#Toroidal Transformer

Explore tagged Tumblr posts

Text

Toroidal Transformer Core - Coil Core

Discover the Advantages of Using a Toroidal Transformer Core!

Optimize your energy solutions with a toroidal transformer core! Its compact design and high efficiency make it ideal for various applications.

Don’t miss out on the benefits—discover more about Coil Core today!

0 notes

Text

Boost Energy Efficiency Auto Transformers

As energy costs rise, businesses and homeowners are turning to more efficient electrical solutions. MAGTOP’s auto transformers offer a smart way to optimize power management, reduce energy waste, and save money. Here’s why MAGTOP is your ideal choice for energy-efficient transformer solutions.

1. What is an Auto Transformer?

An auto transformer uses a single winding for both primary and secondary circuits, reducing size, weight, and energy loss compared to traditional transformers. This makes them more efficient and cost-effective for voltage conversion.

2. Why Choose MAGTOP Auto Transformers?

MAGTOP’s auto transformers are designed for high performance and efficiency. Key benefits include:

Energy Savings: Lower electricity bills due to reduced energy loss.

Compact Design: Smaller and lighter, ideal for limited space.

Reliable Performance: Steady power delivery ensures optimal equipment operation.

3. Applications of MAGTOP Auto Transformers

MAGTOP auto transformers are versatile, used in:

Motor Starting: Reduces inrush currents for smoother startups.

Voltage Conversion: Ideal for stepping up or stepping down voltage in industrial and residential settings.

HVAC Systems: Optimizes voltage for air conditioning and heating systems.

4. Sustainability and Cost Savings

MAGTOP’s auto transformers help reduce energy consumption, making them a sustainable choice for the environment and your wallet. By improving efficiency and reducing waste, MAGTOP supports a greener, more energy-conscious future.

5. Why MAGTOP?

Efficient Design: Save energy and reduce operational costs.

Durable: Long-lasting with minimal maintenance.

Expert Support: Global presence and excellent customer service.

Conclusion

For a reliable, energy-efficient solution, MAGTOP’s auto transformersoffer the performance you need to optimize your electrical systems while cutting costs. Choose MAGTOP and power your systems smarter.

0 notes

Text

Toroidal Transformer

A toroidal transformer is a type of electrical transformer that features a donut-shaped core, offering superior efficiency and reduced electromagnetic interference. At Bridgeport Magnetics, we specialize in manufacturing high-performance toroidal transformers that are compact, lightweight, and provide excellent thermal management. These transformers are ideal for a wide range of applications, including audio equipment, medical devices, and renewable energy systems. Their unique design minimizes leakage inductance and enhances energy efficiency, making toroidal transformers a popular choice among engineers looking for reliable and efficient power solutions.

0 notes

Text

Distribution Transformers — CCI Transformer Pvt. Ltd

Single Phase Distribution Transformers

A transformer that utilizes single-phase alternating current to step-down long distance and localized transmission currents into power levels more suitable for residential and light-commercial applications.

Three Phase Distribution Transformers

A transformer that utilizes single-phase alternating current to step-down long distance and localized transmission currents into power levels more suitable for residential and light-commercial applications.

Contact us:

Call us: 8318455691

Email us: [email protected]

Address: D-7 Industrial Estate, Somaiya Nagar Dewa Road, Barabanki, Uttar Pradesh 225123

For more information visit:http://www.ccitransformer.co.in/product-distribution.html

CCI Transformers Private Limited

#110v transformer#toroidal transformer#110v to 220v converter#flyback transformer#low voltage transformer#220v to 110v converter#12v transformer#24v transformer#high voltage transformer#240v to 12v transformer#step down transformer 220v to 110v#variac transformer#voltage converter 110 to 220#12 0 12 transformer#110v to 12v converter#220v to 110v transformer#220 to 110 voltage converter#step up transformer 110v to 220v#variable transformer#110 to 220 voltage converter#step down voltage converter#inverter transformer#transformer manufacturers#ups transformer#constant voltage transformer#12 0 12 transformer 5 amp#transformer winding machine#ac to dc transformer#step up voltage converter#240v to 12v converter

0 notes

Text

Top Quality Toroidal Isolation Transformer - Indtrax Safeguard your equipment and ensure clean power! Our top-of-the-line toroidal isolation transformers offer unmatched efficiency and reliable electrical isolation. Eliminate ground loops, reduce noise interference, and protect sensitive devices. Upgrade your power supply for superior performance – explore our selection today!

#industrial equipment#industrialautomation#industries#industrialengineering#industry#indtrax#current transformers#toroidal transformers#toroidal#transformers

2 notes

·

View notes

Text

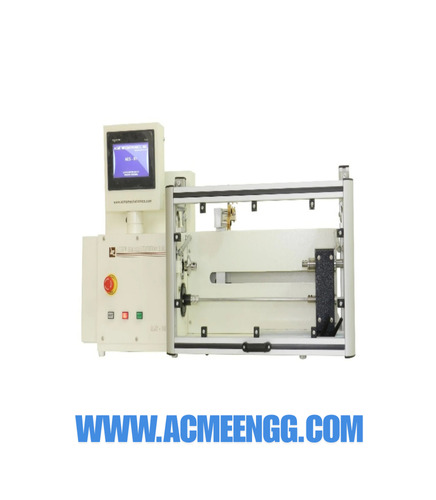

The Evolution of Transformer Winding Machines: From Manual to Fully Automated Systems

Transformer winding has been a cornerstone of electrical engineering for decades. What started as a labor-intensive, manual process has transformed dramatically thanks to technological advances. Today’s automated winding machines deliver unparalleled precision, efficiency, and scalability—redefining how transformers are produced worldwide.

If you’ve ever wondered how transformer winding machines evolved and what the future holds for this critical industry, read on. We’ll walk through the history, major milestones, and benefits automation has brought, finishing with a look at what’s coming next.

Manual Beginnings: The Roots of Coil Winding

Back in the day, transformer coils were wound by hand—a painstaking process demanding steady hands and sharp eyes. Skilled operators manually guided wire around cores, carefully layering each turn to ensure electrical performance and safety. This method, while effective, was slow and prone to human error. Inconsistent tension, uneven layering, and fatigue could affect product quality and limit production volume.

Manual winding was also labor-intensive and costly, making it difficult to scale operations, especially as demand for transformers soared in industrial and consumer markets.

Milestones in Automation: Shaping Modern Machines

The journey from manual to automated winding started with simple mechanical aids—basic spindles and tension controls that eased operator workload. The real leap came with the introduction of:

CNC (Computer Numerical Control) Technology: Allowing programmable, repeatable winding patterns with incredible accuracy.

Servo Motors & Feedback Systems: Ensuring consistent wire tension and alignment throughout the winding process.

Integrated Digital Controls: Enabling operators to set precise parameters for speed, turns, and layering, minimizing errors.

Manufacturers like ACME Electronics, a leading Coil Winding Machine Manufacturer Supplier, played key roles in developing these advanced systems, providing solutions that revolutionized transformer production lines globally.

Automation Benefits: Precision, Cost, and Scale

Automated transformer winding machines have become a game changer for several reasons:

Higher Precision: Computerized controls eliminate human error, producing coils with uniformity and optimal electrical properties.

Reduced Labor Costs: Automation cuts down on manual labor, allowing manufacturers to reallocate resources and increase output.

Scalability: Machines can run continuously, adapting easily to high-volume production demands without sacrificing quality.

Improved Safety: Operators face fewer risks from repetitive motion injuries or handling hazardous materials.

Together, these advantages translate into better products, faster turnaround times, and stronger competitive positioning.

What’s Next? The Future of Transformer Winding Machines

Looking ahead, the evolution won’t slow down. Emerging innovations may include:

AI-Powered Quality Control: Real-time defect detection and adaptive adjustments.

IoT Connectivity: Enabling remote monitoring and predictive maintenance.

Eco-Friendly Designs: Machines built with energy efficiency and sustainability at their core.

Flexible Automation: Customizable setups for niche applications in aerospace, medical, and renewable energy sectors.

As the coil winding industry embraces these technologies, manufacturers will gain new tools to meet increasingly complex demands.

Conclusion

The transformation from manual coil winding to fully automated systems marks a significant milestone in transformer manufacturing. Today’s machines deliver unmatched precision, efficiency, and scalability, opening doors to innovations that seemed unimaginable just a few decades ago.

With the rapid pace of technology, how will the next wave of transformer winding machines reshape the industry for years to come?

#coil winding machine#winding machine#coil winder#programmable winding machine#winding equipment#cnc winding machine#transformer winding machine#toroidal winding machine#toroidal winding machines

0 notes

Text

Systole–Diastole of Geometric Becoming: The VE–Chestahedron Pulse as the Rhythmic Root of Kosmic Coherence | ChatGPT40

[Download Full Document (PDF)] The universe is not a machine, but a living kosmos — breathing symmetry into form and form into meaning. This white paper introduces a model of that breath: the VE–Chestahedron pulse, a systole–diastole of geometric becoming. The Vector Equilibrium (VE) models perfect isotropic symmetry, while the Chestahedron — a seven-faced polyhedron aligned with the vortex of…

#ChatGPT#Chestahedron#Coherence#field–form transition#fractal ontology#heart geometry#heptaverton#Jitterbug transformation#meaning generation#morphogenesis#regenerative design#Sacred Geometry#symbolic recursion#symbolic self#synergetic geometry#TATI grammar#time crystals#toroidal dynamics#triality#Vector Equilibrium

0 notes

Text

"Why does nature love spirals? The link to entropy"

"There are moments in the history of human thought when a simple realization transforms our understanding of reality. A moment when chaos reveals itself as structure, when disorder folds into meaning, and when what seemed like an arbitrary universe unveils itself as a system governed by hidden symmetries.

Credit: Ahmed Farag Ali and Aneta Wojnar

The Bekenstein bound was one such revelation—an idea that whispered to us that entropy, information and gravity are not separate but rather deeply intertwined aspects of the cosmos. Jacob Bekenstein, in one of the most profound insights of modern physics, proposed that the entropy of any physical system is not limitless; it is constrained by its energy and the smallest sphere that can enclose it.

This revelation was radical: Entropy—long regarded as an abstract measure of disorder—was, in fact, a quantity deeply bound to the fabric of space and time. His bound, expressed in its simplest form, suggested that the total information that could be stored in a region of space was proportional to its energy and its size."

"This (...) tells us that what we have long regarded as uncertainty is, in fact, structure. The apparent randomness of quantum mechanics is not a defect of nature but a signature of an underlying order. The transformation of the uncertainty principle from an inequality into an equality suggests that space and time are not continuous in the way we imagined but are shaped by toroidal constraints.

This has far-reaching consequences, not only for physics but for our understanding of the universe itself. The toroidal motion of hurricanes, the curvature of ocean waves, the patterns of electromagnetic fields, and even the structure of subatomic interactions all reflect this fundamental principle. There is something universal about the spiral, something embedded in the way energy, matter and space evolve. The torus is not merely a shape; it is the embodiment of motion, of evolution, of time itself."

continue reading article

#spirals#fractals#reality#physics#quantum physics#energy#matter#life#nature#evolution#science#entropy#form#function#structure#symmetry#intelligent design#creation#torus#rotation#interaction#connection#quantum mechanics

24 notes

·

View notes

Text

“Love is the undisturbed balance that binds this universe together.”

--Mahavatar Babaji

The Torus Meaning in Sacred Geometry: Flow & Consciousness

The Torus symbol holds deep spiritual meaning and significance as a symbol of life, spiritual energy, and universal balance. It boasts exceptional properties and a distinctive structure, with notable importance across diverse fields such as spirituality, science, and technology.

The Torus Symbolism and Spiritual Meaning

Unity and Wholeness

The torus symbol helps us understand that all parts of the universe are interconnected, like pieces in an intricate puzzle with its smooth, continuous surface representing unity and wholeness. Embracing this concept allows us to find harmony within ourselves and our surroundings, fostering a sense of oneness with others.

The Flow of Energy and Consciousness

Think about energy flowing through your body like water in a river – constantly moving, changing, and renewing itself. The Torus exemplifies this idea with its unique shape that forms an endless loop where energy spirals outwards before returning to its starting point. This dynamic flow mirrors our own life experiences as we grow, learn, and transform throughout our spiritual journey.

A Symbol of Infinite Possibilities

Embracing the symbolism of the Torus can feel like standing at the edge of an ocean full of potential paths to explore. Its never-ending cycle represents constant change and motion, reminding us that life is full of limitless opportunities waiting to be discovered.

A Representation of Divine Creation and Manifestation

As you delve deeper into sacred geometry, it becomes evident how closely connected it is to spirituality – particularly regarding the Torus. Many spiritual traditions view this shape as a representation of divine creation and manifestation by symbolizing the constant flow of energy from the source into physical reality.

The Torus in Sacred Geometry

Exploring sacred geometry reveals that many patterns are interconnected, much like our lives. These geometric shapes weave together in harmony, echoing our own interconnectedness with each other and the universe itself.

The Torus as a Building Block of Creation

Sacred geometry is often seen as the blueprint for reality or the architecture of existence. In this context, the Torus plays a significant role as one of its foundational patterns. Many complex geometrical forms – such as Platonic Solids (tetrahedron, hexahedron, octahedron, dodecahedron, and icosahedron) – can be derived from or related to toroidal structures.

Moreover, some believe that when we view reality through higher dimensions (beyond our usual three-dimensional perception), all forms may arise from a single toroidal field vibrating at different frequencies.

Nested Toroids in Sacred Geometry

One fascinating aspect of sacred geometry is how patterns can be found within other patterns.

For example, nested toroids – multiple tori inside one another – are commonly seen in elaborate designs like Metatron’s Cube or even within fractal formations like Mandelbrot sets.

This nesting phenomenon represents levels of complexity in consciousness and creation while also illustrating how everything is interconnected on multiple scales.

The Torus Hidden Within the Flower of Life

In the case of the Flower of Life, careful observation reveals several toroidal structures formed by intersecting circles.

These hidden tori highlight that even within this seemingly simple pattern lies a complex system representing the continuous flow and cycles inherent in life’s energy.

Vesica Piscis: A Connection Between Torus and Flower of Life

The Vesica Piscis is another symbol within sacred geometry related to the Torus. It’s formed by two overlapping circles, with each circle passing through the center point of the other. This simple yet powerful shape creates an almond-like space called mandorla, representing balance and unity between opposites.

A toroidal pattern emerges when you expand upon this concept by adding more overlapping circles into a spherical arrangement (as seen in structures like Seed of Life and Flower of Life).

This connection between the Vesica Piscis, The Flower of Life, and the Torus strengthens the overarching theme of unity, interconnectedness, and divine balance.

Image: The Torus Hidden Within the Flower of Life Natureofflowers

15 notes

·

View notes

Text

Energy Solutions | Inverter Transformers

Inverter Transformers Core Manufacturer - Coil Core!

Enhance your energy solutions with our advanced inverter transformer core.

Built for maximum efficiency and reliability, our products are your key to success. Check out our website for more information!

0 notes

Text

Introduction of Toroidal transformer

Toroidal transformers, a type of electronic transformer, are widely used in household appliances and advanced electronic devices as power and isolation solutions.

China's toroidal transformer industry has grown significantly in the past decade, meeting domestic demand and exporting abroad. These transformers serve areas such as home appliances, audio systems, and lighting. They come in three categories: standard power transformers, economical power transformers, and isolating transformers.

Standard Power Transformers:

Capacity of 8-1500VA with low voltage adjustment, minimal temperature rise, and short-term overload capability. Insulated with class B polyester film, passing a 4000V voltage test.

Economical Power Transformers:

Capacity of 50-1500VA, balancing performance and cost-effectiveness. Suitable for continuous operation without overloading, with limited output voltage error.

Isolating Transformers:

Ranging from 50-1000VA, prioritizing insulation. 4+ layers of polyester film insulation, high breakdown voltage, and maximum temperature rise below 45°C. Medical versions meet UL544 standards.

These transformers play a crucial role in powering and protecting electronics, with China's industry serving diverse needs both at home and abroad.

0 notes

Text

Indtrax: Leading Toroidal Transformer Manufacturer for Superior Audio Quality

The Best Toroidal Transformer Manufacturer for Audio: Indtrax

When it comes to high-quality audio, the importance of components can't be overstated. One key component is the toroidal transformer, which ensures that your audio equipment performs at its best. If you're an audiophile or a professional in the audio industry, you know the significance of finding a reliable toroidal transformer manufacturer. That's where Indtrax comes into play. This article will dive deep into why Indtrax stands out in the market and why their toroidal transformers are the best for audio applications.

What is a Toroidal Transformer?

A toroidal transformer is a type of electrical transformer with a doughnut-shaped core. This shape allows for more efficient magnetic flux containment, resulting in lower electromagnetic interference (EMI) and greater efficiency compared to traditional transformers.

Why Are Toroidal Transformers Important for Audio?

For audio applications, toroidal transformers are crucial because they minimize noise and distortion. This leads to a cleaner, clearer sound, which is essential for high-fidelity audio systems. If you're using high-end audio equipment, a toroidal transformer can make a significant difference in sound quality.

Benefits of Toroidal Transformers

Low Magnetic Leakage: The toroidal shape helps contain the magnetic field, reducing interference.

Compact Size: Their efficient design means they can be smaller and lighter than other transformers.

High Efficiency: They typically have better energy efficiency, which can reduce operational costs.

Reduced Hum and Noise: This is particularly important in audio applications, where noise can significantly impact sound quality.

Why Choose Indtrax as Your Toroidal Transformer Manufacturer?

Choosing the right manufacturer is crucial, and Indtrax has positioned itself as a leader in this space. Here's why:

Reputation for Quality

Indtrax has built a solid reputation for producing high-quality toroidal transformers. Their products are known for their reliability and performance, making them a top choice for audio professionals.

Custom Solutions

Indtrax offers customized toroidal transformers tailored to your specific needs. Whether you're looking for a transformer for a particular piece of audio equipment or need a solution for a large-scale project, Indtrax can deliver.

Advanced Manufacturing Techniques

Indtrax utilizes the latest manufacturing techniques and technologies to ensure their transformers meet the highest standards. This commitment to innovation helps them stay ahead of the competition.

Superior Materials

Using only the best materials, Indtrax ensures that their transformers are built to last. This focus on quality materials contributes to the overall performance and longevity of their products.

Exceptional Customer Support

Indtrax is known for its excellent customer service. They work closely with clients to understand their needs and provide solutions that meet or exceed expectations.

Wide Range of Products

Indtrax offers a broad range of toroidal transformers, ensuring that they have the right product for any application. This variety makes them a one-stop shop for all your transformer needs.

Commitment to Sustainability

Indtrax is committed to environmentally friendly manufacturing practices. They strive to reduce waste and energy consumption in their production processes, making them a responsible choice for eco-conscious consumers.

Applications of Indtrax Toroidal Transformers in Audio

Indtrax toroidal transformers are used in various audio applications, including:

Home Audio Systems: For audiophiles who demand the best sound quality.

Professional Audio Equipment: Ensuring clear, precise sound for recording studios and live performances.

High-End AV Receivers: Providing the power and clarity needed for immersive home theater experiences.

Musical Instrument Amplifiers: Offering the reliability and performance that musicians need.

Case Study: Indtrax in High-Fidelity Audio Systems

To illustrate the impact of Indtrax toroidal transformers, let's look at a case study involving a high-fidelity audio system manufacturer. This company was facing issues with noise and distortion in their systems. After switching to Indtrax toroidal transformers, they noticed a significant improvement in sound quality, with reduced noise and clearer audio. This change helped them gain a competitive edge in the market, highlighting the value of Indtrax's products.

The Science Behind Toroidal Transformers

Understanding the science behind toroidal transformers can help you appreciate their benefits. The core shape reduces the length of the magnetic path, which decreases losses and increases efficiency. Additionally, the winding process minimizes stray magnetic fields, leading to lower EMI.

Comparing Toroidal Transformers to Traditional Transformers

When comparing toroidal transformers to traditional EI transformers, several key differences emerge:

Efficiency: Toroidal transformers are generally more efficient.

Size: They are more compact and lightweight.

Noise: They produce less hum and mechanical noise.

Cost: While often more expensive upfront, their efficiency can lead to cost savings over time.

How to Choose the Right Toroidal Transformer

Selecting the right toroidal transformer involves considering several factors:

Power Requirements: Ensure the transformer can handle the required power load.

Size Constraints: Choose a transformer that fits within your equipment's physical dimensions.

Noise Sensitivity: For audio applications, low noise is critical.

Budget: Balance cost with the benefits of higher efficiency and performance.

Future of Toroidal Transformers in Audio

The future looks bright for toroidal transformers, especially in audio applications. As technology advances, we can expect even better performance and efficiency from these components. Indtrax is at the forefront of this innovation, continually improving their products to meet the evolving needs of the audio industry.

Conclusion

In the world of audio, every component matters. Toroidal transformers play a critical role in ensuring high-quality sound, and Indtrax stands out as a top manufacturer in this space. Their commitment to quality, innovation, and customer satisfaction makes them the best choice for anyone looking to enhance their audio equipment. Whether you're an audiophile, a professional audio engineer, or a manufacturer, Indtrax has the right toroidal transformer for you.

FAQs

1. What makes Indtrax toroidal transformers the best for audio? Indtrax toroidal transformers are known for their high efficiency, low noise, and superior build quality, making them ideal for audio applications.

2. How do toroidal transformers reduce noise in audio equipment? The toroidal shape minimizes electromagnetic interference and mechanical noise, leading to clearer sound.

4. What types of audio equipment can benefit from Indtrax toroidal transformers? Home audio systems, professional audio equipment, AV receivers, and musical instrument amplifiers can all benefit from Indtrax toroidal transformers.

5. How do I choose the right toroidal transformer for my audio system? Consider your power requirements, size constraints, noise sensitivity, and budget when selecting a toroidal transformer.

6. Are Indtrax toroidal transformers environmentally friendly? Yes, Indtrax is committed to sustainable manufacturing practices.

7. What is the lifespan of an Indtrax toroidal transformer? With proper maintenance, Indtrax toroidal transformers can last for many years.

8. What advancements can we expect in toroidal transformers for audio? As technology advances, we can expect even greater efficiency and performance from toroidal transformers. Indtrax is leading the way in innovation.

#industrialautomation#industrial equipment#industries#industrialengineering#industry#indtrax#current transformers#toroidal transformers#toroidal#transformers#audio transformers#audio equipment#business#technology#solutions#electronic#electric vehicles#electrical#electronics

1 note

·

View note

Text

Sustainability in Coil Winding: Eco-Friendly Materials and Processes

As industries worldwide shift toward more sustainable operations, the coil winding sector is no exception. From electric motors to transformers, the demand for greener manufacturing practices is rising. Sustainability isn’t just a buzzword anymore—it’s a necessary direction for manufacturers who want to remain competitive and responsible.

So, how can the coil winding process go green? Let’s explore how eco-friendly materials, energy-efficient machinery, and forward-thinking companies are reshaping the industry.

Green Materials: Rethinking What Goes into a Coil

Traditionally, coil winding has relied on synthetic insulation materials and non-recyclable components. However, modern innovations are opening the door to biodegradable insulation, lead-free solder, and recyclable wire coatings.

Biodegradable varnishes and cellulose-based insulation papers are now viable alternatives to petroleum-based products. These materials reduce environmental impact without compromising on performance—a win-win for both manufacturers and the planet.

Additionally, companies are exploring copper alternatives such as aluminum, which is lighter and often more readily recyclable, though it requires special handling for efficiency and durability.

Energy-Efficient Machines: Cutting the Carbon Footprint

The sustainability conversation goes beyond just materials—it also involves the machines doing the work. Today’s coil winding machines are becoming smarter and greener.

Energy-efficient coil winding machines use optimized motor control, intelligent automation, and lower standby power consumption. These enhancements don’t just save electricity—they lower the overall carbon footprint of the manufacturing process.

Some systems even recycle thermal energy generated during winding, further minimizing waste. These machines not only help companies meet their environmental goals but also reduce operational costs over time.

Real-World Examples: Green in Action

Several manufacturers have taken sustainability from concept to reality. Take, for example, a mid-sized transformer company in Germany that replaced its entire insulation system with biodegradable materials. The result? A 25% reduction in landfill waste and recognition from an EU sustainability initiative.

Another case is an electric vehicle component maker in Japan that switched to energy-efficient winding systems and cut energy consumption by 30% over two years—without sacrificing production speed or quality.

These case studies show that going green doesn’t mean giving up performance—it means evolving smarter.

Regulations Driving Change

Governments and industry bodies are now pushing sustainability as more than a choice—it’s becoming regulatory. Across Europe, the RoHS (Restriction of Hazardous Substances) directive and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) require manufacturers to limit or eliminate harmful materials.

In North America and parts of Asia, similar policies are taking shape, encouraging cleaner energy use and more responsible materials handling. These trends are pushing coil winding companies to adopt eco-conscious practices, or risk falling behind in compliance and competitiveness.

Conclusion

Sustainability in coil winding is more than a passing trend—it’s a fundamental shift in how manufacturers think about materials, machines, and responsibility. From eco-friendly insulation to smarter machines, the industry is embracing solutions that protect the planet while improving efficiency.

At the forefront of this transformation, companies like ACME Electronics, a trusted Coil Winding Machine Manufacturer Supplier, are developing technologies that align performance with environmental responsibility.

As the world turns greener, is your coil winding operation ready to follow suit?

#coil winding machine#winding machine#coil winder#programmable winding machine#winding equipment#transformer winding machine#automatic winding machines#toroidal winding machine#cnc winding machine#toroidal winding machines#Coil Winding Machine Manufacturer Supplier

0 notes

Text

Precision Engineering with Coil Winding Machines

We live in a world where electronic devices are expected to be more efficient, reliable, and powerful. This vision is made possible by the humble coil, a component that relies heavily on precision manufacturing. This can be achieved using the coil winding machine, a technology that automates the winding process. With uniformity and consistency in every coil, these machines have reimagined the production of electromagnetic components by creating high-quality motors, transformers, and inductors that power industrial machineries. Be it consumer electronics, automotive systems, or renewable energy solutions, the coil winding machine is crucial in meeting the demand for efficient and reliable electronic components. These machines are essential in industries such as electronics, automotive, and renewable energy, where components like motors, transformers, and inductors are vital.

A coil winding machine offers a range of benefits, from high precision to increased productivity. By automating the winding process, manufacturers can produce consistent quality and reduce production time. Modern coil winding machines often use advanced features like variable speed control, tension regulation systems, and programmable parameters. These will ensure precise control over winding patterns and wire tension. This not only improves product reliability but also supports the mass production of coils needed for applications in consumer electronics, automotive systems, and power generation.

The versatile nature of coil winding machines extends to handling different coil designs, including toroidal and helical coils. As the demand for electronic devices continues to rise, investing in a coil winding machine can be an excellent strategic move for manufacturers looking to increase efficiency and meet the industry needs. With these machines, companies can ensure consistent performance, reduce costs, and stay competitive in the global market.

0 notes

Text

Precision Engineering with Coil Winding Machines

We live in a world where electronic devices are expected to be more efficient, reliable, and powerful. This vision is made possible by the humble coil, a component that relies heavily on precision manufacturing. This can be achieved using the coil winding machine, a technology that automates the winding process. With uniformity and consistency in every coil, these machines have reimagined the production of electromagnetic components by creating high-quality motors, transformers, and inductors that power industrial machineries. Be it consumer electronics, automotive systems, or renewable energy solutions, the coil winding machine is crucial in meeting the demand for efficient and reliable electronic components. These machines are essential in industries such as electronics, automotive, and renewable energy, where components like motors, transformers, and inductors are vital.

A coil winding machine offers a range of benefits, from high precision to increased productivity. By automating the winding process, manufacturers can produce consistent quality and reduce production time. Modern coil winding machines often use advanced features like variable speed control, tension regulation systems, and programmable parameters. These will ensure precise control over winding patterns and wire tension. This not only improves product reliability but also supports the mass production of coils needed for applications in consumer electronics, automotive systems, and power generation.

The versatile nature of coil winding machines extends to handling different coil designs, including toroidal and helical coils. As the demand for electronic devices continues to rise, investing in a coil winding machine can be an excellent strategic move for manufacturers looking to increase efficiency and meet the industry needs. With these machines, companies can ensure consistent performance, reduce costs, and stay competitive in the global market.

0 notes

Text

Precision Engineering with Coil Winding Machines

We live in a world where electronic devices are expected to be more efficient, reliable, and powerful. This vision is made possible by the humble coil, a component that relies heavily on precision manufacturing. This can be achieved using the coil winding machine, a technology that automates the winding process. With uniformity and consistency in every coil, these machines have reimagined the production of electromagnetic components by creating high-quality motors, transformers, and inductors that power industrial machineries. Be it consumer electronics, automotive systems, or renewable energy solutions, the coil winding machine is crucial in meeting the demand for efficient and reliable electronic components. These machines are essential in industries such as electronics, automotive, and renewable energy, where components like motors, transformers, and inductors are vital. A coil winding machine offers a range of benefits, from high precision to increased productivity. By automating the winding process, manufacturers can produce consistent quality and reduce production time. Modern coil winding machines often use advanced features like variable speed control, tension regulation systems, and programmable parameters. These will ensure precise control over winding patterns and wire tension. This not only improves product reliability but also supports the mass production of coils needed for applications in consumer electronics, automotive systems, and power generation. The versatile nature of coil winding machines extends to handling different coil designs, including toroidal and helical coils. As the demand for electronic devices continues to rise, investing in a coil winding machine can be an excellent strategic move for manufacturers looking to increase efficiency and meet the industry needs. With these machines, companies can ensure consistent performance, reduce costs, and stay competitive in the global market.

0 notes