Industrial designer and Masters by Research candidate developing transtibial cycling-specific prostheses through additive manufacturing

Don't wanna be here? Send us removal request.

Text

Previous experiments

Initially, several design concepts were generated from the data gathered during the "Problem Definition" phase and based on the analysis of literature in the field and the accounts of specialists. These concepts led to a preliminary “Experimentation” phase, where they were explored using 3D printing to ascertain their respective potential to be further refined and used in the later stages of the research.

For the designer-researcher to explore the possibilities offered by the technology, these concepts were split between aesthetic and functional characteristics. This entailed investigating the potential of developing both products (prosthetic parts such as sockets and feet) and processes (experiments with printing methods and printing optimisation). Experiments into 3D printing post-processing were also performed to assess if printed parts could benefit from thermal treatment to improve mechanical performance. Finally, in response to data obtained from the interviews with experts and amputees , the design concepts were reassessed, evaluated and re-organised in relation to participants��� inputs as crucial design criteria.

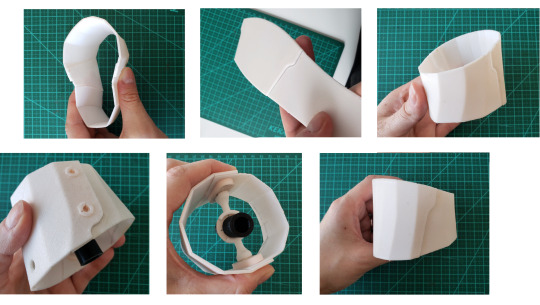

Rigid/ Flexible filament printing method

In this 3d printing method, the flexible and rigid materials are mixed to create hinges and joints that are more resilient, flexible and resistant to impact. The use of flexible material in the internal structure of the prosthetic limb also aims to act as a shock absorber.

The parts are designed to be printed "unfolded" on the printer bed and later assembled in an attempt to minimize printing time and post-processing.

"O"Foot/ Pedal connector

This concept consists in an adapted foot that functions as a regular foot for walking small distances and for support when the user is getting on and off the bike, and that allows the user to connect his prosthesis to the bike pedal, acting as a cycling shoe.

The foot is composed of two parts: the outer part, printed with rigid filament, in a "O" shape. This part was designed to function similarly to a C shaped prosthesis, in which the feet structure stores and returns energy; and the internal part, printed with flexible filament and designed to fit to the bicycle pedal.

The possibility of connecting the prosthetic leg to the pedal allows the user to have a similar power transmission to that of clip-in pedals, without the risk of losing balance when clipping in and off the bicycle.

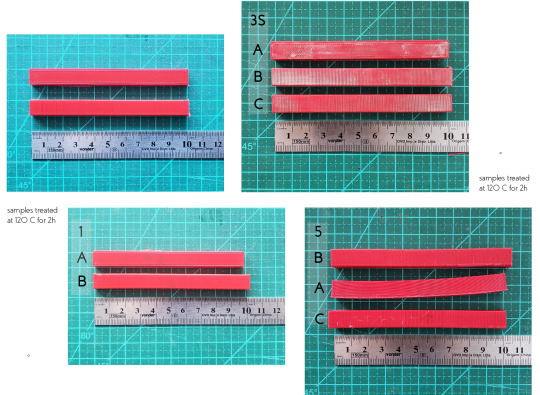

Post Processing

The objective of this study is to explore how Annealing, a heat treatment process used to increase the strength and ductility, affects 3d printed parts and can be used to enhance mechanical properties and change 3d printed parts' degree of crystallinity.

The way the filament is extruded during the printing process, heating and cooling quickly, causes the material's internal structure to reorganize itself in large crystals, becoming prone to retain stress and compromising the structural integrity and the strength of the piece. The parts can be annealed to rearrange the polymeric macromolecules to an ordered state.

Without access to the machinery needed to test heat resistance and impact strength, it is not possible to measure how the annealing process, and the change of the crystalline structure of the material, affects the mechanical properties of 3D printed parts.

However, using an electric oven, the researcher was able to assess how the thermal treatment can deform the parts' shape and if it was possible to minimize the warp effect.

0 notes

Text

Cycling-specific prosthesis - Case study

sketchfab

Despite the use of modern technologies in the prosthesis manufacturing process, the direct contact between the socket and residual limb can be a source of discomfort for its user, caused by the mutual pressure interaction between the prosthesis and the stump. In the previous studies of this research, pressure sensors were used to find and determine the pressure points between the socket and residual limb, adjusting the model to the user's body data and avoiding possible skin damage and pain. Having all prosthetic limb parts defined within Grasshopper scripts has the advantage of allowing straightforward adjustments of settings to meet the particular needs of an amputee in the design and production process.

The participant whose data was used as base for the prosthetic limb developed has a high degree of sensitivity on the bottom of their amputated limb, and the impacts coming from the prosthetic limb need to be redirected from the bottom of the stump to its front.

A 3D scan of the user's lower limbs was used to determine the measurements for the prosthetic limb through a process of mirroring. The socket is built from the 3D CAD model obtained by the 3D scanning of the user's residual limb using a Quantum FaroArm 3D Scanner. The scan was inserted into the script developed on Grasshopper and its settings adjusted (wall thickness, wall density, height and positioning on the scan).

0 notes

Text

Cycling Foot

https://sketchfab.com/models/40e9307579134b4ca92d5d773f2b9f07/embed

Modern cycling prostheses are designed to attach the socket directly through a pylon to the bike pedal cleat system, allowing efficient power transfer. However, using the cleat system can increase the risk of injuries, as it can be harder to disconnect the prosthesis from the pedal.

Observing a cycling prosthesis used by one of the participants of the project, it was possible to see clear signs of wear in the areas of the prosthetic foot that have contact with the ground when the user needs to walk or get on and off the bicycle.

The initial concept for the foot used replaceable football boot studs to support the part and protect the sole of the foot and the cleat from contact with the ground. These studs were later removed and replaced by 3D printed TPU parts.

The foot is a modular part that is attached to the pylon through an angular joint and mechanically retained through the cleat bolts to the pylon, preventing the piece from moving in any direction.

The foot is composed of three main parts: the sole, the toe/heel bumpers and the foot main body.

0 notes

Text

Patient-specific prosthetic socket

sketchfab

In this study, the researcher proposes a development process for the design and production of cycling patient-specific socket targeting transtibial amputees.

The socket is built from the 3D CAD model obtained by 3D scanning a user's residual limb. From this scan, it is possible to define the surface that creates the socket's shape and make sure that the final product generated respects the user's limb without creating interference that could lead to discomfort or injury.

The scan data forms the base from which the Parametric Design scripts using the software's Visual Programming Language are developed to set the product's key design parameters as a set of automatic steps. Using the external perimeter of the user's residual limb as the base surface a script was developed in Grasshopper to define the socket internal wall as an offset of the user's stump.

This project consists of the design of computational process to generate an adjustable socket using the amputee's body scan. In particular, it focuses on exploring the potential roles of parametric modelling in the design of the socket, using the user's body scan to determine the shape of the internal wall of the product, and force sensor inputs to change the density and flexibility of the material. This process significantly automates the socket measurement, making and adjustment process by replacing manual actions with a computational process that leads directly to a socket being 3D printed and tested.

Once the details and measurements are defined, the model then can be prepared for 3D printing.

1 note

·

View note