Don't wanna be here? Send us removal request.

Text

How an Economical Box Maker Machine Can Improve Efficiency Without Breaking the Bank

In today’s fast-paced packaging and logistics industry, efficiency and cost-effectiveness are two pillars that determine success. Whether you’re a small-scale packaging startup or an established manufacturer, the need to optimize production without overspending is crucial. This is where an Economical Box Maker Machine steps in as a smart investment, offering excellent value without compromising on essential functionality.

For businesses seeking high productivity and flexibility, budget-friendly Corrugated Box Making Machines are proving to be indispensable. With growing demand for custom packaging and fast turnarounds, the right machinery can boost both performance and profitability. But is it possible to stay within budget and still meet your operational goals? Absolutely.

Understanding the Economical Box Maker Machine

An Economical Box Maker Machine is specifically designed to deliver efficient box production while keeping manufacturing costs low. It’s a practical solution for companies that need to produce boxes in-house but may not yet require a fully automated, high-capacity system like a Heavy Duty Box Maker Machine.

These machines often combine basic yet powerful functions—such as creasing, cutting, slitting, and slotting—and are suitable for small to medium production runs. While they may not carry all the bells and whistles of larger models, their strength lies in reliable performance, compact design, and affordability.

Benefits of Choosing an Economical Box Maker Machine

1. Reduced Capital Investment

The most apparent advantage is the lower upfront cost. An Economical Box Maker Machine allows you to start or upgrade your packaging operations without a significant financial burden. It’s especially ideal for startups or businesses transitioning from manual box-making to semi-automated production.

2. Lower Operating Costs

Not only is the machine itself affordable, but it also typically consumes less power, requires fewer operators, and involves minimal maintenance compared to advanced Heavy Duty Box Maker Machines. Over time, this translates into noticeable savings on operational expenses.

3. Space-Saving Design

Most economical machines are compact and require minimal floor space. This makes them a perfect fit for small production units or businesses working in urban environments with limited real estate.

4. Quick Setup and User-Friendly Operation

Many budget-friendly models come with straightforward controls, intuitive interfaces, and quick-change features. This ease of use means that operators don’t need extensive training to run the machine efficiently, allowing companies to get started faster and avoid production delays.

How It Improves Operational Efficiency

Even at a lower price point, an Economical Box Maker Machine brings in efficiency by:

Reducing Lead Time: In-house production of corrugated boxes eliminates delays caused by third-party suppliers.

Enabling On-Demand Customization: These machines support various box sizes and styles, giving businesses the flexibility to cater to different client needs.

Minimizing Waste: With precise cutting and creasing, material wastage is significantly reduced, making operations more cost-effective and sustainable.

This makes economical machines a valuable addition to any facility focused on lean manufacturing.

Why Corrugated Box Making Machines Are Still Essential

Whether you choose an entry-level model or a high-performance unit, Corrugated Box Making Machines play a vital role in packaging today. They offer precision, consistency, and scalability for packaging operations of all sizes.

Corrugated boxes remain the most popular choice for e-commerce, retail, and shipping applications due to their durability and eco-friendliness. Machines built to handle this material efficiently are necessary for any business looking to succeed in the packaging domain.

Conclusion

An Economical Box Maker Machine is not just a cost-saving measure—it’s a gateway to operational efficiency, customization, and long-term growth. While larger businesses may benefit from the high throughput of Heavy Duty Box Maker Machines, smaller operations can make a significant impact with compact, efficient, and affordable models.

By integrating a reliable Corrugated Box Making Machine into your production line, you not only gain control over your packaging processes but also reduce dependency on external suppliers, shorten turnaround times, and enhance product delivery standards.

In a market that demands speed, flexibility, and value, economical box-making solutions are helping businesses scale without overspending—making them a smart choice for the future of packaging.

0 notes

Text

How a Multifunctional Box Machine Can Streamline Your Packaging Process

In today's competitive packaging industry, speed, customization, and efficiency are key. Businesses are under constant pressure to deliver quality packaging that meets market demands while minimizing production costs and operational delays. This is where the Multifunctional Box Machine has emerged as a game-changer. Designed to handle multiple processes in a single workflow, this advanced equipment can significantly simplify and speed up box production across industries.

Whether you're a packaging manufacturer, an e-commerce company, or a logistics firm, investing in a Multifunctional Box Machine can revolutionize your operations—especially when paired with a cost-effective carton box making machine and a high-performing cardboard box making machine.

What Is a Multifunctional Box Machine?

A Multifunctional Box Machine is a versatile piece of equipment capable of performing several packaging tasks, such as feeding, creasing, slotting, cutting, folding, and gluing—all within one streamlined system. Unlike traditional machines that focus on one or two specific tasks, these multifunctional units integrate multiple steps into one continuous, automated workflow.

The result? Faster turnaround times, reduced labor costs, and less need for multiple standalone machines—all of which contribute to a more efficient production process.

The Advantages of Using a Multifunctional Box Machine

1. Integrated Workflow

The most obvious benefit of a Multifunctional Box Machine is its ability to automate the entire box-making process from start to finish. It eliminates the need to transfer materials between separate machines, reducing manual handling and potential errors. This kind of integration improves output speed and enhances product consistency, making it ideal for high-volume production.

2. Cost and Space Efficiency

Investing in a single machine that handles multiple functions is far more economical than buying separate units for each step of the process. For small to medium-sized businesses, space constraints are also a challenge. A cost-effective carton box making machine with multifunctional capabilities can reduce the need for large production floors and help you make the most of your existing workspace.

3. Flexibility and Customization

Modern customers demand personalized packaging, and businesses need equipment that can adapt quickly to varying orders. A Multifunctional Box Machine is designed with flexible settings that allow operators to adjust dimensions, styles, and box types with minimal setup time. Whether you're producing standard shipping cartons or branded retail boxes, this machine can handle it all.

4. Labor Reduction and Operational Efficiency

Manually operating several machines requires a larger workforce and increases the risk of delays or inconsistencies. With a multifunctional solution, fewer workers are needed to operate the system, allowing businesses to reallocate human resources to other critical areas. This automation not only cuts costs but also boosts overall operational efficiency.

5. Enhanced Product Quality

Since the entire box-making process is contained within one machine, the chances of material misalignment or defects are greatly reduced. These machines often come with advanced controls, sensors, and monitoring systems that maintain precise measurements and consistent performance, resulting in a superior final product.

Why It Matters in Today’s Packaging Landscape

The growing shift toward eco-friendly packaging and customized solutions has made traditional packaging methods less effective. Customers expect quicker turnarounds, high-quality finishes, and sustainable options—all while businesses aim to keep operational costs in check.

Using a cardboard box making machine that offers multifunctionality not only aligns with these changing needs but also gives manufacturers a competitive edge. It supports on-demand production, reduces waste, and helps brands scale their operations without massive capital investments.

How to Choose the Right Multifunctional Box Machine

When selecting a Multifunctional Box Machine, here are a few factors to consider:

Production Capacity: Choose a machine that matches your output requirements and allows room for future scaling.

Material Compatibility: Ensure the machine can handle different grades of corrugated board or cardboard.

Customization Features: Look for adjustable settings for box sizes, slotting depth, folding styles, and printing options.

Automation Level: Machines with automated changeover and touchscreen interfaces simplify operation and reduce training time.

Price vs. Value: While the cheapest option may be tempting, focus on long-term ROI. A cost-effective carton box making machine should balance affordability with performance and durability.

Final Thoughts

A Multifunctional Box Machine is no longer a luxury—it's becoming a necessity for packaging operations that want to remain competitive, efficient, and responsive to market demands. Combined with a smart investment in a cost-effective carton box making machine or a high-quality cardboard box making machine, this equipment has the potential to drastically improve productivity, reduce costs, and elevate the quality of your packaging solutions.

As industries continue to innovate and adopt automation, businesses that invest in multifunctional machinery now will be well-positioned to lead the way in packaging excellence.

0 notes

Text

How Modern Carton Box Machines Are Transforming the Packaging Industry

In today's fast-paced commercial world, the demand for durable, cost-effective, and eco-friendly packaging is higher than ever. Businesses across industries—from e-commerce to FMCG—require packaging solutions that not only protect their products but also enhance brand presentation and support sustainability efforts. At the heart of these packaging operations lies an essential piece of equipment: the carton box making machine.

Over the last decade, major advancements in packaging machinery, especially in carton box machines and cardboard box making machines, have significantly reshaped the packaging industry. These modern machines are faster, smarter, and more versatile than their traditional counterparts, offering businesses the ability to meet growing market demands with efficiency and precision.

The Evolution of Carton and Cardboard Box Machines

Historically, the process of manufacturing packaging boxes was labor-intensive, time-consuming, and prone to errors. Traditional machines required constant manual intervention and were limited in terms of design flexibility. Today, things have changed dramatically.

The new generation of carton box machines and cardboard box machines come equipped with digital interfaces, automation capabilities, and modular designs. These innovations allow manufacturers to streamline production, reduce waste, and create customized packaging solutions with minimal downtime.

Key Benefits of Modern Carton and Cardboard Box Machines

1. Automation for Increased Efficiency

Modern carton box making machines are highly automated, reducing the need for manual labor and increasing production speeds. They can perform tasks such as feeding, cutting, creasing, slotting, printing, folding, and gluing—all within a single, integrated workflow. This level of automation helps manufacturers meet tight deadlines and large-volume orders without compromising on quality.

2. Versatile and Customizable Output

Unlike older models that were built to handle a limited range of box sizes and types, the latest cardboard box making machines offer impressive flexibility. Whether a business needs small shipping cartons, large corrugated boxes, or customized printed cartons, modern machines can be quickly adjusted to meet diverse packaging needs. This capability is especially useful for businesses in e-commerce and retail that rely on branding and tailored packaging experiences.

3. Energy and Material Efficiency

Modern cardboard box machines are designed with energy efficiency and sustainability in mind. Advanced sensors and precision controls help reduce material waste during production, and many models support the use of recycled cardboard. This not only cuts down on production costs but also aligns with global sustainability goals—a major selling point for eco-conscious consumers and companies.

4. Improved Accuracy and Quality Control

Thanks to digital controls and real-time monitoring systems, the risk of human error in modern packaging machinery is drastically reduced. Carton box making machines today can consistently deliver high-quality boxes with precise dimensions, clean cuts, and accurate folds. Additionally, built-in diagnostic tools help identify issues before they disrupt the workflow, ensuring uninterrupted production.

Applications Across Industries

The versatility of carton box machines and cardboard box making machines has made them indispensable in a wide range of industries:

E-commerce and Logistics: For fast delivery and secure shipping, strong and lightweight cardboard boxes are a necessity. Modern machines make it easy to scale packaging production as online orders grow.

FMCG (Fast-Moving Consumer Goods): Products such as beverages, electronics, and toiletries need attractive, durable cartons that offer both functionality and shelf appeal.

Apparel and Footwear: Custom box designs with branded prints and die-cut features help elevate the unboxing experience.

Food and Beverage: With health and hygiene being top priorities, food-grade cardboard packaging requires consistent quality and tamper-evident sealing—tasks that modern machines handle with precision.

The Future of Box Making Machines

With the rapid pace of digital transformation and increasing demand for customized packaging, carton box machines are only going to get smarter. The future of cardboard box making machines lies in:

AI Integration: Predictive maintenance and automatic optimization based on machine learning algorithms.

IoT Connectivity: Real-time monitoring, remote diagnostics, and performance tracking.

Sustainability: Continued improvements in material efficiency and support for biodegradable or recycled packaging solutions.

On-Demand Manufacturing: Smaller, modular machines for localized packaging solutions, especially for startups and small businesses.

These technological shifts are not just making packaging more efficient—they are redefining what’s possible in branding, logistics, and customer experience.

The packaging industry is undergoing a revolution, and carton box making machines are at the center of it. Whether you're a large-scale manufacturer or a small business looking to scale operations, investing in a modern carton box machine or cardboard box making machine can provide a competitive edge in terms of productivity, quality, and sustainability.

As customer expectations continue to rise, businesses that adopt advanced packaging machinery early will be better equipped to deliver fast, reliable, and customized solutions—making the switch not just a smart move, but a necessary one.

0 notes

Text

Benefits of Using Automated Box Making Machines

In the competitive world of packaging, efficiency and precision are paramount. Businesses are constantly seeking ways to optimize their processes, and one of the most effective solutions is investing in an automated box making machine. These machines are revolutionizing the way companies produce corrugated boxes, offering a multitude of advantages that can significantly impact your bottom line.

The Power of Automation: Why Choose a Box Making Machine?

Enhanced Efficiency and Productivity: A key benefit of an automated box making machine is its ability to drastically increase production speed. These machines operate at a much faster pace than manual labor, allowing you to produce a larger volume of boxes in a shorter period. This translates to increased throughput and faster order fulfillment.

Consistent Quality and Precision: Manual box making is prone to human error, resulting in inconsistent box sizes and shapes. An automated box making machine, on the other hand, delivers precise and consistent results every time. This ensures that your products are packaged in uniform, high-quality boxes, enhancing your brand image.

Reduced Labor Costs: By automating the box making process, you can significantly reduce your reliance on manual labor. This translates to lower labor costs and increased profitability. An automated box making machine can perform the work of multiple employees, freeing up your workforce for other essential tasks.

Minimized Material Waste: An automated box making machine utilizes advanced cutting and folding techniques to minimize material waste. This not only reduces your material costs but also contributes to a more sustainable packaging process. Precise cuts lead to less scrap.

Increased Flexibility and Customization: Modern box making machines offer a high degree of flexibility, allowing you to easily switch between different box sizes and designs. This enables you to meet the diverse packaging needs of your customers and adapt to changing market demands.

Improved Safety: Automating the box making process reduces the risk of workplace injuries. Manual box making can involve repetitive motions and the use of sharp tools, which can lead to accidents. An automated box making machine minimizes these risks, creating a safer work environment for your employees.

Scalability: As your business grows, your packaging needs will increase. An automated box making machine allows you to easily scale your production to meet the demands of your expanding business.

Investing in a Box Making Machine: A Strategic Decision

Investing in an automated box making machine is a strategic decision that can bring numerous benefits to your business. From increased efficiency and reduced costs to improved quality and safety, these machines are transforming the packaging industry.

Conclusion

If you're looking to streamline your packaging operations, improve efficiency, and reduce costs, consider investing in an automated box making machine. It's a powerful tool that can help you take your business to the next level.

0 notes

Text

Box Maker Machines: The Key to Efficient and Custom Packaging Solutions

In today’s fast-paced business environment, packaging plays a crucial role in ensuring product safety, branding, and customer satisfaction. Companies are constantly seeking ways to improve their packaging processes while maintaining efficiency and reducing costs. This is where box maker machines come into the picture, revolutionizing the way packaging is handled across various industries.

From small businesses to large-scale manufacturers, investing in a box machine can significantly enhance productivity and streamline operations. However, understanding box machinery price and the factors influencing it is essential for making an informed purchase decision. In this article, we will explore how box maker machines are transforming packaging solutions and why they are becoming an indispensable asset for businesses worldwide.

1. The Role of Box Maker Machines in Modern Packaging

A box maker machine is designed to automate the process of creating packaging boxes with precision and efficiency. These machines handle various tasks, including cutting, folding, and assembling boxes, making them ideal for businesses that require custom packaging solutions.

Key Advantages of Box Maker Machines:

Automation: Eliminates manual labor, reducing errors and improving efficiency.

Customization: Enables businesses to create custom-sized and branded packaging.

Speed: Enhances production capacity, allowing businesses to meet high demand.

Cost-Effectiveness: Reduces waste by optimizing material usage.

A box machine can be used across multiple industries, including e-commerce, food and beverage, pharmaceuticals, and logistics, making it a versatile solution for various packaging needs.

2. How Box Maker Machines Improve Efficiency

Efficiency is a top priority for businesses, and a box maker machine plays a significant role in optimizing packaging operations.

1. Reducing Production Time

A manual packaging process can be time-consuming and prone to inconsistencies. A box machine automates the entire production cycle, significantly reducing the time required to produce each box.

2. Precision and Consistency

One of the biggest advantages of automated box maker machines is their ability to produce uniform boxes with precise dimensions, ensuring consistency across all packaging. This is crucial for industries where packaging quality directly impacts brand reputation.

3. Lowering Material Waste

Advanced box machines use materials efficiently, minimizing waste and reducing production costs. This is especially beneficial for companies focused on sustainability and cost savings.

3. Custom Packaging Solutions with Box Maker Machines

Custom packaging has become a key differentiator for brands looking to enhance customer experience. With a box maker machine, businesses can easily design and produce boxes tailored to their specific requirements.

Benefits of Custom Packaging with a Box Maker Machine:

Brand Identity – Printed logos, colors, and unique designs help establish a strong brand presence.

Product Protection – Custom-sized boxes ensure a snug fit, reducing the risk of damage during transit.

Eco-Friendly Solutions – Businesses can choose sustainable materials and optimize box sizes to minimize waste.

For businesses in e-commerce and retail, a box machine allows them to create eye-catching and durable packaging, enhancing both aesthetics and functionality.

4. Understanding Box Machinery Price: Factors That Influence Cost

When investing in a box maker machine, understanding the box machinery price and the factors that affect it is crucial. Prices can vary significantly based on the machine’s specifications, features, and capabilities.

Factors Affecting Box Machinery Price:

1 Machine Type and Capacity

Entry-level box machines designed for small businesses cost less than industrial-grade machines.

High-speed, high-capacity machines typically come at a premium price due to their advanced features.

2 Customization and Printing Capabilities

Machines with integrated printing, embossing, or branding capabilities are more expensive.

Businesses looking for custom packaging solutions should consider machines that offer in-line customization.

3 Automation and Technology

Fully automated machines that require minimal human intervention are priced higher but offer better efficiency.

Some box maker machines come with AI-driven technology for predictive maintenance and real-time monitoring.

4 Brand and Manufacturer

Leading manufacturers may charge a higher price for their machines due to better build quality, reliability, and after-sales support.

Investing in a reputable brand ensures longevity and better service.

5 Additional Features and Attachments

Some box machines offer additional features such as auto-gluing, die-cutting, and digital printing, which can affect the overall price.

By evaluating these factors, businesses can choose a box maker machine that aligns with their budget and operational needs.

5. Future Trends in Box Maker Machines and Packaging Automation

The packaging industry is evolving, and box maker machines are at the forefront of these changes. Here are some key trends shaping the future of packaging automation:

- Smart and AI-Driven Box Machines

Newer box machines are integrating AI to optimize performance, predict maintenance needs, and enhance productivity.

- Eco-Friendly Packaging Solutions

With increasing focus on sustainability, modern machines are designed to work with biodegradable and recyclable materials, reducing environmental impact.

- On-Demand Packaging

Businesses are adopting on-demand packaging solutions, allowing them to create boxes in real time, minimizing storage costs and material wastage.

- IoT Integration

Many box maker machines now come with IoT capabilities, enabling remote monitoring and automated adjustments based on real-time data.

Investing in a modern box machine ensures that businesses stay ahead of the competition while adapting to the latest industry advancements.

6. How to Choose the Right Box Maker Machine for Your Business

Selecting the right box maker machine depends on various factors, including production needs, budget, and long-term goals.

- Consider These Points When Buying a Box Machine:

1 Production Volume: Choose a machine that matches your daily output requirements.

2 Customization Needs: If you require custom branding, opt for a machine with printing capabilities.

3 Material Compatibility: Ensure the machine can handle different types of packaging materials.

4 Budget and ROI: Compare the box machinery price and assess its long-term return on investment.

5 After-Sales Support: Look for a manufacturer that offers maintenance services and spare parts availability.

By carefully evaluating these factors, businesses can invest in a box maker machine that maximizes efficiency and cost savings.

Conclusion

The packaging industry is undergoing a major transformation, and box maker machines are leading the way in enhancing efficiency, customization, and sustainability. Whether you are a small business or a large-scale manufacturer, investing in a box machine can provide significant benefits, from reducing production costs to improving brand recognition.

While box machinery price varies depending on the machine��s features and capabilities, the long-term benefits far outweigh the initial investment. With automation, eco-friendly solutions, and technological advancements shaping the future, now is the perfect time for businesses to adopt modern box maker machines and stay ahead in the competitive packaging landscape.

If you're looking to improve your packaging process, reduce waste, and enhance customer experience, a box maker machine is the key to achieving these goals.

0 notes

Text

How a Carton Box Maker Machine Can Boost Your Packaging Efficiency

In today’s fast-paced business environment, efficiency is the cornerstone of success, especially in industries reliant on packaging. Whether you’re in e-commerce, manufacturing, or logistics, packaging plays a vital role in ensuring products reach customers safely and on time. A Carton Box Maker Machine has emerged as a game-changing solution for businesses aiming to enhance their packaging efficiency and reduce operational costs.

In this article, we will explore the benefits of a Carton Box Maker Machine, its impact on business productivity, and how it compares to traditional Box Making Machines and Heavy Duty Box Maker Machines for larger-scale operations.

1. What Is a Carton Box Maker Machine?

A Carton Box Maker Machine is an advanced piece of equipment designed to automate the production of carton boxes. From cutting and creasing to folding and gluing, these machines handle every step of the box-making process. They are capable of producing boxes in various shapes, sizes, and designs, making them suitable for a wide range of industries.

Unlike traditional Box Making Machines, which often require manual input and are limited in output, carton box makers are built for speed, precision, and customization. They are particularly useful for businesses with high packaging demands or those needing tailored packaging solutions.

2. Enhancing Packaging Efficiency with Automation

The primary advantage of a Carton Box Maker Machine is its ability to automate the packaging process. Automation eliminates the need for manual labor in repetitive tasks, significantly boosting efficiency. Here’s how:

Faster Production: These machines can produce hundreds or even thousands of boxes per hour, ensuring you can meet tight deadlines and scale production as needed.

Consistency in Quality: Automation reduces human error, resulting in boxes with uniform dimensions and structural integrity. This consistency is crucial for protecting products during transit.

Time Savings: By handling multiple tasks simultaneously, a carton box maker minimizes production time, allowing businesses to focus on other critical operations.

3. Customization for Diverse Packaging Needs

Modern Carton Box Maker Machines offer unparalleled customization options. Businesses can create boxes tailored to specific product dimensions, reducing the need for excess filler materials and improving the overall unboxing experience for customers.

Customization also extends to branding. Many machines come equipped with features that allow for the integration of logos, designs, and other branding elements, helping businesses stand out in a crowded market.

4. Cost Savings and Return on Investment

While the initial investment in a Carton Box Maker Machine might seem significant, the long-term cost savings are undeniable. Here’s why:

Reduced Labor Costs: With automation, fewer employees are needed for box production, lowering labor expenses.

Material Optimization: Advanced machines are designed to use materials efficiently, minimizing waste and reducing overall costs.

In-House Production: Producing boxes in-house eliminates the need for outsourcing, saving money on transportation and third-party production fees.

For larger operations, a Heavy Duty Box Maker Machine might be the better option. These machines are designed to handle thicker materials and produce bulk quantities, making them ideal for heavy-duty packaging needs.

5. Improved Scalability for Growing Businesses

As businesses grow, their packaging needs increase. A Carton Box Maker Machine provides the flexibility to scale production without significant additional investment. Many modern machines are modular, allowing businesses to upgrade components or add features as needed.

Whether you’re a small business looking to expand or an established company aiming to optimize operations, these machines offer a scalable solution to meet evolving demands.

6. Sustainability and Eco-Friendly Packaging

Sustainability is no longer just a buzzword; it’s a priority for businesses and consumers alike. Many Box Making Machines, including carton box makers, are designed with sustainability in mind.

Efficient Material Use: These machines are programmed to cut materials precisely, reducing waste and conserving resources.

Recyclable Materials: Carton boxes produced by these machines are typically recyclable, aligning with eco-friendly practices.

Energy Efficiency: Newer models are built to consume less energy, making them a greener choice for businesses.

By adopting a Carton Box Maker Machine, companies can contribute to environmental sustainability while appealing to eco-conscious customers.

7. Real-Life Applications Across Industries

The versatility of a Carton Box Maker Machine makes it a valuable asset across multiple industries:

E-commerce: Efficiently produce customized boxes to meet the demands of online retailers.

Food & Beverage: Create food-safe packaging that aligns with brand identity.

Consumer Goods: Offer tailored packaging solutions for various products, from electronics to cosmetics.

Logistics: Enhance operational efficiency with sturdy boxes for shipping and storage.

8. Future Trends in Box Making Machines

The packaging industry is constantly evolving, and so are the technologies driving it. Here are some trends to watch for:

Integration with AI: Machines capable of real-time adjustments based on production data.

Smart Interfaces: User-friendly systems with remote monitoring capabilities.

3D Printing Integration: Combining traditional box-making with 3D printing for enhanced customization.

Final Thoughts

A Carton Box Maker Machine is more than just a piece of equipment—it’s a strategic investment in efficiency, sustainability, and business growth. Whether you’re looking to improve production speed, reduce costs, or offer tailored packaging solutions, this technology has the potential to transform your operations.

For businesses with heavier packaging needs, exploring options like a Heavy Duty Box Maker Machine is also worth considering. Regardless of your choice, adopting modern Box Making Machines ensures that your business remains competitive in an ever-changing market.

Take the leap into automation and watch your packaging process become a cornerstone of your success.

0 notes

Text

Automated Packaging Machines Improve Business ROI

In today’s competitive market, businesses are constantly looking for ways to improve efficiency, reduce costs, and maximize return on investment (ROI). One of the most effective strategies to achieve these goals is by integrating Automated Packaging Machines into production processes. In this article, we’ll explore how investing in advanced Corrugated Box Making Machines and other packaging solutions can enhance business ROI.

1. Efficiency with Corrugated Box Making Machine

A modern Corrugated Box Making Machine streamlines the box production process, minimizing manual intervention and reducing production time. These machines ensure precision and consistency, helping businesses meet high-volume demands while maintaining quality.

2. Versatility of a Box Maker Machine

The flexibility of a Box Maker Machine allows businesses to produce a variety of box sizes and styles without extensive reconfigurations. With a Corrugated Box Maker Machine, companies can adapt quickly to market changes and customer demands, ensuring better resource utilization and minimized downtime.

3. Cost-Effective Investment in Box Maker Machine Price

While the initial box maker machine price might seem like a substantial investment, the long-term savings are significant. Automated box machines reduce labor costs, minimize errors, and optimize material usage, providing an impressive ROI over time.

4. Precision and Reduced Material Wastage with Boxmaker Machine

Advanced boxmaker machines offer precision engineering, reducing material wastage and ensuring accurate cuts. By minimizing errors and resource waste, businesses can save significantly on raw material costs, directly impacting profitability.

5. Automation with Corrugated Box Making Machine

Automation is key to improving ROI. A fully automated corrugated box making machine can handle repetitive tasks like cutting, folding, and gluing with minimal human supervision. This not only speeds up production but also enhances consistency and reduces labor expenses.

Conclusion

Investing in Corrugated Box Making Machines and other automated packaging solutions is not just about reducing costs—it’s about improving overall efficiency, minimizing waste, and maximizing ROI. As businesses continue to scale, automation remains a critical factor in achieving sustainable growth and profitability.

Source: https://boxmakertech.com/automated-packaging-machines-improve-business-roi/

0 notes

Text

Innovations in Corrugated Box Machines: The Future of Packaging Technology

The packaging industry is at the forefront of innovation, driven by the need for efficiency, sustainability, and customization. At the heart of this evolution is the Corrugated Box Machine, a marvel of engineering that has revolutionized how businesses produce packaging solutions. With rapid technological advancements, Corrugated Box Maker Machines are now more efficient, versatile, and cost-effective than ever before.

In this article, we’ll explore the latest innovations in corrugated box-making technology and their impact on the packaging industry.

1. Automation Redefined

Modern Corrugated Box Making Machines are designed with advanced automation capabilities. From feeding raw materials to cutting, folding, and gluing, these machines streamline every step of the box production process. This level of automation not only reduces the reliance on manual labor but also ensures consistent quality.

The integration of smart sensors and IoT technology enables real-time monitoring of the production process, minimizing downtime and improving efficiency. Businesses can now produce large volumes of boxes in a fraction of the time, meeting the demands of fast-paced industries like e-commerce and logistics.

2. Customization at Its Best

Today’s customers demand personalized packaging solutions, and Corrugated Box Machines are rising to the challenge. Equipped with cutting-edge technology, these machines can produce boxes in various shapes, sizes, and designs to suit specific needs.

Whether it’s branding with logos or creating unique structural designs, modern box-making machines offer unmatched customization options. This flexibility helps businesses cater to niche markets and enhance their brand visibility.

3. Sustainability in Focus

As environmental concerns grow, sustainability has become a critical factor in packaging innovation. Many Corrugated Box Maker Machines are now designed with eco-friendly features, such as reduced energy consumption and optimized material usage.

These machines can produce sturdy boxes using minimal raw materials, reducing waste and promoting sustainable practices. By investing in such technology, businesses not only lower their carbon footprint but also align with consumer preferences for environmentally responsible brands.

4. Cost-Effective Solutions

Although the initial corrugated box machinery price may seem steep, the latest innovations make these machines a cost-effective investment. Features like automated material handling and precision cutting reduce material wastage, saving money in the long run.

Additionally, producing boxes in-house eliminates the need for outsourcing, further cutting costs. With their ability to handle large-scale production efficiently, these machines ensure a quicker return on investment.

5. Integration of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are transforming the capabilities of Corrugated Box Making Machines. AI-driven systems analyze production data to optimize workflows, predict maintenance needs, and improve overall performance.

For example, machine learning algorithms can identify patterns in production, enabling machines to make real-time adjustments for better efficiency. This innovation not only reduces downtime but also ensures consistent quality output.

6. Enhanced User Interfaces

User-friendly interfaces are another significant innovation in modern Corrugated Box Maker Machines. With touchscreen controls and intuitive software, operators can easily manage production settings, monitor performance, and troubleshoot issues.

This ease of use reduces training time and ensures that businesses can maximize the potential of their machines from day one.

7. Scalability for Growing Businesses

As businesses expand, so do their production needs. The latest Corrugated Box Machines are designed to grow with your business. Modular designs and upgradable components make it easy to scale production without requiring a complete overhaul of equipment.

Final Thoughts

The advancements in Corrugated Box Making Machines have ushered in a new era for the packaging industry. From automation and customization to sustainability and AI integration, these innovations are reshaping how businesses approach packaging.

While the corrugated box machinery price may vary based on features and capabilities, the long-term benefits far outweigh the costs. By adopting these state-of-the-art machines, businesses can enhance productivity, reduce costs, and stay competitive in a rapidly evolving market.

As technology continues to evolve, the future of Corrugated Box Maker Machines looks brighter than ever. Investing in these innovations is not just a step forward—it's a leap toward a more efficient, sustainable, and profitable future.

0 notes

Text

Top Benefits of Investing in a Corrugated Box Making Machine for Packaging Solutions

In today’s fast-paced business environment, efficiency and cost-effectiveness are paramount for companies in the packaging industry. A Corrugated Box Making Machine is a game-changer that offers unparalleled benefits, streamlining operations and enhancing productivity. Whether you run a small packaging unit or a large-scale manufacturing facility, investing in a Corrugated Box Maker Machine is a strategic move that can drive growth and profitability.

Here are the top benefits of incorporating a corrugated box making machine into your production process:

1. Enhanced Production Efficiency

Manual production of corrugated boxes can be time-consuming and labor-intensive. A Corrugated Box Machine automates the process, significantly increasing the speed of production. These machines can produce a large volume of boxes in a fraction of the time it takes to do so manually, ensuring that your business meets tight deadlines and large orders without compromising quality.

2. Superior Quality and Consistency

One of the standout advantages of using a Corrugated Box Maker Machine is the consistent quality it delivers. Manual processes often result in variations that can affect the strength and durability of the boxes. With a machine, you can maintain uniformity in box dimensions, structure, and durability, which is crucial for branding and customer satisfaction.

3. Cost Savings in the Long Run

While the initial corrugated box machinery price might seem like a significant investment, the long-term savings outweigh the upfront costs. Automating the box-making process reduces labor costs and material wastage, leading to a more efficient use of resources. Additionally, the ability to produce custom-sized boxes in-house can eliminate the need for outsourcing, further reducing expenses.

4. Customization Flexibility

Modern Corrugated Box Machines come equipped with advanced features that allow businesses to produce customized boxes tailored to specific client requirements. From different sizes and designs to personalized branding, these machines offer flexibility that can help businesses cater to niche markets and expand their customer base.

5. Reduced Material Wastage

Material wastage is a common concern in packaging production. A Corrugated Box Making Machine is designed to optimize material usage by precisely cutting and shaping corrugated sheets. This not only minimizes waste but also contributes to a more sustainable production process, which is increasingly important in today’s eco-conscious market.

6. Scalability for Growing Businesses

As your business grows, so does the demand for efficient production processes. A Corrugated Box Maker Machine can easily scale to meet increased production needs. With features like automated adjustments and high-speed operation, these machines ensure your business can handle growth seamlessly without the need for significant additional investments.

7. Improved Profit Margins

By reducing production costs, minimizing errors, and increasing efficiency, businesses can enjoy higher profit margins. Furthermore, the ability to meet larger orders and provide customized solutions gives companies a competitive edge, driving more sales and repeat business.

8. Competitive Advantage in the Market

Investing in the latest Corrugated Box Machine technology demonstrates a commitment to quality and innovation. It helps businesses stay ahead of the competition by delivering superior products and meeting client demands faster.

Conclusion

A Corrugated Box Making Machine is more than just a piece of equipment; it is a valuable asset that can revolutionize your packaging operations. With benefits ranging from cost savings and efficiency to enhanced product quality, the investment is worth every penny. Although the corrugated box machinery price may vary based on features and specifications, the long-term advantages far outweigh the cost.

For businesses looking to thrive in the competitive packaging industry, now is the perfect time to explore the wide range of Corrugated Box Machines available and take the first step toward operational excellence.

0 notes

Text

Cost-Effective Carton Box Making Machine: A Game-Changer for Packaging Solutions

In today’s competitive business landscape, finding a cost-effective solution for packaging can significantly impact operational efficiency and cost savings. For industries that rely heavily on consistent, durable, and customizable packaging, investing in a Heavy-Duty Box Maker Machine is essential. Not only do these machines offer robust performance, but they also streamline the entire packaging process, making it more efficient and scalable.

Understanding the Importance of Corrugated Box Machinery

Corrugated boxes are a cornerstone of secure packaging. Whether for shipping, storage, or product display, these boxes offer protection, durability, and branding potential. However, producing them at scale without a Corrugated Box Machinery solution can lead to increased costs and slower turnaround times. A Box Making Machine designed specifically for corrugated materials can efficiently handle large volumes, reducing both material waste and production time.

Advantages of a Cost-Effective Corrugated Box Manufacturing Machine

1. Enhanced Production Efficiency: With a Corrugated Box Manufacturing Machine, businesses can produce boxes quickly, meeting large demands without the need to outsource. This machinery simplifies the production process and allows companies to adjust box sizes based on specific requirements.

2. High-Quality Boxes: Investing in a Corrugated Box Making Machine ensures the production of high-quality boxes that meet industry standards. The machine’s precision technology enables consistent cutting, creasing, and folding, leading to uniform box quality.

3. Flexibility in Design: A Corrugated Box Machine can handle various box designs, accommodating different sizes, thicknesses, and specifications. This versatility is crucial for businesses that need to create packaging for diverse product lines or frequently update their box designs.

4. Cost Savings: By using a cost-effective Heavy-Duty Box Maker Machine, businesses can cut down significantly on costs associated with purchasing pre-made boxes or outsourcing packaging. This not only saves on overhead expenses but also gives companies better control over their packaging budgets.

5. Eco-Friendly Options: Many corrugated box machines allow for the use of recycled materials, aligning with sustainable business practices. This reduces the environmental footprint, appealing to eco-conscious consumers and helping companies meet sustainability targets.

Key Features to Look for in a Box Making Machine

When selecting a Corrugated Box Making Machine, it’s essential to focus on specific features that meet your operational needs. Key features include:

– Adjustable Box Dimensions: Look for machines that allow customization of box sizes to accommodate a variety of products.

– Durability: Choose a heavy-duty model that can withstand continuous use and has a robust build.

– Ease of Use: User-friendly interfaces and automation options ensure that your team can operate the machine with minimal training.

– Material Efficiency: Some machines are designed to reduce material waste, which can lead to significant cost savings over time.

– Speed and Precision: High-speed production capabilities, combined with precise cutting and folding, are crucial for maintaining production efficiency without compromising quality.

How a Cost-Effective Box Making Machine Impacts the Bottom Line

By integrating a cost-effective Corrugated Box Machine into the production process, businesses can streamline their operations, reduce outsourcing costs, and enhance product presentation with custom-made boxes. This machinery is ideal for small to medium businesses that aim to keep costs low while maintaining a high standard of packaging quality.

Conclusion

The demand for reliable, durable, and customizable packaging solutions is on the rise, and a cost-effective carton box making machine is the ideal investment for any business looking to optimize its packaging process. From increasing production speed to cutting down costs and supporting eco-friendly initiatives, this machinery offers several benefits that contribute to operational success. For companies ready to take their packaging solutions to the next level, a Heavy-Duty Box Maker Machine can be a transformative addition.

Contact us for cost-effective carton box making machine

Source: https://boxmakertech.com/cost-effective-carton-box-making-machine/

0 notes

Text

Revolutionizing Packaging with Advanced Corrugated Box Making Machines

In the evolving world of packaging, businesses need to stay ahead with technology that boosts efficiency and ensures quality output. At Boxmaker Tech, we specialize in delivering cutting-edge solutions for the manufacturing of corrugated boxes, helping businesses streamline their packaging operations while maintaining high standards of quality. Our corrugated box manufacturing machines are designed to meet the rigorous demands of modern production environments, ensuring you get the best possible results every time.

The Future of Packaging: Corrugated Box Making Machines

Packaging isn’t just about enclosing a product; it’s about protecting and presenting it in a way that reflects the value of the brand. Our corrugated box making machines are engineered to produce boxes that are strong, durable, and customizable to your specifications. With features like automated feeding, cutting, and gluing, these machines simplify the production process while maintaining accuracy and speed. Whether you’re looking for a solution to mass-produce shipping boxes or bespoke packaging, Boxmaker Tech offers the right machinery to handle every requirement.

Affordable Solutions with Our Corrugated Box Machinery

At Boxmaker Tech, we believe in offering high-performance corrugated box machines at prices that make sense for your business. We understand that cost-efficiency is crucial, which is why we provide a range of options that cater to different production capacities and budgets. Our corrugated box machinery prices are designed to provide great value, ensuring you get maximum return on your investment without compromising on quality or performance.

Versatile and Reliable Corrugated Carton Box Making Machines

Every packaging requirement is unique, and so is our approach to delivering solutions. Our corrugated carton box making machines are highly versatile, capable of producing a variety of box types and sizes. From simple designs to complex structures, these machines allow businesses to manufacture high-quality packaging with precision. With automated systems that reduce manual intervention, you can rely on consistent output that meets the standards of even the most demanding industries.

Why Choose Boxmaker Tech?

– Efficiency & Innovation: Our box making machine incorporate the latest technology to optimize the production process, ensuring speed without sacrificing quality.

– Custom Solutions: We offer machines that can be tailored to your specific business needs, allowing you to create packaging solutions that align perfectly with your operational goals.

– Affordable Pricing: We maintain competitive corrugated box machinery prices, making high-end technology accessible to businesses of all sizes.

– Expert Support: From choosing the right machine to installation and after-sales support, our team of experts is here to help every step of the way.

Elevate Your Packaging Game with Boxmaker Tech

Packaging plays a critical role in your business’s success, and at Boxmaker Tech, we are dedicated to helping you elevate your operations with our state-of-the-art corrugated box maker machines. Whether you’re looking to improve production efficiency, reduce costs, or enhance the quality of your packaging, our machines provide the perfect solution to meet your goals.

Invest in the future of your business with Boxmaker Tech, and experience the difference that precision-engineered corrugated box manufacturing machines can make. Contact us today to learn more about how we can help transform your packaging operations and to know the Corrugated Box Machinery Price.

Visit us for more details https://boxmakertech.com/

SOURCE:https://boxmakertech.com/revolutionizing-packaging-with-advanced-corrugated-box-making-machines/

0 notes

Text

Eco-Friendly Corrugated Box Machinery: Shaping Sustainable Packaging

In an era where environmental sustainability is a key concern for industries worldwide, the packaging sector is experiencing a transformative shift towards eco-friendly practices. Corrugated boxes, known for their recyclability, are already a popular choice in sustainable packaging. However, the machinery used to produce these boxes is now evolving to meet even higher standards of environmental responsibility. The development of advance corrugated box machinery is playing a crucial role in this transformation, providing businesses with the tools they need to create high-quality packaging with minimal environmental impact.

The Demand for Sustainable Packaging Solutions

Consumers and businesses alike are demanding greener packaging solutions. E-commerce, retail, and logistics industries heavily rely on packaging, and as environmental awareness grows, so does the need for packaging that is not only functional but also eco-friendly. Corrugated box making machines are at the forefront of this shift, enabling manufacturers to produce packaging with reduced waste, lower energy consumption, and minimal carbon footprint.

How Eco-Friendly Corrugated Box Machinery is Leading the Way

Eco-friendly corrugated box maker machines are designed with sustainability in mind. From energy-efficient operations to reduced waste output, these machines are a significant leap forward from traditional manufacturing methods. Below are some of the key innovations in this field:

1. Energy-Efficient Motors and Systems

One of the most significant environmental advancements in advance corrugated box machinery is the use of energy-efficient motors and automated systems. These machines are optimized to use less power without compromising production speed or quality. In particular, variable speed drives (VSDs) have been incorporated into many corrugated box machines to ensure that energy is only used when necessary. This not only reduces overall energy consumption but also lowers operational costs, making it an eco-friendly and economical choice for businesses.

2. Reduced Waste through Precision Engineering

Modern carton box making machines are designed to minimize material waste by using precision engineering. Advanced software controls the cutting, folding, and printing processes, ensuring that each sheet of corrugated material is utilized to its fullest extent. Any leftover material can be collected and recycled, reducing the amount of waste that ends up in landfills. This approach to minimizing waste is a core principle of sustainable packaging production, and it's increasingly becoming the industry standard.

3. Recycled and Recyclable Materials

Sustainable packaging isn’t just about the manufacturing process; it’s also about the materials used. Many manufacturers now use recycled corrugated paper to create new boxes, and corrugated box maker machines are being tailored to handle these materials effectively. In addition to using recycled materials, the boxes produced are fully recyclable, promoting a circular economy where materials are continuously reused rather than discarded.

By using eco-friendly corrugated box machinery, businesses can ensure that their products are packaged in a way that supports sustainability at every stage of the product life cycle. Not only does this reduce environmental impact, but it also aligns companies with growing consumer expectations for green products.

4. Automation and Smart Production Lines

The integration of automation and smart technologies in corrugated box making machines allows manufacturers to improve efficiency while reducing environmental impact. Automated production lines enable machines to run with minimal human intervention, optimizing energy use and reducing waste.

These systems can also collect data in real-time, allowing manufacturers to monitor energy consumption, material usage, and production rates. With this information, adjustments can be made to enhance sustainability further. For instance, the machine can be programmed to adjust the production process based on the type of material being used, ensuring that it operates as efficiently as possible with each run.

5. Water-Based and Eco-Friendly Inks

Printing on corrugated boxes has also become more environmentally conscious. Advanced corrugated box machinery now supports the use of water-based inks, which are non-toxic and have a much lower environmental impact compared to traditional solvent-based inks. These inks are not only safer for the environment but also produce high-quality prints, making them a win-win for businesses looking to enhance the aesthetic appeal of their packaging without harming the planet.

The Future of Sustainable Corrugated Box Production

The future of carton box making machines and the broader corrugated packaging industry is centered around sustainability. As technology continues to advance, we can expect to see even more eco-friendly innovations. Some of the trends likely to shape the future include:

Solar-Powered Machinery: Solar energy is increasingly being incorporated into industrial operations, and corrugated box manufacturing is no exception. Solar-powered machines could significantly reduce the industry’s reliance on non-renewable energy sources.

Biodegradable Coatings: While corrugated boxes are recyclable, adding biodegradable coatings to make them even more environmentally friendly is a growing trend. These coatings would break down naturally in the environment, further reducing the ecological impact.

Closed-Loop Manufacturing: In the future, we may see more packaging companies adopt closed-loop systems where all waste materials are reused within the production process. This could be facilitated by increasingly efficient corrugated box maker machines capable of handling a wider variety of recycled materials.

Conclusion

As businesses and consumers become more environmentally conscious, the role of advance corrugated box machinery in promoting sustainable packaging practices is more important than ever. By using energy-efficient systems, reducing waste, and utilizing recycled materials, these machines are helping to shape the future of eco-friendly packaging. For businesses looking to meet growing environmental demands, investing in eco-friendly corrugated box making machines is not only a smart move but also a critical step toward a greener future.

0 notes

Text

Boost Your Production with Advanced Corrugated Box Machinery

In the dynamic world of packaging, having the right equipment is crucial for efficiency and quality. At boxmaker.tech, we offer a range of state-of-the-art corrugated box making machines designed to meet your production needs. Our machines are engineered for precision, speed, and reliability, ensuring your business stays ahead of the competition.

Corrugated Box Machinery Price: Affordable Excellence

Our corrugated box machinery is priced competitively to help you cut costs and increase profits. Despite the affordability, these machines do not compromise on quality or performance. The advanced features integrated into our equipment provide the highest efficiency and versatility in the market.

Innovative Box Making Machine for Short-Run and Serial Production

Our flagship box making machine, the BM2508-Plus, and the HMG200, are renowned for their simple yet robust designs. They are specialized for low to medium volume heavy-duty box production, handling everything from E flute to AAA flute with ease. With the ability to process sheets with thickness ranging from 2mm to 10mm, these machines cater to a wide array of packaging requirements.

Precision and Quality in Every Cut

Equipped with four cutting knives rotated by servo motors, our corrugated box machines ensure beautiful and flat sides on every box. The integrated slotting knife and creasing beam design enhance the precision of slotting and creasing, making your boxes not only functional but also aesthetically pleasing. The slotting width ranges from 7mm to 16mm, delivering excellent cutting performance without any burrs. Check corrugated box machine features.

Advanced Features for Optimal Performance

Our machines come with a continuous cardboard feeding system powered by a vacuum pump, ensuring accurate and consistent feeding. Additionally, the inline cold gluing auto application feature eliminates the need for an extra gluing machine, streamlining your production process.

Versatile and Efficient Box Maker Machine

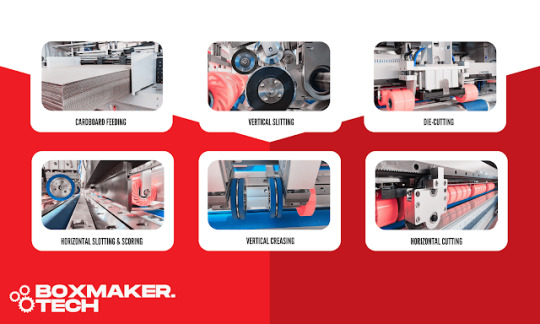

The box maker machines at boxmaker.tech are compact yet powerful, integrating horizontal slotting and scoring, vertical slitting and creasing, and horizontal cutting all in one unit. They can produce specialized features such as hand holes, vent holes, and special-shaped rounded corners, catering to diverse packaging needs.

Reliable and Efficient Production

With two 500mm symmetrical slotting knives and four scoring/creasing wheels, our machines deliver the highest efficiency and versatility in box making. The cheap module and easy replacement features ensure minimal downtime and maximum productivity.

Comprehensive Support and Fast Shipping

At boxmaker.tech, we handle all details of your order, providing fast shipping to ensure timely delivery. Our excellent R&D team allows you to market test your business ideas before making final decisions, helping you monitor and control your risks effectively.

Conclusion

Choosing the right corrugated box manufacturing machine can significantly impact your production efficiency and profitability. At boxmaker.tech, we offer top-of-the-line corrugated box making machines at competitive prices, equipped with advanced features to meet all your packaging needs. Explore our range today and take your production to the next level.

For more information visit website - Boxmaker.tech

Contact us to know corrugated box machinery price

Downlaod products catalogue here Advanced Corrugated Box Machinery

1 note

·

View note