Aosua company was established in 2009,mainly deal in cooling ,ventilation.It is located in a small city-shangyu,which near the shanghai and ningbo. 1)competitiveness:highest quality products,the best price,perfect service. 2)Professionalism:all the products are going over before leaving the factory, we will continue to improve our after-sales service system so that customers no worries. 3)Design and development:the introduction of foreign advanced equipment, first-class management level and economic strength,we also establish long-time relationship with famous universities in beijing and shanghai at the same time Our products:cooling tower,closed cooling tower,spares of cooling tower(sprinkler,socket,inlet louver and so on),fan, evaporative condenser Evaporated condenser and so on. Our products are sought after by those who demand the highest quality top performance superior customer service.Now our company have grown to be a world-class manufacturer of cooling tower.We continuously strive to be the best by fostering a quality culture based upon teamwork responsibility accountability communication.Our strength is the diversity of products fast delivery competitive pricing professional technical. If you are interested in any of our products or have any suggestion,please feel free to contact us. We are looking forward to forming successful business relationships with you. https://www.auvc.com/

Don't wanna be here? Send us removal request.

Text

Wet Cooling Tower

Wet cooling tower refers to a cooling tower with external spray and relying on water evaporation for cooling. The heat is carried out by the cooling liquid and dissipated in the air through conduction and evaporation, which is called wet cooling.

Wet cooling tower includes round cooling tower, square cross flow cooling tower and square counter flow cooling tower.

Advantages of Wet Cooling Tower

a. The structure of the whole wet cooling tower is light and exquisite, easy to assemble, strong and durable, with a good cooling effect.

b. The natural draft wet cooling tower is beautiful and durable, convenient for logistics transportation, assembly and maintenance.

c. The cooling tower has high heat exchange efficiency, the limit temperature of water cooling is the wet bulb temperature of the air.

Why Choose Wet Cooling Tower?

The wet cooling tower includes a circular cooling tower, a square cross flow cooling tower, and a square counter flow cooling tower. Compared with dry cooling tower, the wet cooling tower has smaller volume and higher heat dissipation efficiency, which can effectively control water pollution. The wet cooling tower is widely used in every department of the national economy, especially in cooling water circulation systems.

https://www.auvc.com/products/wet-cooling-tower/

0 notes

Text

Wet And Dry Cooling Tower

The wet and dry cooling tower is actually a combination of a closed cooling tower, cooler and wet cooling tower. The wet and dry cooling tower is a horizontal evaporative cooling tower. The process fluid flows through the pipe and the air flows outside the pipe. They are not in contact with each other. The wet and dry cooling tower is suitable for various cooling systems with high requirements for circulating water quality.

Advantages of Wet and Cooling Tower

a.The process of water evaporation and air cooling, heat and mass transfer are integrated, and the fin precooling section and water film evaporation section of air cooling are combined to enhance heat transfer.

b.The overall investment cost of the system is less, the operation fault is less, the maintenance time is short, and the operation cost is low.

c.The process fluid can be condensed and cooled at one time without installing other cooling devices and cooling towers.

d.Reasonable heat load ratio, effective precooling measures for the inlet medium, avoiding the scaling sensitive area outside the tube, greatly reducing the scaling phenomenon in the evaporation section.

e.The combination of air cooling and evaporative cooling has a wide range of application, good performance of demisting and antiscaling, and can realize dry operation without water in winter, which greatly saves water consumption and operation cost.

f.Using frequency conversion and other automatic control technology, the process index control is accurate.

g.The flexible design of coil bundle can effectively eliminate the thermal stress in the process of equipment manufacturing and operation.

h.Modular design, easy to manufacture, install, repair and maintain.

Why Choose Wet And Dry Cooling Tower?

The wet and dry cooling tower completely eliminates the harm of the cooling water system caused by sundries and scale. The softened cooling water circulates in the closed circuit in the system and does not directly contact the external environment. The wet and dry cooling tower eliminates the efficiency reduction and dirty fault caused by floating objects, dust and harmful ions entering the cooling water system and accumulating. The wet and dry cooling tower can not only save energy but also maintain water quality.

https://www.auvc.com/products/wet-and-dry-cooling-tower/

0 notes

Text

Square Counter Flow Non-basin Cooling Tower(AFW)

The square counter flow non-basin cooling tower refers to the cooling tower without a basin. Its principle is the same as a counter-flow square tower. The water flow falls vertically in the tower, and the direction of airflow is opposite to that of water flow. The water exchanges heat and mass with the air flowing through it, resulting in a drop in water temperature.

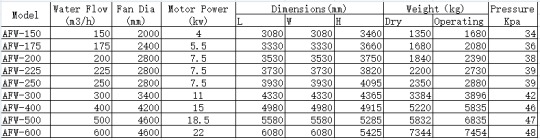

Parameter Of Square Counter Flow Non-Basin Cooling Tower

Precautions for installation of Square Counter Flow Non-Basin Cooling Tower

A、 Appropriate installation site should be selected

The ground bearing capacity should refer to the operating weight of the cooling tower and the design installation coefficient to check the bearing capacity of the installation foundation.

Environmental conditions:

a. The short distance between the air inlet end and adjacent buildings shall not be less than 1.5 times the tower height.

b. It should not be installed in substations, boiler, and other places with a heat source. Keep the top of the tower away from an open fire.

c. It should not be installed in places where corrosive gas exists, such as chimneys and hot springs.

B、 Installation instructions:

a. The foundation of the counterflow cooling tower shall be embedded with a horizontal steel plate according to the specified size. The height of each foundation surface shall be on the same horizontal plane, and the elevation error shall be within 1 mm, and the middle error of the intersection shall be within 2 mm.

b. The tower body should be placed horizontally, and the whole foundation should be built if possible.

c. When installing the water tower, the installation personnel should step on the reinforcing ribs of the chassis to avoid crushing the chassis. In addition, when installing the card shell, chassis and other fiber arts, the screws should be inserted first, and then gradually tightened in order to avoid deformation of the shell and chassis. Confirm that the chassis is not deformed, and the contact area and nearby are clean. Only when it is dry can the fiber blanket and resin be set at the joint to avoid water leakage.

Square Counter Flow Non-Basin Cooling Tower

https://www.auvc.com/products/square-counter-flow-non-basin-counter-flow-cooling-tower/

0 notes

Text

Square Cooling Tower

The square cooling tower is a kind of cooling water equipment, which can be divided into counter flow and cross flow cooling towers. Because this type of cooling tower has a square appearance, it is called a square cooling tower or a rectangular cooling tower, which can be connected in parallel. The square shape cooling tower is widely used in air conditioning, power plant, refrigeration, plastic chemical industry and other fields.

Advantage of Square Cooling Tower

a.Reliable: the unique and rational design of the external turbine is installed outside the air duct of the cooling tower, which is convenient for maintenance and repair. The structure is the same as that of the traditional cooling tower motor and reducer. The mechanical noise and failure rate of the traditional motor are eliminated, and the operation is stable and reliable.

b.Cooling efficiency guarantee: with the change of season, the cooling system will change. Three brake valves are specially designed for the external turbine to make the fan speed increase or decrease with the increase or decrease of circulating water flow and the air volume increase or decrease so that the air-water ratio of the cooling tower is stable in the best state and the best operation effect is achieved

c.Environmental protection: after the external turbine replaces the motor, it can reduce the mechanical noise and vibration, and reduce the user's energy.

d.Energy saving: make full use of the return water pressure of the circulating water system to convert it into mechanical energy, and replace the motor drive with the external turbine to achieve 100% energy saving.

e.Safety: fundamentally eliminate the motor, electric control and leakage damage, provide a guarantee for safe and continuous operation, can be safely operated in any explosion-proof environment.

Why Choose Square Cooling Tower?

As a professional cooling tower manufacturer, our company specializes in the production of square cooling tower, corrosion resistance, high strength, lightweight, small size, less occupation, beautiful, and transportation, installation and maintenance are more convenient, so it is used in air conditioning refrigeration, electric power, textile, chemical, injection molding and other industries, cooling water circulation system is suitable. Products maded by our cooling tower company are well received by users for their excellent performance, high quality and low price.

https://www.auvc.com/products/square-cooling-tower/

0 notes

Text

Round Cooling Tower

The round cooling tower uses the contact between air and water to cool the water, and uses water as the circulating coolant to absorb heat from the tower and discharge it to the atmosphere, so as to reduce the air temperature in the tower and produce cooling water for recycling. Its shape is "round", so it is called round cooling tower. The round cooling tower is suitable for small and medium-sized circulating cooling water system with water quantity and multi-source distributed layout.

Advantage of Round Cooling Tower

a. Reliable operation, durable and convenient assembly;

b. The water collecting bucket has a large capacity and is equipped with manual and automatic water replenishment device and sewage and overflow pipe, without the need to design water tank separately;

c. Low cost, lightweight, small wind resistance and good stability;

d. The FRP round cooling tower has good stability and strength and can withstand the earthquake crack degree of 8 and 12 typhoon.

Why Choose Round Cooling Tower?

The round cooling tower produced by our company is suitable for small and medium-sized circulating cooling water system with water quantity and multi-source distributed layout, and the layout is very flexible and convenient. Round cooling tower is more classic, technology has become mature, widely used in the market, popular product cost is relatively low.

https://www.auvc.com/products/round-cooling-tower/

0 notes

Text

Open Circuit Cooling Tower

The open cooling tower has no air duct, the ventilation of the cooling tower depends on the natural wind force, and the cooling tower is equipped with a hundred leaf windows around the drenching filler. The type of open circuit cooling tower has an open recirculating cooling water system. It is used to spray the circulating water into the filler of fiberglass and spray through the water to contact with the air, so as to achieve heat exchange. The fan circulate the air flow in the tower and bring out the hot air flow after heat exchange with the water so as to achieve cooling.

Open circuit cooling tower includes round cooling tower, square counter flow cooling tower and square cross flow cooling tower.

Advantages of Open Circuit Cooling Tower

a. The open cooling tower has the advantages of simple structure and low cost.

b. Easy to clean, maintain and repair.

c. Open cooling tower is one of the most commonly used cooling equipment in the early stage

d. Most of the open cooling towers use glass fiber reinforced plastics, which is a kind of reinforced plastics with glass fiber or its products as reinforcement materials. It has the corrosion resistance of glass and the hardness of steel, so the production cost is relatively low.

Why Choose Open Circuit Cooling Tower?

Open circuit cooling tower is a kind of environmental protection cooling equipment with low cost, excellent performance and wide range of application. We usually use open circuit cooling tower in industrial cooling.

https://www.auvc.com/products/open-circuit-cooling-tower/

0 notes

Text

Mechanical Draft Cooling Tower

A mechanical draft cooling tower, also known as a mechanical draft tower, is a cooling tower ventilated by wind, which is the main equipment of circulating water evaporative cooling. Mechanical draft cooling tower is widely used in petroleum, chemical, metallurgical and other industries.

The mechanical draft cooling tower includes a round cooling tower, square counter flow cooling tower, square cross flow cooling tower and closed cooling tower.

Advantage of Mechanical Draft Cooling Tower

The advantages of mechanical draft cooling tower are compact structure, small volume, light weight, convenient installation, not affected by external wind, reliable cooling effect; less loss of cooling water blowing, higher cooling efficiency, high water spraying density, less one-time investment.

Why Choose Mechanical Draft Cooling Tower?

Compared with the natural draft cooling tower, the mechanical draft cooling tower has the advantages of stable ventilation, uniform distribution of air and water in the tower, and high cooling efficiency, so more people choose the mechanical draft cooling tower. We, a professional cooling tower manufacturer, provide you with high-quality and inexpensive mechanical draft cooling towers.

https://www.auvc.com/products/mechanical-draft-cooling-tower/

0 notes

Text

Cooling Tower Gearbox For Marley

Marley gearbox reducer is a kind of reduction equipment used for cooling tower. It adopts two-stage (spiral bevel / spiral) gear to reduce the speed. Its structure is simple and reliable. Compared with low-level gear set, it has longer service life and reduces the sound by more than 30%.

Repair And Daily Maintenance Of Cooling Tower Gearbox For Marley

Attention should be paid to the maintenance of gear reducer: keep the gear reducer clean and dust-free. Always check the appearance of the gear reducer for misaligned parts. Thickener reducers usually check whether the bearings have been replaced or refueled, and check the incoming terminals.

If the gear condition is to be maintained, the gear reducer of thickener will run continuously, so routine maintenance is very important. Thickener reducer gear reducer work, please pay attention to the working environment, do not excessive turbulence, so as not to damage or shorten the gear reducer.

Check the appearance, whether the fan works normally, whether there is abnormal vibration, whether the coupling is reliable, whether the base is fixed, whether the bearing works normally (listen to the sound), whether the temperature is normal (infrared thermometer), whether the current is normal (clamp type ammeter) the reducer must also check the carbon brush and slip ring. If on the one hand there is an abnormality, the gear reducer must be repaired quickly.

Maintenance Method Of Cooling Tower Gearbox For Marley

a. The selected power is too large; Solution: re select or add cooling device

b. The bearing is overheated; The reason is that the axial clearance is too small; Solution - readjust the bearing clearance.

c. Poor lubrication (too slow speed, less oil and others); Solution - oil properly or use other lubrication methods.

d. The coaxiality error of coupling is too large; Solution - adjust the coupling.

e. Premature wear and broken teeth of gears; The reason is the excessive power; Solution - retype.

https://www.auvc.com/products/marley-gearbox/

0 notes

Text

Cooling Tower Fan For Marley

The fan of Marley cooling tower adopts hollow aluminum alloy extruded blade, and the fan is adjustable angle type, which can meet the different requirements of customers on air volume and other process aspects.

Function Of Cooling Tower Fan For Marley

The industrial cooling tower fan is basically upward suction, and the purpose is to take away the heat emitted by the cooling water after contact with the air. When installing, pay attention to the concave surface upward, and then turn clockwise when looking down. Both cross flow tower and counter flow tower are upward suction, which not only takes away the heat, but also forms an upward force to reduce the splashing of water drops!

Installation Of Cooling Tower Fan For Marley

a. The foundation of the fan shall be horizontal and firm, and the height of the foundation shall be ≥ 200 mm.

b. The fan and the air duct shall be connected by flexible hose (flexible material and non combustible), the length shall not be less than 200 mm, and the pipe diameter shall be the same as the inlet and outlet size of the fan. In order to ensure that there is no distortion of the hose during the operation of the system, the tightness of the hose should be appropriate. For the canvas hose installed at the suction end of the fan, it can be installed slightly tight to prevent the fan from being sucked in during operation and reduce the cross-section size of the canvas hose.

c. The steel support of the fan must be fixed on the concrete foundation, and the rubber damping pad must be added between the steel support and the foundation. All the fan and motor components are installed on the whole steel support, and the steel ground frame is installed on the damping pad on the top of the foundation. The damping pad should preferably be multi hole rubber plate.

d. The diameter of the outlet of the fan can only be larger, but not smaller. Finally, the outlet should be installed with insect proof net, and the rain cap should be added when it is inclined to the upper air outlet.

https://www.auvc.com/products/marley-cooling-tower-fan/

1 note

·

View note