Don't wanna be here? Send us removal request.

Text

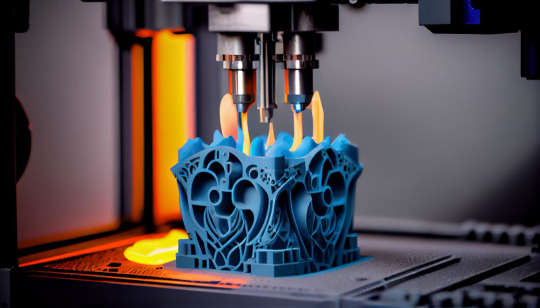

Fastest 3D Printing Methods You Must Know in 2025

In the fast-moving world of medical devices, speed isn’t just an advantage—it’s a necessity. By 2025, 3D printing has firmly established itself as the preferred method for rapid prototyping, enabling device manufacturers to accelerate design cycles and deliver precise, test-ready models faster than ever.

The surge in demand speaks volumes: over 40% of industrial 3D print jobs are now dedicated to medical device prototyping. This shift reflects an industry that no longer has room for slow iterations. With advancements in robotics, micro devices, and sensor technologies, the pressure is on to validate designs quickly and bring life-saving innovations to market without delay.

Why Fast Prototypes Matter

Traditionally, developing medical devices meant waiting months for the first CNC-cut test unit to come off the line. That timeline collapsed during the COVID-19 pandemic. Ventilator parts, swab guides, and face shields were designed, printed, and on the road in days instead of months.

Rapid prototyping services have become essential for medical device companies wanting to lead the field. Shorter design cycles help teams test more, gather user feedback sooner, and move more quickly through regulatory steps. When every hour counts for a life-saving product, picking the right 3D printing method matters a lot.

5 Fastest 3D Printing Technologies for Medical Prototypes in 2025

1. Stereolithography (SLA) – Still the Fastest

SLA remains the top choice for medical prototyping in 2025. The newest printers can make smooth, detailed parts in just 2 to 4 hours, depending on the design and size.

Key Advantages: Modern SLA systems can print at nearly 50 mm/hour and create surfaces so smooth that many parts do not need sanding or polishing. Biocompatible resins are widely available, and the printers maintain accuracy within ±0.1 mm, vital for devices that must fit together and work perfectly.

Best Applications: SLA is ideal for surgical guides, dental models, hearing aid shells, and detailed anatomical models used in surgical planning.

2. Carbon DLS (Digital Light Synthesis) – Super Fast, Super Strong

Carbon DLS prototyping revolutionizes additive manufacturing. By using continuous liquid interface production (CLIP), it trades the slow layer-by-layer method for a continuous flow, letting parts form 25 to 100 times faster than before.

Since its launch, Carbon DLS has become the standard for the medical device sector. Giants like Johnson & Johnson and Riddell trust it for critical components. Fast production counts, but strength and reliability do too, and Carbon DLS excels at both. That makes it ideal for medical prototypes that must move straight from the printer to the clinic.

Performance Numbers: Carbon DLS speeds can top 100 mm/hour while still meeting production-grade material specs. Parts emerge with smooth surfaces and zero layer lines. Plus, you can choose FDA-approved resins, so you’re ready from the start.

Best Application Areas: Carbon DLS shines in functional prosthetics, orthopedic implants, surgical tools, and wearable medical devices.

3. Multi Jet Fusion (MJF) – High-Speed Batch Production

HP’s Multi Jet Fusion is built to boost prototype output fast.

It prints entire batches of medical devices at once by using inkjet heads to spray fusing and detailing agents onto a powder bed. This fast process produces strong and reliable parts without compromise.

Designed for production, MJF also fits the fast design loops that medical device R&D squads depend on. With the same printer, you can move from a handful of prototypes to hundreds of final parts in one go. The process produces tight tolerances and excellent mechanical strength, meeting the needs of devices that must perform under real conditions.

Key Benefits: HP’s Multi Jet Fusion technology combines speed and scale without the need for support structures. Parts have uniform mechanical properties in every direction, making them ideal for quick iterations and larger production runs without raising costs.

Ideal Applications: Enclosures for medical devices, complex internal mechanisms, and high-volume batches of functional prototypes for testing.

4. Selective Laser Sintering (SLS) - Fast and Flexible

SLS is still the top choice for early-stage medical device prototypes. It offers a large range of biocompatible powders and makes it easy to build complex geometries without the hassle of support materials. Latest laser upgrades and better powder-handling methods have pushed the build speed even higher.

Key Benefits: SLS can create detailed internal geometries and hollow channels while running without support. The latest advancements speed up layer times and powder recovery without sacrificing quality, keeping SLS a proven choice for medical applications.

Best Uses: Brokering complex assemblies, designing moving parts, and making devices that combine several material properties.

5. PolyJet Technology - Multi-Material Potential

PolyJet 3D printing excels when a prototype must show several materials, hardness levels, or colors in one part. The printer can jet rigid and flexible resins simultaneously, producing prototypes that look and feel just like the final device.

Strengths: The ability to mix materials in a single build cycle leads to smooth surfaces and tight tolerances. With a wide library of resins, PolyJet is ideal for prototypes that require realistic function and finish right off the printer.

Applications: This is an excellent fit for devices that need soft outer skins and rigid inner frames, for components that flex and hold their shape, and for medical touch controls that respond to gentle swipes.

Design for Additive Manufacturing (DfAM) in Medical Applications

Come 2025, Design for Additive Manufacturing (DfAM) is even more intuitive. AI-driven design platforms coach engineers to refine prototypes so they print quicker and shine brighter. Learning DfAM rules is the first step to unlocking the full power of next-generation printers.

Core DfAM Rules for Medical Devices

Geometric Optimization: 3D printing opens doors for shapes that dies and molds can’t achieve. We can craft featherweight lattice scaffolds, smooth-curved cooling ducts in surgical handpieces, and winding fluid channels all in one build.

Material Considerations: Each printing process offers a unique set of material behaviors. DfAM steers teams to the right resin, metal, or polymer and lets them design features that leverage that material’s greatest strengths, while still meeting medical standards and ensuring biocompatibility.

Support Structure Minimization: New DfAM strategies enable engineers to cut down or completely eliminate scaffolding. That’s transformative for devices with delicate inner cavities or thin walls that risk damage when supports come off.

Cost of Rapid 3D Printing for Medical Prototypes

Understanding the cost structure of the latest 3D printing methods helps med-device companies select the best path for prototypes. In 2025, here’s how the numbers now line up.

SLA Printing Costs: Resin now runs between $150 and $300 per kilogram. When you add overhead and print time, most prototypes land between $25 and $150 each. Setup still takes about 30 to 60 minutes.

Carbon DLS Prototyping Costs: Resin for this approach is pricier, at $200 to $400 per kilogram. Still, finished parts usually run $50 to $200 each. The lower cost comes from a faster finishing workflow that trims labor time.

MJF Printing Costs: Nylon powder sits at $80 to $150 per kilogram. This method pays off for medium-to-large batches, bringing per-part costs down when you run several prototypes at once.

Don’t forget TCO. Include post-processing, inspection, and how fast you can pivot a design. Technologies that print faster can outweigh higher material costs by shrinking the product timeline and getting devices to market sooner.

How to Get Started with Medical Device Rapid Prototyping

Starting in medical device prototyping requires smart planning and the right team. Follow these steps, and you’ll be on the right path:

1. Define Requirements

Begin by writing down the key needs for your prototype:

The device’s intended function and the performance benchmarks it must hit

Biocompatibility and regulatory guidelines must be satisfied

A clear timeline and budget that you can stick to

Testing and validation phases, including when each will happen

2. Technology Selection

Choose the best 3D printing method based on these factors:

The complexity of the part geometry

The material properties and biocompatibility you demand

The number of prototypes you want and how quickly you want to change them

The surface finish and size accuracy are non-negotiable

3. Partner Selection

Pick a rapid prototyping firm by checking:

Their available technologies and machines

Their experience with medical devices and necessary certifications

Their quality management systems and how they align with regulatory needs

Their lead times and whether they can meet your volume

Top Providers of Medical Device Rapid Prototyping in 2025

In 2025, these firms are leading the way in speed and reliability for medical device prototypes:

MediPrint Prototypes: Known for biocompatible polymers and quick iteration cycles.

ExactMed Solutions: Offers a full suite of certifications and a wide material library.

3DMed Labs: Specializes in complex geometries and precision finishing.

RapidMed Partners: Strong in low-volume production and regulatory filing support.

ProtoMed Dynamics: Combines metal and polymer printing for hybrid prototypes.

Choose a provider that lines up with your project needs, and you’ll have the support to turn your idea into a working prototype.

As of 2025, the medical device prototyping market features several leading companies known for customised support:

APRIOS continues to set the standard by combining the latest 3D printing technology with years of medical device know-how. They offer complete service, from refining the initial design and picking the best materials to steering you through the regulatory maze.

Carbon remains the leader in DLS printing, providing advanced printers and direct support for prototype development. Their deep materials expertise and ability to transition to full-scale production make them the partner of choice for parts that must match the final product’s performance.

Stratasys delivers a comprehensive suite of PolyJet and FDM printers made specifically for the medical field. Their FDA-cleared resins and extensive library of biocompatibility documents streamline the compliance process from the start.

EOS supports the market with durable SLS and SLM systems that use certified medical-grade powders, making them the top choice for metal implants and customized surgical tools.

Why APRIOS Stands Out for Medical Device Prototyping

APRIOS is the trusted source for medical device companies that require quick, accurate prototypes in a single pass. Their experts understand every phase of the product lifecycle, from the first design sketch to the final FDA documentation checklist.

Why Choose APRIOS? APRIOS merges SLA, SLS, MJF, and Carbon DLS into one smooth process, supported by a crew fluent in engineering and regulatory speak. Their ISO 13485 quality system keeps the pace fast, runs on-time shipping promises, and carves out design changes using DfAM smarts.

Whether you’re a fresh startup designing your first implant or a major OEM launching the latest diagnostic system, APRIOS is the trusted partner that turns bench ideas into clinical-ready prototypes.

Future Trends in Medical Device 3D Printing

By 2025, several exciting trends will change how we prototype medical devices:

AI-Driven Design Tweaks: Smart machine-learning programs are now adjusting 3D-printing designs on the fly, reducing the number of trial-and-error loops and making it much more likely that the first print will work perfectly.

Green Materials: Biopolymer filaments and photopolymers that come from renewable resources, along with fully recyclable powders, are fast becoming the standard. These help medical companies meet sustainability targets while still delivering safe, high-performance components.

Hybrid Manufacturing: Combining 3D printing with injection molding and CNC machining allows engineers to create prototypes that look, feel, and perform like the finished device. These parts are still easy to change, making iterative testing quicker.

Real-Time Quality Checks: New sensors, cameras, and AI algorithms monitor every single layer as it prints, spotting defects the moment they happen. This means less wasted material and fewer costly reprints.

Conclusion

In 2025, medical device prototyping stands ready for dramatic leaps. Breakthrough platforms like Carbon DLS, the latest SLA printers, and Multi Jet Fusion have pushed the limits of speed, precision, and functional performance, empowering innovators to turn ideas into on-the-bench prototypes faster than ever.

Success now hinges on more than the fastest machine. Device developers must balance materials science, clever geometry, regulatory insight, and scalable production strategy. By collaborating with partners like APRIOS and embedding Design for Additive Manufacturing from day one, teams can compress the schedule while protecting quality and compliance.

As the technology landscape keeps evolving, early adopters of these advanced printers and proven workflows will be the first to place life-saving devices into the hands of clinicians and patients. The future of healthcare depends on our ability to prototype, test, and refine with unprecedented speed, and the 3D printing solutions of 2025 have already brought that future into the present.

FAQs

1. What is the fastest 3D printing method for medical prototypes in 2025? The fastest method is Carbon DLS (Digital Light Synthesis), which uses a continuous printing process to produce strong, high-quality parts up to 100 mm/hour. It's ideal for functional, clinic-ready medical prototypes.

2. Why is SLA still popular for medical device prototyping? Stereolithography (SLA) remains a favorite due to its high precision, smooth surface finish, and availability of biocompatible resins. It's especially useful for surgical guides, dental models, and anatomical replicas.

3. How do I choose the right 3D printing method for my medical prototype? Consider factors such as part complexity, required material properties, surface finish expectations, biocompatibility, and production speed. Matching your needs to the method—SLA, DLS, MJF, SLS, or PolyJet—ensures better performance and efficiency.

4. Can these 3D printing methods meet FDA or ISO standards? Yes. Many technologies—especially Carbon DLS, SLS, and PolyJet—use FDA-cleared resins or ISO 10993-certified materials. Providers like APRIOS also operate under ISO 13485 quality systems to support regulatory compliance.

5. How fast can I get a prototype printed using these methods? Depending on the method and complexity, you can receive a prototype within 1–3 days. Carbon DLS and MJF are especially known for quick turnaround times in both individual and batch runs.

#3DPrintedPrototypes#RapidPrototyping#PrototypingServices#MedicalDevicePrototypes#MedicalPrototyping#Aprios

0 notes

Text

How Carbon DLS Technology Is Revolutionising Medical Device Development Through Advanced 3D Printing?

The medical device industry stands at the precipice of a technological revolution. As healthcare demands grow more complex and personalised, traditional manufacturing methods struggle to keep pace with the need for precision, speed, and customisation. Enter Carbon Digital Light Synthesis (DLS) technology—a groundbreaking advancement transforming how medical professionals approach device development and patient care.

The Evolution of Medical Device Manufacturing

Medical device development has traditionally been a lengthy, expensive process fraught with regulatory hurdles and manufacturing constraints. Conventional prototyping methods often required weeks or months to produce functional models, creating bottlenecks that delayed life-saving innovations from reaching patients who needed them most.

3D 3D-printed prototypes have emerged as a game-changer in this landscape, offering unprecedented speed and flexibility in medical device creation. Unlike traditional subtractive manufacturing, additive manufacturing enables the creation of complex geometries that were previously impossible or prohibitively expensive to produce.

The healthcare sector's adoption of three-dimensional printing technology has accelerated dramatically, with applications ranging from surgical planning models to custom prosthetics. However, not all printing technologies are created equal, and the medical field demands the highest standards of precision, biocompatibility, and mechanical properties.

Understanding Carbon DLS Technology

Carbon's Digital Light Synthesis represents a paradigm shift in additive manufacturing. This innovative process combines light, oxygen, and programmable chemistry to produce parts with exceptional surface finish, mechanical properties, and dimensional accuracy that rival traditional manufacturing methods.

The Carbon DLS Prototyping process utilises a unique approach called Continuous Liquid Interface Production (CLIP). This method eliminates the layer-by-layer printing that characterises traditional 3D printing, instead growing objects continuously from a pool of liquid resin. The result is parts with isotropic properties and smooth surface finishes that require minimal post-processing.

What sets Carbon DLS apart is its ability to produce functional prototypes that closely match the performance characteristics of final production parts. This capability is crucial in medical applications where prototype testing must accurately predict real-world performance.

Transforming Medical Device Prototypes

Medical Device Prototypes created through Carbon DLS technology offer several distinct advantages over conventional manufacturing methods:

Enhanced Precision and Accuracy

The precision achievable with Carbon DLS technology enables the creation of intricate medical components with tolerances as tight as ±0.1mm. This level of accuracy is essential for devices that must interface with human anatomy or integrate with existing medical equipment.

Superior Material Properties

Carbon's proprietary resins are engineered to deliver mechanical properties that often exceed those of traditionally manufactured parts. These materials can withstand sterilisation processes, demonstrate excellent biocompatibility, and provide the durability required for medical applications.

Accelerated Development Cycles

Traditional prototyping might take weeks to produce a single iteration. Carbon DLS can produce functional prototypes in days or hours, dramatically accelerating the design-test-iterate cycle crucial for medical device development.

The Power of Rapid Prototyping Services

Rapid Prototyping Services powered by Carbon DLS technology are transforming how medical companies approach product development. These services offer several key benefits:

Speed to Market

Time to market in the medical device industry can mean the difference between life and death. Rapid prototyping services enable companies to move from concept to clinical testing in a fraction of the time required by traditional methods.

Cost-Effective Iteration

The ability to quickly and affordably produce multiple design iterations allows engineers to explore more design possibilities and optimise performance before committing to expensive tooling and production setup.

Risk Mitigation

Early-stage physical prototypes help identify potential issues before they become costly problems in later development phases. This proactive approach reduces the risk of expensive design changes or regulatory delays.

Design for Additive Manufacturing (DfAM) in Medical Applications

Design for Additive Manufacturing (DfAM) principles are compelling when applied to medical device development. This approach involves designing parts specifically to leverage the unique capabilities of additive manufacturing rather than simply adapting existing designs.

Optimized Geometries

DfAM enables the creation of complex internal structures, such as lattice frameworks or conformal cooling channels, that would be impossible to manufacture using traditional methods. These optimised geometries can improve device performance while reducing material usage and weight.

Integrated Functionality

Traditional manufacturing often requires assembling multiple components to achieve the desired functionality. DfAM allows for the integration of various functions into a single printed part, reducing assembly complexity and potential failure points.

Customisation at Scale

Medical devices often require customisation for individual patients. DfAM makes it economically feasible to produce customised devices without expensive custom tooling.

Real-World Applications and Success Stories

The impact of Carbon DLS technology in medical device development extends across numerous applications:

Surgical Instruments

Precision surgical instruments benefit from the exceptional surface finish and mechanical properties achievable with Carbon DLS. These instruments can be designed with ergonomic features and optimised geometries that improve surgeon comfort and patient outcomes.

Prosthetic Components

Custom prosthetic devices require the perfect balance of strength, weight, and comfort. Carbon DLS technology enables the creation of prosthetic components that are both functional and aesthetically pleasing, improving the patient's quality of life.

Diagnostic Equipment

Medical diagnostic equipment often requires precise optical and mechanical components. The dimensional accuracy and surface quality of Carbon DLS parts make them ideal for these demanding applications.

The Aprios Advantage in Medical Prototyping

At Aprios, we've witnessed firsthand how Carbon DLS technology transforms medical device development. Our expertise in advanced manufacturing processes enables us to help medical device companies leverage these capabilities to accelerate innovation and improve patient outcomes.

Our team understands the unique challenges facing medical device manufacturers, from stringent regulatory requirements to the need for biocompatible materials. We work closely with clients to optimise their designs for Carbon DLS production, ensuring that prototypes meet performance requirements and provide valuable insights for future development.

Overcoming Traditional Manufacturing Limitations

Traditional manufacturing methods impose significant constraints on medical device design. Injection moulding requires expensive tooling, CNC machining can't create complex internal geometries, and conventional prototyping methods often can't produce parts with the necessary material properties.

Carbon DLS technology eliminates many of these constraints, enabling designers to focus on optimising device performance rather than working around manufacturing limitations. This freedom leads to more innovative designs and ultimately better patient outcomes.

Future Implications and Industry Trends

The adoption of Carbon DLS technology in medical device development represents more than just a manufacturing upgrade—it's a fundamental shift toward more personalised, efficient healthcare solutions. As the technology matures, we can expect to see even more sophisticated applications and improved material properties.

Integrating artificial intelligence and machine learning with Carbon DLS technology promises to further optimise the design and production process, potentially enabling real-time device performance optimisation based on patient-specific data.

Quality Assurance and Regulatory Considerations

Medical device manufacturers must navigate complex regulatory landscapes while maintaining the highest quality standards. Carbon DLS technology supports these requirements through consistent, repeatable production processes and comprehensive quality control measures.

The technology's ability to produce parts with consistent mechanical properties and dimensional accuracy helps manufacturers meet FDA and other regulatory requirements more efficiently than traditional prototyping methods.

Conclusion: The Future of Medical Device Innovation

Carbon DLS technology represents a transformative force in medical device development, offering unprecedented precision, speed, and design flexibility capabilities. As healthcare continues to evolve toward more personalised, efficient solutions, the role of advanced manufacturing technologies like Carbon DLS will only become more critical.

The combination of rapid prototyping capabilities, superior material properties, and design freedom enables medical device companies to innovate faster and more effectively than ever before. For companies looking to stay competitive in this rapidly evolving landscape, embracing Carbon DLS technology isn't just an option—it's necessary.

By partnering with experienced providers like Aprios, medical device manufacturers can leverage these advanced capabilities to accelerate their development timelines, reduce costs, and ultimately deliver better solutions to the patients who need them most. The future of medical device manufacturing is here, and the revolutionary capabilities of Carbon DLS technology are shaping it.

#3D Printed Prototypes#Medical Device Prototypes#Rapid Prototyping Services#Design for Additive Manufacturing (DfAM)#Carbon DLS Prototyping

0 notes

Text

Additive Manufacturing vs. Traditional Tooling: When to Choose What?

For product developers and manufacturing teams, choosing between additive manufacturing and traditional tooling isn't just a technical decision—it's a strategic one that affects everything from your development timeline to your bottom line. As manufacturing technologies continue to evolve, this choice has become increasingly complex, with each path offering distinct advantages depending on your specific needs.

You've likely heard the buzz around 3D printing and additive manufacturing, perhaps wondering if these technologies could replace conventional methods like injection molding or CNC machining. The reality is more nuanced: both approaches have their place in modern production strategies, and knowing when to deploy each can give your company a significant competitive edge.

In this comprehensive guide, we'll explore the critical decision factors that should influence your choice between additive manufacturing services and traditional tooling solutions. Whether you're developing medical device prototypes, planning for high-volume production, or seeking the perfect balance between speed and precision, understanding these options is essential for optimizing your manufacturing process.

We'll examine production volumes, material requirements, cost structures, geometric complexity, and numerous other factors that impact this pivotal decision. By the end, you'll have a clear framework for determining which manufacturing approach aligns best with your specific project requirements.

Ready to optimize your production strategy? Let's dive into the world of modern manufacturing methodologies and discover how to make the smartest choice for your next project.

Understanding the Fundamentals: Additive vs. Traditional Manufacturing

Before diving into decision-making criteria, let's establish a clear understanding of what each manufacturing method entails and how they fundamentally differ.

What Defines Additive Manufacturing?

Additive manufacturing builds objects layer by layer from the ground up, following a digital model. Unlike traditional subtractive methods that cut away material, additive manufacturing services add material precisely where needed to create the final product. This approach encompasses various technologies including:

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Direct Metal Laser Sintering (DMLS)

As an additive manufacturing company might explain, the process begins with a digital 3D model that's sliced into thin layers. The machine then builds the object one layer at a time, allowing for unprecedented design freedom and minimal material waste.

The Foundations of Traditional Tooling

In contrast, traditional tooling involves creating specialized tools (like molds or dies) that shape raw materials into final products. Tooling services encompass several well-established manufacturing processes:

Injection molding

Die casting

Stamping

Extrusion

When working with a tooling company, you're investing in durable equipment designed to produce identical parts reliably and repeatedly. Injection molding tooling represents one of the most common forms, where molten material is forced into a mold cavity, cooled, and ejected as a finished part.

The key difference? Traditional methods typically require significant upfront investment but deliver economies of scale with high volumes, while additive methods offer flexibility and lower initial costs but may not be cost-effective for mass production.

Now that we've established the foundations, let's examine when each approach makes the most sense for your manufacturing needs.

Production Volume: The Primary Decision Factor

Perhaps no factor influences the choice between additive manufacturing and traditional tooling more than production volume. Here's how to think about this critical variable:

When Low Volumes Favor Additive Manufacturing

For projects requiring fewer than 100-500 units (depending on size and complexity), additive manufacturing services often provide the most cost-effective solution. Without the need for expensive tooling, you can produce small batches with minimal upfront investment.

This makes additive manufacturing particularly valuable for:

Market testing new products

Producing limited edition items

Creating replacement parts for legacy products

Serving niche markets with specialized needs

Many companies offering design and manufacturing services recommend additive approaches for scenarios where future design changes are likely, as digital models can be modified without scrapping physical tooling.

The Crossover Point: Medium Production Runs

Here's where the decision becomes more nuanced. For production runs between 500-10,000 units, you'll need to carefully analyze the per-unit economics of both approaches. At this scale, the math changes significantly:

Tooling amortization begins to reduce the per-unit cost of traditional methods

Material costs for additive manufacturing remain relatively constant

Labor efficiency favors traditional processes as volume increases

Injection molding service providers can often identify this "crossover point" by analyzing the specific geometry, material, and quality requirements of your project. For medium volumes, quick turn injection molding might offer the best of both worlds—lower-cost tooling optimized for shorter production runs.

When High Volumes Demand Traditional Tooling

For production exceeding 10,000 units, traditional manufacturing methods typically become the clear economic choice. A plastic injection molding company can demonstrate how the economics improve dramatically at scale:

Tooling costs spread across many units become negligible per part

Cycle times for processes like injection molding (seconds) far outpace additive methods (hours)

Material costs are generally lower for traditional processes

When working with an injection molding manufacturer, you'll find that high-volume production efficiency becomes the dominant factor, making traditional tooling the obvious choice for mass-market products.

But volume isn't the only consideration—material requirements play an equally important role in this decision.

Material Considerations: Properties, Performance, and Possibilities

The material requirements of your final product can sometimes dictate your manufacturing approach regardless of other factors. Let's explore how different material needs influence your decision:

Additive Manufacturing's Expanding Material Portfolio

Modern additive manufacturing companies now offer a growing range of materials including:

Various thermoplastics (PLA, ABS, PETG, Nylon)

Photopolymer resins with diverse properties

Metal powders (aluminum, titanium, stainless steel)

Flexible elastomers and rubber-like materials

Composite materials with enhanced properties

This diversity makes additive manufacturing suitable for creating 3D printed prototypes with properties increasingly similar to final production materials. However, limitations remain in terms of material certification, consistency, and long-term performance data—particularly important for regulated industries.

Traditional Manufacturing's Material Advantages

Tooling solutions continue to offer significant advantages when:

Specific material certifications are required (medical, aerospace)

Extremely consistent material properties are necessary

Production requires materials not available for additive processes

Multiple materials must be combined (as with overmolding services)

For medical applications, working with a provider of medical injection molding ensures access to medical-grade polymers with established safety profiles and regulatory acceptance. Similarly, automotive and aerospace applications often require materials with specific performance characteristics best delivered through traditional processes.

Material Decision Framework

When evaluating materials, consider these questions:

Does your application require specific certified materials?

Are material performance properties critical to function?

Will the end-use environment subject parts to extreme conditions?

Do you need materials with long-established performance data?

If you answered "yes" to multiple questions above, traditional manufacturing likely offers advantages. However, for less demanding applications, the material flexibility of additive manufacturing might be perfectly adequate.

Geometric Complexity: When Design Drives Manufacturing Decisions

The geometric complexity of your parts can significantly influence which manufacturing approach makes the most sense. Let's examine how design considerations impact this critical decision:

When Complex Geometries Favor Additive Manufacturing

Additive manufacturing services excel when producing parts with:

Internal channels or complex hollow structures

Organic shapes or topologically optimized designs

Consolidated assemblies (combining multiple parts into one)

Lattice structures for weight reduction

Variable wall thicknesses or textures

A skilled design and manufacturing company can leverage these capabilities to create parts impossible to produce through traditional methods, potentially delivering superior performance with fewer components.

For example, medical device prototypes often benefit from additive manufacturing's ability to create patient-specific geometries or internal structures that enhance functionality while reducing weight.

When Traditional Tooling Handles Complexity Better

Despite additive manufacturing's geometric freedom, traditional methods still outperform in certain scenarios:

When extremely tight tolerances are required

For very smooth surface finishes without post-processing

When consistent wall thickness is critical

For parts requiring specific structural properties

Injection molding services continue to excel at producing parts with consistent material properties throughout, which can be challenging for some additive processes. Additionally, for geometries that fall within traditional manufacturing's capabilities, the surface finish and dimensional accuracy often surpass additive alternatives without extensive post-processing.

Bridging the Gap: Design for Manufacturing

The best approach often involves collaboration between design for manufacturing services and production teams. By considering manufacturing constraints early in the design process, you can:

Optimize geometries for your chosen production method

Reduce costs by eliminating unnecessary complexity

Improve quality by designing with manufacturing capabilities in mind

Many companies now use rapid prototyping services to validate designs through additive manufacturing before investing in tooling, creating a hybrid approach that maximizes the benefits of both methods.

Time-to-Market Considerations: Speed vs. Scale

In today's competitive landscape, development timelines often drive manufacturing decisions as much as technical considerations. Here's how time factors into the additive vs. traditional decision:

Accelerating Development with Additive Manufacturing

When speed is the primary concern, additive manufacturing services offer clear advantages:

No tooling lead time (typically 4-12 weeks for injection molds)

Immediate design iterations without tooling modifications

Rapid transition from CAD to physical parts (often within days)

Ability to test multiple design variants simultaneously

For projects where market timing is critical, the ability to move from concept to functional 3D printed prototypes in days rather than weeks can provide decisive competitive advantages.

The Long-Term Speed of Traditional Manufacturing

While traditional methods require more upfront time investment, they deliver significant speed advantages once tooling is established:

Extremely fast cycle times (seconds vs. hours for additive)

Parallel production capabilities (multiple cavities)

Established quality control processes

Minimal post-processing requirements

A company offering low-volume injection molding might require 3-6 weeks to create initial tooling, but can then produce thousands of parts weekly—far exceeding the production rate of additive methods.

Strategic Hybrid Approaches

The most time-efficient approach often combines both methodologies:

Use rapid prototyping services during design validation

Implement prototype injection molding for pre-production testing

Transition to production tooling for final manufacturing

This approach minimizes time-to-market while ensuring production readiness, creating a smooth transition from development to full-scale manufacturing.

Cost Analysis: Beyond the Price-Per-Part

Understanding the true cost implications of each manufacturing method requires looking beyond simple unit economics to consider the entire product lifecycle:

The Investment Profile of Additive Manufacturing

Additive manufacturing companies typically offer:

Low initial investment (no tooling costs)

Consistent unit costs regardless of volume

Minimal inventory costs (print on demand)

Lower risk for products with uncertain demand

Reduced waste and material costs

These characteristics make additive manufacturing particularly appealing for startups, new product introductions, or situations where capital preservation is critical.

The Economics of Traditional Tooling

Working with a tooling company involves:

Higher upfront investment in tooling

Dramatically decreasing unit costs at scale

Potential tooling maintenance and replacement costs

Inventory considerations for minimum order quantities

Generally lower material costs per part

Companies offering injection molding tooling can often provide detailed cost analyses showing exactly where the economic advantage shifts from additive to traditional methods based on your specific project parameters.

Total Cost of Ownership Considerations

A comprehensive decision should consider these additional factors:

Design change costs (minimal for additive, potentially substantial for tooling)

Quality assurance and rejection rates

Post-processing requirements

Assembly and consolidation opportunities

Transportation and logistics

Digital manufacturing solutions increasingly enable sophisticated cost modeling that accounts for these variables, helping you make decisions based on total lifecycle costs rather than just initial production expenses.

Quality and Certification Requirements

For many industries, quality standards and regulatory requirements may dictate your manufacturing approach regardless of other considerations:

The Certification Advantage of Traditional Manufacturing

If your products require rigorous certification, traditional manufacturing offers significant advantages:

Well-established quality standards and methodologies

Documented material properties and performance data

Consistent process parameters and validation methods

Extensive historical performance data

Companies with ISO-certified manufacturing capabilities can navigate complex regulatory environments more confidently using traditional processes with extensive validation histories.

Quality Control in Additive Manufacturing

While additive manufacturing continues to make strides in quality assurance, challenges remain:

Build-to-build variability

Layer-line effects on mechanical properties

Limited long-term performance data

Evolving inspection and certification protocols

For critical applications where injection molding quality control is essential, traditional methods often provide more consistent results and easier certification paths.

Industry-Specific Considerations

Different sectors have unique quality requirements:

Medical: Medical device prototypes might use additive manufacturing, but production devices typically require validated processes best achieved through medical injection molding

Aerospace: Critical components generally require traditional manufacturing's consistency and material certification

Consumer products: May use either approach depending on performance requirements

Working with specialists in inspection and quality control in manufacturing can help navigate these requirements and determine which approach best satisfies your regulatory needs.

Sustainable Manufacturing: Environmental Considerations

As sustainability becomes increasingly important, environmental impact may influence your manufacturing decisions:

The Environmental Case for Additive Manufacturing

Additive manufacturing services often provide sustainability advantages:

Minimal material waste (only using what's needed)

Reduced transportation impacts (distributed manufacturing potential)

Design optimization for material reduction

End-of-life recyclability for many materials

These factors make additive manufacturing appealing for companies prioritizing reduced environmental footprints.

Traditional Manufacturing's Sustainability Story

Modern tooling solutions have also evolved to address environmental concerns:

Highly efficient material usage at scale

Increasing use of recycled and bio-based materials

Energy-efficient equipment and processes

Durable tooling with long productive lifespans

A forward-thinking plastic injection molding manufacturer can often demonstrate how traditional methods achieve sustainability through efficiency and scale.

Future-Proofing: Flexibility vs. Commitment

A final consideration involves assessing how your manufacturing strategy accommodates future change and uncertainty:

The Flexibility Advantage of Additive Manufacturing

Choosing an additive manufacturing company provides:

Ability to modify designs without additional tooling costs

Easy scaling up or down based on demand

Geographic flexibility in production locations

Capacity to customize individual units

These advantages make additive manufacturing appealing when market uncertainties or frequent design iterations are expected.

When Traditional Tooling Creates Strategic Advantage

Investing in traditional tooling services makes sense when:

Your design is stable and unlikely to change significantly

You've validated market demand through pre-production testing

Economies of scale are critical to your business model

Production volumes justify the initial investment

For established products with predictable demand, the efficiency and cost advantages of traditional manufacturing create substantial competitive barriers.

Conclusion: Making the Strategic Choice

Choosing between additive manufacturing and traditional tooling isn't simply about technology—it's about aligning manufacturing capabilities with your business strategy, product requirements, and market realities.

For early-stage development, low-volume production, or geometrically complex parts, additive manufacturing services provide unmatched flexibility and speed. When moving toward higher volumes, stability, and established material performance, tooling solutions deliver the efficiency and consistency needed for scale.

Many successful manufacturers now implement hybrid approaches, leveraging rapid prototyping services during development before transitioning to injection molding services for production. This strategy capitalizes on the strengths of each methodology while mitigating their respective limitations.

As you evaluate your next project, consider partnering with a design and manufacturing company that offers expertise across both domains. The right manufacturing partner should understand not just the technical trade-offs between additive and traditional methods, but also how these decisions impact your overall business objectives.

By thoughtfully evaluating production volumes, material requirements, geometric complexity, time-to-market pressures, quality standards, and future flexibility needs, you can make manufacturing decisions that position your products—and your business—for success.

Ready to optimize your manufacturing strategy? Contact our team of experts today to discuss your specific requirements and develop a tailored approach that leverages the best of both additive and traditional manufacturing technologies.

#additive manufacturing services#additive manufacturing company#Injection molding tooling#design and manufacturing services#Injection molding service#plastic injection molding company#injection molding manufacturer#3D printed prototypes#medical injection molding#design and manufacturing company#rapid prototyping services#low-volume injection molding#ISO-certified manufacturing#injection molding quality control#inspection and quality control in manufacturing#plastic injection molding manufacturer#tooling solutions

0 notes

Text

DfM vs DfAM: What’s the Right Approach for Your Product Design

When bringing a new product to market, one of the earliest and most consequential decisions you'll make isn't about marketing strategy or pricing—it's about your design approach. The methodology you choose fundamentally impacts everything from production costs and timelines to your product's ultimate quality and performance.

Today's manufacturing landscape presents two primary design philosophies: traditional Design for Manufacturing (DfM) and the newer, increasingly important Design for Additive Manufacturing (DfAM). These approaches represent fundamentally different ways of thinking about how your product will come to life.

For companies seeking design for manufacturing solutions, understanding the distinction between these methodologies isn't just academic—it's essential to your bottom line. Choose incorrectly, and you might face unnecessary costs, production delays, or even design compromises that affect your product's functionality.

In this comprehensive guide, we'll explore:

The fundamental principles behind DfM and DfAM

Critical differences in approach and application

How to determine which methodology fits your specific product needs

Real-world applications in various industries, including medical devices

Integration strategies that leverage the best of both worlds

Future trends shaping design for manufacturing

Whether you're developing consumer products, medical devices, industrial equipment, or specialized components, understanding these design approaches will empower you to make informed decisions that optimize both production efficiency and product performance. Let's dive into the details that matter.

Ready to optimize your product design process? Schedule a consultation call with our engineering team to identify the ideal design approach for your specific needs.

What is Design for Manufacturing (DfM)?

Design for Manufacturing (DfM) represents a traditional but highly refined approach to product development that focuses on optimizing designs for efficient, cost-effective production using conventional manufacturing methods. This methodology has been the backbone of industrial production for decades, evolving alongside manufacturing technologies to create increasingly sophisticated products.

Core Principles of DfM

At its heart, DfM involves anticipating and addressing manufacturing requirements during the earliest stages of product design. Rather than creating a design and then figuring out how to manufacture it (often leading to costly redesigns), DfM integrates manufacturing considerations from day one.

The fundamental principles of design for manufacturing services include:

Material Selection Optimization: Choosing materials that balance performance requirements with manufacturing constraints and cost considerations.

Production Process Alignment: Designing components specifically for the intended manufacturing process, whether injection molding, CNC machining, sheet metal fabrication, or other traditional methods.

Assembly Simplification: Reducing part count, minimizing assembly steps, and standardizing components to streamline production.

Tolerance Management: Designing with appropriate tolerances that maintain functionality while avoiding unnecessarily tight tolerances that drive up costs.

When implemented properly, design for manufacturing solutions lead to products that not only perform as intended but can be efficiently produced at scale with consistent quality.

DfM for Traditional Manufacturing Methods

Different manufacturing processes come with their own design requirements and constraints. Let's explore how DfM principles apply to common production methods:

Injection Molding

Design for Injection Molding requires specific considerations like:

Uniform wall thicknesses to prevent warping and sink marks

Appropriate draft angles for smooth part ejection

Strategic rib placement for structural integrity without excessive material

Gate location planning to minimize visible marks and optimize flow

These considerations are particularly important for high-volume production, where minor design inefficiencies can multiply into significant costs across thousands or millions of units.

CNC Machining

DfM for machined parts focuses on:

Designing geometries accessible to cutting tools

Minimizing the number of machine setups required

Avoiding deep pockets that require specialized tooling

Planning for fixturing and workholding during fabrication

Here's the thing: while these traditional manufacturing methods have significant limitations, they've been refined over decades to achieve remarkable efficiency when designs properly accommodate their constraints.

DfM in Medical Device Development

One area where traditional DfM remains particularly crucial is in DFM for medical devices. The medical device industry faces unique challenges that make thoughtful design for manufacturing essential:

Regulatory requirements demand consistent quality and traceability

Patient safety depends on manufacturing precision and reliability

Sterilization requirements influence material and design choices

High-volume production must maintain exacting standards

For medical device manufacturers, integrating DfM principles early in development helps navigate these challenges while controlling costs. The structured approach of traditional DfM aligns well with the documentation requirements and validation protocols common in regulated industries.

Now let's dive into how additive manufacturing is changing this landscape.

Understanding Design for Additive Manufacturing (DfAM)

While traditional manufacturing methods subtract material (cutting, drilling) or reshape it (molding, forming), additive manufacturing builds objects layer by layer. This fundamental difference requires an entirely different design approach: Design for Additive Manufacturing (DfAM).

Breaking Free from Traditional Constraints

DfAM represents a paradigm shift in how we think about product design. Rather than designing around the limitations of conventional manufacturing processes, DfAM embraces the unique capabilities of additive technologies. This approach offers extraordinary freedom to create previously impossible geometries.

The core advantages of DfAM include:

Complex Geometries: Creating internal channels, lattice structures, and organic shapes that would be impossible or prohibitively expensive with traditional methods.

Part Consolidation: Combining multiple components into single, complex parts to eliminate assembly steps and potential failure points.

Mass Customization: Economically producing variations of a design without the tooling changes required by traditional manufacturing.

Weight Optimization: Developing structures that use material only where needed for strength while minimizing weight in non-critical areas.

What does this mean for you? The ability to reimagine products entirely rather than simply adapting existing designs to manufacturing constraints.

DfAM Principles and Methodologies

Effective DfAM requires understanding both the capabilities and limitations of various additive technologies. Each 3D printing process—whether powder bed fusion, material extrusion, vat photopolymerization, or others—comes with its own design considerations.

Topology Optimization

One of the most powerful DfAM approaches is topology optimization, which uses computational algorithms to determine the optimal material distribution within a design space. This data-driven approach creates structures that:

Maximize strength-to-weight ratios

Distribute stress more effectively

Reduce material usage while maintaining performance

Often result in organic, non-intuitive geometries

Support Structure Considerations

Unlike traditional manufacturing, many additive processes require support structures for overhangs and other challenging geometries. Effective DfAM addresses this by:

Orienting parts to minimize support requirements

Designing self-supporting features where possible

Creating easily removable supports that don't compromise surface finish

Incorporating supports as functional elements of the final design

When DfAM Excels

Design for Additive Manufacturing offers particular advantages in certain scenarios:

Low-volume, high-complexity parts where tooling costs would be prohibitive

Highly customized products tailored to individual user requirements

Lightweighting applications in aerospace, automotive, and other weight-sensitive industries

Consolidated assemblies that reduce part count and assembly complexity

Fluid flow optimization through complex internal channels and structures

Now that we've explored both approaches individually, let's examine how to determine which one best suits your specific project needs.

Choosing the Right Approach: Decision Factors

Selecting between DfM and DfAM isn't a matter of which approach is universally "better"—it's about identifying which methodology aligns with your specific product requirements, production volumes, and business objectives. Here's a systematic framework to guide your decision.

Production Volume Considerations

One of the most significant factors in your design approach decision is the anticipated production volume:

High-Volume Production

For products produced in thousands or millions of units, traditional design for manufacturing solutions often remain the most cost-effective approach. While initial tooling costs for processes like injection molding can be substantial, these costs amortize across large production runs, resulting in very low per-unit manufacturing costs.

DfM excels here because:

Per-part costs decrease dramatically at scale

Process consistency and quality control are well-established

Production speeds for conventional methods typically outpace additive manufacturing

Low-Volume Production

For products with annual volumes in the dozens or hundreds, DfAM often provides compelling advantages:

Elimination of expensive tooling costs

Faster time-to-market without mold creation lead times

Greater design flexibility for iterative improvements

Economic feasibility for customized variants

Geometric Complexity Requirements

The complexity of your product's geometry should heavily influence your design approach:

Simple Geometries

Products with relatively simple geometries—those made primarily of prismatic shapes, uniform wall thicknesses, and limited internal features—often benefit from traditional DfM approaches. These designs readily accommodate conventional manufacturing processes without significant compromise.

Complex Geometries

When your product requires:

Internal channels or structures

Organic, non-uniform shapes

Lattice or honeycomb structures for weight reduction

Consolidated parts with complex interfaces

DfAM provides capabilities that traditional manufacturing simply cannot match, or can only achieve at prohibitive cost.

Material Requirements

Your material selection requirements play a crucial role in determining the appropriate design approach:

Wide Material Selection

Traditional manufacturing offers access to thousands of material formulations with well-documented properties, certifications, and performance histories. If your product requires specific:

Medical-grade polymers with regulatory approvals

High-performance engineering plastics with precise specifications

Materials with specialized characteristics (optical clarity, biocompatibility, etc.)

Traditional design for manufacturing services may provide advantages due to the broader material ecosystem.

Specialized Material Properties

Conversely, additive manufacturing excels with:

Multi-material components

Gradient materials with varying properties

Novel materials specifically formulated for additive processes

Materials with properties tailored through print parameters

Time-to-Market Pressures

Market timing often drives design methodology decisions:

For rapid product development where beating competitors to market represents significant value, DfAM often enables faster development cycles by:

Eliminating tooling lead times (often 8-16 weeks for injection molds)

Facilitating rapid design iterations without tool modifications

Enabling parallel development of multiple design candidates

For products entering established markets where cost optimization matters more than speed, traditional DfM's focus on production efficiency may deliver greater long-term value.

Here's a comparison table summarizing key decision factors:

Factor

Favors DfM

Favors DfAM

Production Volume

High (10,000+ units)

Low to Medium (<1,000 units)

Geometric Complexity

Low to Medium

High

Material Requirements

Standard, well-characterized

Specialized or novel

Time-to-Market

Standard

Accelerated

Cost Structure

Higher upfront, lower per-unit

Lower upfront, higher per-unit

Product Lifecycle

Long, stable

Short, evolving

Hybrid Approaches: Combining DfM and DfAM

The decision between DfM and DfAM isn't always binary. Many successful product development strategies leverage hybrid approaches that combine the strengths of both methodologies. This integration can create powerful synergies that optimize both design performance and manufacturing efficiency.

Strategic Integration Strategies

Effective hybrid approaches typically implement one of several integration strategies:

1. Component-Based Hybridization

In this approach, different components within the same product use different design methodologies based on their specific requirements:

Complex, low-stress components leverage DfAM for geometric freedom

High-stress structural components use traditional DfM for proven reliability

High-volume, simple components utilize conventional manufacturing for cost efficiency

This strategic allocation of design approaches optimizes the overall product while respecting the strengths and limitations of each methodology.

2. Development Phase Hybridization

Another effective approach uses different methodologies at different stages of product development:

Concept development and early prototyping utilize DfAM for rapid iteration

Late-stage prototyping transitions to DfM principles to prepare for mass production

Manufacturing validation uses processes identical to final production

This progression allows teams to maintain agility early while ensuring manufacturability as the design matures.

Case Study: Medical Device Development

The medical device industry provides excellent examples of successful hybrid approaches. Consider a complex surgical instrument development program:

Critical handles and grips are designed using traditional DFM for medical devices to ensure reliable ergonomics and cost-effective production

Complex internal mechanisms leverage DfAM to reduce part count and enable sophisticated functionality

Prototypes use additive manufacturing for rapid testing iterations

Final production implements injection molding for high-volume components alongside selective additive manufacturing for complex subassemblies

This integrated approach delivers a superior product faster than either methodology could achieve independently.

Now let's dive deeper into real-world applications of both approaches.

Real-World Applications and Case Studies

Understanding how DfM and DfAM principles apply in practice helps clarify when each approach delivers optimal results. Let's examine specific applications across different industries.

DfM Success Stories

Consumer Electronics

A leading consumer electronics manufacturer implemented comprehensive design for manufacturing solutions when developing a new portable device. Their approach included:

Material selection optimized for both structural requirements and injection molding process parameters

Design modifications to eliminate undercuts and simplify tooling

Strategic use of snap-fits and self-locating features to reduce assembly time by 47%

Wall thickness standardization to prevent warping and sink marks

The result? Production costs decreased by 22% compared to the previous generation while maintaining premium build quality and reducing assembly defects by over 60%.

Medical Device Manufacturing

A medical diagnostics company applied DFM for medical devices when developing a new point-of-care testing platform:

Components were designed specifically for automated assembly

Material selection focused on biocompatibility and regulatory compliance

Tolerance stacking analysis identified and resolved potential fit issues before tooling

Design validation included manufacturing process simulation

These efforts reduced their production ramp-up time from 9 months to just 7 weeks while maintaining 100% compliance with regulatory requirements.

DfAM Transformations

Aerospace Component Redesign

An aerospace manufacturer redesigned a critical ducting component using DfAM principles:

Consolidated 18 separate parts into a single printed component

Reduced weight by 64% through topology optimization

Improved airflow efficiency by 23% using organic internal geometries

Eliminated multiple assembly operations and potential leak points

The redesigned component not only performed better but eliminated tooling costs and simplified supply chain management.

Customized Medical Implants

A medical device company implemented DfAM to create patient-specific implants:

Each implant is designed using patient CT scan data

Lattice structures promote tissue integration while maintaining strength

Production requires no tooling, enabling economical patient-specific manufacturing

Design-to-delivery time reduced from weeks to days

This application demonstrates how DfAM enables entirely new product categories that would be impossible with traditional manufacturing approaches.

What does this mean for you? The right design approach depends entirely on what you're trying to accomplish—mass production efficiency or design innovation—and sometimes, the best answer involves elements of both.

Future Trends: The Evolving Landscape of Manufacturing Design

The boundary between DfM and DfAM continues to evolve as manufacturing technologies advance and design tools become more sophisticated. Understanding emerging trends helps companies stay ahead of the curve and make forward-looking design decisions.

Artificial Intelligence in Design

AI is transforming both traditional design for manufacturing services and additive approaches:

Generative design algorithms automatically explore thousands of design iterations that balance performance requirements with manufacturing constraints

Machine learning systems predict manufacturing outcomes based on design parameters, enabling proactive optimization

AI-powered design validation tools identify potential issues earlier in the development process

These technologies are breaking down the traditional barriers between design and manufacturing, creating more integrated processes regardless of manufacturing method.

Materials Innovation

Novel materials are expanding the capabilities of both traditional and additive manufacturing:

Advanced composites with engineered properties are becoming compatible with injection molding processes

New additive materials increasingly match or exceed the performance of traditional engineering materials

Multi-material printing capabilities enable previously impossible functional gradients within parts

As material options expand, the decision factors between DfM and DfAM shift from "can it be made?" to "what's the most efficient way to make it?"

Sustainability Considerations

Sustainability is becoming a critical design factor across all manufacturing approaches:

Design for disassembly and recycling is being integrated into traditional DfM principles

DfAM enables material reduction through topology optimization and lattice structures

Lifecycle assessment tools help designers quantify the environmental impact of different design and manufacturing approaches

Forward-thinking companies are finding that sustainable design practices often align with manufacturing efficiency, creating business and environmental benefits simultaneously.

Convergence of Technologies

Perhaps the most significant trend is the gradual convergence of traditional and additive technologies:

Hybrid manufacturing systems combine additive and subtractive processes in single machines

Production lines increasingly integrate both methodologies within unified workflows

Design software bridges the gap between approaches, allowing designers to apply appropriate principles to different features

This convergence suggests that the future won't be about choosing between DfM and DfAM but rather about seamlessly integrating the right approach for each specific design challenge.

Conclusion: Making the Right Choice for Your Product

The choice between Design for Manufacturing (DfM) and Design for Additive Manufacturing (DfAM) represents more than just a technical decision—it's a strategic choice that impacts your product's performance, cost structure, and time-to-market. As we've explored throughout this article, each approach offers distinct advantages for different scenarios.

Traditional DfM continues to excel for high-volume production where cost efficiency and proven materials are paramount. Its structured methodology aligns perfectly with industries requiring regulatory compliance, consistent quality, and established supply chains. For many products, particularly those produced in large quantities, design for manufacturing solutions remain the optimal approach.

Conversely, DfAM unlocks unprecedented design freedom, enabling complex geometries, part consolidation, and customization that traditional methods simply cannot achieve. For low-volume, high-complexity applications or products requiring rapid development, DfAM provides compelling advantages that can transform your approach to innovation.

Many leading companies are discovering that integrating both methodologies—applying each where it delivers the greatest value—creates the optimal development strategy. This hybrid approach harnesses the efficiency of traditional manufacturing alongside the design freedom of additive technologies.

#Design for Injection Molding#DFM for Medical Devices#Plastic Part Design Optimization#design for manufacturing services#design for manufacturing solutions#DfAM

0 notes

Text

Why Design for Injection Molding (DfIM) Is Critical for High-Quality Plastic Parts

Imagine investing months into designing a groundbreaking plastic component—only to discover during production that it warps, cracks, or simply can’t be molded efficiently. This nightmare scenario is all too common when Design for Injection Molding (DfIM) is overlooked. In industries ranging from medical devices to automotive manufacturing, achieving high-quality plastic parts isn’t just about aesthetics or functionality—it’s about ensuring every step of the process, from design to production, aligns seamlessly.

Design for Injection Molding (DfIM) is the secret weapon that transforms good ideas into great products. By integrating principles like plastic part design optimization and leveraging expert injection mold design services, DfIM ensures your parts are manufacturable, cost-effective, and built to last. In this in-depth guide, we’ll explore why DfIM is indispensable, how it applies to specialized fields like DFM for medical devices, and why partnering with a design and manufacturing company—such as Aprios—can make all the difference. Let’s get started.

What Is Design for Injection Molding (DfIM)?

At its core, Design for Injection Molding (DfIM) is a strategic approach within the broader discipline of Design for Manufacturing (DFM). It focuses on tailoring plastic part designs specifically for the injection molding process—one of the most versatile and widely used methods for producing precise, repeatable components. DfIM isn’t just about making a part look good on paper; it’s about anticipating how that design will behave when molten plastic is injected into a mold under high pressure.

The process begins with understanding the unique demands of injection molding: material flow, cooling rates, and mold release. Whether you’re crafting a simple consumer product or a complex component requiring DFM for medical devices, DfIM ensures your design is optimized for production. This might mean adjusting wall thickness, adding draft angles, or rethinking feature placement—all part of plastic part design optimization.

Industries like healthcare, automotive, and electronics rely on DfIM to bridge the gap between creativity and practicality. By working with plastic injection mold design services, companies can avoid costly redesigns and bring their products to market faster. In short, DfIM is the foundation of efficient, high-quality plastic manufacturing.

Why DfIM Is Critical for High-Quality Plastic Parts

Injection molding is a high-stakes game. With pressures reaching thousands of PSI and cycle times measured in seconds, there’s little room for error. A poorly designed part can lead to defects like sink marks, warping, or incomplete fills—issues that compromise both quality and profitability. Here’s why Design for Injection Molding (DfIM) is essential for delivering high-quality plastic parts:

Defect Prevention: Uniform wall thickness is a cornerstone of DfIM. Uneven walls can cause uneven cooling, leading to stresses that distort the final part. Proper draft angles—slight tapers on vertical surfaces—make ejection easier and reduce surface imperfections. These details, often refined through injection mold design services, are what separate a flawless part from a flawed one.

Material Efficiency: Choosing the right resin is only half the battle; DfIM ensures the design maximizes that material’s potential. For instance, a part with excessive thickness wastes material and increases cooling time, while a thin, optimized design—crafted with design for manufacturing solutions—balances strength and efficiency.

Cost Savings: Every iteration of a mold or design tweak costs time and money. By incorporating DFM services early, DfIM minimizes trial-and-error, reduces scrap rates, and shortens production timelines. The result? Lower costs without sacrificing quality.

Consider a real-world example: a manufacturer designing a plastic housing for an electronic device. Without DfIM, they might overlook shrinkage rates, leading to parts that don’t fit their assemblies. With DfIM, they’d account for this upfront, ensuring a perfect fit every time. Across industries, high-quality plastic parts owe their success to this meticulous approach.

DfIM in Action – Key Principles and Best Practices

To truly harness the power of Design for Injection Molding (DfIM), designers must adhere to a set of proven principles. These aren’t just guidelines—they’re the building blocks of manufacturability. Here’s a closer look at the essentials, along with practical applications:

Avoid Sharp Corners and Undercuts: Sharp edges disrupt resin flow and create stress concentrations that can crack under load. Rounding corners improves mold filling and strengthens the part. Similarly, undercuts—features that trap the part in the mold—complicate ejection. Injection mold design services can suggest alternatives, like side actions or redesigns, to keep things simple.

Optimize Ribs and Bosses: Ribs add strength without excessive material, but they must be thin (typically 50-60% of wall thickness) to avoid sink marks. Bosses, used for screws or inserts, need proper spacing and support. These tweaks, part of plastic part design optimization, ensure durability without overcomplicating the mold.

Incorporate Proper Tolerances: Injection molding requires tighter tolerances than, say, 3D printing. DfIM aligns tolerances with the process’s capabilities—typically ±0.005 inches for precision parts. Collaborating with plastic injection mold design services ensures these specs are realistic and achievable.

Take a plastic gear as an example. A DfIM-optimized design might feature rounded tooth profiles, consistent thickness, and a slight draft for easy release—making it both functional and mold-friendly. These best practices, refined through design for manufacturing solutions, turn concepts into production-ready realities.

DfIM for Specialized Applications (e.g., Medical Devices)

When precision and reliability are non-negotiable, DFM for medical devices elevates DfIM to a whole new level. Medical components—like syringe barrels, catheter housings, or implant casings—must meet stringent regulatory standards (e.g., FDA or ISO 13485) while performing flawlessly in life-or-death scenarios.

Here, DfIM goes beyond basic manufacturability. It considers biocompatibility (ensuring materials won’t harm patients), sterilization compatibility, and microscopic tolerances. For instance, a poorly designed mold draft could leave burrs on a surgical tool, posing a contamination risk. DFM development services address these challenges by integrating regulatory insights into the design phase.

A practical case: designing a plastic inhaler component. DfIM ensures airtight seals and smooth surfaces for patient safety, while design for manufacturing services validate the design against medical standards. This specialized focus makes DfIM indispensable for industries where failure isn’t an option.

How Design and Manufacturing Companies Support DfIM

Bringing a plastic part from sketch to shelf is no small feat, and that’s where a design and manufacturing company shines. Companies like Aprios offer a suite of DFM services that amplify DfIM’s impact:

Plastic Injection Mold Design Services: Crafting molds tailored to your part’s geometry, material, and production volume. A well-designed mold can handle millions of cycles without wear.

Prototyping and Testing: Before committing to full production, prototyping—often via 3D printing or soft tooling—lets you validate DfIM principles. Adjustments here save headaches later.

DFM Analysis: Using simulations and expertise, injection mold design services identify potential issues—like resin flow bottlenecks or cooling inefficiencies—early in the process.