one-stop filtration. It was established in 2012 and integrates production and sales. It has cooperated with multiple international aluminum factories to achieve excellent quality and high cost-effectiveness. porous ceramic filter, ceramic foam filter, ceramic filter plate, alumina ceramic foam filter,

degassing machine, degassing system, refining flux , aluminum casting Flux.

launder system . electric launder system, tap out cone,caster tip is the main product.

0 notes

Text

Chinalco International Trade Group achieved the first transaction of alumina futures

At 9 a.m. on June 19, the world's first physically delivered alumina futures was officially listed on the Shanghai Futures Exchange. The first transaction of the main contract AO2311 on the first day of listing was the seller of Chinalco International Trade Group Co., Ltd. Wei Chengwen, member of the party group and deputy general manager of Chinalco, delivered a speech on the spot.

Alumina futures is the first commodity futures listed on the Shanghai Futures Exchange since the promulgation and implementation of the "Futures and Derivatives Law" and the implementation of the registration system for the listing of new futures and options. The listing of alumina futures is an objective requirement to actively integrate into the national strategy, and it is also an important measure to actively serve the high-quality development of the aluminum industry. After the listing of alumina futures, alumina production enterprises and traders can hedge the price fluctuation risks of bauxite and alumina through futures, and electrolytic aluminum enterprises can lock in processing fees through alumina and electrolytic aluminum futures.

Chinalco International Trade Group, as the alumina trading platform of Chinalco, the world's largest alumina supplier, participates in the whole process and promotes the listing of alumina futures. Following the listing of aluminum standard warehouse receipts in 2018 and the first transaction of aluminum options listing in 2020, the first transaction of alumina futures listing was once again achieved. In the future, Chinalco International Trade Group will further take the listing of alumina futures as an opportunity to actively act and make unremitting efforts to promote the high-quality development of the aluminum industry trade market.

Adtech Metallurgical Materials Co., Ltd main products of Adtech :

porous ceramic filter, degassing unit, boron nitride coatings

launder system,tap out cone,caster tip, etc.

0 notes

Text

The 2023 semi-annual work summary meeting of Weiqiao's new energy vehicle business was held

On July 15, the 2023 semi-annual work summary meeting of Weiqiao's new energy vehicle business was held at the headquarters of Weiqiao Entrepreneurship Group. With the theme of "Consolidate the foundation, actual sales are the king, and the game will win", the meeting systematically reviewed the operating results of the group's new energy vehicle business segment in the first half of the year, summed up experience, checked for deficiencies, combined with the group's strategic planning and market competition environment, and clarified the business goals and work directions for the second half of the year.

During the meeting, Zhang Bo, Zhang Hongxia, Zhang Yanhong and other leaders of the group company listened to the report on the strategic planning of the new energy vehicle business. Weiqiao New Energy Vehicle Management Headquarters Central Research Institute and Comprehensive Management Center, BAIC Manufacturing Research Institute, Qingdao, Linyi, Dezhou, Huanghua production bases, 212 off-road vehicle team, Lingtu Automobile team, import and export company and lightweight product center made detailed reports on the work in their respective fields and the plan for the second half of the year. Lu Fujun, President of Weiqiao New Energy Vehicle Management Headquarters, made work arrangements from three aspects: clear strategy, strong execution, and result-oriented.

After carefully listening to the reports and exchanges of various units, Zhang Bo, chairman of the group company, made an important speech.

Zhang Bo emphasized that it is necessary to uphold the long-term principle, fully understand and grasp the strategic significance and development opportunities of the development of the new energy automobile industry, establish firm confidence and belief in victory, promote the construction of a modern industrial system with high-quality development of the manufacturing industry, and create more wealth for the society. It is necessary to strengthen the bottom-line thinking, enhance the ability to prevent and control risks, ensure the steady progress of the target planning of each stage of the new energy vehicle business sector, and strive to achieve a breakthrough against the trend. Zhang Bo scientifically analyzed the market competition pattern and the comparative advantages of Weiqiao's new energy vehicle business sector, and required the management headquarters and all units to focus on the core advantages of the group's entire industrial chain support, overseas strategic layout, and new material research and development, trade time for space, increase domestic and foreign market development efforts, innovate business models, do a good job in industrial platform construction, and strive to create a new industrial chain ecology. Maintain coordinated and efficient development, and continuously strengthen production management, market development and brand building. Zhang Bo pointed out that the key to entrepreneurship lies in people. All units should continue to strengthen the construction of talent teams, constantly enrich the talent teams of production management, scientific research innovation, market development, etc., select good people, use good people to manage good people, and be good at stimulating team vitality and cohesive team strength. Each core team should continue to study and understand the development history, industrial advantages and core culture of Weiqiao Entrepreneurship Group in depth, further boost the entrepreneurial spirit of the officers, and achieve a deeper integration with the group.

Lu Fujun, President of Weiqiao New Energy Vehicle Management Headquarters, made work arrangements

On the 14th, participants from Weiqiao's new energy vehicle business sector visited the enterprise exhibition hall, Zhang Shiping Memorial Hall, Weiqiao textile green intelligent chemical factory, Weiqiao lightweight base, 600KA electrolysis series production line and new material company, and fully understood the development of the two major industrial sectors of our group.

Adtech company strives to build a diligent and studious, meticulous work, sincere service, Wenmin hard work, scientific operation, to create high-quality products; be a person first, then do things; social benefits and corporate benefits grow simultaneously; customer satisfaction, employees are happy, and sustainable development Harmony type enterprise. The main products of adtech are porous ceramic filter,ceramic foam filter, deep bed filter,degassing unit, degassing machine.refining flux , aluminum casting Flux.launder system . tap out cone,caster tip, etc.To learn more, please follow website: http://www.adtechamm.com/ Contact: [email protected]

1 note

·

View note

Text

Zheng Shuwei, deputy general manager of Chinalco Logistics Group, and his entourage visited Yunnan Aluminum Logistics for investigation

From July 9th to 10th, Zheng Shuwei, the deputy general manager of Chinalco Logistics, He Jun, the person in charge of the information development center, and Liu Bei, the person in charge of the network freight platform, went to Yunnan Aluminum Logistics for research and guidance. Pu Xuetao, Secretary of the Party Committee and General Manager of Yunnan Aluminum Logistics, and heads of relevant departments accompanied the investigation.

At the research meeting, Zheng Shuwei listened to the person in charge of the relevant department of Yunallu Logistics about the overall situation of Yunalluminum Logistics' recent logistics and transportation, and conducted in-depth communication on the current network freight platform operation status, existing problems, and next-step work plans of Yunallu Logistics. Regarding how to further improve the management of the online freight platform in the future, he emphasized four points: first, we must strengthen our understanding of the operation of the online freight platform, sort out the existing management mechanism, road transportation, and business processes, and find out the problems in our own management; It is to strengthen the source management of the operation of the network freight platform, cultivate its own capacity pool, and improve the ability to actively control capacity resources; the third is to strengthen the management and control of the road transport process, strengthen communication with drivers, suppliers and other parties, and do a good job in all aspects of transport The fourth is to strengthen the supervision and inspection of the implementation of various systems, improve the supervision and inspection mechanism, clarify the responsibilities at all levels, avoid various potential risks in the network freight process, and contribute to the improvement of the overall management ability of the Chinalco Logistics network freight platform strength.

After the meeting, Zheng Shuwei and his entourage successively visited Nankun Railway Qidian Station and Qidian Railway Special Line, Logistics Park, Industry-Education Integration Base, FMCG Warehouse, Industrial Silicon Futures Delivery Warehouse, Grain Reserve Warehouse, etc. to conduct on-site investigations. During the survey, Zheng Shuwei fully affirmed the achievements of Yunalco Logistics in logistics management in recent years and the overall planning of the future logistics park. He pointed out that Yunnan Aluminum Logistics should give full play to the existing logistics location advantages, industrial advantages, special line foundation, transportation volume scale, storage resources, infrastructure, futures delivery warehouses and other existing advantages, strengthen cooperation with surrounding enterprises, and integrate surrounding logistics resources , on the basis of the existing logistics volume, actively expand socialized logistics business, increase the types of logistics transportation, and continuously improve market share and competitiveness; relying on Qidian Railway Freight Station, Nankun Railway, and China-Laos Railway Conditions, actively promote road-rail multimodal transport, and strive to build an influential logistics enterprise.

Adtech Metallurgical Materials Co., Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of Adtech :

honeycomb ceramic filter, ceramic foundry filters .alumina ceramic foam filter.

degassing system, degassing aluminum.

refining flux , aluminum casting Flux.

launder system . electric launder system . flow control unit,

tap out cone,caster tip, etc.

#aluminumdegassing#aluminumingot#aluminumfiltration#aluminumprocessing#aluminumfactory#degassingunit

0 notes

Text

Chinalco Shanxi New Materials Limestone Mine Division achieved the time task of "double over half"

In the first half of the year, Chinalco Shanxi New Materials Limestone Mine Business Department carefully organized production, cadres and employees worked together in the same direction, and carried out in-depth work such as all-factor benchmarking, quality improvement and efficiency enhancement. As of the end of June, the mine supply completed 52% of the annual plan; 58.8% of the annual plan target was achieved in terms of income and efficiency, and the production and operation task target of "positive year-on-year growth and more than half of the tasks" was successfully achieved.

In order to ensure the full completion of the target task of turning losses into profits for the whole year, the Limestone Mine Division has strengthened the production command centered on scheduling, focusing on the balance of mining and stripping, and reasonably equipped truck shovels by confirming the transportation distance and shovel loading conditions. At the same time, solidly carry out labor competitions in terms of output, cost, equipment, safety, etc., implement heavy rewards and punishments, and fully stimulate employees' enthusiasm for work. In the mining and stripping work area, through measures such as strengthening quality control, the subjective initiative of the repairing, posting, and point-checking employees was fully mobilized, and the comprehensive inspection of the gyratory crusher was completed in only 2 days. The overall efficiency of the equipment has been steadily improved, and the average daily raw ore production is 5,000 More than tons, creating favorable conditions for high production. Combined with activities such as "two belts and two innovations" and "creation of party members' value", we will report and comment on the work of party members' waste identification and rectification every month, establish a tracking account, grasp the work progress, pass on the pressure layer by layer, and strive to be a "reduced budget" This expert". As of the end of June, the 19 "waste identification and rectification" projects of the business unit had created a total of 210,000 yuan, effectively improving the ability and level of the party organization to integrate into the work of the center.

Adtech Metallurgical Materials Co., Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of Adtech :

,ceramic foam filter, ceramic filter plate, alumina ceramic foam filter,

degassing machine, degassing system.

boron nitride coatings , refining flux , aluminum casting Flux.

launder system . electric launder system . flow control unit,

tap out cone,caster tip, etc.

To learn more, please follow website: http://www.adtechamm.com/

Contact: [email protected]

1 note

·

View note

Text

Documentary of Yunal Aluminum Haixin's practice of green development

Paint the background of green, low-carbon and high-quality development with the attitude of struggle

——Yun Aluminum Haixin's practice of green development documentary

The report of the 20th National Congress of the Communist Party of China pointed out that it is necessary to accelerate the green transformation of the development mode, implement a comprehensive conservation strategy, develop green and low-carbon industries, advocate green consumption, and promote the formation of green and low-carbon production methods and lifestyles. This major strategic decision-making arrangement provides a fundamental basis for promoting the country to achieve the goal of carbon peaking and carbon neutrality.

As the vanguard of the green aluminum production capacity of Yunalco, Yunalco Haixin Aluminum Co., Ltd. (hereinafter referred to as Yunalco Haixin) has always been adhering to the development concept of "green water and green mountains are golden mountains and silver mountains", and "responsible Chinalco, green Haixin" "Incorporated into the whole process of the company's development planning, business decision-making and production activities, continuously increase the proportion of green and low-carbon development, deeply promote green manufacturing, build low-carbon factories, promote clean production, pursue energy saving and consumption reduction, strengthen technological innovation, and promote high-tech quality development.

Pollution reduction and carbon reduction: clean production has achieved remarkable results

Cleaner production plays an important role in promoting the synergy of pollution reduction and carbon reduction, and helping to achieve carbon peaking and carbon neutrality. In order to create a green production environment and reduce the pollution discharge of production water, so as to achieve the goal of driving high-quality development with a green engine, Yunaluminum Haixin has built a set of initial rainwater collection ponds with a daily processing capacity of 2,000 cubic meters to achieve preliminary of water treatment. In addition, Yunlu Haixin has also built two sets of domestic sewage treatment systems with a daily treatment capacity of 480 cubic meters and one set of production wastewater treatment systems with a daily treatment capacity of 250 cubic meters, further improving the rain and sewage diversion system inside the factory. The production wastewater treatment system adopts technologies such as multi-media filtration, ultrafiltration, reverse osmosis, and MVR evaporation and crystallization. Reuse of domestic water, plant greening, to achieve zero discharge of sewage.

In accordance with the construction requirements of the green hydropower aluminum processing integration project, Yunal Aluminum Haixin has also built 6 sets of flue gas purification systems and 40 sets of single-machine bag dust collection systems in the factory area. Through the use of alumina dry purification adsorption and semi-dry desulfurization technology , After the electrolytic flue gas is purified, the emission concentration is much higher than the national emission standard, and the pollutants are ultra-low emission. At the same time, Yunaluminum Haixin vigorously promotes the harmless disposal and resource utilization of hazardous waste. In July 2020, the carbon slag resource utilization system with an annual processing capacity of 7,000 tons will be completed and put into operation. It adopts non-secondary pollution treatment technology to realize the Recycling, reduction, and harmless utilization of hazardous waste. Since the start of the project, more than 19,000 tons of carbon slag have been processed, and the output value of recycled electrolyte with a purity greater than or equal to 98.0% has reached more than 9,000 tons. Low-emission low-carbon products are manufactured, and reliable, safe, green and environmentally friendly primary aluminum and aluminum alloy products are created.

Resource recycling: energy saving and consumption reduction

Under the guidance of the national "dual carbon" target policy, Yunal Aluminum Haixin gives full play to the leading role of science and technology, stimulates the internal power of green innovation, focuses on "energy saving, consumption reduction, pollution reduction, and efficiency improvement", and achieves low energy consumption and high efficiency through refined management , actively using the latest pollution reduction technology system, focusing on improving the quality of circulating water sources, through continuous improvement of energy consumption online monitoring system, online monitoring, and remote operation, intelligent water control is achieved, and the efficiency of recycled water is greatly improved. According to statistics, from 2021 to 2022, the water resource recycling rate of Yunnan Aluminum Haixin will reach 90%, effectively realizing zero discharge of sewage. In August 2022, the company was awarded the "Yunnan Provincial Water-saving Benchmarking Enterprise", and ranked first in the electrolytic aluminum industry with an outstanding water intake of 0.18 cubic meters per ton of aluminum, and ranked second overall.

Constrained by the "dual control" policy of energy consumption, Yunal Aluminum Haixin actively changed its development thinking, took the practice of ecological development, and built a green Haixin as the main line, carefully and meticulously managed from the source, and strictly controlled the output of energy consumption , by exploring the recovery and utilization of waste heat from electrolysis flue gas, recovering waste heat from the flue gas purification system, and heating cold water into hot water, it satisfies the use of office buildings, shift dormitories, canteens, heating, etc. in the factory area and living area to the greatest extent. While life is convenient, it also exerts great economy and applicability. In 2022, Yunaluminum Haixin will provide about 36,000 cubic meters of hot water throughout the year, the direct current power consumption per ton of aluminum will be reduced by about 68 kWh year-on-year, and the auxiliary power consumption per ton of aluminum will be reduced by about 120 kWh year-on-year. A solid foundation has been laid for achieving the goals of carbon peaking and carbon neutrality.

Green Technology: Technological innovation is becoming more and more perfect

Innovation promotes development, and technology leads the future. As a leading scientific and technological innovation enterprise in the electrolytic aluminum industry, Yunlu Haixin has always attached great importance to research and innovation in the field of project technology. Through government support and talent introduction, it has successively participated in the "Key Technology Research and Technology Project for Efficient Recycling of Aluminum Resources" "Development and application of 7,000 tons of carbon slag thermal treatment technology", "Research and development of aluminum electrolytic semi-dry desulfurization technology" and other projects have achieved phased technological breakthroughs, integrated multiple innovative technologies, and achieved great success in R&D, production, and quality control Several aspects have been effectively integrated with production and operation.

During the opening of the tank, due to process requirements, the tank cover door is frequently opened and closed, resulting in fugitive emissions. The fine particle dust cannot be absorbed through the desulfurization tower air duct in a timely and sufficient manner, and diffuses to the external space through the roof ventilator. In order to reduce the environmental impact caused by fugitive emissions, Yunaluminum Haixin adopts the advanced technology of micron-level dry fog dust suppression. By arranging dry-fog nozzles along the roof ventilator, it sprays micron-level dry fog with the same particle size as the dust The loose dust is condensed and collected, and its settlement is accelerated to achieve the purpose of dust suppression. After the system was put into operation, the dust suppression rate reached 90%. Compared with the start-up period of the first-phase electrolyzer of the project, the fugitive emissions in the factory area and the external environment have been significantly improved, greatly reducing the environmental risk during the start-up period.

In recent years, Yunaluminum Haixin has devoted itself to the research and development of new energy-saving equipment, and put it into trial operation at a 10 kV air compressor station. Through the comparison of one month's operation data, the electricity consumption of Yunallu Haixin has been reduced by about 10% compared with that before the equipment is used, which can save more than 3.8 million kWh of electricity every year. By comparing the use effect of motor power savers in benchmarking enterprises, the Yunlu Haixin R&D team boldly researched and tried to select suitable pilot sites to install power savers on 22 motors. After the test is up to standard, it will be promoted and used throughout the company.

The rise of green, the future can be expected. Green, low-carbon and sustainable development has become an important trend for Yunal Haixin to move towards high-quality development. In the future, under the guidance of the spirit of the 20th National Congress of the Communist Party of China, Yunal Haixin will actively fulfill the sacred duties of ecological civilization construction and ecological environment protection, continue to explore on the road of sustainable green development, and integrate the concept of green development into every production In the session, with the posture of struggle, we will paint the background of green, low-carbon and high-quality development, and write a new chapter in Haixin's green development for building the southwest base of Chinalco's aluminum industry worth 100 billion yuan.

Adtech Metallurgical Materials Co., Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, The main products of Adtech :

porous ceramic filter,ceramic foam filter, alumina ceramic foam filter,

degassing unit, degassing equipment.

boron nitride coatings ,granular flux, refining flux.

launder system ,flow control unit.

tap out cone,caster tip, etc.

#aluminumdegassing#porousceramicfilter#aluminumfiltration#aluminumingot#aluminumfactory#aluminumprocessing#aluminum

0 notes

Text

Dongxing Jiayu: The company's tough action has achieved phased results

Recently, Jiayu New Material Co., Ltd. has received frequent good news. Not only have all the business indicators completed the double goal of "more than half of the time and more than half of the tasks", but also achieved phased results in "improving quality and efficiency, and tackling key actions". The 42 measures were all pushed forward in accordance with the weekly report and monthly summary mode, and the tackling of key actions achieved good results.

Improve quality and efficiency

In terms of sales, the company actively researched and judged the prices of raw and auxiliary materials, adjusted the alloy procurement strategy in a timely manner, benchmarked against tables, and reduced procurement costs in a targeted manner. Through hard work, the company has saved 170% of the alloy procurement cost target from January to July, exceeding the full quota. The key goal of purchasing raw and auxiliary materials in 2019.

In terms of equipment transformation, at the beginning of the year, the goal was set for the energy consumption of the smelting furnace, and it was proposed to carry out one-to-two transformation of the smelting furnace. This equipment transformation is a bold attempt by the company to save energy costs. After repeated research and demonstration, a detailed and feasible plan has been formulated. The transformation plan was completed and put into production on June 26. The operation effect is good, and the electricity consumption can be saved by more than 30 degrees per ton of aluminum.

In terms of production efficiency improvement, in order to break through the problems of low production efficiency and few alloy varieties of traditional aluminum alloy casting and rolling, the company imported 6 pieces of KME B95 copper alloy roll sleeves for casting and rolling (specification Ø850×1700mm) from German Kaimei Company (KME) Conduct casting and rolling tests to increase casting and rolling speed and expand the production of alloy varieties. At present, in the high-speed casting and rolling test of 1100 alloy curtain wall products with copper roller sleeves, the casting and rolling speed has been stabilized at more than 2m/min, reaching 1.9-2 times that of ordinary steel rollers, and a breakthrough has been made.

In addition, the company reduced the company's average financing cost by 0.7% by strengthening internal fund management and control, improving the efficiency of fund use, rationally planning funds, refinancing loans in advance and delaying loan renewals, effectively saving financial costs. At the same time, increase efforts to broaden financing channels, inject fresh blood into the company's funds, coordinate bank credit enhancement, and successfully introduce Bank of Communications to cooperate with the company.

The company will continue to press stubble to promote the implementation of various measures to ensure the goal and tackle key actions, make greater contributions to the high-quality development of the aluminum industry, and submit satisfactory answers with excellent results.

Adtech was established in 2012, and the Chinese factory was put into production at the end of 2013. Adtech is an unremitting and enterprising brand pioneer, focusing on the R & D and manufacturing of "online degassing filter equipment, ceramic filter plates, hot top casting accessories, casting nozzle plates, repair agents and solvents" international enterprise. The company has successively developed dozens of series of products, so far it has covered a full range of equipment, filtration and high-temperature materials required by the aluminum alloy casting industry. The main products of Adtech are:

honeycomb ceramic filter .ceramic foundry filters, alumina ceramic foam filter.

degassing unit, degassing machine, degassing system.

granular flux, refining flux , aluminum casting Flux.

launder system . electric launder system . flow control unit,

tap out cone,caster tip, etc.

#aluminumdegassing#porousceramicfilter#degassingunit#aluminumfiltration#aluminumingot#aluminumprocessing#aluminumfactory

0 notes

Text

Chinalco Assets went to Zhongzhou Aluminum Plant to carry out special inspections

In order to thoroughly implement the relevant work requirements of the State-owned Assets Supervision and Administration Commission of the State Council and Chinalco on carrying out special rectification in the field of engineering construction, on June 12, a group of three from the second inspection team of Chinalco Assets went to the Administrative Management Department of Zhongzhou Aluminum Plant to carry out the "2023 Engineering Construction Field Special rectification and inspection” work.

The inspection team fully affirmed the development of the investment management work of Zhongzhou Aluminum Plant, and pointed out opinions and rectification suggestions for the problems and weaknesses found in the inspection. Through this special inspection, the level and risk control awareness of the investment management personnel of Zhongzhou Aluminum Plant in implementing law-based corporate governance and compliance operations and risk control has been further improved, and it has provided effective help for enterprises to prevent investment and operation risks.

A prerequisite for the manufacture of 7-series aluminum alloys is the manufacture of high-purity primary aluminum. AdTech has been focusing on providing a one-stop service for molten aluminum purification for many years. Our main products include degassing units, porous ceramic filters, deep bed filters, caster tips, tap cones, rotary degassing, aluminum, and more. Please email us via [email protected] if you need ceramic foam filters

#aluminumdegassing#aluminumingot#porousceramicfilter#degassingunit#aluminumprocessing#aluminumfactory#aluminumfiltration

0 notes

Text

Chalco Guangxi held a special working meeting on science and technology in June

On June 21, Chinalco Guangxi Branch and Pingguo Aluminum Co., Ltd. held a June science and technology special work meeting. Secretary of the Party Committee and General Manager of Guangxi Branch, Chairman of Guangxi Hualei New Materials Co., Ltd. Huang Weiping, Deputy Secretary of the Party Committee of Guangxi Branch, Chairman of the Labor Union, Deputy General Manager of Guangxi Hualei Xiong Lin, Chief Financial Officer of Guangxi Branch, Executive of Pingguo Aluminum Director Zheng Lihai, Deputy General Managers of Guangxi Branch He Haibo and Shi Jinjun, General Manager of Pingguo Aluminum Zhou Sports, Assistant General Manager of Guangxi Branch Zhang Zhongyun, Zhong Sheng, Chinalco Red Mud Comprehensive Utilization Technology Center and Guangxi Branch, Pingguo The heads of secondary units of the aluminum industry and relevant functional departments attended the meeting.

At the meeting, the Production Technology Department of Guangxi Branch summarized the development of scientific and technological work and the achievements of Guangxi Branch and Pingguo Aluminum since May, pointed out the existing problems and deficiencies, and reported the implementation plan of technological innovation, and proposed the next step Work plans and measures. The participants raised the difficulties and problems that need to be solved by the company's coordination, and made supplementary explanations on related matters.

The leaders attending the meeting focused on the overall coordination of scientific and technological work, determined the direction of scientific research work, increased the cultivation of scientific and technological personnel, prepared for next year's project declaration in advance, further optimized the work process and improved work efficiency, improved the intelligent construction project plan, and accelerated the scientific and technological project. Specific work requirements were put forward in terms of implementation progress, replication and promotion of good practices and experience.

Huang Weiping pointed out that scientific and technological work is an important way for enterprises to improve competitiveness, promote cost reduction and increase efficiency, improve employee working conditions, and improve labor productivity and management level. At present, the company has great potential to promote scientific and technological progress, and it is also very urgent. The main leaders of each unit must take the lead, and the leaders in charge must earnestly implement specific tasks.

Huang Weiping emphasized that, first, scientific research should be carried out in accordance with the project management method. It is necessary to set up a research group to implement batch and classified management, implement a project responsibility system, carry out classified evaluation and assessment, and grasp the scientific research work in a more detailed, deeper, and tighter manner. The second is to do a good job in the benefit accounting and evaluation of scientific research projects to ensure that the results of scientific research are objective and fair. The third is to prepare for the annual scientific and technological work conference. It is necessary to carefully summarize scientific and technological work, arrange and deploy the next step of work, commend and reward advanced individuals in scientific and technological work, and create a good atmosphere and work orientation for scientific and technological innovation. The fourth is to persist in scientific research with a scientific spirit. We must be serious, seek truth from facts, follow objective laws, respect science and talents, and guide specific scientific research activities with a scientific spirit; we must treat scientific research work with a tolerant attitude, protect the enthusiasm of scientific and technological workers, and encourage everyone to dare to think, do, and innovate; All units must maintain a good momentum, continue to do a good job in scientific and technological work, and make greater contributions to reducing costs and increasing efficiency for enterprises.

Adtech was established in 2012, and the Chinese factory was put into production at the end of 2013. Adtech is an unremitting and enterprising brand pioneer, focusing on the R & D and manufacturing of "online degassing filter equipment, ceramic filter plates, hot top casting accessories, casting nozzle plates, repair agents and solvents" international enterprise. The company has successively developed dozens of series of products, so far it has covered a full range of equipment, filtration and high-temperature materials required by the aluminum alloy casting industry. The main products of Adtech are:

porous ceramic filter, ceramic foam filter, ceramic filter plate, casting filt. alumina ceramic foam filter.

degassing unit, degassing machine.

boron nitride coatings , metallurgical flux.

launder system . electric launder system.

tap out cone,caster tip, etc.

#aluminumdegassing#degassingunit#aluminum#aluminumprocessing#aluminumfactory#aluminumingot#aluminumfiltration

0 notes

Text

【Expand the application of aluminum (116)】Aluminum can be used in transmission poles and towers

At present, most of my country's transmission towers are made of steel, which has been used for more than 200 years. However, the disadvantages of iron towers are that they are dense, heavy and inconvenient to transport. Especially in mountainous and plateau areas, transportation, installation and maintenance are difficult. It is laborious and must be maintained regularly, otherwise it will rust and even be damaged. But if the steel it uses is replaced by aluminum, it will be different. In the past, I was worried that the strength of aluminum was not high, but now it is not a problem to manufacture it with ultra-high-strength aluminum alloy. This alloy has a high enough strength that it is more than enough to make transmission and distribution towers, and it is fully capable.

The State Grid Corporation headquarters management science and technology project "High-strength aluminum alloy transmission tower design and processing technology and standardization research" led by China Electric Power Research Institute (hereinafter referred to as EPRI) passed the acceptance inspection. Conventional transmission towers are made of steel and must be hot-dip galvanized to prevent corrosion. However, galvanizing is not good for the environment. At the same time, the galvanized layer will fall off after a long time of use, and it is not easy to transport materials when erecting towers in rugged mountainous areas.

Therefore, the project team explored the use of high-strength aluminum alloy materials to replace traditional steel materials, carried out technical research and development of high-strength aluminum alloy materials in transmission towers, formed high-strength aluminum alloy tower raw materials, and realized the processing of tower materials without galvanizing and reducing the quality by nearly 45%.

The results of the project have passed the acceptance test in December 2022 and can be used for material selection, structural design and product processing of aluminum alloy transmission towers.

The Institute of Power Transmission and Distribution Engineering of the Chinese Academy of Sciences used the research results of the project to carry out the true type test of China's first self-supporting aluminum alloy pole tower. The test tower uses 7A21 and 7A41 high-strength aluminum alloy materials, and adopts the new YT section profile newly developed by the Electric Power Research Institute. The test tower is equipped with 60 strain measurement points and 12 displacement observation points, and the strain measurement and displacement observation of the important components, nodes and overall deformation of the aluminum alloy tower are carried out throughout the process. There are 6 working conditions in the test, and the overload test of the 90° windy condition is carried out. The test successfully verified the rationality of the design method and processing technology of the high-strength aluminum alloy tower.

The research team of the Chinese Academy of Sciences and other projects explored a new route for the application of high-strength aluminum alloy materials in power transmission self-supporting towers, and proposed new solutions to solve the problems of mountainous tower material transportation, galvanizing pollution and anti-corrosion maintenance, and promoted the tower industry in new material research and development, Technological progress in design, scientific research, processing, and construction.

7A21 and 7A41 alloys are Chinese brand alloys, and their original alloys are 7021 and 7041, which means that the composition and properties of 7A21 are equivalent to those of 7021 alloys, and the composition and properties of 7A41 alloys are equivalent to those of 7041 alloys. 7021 is an Al-Zn-Mg alloy, and 7041 is an Al-Zn-Mg-Cu alloy. According to the habits of the aluminum industry, they should be called super-strength alloys rather than high-strength aluminum alloys. 7021 alloy is an American alloy, registered in the Aluminum Association of America in 1976, its calibration composition (mass%): Si0.25, Fe0.40, Cu0.25, Mn0.10, Mg (1.2 ~ 1.8), Cr0 .05, Zn (5.0-6.0), Ti0.10, Zr (0.08-0.18), other impurities single 0.05, alloy 0.15, and the rest Al. 7041 alloy is a French alloy, registered in the American Aluminum Association in 2008, its calibration composition (mass%): Si0.15, Fe0.25, Cu (0.40-0.9), Mn0.04, Mg (1.5-2.3 ), Cr 0.04, Zn (5.7-6.7), Ti0.06, Zr (0.05-0.12), other impurities 0.05 individually, 0.15 in total, and the rest Al. This is a very clean alloy with very low content of impurities Si and Fe.

On January 12 this year, the world's Z tallest transmission tower with a height of 385 meters was successfully capped in Jiangsu. The iron tower is an important part of the 500 kV power transmission line project from Taizhou Fengcheng to Wuxi Meili. After the project is completed, about 28.9 billion kwh of clean electricity can be sent from the north bank of the Yangtze River to the south bank of the Yangtze River every year, meeting the needs of about 8 million households. daily electricity needs.

Adtech Metallurgical Materials Co., Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of Adtech :

porous ceramic filter, ceramic foam filter.

degassing unit, degassing equipment.

boron nitride coatings , metallurgical flux.

launder system . electric launder system .

tap out cone,caster tip, etc.

0 notes