#Plastic Part Design Optimization

Explore tagged Tumblr posts

Text

DfM vs DfAM: What’s the Right Approach for Your Product Design

When bringing a new product to market, one of the earliest and most consequential decisions you'll make isn't about marketing strategy or pricing—it's about your design approach. The methodology you choose fundamentally impacts everything from production costs and timelines to your product's ultimate quality and performance.

Today's manufacturing landscape presents two primary design philosophies: traditional Design for Manufacturing (DfM) and the newer, increasingly important Design for Additive Manufacturing (DfAM). These approaches represent fundamentally different ways of thinking about how your product will come to life.

For companies seeking design for manufacturing solutions, understanding the distinction between these methodologies isn't just academic—it's essential to your bottom line. Choose incorrectly, and you might face unnecessary costs, production delays, or even design compromises that affect your product's functionality.

In this comprehensive guide, we'll explore:

The fundamental principles behind DfM and DfAM

Critical differences in approach and application

How to determine which methodology fits your specific product needs

Real-world applications in various industries, including medical devices

Integration strategies that leverage the best of both worlds

Future trends shaping design for manufacturing

Whether you're developing consumer products, medical devices, industrial equipment, or specialized components, understanding these design approaches will empower you to make informed decisions that optimize both production efficiency and product performance. Let's dive into the details that matter.

Ready to optimize your product design process? Schedule a consultation call with our engineering team to identify the ideal design approach for your specific needs.

What is Design for Manufacturing (DfM)?

Design for Manufacturing (DfM) represents a traditional but highly refined approach to product development that focuses on optimizing designs for efficient, cost-effective production using conventional manufacturing methods. This methodology has been the backbone of industrial production for decades, evolving alongside manufacturing technologies to create increasingly sophisticated products.

Core Principles of DfM

At its heart, DfM involves anticipating and addressing manufacturing requirements during the earliest stages of product design. Rather than creating a design and then figuring out how to manufacture it (often leading to costly redesigns), DfM integrates manufacturing considerations from day one.

The fundamental principles of design for manufacturing services include:

Material Selection Optimization: Choosing materials that balance performance requirements with manufacturing constraints and cost considerations.

Production Process Alignment: Designing components specifically for the intended manufacturing process, whether injection molding, CNC machining, sheet metal fabrication, or other traditional methods.

Assembly Simplification: Reducing part count, minimizing assembly steps, and standardizing components to streamline production.

Tolerance Management: Designing with appropriate tolerances that maintain functionality while avoiding unnecessarily tight tolerances that drive up costs.

When implemented properly, design for manufacturing solutions lead to products that not only perform as intended but can be efficiently produced at scale with consistent quality.

DfM for Traditional Manufacturing Methods

Different manufacturing processes come with their own design requirements and constraints. Let's explore how DfM principles apply to common production methods:

Injection Molding

Design for Injection Molding requires specific considerations like:

Uniform wall thicknesses to prevent warping and sink marks

Appropriate draft angles for smooth part ejection

Strategic rib placement for structural integrity without excessive material

Gate location planning to minimize visible marks and optimize flow

These considerations are particularly important for high-volume production, where minor design inefficiencies can multiply into significant costs across thousands or millions of units.

CNC Machining

DfM for machined parts focuses on:

Designing geometries accessible to cutting tools

Minimizing the number of machine setups required

Avoiding deep pockets that require specialized tooling

Planning for fixturing and workholding during fabrication

Here's the thing: while these traditional manufacturing methods have significant limitations, they've been refined over decades to achieve remarkable efficiency when designs properly accommodate their constraints.

DfM in Medical Device Development

One area where traditional DfM remains particularly crucial is in DFM for medical devices. The medical device industry faces unique challenges that make thoughtful design for manufacturing essential:

Regulatory requirements demand consistent quality and traceability

Patient safety depends on manufacturing precision and reliability

Sterilization requirements influence material and design choices

High-volume production must maintain exacting standards

For medical device manufacturers, integrating DfM principles early in development helps navigate these challenges while controlling costs. The structured approach of traditional DfM aligns well with the documentation requirements and validation protocols common in regulated industries.

Now let's dive into how additive manufacturing is changing this landscape.

Understanding Design for Additive Manufacturing (DfAM)

While traditional manufacturing methods subtract material (cutting, drilling) or reshape it (molding, forming), additive manufacturing builds objects layer by layer. This fundamental difference requires an entirely different design approach: Design for Additive Manufacturing (DfAM).

Breaking Free from Traditional Constraints

DfAM represents a paradigm shift in how we think about product design. Rather than designing around the limitations of conventional manufacturing processes, DfAM embraces the unique capabilities of additive technologies. This approach offers extraordinary freedom to create previously impossible geometries.

The core advantages of DfAM include:

Complex Geometries: Creating internal channels, lattice structures, and organic shapes that would be impossible or prohibitively expensive with traditional methods.

Part Consolidation: Combining multiple components into single, complex parts to eliminate assembly steps and potential failure points.

Mass Customization: Economically producing variations of a design without the tooling changes required by traditional manufacturing.

Weight Optimization: Developing structures that use material only where needed for strength while minimizing weight in non-critical areas.

What does this mean for you? The ability to reimagine products entirely rather than simply adapting existing designs to manufacturing constraints.

DfAM Principles and Methodologies

Effective DfAM requires understanding both the capabilities and limitations of various additive technologies. Each 3D printing process—whether powder bed fusion, material extrusion, vat photopolymerization, or others—comes with its own design considerations.

Topology Optimization

One of the most powerful DfAM approaches is topology optimization, which uses computational algorithms to determine the optimal material distribution within a design space. This data-driven approach creates structures that:

Maximize strength-to-weight ratios

Distribute stress more effectively

Reduce material usage while maintaining performance

Often result in organic, non-intuitive geometries

Support Structure Considerations

Unlike traditional manufacturing, many additive processes require support structures for overhangs and other challenging geometries. Effective DfAM addresses this by:

Orienting parts to minimize support requirements

Designing self-supporting features where possible

Creating easily removable supports that don't compromise surface finish

Incorporating supports as functional elements of the final design

When DfAM Excels

Design for Additive Manufacturing offers particular advantages in certain scenarios:

Low-volume, high-complexity parts where tooling costs would be prohibitive

Highly customized products tailored to individual user requirements

Lightweighting applications in aerospace, automotive, and other weight-sensitive industries

Consolidated assemblies that reduce part count and assembly complexity

Fluid flow optimization through complex internal channels and structures

Now that we've explored both approaches individually, let's examine how to determine which one best suits your specific project needs.

Choosing the Right Approach: Decision Factors

Selecting between DfM and DfAM isn't a matter of which approach is universally "better"—it's about identifying which methodology aligns with your specific product requirements, production volumes, and business objectives. Here's a systematic framework to guide your decision.

Production Volume Considerations

One of the most significant factors in your design approach decision is the anticipated production volume:

High-Volume Production

For products produced in thousands or millions of units, traditional design for manufacturing solutions often remain the most cost-effective approach. While initial tooling costs for processes like injection molding can be substantial, these costs amortize across large production runs, resulting in very low per-unit manufacturing costs.

DfM excels here because:

Per-part costs decrease dramatically at scale

Process consistency and quality control are well-established

Production speeds for conventional methods typically outpace additive manufacturing

Low-Volume Production

For products with annual volumes in the dozens or hundreds, DfAM often provides compelling advantages:

Elimination of expensive tooling costs

Faster time-to-market without mold creation lead times

Greater design flexibility for iterative improvements

Economic feasibility for customized variants

Geometric Complexity Requirements

The complexity of your product's geometry should heavily influence your design approach:

Simple Geometries

Products with relatively simple geometries—those made primarily of prismatic shapes, uniform wall thicknesses, and limited internal features—often benefit from traditional DfM approaches. These designs readily accommodate conventional manufacturing processes without significant compromise.

Complex Geometries

When your product requires:

Internal channels or structures

Organic, non-uniform shapes

Lattice or honeycomb structures for weight reduction

Consolidated parts with complex interfaces

DfAM provides capabilities that traditional manufacturing simply cannot match, or can only achieve at prohibitive cost.

Material Requirements

Your material selection requirements play a crucial role in determining the appropriate design approach:

Wide Material Selection

Traditional manufacturing offers access to thousands of material formulations with well-documented properties, certifications, and performance histories. If your product requires specific:

Medical-grade polymers with regulatory approvals

High-performance engineering plastics with precise specifications

Materials with specialized characteristics (optical clarity, biocompatibility, etc.)

Traditional design for manufacturing services may provide advantages due to the broader material ecosystem.

Specialized Material Properties

Conversely, additive manufacturing excels with:

Multi-material components

Gradient materials with varying properties

Novel materials specifically formulated for additive processes

Materials with properties tailored through print parameters

Time-to-Market Pressures

Market timing often drives design methodology decisions:

For rapid product development where beating competitors to market represents significant value, DfAM often enables faster development cycles by:

Eliminating tooling lead times (often 8-16 weeks for injection molds)

Facilitating rapid design iterations without tool modifications

Enabling parallel development of multiple design candidates

For products entering established markets where cost optimization matters more than speed, traditional DfM's focus on production efficiency may deliver greater long-term value.

Here's a comparison table summarizing key decision factors:

Factor

Favors DfM

Favors DfAM

Production Volume

High (10,000+ units)

Low to Medium (<1,000 units)

Geometric Complexity

Low to Medium

High

Material Requirements

Standard, well-characterized

Specialized or novel

Time-to-Market

Standard

Accelerated

Cost Structure

Higher upfront, lower per-unit

Lower upfront, higher per-unit

Product Lifecycle

Long, stable

Short, evolving

Hybrid Approaches: Combining DfM and DfAM

The decision between DfM and DfAM isn't always binary. Many successful product development strategies leverage hybrid approaches that combine the strengths of both methodologies. This integration can create powerful synergies that optimize both design performance and manufacturing efficiency.

Strategic Integration Strategies

Effective hybrid approaches typically implement one of several integration strategies:

1. Component-Based Hybridization

In this approach, different components within the same product use different design methodologies based on their specific requirements:

Complex, low-stress components leverage DfAM for geometric freedom

High-stress structural components use traditional DfM for proven reliability

High-volume, simple components utilize conventional manufacturing for cost efficiency

This strategic allocation of design approaches optimizes the overall product while respecting the strengths and limitations of each methodology.

2. Development Phase Hybridization

Another effective approach uses different methodologies at different stages of product development:

Concept development and early prototyping utilize DfAM for rapid iteration

Late-stage prototyping transitions to DfM principles to prepare for mass production

Manufacturing validation uses processes identical to final production

This progression allows teams to maintain agility early while ensuring manufacturability as the design matures.

Case Study: Medical Device Development

The medical device industry provides excellent examples of successful hybrid approaches. Consider a complex surgical instrument development program:

Critical handles and grips are designed using traditional DFM for medical devices to ensure reliable ergonomics and cost-effective production

Complex internal mechanisms leverage DfAM to reduce part count and enable sophisticated functionality

Prototypes use additive manufacturing for rapid testing iterations

Final production implements injection molding for high-volume components alongside selective additive manufacturing for complex subassemblies

This integrated approach delivers a superior product faster than either methodology could achieve independently.

Now let's dive deeper into real-world applications of both approaches.

Real-World Applications and Case Studies

Understanding how DfM and DfAM principles apply in practice helps clarify when each approach delivers optimal results. Let's examine specific applications across different industries.

DfM Success Stories

Consumer Electronics

A leading consumer electronics manufacturer implemented comprehensive design for manufacturing solutions when developing a new portable device. Their approach included:

Material selection optimized for both structural requirements and injection molding process parameters

Design modifications to eliminate undercuts and simplify tooling

Strategic use of snap-fits and self-locating features to reduce assembly time by 47%

Wall thickness standardization to prevent warping and sink marks

The result? Production costs decreased by 22% compared to the previous generation while maintaining premium build quality and reducing assembly defects by over 60%.

Medical Device Manufacturing

A medical diagnostics company applied DFM for medical devices when developing a new point-of-care testing platform:

Components were designed specifically for automated assembly

Material selection focused on biocompatibility and regulatory compliance

Tolerance stacking analysis identified and resolved potential fit issues before tooling

Design validation included manufacturing process simulation

These efforts reduced their production ramp-up time from 9 months to just 7 weeks while maintaining 100% compliance with regulatory requirements.

DfAM Transformations

Aerospace Component Redesign

An aerospace manufacturer redesigned a critical ducting component using DfAM principles:

Consolidated 18 separate parts into a single printed component

Reduced weight by 64% through topology optimization

Improved airflow efficiency by 23% using organic internal geometries

Eliminated multiple assembly operations and potential leak points

The redesigned component not only performed better but eliminated tooling costs and simplified supply chain management.

Customized Medical Implants

A medical device company implemented DfAM to create patient-specific implants:

Each implant is designed using patient CT scan data

Lattice structures promote tissue integration while maintaining strength

Production requires no tooling, enabling economical patient-specific manufacturing

Design-to-delivery time reduced from weeks to days

This application demonstrates how DfAM enables entirely new product categories that would be impossible with traditional manufacturing approaches.

What does this mean for you? The right design approach depends entirely on what you're trying to accomplish—mass production efficiency or design innovation—and sometimes, the best answer involves elements of both.

Future Trends: The Evolving Landscape of Manufacturing Design

The boundary between DfM and DfAM continues to evolve as manufacturing technologies advance and design tools become more sophisticated. Understanding emerging trends helps companies stay ahead of the curve and make forward-looking design decisions.

Artificial Intelligence in Design

AI is transforming both traditional design for manufacturing services and additive approaches:

Generative design algorithms automatically explore thousands of design iterations that balance performance requirements with manufacturing constraints

Machine learning systems predict manufacturing outcomes based on design parameters, enabling proactive optimization

AI-powered design validation tools identify potential issues earlier in the development process

These technologies are breaking down the traditional barriers between design and manufacturing, creating more integrated processes regardless of manufacturing method.

Materials Innovation

Novel materials are expanding the capabilities of both traditional and additive manufacturing:

Advanced composites with engineered properties are becoming compatible with injection molding processes

New additive materials increasingly match or exceed the performance of traditional engineering materials

Multi-material printing capabilities enable previously impossible functional gradients within parts

As material options expand, the decision factors between DfM and DfAM shift from "can it be made?" to "what's the most efficient way to make it?"

Sustainability Considerations

Sustainability is becoming a critical design factor across all manufacturing approaches:

Design for disassembly and recycling is being integrated into traditional DfM principles

DfAM enables material reduction through topology optimization and lattice structures

Lifecycle assessment tools help designers quantify the environmental impact of different design and manufacturing approaches

Forward-thinking companies are finding that sustainable design practices often align with manufacturing efficiency, creating business and environmental benefits simultaneously.

Convergence of Technologies

Perhaps the most significant trend is the gradual convergence of traditional and additive technologies:

Hybrid manufacturing systems combine additive and subtractive processes in single machines

Production lines increasingly integrate both methodologies within unified workflows

Design software bridges the gap between approaches, allowing designers to apply appropriate principles to different features

This convergence suggests that the future won't be about choosing between DfM and DfAM but rather about seamlessly integrating the right approach for each specific design challenge.

Conclusion: Making the Right Choice for Your Product

The choice between Design for Manufacturing (DfM) and Design for Additive Manufacturing (DfAM) represents more than just a technical decision—it's a strategic choice that impacts your product's performance, cost structure, and time-to-market. As we've explored throughout this article, each approach offers distinct advantages for different scenarios.

Traditional DfM continues to excel for high-volume production where cost efficiency and proven materials are paramount. Its structured methodology aligns perfectly with industries requiring regulatory compliance, consistent quality, and established supply chains. For many products, particularly those produced in large quantities, design for manufacturing solutions remain the optimal approach.

Conversely, DfAM unlocks unprecedented design freedom, enabling complex geometries, part consolidation, and customization that traditional methods simply cannot achieve. For low-volume, high-complexity applications or products requiring rapid development, DfAM provides compelling advantages that can transform your approach to innovation.

Many leading companies are discovering that integrating both methodologies—applying each where it delivers the greatest value—creates the optimal development strategy. This hybrid approach harnesses the efficiency of traditional manufacturing alongside the design freedom of additive technologies.

#Design for Injection Molding#DFM for Medical Devices#Plastic Part Design Optimization#design for manufacturing services#design for manufacturing solutions#DfAM

0 notes

Note

pro football player!bllk with girlfailure gf 🙏

“𝐛𝐫𝐚𝐢𝐧𝐜𝐞𝐥𝐥 𝐧𝐨𝐭 𝐟𝐨𝐮𝐧𝐝”

a/n: reader is me i fear because i had apple maps on and turned left when siri said turn right (i ain’t ever living that down)

ft. isagi yoichi, itoshi rin, itoshi sae, nagi seishiro, mikage reo, kaiser michael, shidou ryusei, aiku oliver

isagi yoichi

"i’m not saying you're a disaster, love, but i just saw the smoke coming from the toaster and knew you tried to make soup again."

yoichi is genuinely concerned for your wellbeing on a daily basis. he’s in the peak of his athletic prime – eating clean, training consistently, and optimizing performance… and then there’s you, googling “can i eat expired pudding if i microwave it?”

he keeps track of your life with the dedication of a world cup coach. daily alarms set for you. calendar events for you. a literal google doc titled "how to not die this week – for my girlfriend."

“yoichi, i accidentally took a sleeping pill instead of my vitamin again. at 2pm.” “... okay, stay on the phone while i cancel your dentist appointment and put you in bed.”

when you showed up to one of his games wearing a shirt with his face on it, backwards, he didn’t even blink. he just fixed it for you mid-tunnel entrance like he was adjusting his jersey.

he tells reporters, “she keeps me grounded.” what he means is you walked into a glass wall yesterday trying to wave at a squirrel.

itoshi rin

"you’ve burned water. explain to me how that’s even physically possible."

rin is the definition of organized. you? you just poured orange juice into your cereal because you were “half-awake and the cartons looked the same.”

he constantly looks like he’s asking god why he’s being tested. but despite the judgmental sighs and eternal frown, he never lets anyone else talk down to you.

“i couldn’t figure out how to put gas in the car so i called triple A and cried.” “... i’m going to show you how to do it. we’re going right now. bring your notebook.”

he sets emergency funds aside just for your monthly “life mistake.” like the time you bought a fake designer purse that turned out to be a lunchbox.

but he remembers everything. your favorite candy. how you like your grilled cheese (burnt, apparently). which socks help when you’re overwhelmed.

once you got lost in IKEA and called rin in a panic. he tracked you down like joe goldberg.

itoshi sae

"i make millions a year and my girlfriend just got stuck in a revolving door."

sae is rich, classy, and elegant. you once mistook a bidet for a drinking fountain. opposites, baby.

he acts all nonchalant and "ugh," but he's always silently picking up the pieces after you’ve caused another minor catastrophe.

“i thought the microwave was the oven and now the plastic is part of my dinner.” “okay. i’m ordering sushi. don’t eat it. i mean it.”

he’s weirdly patient with you. will roast you endlessly, but also brush your hair out of your face while saying “idiot” in the gentlest voice ever.

once, you tripped walking up the stadium stairs and spilled a nacho tray onto a stranger. he didn’t even blink. just pulled out his black card and paid for all the ruined food.

“do i like her because she’s cute? no. it’s the comedy. i never know what she’ll break next.”

nagi seishiro

"wait… you were supposed to go to work today? oh no."

you both forgot what day it was and slept through a meeting. your lives are one long nap and an accidental door dash order.

nagi genuinely doesn’t care about your failures. he just kind of blinks and goes “eh, sounds annoying. let’s lie down.”

“sei, i think i broke the vacuum.” “cool. guess we don’t clean now.”

you once forgot to bring your passport to the airport. he forgot his shoes. you were that couple. the airline staff pitied you.

he lets you stack your chaos on top of his. gets a little spark in his eyes when you mess something up. “you’re funny,” he says as you spill water on your laptop.

surprisingly supportive. doesn’t fix things, but he’ll cuddle you while you cry about them.

“i ruined the job interview.” “eh. next one. let’s get ice cream.”

mikage reo

"my baby can’t do taxes or read maps, but she’s hot so it’s fine."

he’s so ridiculously rich and competent, and you’re just trying to remember your email password from middle school.

constantly watching you with an amused expression like “wow. she’s really out here giving it her best. adorable.” like you said “i think i wanna become an astronaut” and he started looking up NASA internships.

“reo, i tried to meal prep and now there’s rice in the ceiling fan.” “that’s talent. you want a private chef?”

he buys you a new phone every time you drop one in the toilet. it’s happened four times.

he sends you voice notes like “baby, remember to eat today” and you reply “does chocolate count?” and he’s like “only if you eat six.”

will absolutely drop $30k on something to make your life easier and then call it a “just because you’re a princess” gift.

kaiser michael

"schatz, why are you crying?" "i tried to braid my hair and now there’s a comb stuck in the wall."

kaiser is such a showoff. pro athlete, media darling, good with money, sharp as hell. you? you tried to fix the wi-fi by blowing on it like a nintendo cartridge.

he lives for your mess. he thinks it’s hilarious. he’ll walk into a room you destroyed and be like “wow. modern art. you’ve outdone yourself.”

“kaiser, i accidentally sent my manager a meme instead of my availability.” “did they laugh? no? then resend with context.”

he’ll bully you for your mistakes but then drop everything to help you anyway. “you’re lucky i like you. and that you look hot when confused.”

secretly addicted to you needing him. will pout if you fix something yourself.

“you didn’t call me when your sink broke?” “i googled it.” “what the hell. i was emotionally prepared to be your hero.”

shidou ryusei

"guess what i just did!" "lit something on fire?" "how did you know!?"

you two are absolute chaos. you keep failing at life and he cheers you on like it’s a sport.

“i just sent an angry email to the wrong person.” “HELL YEAH BABY. make it worse! want me to reply with a meme?”

he loves how you panic over small things while he eggs you on. “i lost my shoe!” “go barefoot! embrace the primal life!”

he brings out your most unhinged side and encourages your impulsive decisions. “should i dye my hair pink?” “only if you let me do it with kitchen bleach.”

somehow, when you’re both together, things work?? the disasters cancel out??? or at least no one’s bored.

“she’s dumb, and she’s mine. and if anyone says anything else i’ll headbutt them into next week.”

aiku oliver

"you’re not a failure. you just have a very… creative approach to life. and gravity."

he’s the charming, cocky pretty boy captain and you once fell down an escalator because you were texting.

he calls you “baby” in that teasing voice every time you mess something up. “baby… you really locked yourself out again?” “yes…” “adorable. hold on, let me come save your helpless little ass.”

literally spoils you rotten to compensate for your chaos. you messed up your entire skincare routine and he booked you a five-star spa appointment.

jokes that you’re his "clumsy little gremlin" and kisses your forehead after you bump into a pole.

also weirdly proud of your fails. tells his teammates about them like fun facts. “my girl once put dish soap in the laundry machine. we had bubbles for hours."

he likes that you need him. not in a weird possessive way, just in the fun way.

“she keeps life spicy. also, she accidentally started a fire once by microwaving foil.”

© 𝐤𝐱𝐬𝐚𝐠𝐢

#blue lock#blue lock x reader#bllk#bllk x reader#blue lock headcanons#isagi yoichi x reader#yoichi isagi x reader#rin itoshi x reader#itoshi rin x reader#itoshi sae x reader#sae itoshi x reader#nagi seishiro x reader#seishiro nagi x reader#mikage reo x reader#reo mikage x reader#kaiser michael x reader#michael kaiser x reader#shidou ryusei x reader#ryusei shidou x reader#aiku oliver x reader#oliver aiku x reader#braincell not found

600 notes

·

View notes

Text

Fionna and Cake theory: Simon the Artist

Nothing like a good old creative panic attack.

Fionna and Cake good. Haven’t been excited about a show like this in a long time, though it being a part of Adventure Time does help quite a bit. I was holding on to some cautious optimism for the show when it was announced as yet another big IP series covering the multiverse (still waiting to groan at THAT scene where Prismo has to explain to us about there being infinite universes), but as usual, Adventure Time’s crew continues to surprise me with its creativity, humor, and thematic resonance.

The most striking part about Fionna and Cake so far is just how deliberately the show wants us to differentiate it from the original Adventure Time.

We’re getting shots where Simon pops an artery from his arm, a theme song that explicitly talks about suicidal ideation, discussions of rent and financial problems, and curses no longer disguised with AT’s usual dialogue. Adventure Time has always had violence, thematic density, and juvenile rating pushers, but they were always reserved at small points. Meanwhile, these are factors that are just casually shown and discussed in Fionna and Cake every 3 minutes or so. This is not an all-ages miniseries, it’s for young adults. (hint: this will be relevant later)

Let’s get right into it. This is much less a speculative lore theory and more on what thematic direction the story may be going.

Before we do, let’s get this out of the way first. This theory assumes that the current Fionna and Cake world is all a part of Simon’s head and not merely a separate multiverse, which… I’m certain is fact for the following reasons.

The immediately obvious piece is that Fionna and Cake was always the Ice King’s fanfiction. Now if you’re versed in AT’s continuity you’re probably going to be asking about the red light in Fionna and Cake + Fionna and… I’ve no answer for it unfortunately. It’ll probably be relevant later in the series and possibly age this post like milk but for now, we’re not here to focus on the how, but the why.

Second is that the intro and the ending of Ep 2 literally show Fionna’s world spilling right out of Simon’s head like an animated world out of a frozen brain. If that isn’t clear enough-

Didn't realize this until writing, but these glasses are just plastic made to look like Betty's

There’s no other explanation for this other than that this world is artificial or influenced by Simon in some sense. Fionna even specifies that the statue went under renovation 12 years ago, but nobody seems to know who it is. Considering how Finn looks in the episode, it’s likely that it’s been that long since Betty’s sacrifice in the finale.

With that out of the way, here it goes.

The reason Fionna and Cake exist in the first place is because the creators found Natasha Allegri’s genderswap designs charming and wanted an in-universe reason to use them the Ice King wanted to create trashy, wish fulfillment through art. It was a phase.

Definitely changed that image for publishing.

Simon can argue if they’re good or bad but it’s undeniably his art. It’s not just a portfolio he left behind in a closet, it’s an experience that was shared with a larger audience.

And even if wasn’t liked at first, the citizens of Ooo seemed to have come around to it. And some of them love it!

Whether Simon likes it or not, he has a fan base that is so endeared to the story he made all those years ago that they demand he makes more. Why let a good story, loved by many, go to rest when you still have some life and creativity left in you?

Can't move on in more ways than one.

Except, the problem is that Simon isn’t Ice King anymore. He’s aged out of it.

His real passion is history, he's an adult who who finds passion in the mundane and antiques from the past. And frankly, there isn’t much room for wish-fulfillment and fantasy anymore. Simon has responsibilities. He has a job and a daughter in a world that is moving faster than he can process.

And where Ice King wrote about looking for love, Simon has already had it.

And lost it. His mind isn’t focused on the rosiness of finding new love, it’s grieving the one he already thought was the one.

Wasn't he supposed to be good with kids?

Despite his new life experiences, all his peers seem to want from him is to make more of what they’re familiar with.

A story made from wants and wishes that he doesn’t even have anymore.

A story that was literally made by someone else at a different time. It’s a fiction he cannot connect to anymore, art that he’s embarrassed by. Yet also jealous of. Because at one point, the body Simon used to be in understood what exactly was missing from his life and could express that easily.

Seeing it again is like experiencing a retrospection of a cringey loser you don’t want to imagine having ever been. It’s not you anymore, and you don’t want to be reminded of that.

Because despite him having a new creative passion, no one seems to care about that. All they want is Fionna and Cake. And what is more lonely than other people misunderstanding what you’re trying to express?

If I failed to make it clear somehow, my theory is that: Simon’s relationship with Fionna and Cake is a metaphor for creators growing out of their art. And this new Fionna and Cake world is still comfort art born out of Simon’s current desires and perceptions.

The snippet subtitles this “child holding a phone”. I guess I’m wrong. Essay over.

Episode 1 and 2 both have direct parallels with each other. They’re both about a protagonist who are feeling displaced from their world, living a phase of losing a significant other, leaving a thankless job, wearing a mask of stability in front of the people they care for, seeking a guru at the heart of the forest, and concluding that they no longer belong in their current world.

But more importantly, Fionna and Cake (the characters, the world, and the show) are no longer for an all-ages crowd. Fionna and Cake now feature young adults, curses, gore, alcohol, partial nudity, financial issues, morning routines, mid-life crisis, and overt suicidal ideation. These are the feelings that Simon relates to and possibly desires to express through art. Thus, his story and our new miniseries have warped that way.

Am I overthinking this? No. How dare you assume that.

Is equating the unconscious writings of his dementia-ridden self to Simon as his younger self seem a bit odd? ….Kinda. Again, it’s not the how but the why that matters in this case. I'm NOT crazy, I have proof that there is some acknowledgment of this directly in the show.

Rewatch the bar scene and apply this reading of the episode to what Simon says there:

“Your old stuff, Fionna and Cake, honest to glob my man, is an inspiration to me.”

“My old stuff, I don’t really want to talk about my old stuff…”

“Why not? You should be proud! You wrote an entire extended universe in a fugue state if you think about it.”

"Simon cringes"

If you have ever shared art with a group of people in the past, you’ve had this conversation.

Not likely, not possibly, no perhapses. You HAVE.

And Fionna and Cake being an epilogue to a massive award-winning, near-decade-spanning, cultural sensation 5 years after it ended, might result in its creators feeling very retrospective about what audiences want from them now.

And how difficult it’s going to be to tell new experiences and tones from what’s come before. Also, come on. “Extended Universe?” That doesn’t sound like Fionna and Cake. That sounds a lot like something else.

Again, seems bad with this kid.

One of the more profound shots in the main trailer for the show features the inconspicuously Finn-like kid crouching at her Fionna and Cake book in Simon’s trash. I believe this character is going to have a major role in two ways. Convincing Simon to be proud of what he’s accomplished and/or embracing that Simon wants to move away from his original work in order to create something new, or perhaps more likely, reinvent Fionna and Cake into what Simon relates to now.

We’ll just have to see what Simon thinks of his new Fionna next week.

PS. Talking as a fan now, WHAT IS UP WITH THE 1000+ TREEHOUSE IN THE INTRO?!!! ARE WE REVISITING THIS TIMELINE AGAIN?

SOMEONE TELL ME NOW!!!

#television#adventure time#fionna and cake#simon petrikov#fionna campbell#animation#speculation#theories#fan theory#character analysis#discussion#adventure time spoilers#fionna and cake spoilers

561 notes

·

View notes

Note

5 facts about Moth Wizard that you find important? or your top 5 characters? 👀

Hi sorry this took a while, keeping it within a reasonable length and on topic was a challenge but I'm really happy with how it turned out and it was a lot of fun! Thank you for the ask!!

5 Moth Wizard Facts:

1. The General Setting

Moth Wizard takes place hundreds of years in the future and the setting is a mix of optimism, dreams to help me cope with the present, and justification for the post-apocalyptic fantasy aesthetic. This includes "mildly utopian" settlements being common globally, prehistoric dinosaurs roaming the Earth, and a lot of overgrown ruins of the modern world. The rotting corpse of capitalism itself. One day all the concrete will be dust and even plastic will learn to decay, but we will still be here, building something better.

2. A Precious "Detail"

The most important (to me and to the characters) and self-indulgent piece of dreaming a better future is not actually going to be plot relevant much. The Third Temple stands in Jerusalem. Despite everything, after more than two thousand years of persecution in exile, the Jews survived, made it home, and thrived. Opinions differ on whether to finish painting your house.

3. The Apocalypse

If it's "post-apocalyptic" there must have been an apocalypse to be post. Looking at what's become of the world in recent years I'd say it's already started in our time. Ours will hopefully somehow change course but theirs didn't. Things only escalated until the flames burned out. And the world would never see such horrors again. But importantly, it was not worth it. Billions of people died, countless ecosystems destroyed and species lost, many large parts of the world rendered uninhabitable to most life. It didn't have to go this way. A rainbow above the ashes. This was not justice. Everything we built in the ruins was built in spite of what happened.

4. Magic

The magic system is designed such that, in theory, anyone could use it to do almost anything. In practice, it requires a very specific mindset, focus, and (if one wants to do it with any consistency and accuracy) a lot of practice. The most important factor, in what actually happens when attempting to do magic, is expectation. Trying to cast a fireball will never result in ice cubes, but it can result in nothing happening except embarrassment of the caster, if they are not fully convinced that they will, in fact, cast a fireball. Even considering what to do in case a spell fails can cause the spell to fail. This is why most wizards tend to specialize, really knowing what your Thing is and that it always works really helps make it always work.

5. Moth Wizard in the Narrative

The titular Moth Wizard himself is an autistic Jew and his role in the story, as I plan to tell it, doesn't easily fit into categories like "protagonist". Moth Wizard is supposed to be sort of like an anthology. A collection of almost unrelated stories, which, if analyzed in isolation and purely as a series of events rather than a specific narrative, would each have different main characters. The thing they would have in common is that Moth Wizard would be there as a side character, someone helping the protagonist with their goal. But the way I plan to tell these stories with clear main characters is following Moth Wizard's perspective. But not entirely taking his perspective either. It is not a story we see through his eyes. You can think of it like a nature documentary, with David Attenborough following the side character life of this peculiar moth... wizard.

Thanks again for the ask!! :3

#ask the tooth folk#ok to reblog#sfw#personal#viktorsbedpartner#Moth Wizard#You Will Be Seeing This Post Again#tw war#cw war#war cw

15 notes

·

View notes

Text

Game Review: Factorio: Space Age (pt 2)

This is the second part of my review of Factorio: Space Age, covering the planets. This will have more spoilers than the previous section, but also include more cohesive thoughts on the expansion as a whole.

Vulcanus

Once you've built a spaceship, you have a choice of three planets to go to, and you can do them in any order you'd like. Each planet comes with its own researchable rewards, which require you to build up a base on the planet capable of making a science pack and shipping it into space (or alternately, to remake all sciences on the planet, but this is stupid and pointless given what lies further down the tech tree).

I chose Vulcanus first. There are five resources here, three of which can't be found anywhere else: coal, sulfuric acid, calcite, tungsten ore, and lava. Lava gets used to make anything having to do with copper and iron using the foundry, which is most of the things in Factorio. Sulfuric acid gets used with calcite to make water, which is one of the notable things missing from Vulcanus, along with oil. Plastic requires a long chain to make: coal liquefaction into heavy oil into light oil into petroleum into plastic. Because rockets require plastic twice (LDS and blue chips), you eventually need to set up a fairly sizeable build for this.

I didn't find any of this to be too interesting. Infinite resources are at least different, but there was nothing that fundamentally changed how I view the game, and I ended up setting up a bus with more fluids than usual, mostly making on-site plates, pipes, steel, etc. The art for it is cool, and impassable lava is at least a little constraining, but I didn't feel like it was all that great.

Tungsten ore is the main material from Vulcanus, and it's defended by the other major thing that makes the place unique, the worms. Each worm has a territory, and until you've killed your first worm, you don't have access to a tungsten ore patch, only loose scraps that have been laying around.

The worms are long and segmented, very distinct from the biters. They disable electronics with their attacks, making fountains of lava beneath you, and overall I think they're cool ... except that they're a little too easy to defeat. I set up a grid of 50 turrets with armor-piercing ammo, and that proved sufficient.

This is a boring solution. I wish it didn't work. It was the first thing I tried, and afterward I thought ... well, what was the point of that? I don't have a good solution to what you'd want to do to stop this from working, but I do think this is sort of bad design, since it's a "more dakka" solution. I've also seen that you can build a tank and take one out with a single uranium shell, which is even worse design. What I wanted was a fight were I needed to use poison capsules, land mines, strategically placed turrets, etc., some kind of mixed-asset offensive package, and what I got was fifty turrets in a stupid grid. I really do try to not be one of those players that optimizes myself out of having fun, but it's hard to motivate myself to do something the pointlessly hard way when there's something simple, easy, and foolproof.

The other thing about demolishers is that they have their own territory, and that territory never changes. This means that if you want to expand beyond a relatively modest starting patch, you need to kill them ... but unless you're going for a megabase, you don't need to kill more than three or four of them across the entire time playing the game, and since they only attack if you build in their territory, those worm encounters become like 1% of the Vulcanus experience.

I would have liked if the worm territories changed. I think it would have been cool if they fought each other for dominance over an area in a way you could capitalize on, or if they would expand into places that no one had claimed, or places a dead rival had left behind. It would have been cool to require the player to build up some do-nothing machines or other infrastructure to keep the worms back, like a sort of "build this at the edge of your territory to be in constant motion to convince the worms that it's occupied" type of thing. But instead, you just kill the worms and that's that, you never see them again unless you go hunting them. According to my end-of-game statistics, I killed 8 small demolishers and 2 medium demolishers, which was probably 5 more worms than I needed to kill, since I ended up with a lot of empty space I didn't do anything with.

So overall, Vulcanus is the weakest of the planets for me, and I think that's at least partly down to the under-use of the worms and the simplicity of the "new" mechanics.

Fulgora

Fulgora contains the ruins of a vast civilization, and there are no resources except the heavy oil between islands and the scrap that's left behind. Solar is terrible on Fulgora, but there are lightning storms at night, and lightning towers can collect it into accumulators to power your base.

Scrap gets "recycled" into a bunch of different things, and so it quickly because a nightmare of sorting things out, dealing with excess products, and turning complex materials into simple ones. There are no iron plates, those need to be recycled from iron gears. There are no copper platers, those need to be recycled from copper wire. Blue chips, which in any other circumstance need to be jealously guarded, are found in abundance.

I found this to be great fun. The challenge is certainly unique, turning the production chain on its head, but it has a nice "ramp" to it, as first you get a pile of crap, then you turn it into things, then you uncover excesses that are gumming it up, and the problems keep coming, but they usually come after you've solved some other problem.

When I started, I did a sushi belt (ed. - a sushi belt is a belt that contains multiple unsorted good, controlled by circuit conditions which allow certain limits of each item to go by, named after conveyor belt sushi restuarants), which was good enough for the short term and got me all the basic technologies, but ran into all the problems that come with a sushi belt, and switched over to a belt-based sorting system of splitters that could handle two full green belts of scrap input.

There is, for me, one big miss on Fulgora, which is that the lightning storms are basically not a challenge at all. You set up a grid of substations, each with a lightning rod, and that protects your base. You set up accumulator fields on one tip of the island, and this is a pretty boring solution. If you went to Gleba first, you can instead set up heating towers that burn the fuel you get from scrap, but this doesn't seem like it saves terribly much more space, and either way you need the lightning towers, so I'm not sure it's worth anything, and I never implemented that plan.

One of the other big challenges of Fulgora is that it's a set of islands, and there's no way to place anything on the oil sands. Additionally, there are two types of islands, one with a fair amount of space and minimal scrap, the other with tons of scrap and almost no room. In theory, this encourages a rail world, but in practice, the first island I plopped down on was the one I stayed on the entire time, and my rail network, such as it was, extended to only two of the smaller islands to guarantee all the scrap I would ever need. I think I rolled high on one of those islands: 63M scrap is a ton, but that's what I ended up with on default settings. With the drills from Vulcanus, expected output is double that, and with the legendary drills I can now produce, it would be 787M. There's simply not a need to place rails elsewhere.

I do feel that Fulgora would have benefitted from some enemies of some kind, either those that lived on the oil fields, so you'd have to build defenses on the edges of the islands, or some kind of robot enemy that you needed to kill to take islands from. Given the setup of an abandoned high-tech planet, and the electrical weapons you unlock there, it would have been nice to have some reason or chance to use them. I've definitely played Factorio scenarios with bot opponents and buildings that can be captured after the AI's defenses have been breached.

Still, the scrap sorting puzzle was a good one, with many solutions, and Fulgora was a ton of fun.

Gleba

Gleba is a swampy fungi planet. There are no conventional resources except for stone, and pretty much everything else is derived from two plants, jellynut and yamako, that get broken down.

The main mechanic of the planet is spoilage, where materials break down over time. Jellynut and yamako last for about an hour, the products you get from them are much less, a material made from both of them, bioflux, lasts a lot longer, and nutrients, which are fed to the new building, the biochamber, last hardly any time at all.

Spoilage is cool because it requires a very different mindset. Normally in Factorio, you're building up big buffers to minimize downtime. On Gleba, you want as little buffer as possible, just constant rivers of materials flowing by to be as fresh as possible, because if anything stays still for too long, there's a chance it'll spoil, which will stop the machine trying to take the ingredient, which can create a spoilage cascade.

My initial plan was to have some kind of circuit-based just-in-time system, where every machine would be monitored in order to see what ingredients it needed, and everything would be made fresh-to-order.

I ended up not doing this, mostly because demand stays relatively constant, and where it doesn't stay constant, you can just eat the spoilage costs. There's so much abundance that you really don't need to care about half your crops going to waste.

The other reason I didn't end up going with this is because unfortunately, the "river of goods" solution has essentially no complications to it, and you can simply dump everything into a recycler/incinerator at the end. In some of the Factorio overhaul mods, this concept is called "voiding", a way of dealing with byproducts, and if you make voiding easy, you essentially remove a logistical challenge, which means less gameplay. I kind of get why they made this easy, but ... I don't know. I did kind of want something that would require a big, complicated solution, a factory that dances on the edge of clogging itself up.

I ended up with a completely belt-based system, with a belt of jelly and mash, then a belt of bioflux, all nutrients made on demand, and production lines in defined blocks. The final build does 520 science/minute, which becomes 2Ks/m with full-prod biolabs, most of which goes into the trash, since it's not actually consumed all the time.

One of my favorite little puzzles of Gleba was the metals, which are produced with bacteria that spoil in a minute, becoming ore. There's a process, with bioflux, of having bacteria make more bacteria, but if the bacteria ever stop flowing (if, for example, you have enough ore), then they spoil and die, and the whole production line stops. So you need to build in a little kickstart system that will inject new bacteria if it's needed, and I found that to be delightful to work on.

The other major thing on Gleba are the enemies, which are pentapods. Pentapod eggs are necessary to make biochambers and science, but after you have one, you can set up breeding, which is dangerous given they can make more of themselves, but definitely the way to go. There are three forms of pentapod, all with their own weaknesses, and ...

Look, I went to Gleba last, but I put up a defensive wall fairly early on using only materials that I had gotten from Gleba, and then basically never had any cause to think about the pentapods again. Because I slapped this down with blueprints, it took all of ten minutes, most of which was spent fixing the kind of scuffed corners (skill issue). So I would say the amount that I actually got to experience the pentapods was pretty minimal. I also shipped in four artillery turrets that are crowded around a box of ammo, supplied by site-made shells using imported tungsten, and the circle almost entirely contains my pollution cloud, so in theory it's just an easily solved problem.

It might have been different if I had gone to Gleba first, I don't know and can't say without actually doing that, but I would have liked a little more of a challenge, and this might be where being a veteran hinders me.

Overall, I really enjoyed Gleba, the mechanics were new and unique, the little puzzles inherent in design were interesting, and I thought that overall it had the best art direction of the four planets, which is saying something, because I think they're all great on the front.

Aquilo

On every other planet, a "cold start" is possible, building up from just what you find laying around. Aquilo is different: it's a planet with ammonia oceans and some scattered liquid vents, and part of the point of it is that you need materials from outside, including anything made from iron, copper, or stone. You can't softlock on other planets, but you can softlock on Aquilo.

Aside from requiring pretty solid planetary logistics, Aquilo's main mechanic is heat. It's cold enough there that bots don't work very well, and everything has to have a heat pipe near it for it to function, including pipes and belts. To heat up a heat pipe takes either nuclear, fusion, or the heat towers that burn up fuel, and if the heat ever stops flowing, everything will seize up, requiring heroic efforts to get running again.

There's not all that much to Aquilo. You pull up slurry from the ocean, split it into ammonia and ice, use them together to make ice platforms, import concrete, and then combine oil and ammonia to make rocket fuel, which is used to both launch rockets and to toss into heating towers for power and heat to keep everything running.

The science pack is easy, though it require imported holmium plate, and my entire 200 science per minute production line was run off a tiny cluster of buildings that would have been pretty trivial to expand.

It seems to me that Aquilo is at least partly inspired by Seablock, an infamous mod where you start with almost nothing on a tiny island that you have to expand with the mineral sludge you dredge up with an offshore pump. But Seablock is a very long mod, one that typically takes hundreds of hours, and here ... well, there are a handful of challenges, and they're not all that challenging. I think I could probably list them out now.

Making ammonia also makes ice. You can void excess ice through repeated recycling, but ammonia can't be voided except by combining it with crude oil to make solid fuel, which can then be put in an incinerator. I solved this problem with a simple circuit condition.

Science and some crafting uses coolant, which must be cooled back down after use. If you just keep making coolant, eventually the system will seize up, since you won't be able to put more hot coolant into the system. But because this is a lossy cycle (you lose half the coolant) you can just hook a pump up to a tank and only inject more hot coolant into the system when below a threshold.

Outposts need their own heating for the pumps to work, and those outposts are, on default settings, quite far away. This requires setting up a self-sufficient little heating module that's either serviced by train or which runs entirely with materials found at the outpost. I ended up doing two different modules, one for oil outposts and the other for everywhere else ... but I never actually had to use them, because there were sufficient resources for tens of thousands of resources right next to the starting area.

As the "final boss", I am underwhelmed, and even as one of four planets I find myself a little underwhelmed. I don't know how much postgame stuff I'm going to do, but I can't see that there's going to be much challenge in going large on Aquilo, except that I might have to build another ship for moving in materials (as currently I have a single ship that makes a circuit of the solar system for materials and also handles shipments of science).

There is also, again, a lack of enemy. Once the rocket fuel setup was done, I had a single scare when ammonia backed up and stopped ice production, which shut down the water chem plant, which killed the turbines and stopped power to the entire base. But that didn't even freeze anything out, and it was fixed pretty easily from a restart module I'd built earlier, and after that, the ammonia issue was fixed to never have that problem again. If the cold is the enemy, it's not enough of one for my tastes.

Integration

With each planet you conquer, you get a new science pack, which opens up new technologies, and in theory you, can use them on other planets. These buildings are very powerful, and so there's some incentive to return to old factories, rip up old designs, and install new ones using the better buildings.

I did eventually do this, but I'm not sure how much I actually needed to. My furnace stacks were replaced by the foundries from Vulcanus, supplies by a hauler ship exclusively for calcite, though I did make an abortive attempt to just harvest calcite from space using a stationary space platform.

(I made four of them before giving up on the project, and found out only later that asteroid spawn rates depend on how many chunks large the ship is, so the ideal build has asteroid collectors on very long arms, and there's nothing in the game that tells you about the asteroid spawning thing, so ... whatever, it's opaque and very gamey hidden stuff, of the kind that I hate.)

I replaced my circuit production areas with the EMP, which saved vast quantities of resources and also made more circuits at a much faster rate within the same blueprint. I upgraded most belts to green.

I didn't end up using the biochambers much, in part because they need nutrients to run, and 50% prod with more module slots is great, but not so great that I wanted to set up a biter egg farm that could potentially blow up in my face.

Cryochambers just came too late for me to implement them anywhere, though I probably would if I kept playing to the megabase stage, or if I'm gunning for an achievement that requires updating Nauvis.

So I think, strangely, when considering how the planets impact each other, they ... kind of don't all that much? Yes, having foundries on Gleba means that you can make all your belts and things at a fraction of the cost, but how much doesn't that really impact anything? It meant that my ore production areas could be smaller, I guess. Is that worth anything? I kind of don't think so, if I'm considering the main gameplay to be in terms of design and decisions. Foundries saved me from having to lay down a furnace stack. EMPs saved me from having to have expansive red circuit lines to get the blue chips necessary for rocket launches.

Ideally, I would have liked one or two killer techs that mostly work through combining each planet's "thing". Like imagine that there was a combination recycler and foundry that melted down whatever was put into it, giving you molten copper and iron in exchange, creating a whole new kind of problem in exchange for ... I don't know, much much faster recycling, or less loss from recycling, or maybe a recipe that allowed true voiding. Or if you went to Gleba and then Vulcanus, and were able to bring biochambers that would allow the cultivation of some new specimen specific to that environment, maybe something that would allow better plastic production, or could pull water out of the air, both of which are kind of a pain in the ass on Vulcanus. Couldn't there be some kind of new bacteria swimming in the oil sands of Fulgora? Not something that would trivialize any challenge, something that would be a reward for having two flavors of research from two different planets. Ideally, there'd be six of these in total, allowing for each pair to benefit each other pair, but at that point I start to feel like I'm just asking for new content.

I cracked my game back open to check the tech tree, and all the Aquilo techs require all three planets. The are two techs that require mixed packs: Rail Support Foundations, which simplify rails for Fulgora, and Railgun Damage, which increases the power of the railgun. That's it. This screams missed opportunity to me.

So in terms of how the planets and their mechanics interact with each other ... I would say that they mostly don't, which is a bit of a shame. The biochamber in particular requires nutrients, which makes it effectively unusable on Vulcanus and Fulgora ... unless you're shipping in heroic quantities of bioflux, I guess, though I don't think that I could ever see myself doing that. I guess maybe on Vulcanus, which has the aforementioned plastics problem? But it feels like the kind of thing that would mostly be done for a stunt rather than because it was actually the right thing to do. And potentially on Nauvis, but it does seem like a megabase thing to do, rather than normal play. I will have to do the math, this too might be a skill issue.

(Real quick: 1 Bioflux makes 8 nutrients in a standard biochamber, which is 12 with prod, which is 24 MJ. A biochamber consumes 500kW, so with no spoilage nutrients allow 2 crafts of the 2 second oil cracking recipes, which means that every Bioflux can, at most, turn 960 heavy oil into 1080 light oil rather than the 720 light oil it would normally crack into. But obviously since the Bioflux has to be shipped in, it ends up being less than that. This is obviously more effective than shipping over oil itself, but ... man, I don't know, this seems very weak, even with adding in productivity to other steps. I guess the use case in Nauvis, where you're in theory shipping Bioflux anyway in order to feed captive biters, but that's still premised on an oil shortage that I never actually experienced.)

I do also want to say that quality had very little impact on my play. I tended to carry around some high quality quality modules and use them when crafting infrastructure, but in most cases it just wasn't much to write home about. It's most important for the ships, and for personal stuff, but it never felt that important.

And finally, I do want to give a shoutout to how easy and effective remote viewing was. One of the things I'm going to eventually do, after a Factorio break, is the 40 hour achievement run, and I have to imagine that a lot of that is just landing on a planet, doing the unlocks, building a rocket to get back, then having starter bots do all the actual base building for me, which is pretty cool.

Conclusion

Space Age took me about 140 hours, and I would say that about 10 of that was idle time while I was waiting for legendary ship parts or for a buildup of materials. The Jacknape-class ships have an issue with ammo production where they can more or less keep up with rockets, but the belt buffer goes from the front of the ship to the back, meaning that it empties from where it's needed most, rather than emptying where it's needed least, and yeah, having a fully stacked buffer takes a hot minute of waiting. Similarly, the quality module I made works over sufficient time scales, but especially while waiting on quality quality modules, there's a real temptation to just leave it running rather than actively playing.

130 hours for a veteran player is a long time for an expansion, much longer than I would have expected, even knowing what I knew about the expansion going in. Some of that time I don't count as expansion time, like all the parts where I was just doing normal Factorio stuff, and I did end up building adapted malls on each of the planets, which added on more time that could have been cut out by making an effective blueprint the first go-around, and which I don't really count as expansion time, because there's not much that's unique about making the new malls. But even if I'm arbitrarily cutting things out, that's still a ton of time.

Overall, I'm extremely happy with it, and I think I'll be more happy with it once there's another round of iteration, QoL, changes based on feedback, and modding. The modding scene for Factorio is really really good, and I have to imagine that the expansion is only going to make it better, particularly some of the changes that were made to implementation.

But I do think that it could have been more, and maybe this is just coming from a guy with more than a thousand hours in this game and multiple overhaul mods under his belt. It's very possible I would have had a better time with it if I'd chosen a higher difficulty, though of course that's very hard to know ahead of time. Certainly there were some design misses for me, and at least some of that is because I have enough experience that I can fix things with circuitry, plan a base that doesn't immediately become spaghetti, and see the deadlocks coming. I'm not saying that it wasn't hard, because parts of it certainly were, and I'm not saying that I made a bunch of perfect bases with no major flaws, because there were designs that needed to be ripped out and belts that needed to squeak through. But I think I would have preferred more complexity, more problems, more more more, and I'll have to hope that mods can give it to me.

All that said, this is the best expansion I've ever played, they put a ton of work into making sure that every planet was truly different from the others artistically and mechanically, and it's a 10/10 from me.

(I do plan on getting all achievements ... eventually. The "win in 40 hour" achievement seems very doable, and that's the hardest of the lot, though the others might take some significant time. It took me multiple years to finally getting around to doing the last green chip achievement, so I'm in no rush.)

22 notes

·

View notes

Text

DP3 - Research Project - Mediator Spaces

Week 2:

I started to explore and test materials this week, by mixing plaster with sand, salt and shells in different ratios, I casted several samples of materials. Further, I used casting to explored the idea of having Tribo-Panels connected to the skin of the building space to potentially generate energy. I should make more samples for structural testings next week, keep investigate different mixtures to find the optimal one, (having oysters as a protective sacrificial layer), and do more literature reading on the mechanical theory of the energy systems.

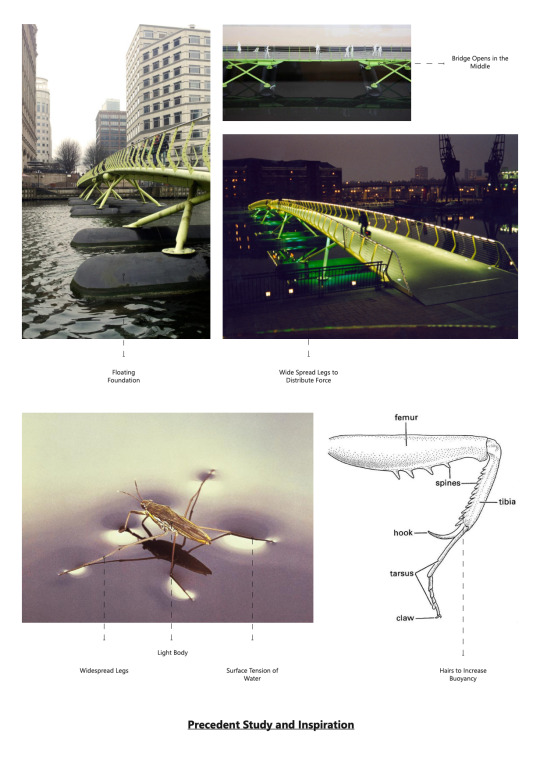

Inspired by the floating bridge and insects, I designed aero-limbs systems for the first buildings space, I should iterate on this design and explore the possibility of using anchors to support the buildings.

I also communicated the idea of buildings space 1, gathering space for oysters and salt erosion, through an axo; and the organisation of spaces. The idea is to have different circulation systems in the building to guide people through differently during high tide and low tide, the bunker lab would study how hostile environment would affect different people's behavior (e.g. small scale simulation space to get people's arm trapped). I will layer another layer of iterated plan next week in more details. The spaces can be more Interlocked as well.

Notes:

Measurable info for maps: Overview, zoomed in and section of high and low tides

research architectural projects in Blackpool

Archaeological maps of samples collected

Bigger social and env. responsibility of project

Labs to map different parts of the area

sacrificial and protective layer with structural core

Part static building with part buoyant

Lost Pier, fast moving Sands

shells with plaster to take more loads?

Literature study of energy systems

Making quicksand model

Using plastics bags to visually test wind

Torch for sun-path study

Orthographic and Stareographic of sunpath

Retreating Village, Smout Allen

Walters Yard, London

Arctic Research Station, icecap melting

Hugh Broughton, Axo

12 notes

·

View notes

Text

Weep Holes: An Essential Component For Structural Integrity

The world of construction methodologies is vast, dynamic, and continuously evolving. Among the myriad of procedures and mechanisms crucial to the development of robust structures, a particularly crucial yet often overlooked feature is the ‘weep hole.’ In this blog, we delve deeper into what weep holes are, focus mainly on their application in cinder block structures, reasons for their installation near the footing, and the benefits that they provide related to relieving water trapped within a structure.

To begin with, let’s establish what Weep Holes are. Weep holes, as the name suggests give an image of something that exudes, seeps out, or, indeed, weeps. In construction parlance, they are purposely drilled in a structure to allow the movement of water or to let it escape from within.

Though these holes can be integrated into several types of structural system, their use is widely popular in cinder block constructions. Cinder blocks, also known as concrete masonry units, are commonly used in residential as well as commercial construction due to their affordability, strength, and insulation properties. Their design usually involves hollow cores, or cavities, that can unintentionally trap water within. Whether it’s from groundwater, landscape irrigation, or rainfall, the cinder block can host this water, giving birth to many potential issues such as mold, mildew, efflorescence, or even structural failure if water freezes and expands.

Therefore, to alleviate these concerns, weep holes are drilled into the cinder blocks, typically in the bottom row and near the footing. Placed lower down because water tends to flow to the lowest point due to gravity, these openings play a vital role in the overall health and longevity of the structure.

When water is present in the hollow cavities of the cinder block, the weep holes facilitate an escape route. But it isn’t just about aiding drainage; these holes also play an essential part in the structure’s ventilation, helping trapped moisture to dry up more quickly.

One might wonder–why near the footing? The footing of a building is the lowest part of the structure, usually installed below ground level. For blocks near the footing, water accumulation is most likely due to their proximity to the ground. To prevent rising dampness creeping up into the structure and ensure optimal effectiveness, weep holes are strategically drilled near the footing.

One concern that often arises about weep holes is the threat of small creatures or pests entering through them. To prevent this, weep holes are generally covered with plastic, steel, or another type of mesh to allow water escape but deter critters.

Let’s sum up the importance of weep holes: They are not a construction afterthought but an essential design feature engineered to prolong and conserve the structural integrity of cinder block structures, whether they be a garden wall, chicken coop, house, or commercial building. By simultaneously promoting ventilation and facilitating the drainage of trapped water within the cinder blocks’ hollow cavities, weep holes help to prevent the onset of undesirable moisture issues, water damage, and structural instability.

So the next time you come across some random, small holes in a structure, remember, they aren’t gaps in design or construction; they’re mitigating water damage one drop at a time. This is the importance of an often overlooked, yet vital construction element – the weep hole.

Tagged Essential Component For Structural Integrity, Structural Integrity

#Essential Component For Structural Integrity#Structural Integrity#foundation repair#foundation solutions#foundation contractor#foundation experts#foundation repair solutions#foundation services#residential foundation repair services#foundation repair near me#foundation solution#signs of foundation problems

7 notes

·

View notes

Text

I'm sorry to all the people sore about the new packaging for Nendoroids, but some of these comments make it sound like you wouldn't have preordered, if you got the new box design that replaces all the plastic packaging with paper. o.o? Are you guys Nendoroid collectors or box collectors?

I don't know if you've heard this before, but GoodSmile figures cannot remain in the box. You're not preserving any collectibility by displaying your figures forever in the box. You're thinking of WESTERN figures and those figure producers' plastics. GoodSmile representatives have said several times, the plastic that GoodSmile uses to make their figures will DEGRADE if left unopened, in the box! The plastiziser will melt the figure surfaces and turn some platics into horrible discolorations.

Are you guys really buying articulated figures with swappable parts, to not play with them? Even my $120 scale figure, that i was afraid to touch, had swappable parts which i swapped and therefore, handled the figure, to set for optimal display.

How do you guys even have the room to keep all that plastic? I can't wait to have collapsible paper packaging, to save space, avoiding the struggle to throw it all away and wonder if it'll even get recycled. Some of you may have the money to buy all your figures and all the space you want. But some of us are just barely scraping together money for just the figures and can't afford to just get more storage/living space, just for packaging. I would love to just keep all my packaging, in case i decide to sell some of my figures in the future, but a lot of us have limited space and have to make tough choices.

Companies have to stop producing so much plastic. We still need plastic for our figures to be made out of, and if something needs to be cut, I'd rather it be the packaging. Recycling isn't working, and has been proven to be a scam in a lot of cases. China is no longer buying the world's trash to process or recycle. Japan has started new laws in 2022, to reduce plastic packaging by 2030 and become plastic-free by 2050. What do you expect to happen? For Good Smile Company to break the law, just so we can display their figures in the box---which will destroy the figures anyway? GoodSmile is not Tokyu or Mitsubishi. They don't have the power to bend laws to their whims.