BOLE RP & M CO.,LTD is a high-tech rapid prototyping and precision CNC machining facility that was founded in 2007. BOLE provides services in sheet metal fabrication, vacuum casting, 3D printing, Hermle &DUG 5 axis machining, 3 & 4 axis precision batch milling, CNC lathe turning, and injection molding.

Don't wanna be here? Send us removal request.

Text

Die Casting: Precision Manufacturing at Scale

Die casting is a sophisticated manufacturing process known for its ability to produce high-precision, complex parts with remarkable efficiency. This method, widely utilized across industries ranging from automotive to electronics, hinges on the precise injection of molten metal into a reusable steel mould, or dies. Let’s explore how die casting has become a cornerstone of modern manufacturing.

The Die Casting Process

Die casting involves injecting molten metal, typically aluminum or zinc alloys, into a die cavity under high pressure. This pressure ensures that the liquid metal fills the intricate details of the die, resulting in parts with consistent dimensions and fine surface finishes. Once the metal solidifies, the die opens, revealing the finished product. This method allows for rapid production cycles and the creation of parts with complex geometries that would be difficult or impossible to achieve with other manufacturing processes.

Applications across Industries

The versatility of die casting China makes it indispensable in various industries. In automotive manufacturing, die-cast components include engine blocks, transmission housings, and structural components due to their lightweight, durable properties. In electronics, die casting produces precise casings and heat sinks that protect sensitive components while ensuring efficient heat dissipation. The aerospace industry relies on die-cast parts for their high strength-to-weight ratio and reliability.

Advantages and Benefits

Die casting offers numerous advantages, making it a preferred choice for mass production of metal parts. It provides excellent dimensional accuracy and surface finish, reducing the need for secondary machining operations. The process is highly automated, leading to consistent quality and lower labor costs. Additionally, die-cast parts exhibit superior mechanical properties, such as high strength and thermal conductivity, enhancing their performance in demanding applications.

Technological Innovations

Recent advancements in die-casting technology continue to expand its capabilities. Innovations include vacuum-assisted die casting for reducing porosity and improving part integrity, as well as hot chamber and cold chamber die casting variations to accommodate different metal alloys and production requirements. Automation and robotics further optimize production efficiency and quality control, ensuring that die casting remains competitive in a global manufacturing landscape.

Future Outlook

Looking forward, Die casting manufacturer is poised to evolve alongside advancements in materials science and digital manufacturing technologies. Trends such as the use of eco-friendly alloys and enhanced process monitoring through IoT and AI promise to further enhance sustainability and efficiency. As industries demand lighter, stronger, and more complex parts, die casting stands ready to meet these challenges with innovation and precision. In conclusion, die casting exemplifies precision manufacturing at scale, enabling the production of intricate metal components essential to modern technology and industry. Its ability to deliver high-quality parts efficiently positions die casting as a cornerstone of manufacturing excellence, driving innovation and shaping the future of industrial production.

1 note

·

View note

Text

The Revolution of 3D Printing: Shaping the Future

In the realm of manufacturing and design, 3D printing has emerged as a transformative technology, promising to redefine how we create, innovate, and produce goods. Unlike traditional manufacturing methods that often involve subtractive processes (cutting or drilling materials), 3D printing, also known as additive manufacturing, builds objects layer by layer from digital designs. This revolutionary approach opens up a world of possibilities across various industries, from healthcare to aerospace, and even in everyday consumer products.

Innovation Unleashed

One of the most compelling aspects of 3D printing is its ability to democratize innovation. Previously, prototyping and manufacturing new products required substantial investment in tooling and specialized equipment. With 3D printing, entrepreneurs, designers, and engineers can quickly iterate designs at a fraction of the cost and time. This accessibility fosters creativity and accelerates the development of novel solutions across industries.

Applications Across Industries

In healthcare, 3D printing China enables the creation of customized prosthetics, implants, and even pharmaceuticals tailored to individual patients' needs. This personalization not only enhances patient care but also reduces costs and improves treatment outcomes. Similarly, in the aerospace and automotive industries, 3D printing allows for lightweight yet durable components that enhance fuel efficiency and performance.

Environmental Impact

Beyond its industrial applications, 3D Printing services hold promise for sustainability. Minimizing material waste compared to traditional manufacturing methods, aligns with growing environmental concerns. Additive manufacturing techniques also enable the use of recycled materials and biodegradable polymers, further reducing the carbon footprint of production processes.

Challenges and Future Outlook

Despite its promise, 3D printing faces challenges such as scalability for mass production, material limitations, and regulatory considerations. However, ongoing research and development efforts are addressing these issues, paving the way for broader adoption and integration into mainstream manufacturing.

Looking ahead, the future of 3D printing appears promising. Advances in technology continue to push boundaries, with innovations like multi-material printing and larger-scale printers expanding its capabilities. As costs decrease and capabilities increase, we can expect to see 3D printing play an increasingly significant role in shaping the future of manufacturing, design, and beyond.

In conclusion, 3D printing represents not just a technological advancement but a paradigm shift in how we conceive and create objects. Its impact spans industries and applications, offering limitless potential for innovation and sustainability. As we embrace this transformative technology, we stand at the brink of a new era where imagination truly meets creation, and the possibilities are limited only by our creativity. Top of Form.

Follow our Facebook and Twitter for more information about our product.

#3D Printing China#Best 3D Printing Services#3D Printing services#3D Printing#Custom 3D Printing Services

1 note

·

View note

Text

Injection Moulding: Precision, Efficiency, and Versatility

In manufacturing, injection moulding stands out as a cornerstone technology renowned for its precision, efficiency, and versatility. This widely adopted process revolutionizes the production of intricate and complex parts across various industries, from automotive and electronics to medical devices and consumer goods. The Process Unveiled Injection moulding China involves injecting molten…

View On WordPress

#Injection Moulding#Injection Moulding China#Injection Moulding manufacturer#Injection Moulding supplier

0 notes

Text

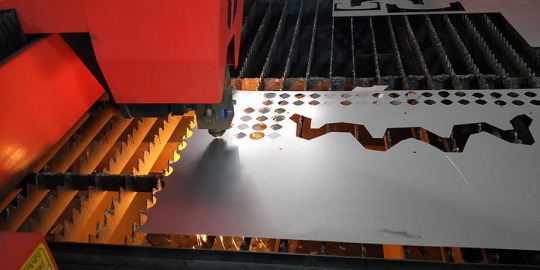

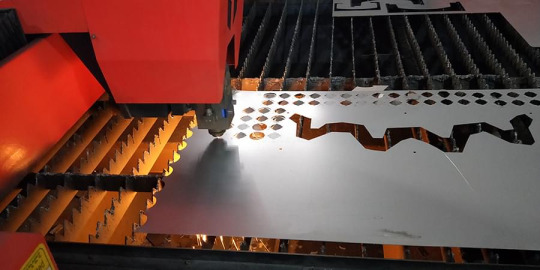

Key Processes Involved in Sheet Metal Fabrication

Sheet metal fabrication is the process of forming, cutting, and shaping thin metal sheets into various shapes and structures. It’s a crucial manufacturing technique used across industries for creating components and products with specific dimensions and characteristics. Key processes involved in sheet metal fabrication include: Cutting: Sheets of metal are cut into smaller sections or specific…

View On WordPress

#Online Sheet Metal Fabrication#Sheet Metal Fabrication#Sheet Metal Fabrication Process#Sheet Metal Fabrication services

0 notes

Text

Significance of Outsourcing your CNC Machining Services

Outsourcing CNC machining services to vendors that offer prototype design engineering services allows businesses to achieve more while saving money. The introduction of CNC expands the number of alternatives available to organizations, yet this diversity might make it difficult to select the best provider for specific needs.

Why outsource your CNC machining needs?

Save money

CNC machines are costly and need specific tools and training, making them out of reach for many small firms. Furthermore, CNC machines are huge, and enterprises must provide enough room in their workplaces to handle these massive pieces of equipment.

Outsourcing your CNC machining requirements to CNC machining professionals who provide prototype design services might reduce worries about the expenses involved with owning, housing, and operating such equipment. This method saves you money and allows you to devote more time and resources to key business activities while using the experience of prototype design specialists.

Improve the production process.

CNC machines are cutting-edge equipment that may rapidly improve both production efficiency and item quality. These devices are useful for producing identical designs regularly. Rather than incurring tooling expenditures with each manufacturing run, you may outsource these requirements to bespoke product package design services, saving time, effort, and money.

Remember that CNC machine operations must be continuously monitored to ensure the manufacture of high-quality components and parts. Outsourcing your CNC Machining China requires less manual work from your staff. As a consequence, you may focus more on other key activities and jobs within your company, such as working with custom product package design services to improve the appearance of your items.

Wide-ranging capacities

Flexibility is a significant benefit of outsourcing your CNC machining requirements, particularly when working with design for manufacturability (DFM) specialists. In-house CNC machining might have limitations, especially when launching new items. Additional equipment investments may be required to accommodate increasing demand and scale output.

However, these constraints may be overcome by outsourcing your CNC Machining services requirements to specialist manufacturing businesses, which include DFM design services. These firms have access to a diverse range of CNC machining equipment, and their skills go far beyond the quantity of CNC machines. In addition to offering a variety of materials and file formats, they are capable of handling secondary processes like heat treatment and anodizing, resulting in full production solutions.

1 note

·

View note

Text

Components of CNC Lathe Machining

Lathe machines are commonly identified by a swing, the maximum working diameter that swings the lathe bed. A lathe swing is used to spin things that can be chopped, sanded, or drilled. Other lathe machine parameters include the length of the bed. Let’s examine the key components of a CNC Lathe Turning: Headstock CNC The lathe machine makes use of a headstock, which is an important component of…

View On WordPress

0 notes

Text

Top Boons of 5-axis CNC Machining

5 axis machining is now the most feasible choice for all types of machining jobs, not only the most difficult ones that require longer tool reach. 5-axis CNC machining is widely utilized for the most complex and precise jobs. This manufacturing approach is expected to provide significantly improved precision.

5-axis custom machining services provide a variety of advantages

Higher speed

5-axis machining allows the use of shorter cutting tools since the head may be lowered and the cutter is directed to the surface. You might expect better outcomes by increasing cutting speed and tool vibration.

Increased productivity

One of the most time-consuming parts of 3-axis machining is setting up a workpiece many times because it needs to be reoriented. This is required if an item needs to be machined on all or multiple sides, as the cutting tool remains at a fixed angle. A machinist must be physically present to rotate the component once machining on one side is completed for these 3-axis operations, and this human need can be a significant bottleneck in production.

5-axis machining by 5 axis machining manufacturer significantly minimizes the need for repeated setups since the movement of the table or spindle allows the cutting tool to approach the workpiece from various angles without removing it from the machine and resetting it. This leads to higher productivity throughout the whole process.

Hiring a dependable 5-axis machining services

Make sure your production team has been in operation for a significant amount of time. They should be highly experienced and qualified to ensure the quality of the job and timely completion. A corporation should be dependable and trustworthy.

Before selecting a firm, do not be afraid to ask questions regarding their 5-axis machining capabilities. A machine must also be of superior quality and capable of doing this task within a certain timeframe.

Inquire about the pricing of their services. Make sure you pay for what you get, and that the price matches the quality of the goods. Also, be informed of the materials they will be employing.

Main Source: https://bolesolutions.mystrikingly.com/

#5 axis machining manufacturer#5 Axis Machining Supplier#5 axis machining services China#5 Axis Machining Center

2 notes

·

View notes

Text

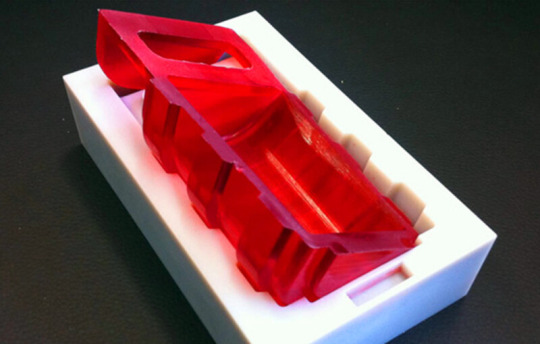

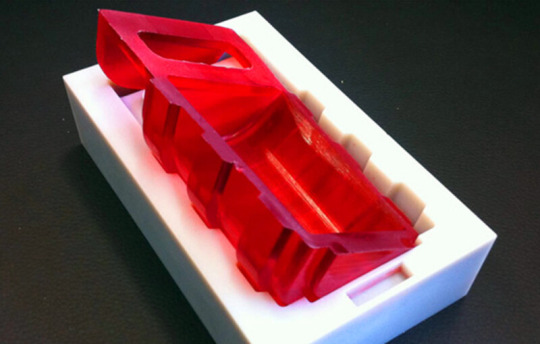

Rapid Prototyping: The Advanced Aspect of Manufacturing

Rapid prototyping and manufacturing by Rapid prototyping manufacturer is the technique of swiftly producing physical components or models with three-dimensional (3D) printing technology. With this technology, designers may use specialized software to produce a digital model of a part or product. The program then transfers the digital model to a 3D printer. It generates a physical reproduction of…

View On WordPress

#Metal Rapid Prototyping Services#Rapid Prototype#Rapid prototyping manufacturer#Rapid Prototyping Services#Rapid prototyping Supplier

1 note

·

View note

Text

CNC lathe turning offers several advantages over manual turning

CNC lathe turning is a precise and efficient machining process used to shape cylindrical workpieces using a lathe machine controlled by computer numerical control (CNC). Here’s a step-by-step overview of the CNC lathe turning process: Workpiece Preparation: The process begins with selecting a raw material, usually a cylindrical bar or rod made of metal, plastic, or other materials. The workpiece…

View On WordPress

#CNC Lathe Turning#CNC Lathe Turning China#CNC Lathe Turning manufacturer#CNC Lathe Turning process#CNC Lathe Turning supplier

1 note

·

View note

Text

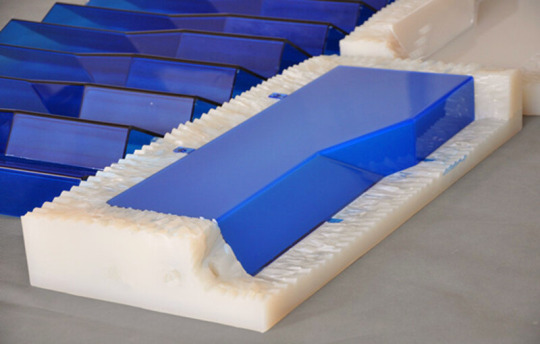

Working of Vacuum Casting and Its Multiple Uses

To make complicated components, a liquid substance is sucked into a silicone mold under vacuum. This method is known as vacuum casting. Rubber and plastic are examples of elastomers that are utilized as liquid materials in vacuum casting.

Since polyurethane resin, a kind of elastomer is employed as the casting medium, vacuum casting is also frequently referred to as polyurethane casting or urethane casting. When producing plastic components, vacuum casting is a more cost-effective method than injection molding because of its reduced manufacturing costs.

For batch manufacturing and other low-volume production tasks, vacuum casting is a great method of production. Vacuum casting is widely utilized in India's manufacturing of industrial electronics, FMCG, and consumer goods.

How do you work with vacuum casting?

Injection molding, in which cast material is poured into molds to create items, and vacuum casting services are very comparable processes. The kinds of molds used in injection molding and vacuum casting differ from one another.

Molds for injection molding might be formed of steel, aluminum, or other materials. Silicone molds are utilized in vacuum casting, nevertheless. This significantly lowers the mold-making cost because silicone is more affordable and has better durability.

Polyurethane is the most often utilized casting material in this procedure. The qualities of various polyurethanes vary, including good shock and temperature resistance, elasticity, flexibility, and structural stiffness. Thus, different polyurethanes may be employed depending on the kind of product being created.

Vacuum casting uses

Making complicated and sophisticated goods may be accomplished more cost-effectively and efficiently with vacuum casting as opposed to the conventional injection molding method.

Due to its efficient production process, vacuum casting finds widespread application in the fabrication of commercial items. The following are a few industries that employ vacuum casting:

Manufacturing of consumer goods

Vacuum casting is a more effective method of producing consumer goods including combs, hair brushes, makeup packaging, sunglasses, pens, and other stationery.

Industry of Food and Beverages

Vacuum casting is used to create food and beverage containers, bottles, cans, mugs, and glasses. Due to the process's great efficiency and ability to produce goods quickly, vacuum casting is widely utilized in various industries where rapid manufacture is essential.

Advanced industry

Excellent heat and shock resistance is a feature of polyurethanes. Therefore, the recommended production procedure for creating electrical device housings is vacuum casting by Vacuum Casting Manufacturer using polyurethanes.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Explore vacuum casting#Vacuum Casting Services China#Vacuum Casting Manufacturer#Vacuum Casting supplier

2 notes

·

View notes

Text

Various Types of Metals Used in Sheet Metal Fabrication

The process of cutting, bending, punching, and welding thin, flat metal sheets into different forms is known as sheet metal fabrication. Sheet metal fabrication is a process used to form and configure various metals, including aluminum, titanium, steel, copper, tin, brass, and steel. Silver, gold, and platinum are good ornamental metals. Many different things with differing thicknesses are made…

View On WordPress

#Online Sheet Metal Fabrication#Sheet Metal Fabrication#Sheet Metal Fabrication Process#Sheet Metal Fabrication services#Sheet Metal Fabrication Techniques

1 note

·

View note

Text

A Basic Overview About CNC Turning

The technology provided by CNC turning services is often used to create cylindrical pieces out of different materials. CNC Lathe Turning, in contrast to CNC milling, involves rotating the workpiece while introducing a stationary tool into it. To create very complicated pieces, advanced CNC turning centers go one step further and incorporate cutting capabilities into the machine. The technique of…

View On WordPress

#CNC Lathe Turning#CNC Lathe Turning China#CNC Lathe Turning manufacturer#CNC Lathe Turning process#CNC Lathe Turning supplier

1 note

·

View note

Text

Know About the Post-Processing in Rapid Prototyping

Rapid Prototyping China is a ray of efficiency and inventiveness in the field of product development and innovation. By offering quick iterations and concrete concept representations, it transforms conventional methodologies. However, inside this miracle of contemporary engineering, there is a critical—often disregarded but unquestionably necessary—step called post-processing. It's the period of transformation that unlocks the actual potential of a rough prototype and turns it into a polished masterpiece.

Enhancement of Visual Appeal

Even in the world of prototypes, first impressions count. Post-processing makes it possible to improve the visual appeal of a prototype by removing flaws and rounding off edges. Simple models may be transformed into visually beautiful representations by using techniques like painting, polishing, or sanding, which can improve the model's aesthetic appeal and professionalism.

The perception of a product is greatly influenced by its aesthetics, which also affects consumer acceptability and engagement. Consequently, spending money on post-processing guarantees that prototypes not only work effectively but also grab attention due to their striking appearance.

Improvement of Material

Chinese Rapid Prototyping Services relies heavily on material selection, which affects characteristics like strength, flexibility, and durability. Nevertheless, the intrinsic qualities of raw materials could not meet the required standards. A solution is provided by post-processing, which enhances material qualities to satisfy demands. One can achieve desired characteristics like heat resistance, conductivity, or waterproofing by applying coatings, surface treatments, or chemical procedures. Post-processing broadens the possibilities by improving material qualities, making prototypes more resilient to real-world use and more environment-adaptable.

Individualization and Tailoring

Each product is different from the others and meets the demands of different users. Post-processing makes it easier to customize and personalize prototypes to suit these unique tastes. Prototypes may be given individuality and flare by post-processing, which includes adding textures, engravings, and detailed detailing. It also makes it possible to incorporate branding components, which promote brand loyalty and awareness.

Iterative Enhancement

Iteration is the lifeblood of Rapid Prototype; each cycle improves and refines the idea. Post-processing provides insightful input for iteration cycles, acting as a stimulus for iterative progress. Designers can identify areas for improvement and identify strengths and shortcomings by evaluating post-processed prototypes. Prototypes are refined through iterative development, which encourages ongoing learning and innovation.

#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Chinese Rapid Prototyping Services

2 notes

·

View notes

Text

The Importance of High-tech Rapid Prototyping

In the industrial industry, precision is not only desirable—it is essential. Consider a situation in which parts of a jet engine are even marginally machined incorrectly or misaligned. The repercussions can be disastrous and might cause the engine to fail in midair. Precision becomes the key to success in sectors like aerospace, automotive, and medical where safety and dependability are non-negotiable. Put simply, it's the capacity to manufacture parts or components that precisely conform to given dimensions, tolerances, and quality requirements. It takes state-of-the-art equipment, painstaking attention to detail, and highly competent operators to achieve this degree of accuracy. This is the sweet spot for Precision CNC Machining.

So how precisely can CNC machining accomplish such high precision levels?

Computerized Control: Advanced computer software is the brains of CNC machining, translating digital design requirements into exact motions and orders for the milling tools. This removes the possibility of human error and guarantees the highest level of precision in each cut, drill, and mill.

Superior Quality Equipment: Modern spindles, tools, and cutting implements that are designed to provide exact results are standard on CNC machines. These devices may operate at extremely tight tolerances, which are sometimes expressed in microns, guaranteeing an accurate reproduction of even the minutest features.

Consistency: The ability of CNC machining and High-tech Rapid Prototyping to manufacture similar components with little variance is one of its main advantages. A machine program that has been developed and tuned may be repeated endlessly with reliable outcomes. In fields where stability and dependability are critical, this degree of constancy is priceless.

Advanced Techniques: Multi-axis milling, turning, EDM (Electrical Discharge Machining), laser cutting, and other state-of-the-art methods are all included in CNC machining. With unmatched accuracy and efficiency, manufacturers can handle complicated geometries and materials thanks to these procedures.

Quality Assurance: CNC systems frequently include integrated quality control mechanisms including automated inspections, feedback loops, and real-time monitoring in addition to accurate machining. This reduces waste and rework by guaranteeing that any deviations from the intended standards are quickly identified and fixed. It is impossible to exaggerate the value of accuracy in production. Precision by Precision CNC Machining Manufacturer plays a crucial role in today's competitive economy, as it ensures everything from satisfying regulatory requirements and consumer expectations to assuring product performance and dependability.

Follow our Facebook and Twitter for more information about our product

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company

2 notes

·

View notes

Text

Three Crucial Controlling Aspects of Die Casting

In the industrial industry, control and accuracy are critical. This is never more apparent than in Die Casting, a procedure that needs precise specifications to reliably and effectively create high-quality parts. The three essential components of control—injection speed, temperature, and pressure—are at the center of this undertaking. These three variables have a significant impact on die-casting…

View On WordPress

1 note

·

View note

Text

Learn About the Basics of Vacuum casting

Within the dynamic realm of production and prototyping, urethane casting is a unique technology that provides cost-effectiveness, accuracy, and diversity. Urethane casting has become the industry standard for a variety of applications, from complex prototypes to small-batch production runs, including consumer electronics, medical equipment, and the automotive and aerospace sectors.

Gratitude Casting of Urethane

The first step in the procedure is to create a master pattern, which is usually done via fast prototyping techniques like CNC machining or 3D printing. The silicone molds that are made from this master pattern are used to pour polyurethane resin into. The resin mimics the fine features of the master design once it has dried, producing pieces that are excellent and ready for manufacturing.

Flexibility throughout Sectors

The adaptability of urethane casting across sectors is one of its most noteworthy benefits. Urethane casting may be used for a variety of purposes, including the production of end-use components and prototypes for new product development. For instance, urethane casting makes it possible to quickly iterate ideas for dashboard panels, interior trim, and lighting fixtures in the car industry. Similar to this, urethane casting makes it easier and faster to produce unique medical device housings, surgical instruments, and prosthetic components in the medical profession. Vacuum casting also offers flexibility.

Benefits Compared to Conventional Approaches

When compared to conventional production techniques like CNC machining and injection molding, urethane casting has several significant benefits. The most important factor is cost-effectiveness. Because urethane casting requires less tooling up front, it's a great option for low-volume production runs if standard tooling costs are too high. Urethane casting also has a short turnaround time, which enables companies to quickly develop and refine ideas without having to wait for long lead periods.

Additionally, the design freedom provided by urethane casting makes it feasible to produce intricate surface details, undercuts, and complicated geometries that would be difficult or impossible to accomplish with alternative manufacturing processes. This versatility also applies to the choice of material, since a variety of polyurethane resins are available to satisfy certain performance needs, including those related to hardness, flexibility, and chemical resistance. You can Explore vacuum casting also.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Urethane Casting#Explore vacuum casting#Custom Vacuum Casting Services

2 notes

·

View notes

Text

Exploring the Depth of Sheet Metal Fabrication

A vital component of contemporary manufacturing, sheet metal fabrication serves a variety of sectors, including electronics, automotive, aerospace, and construction. It’s a multidimensional craft where thin metal sheets are shaped and worked into different parts and structures. The Craft of Molding Forming is the art at the core of sheet metal manufacture. To create the appropriate shapes and…

View On WordPress

#Online Sheet Metal Fabrication#Sheet Metal Fabrication#Sheet Metal Fabrication Process#Sheet Metal Fabrication services#Sheet Metal Fabrication Techniques

1 note

·

View note