#5 Axis Machining Center

Text

Top Boons of 5-axis CNC Machining

5 axis machining is now the most feasible choice for all types of machining jobs, not only the most difficult ones that require longer tool reach. 5-axis CNC machining is widely utilized for the most complex and precise jobs. This manufacturing approach is expected to provide significantly improved precision.

5-axis custom machining services provide a variety of advantages

Higher speed

5-axis machining allows the use of shorter cutting tools since the head may be lowered and the cutter is directed to the surface. You might expect better outcomes by increasing cutting speed and tool vibration.

Increased productivity

One of the most time-consuming parts of 3-axis machining is setting up a workpiece many times because it needs to be reoriented. This is required if an item needs to be machined on all or multiple sides, as the cutting tool remains at a fixed angle. A machinist must be physically present to rotate the component once machining on one side is completed for these 3-axis operations, and this human need can be a significant bottleneck in production.

5-axis machining by 5 axis machining manufacturer significantly minimizes the need for repeated setups since the movement of the table or spindle allows the cutting tool to approach the workpiece from various angles without removing it from the machine and resetting it. This leads to higher productivity throughout the whole process.

Hiring a dependable 5-axis machining services

Make sure your production team has been in operation for a significant amount of time. They should be highly experienced and qualified to ensure the quality of the job and timely completion. A corporation should be dependable and trustworthy.

Before selecting a firm, do not be afraid to ask questions regarding their 5-axis machining capabilities. A machine must also be of superior quality and capable of doing this task within a certain timeframe.

Inquire about the pricing of their services. Make sure you pay for what you get, and that the price matches the quality of the goods. Also, be informed of the materials they will be employing.

Main Source: https://bolesolutions.mystrikingly.com/

#5 axis machining manufacturer#5 Axis Machining Supplier#5 axis machining services China#5 Axis Machining Center

2 notes

·

View notes

Text

What Should Pay Attention to in the Operation of High-Speed 5-Axis Machining Center?

High-speed 5-axis machining center is an advanced processing equipment, with high precision, sound speed and high efficiency characteristics. It is usually used for processing complex and difficult parts, such as aerospace, medical equipment, automotive parts, etc. When operating a high-speed 5-axis machining center, special attention needs to be paid to the following points:

1. Familiar with the structure and principle of the equipment: the operator needs to be familiar with the structure and working principle of the high-speed 5-axis machining center, understand the name of each axis, the range of motion and restrictions, and master the control system and programming method of the machining center. Only with a deep understanding of the structure and principle of the equipment can we correctly operate and use the high-speed 5-axis machining center for processing.

2. Strictly follow the operating procedures: the operator should strictly follow the operating procedures, including wearing personal protective equipment, avoid body parts close to the moving parts, avoid strong light exposure, etc. In addition, safety devices such as safety doors, warning lights and emergency stop buttons need to be checked regularly to ensure that they are in good working condition.

3. Equipment inspection and maintenance: before use, it is necessary to maintain and check the equipment. First, check whether the tool is worn, and if it is worn, it needs to be replaced. Secondly, check whether the fixture is stable and firm. Clean the equipment to prevent dust and foreign matter from entering the equipment. At the same time, it is also necessary to carry out real-time monitoring of the equipment during the processing process to discover and deal with problems in time.

4. Material preparation and processing: before 5-axis processing, it is necessary to prepare the required materials and ensure the quality and accuracy of the materials. At the same time, in order to avoid temperature changes affecting the processing, the material should be placed in a constant temperature environment. After the processing is completed, it is also necessary to process the workpiece, including cleaning, inspection and maintenance.

5. Safety control: the operator needs to strictly control the safety risks in the processing process, such as the cutting and cutting methods, the length and diameter of the cutting county, and the setting of cutting parameters. In the processing process, it is also necessary to pay attention to observe the processing situation, adjust the cutting parameters and tool status in time, and avoid collision or over-cutting errors.

6. Programming and setting: the operator needs to be familiar with the programming language and programming method of the high-speed 5-axis machining center, and can perform the correct programming and setting according to the processing needs. In the programming process, it is necessary to pay attention to the planning of the tool path, the setting of cutting parameters, the distribution of machining allowance and other issues to ensure the stability and accuracy of the machining process.

7. Training and experience accumulation: operators need to go through professional training and practice, practice the accumulation of experience, and constantly improve their skill level and operational experience. Through continuous learning and practice, operators can better master the operation skills and maintenance methods of high-speed 5-axis machining centers, and improve the utilization rate and service life of equipment.

0 notes

Text

RAY Mechatronics & Machinery Pvt Ltd is an authorized supplier of cutting-edge Computer Numerical Control (CNC) machines designed for advanced manufacturing processes. Our machines operate based on CAD programs, streamlining instructions for precise production. Our CNC units stand out by significantly reducing manufacturing duration and enhancing precision. Our Takumi VMC enables workpiece rotation along two additional axes beyond the standard three, significantly enhancing precision and flexibility. This innovative feature contributes to minimized material wastage and reduced reliance on specialized labor. Experience heightened accuracy and efficiency with our advanced Takumi VMC technology.

Our product spectrum accommodates diverse needs and comprises the BC, G, H, PV, UB, UC, UR, and U series, each tailored to specific requirements, notably in tool and mold fabrication. To improve your manufacturing efficiency, elevate operational speed, and utilize an upgraded industrial approach, contact us at 080-28394443. Upgrade your manufacturing process with RAY Mechatronics & Machinery Pvt Ltd.

#Takumi VMC#Takumi Milling Machine#Takumi Vertical Machine Center#Takumi machine tool#5 Axis Machining Centers#double column machining center#double column vmc machine

1 note

·

View note

Text

The Advantages of Multitasking Machines and 5-Axis Turnmills in Aerospace Manufacturing

As the aerospace industry continues to evolve, manufacturers are constantly seeking new ways to improve production efficiency and reduce costs without compromising quality. One such solution is the use of multitasking machines and 5-axis turn mills, which offer a range of benefits for aerospace manufacturing.

Multitasking Machines for Increased Productivity

Multitasking machine, as the name suggests, are capable of performing multiple operations on a single device, such as milling, turning, drilling, and tapping. This allows for increased productivity and reduced cycle times, as parts can be machined in a single setup without the need for multiple machines or tool changes.

In addition to their versatility, multitasking machines offer greater precision and accuracy thanks to their advanced control systems and software. This is especially important in aerospace manufacturing, where tight tolerances and complex geometries are typical.

The Power of 5-Axis Turnmills

The 5-axis turn mill takes multitasking to the next level, offering the ability to perform simultaneous milling and turning operations. This provides greater efficiency and flexibility, as parts can be machined in a single setup with minimal handling or repositioning.

Moreover, these turn mills can produce features that are difficult or impossible to machine using traditional methods. This is particularly useful in aerospace manufacturing, where parts often have complex shapes and contours.

Hydraulic Fixtures for Machining Centers

Another key highlight of using multitasking machines and 5-axis turn mills in aerospace manufacturing is the ability to use hydraulic fixtures for machining centres. These fixtures allow for easy and accurate clamping of parts, reducing the risk of errors and ensuring consistent quality.

Hydraulic fixtures also offer greater flexibility and thus can be easily reconfigured for different parts or setups. This makes them ideal for aerospace manufacturing, where parts are often produced in low to medium volumes with frequent design changes.

The Cost Savings of Multitasking Machines and 5-Axis Turnmills

In addition to their productivity and precision advantages, multitasking machines and 5-axis turn mills also helps with cost savings for aerospace manufacturers. By consolidating multiple operations into a single machine, these technologies can reduce the need for extra equipment and tooling, as well as the labour required to operate them.

The increased accuracy and precision of these machines can reduce the need for secondary operations or manual adjustments, which can add time and cost to the manufacturing process. This can lower production costs and increase profitability for aerospace manufacturers.

Conclusion

In conclusion, using multitasking machines and 5-axis turn mills, along with hydraulic fixtures for machining centres, can provide significant advantages for aerospace manufacturing. These technologies offer greater productivity, precision, and flexibility, making them ideal for the demands of this industry.Widma is a leading provider of advanced machining solutions, including multitasking machines, 5-axis turn mills, and hydraulic fixtures. By partnering with Widma, aerospace manufacturers

0 notes

Text

Best Greetings

How Do The Solar Planets Move?

(1)

Let's explain the idea by the next example

Example

We have a machine of gears- the machine has 9 gears and it moves as following

The first gear rotates around its axis (5 rotations) to cause the second gear to rotate one rotation only

The second gear rotates around its axis (5 rotations) to cause the third gear to rotate one rotation only – and all gears use this same rule

Let's see how the machine works

The first gear rotates (390625 rotations) to cause the second gear to rotate (78125 rotations)

The second gear (78125 rotations) causes the third gear to rotate (15625 rotations)

The Third gear (15625 rotations) causes the fourth gear to rotate (3125 rotations)

The Fourth gear (3125 rotations) causes the fifth gear to rotate (625 rotations)

The Fifth gear (625 rotations) causes the sixth gear to rotate (125 rotations)

The sixth gear (125 rotations) causes the seventh gear to rotate (25 rotations)

The seventh gear (25 rotations) causes the Eighth gear to rotate (5 rotations)

The Eighth gear (5 rotations) causes the ninth gear to rotate (one rotation)

Someone eyes see the ninth gear rotates around its axis one rotation and understand NOTHING of the whole machine

Shortly– the fact is that

The solar system moves similarly typically for this machine of gears–

The planets motions cause to accumulate the motion energy in the solar system.

(2)

The solar system is used from one light beam energy- means-

The planets matters and distances are created out of one light beam energy, where this light beam velocity is 1.16 million km /s

The space and time creation consumed the energy and left small part of energy as one light beam its velocity 300000 km/s

Shortly – the solar system is similar to one sea of water (one ocean of water)

The sea creation consumed the energy of the original light beam (its velocity 1.16 million km /s) and after this sea creation the rest energy is found as one light beam its velocity 300000 km/s – this rest energy we can imagine as one wave moves through The Sea

Shortly

The Solar System Is Consisted Of Space And There's One Wave (Its Velocity 300000 km/s) Moves Through This Space.

(3)

Now –

Te Solar System needs To Create A Stationary Point (Its velocity Zero) relative to the moving wave (its velocity is 300000 km/s)

This is the basic information in the solar system design-

The stationary point is so important for the solar system motion- because- the different velocity between the wave motion (300000 km/s) and the stationary point (Zero) can store the energy-

But- the stationary point creation is so complex process because (all things in the solar system move by this wave motion its velocity 300000 km/s)

Clearly- we need to create a stationary point on the sea page while the sea water moves continuously- the difficulty is seen clearly

For that the solar system uses 2 procedures for this process

The First Procedure

The wave its velocity 300000 km/s revolves around a point in space (any point in space), the revolution motion creates 2 equal velocities on both sides of the revolution- the two velocities are equal in value and opposite in direction- their total be equal Zero-means- the revolution motion causes to create a stationary point in the center of the revolution.

(Notice This Stationary Point Will Be The Sun)

The Second Procedure

The previous idea is correct theoretically- but –the velocity 300000 km/s is a huge one and to decrease it to Zero velocity this is a complex process – for that- the wave (300000 km/s) created small waves with low velocities- and these small waves are used to decrease the velocity 300000 km/s gradually-

(These small waves are the planets and they are created to decrease the velocity 300000 km/s to Zero gradually)

The Solar System Uses A Complete System Of Velocity

Because the velocity 300000 km/s is decreased to Zero by using (the planets velocity) the small waves low velocities- the low velocities are used as steps to decrease the unified wave velocity (300000 km/s) to be (Zero)- this process decreases the velocity gradually from 300000 km/s to Zero depending on these small waves velocities (the planets velocities)

Shortly – the solar system has one complete system of velocities, Starting from Zero and reaching to 300000 km/s where the planets velocities are the steps between the two velocities – let's prove this idea here

(4)

The Solar System Motion Description

Let's review the general motion description-

In the revolution around the sun there are 2 motions

(1st Motion) the mother wave its velocity =300000 km/s

(2nd Motion) the planets motions by their velocities

The Two Players Move Revolving Around The Sun Continuously

This description I reach by my hypothesis of the mother wave velocity 300000 km/s – as explained in the preface-

BUT

we can reach to this same description by planet motion energy analysis – without my hypothesis – to prove that we need to review the planet motion energy analysis

Planet Motion Energy Analysis

Where's Planet motion energy?

Any moving body produces energy (1/2 mv^2)- so- (where's Planet motion energy?)

The planet can't store its motion energy inside its own body because it would raise its temperature and no planet temperature is raised by its motion- so where's Planet motion energy?

This question is answered in (Space Nature Analysis)

And we know that, (Planet Motion Energy Is Stored In The Space)

The space is similar to the sea of water and the planet motion through the space is similar to a fish swimming through the sea– and – as the fish swimming energy creates waves in the sea– the planet motion energy creates waves in the space- these waves are very similar to the water waves – they move freely far from their source and can be reflected (typically as the water waves)

Based on this vision- the planets move and produce motions energies in the space- and this energy is stored in the space in waves form- then the planets motions energies waves Are Unified Together Into One Unified Wave-

That creates the same picture - The planets revolve around the sun and there's one unified wave also revolves around the sun with the planets- this one unified wave velocity = the planets velocities total- the pictures are typical-

It's the same description- but - there's only One Difference which is-

In the mother wave description the mother wave velocity is 300000 km/s

In the planet motion energy analysis description the mother wave velocity is = the planets velocities total

Then we have to ask-

What's The Relationship Between The Planets Velocities Total With The Speed Of Light 300000 km/s? let's answer this question in following…

(5)

THE PLANETS VELOCITIES TOTAL ANALYSIS

The 9 planets velocities total is 176 km/s– I add the Earth moon velocity= the Earth velocity 29.8 km/s because they revolve around the sun together.

(I add the moon velocity because the total motion energy is stored in the moon orbit)

176 km/s +29.8 km/s = 205.8 km/s

Now let's ask (what's the relationship between 205.8 km/s and the mother wave velocity = speed of light 300000 km/s)

300000 km =7.1 x (205.8)^2

The equation tells

7.1 is Lorentz Length Contraction Effect (for a velocity 297000 km/s = 0.99 speed of light) – means -the motion with velocity (99% speed of light) causes length contraction with rate 7.1

Shortly - the solar system has a different velocity =300000 km/s, this motion is done for one second, passes 300000 km- and because of Lorentz length contraction effect this distance 300000 km is contracted to be (42253 km = 300000 km/7.1), by that the solar system moves 42253 km in comparison with 300000 km because of Lorentz length contraction effect.

Where 42253 km = (205.8 km)^2 – (But Why Is The Velocity Squared?)

The Squared Velocity Reason

42253 km = (205.8 km)^2 - the squared velocity value is used for the rate of time using – but let's review the summarized idea here and prove it later.

The unified wave velocity (205.8 km/s) relative to the stationary point (the sun) creates a rate of time- means (one second of the unified wave clock = 205.8 seconds of the stationary point clock)

The unified wave is reflected in the solar system- that causes to reflect the players- by that (one second of the stationary point clock= 205.8 seconds of the unified wave clock)

The unified wave (205.8km/s) moves in (205.8 seconds) a distance = 42253 km

By that- the distance 42253 km is passed by the unified wave in (205.8 seconds) of the unified wave clock but in One Second of the stationary point clock.

By Lorentz contraction rate (7.1) this distance (42253 km) be equal (300000 km) by that – a distance 300000 km is passed on a period of time (one second of the stationary point (the sun) clock) – that creates the different velocity 300000 km/s

Notice No. (1)

Lorentz contraction effect with rate (7.1) caused the distance 300000 km to be 42253 km – but it's difficult to explain how (42253 km) can be (300000 km)- only I can say the energy is reflected in the solar system and that causes to reflect the effects.

Notice No. (2)

This analysis for the planets velocities total still need more explanation because we need to study the rates of time which are used by the planets motions – the rates of time will explain this equation clearly and also will give us more data supports this equation idea –

Notice No. (3)

1461 =7.1 x 205.8

The data shows the rate of time (1=1461) is found also behind this equation- the point is that – the cycle (1461 days = 365 +365 +365 +366) – this is the Earth cycle and that tells the different velocity (300000 km/s) doesn't only depend on the planets velocities total (205.8 km/s) but also it depends on the Earth cycle (1461 days) shows that many reasons push to this different of velocity and for that this velocity uses different data in the solar system – the rate of time discussion will explain this using clearly- for that we study the rates of time in point (10)

Thanks a lot – kind regards

Please read

Planet Diameter Equation Shows The Matter Origin (The Proves Discussions)

or

Gerges Francis Tawdrous +201022532292

Physics Department- Physics & Mathematics Faculty

Peoples' Friendship university of Russia – Moscow (2010-2013)

Curriculum Vitae https://www.academia.edu/s/b88b0ecb7c

E-mail [email protected], [email protected]

ORCID https://orcid.org/0000-0002-1041-7147

Facebook https://www.facebook.com/gergis.tawadrous

VK https://vk.com/id696655587

Tumblr https://www.tumblr.com/blog/itsgerges

Researcherid https://publons.com/researcher/3510834/gerges-tawadrous/

Google https://scholar.google.com/citations?user=2Y4ZdTUAAAAJ&hl=en

Livejournal https://gerges2022.livejournal.com/profile

Pocket https://getpocket.com/@646g8dZ0p3aX5Ad1bsTr4d9THjA5p6a5b2fX99zd54g221E4bs76eBdtf6aJw5d0?src=navbar

PUBLICATIONS

box https://app.box.com/s/47fwd0gshir636xt0i3wpso8lvvl8vnv

Academia https://rudn.academia.edu/GergesTawadrous

List of publications http://vixra.org/author/gerges_francis_tawdrous

Slideshare https://www.slideshare.net/Gergesfrancis

#физика#математика#астрономия#наука#геометрия#космос#электричество#механика#философия#астрофизика#решение задач#школа#10 класс#ошибки#учеба#задачи#русская школа#школа вампиров#русский tumblr#physics#astrophysics#quantum physics#наш физик легенда#астрономи космос наука#science side of tumblr#artists on tumblr#photographers on tumblr#physique#astronomy#квантовая физика

2 notes

·

View notes

Text

absolutely the most boring braindump of a Post Abt Chest Management Solutions, lmao, ergo cut for length—

am hanging around in one of the cotton fruit of the loom ~bralettes~ i bought recently (3 for $15! unbelievable bargain probably made possible by a sweatshop somewhere! no ethical consumption &c!), which like—truly is any word better designed 2 induce dysphoria. like i already hated talking abt myself and bras in the same sentence and now: a further feminizing diminutive suffix!! rigged for hir displeasure!—and thinking like.

(1) thrilled to have found an approach 2 the problem [some people call their tits 'the girls.' i call mine 'the problem.'] that's as comfortable as these. like i accidentally slept in one last night because i didn't get the discomfort cue that normally prompts me to strip down for sleep. extremely can't complain in that regard.

(1b) …does that mean i should really try a size down for better more flattening compression tho. very possibly! but i guess really it depends on whether this set shrinks in the wash much, so like. stay tuned.

(2) the fabric of these is still probably too heavy for really hot weather, i'm guessing, and regardless of thickness cotton just inherently absorbs rather than wicking, so. problem not fully solved. but for the current warm-but-not-sweltering temps these are pretty good. definitely an improvement over nylon against clammy skin.

(3) it continues to be deeply baffling to me that so many people, if the market is to be believed, prefer non-racerback straps for everyday wear. like—these bralettes i bought are essentially just incredibly basic cropped camisoles with some elastic at the bottom hem, and while they weren't totally horrendous in that configuration, i unpicked the stitching on the straps and reattached them at the center back to make a rough-and-ready racerback like so: _\/_ and it was just. immediately vastly more comfortable not to have the straps crossing my shoulder blades. like i accept that we're all different and have different prefs but part of me is just like '…are ppl who prefer that style sure that isn't just familiarity/false consciousness speaking tho.'

(4) the one thing abt these bralettes that still isn't really ideal, but which would be a much bigger project to fix, is that like. not all of us need this much fabric along the vertical axis, lol. like obviously they make these as long as they do to accommodate the amount of tissue in larger chests, and like, thumbs up for that, but for those of us who don't present with that degree of convexity, it's just like. this garment could've been a solid inch shorter and still accomplished its goals?? and so you wind up with extra fabric and either have to roll the band up to reel in the slack or else just live with it bunching up in the eaves, and like, neither approach is totally terrible but. could be better!!

and yeah, i could unpick the stitching on the elastic and cut an inch off the bottom and then work out how to reassemble things, but like. the strap relocation was easy and i could do it by hand while watching tv, whereas elastic is intimidating and also that's more sewing than i really want to do by hand. so in theory i'd want to figure out how to do it on the machine which. is also intimidating. so i'm just living with it, at least for now.

finally & probably most importantly (5) spending this much brainspace [i mean like. just look at this stupid fucking hydra of a post.] on Problem Management does make me mad, lol. like. most of the time it just feels easier to accept the situation and strap it down to something ignorable than to seek out a surgical remedy that's separated from me by so many barriers (expense/current lack of insurance, soc anx, perfectionism, serious uncertainty abt whether it would actually on the whole be an improvement vs just Differently Wrong, fear of increased transphobia), but when it's like. well now i'm having to actively engage with the problem and spend time and thought and money and effort on it anyway, just in ways that make me feel powerless and resentful rather than self-actualized and hopeful… blegh.

#truly just. extremely boring but i wanted all these thoughts OUT of my head instead of still sloshing around in there.#luv 2 transcribe literally 2 unnecessary pages' worth of brainbuzz.#journaling#sartorial#domesticities#feelingsblogging#embodiment (is violence)

3 notes

·

View notes

Text

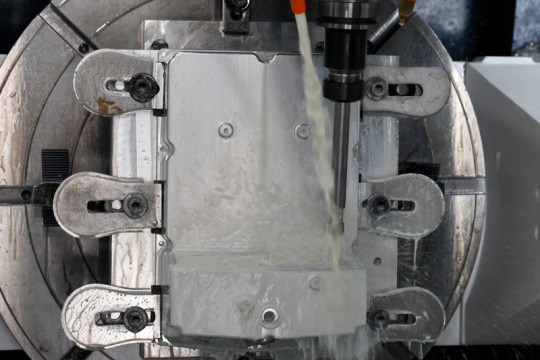

Application of 3+2 CNC Machining in Mold Making Factory

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

17 key tips for milling applications

Milling is the process of holding a blank in place and using a high-speed rotating milling cutter to travel over the blank to cut out the desired shape and features.

Conventional milling is more often used to mill simple shapes/features such as contours and slots. CNC milling machines can perform machining of complex shapes and features.

Milling and boring machining centers can perform 3-axis or multi-axis milling and boring for machining, molds, inspection tools, tire tools, thin-walled complex surfaces, artificial prostheses, blades, etc. In the selection of CNC milling and processing content, should give full play to the advantages and key role of CNC milling machine.

In the actual production of milling processing, including machine settings, workpiece clamping, tool selection and other aspects of application skills, this issue for you to briefly summarize the 17 points of milling processing, each point is worthy of in-depth mastery.

1. Power capacity

Check the power capacity and machine rigidity to ensure that the machine can use the required milling tool diameter.

2. Workpiece stability

Workpiece clamping conditions and considerations.

3. Overhang

Make the tool overhang on the spindle as short as possible during machining. 4.

4. Selecting the correct milling cutter tooth pitch

Use the correct tooth pitch of the milling cutter for the process to ensure that no excessive inserts are involved in the cut, which would otherwise cause vibration.

5. Cutter draft

For narrow workpieces or milling with gaps, ensure that there is sufficient insert draft.

6. Insert groove type selection

Whenever possible, use positive front-angle slotted indexable inserts to ensure smooth cutting action and minimum power consumption.

7. Use the correct feed

Ensure proper feed of the insert used by using the recommended maximum chip thickness to achieve the correct cutting action.

8. Cutting direction

Use smooth milling whenever possible.

9. Part Considerations

Workpiece material and configuration, as well as the quality requirements of the surface to be machined.

10. Insert material selection

Select the slot type and material according to the type of workpiece material and type of application.

11. Vibration damping milling cutters

For longer overhangs exceeding 4 times the tool diameter, the tendency to vibrate becomes more pronounced and the use of vibration damping tools can significantly improve productivity.

12. Main deflection angle

Select the most suitable main deflection angle.

13. Milling tool diameter

Select the correct diameter according to the width of the workpiece.

14. Milling tool position

Position the milling cutter correctly. 15.

15. Milling cutter cut-in and cut-out

It can be seen that by circular plunge, the chip thickness during retraction is always zero, thus enabling higher feeds and longer tool life.

16. Coolant

Coolant is used only when deemed necessary. As a rule, milling is better executed without coolant.

17. Maintenance

Follow tool maintenance recommendations and monitor tool wear.

3 notes

·

View notes

Text

Electric Bike Winter Maintenance Guide!

The weather is getting colder and colder, presumably many friends are still rain or shine, and can't bear to close the car. If a worker wants to do a good job, he must first sharpen his tools. Electric bicycles can be said to be sports machines. To make this machine exert its maximum power, you must pay attention to the maintenance of your car when riding in winter. A comprehensive inspection of your car after leaving the car can not only prolong the service life of the car. It can eliminate many hidden dangers and improve safety! Let's take a look at the winter maintenance guide for electric bike!

Maintenance description and purpose of each part of the bicycle:

1. Head

Maintenance description: Check whether the bearings at the upper and lower ends of the head tube can be used normally, clean and oil the bearings.

Maintenance purpose: to clean the dust and sludge of the bearings in the head tube, to prevent bearing damage, rust and abnormal noise.

2. Axis

Maintenance description: Check whether the center shaft can be used normally, clean and oil the bearings.

Maintenance purpose: to clean the dust and sludge in the bottom bracket and bottom bracket to prevent damage, rust and abnormal noise of the bottom bracket.

3. Wheel front and rear hubs

Maintenance description: Check whether the hub can be used normally, clean and oil the balls in the hub.

Maintenance purpose: Check whether the hub can be used normally, clean and oil the balls in the hub.

4. Wheel set adjustment (front and rear wheels)

Maintenance description: Put the wheel set on the ring adjustment table to check whether it is deflected, and adjust it according to the situation (Nalong)

Maintenance purpose: to reduce the deflection of the wheel set to make the handling better.

5. Transmission system (front and rear derailleurs, flywheels, chains, cranksets)

Maintenance description: Check the transmission system: whether the front and rear derailleurs, flywheels, chains, and chainrings can be used normally, clean the dust and sludge, replace with new oil, and adjust the gear.

Maintenance purpose: reduce excessive wear caused by sludge and other sundries, and prolong the service life of flywheel and chain.

6. Frame

Care Description: Clean the body and remove stains.

Electric bike maintenance process

Step 1: Clean the Dirt

If the body is not very dirty, just wipe it with a damp soft cloth; if there are many mud spots, you can wash it with a water hose. It should be noted that the pressure of the water column should not be too high. At the same time, the rotating parts such as triaxial and headset cannot be washed directly with water. A toothbrush can be used for places that cannot be wiped by a rag, and the upper tube of the front fork should also be removed with a toothbrush to avoid scratches during shock absorbers. Both the rim and the brakes need to be cleaned to remove the impurities embedded in the brakes and reduce unnecessary wear and tear. Brakes and shift cables should also be wiped clean. If there is a lot of mud and sand, the wire tube can be removed and the internal chain can be cleaned with the spray pressure of the anti-rust agent. The most dust-absorbing place on the whole car, wipe off the stains with a rag. If it is very dirty, you can use an anti-rust agent to clean it. Remember to dry the chain after completion to facilitate subsequent chain oiling.

Step 2: Lubricate

Brake and shifting line pipes need to be re-oiled after cleaning, and grease lubricating oil with weak fluidity is suitable for use on the line pipes. The chain is an important part of the transmission, and it also has high requirements for oiling. Generally, 5-6 drops can be added at a time. After adding, let the chain fully rotate, and at the same time bring lubricating oil to each tooth piece, and dry the chain with a rag after adding. After cleaning the upper tube of the front fork, special lubricating oil should be used to keep the front fork moving smoothly in winter.

Step 3: Prevent Rust

After riding, it is recommended to apply some anti-rust agent to the various screws and transfer points on the bicycle. Firstly, it is anti-rust, and secondly, it is also good for future disassembly.

Electric Bike Winter Maintenance Guide!

3 notes

·

View notes

Text

The different shafts of the Swiss lathe

Hello everyone, here at HANBS, I'm Sonya, and today I'm sharing with you the different shafts of the Swiss lathe, mainly to introduce the role of the shafts in the swiss lathe, why do we need so many shafts? What is its role embodied?

The swiss lathe (Swiss type cnc lathe/Sliding headstock cnc lathe) is known for its high precision and efficiency, and is especially suitable for small parts machining. They are divided into different types according to the number of axes and different configurations, today we will introduce 3-axis, 5-axis, 6-axis (Y2 axis) and so on. The following is a detailed explanation of each type.

1. 3-axis swiss lathe.

Involved axes: X1, X2, C-axis

Key features:

X1 axis: Controls the movement of the tool in the radial direction (perpendicular to the workpiece).

X2 axis: controls the movement of the tool in the longitudinal direction (along the length of the workpiece).

C-axis: Controls the rotation of the spindle for drilling and milling operations on the radial and end faces of the workpiece.

Although there are only 3 axes, it is possible to add other accessories to make it more unique by making it a specialized machine for parts.

APPLICATIONS:

This lathe is mainly used for simple turning, drilling and basic milling operations, and is suitable for machining cylindrical or slightly curved parts, but has limited ability to machine complex geometries.

2. 5-axis swiss lathe

Axes involved: X1, Y1, Z1, C1, C2 axes

Key Features:

X1, Z1: Used for turning and basic milling operations, similar to a 3-axis lathe.

Y1 axis: adds an extra lateral movement for eccentric milling and drilling operations.

C1/C2 axis: Controls the rotation of the main spindle (C1) and sub-spindle (C2) to realize machining of both ends of the workpiece.

The swiss lathe at this time can process the main and sub-spindles at the same time, which greatly improves the working efficiency.

Applications:

The 5-axis swiss lathe is capable of machining parts with more complex part geometries, and is especially suitable for parts that require multi-face milling, off-center drilling or contouring. Commonly used in aerospace, medical and other industries that require high precision and complexity.

3. 6-axis (Y2) swiss lathe

Axes involved: X1, Y1, Z1, X2, Y2, Z2

Key Features:

X1, Y1, Z1: Mainly used for turning and milling operations on the spindle side, providing complete machining freedom.

X2, Y2, Z2: Used for machining operations on the sub-spindle side, enabling simultaneous machining of both ends of the workpiece.

Y2 axis: Allows complete milling, drilling and contouring operations on the sub-spindle side.

Simultaneous machining: the main spindle and the subspindle can be operated independently of each other, allowing two different machining operations to be carried out in different positions on the same workpiece.

The 6-axis swiss lathe allows for simultaneous machining of the main and sub-spindles, and with the addition of the Y2 axis, allows both the main and sub-spindles to be independent machining fields, further reducing machining times.

Applications:

The 6-axis (Y2) configuration is ideally suited for the machining of complex parts, especially those requiring multiple operations. The simultaneous machining function of the main spindle and the sub-spindle significantly reduces machining cycles and increases efficiency. Commonly used for mass production of medical devices, watch components and complex aerospace parts.

Summary

3-axis swiss lathe: for basic turning, drilling and face milling operations.

5-axis swiss lathe: offers greater flexibility in machining skills, the ability to machine complex geometries, support for eccentric milling, and the ability to control both the spindle and the subspindle simultaneously.

6-axis (Y2) swiss lathe: offers maximum flexibility, allowing simultaneous machining of both main and sub spindles, working in tandem, suitable for efficient machining of precise and complex parts.

Today's sharing is here, I hope to help those who need it, we will be the next chapter of these different types of axis machines for further derivation of the explanation. See you in the next installment.

www.hanbscnc.com

0 notes

Text

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

3 notes

·

View notes

Text

What Industries Is Precision Machining Applicable To?

Precision machining is applicable to a wide range of industries including, but not limited to automotive, aerospace, biomedical, petrochemical, energy, environmental protection, etc. due to its high accuracy, quality and flexibility.

Aerospace

The aerospace sector places extremely high demands on the precision, strength and weight of parts and assemblies. Precision machining technology is used in the manufacturing of engine components, turbine blades, turbine disks, aeronautical instruments, propulsion systems, satellite parts and structural components such as hulls, wings and empennage. These parts require extremely high geometric accuracy, surface quality and material properties to ensure the performance, safety and reliability of the aerocraft. (Ultra-precision machining technology is used in the manufacturing of precision engine parts, aerospace structural components, guidance and control elements, etc., which is widely used in satellite manufacturing, automatic spacecraft rendezvous and docking, satellite guidance and control, etc.)

Biomedical

Ultra-precision machining technology is used in the manufacturing of diagnostic devices, medical devices, medical equipment parts, surgical instruments, artificial human implants such as artificial joints, bone plates, spinal screws, cardiac stents, etc. in which medical devices are manufactured with stringent requirements for precision and quality to ensure their safety and effectiveness in clinical use. These devices require precise dimensions and shapes, as well as smooth surfaces to minimise human rejection and increase biocompatibility.

Automobile

Automobiles are made up of thousands of precision parts, and the fineness of these parts directly affects their performance and safety. In automotive manufacturing, precision machining technology is used to produce key components such as engine parts, braking systems, steering systems, transmission components, suspension systems parts, precision instruments and body electronics. CNC Precision Machining can help manufacturers produce more accurate, safe and durable automotive parts. High precision machining not only improves the performance and reliability of automobiles, but also promotes the automation and intelligent development of the automotive industry.

Petrochemical, Energy and Environmental Protection

Ultra-precision machining technology is used in the manufacturing of gases, liquids and solid tanks, wind and solar power generation heavy machinery equipment, electrical equipment and nuclear reactor components, etc., in addition to the manufacturing of environmental protection equipment, metrology equipment and so on.

Electronic Device

Modern electronic products such as smartphones, computers, and wearable devices rely on precision machining technology for many of their internal key components. For example, mobile phone housings, chip packages, miniature sensors and circuit boards all require high precision machining technology to ensure product performance and stability.

Optics and Photoelectricity

Optical instruments such as microscopes, telescopes, astronomical telescopes, camera lenses, optical lens, fibre optic communication devices, laser components, etc. require precision machining technology in their manufacturing process to ensure the accuracy and surface quality of optical components. Small errors in these components can have a significant impact on imaging quality.

Semiconductor

The semiconductor industry also has a high demand for precision machining technology. The production, packaging and testing of semiconductor wafers requires the use of high-precision equipment and processes to ensure product quality and performance.

Railway

In the field of rail transportation, such as high-speed trains, underground vehicles and other rail vehicles above the precision electronic equipment shell of custom and structural components, such as the manufacturing and processing, need to be supported by precision machining technology.

To summarize, precision machining technology plays a vital role in modern industry, covering multiple fields from high-tech products to daily necessities. The application areas of precision machining technology will continue to expand as technology continues to advance and demand continues to increase.

#design#autos#business#cnc machining#prototyping#precision machining#prototype#prototype machining#rapid prototyping#machining parts#cnc precision machining#precisionmanufacturing#high precision#5 axis machining#cnc parts company#cnc parts factory#cnc machining center

1 note

·

View note

Text

Used Sheet Fed / Offset Machine for SALE

Heidelberg - CD 102-5+LX

Buy Directly from SELLER -

Number of color: 5

Max sheet size: 72 x 103 cm / 28.3 x 40.5 inch

Manufacturer: Heidelberg

Year: 2013

Machine Availability: Immediately from stock

Price: On Request

Location: Netherlands

#print #offset #machinedalal

0 notes

Text

Hermle C 250 U with Heidenhain 640 Control: The Ultimate Precision Tool for Advanced Machining

When it comes to advanced CNC machining, the Hermle C 250 U stands out as one of the best options for 5-axis machining centers. Designed to handle complex jobs with precision, the Hermle C 250 U paired with the Heidenhain 640 control system offers unparalleled flexibility and control. Whether you’re in the automotive or mold-making industry, this machine brings high efficiency, reliability, and…

0 notes

Text

5-axis milling process: A complete overview

Introduction:

Milling is an important process in the manufacturing industry, and technological advancements have led to the development of 5-axis turn-mill machines. These machines can perform complex and intricate milling tasks with precision and speed. In this article, we will highlight an overview of the 5-axis milling process, its working, benefits, and applications in major industries.

Working of a 5-axis turn-mill:

The 5-axis turn-mill machine is designed to provide high accuracy and flexibility in milling operations. This machine has a rotating work table and five axes of motion, which allow the cutting tool to move in all directions, providing maximum flexibility in machining. As a result, the cutting tool can easily reach difficult angles, contours, and features. In addition, the workpiece can be machined in a single setup, reducing setup time and increasing efficiency.

Top Benefits of a 5-axis turn-mill:

Increased Precision: 5-axis turn-mill machines are designed to deliver high precision and accuracy in milling operations. The device can move the cutting tool in all directions, providing access to complex and difficult-to-reach features and contours.

Increased Flexibility: 5-axis turn-mill machines provide maximum flexibility in machining operations. These machines can quickly produce complex geometries, contours, and features, reducing the need for additional setups and procedures.

Reduced Setup Time: These machines can machine the workpiece in a single setup, reducing the need for multiple setups and increasing efficiency.

Improved Surface Finish: 5-axis turn-mill machines can produce high-quality surface finishes, reducing the need for additional finishing operations.

Reduced Scrap: The 5-axis turn-mill machine can machine the workpiece with high precision, reducing scrap and increasing efficiency.

Cost-Effective: Although 5-axis turn-mill machines are expensive, they are a cost-effective investment in the long run. These machines provide increased efficiency, reduced scrap, and reduced setup time, resulting in a quick return on investment.

Enhanced Safety: The 5-axis turn-mill machine has various safety features, ensuring that the device is safe to operate. These features include automatic tool changers, hydraulic fixtures, and interlocked doors.

Application of 5-axis turn-mill in Major Industries:

The 5-axis turn-mill machine is used in various industries such as aerospace, automotive, medical, and general engineering. For example, in the aerospace industry, these machines produce complex turbine blades and other aerospace components.

In the automotive sector, 5-axis turn-mill machines are used to produce complex engine blocks and transmission cases. Finally, in the medical industry, these machines are used to build complex medical implants and surgical instruments.

Conclusion:

A 5-axis turn-mill machine is an essential machine in the manufacturing industry. The benefits of using a 5-axis turn-mill machine include increased precision, flexibility, reduced setup time, improved surface finish, reduced scrap, cost-effectiveness, and enhanced safety. WIDMA is a well-known manufacturer of 5-axis turn-mill machines and offers a wide range of machines to suit various industrial applications.

From CNC to Hydraulic Fixtures for Machining Centers, WIDMA specialises in providing the best of what the industries need. In conclusion, the 5-axis turn-mill machine is an advanced and powerful tool that significantly benefits the manufacturing industry.

0 notes

Text

Ensuring Precise Dimensions: The Art of Custom Plastic Profile Extrusion

Whether it’s creating components for machinery or crafting intricate parts for consumer products, the ability to achieve precise dimensions is crucial. One technology that excels in this arena is custom plastic profile extrusion. In this article, we’ll explore the art of custom plastic profile extrusion and how it revolutionizes manufacturing processes by ensuring precise dimensions.

Channels Ready for Immediate Use

Flexibility in Application

Custom plastic profiles are designed to be ready for immediate use, offering unparalleled flexibility in application. These profiles can be seamlessly integrated into existing systems without the need for extensive modifications, saving time and resources.

Rapid Adaptation to Specifications

One of the key advantages of custom plastic profile extrusion is its ability to rapidly adapt to specific requirements. Manufacturers can easily tailor profiles to meet the exact dimensions and specifications of each application, ensuring a perfect fit every time.

Seamless Integration with Existing Systems

Custom plastic profiles are engineered to integrate seamlessly with existing systems, minimizing downtime and disruption during installation. This allows manufacturers to upgrade their equipment and processes without costly delays or production interruptions.

Capacity for Diverse Orders

Prototype Trials

Custom plastic profile extrusion offers the flexibility to accommodate small-scale prototype trials, allowing manufacturers to test new designs and concepts with minimal investment. This enables rapid iteration and refinement, leading to faster time-to-market for new products.

Large Production Runs

In addition to prototype trials, custom plastic profile extrusion has the capacity to handle large production runs with ease. With nine primary production lines and four co-extrusion lines, manufacturers can scale up production to meet high-volume demands without sacrificing quality or precision.

State-of-the-Art Production Lines

Primary Production Lines

The state-of-the-art production lines are equipped with the latest technology to ensure consistent quality and high throughput rates. This helps to meet tight deadlines and deliver superior products to our customers.

Co-Extrusion Lines

The co-extrusion lines allow the production of complex profiles with multiple layers, expanding design possibilities and enhancing product performance. This advanced technology creates custom solutions for even the most demanding applications.

Plastic Extrusion Design Engineering

Precision Design Capabilities

Experienced engineers have the expertise to design custom profiles with precision and accuracy. Using advanced CAD software and simulation tools, It optimizes profiles for performance, durability, and cost-effectiveness.

Innovation in Profile Development

Experienced engineers are constantly exploring new materials, processes, and techniques to push the boundaries of what’s possible in custom plastic profile extrusion.

Plastic Extrusion Tooling

Advanced Tool Room Facilities

The room is equipped with cutting-edge machining technologies, including 5-axis wire EDM and CNC machining centers. This allows high-quality tooling with precision and efficiency.

Tailored Tooling Solutions

It also offers customized tooling solutions to meet the unique requirements of each project. Whether it’s rapid prototyping or iterative design processes, tooling capabilities ensure the delivery of perfect solutions for your needs.

Plastic Extrusion Fabrication

Comprehensive Fabrication Services

In addition to extrusion, Fabrication services add value to your products. From punching and routering to drilling and printing, It has the expertise and equipment to handle all aspects of production.

Enhanced Product Finishing

The finishing services include surface treatments, coatings, and quality assurance measures to ensure that your products meet the highest standards of quality and performance. With attention to detail and commitment to excellence, you can trust Custom Plastic Profile Extrusion to deliver superior results every time.

Incorporating 3D Printing

Prototyping Capabilities

Our 3D printing capabilities enable rapid prototyping and iteration, allowing you to test new designs and concepts quickly and cost-effectively.

Customization and Personalization

With 3D printing, it can create custom profiles with unique features and designs, allowing you to differentiate your products and stand out in the market.

FAQs

Are custom plastic profiles suitable for small-scale projects?

Yes, custom plastic profiles are highly adaptable and can be tailored to meet the requirements of small prototype trials.

How quickly can custom plastic profiles be produced?

Production times vary depending on the complexity and volume of the order. However, manufacturers often offer rapid turnaround times to meet tight deadlines.

What materials can be used for custom plastic profile extrusion?

A wide range of thermoplastic materials can be used for custom profile extrusion, including PVC, ABS, HDPE, and more.

Are custom plastic profiles suitable for outdoor applications?

Yes, custom plastic profiles can be engineered to withstand harsh environmental conditions, making them ideal for outdoor use.

Can custom plastic profiles be recycled?

Yes, many thermoplastic materials used in custom profile extrusion are recyclable, contributing to sustainability efforts.

Conclusion

In conclusion, custom plastic profile extrusion is a versatile and efficient manufacturing process that revolutionizes the way we produce components and products. With its ability to ensure precise dimensions and tailor-made solutions, custom plastic profile extrusion offers numerous benefits for various industries. From flexible application to seamless integration with existing systems, this technology provides manufacturers with the tools they need to stay competitive in today’s market.

Ready to experience the benefits of custom plastic profile extrusion for your next project? Contact Lakeland Plastics today to bring your vision to reality with precision and excellence.

0 notes