Don't wanna be here? Send us removal request.

Text

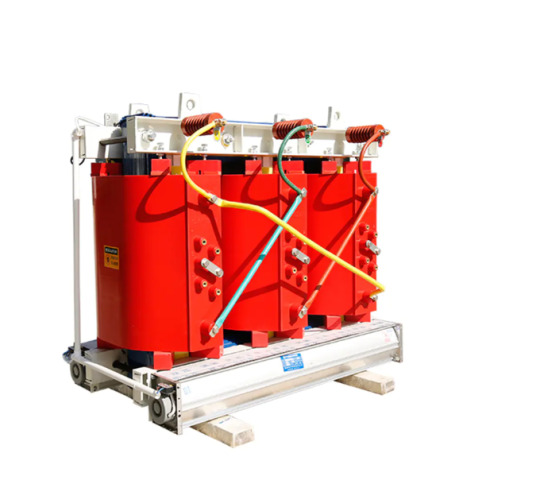

The Structural Characteristics Of Dry-Type Transformers

1. Safe, fireproof, non-polluting, and can be directly operated in the load center;

2. Using domestic advanced technology, it has high mechanical strength, strong short circuit resistance, small partial discharge, good thermal stability, high reliability, and long service life;

3. Low loss, low noise, obvious energy-saving effect, and maintenance-free;

4. Good heat dissipation performance, strong overload capacity, and can increase the capacity to operate when forced air cooling;

5. Good moisture-proof performance, suitable for operation in high humidity and other harsh environments;

6. Dry-type transformers can be equipped with perfect temperature detection and protection systems. The intelligent signal temperature control system is adopted, which can automatically detect and display the respective working temperature of the three-phase windings, can automatically start and stop the fan, and has function settings such as alarm and trip;

7. Small size, lightweight, less space occupation, and low installation cost.

0 notes

Text

The Structure Of The Toroidal Transformer

Iron core: The iron core of the toroidal transformer is produced by continuously rolling the oriented silicon steel strip with a fixed or variable width on the appropriate core, and annealing at high temperature to relieve the stress.

Since the orientation direction of the steel strip is consistent with the direction of the magnetic flux, the performance of the core material can be fully exerted by winding the iron core.

Winding: Copper wire, aluminum wire, and copper-clad aluminum wire can be wound by a winding machine. When winding, it is divided into primary and secondary, the primary is the input voltage, and the secondary is the output voltage/current.

Insulation: It is used for primary and secondary insulation, inter-turn insulation, iron core insulation, and insulation between shells. The materials used include various insulation forms such as cardboard, epoxy resin, and insulating tape, which can well protect the toroidal transformer from short circuits, open circuits, and other undesirable phenomena.

Working principle of toroidal transformer:

When an alternating current passes through the coil, an induced electromotive force is generated. When the voltage at both ends of the coil is equal, the generated electromotive force is the largest; otherwise, it is the smallest. In order to make the coil generate the maximum induced electromotive force, it is necessary to try to reduce the variation range of the magnetic flux, which requires changing the strength of the magnetic field distribution or adjusting the magnitude of the excitation current to control the inductive reactance and capacitive reactance of the coil.

Advantages of toroidal transformers:

Low standby energy consumption and lower no-load loss save more energy for standby;

High working efficiency, high energy conversion efficiency, and efficient green power supply.

There is no high-frequency electromagnetic radiation, and the power-frequency electric field and the power-frequency magnetic field generated by it have a completely negligible impact on the environment and the human body. It is a healthy power supply.

With good low-temperature characteristics, it can still start normally in an environment of minus 40 degrees, and work for a long time.

Small internal resistance, strong anti-interference ability, small size, and high cost-performance ratio when making high-power power supplies.

The electrical performance is excellent, and its electric strength and resistance to heat and humidity are much higher than the industry standard.

0 notes

Text

EI Transformer Chassis Mounting Transformer Electronic Transformer EI57 20VA

Classification: Power Transformer

Structure Classification: EI Iron-core Transformer

Sort by Phase Number: Single Phase Transformer

Input Voltage: 110V, 220V, 380V (customizable)

Output Voltage: 6V-220V (customizable)

Frequency: 50Hz/60Hz

Insulation Class: Class E-B-F-H

Features and Advantages:

Low Price

High saturation voltage

Long service life

Allow short time overload, can provide excess power or provide excess current (1-3 times rated current)

Application Areas:

TV power supply, monitor, switching power supply, navigation, medical equipment, instruments, air conditioners, flue-cured tobacco drying equipment, etc.

0 notes

Text

Toroidal transformers benefit the application by providing high electrical efficiency and less magnetic interference, small in size which also makes them absolutely light in weight.

0 notes

Text

What Is Auto Transformer

Auto Transformer is a laminated core transformer with only one winding on it. An Auto Transformer is similar to a two-winding transformer, but the primary and secondary windings are connected differently. Both the primary side and the secondary side share a portion of the winding. When the load is turned on, part of the load current is taken directly from the power supply, while the rest is obtained through transformer action. The voltage regulator is an Auto Transformer.

Advantages of Auto Transformer:

cheaper and more efficient;

There is less leakage inductance between primary and secondary, so there are fewer losses;

Simple construction for OEM;

Smaller footprint for the same VA rating.

The main purpose of an Auto Transformer is to adjust the voltage of the transmission line, which can be used to transform the voltage. The Auto Transformer has only one winding and can automatically adjust the voltage according to the load. These transformers require AC power to function properly and cannot use DC power.

Applications of Auto Transformer include:

Used as a starter, supplying up to 50 to 60% of the full voltage to the starter of squirrel cage induction motors during starting;

For small lifts on distribution cables to correct for voltage drops;

used as a voltage regulator;

It is used in power transmission and distribution systems, audio systems, railways, etc., and simply acts as a voltage converter.

0 notes

Text

Introduction To Dry Type Transformer

Like any other electronic device, the Dry Type Transformer is composed of various components to ensure the efficiency of its function. Although there are various types of transformers, Dry Type Transformers are the most commonly used as they have many advantages such as enhanced security, etc.

Dry Type Transformers, also known as cast resin transformers, are solid. That means it doesn't have any rotating parts. Because of this, these types of transformers maximize the use of environmentally friendly temperature insulation systems to function properly.

Unlike liquid-type transformers that rely on other materials such as oil and fire to function, the Dry Type Transformer works through voltage changes. Therefore, when handling these types of transformers, it is air, not other types of liquids, that is cooled. You can easily cool the coils by simply placing the Dry Type Transformer in a well-ventilated room.

With the Dry Type Transformer, you don't have to keep it inside a refractory vault or collection basin like you would with a traditional liquid transformer. In addition, they do not release any harmful gases and are therefore environmentally friendly, even when installed indoors.

0 notes

Text

Current Transformers (CTs) are used in medium voltage (MV) and high voltage (HV) installations to provide electrical output images for protection devices, relays, and metering instruments. They are configured to provide current in their secondary windings that are related to the current flowing in their primary windings.

0 notes

Text

The Role Of Voltage Transformers

A Voltage Transformer (VT for short, Potential Transformer for short PT) is similar to a transformer and is an instrument used to transform voltage.

A voltage transformer is an indispensable electrical appliance in power transmissions and power supply systems such as power plants and substations. A precision voltage transformer is an instrument used in the electrical testing laboratory to expand the quantity limit and measure voltage, power, and electric energy. Voltage transformers are very similar to transformers in that they are used to transform the voltage on the line.

Why do you need to change the voltage on the line? This is because according to the different conditions of power generation, transmission, and electricity consumption, the voltages on the lines are different in magnitude, and the difference is very different. Some are low-voltage 220V and 380V, and some are high-voltage tens of thousands of volts or even hundreds of thousands of volts. To directly measure these low-voltage and high-voltage voltages, it is necessary to make corresponding low-voltage and high-voltage voltmeters and other instruments and relays according to the size of the line voltage. This will not only bring great difficulties to the manufacture of the instrument, but more importantly, it is impossible to directly make a high-voltage instrument and measure the voltage directly on the high-voltage line, and it is absolutely not allowed.

0 notes

Text

Introduction Of Elevator Transformer

An elevator transformer is an electrical component used to control the lift, speed, and direction of an elevator, and its function is to convert electrical energy into mechanical energy.

It includes four parts: rectifier, filter, voltage regulator, and inverter. A large amount of electromagnetic energy will be generated during elevator operation. If this energy cannot be effectively converted into mechanical kinetic energy, energy will be wasted. The device that converts electrical energy into mechanical energy - the "transformer" is the equipment used to complete this conversion task.

A transformer is a common electrical device. It has a wide range of applications in both power equipment and various electronic equipment. In different application environments, the role of the transformer is also different. In the power system, the transformer is used for power transmission and transformation; in the circuit, the transformer is mainly used to increase or decrease the AC voltage, or to transform the impedance.

Widely used in lighting, machine tools electrical appliances, mechanical and electronic equipment, medical equipment, rectifiers, military, aerospace, etc. Product performance can meet various special requirements of users.

0 notes

Text

Benefits Of Dry-Type Transformer

Take Epoxy Resin Cast Dry-Type Transformer Power Supply Distribution Transformer 10kv 35kv for example, Epoxy Resin Cast Dry-Type Transformer Power Supply Distribution Transformer 10kv 35kv is a power transformer, and the type is a dry-type transformer. Dry-type transformers rely on air convection for cooling and are generally used for local lighting and electronic circuits. Dry-type transformers are widely used in local lighting, high-rise buildings, airports, terminal CNC machinery, equipment, etc. Simply speaking, dry-type transformers refer to transformers whose iron cores and windings are not immersed in insulating oil. Cooling methods are divided into natural air cooling (AN) and forced air cooling (AF). Under natural air cooling, the transformer can run continuously for a long time under the rated capacity. When forced air cooling, the output capacity of the transformer can be increased by 50%. It is suitable for intermittent overload operation or emergency accident overload operation; due to the large increase in load loss and impedance voltage during overload, it is in a non-economic operation state, so it should not be in continuous overload operation for a long time. The winding method is the high-voltage coil, low-voltage coil, frequency: 50Hz/60Hz, and the insulation level is FH.

Features and advantages include good overall rigidity, high mechanical strength, strong resistance to sudden short circuits, shock absorption and high impact performance.

0 notes

Text

Epoxy Resin Injection Dry-Type Transformer Development

As early as in the 70s Shanghai and Beijing transformer factory successively developed thick insulation with quartz powder filler in the vacuum state casting epoxy resin encapsulated dry-type transformers, from then on dry-type transformers in China officially become a batch supply of a new generation of products, although at that time it was replaced by the thin insulation technology of pure epoxy resin due to some problems in the material, manufacturing process, after all, it created a good start for dry-type transformers, promoting the development of dry-type transformer technology in China.

1 note

·

View note