Text

Maximizing Efficiency: Tips for Proper Hydraulic Oil Management

Hydraulic systems are integral to the functionality of various industrial and mobile equipment, providing power transmission and control for a multitude of applications. Proper hydraulic oil management is essential for ensuring the efficiency, reliability, and longevity of hydraulic systems. By implementing effective oil management practices, stakeholders can optimize system performance, minimize downtime, and extend equipment service life. Here are some tips for maximizing efficiency through proper hydraulic oil management:

1. Select the Right Hydraulic Oil:

Choose hydraulic oil that meets the requirements specified by equipment manufacturers, including viscosity grade, performance specifications, and additive formulations. Consider factors such as operating temperature, load conditions, and environmental considerations when selecting hydraulic oil to ensure optimal performance and compatibility with system components.

2. Monitor Oil Condition:

Regularly monitor the condition of hydraulic oil through visual inspections, oil analysis, and performance testing. Check for signs of contamination, oxidation, viscosity changes, and additive depletion. Implement a proactive oil sampling and analysis program to detect potential issues early and take corrective action to prevent equipment damage and downtime.

3. Maintain Cleanliness:

Maintain cleanliness throughout the hydraulic system to prevent fluid contamination and minimize wear on components. Use proper filtration systems to remove particulate matter, water, and air from the hydraulic oil. Implement best practices for fluid handling, storage, and transfer to minimize the introduction of contaminants into the system.

4. Control Operating Temperatures:

Monitor and control operating temperatures within the recommended range to prevent thermal degradation of hydraulic oil. Ensure proper cooling and ventilation of hydraulic systems to dissipate heat effectively and maintain oil stability. Consider using heat exchangers, coolers, or temperature-regulating additives to manage operating temperatures in extreme conditions.

5. Perform Regular Maintenance:

Implement a proactive maintenance schedule for hydraulic systems, including oil changes, filter replacements, and system inspections. Follow manufacturer recommendations for maintenance intervals and procedures to ensure optimal performance and reliability. Address any issues identified during routine maintenance promptly to prevent equipment downtime and costly repairs.

6. Train Operators and Maintenance Personnel:

Provide comprehensive training to operators and maintenance personnel on proper hydraulic oil management practices, including handling, storage, sampling, analysis, and maintenance procedures. Empower personnel to recognize potential issues and take appropriate action to maintain system efficiency and integrity.

7. Document and Record Keeping:

Maintain detailed records of hydraulic oil usage, maintenance activities, oil analysis results, and equipment performance data. Documenting these records enables trend analysis, troubleshooting, and proactive decision-making to optimize hydraulic system efficiency and reliability over time.

Conclusion:

In conclusion, proper hydraulic oil management is essential for maximizing the efficiency, reliability, and longevity of hydraulic systems. By selecting the right hydraulic oil, monitoring oil condition, maintaining cleanliness, controlling operating temperatures, performing regular maintenance, training personnel, and documenting records, stakeholders can ensure optimal performance and minimize downtime in industrial and mobile applications. Effective hydraulic oil management practices contribute to enhanced equipment productivity, reduced operating costs, and improved overall performance, ultimately driving operational excellence and competitive advantage in various industries.

0 notes

Text

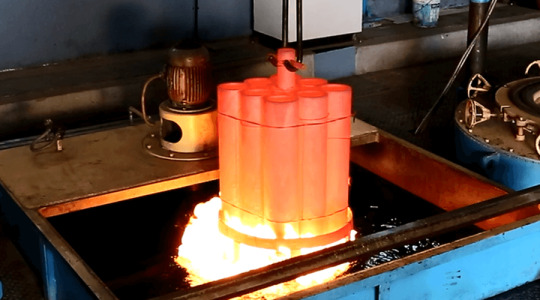

Tempering Oil Techniques: Optimizing Metal Properties for Durability

In the realm of metallurgy, optimizing the properties of metals for durability is essential for ensuring their reliability and longevity in various applications. Among the arsenal of heat treatment methods available, tempering oil techniques stand out as effective means to refine and enhance metal properties. This article delves into the intricacies of tempering oil techniques, exploring how they are utilized to optimize metal properties for durability.

Understanding Tempering Oil Techniques

Tempering oil techniques involve a specialized heat treatment process aimed at modifying the mechanical properties of metals, particularly steel alloys. Unlike rapid cooling methods like water quenching, tempering oil techniques focus on controlled heating followed by immersion in oil for gradual cooling. This process allows for the adjustment of hardness, toughness, and ductility in the metal, ultimately optimizing its durability.

The Tempering Process

The tempering process begins after the initial hardening or quenching stage in metal fabrication. Once the steel component reaches its critical temperature and undergoes quenching to achieve maximum hardness, it progresses to tempering. During tempering, the metal is heated to specific temperatures within a predetermined range, typically between 200°C to 600°C (392°F to 1112°F), depending on the desired outcome. Subsequently, the steel is immersed in tempering oil, initiating a controlled cooling process that imparts the desired mechanical characteristics to the metal.

Optimizing Metal Properties for Durability

Tempering oil techniques offer several strategies for optimizing metal properties for durability:

Enhanced Toughness: By tempering the hardened steel, tempering oil mitigates excessive brittleness acquired during quenching, resulting in improved toughness and resistance to impact. This enhanced toughness ensures the metal can withstand harsh operating conditions without failure.

Improved Ductility: Tempering alleviates internal stresses within the metal structure, enhancing ductility without compromising strength. This improved ductility allows the metal to deform plastically under load, reducing the risk of fracture and enhancing its resilience to cyclic loading.

Uniform Hardness: Tempering oil techniques ensure a more uniform and controlled cooling process, minimizing the risk of distortion or cracking in the metal. This uniform hardness throughout the material enhances its wear resistance and fatigue life, contributing to its overall durability.

Tailored Properties: Through precise control of tempering parameters such as temperature and time, metallurgists can tailor the properties of the metal to meet specific durability requirements. Whether it's optimizing for wear resistance, corrosion resistance, or fatigue resistance, tempering oil techniques provide the flexibility to achieve the desired performance characteristics.

Applications in Various Industries

The application of tempering oil techniques spans across diverse industries, including automotive, aerospace, manufacturing, and construction. Components such as engine parts, gears, tools, and structural steel benefit from these techniques to enhance their durability and reliability in demanding applications. From improving the lifespan of automotive components to ensuring the structural integrity of critical infrastructure, tempering oil techniques play a vital role in optimizing metal properties for durability.

Conclusion

In conclusion, tempering oil techniques are invaluable tools in the pursuit of optimizing metal properties for durability. By carefully controlling the tempering process, metallurgists can tailor the mechanical characteristics of metals to meet the stringent demands of various industries. Whether it's enhancing toughness, improving ductility, or achieving uniform hardness, tempering oil techniques offer versatile solutions for optimizing metal durability. As industries continue to evolve and innovate, tempering oil techniques remain indispensable in the quest for durable and reliable metal components.

0 notes

Text

Applications of Oil Quenching: From Automotive to Aerospace

Oil quenching, a heat treatment process revered for its transformative effects on metal components, finds diverse and extensive applications across various industries. From the demanding requirements of the automotive sector to the rigorous standards of aerospace engineering, oil quenching plays a vital role in enhancing the mechanical properties of critical components. Let's explore how this technique is applied in automotive and aerospace industries:

Automotive Industry

In the automotive industry, where reliability, durability, and performance are paramount, oil quenching is indispensable for the production of essential components such as:

Gears

Gears are subjected to high loads, stresses, and frictional forces during operation. Oil quenching imparts exceptional hardness and wear resistance to gear components, ensuring smooth and efficient power transmission in automotive drivetrains.

Shafts

Shafts serve as crucial mechanical linkages in automotive systems, transmitting rotational motion and torque between components. Oil quenching enhances the strength and fatigue resistance of shafts, enabling them to withstand the rigors of continuous operation under varying loads.

Bearings

Bearings play a pivotal role in reducing friction and facilitating smooth motion in automotive assemblies. Oil quenching increases the hardness and toughness of bearing components, prolonging their service life and enhancing the reliability of automotive systems.

Aerospace Sector

In the aerospace sector, where safety, performance, and weight savings are paramount considerations, oil quenching is employed in the manufacturing of critical components such as:

Aircraft Engine Components

Aircraft engines operate under extreme conditions of temperature, pressure, and mechanical stress. Oil quenching is used to enhance the strength, fatigue resistance, and thermal stability of engine components such as turbine blades, shafts, and housings, ensuring optimal performance and reliability in flight.

Landing Gear Components

Landing gear assemblies undergo repeated cycles of loading and unloading during takeoff, landing, and taxiing. Oil quenching imparts high strength, toughness, and wear resistance to landing gear components, ensuring their structural integrity and operational safety under dynamic loading conditions.

Structural Components

Aircraft structural components, such as fuselage frames, wing spars, and control surfaces, must withstand aerodynamic forces, vibration, and thermal cycling. Oil quenching is utilized to enhance the mechanical properties of these components, including strength, stiffness, and fatigue resistance, while minimizing weight to meet stringent performance requirements.

Conclusion

Oil quenching serves as a cornerstone of materials engineering, offering unparalleled capabilities for enhancing the mechanical properties of metal components in both automotive and aerospace applications. From gears and shafts in automotive drivetrains to turbine blades and structural frames in aircraft, the transformative effects of oil quenching are instrumental in ensuring the reliability, performance, and safety of critical components in diverse industries. As technology continues to advance and engineering challenges evolve, oil quenching remains a trusted and indispensable technique for meeting the demanding requirements of modern manufacturing and design.

0 notes

Text

Beyond Lubrication: The Multi-Faceted World of Hydraulic Fluids

In the intricate realm of machinery and industrial systems, hydraulic fluids play a role far beyond mere lubrication. This exploration, titled "Beyond Lubrication," delves into the multifaceted world of hydraulic fluids, uncovering the diverse roles these fluids play in ensuring optimal system performance. By understanding the complexities and contributions of hydraulic fluid, businesses and enthusiasts can elevate their knowledge and make informed decisions for sustained efficiency and longevity in their hydraulic systems.

The Dynamic Tapestry of Hydraulic Fluids

1. Power Transmission and Energy Transfer

Embark on a journey through the dynamic tapestry of hydraulic systems, where fluids serve as conduits for power transmission and energy transfer. Explore how this fundamental function underpins the dynamic movement and operation of machinery.

2. Lubrication: Nurturing the Heart of Machinery

Delve into the nurturing role of hydraulic fluids in lubricating critical components. Uncover how this lubrication is not merely about reducing friction but is a vital element in preserving the integrity and functionality of essential machine parts.

3. Heat Dissipation: Cooling the Machinery

Explore the often-overlooked aspect of heat dissipation. Hydraulic fluids act as coolants, absorbing and dissipating heat generated during operation, preventing the system from overheating and ensuring consistent performance.

Types of Hydraulic Fluids: A Palette of Possibilities

1. Mineral Oils, Synthetics, and Bio-based Options

Survey the diverse palette of hydraulic fluids, ranging from traditional mineral oils to advanced synthetic and environmentally friendly bio-based formulations. Understand the unique properties of each, allowing for tailored choices based on specific industrial needs.

Key Considerations in the Hydraulic Fluid World

1. Viscosity and Temperature Stability

Appreciate the critical role of viscosity in hydraulic fluids and its impact on system performance. Delve into the importance of temperature stability, ensuring optimal fluid viscosity across varying operating conditions.

2. Wear Protection and Lubrication Properties

Uncover the multifaceted contributions of hydraulic fluids in providing wear protection and lubrication. Explore the additive components that not only safeguard components but also extend the overall service life of machinery.

3. Oxidation Resistance: A Shield Against Aging

Dive into the concept of oxidation resistance and its role in preventing fluid aging. Examine how antioxidants act as a shield, preserving the fluid's integrity and ensuring consistent performance over time.

4. Water Tolerance and Contamination Control

Learn about the impact of water on hydraulic fluids and the necessity of water tolerance. Explore contamination control measures to maintain fluid cleanliness and safeguard against impurities that could compromise system efficiency.

Crafting Excellence: Practical Insights for Users

1. Compatibility with System Components

Examine the critical factor of compatibility between hydraulic fluids and system components. Understand how selecting fluids that align with materials used in seals, hoses, and pumps is essential for seamless operation.

2. Environmental Considerations

Explore the environmental landscape of hydraulic fluids. Consider eco-friendly options and biodegradable formulations, aligning with sustainability goals and responsible industrial practices.

Sustaining the Multi-Faceted World: Fluid Analysis and Contingency Planning

1. Regular Fluid Analysis for Proactive Maintenance

Highlight the importance of regular fluid analysis as a proactive maintenance strategy. Understand how routine testing can identify potential issues early, allowing for timely intervention and minimizing the risk of system failures.

2. Contingency Planning for Fluid Changes

Explore the meticulous planning involved in fluid changes, encompassing draining, flushing, and replenishing hydraulic fluids. Acknowledge how a well-executed fluid change strategy is fundamental for sustaining optimal system performance.

Conclusion: Elevating Understanding, Ensuring Excellence

In conclusion, "Beyond Lubrication" serves as an exploration of the multifaceted world of hydraulic fluids. By understanding the intricate roles these fluids play in power transmission, lubrication, heat dissipation, and more, businesses and enthusiasts can elevate their understanding and make informed decisions. This guide empowers decision-makers to appreciate the complexity and contributions of hydraulic fluids, ensuring sustained efficiency, longevity, and optimal performance in their hydraulic systems across diverse industries.

0 notes

Text

Crafting Success: How to Evaluate and Partner with a Premium Polymer Supplier

In the intricate world of manufacturing and industry, the selection of a premium polymer supplier is a strategic decision that can significantly impact the success of your business. This article provides a comprehensive guide on "Crafting Success," offering insights on how to evaluate and form partnerships with premium polymer suppliers. By understanding the key criteria and considerations, businesses can embark on a journey towards excellence in materials sourcing.

Navigating the Landscape of Premium Polymer Suppliers

1. Establishing Your Requirements and Goals

Begin by clearly defining your requirements and goals. Understand the specific applications, performance criteria, and industry standards relevant to your business. This clarity will serve as a foundation for evaluating potential polymer suppliers.

2. Assessing Technical Expertise and Product Range

A premium polymer supplier is characterized by technical expertise and a diverse product range. Evaluate the supplier's proficiency in understanding your industry's unique needs and ensuring that their product offerings align with your requirements.

3. Quality Assurance and Consistency

Premium polymer suppliers prioritize quality assurance and consistency in their materials. Scrutinize their quality control processes, certifications, and track record for delivering consistent, high-quality materials that meet or exceed industry standards.

Key Criteria for Evaluation

1. Customization Capabilities

A premium polymer supplier offers customization capabilities to tailor materials to your specific applications. Assess their flexibility in adjusting formulations to meet unique requirements, ensuring that you receive materials perfectly suited to your manufacturing processes.

2. Supply Chain Reliability

Reliable supply chain management is a crucial aspect of premium polymer suppliers. Evaluate their ability to ensure timely deliveries, maintain consistent availability, and adapt to changes in demand or market conditions to prevent disruptions in your manufacturing operations.

3. Commitment to Sustainability

As sustainability becomes increasingly important, assess a premium polymer supplier's commitment to ethical and sustainable practices. Look for suppliers who prioritize responsible sourcing, eco-friendly manufacturing processes, and overall environmental stewardship.

Building a Lasting Partnership

1. Communication and Collaboration

Open and transparent communication is vital for building a lasting partnership. Premium polymer suppliers actively engage in collaborative discussions, providing insights, recommendations, and ongoing support to optimize the use of their materials in your applications.

2. Case Studies and References

Explore case studies and references from the supplier's existing clients. Real-world examples showcase how the supplier has contributed to the success and innovation of other businesses, providing valuable insights into their capabilities and reliability.

3. Future-Forward Vision

A premium polymer supplier should align with your long-term goals. Evaluate their commitment to innovation, research, and development, ensuring that they stay at the forefront of industry advancements and contribute to your business's future success.

Conclusion: Forging a Path to Excellence in Materials Sourcing

In conclusion, "Crafting Success" in partnership with a premium polymer supplier involves a meticulous evaluation process and a focus on long-term collaboration. By prioritizing technical expertise, customization, supply chain reliability, sustainability, and effective communication, businesses can make informed decisions that pave the way for excellence in materials sourcing. Choose a premium polymer supplier that aligns with your vision, and embark on a journey of crafting success in your industry endeavors.

0 notes

Text

Lubricating Excellence: Optimizing Machinery Performance with Slideway Lubricants

In the intricate world of machinery, where precision and performance are paramount, slideway lubricants emerge as the lubricating maestros, orchestrating a symphony of efficiency and reliability. "Lubricating Excellence" offers a comprehensive exploration into the vital role of slideway lubricants, revealing their profound impact on optimizing machinery performance and elevating industrial operations to a new echelon.

The Art of Precision Lubrication:

Embark on a journey into the artistry of precision lubrication provided by slideway lubricants. These specialized fluids are not merely lubricants; they are architects of excellence, meticulously coating and protecting crucial components to ensure seamless and efficient machinery performance.

Friction Reduction: The Key to Efficiency:

Dive deep into the science behind slideway lubricants as unparalleled friction-reducing agents. By minimizing resistance between moving parts, these lubricants pave the way for enhanced operational efficiency, contributing to smoother motions and more reliable machinery performance.

Preserving Precision in Every Movement:

Explore how slideway lubricants act as custodians of precision in machinery operations. In environments demanding accuracy and consistency, these lubricants play a pivotal role in preserving the integrity of movements, ensuring that machinery operates with the exactitude required for optimal performance.

Wear Protection for Prolonged Lifespan:

Witness the safeguarding effect of slideway lubricants against wear and tear. By forming a protective shield on critical surfaces, these fluids mitigate the impact of friction and abrasion, contributing to the prolonged lifespan of machinery components and ultimately optimizing overall performance.

Versatility Across Industries and Applications:

Uncover the versatility of slideway lubricants as they seamlessly adapt to the diverse landscapes of industrial applications. From heavy-duty manufacturing to precision-centric sectors, these lubricants showcase their adaptability, becoming the common denominator in the pursuit of optimized machinery performance.

Enhancing CNC and Precision Machining:

Navigate through the impact of slideway lubricants on CNC machining and precision operations. In these realms where every micron matters, these lubricants emerge as the lubricating virtuosos, ensuring that the precision of every cut and movement is preserved, thereby elevating the overall machinery performance.

Maintenance Practices for Sustained Excellence:

Understand the importance of meticulous maintenance practices in sustaining lubricating excellence. Regular inspections, precise application techniques, and adherence to maintenance schedules are integral elements in ensuring that slideway lubricants continue to optimize machinery performance over time.

Environmental Responsibility in Lubrication:

Witness the evolution of slideway lubricants towards environmental responsibility. As industries embrace sustainable practices, these lubricants evolve to meet eco-friendly standards, aligning their role in machinery optimization with broader environmental consciousness.

Conclusion:

"Lubricating Excellence" concludes with the recognition that slideway lubricants are the unsung heroes, infusing machinery with precision and efficiency. Their silent but powerful role in optimizing performance is the hallmark of industrial excellence. As industries strive for higher standards, acknowledging and maximizing the potential of slideway lubricants become imperative, ensuring that machinery not only operates but excels at the pinnacle of performance.

0 notes

Text

Machining Mastery: How the Right Coolant Enhances Cutting Performance

In the intricate world of machining, precision is the ultimate goal, and achieving mastery in this craft requires more than just cutting-edge tools—it demands the right coolant. "Machining Mastery" delves into the symbiotic relationship between precision cutting and the role of cutting coolants, uncovering how the right fluid can elevate cutting performance to unparalleled levels.

Optimized Heat Management:

At the core of machining mastery lies the ability to effectively manage heat generated during cutting. The right coolant acts as a thermal conductor, swiftly carrying away excess heat from the cutting zone. This meticulous heat management not only safeguards the cutting tool from thermal stress but also ensures consistent material removal, contributing to enhanced cutting precision.

Prolonged Tool Life and Reduced Wear:

The mastery of machining extends beyond the precision of a single cut; it encompasses the longevity of the tools themselves. The right cutting coolant serves as a guardian, forming a protective layer that minimizes friction between the tool and the workpiece. This reduction in friction translates into prolonged tool life, reduced tool wear, and ultimately, a significant boost in overall cutting performance.

Chip Control for Uninterrupted Operations:

In the realm of machining mastery, chip control is a non-negotiable factor. The right coolant facilitates efficient chip evacuation, preventing chips from accumulating and interfering with the cutting process. Uninterrupted operations translate to consistent results, and the mastery lies in the fluid's ability to keep the machining environment free from chip-related disruptions.

Precision Lubrication for Impeccable Finishes:

Beyond mere cooling, machining mastery demands precision lubrication. The right coolant ensures a uniform and effective lubrication layer, enabling smoother interactions between the tool and workpiece. This meticulous lubrication contributes to impeccable surface finishes, meeting the exacting standards of industries where precision is paramount.

Adaptable Formulations for Varied Applications:

True machining mastery acknowledges the diversity of applications and materials. The right cutting coolant is not a one-size-fits-all solution; instead, it offers adaptability. Whether machining ferrous metals, non-ferrous alloys, or delicate composites, the coolant's formulation can be tailored to the specific demands of the application, showcasing its versatility in mastering various machining challenges.

Smart Fluids for Smart Machining:

In the era of smart manufacturing, machining mastery incorporates intelligent solutions. The right cutting coolant goes beyond conventional formulations, integrating smart technologies for real-time monitoring and optimization. This digital synergy enhances not only cutting precision but also the overall efficiency of machining operations.

Environmental Responsibility and Sustainability:

A true master in machining understands the responsibility to the environment. Cutting coolants are evolving to embrace sustainability without compromising performance. Manufacturers are developing eco-friendly formulations, aligning with the global shift towards green manufacturing practices.

Conclusion:

"Machining Mastery" unfolds the intricate dance between precision cutting and the indispensable role of the right cutting coolant. Beyond a mere lubricant or coolant, it is a key player in achieving mastery in the art of machining. As industries continue to push the boundaries of what is possible, the right cutting coolant stands as a testament to how fluid dynamics can elevate machining to a realm of unparalleled precision and performance.

0 notes

Text

Elevating Forging Performance: How Hatebur Approved Lubricants Make a Difference

Forging is an art that demands precision, strength, and consistency. To achieve peak performance in forging operations, one crucial element is the choice of lubricants. Hatebur approved lubricants have emerged as a game-changer in the industry, making a substantial difference in the quest for superior forging performance. In this article, we will explore how Hatebur approved lubricants have the power to elevate forging performance and the significant impact they make in this demanding and intricate process.

The Indispensable Role of Lubricants in Forging

Lubricants in forging operations are far more than just auxiliary substances; they are essential components with a broad spectrum of functions:

Friction Reduction: Lubricants minimize friction between the workpiece and the forging dies, reducing wear on equipment and extending the lifespan of tools.

Enhanced Material Flow: Proper lubrication ensures the smooth and uniform flow of material, resulting in higher precision and fewer defects.

Heat Dissipation: Lubricants help dissipate heat, preventing overheating during the forging process.

Prevention of Seizures: Lubricants prevent the workpiece from sticking to the die surfaces, ensuring a smooth and precise forging process.

How Hatebur Approved Lubricants Make a Difference:

Exceptional Lubricity: Hatebur approved lubricants are celebrated for their exceptional lubricity. This characteristic significantly reduces friction, promoting precise and uniform metal flow. The result is less wear and tear on forging dies and tools, leading to extended equipment life and reduced maintenance costs.

Precision Enhancement: These lubricants are meticulously designed to enhance precision in forging operations. They play a pivotal role in the production of components with tight tolerances and minimal defects, a vital aspect in industries where quality and consistency are paramount.

Efficient Heat Management: Hatebur approved lubricants excel in heat dissipation, ensuring that the forging process remains within the desired temperature range. This not only prevents overheating but also maintains the integrity of the material, ultimately leading to higher-quality products.

Seizure Resistance: The risk of workpiece seizure is significantly reduced when using Hatebur approved lubricants. This ensures a smooth and uninterrupted forging process.

Material Compatibility: These lubricants are formulated to be compatible with a wide range of materials, enhancing their properties and finish.

Advantages of Using Hatebur Approved Lubricants:

Enhanced Efficiency: Reduced friction, efficient heat management, and minimized equipment wear lead to a more efficient forging process.

Superior Product Quality: The use of Hatebur lubricants results in higher precision and superior product quality, with tight tolerances and minimal defects.

Extended Equipment Lifespan: The lubricating and cooling properties of these lubricants extend the life of forging dies and tools, reducing maintenance and replacement costs.

Cost Savings: Reduced equipment maintenance, longer tool lifespan, and enhanced precision lead to significant cost savings for manufacturers.

In Conclusion:

Hatebur approved lubricants stand as a transformative force in the world of forging, elevating performance and contributing to the production of high-quality metal components. With their remarkable lubricity, efficient heat management, seizure resistance, and material compatibility, these lubricants are the key to achieving superior forging performance. Manufacturers that opt for Hatebur approved lubricants can expect improved product quality, extended equipment lifespan, and substantial cost savings, making them a valuable asset in the pursuit of forging excellence.

0 notes

Text

Liquid Gold for Precision: The Key Attributes of the Finest Rolling Oil

Metalworking processes, such as rolling, require the utmost precision to produce high-quality products. In this pursuit of perfection, the choice of rolling oil is paramount. Often referred to as "liquid gold" for its value in metalworking, the finest rolling oil possesses distinct attributes that are crucial for achieving precision and excellence in the industry. This article will delve into the key characteristics of top-tier rolling oil and how it contributes to the art of precision in metalworking.

The Vital Role of Rolling Oil

Rolling oil is more than a mere lubricant in metalworking; it serves as a multifaceted solution with several indispensable functions:

Lubrication: Rolling oil minimizes friction between metal and rolling equipment, reducing wear and extending the life of tools and machinery.

Cooling: The rolling process generates substantial heat due to pressure and friction. Rolling oil acts as a coolant, effectively dissipating heat and preventing damage to both the metal and the equipment.

Surface Finish: The quality of the metal product's surface finish is directly impacted by the rolling oil, ensuring a smooth, consistent appearance.

Cleanliness: Rolling oil assists in washing away debris, metal fines, and contaminants, thus keeping the rolling equipment clean and preventing damage.

Attributes of the Finest Rolling Oil:

Superior Lubricity: The best rolling oil boasts exceptional lubricity, which minimizes friction and ensures a smooth rolling process. This quality reduces tool wear, extends the life of rolling equipment, and enhances overall efficiency.

Efficient Cooling Properties: Effective cooling is crucial to prevent overheating and maintain the structural integrity of the rolled metal. Top-tier rolling oil excels in efficiently dissipating heat.

Cleanliness and Filtration: High-quality rolling oil is easy to filter, ensuring the removal of contaminants and maintaining a clean working environment. Clean oil minimizes the risk of equipment damage and surface imperfections.

Corrosion Resistance: The finest rolling oils offer corrosion protection, preserving the condition of both the rolled metal and the rolling equipment.

Material Compatibility: Rolling oil should be compatible with the specific material being rolled, enhancing its properties and finish.

Advantages of Using the Finest Rolling Oil:

The choice of the finest rolling oil provides numerous benefits for metal manufacturers:

Enhanced Efficiency: Reduced friction and efficient cooling contribute to faster and more precise rolling processes.

Extended Equipment Lifespan: The lubricating and cooling properties of high-quality rolling oil prolong the life of rolling equipment.

Superior Product Quality: Premium rolling oil results in higher quality finished metal products with smooth surfaces and reduced imperfections.

Cost Savings: By minimizing equipment maintenance and reducing downtime, top-notch rolling oil can lead to significant cost savings.

In Conclusion:

Choosing the finest rolling oil is instrumental for manufacturers aiming to achieve precision, efficiency, and high-quality metal products. With attributes like superior lubricity, efficient cooling, cleanliness, corrosion resistance, and material compatibility, the finest rolling oil is the key to achieving precision in metalworking. Manufacturers who invest in premium rolling oils can expect improved efficiency, cost savings, and superior product quality, all of which are essential for success in the competitive field of metalworking.

0 notes

Text

Polymer Quenchants for Sustainable Heat Treatment Practices

The pursuit of sustainability in manufacturing has become a global imperative. In the realm of heat treatment processes, which play a critical role in various industries, the choice of quenching media is essential for achieving not only desirable material properties but also sustainable practices. Polymer quenchants have emerged as a key solution for enhancing both the environmental and operational sustainability of heat treatment. This article explores the use of polymer quenchants as a means of fostering sustainability in heat treatment practices.

Sustainability in Heat Treatment

Sustainable heat treatment practices encompass a range of objectives, including reduced environmental impact, energy efficiency, resource optimization, enhanced worker safety, and cost-effectiveness. The use of polymer quenchants aligns with these objectives in several ways.

Advantages of Polymer Quenchants for Sustainability

Reducuced Environmental Impact:

a. Biodegradability: Many polymer quenchants are formulated to be biodegradable, making them environmentally friendly. In case of spills or leaks, these quenchants break down naturally, reducing their impact on ecosystems.

b. Low Emissions: Polymer quenchants produce fewer emissions during the quenching process compared to traditional oil or water quenchants, contributing to improved air quality in the workplace and the surrounding environment.

Energy Efficiency:

a. Heat Dissipation: Polymer quenchants help dissipate heat effectively, reducing the risk of overheating and allowing for more controlled and uniform temperature distribution. This contributes to energy efficiency by minimizing the energy required for cooling and maintaining optimal quenching temperatures.

b. Friction Reduction: Lower friction in the quenching process translates to more efficient cooling and lower energy consumption.

Resource Optimization:

a. Tool Life Extension: Polymer quenchants reduce the wear and tear on quenching equipment, extending the lifespan of the tools. This, in turn, reduces the need for frequent replacements, saving resources and costs.

b. Material Efficiency: Controlled cooling rates achieved with polymer quenchants result in fewer material defects, reducing waste and optimizing material efficiency.

Health and Safety:

a. Worker Health: Polymer quenchants are typically non-toxic and safer for workers, minimizing exposure to hazardous chemicals and fumes. They contribute to a healthier work environment.

b. Regulatory Compliance: Many polymer quenchants comply with local and international safety and environmental regulations, ensuring a safe and sustainable work environment.

Cost-Effectiveness:

a. Total Cost of Ownership (TCO): Although polymer quenchants may have a higher upfront cost, their long-term savings in terms of extended tool life and reduced energy consumption often make them more cost-effective.

b. Efficiency Gains: By using polymer quenchants, heat treatment processes can become more efficient, leading to increased production rates and lower operational costs.

Conclusion

Polymer quenchants have emerged as a sustainable and efficient solution for heat treatment practices. Their ability to reduce the environmental impact, improve energy efficiency, optimize resource usage, enhance worker safety, and offer long-term cost savings makes them a powerful tool in achieving sustainable heat treatment practices. By choosing polymer quenchants that align with specific material and process requirements and complying with environmental regulations, manufacturers can foster a cleaner, greener, and more sustainable approach to heat treatment while still achieving high-quality results. Polymer quenchants are not only a responsible choice but also a significant step towards a more sustainable future in manufacturing.

0 notes

Text

Key Considerations for Sustainable Forging Lubricant Solutions

In today's manufacturing landscape, sustainability has become a paramount concern. Industries are increasingly seeking ways to reduce their environmental impact and enhance resource efficiency. This article focuses on sustainable forging lubricant solutions and the key considerations that can help forge a path toward eco-friendly, efficient, and cost-effective metalworking practices.

Sustainability in Forging

Sustainable forging involves the reduction of adverse environmental effects, efficient resource utilization, and long-term economic viability. It also encompasses responsible use of materials and the well-being of workers. Sustainable forging lubricants play a pivotal role in achieving these objectives.

Key Considerations for Sustainable Forging Lubricant Solutions

Environmental Impact:

a. Biodegradability: Opt for forging lubricants that are biodegradable. These lubricants break down naturally, reducing the impact on ecosystems in the event of spills or leaks.

b. Low Emissions: Choose lubricants that produce fewer emissions during the forging process, contributing to better air quality in the workplace and the surrounding environment.

c. Reduced Waste: Sustainable lubricants can be recycled or disposed of more responsibly, contributing to waste reduction and minimizing landfill impact.

Energy Efficiency:

a. Heat Dissipation: Lubricants that efficiently dissipate heat can contribute to lower energy consumption by helping maintain optimal forging temperatures.

b. Friction Reduction: Minimizing friction through lubricants leads to more efficient metal flow, which requires less force and, consequently, less energy.

Resource Optimization:

a. Tool Life Extension: Lubricants that extend the lifespan of dies and equipment reduce the need for frequent replacements, saving both resources and costs.

b. Material Efficiency: Controlled metal flow achieved with lubricants can help reduce material waste, as less metal is lost to defects or inaccuracies.

Health and Safety:

a. Worker Health: Prioritize lubricants that are safer for workers, minimizing exposure to hazardous chemicals and fumes, and ensuring a healthier work environment.

b. Regulatory Compliance: Ensure that the chosen lubricants comply with local and international safety and environmental regulations.

Cost-Effectiveness:

a. Total Cost of Ownership (TCO): Consider the TCO of sustainable lubricants. While they may have a higher upfront cost, the long-term savings from extended tool life and reduced energy consumption can make them more cost-effective.

b. Efficiency Gains: Sustainable lubricants can lead to more efficient forging processes, which can, in turn, increase production rates and lower operational costs.

Consultation and Research:

a. Consult with lubricant suppliers or manufacturers to identify sustainable options that meet your specific forging needs.

b. Stay informed about the latest developments in sustainable lubricants, as new formulations and technologies are continually being introduced.

Conclusion

Sustainability in forging is no longer an optional consideration; it is a necessity for the modern manufacturing industry. Choosing the right forging lubricant is a critical step in the journey toward a more sustainable and environmentally responsible metalworking practice. By considering the environmental impact, energy efficiency, resource optimization, health and safety, and cost-effectiveness of lubricants, manufacturers can make informed choices that not only benefit their bottom line but also contribute to a cleaner, greener, and more sustainable future for the forging industry. Sustainable forging lubricants are not only a responsible choice but also a step toward securing the future of metalworking.

0 notes

Text

Quenching Oils vs. Water Quenching: Making the Right Selection

In the world of heat treatment, where the goal is to transform metals into stronger, more durable materials, the choice of quenching method is a critical decision. Two primary options stand out: quenching oils and water quenching. Each method has its advantages and considerations. In this article, we'll explore the differences between quenching oils and water quenching and help you make the right selection for your heat treatment needs.

Understanding the Quenching Process

Quenching is a crucial step in the heat treatment of metals, where hot materials are rapidly cooled to achieve desired mechanical properties. This process involves controlling the rate of cooling to achieve specific results, such as increased hardness, strength, and toughness.

Quenching with Oils

Advantages of Quenching Oils:

Controlled Cooling: Quenching oils offer a more controlled and gradual cooling process compared to water, reducing the risk of cracking or distortion in the metal.

Minimized Distortion: Oils are effective at minimizing the distortion and warping of components, ensuring that the final product retains its shape and integrity.

Surface Finish: Quenching oils can result in a smoother surface finish compared to water quenching, which can leave a rougher surface due to rapid cooling.

Reduced Risk of Cracking: The slower cooling rate provided by quenching oils reduces the risk of thermal shock and cracking in some materials.

Disadvantages of Quenching Oils:

Slower Cooling: Quenching oils generally provide slower cooling rates compared to water, which can be a disadvantage for some applications requiring rapid cooling.

Flammability: Quenching oils are flammable and require safety precautions to minimize fire hazards.

Quenching with Water

Advantages of Water Quenching:

Rapid Cooling: Water quenching provides extremely rapid cooling rates, which can be advantageous for achieving specific material properties quickly.

Cost-Effective: Water is readily available and cost-effective compared to specialized quenching oils.

High Heat Capacity: Water has a high heat capacity, making it effective at absorbing and dissipating heat from the metal.

Disadvantages of Water Quenching:

Rapid Cooling Can Cause Cracking: The high cooling rate of water can lead to thermal shock and cracking in some materials, making it less suitable for certain applications.

Distortion Risk: Water quenching can result in greater distortion and warping of components compared to quenching oils.

Making the Right Selection

The choice between quenching oils and water quenching depends on several factors:

Material Type: Consider the type of metal or alloy being treated and its specific heat treatment requirements.

Required Properties: Determine the desired material properties after heat treatment, such as hardness, strength, and toughness.

Quenching Method: Evaluate the quenching method that aligns with your material and application needs, whether it's gradual cooling with quenching oils or rapid cooling with water.

Safety Considerations: Be aware of safety concerns, particularly when working with flammable quenching oils.

Equipment Compatibility: Ensure that your heat treatment equipment is compatible with the chosen quenching method.

Conclusion

Choosing between quenching oils and water quenching is a crucial decision in the heat treatment process. Each method has its advantages and considerations, and the choice should align with the specific material, desired properties, and safety requirements of your application. Whether you opt for controlled cooling with quenching oils or rapid cooling with water, the right selection will ultimately determine the success of your heat treatment process.

0 notes

Text

The Unsung Hero of Machining: How Honing Oils Improve Surface Finish

In the world of precision machining, where the quest for perfection and surface quality is unending, there's an unsung hero that often goes unnoticed—the humble honing oil. Precision machining processes, such as honing, rely on more than just machinery and skilled operators; they depend heavily on the choice of honing oil. In this article, we'll shed light on how honing oils play a pivotal role in improving surface finish, an essential element in achieving machining excellence.

The Art of Honing

Honing is a machining process employed to refine the surface finish and geometry of bores and cylindrical surfaces. It distinguishes itself by its ability to deliver exceptionally fine surface finishes and tight dimensional tolerances. This precision makes honing indispensable in industries where quality and accuracy are paramount.

The Hidden Power of Honing Oils

At the heart of the honing process lies a critical element—honing oil. This specialized lubricant may seem inconspicuous, but it carries out a range of crucial functions that directly impact the surface finish:

Cooling: During honing, friction between the abrasive stones or tools and the workpiece generates heat. Honing oil acts as a coolant, absorbing and dissipating this heat. Effective cooling prevents thermal damage to the workpiece and ensures consistent quality.

Lubrication: Honing oil reduces friction between the abrasive tools and the workpiece. Reduced friction leads to smoother, controlled material removal, minimizing wear on both the tool and workpiece.

Chip Removal: Material removal during honing generates chips and debris. Honing oil aids in flushing these particles away, ensuring a clean and unobstructed interface between the abrasive surfaces and the workpiece.

Surface Finish: Perhaps the most crucial role of honing oil is its impact on the final surface finish. The choice of honing oil can significantly influence surface roughness, texture, and overall quality.

Selecting the Right Honing Oil

Choosing the correct honing oil is a pivotal decision that directly affects machining outcomes. Here are key considerations when selecting the right honing oil:

Viscosity: Honing oils come in various viscosities. The choice depends on the specific honing application and the desired surface finish. Thicker oils may be suitable for heavy-duty honing, while thinner oils may be preferred for finer finishes.

Additives: Many honing oils contain additives that enhance performance. These additives can include anti-wear agents, extreme pressure (EP) additives, and rust inhibitors. Evaluate whether these additives align with your application's needs.

Compatibility: Ensure that the honing oil is compatible with both the materials being machined and the honing equipment in use. Incompatibility can lead to performance issues and equipment damage.

Environmental Considerations: Be aware of environmental regulations and consider biodegradable or environmentally friendly honing oils when applicable.

Conclusion

Honing oils may not receive the spotlight in precision machining, but their role in improving surface finish is nothing short of heroic. By providing cooling, lubrication, chip removal, and influencing surface quality, honing oils are indispensable in achieving machining excellence. The careful selection of the right honing oil can elevate the quality of machined components, extend tool life, and ensure that the surfaces meet the highest standards of finish and precision. In the world of machining, where perfection is the goal, honing oils are the unsung heroes working silently to deliver impeccable results.

0 notes

Text

Gear Manufacturing Unveiled: The Science Behind Effective Hobbing Oils

Behind the precision and intricacy of gear manufacturing lies a realm of scientific marvels, and at the heart of this craftsmanship lies a seemingly simple element – hobbing oils. These unassuming fluids are the embodiment of scientific ingenuity, playing a crucial role in ensuring the accuracy and efficiency of gear cutting processes. In this article, we dive into the science behind effective hobbing oils and their transformative impact on the world of gear manufacturing.

The Dance of Metal: Gear Manufacturing as an Art and Science

Gear manufacturing is the art of shaping metal into intricate tooth profiles, and it's a dance between craftsmanship and science. Hobbing oils step onto the stage as scientific companions, facilitating this dance by offering lubrication, cooling, and debris management that is crucial for achieving precision in gear cutting.

Lubrication: The Key to Reduced Friction

Friction is the enemy of precision in gear manufacturing. Hobbing oils act as lubricants, forming a protective barrier between the cutting tool and the gear material. By doing so, they minimize the friction that could lead to wear and tear. The science behind effective lubrication lies in the molecular composition of these oils, which forms a film that reduces the contact between surfaces, enabling smoother motion and precise tooth profile creation.

Cooling: The Battle Against Heat

Heat is an inevitable byproduct of the cutting process, and excessive heat can distort the final product. Hobbing oils function as efficient coolants, utilizing principles of heat transfer to dissipate the generated heat quickly. The oils' ability to carry heat away from the cutting zone is a result of their thermal properties, ensuring that the gear material retains its structural integrity and dimensional accuracy.

Debris Management: Channeling the Chips

In gear cutting, metal chips are formed as material is removed to create tooth profiles. These chips must be managed effectively to avoid obstructing the cutting process. Hobbing oils, with their specific viscosity and flow characteristics, aid in carrying away these chips from the cutting zone. This principle of fluid dynamics ensures that chips are evacuated, allowing the cutting tool to maintain optimal contact with the gear material.

Viscosity and Formulation: Tailoring to Gear Cutting Needs

The effectiveness of hobbing oils is closely tied to their viscosity and formulation. Viscosity, a measure of a fluid's resistance to flow, is carefully calibrated to ensure optimal coverage and lubrication. The formulation of hobbing oils considers factors such as cutting speed, gear material, and cutting conditions. The balance of these properties is where the science of effective hobbing oils truly comes to life.

Enhancing Efficiency and Precision Through Chemistry

Effective hobbing oils are a result of meticulous chemical engineering. The selection of base oils, additives, and performance enhancers is rooted in scientific research and expertise. Each component is chosen for its ability to create a harmonious blend that reduces friction, manages heat, and optimizes chip evacuation. The synergy of these elements is the science behind hobbing oils' efficacy in gear manufacturing.

Conclusion: The Subtle Science That Drives Precision

Effective hobbing oils are not mere lubricants; they are the embodiment of intricate scientific principles. They reduce friction through molecular interactions, manage heat through thermal dynamics, and optimize chip evacuation through fluid dynamics. The careful formulation of these oils involves a deep understanding of materials, chemistry, and physics. As gear manufacturing unveils its intricate science, hobbing oils stand as a testament to the silent yet powerful role that science plays in achieving precision, efficiency, and excellence in the creation of gears.

0 notes

Text

From Raw Material to Excellence: Wet Temper Fluids in Steel Coil Production

The journey from raw material to excellence in steel coil production is a meticulously orchestrated process that demands attention to detail at every stage. Among the myriad factors that contribute to this journey, the role of wet temper fluids is emerging as a critical element in achieving unparalleled quality and performance. In this article, we explore the transformative impact of wet temper fluids on the path from raw material to excellence in steel coil production.

The Starting Point: Raw Material and Ambitions

Steel coil production begins with raw materials that hold the potential for greatness. These materials undergo a series of refining and processing steps to reach their intended mechanical properties and characteristics. The ambition to create exceptional steel coils drives manufacturers to seek innovative methods that go beyond traditional manufacturing approaches.

Unlocking Potential Through Heat Treatment

Heat treatment is the cornerstone of steel coil production, where the raw material transforms into a material of exceptional strength and durability. Wet temper fluids step in at this critical juncture to provide precise control over the cooling process. By guiding the cooling rates, these fluids enable manufacturers to dictate the microstructure of the steel, thereby determining its final mechanical properties.

Customization: Tailoring Coils to Specific Demands

One of the remarkable features of wet temper fluids lies in their versatility. Different steel grades require distinct mechanical properties to meet the diverse demands of various industries. Wet temper fluids can be formulated and applied to cater to these specific requirements, ensuring that each coil is tailored to deliver the desired characteristics. This customization enriches the value that steel coil manufacturers can offer to their clients.

The Symphony of Consistency and Precision

In the pursuit of excellence, consistency and precision play a symphonic role. Wet temper fluids act as the conductors of this symphony, ensuring that every coil undergoes the same controlled cooling process. The result is a consistent microstructure that translates to uniform mechanical properties across the entire production batch. This consistency elevates the reliability and performance of the final products.

Elevating Efficiency and Quality

Efficiency and quality are inseparable companions in steel coil production. Wet temper fluids enhance efficiency by enabling rapid and controlled cooling, thus reducing the overall time required for heat treatment. This efficiency not only boosts productivity but also minimizes the risk of distortion and related post-treatment corrections. Ultimately, the combination of efficiency and quality enhances the competitiveness of manufacturers in a demanding market.

The Path to Excellence: Continuous Improvement and Innovation

Excellence is not a destination but a journey of continuous improvement and innovation. By embracing wet temper fluids and their transformative capabilities, steel coil manufacturers embark on a path of perpetual advancement. The integration of fluid precision not only enhances the immediate production process but also fosters an environment of innovation that paves the way for future breakthroughs.

Conclusion

From raw material to excellence, the role of wet temper fluids in steel coil production is both pivotal and transformative. These fluids guide the evolution of steel from its nascent state to a material of unparalleled strength and resilience. The utilization of wet temper fluids represents a commitment to precision, consistency, and customization – values that shape the journey towards producing steel coils that exceed expectations and set new standards of excellence in the industry.

0 notes

Text

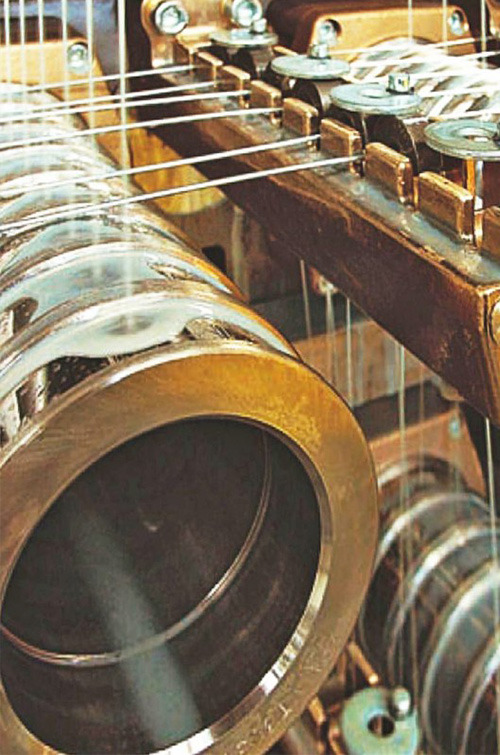

Unlocking the Benefits of Knitting Oil: Enhancing Needle Durability and Performance

In the realm of textile manufacturing, knitting is a vital process that relies on the performance and longevity of knitting needles. To optimize knitting operations and ensure consistent quality, enhancing the durability and performance of knitting needles is essential. Knitting oil, a specialized lubricant, holds the key to unlocking numerous benefits that significantly improve needle durability and overall knitting performance. In this blog, we will explore the advantages of using knitting oil and how it enhances needle durability and performance in textile manufacturing.

Minimizing Needle Friction and Wear:

Knitting oil acts as a protective lubricant, reducing friction between the knitting needles and the yarn during the knitting process. This minimizes wear and tear on the needles, preventing premature needle deterioration and extending their lifespan.

Ensuring Smooth and Consistent Needle Movement:

With the application of knitting oil, knitting needle movement becomes smoother and more consistent. This ensures uniform stitch formation and reduces the likelihood of yarn breakages, leading to improved knitting quality and enhanced performance.

Protecting Needle Integrity:

Knitting oil forms a protective layer on the needles, reducing stress and preventing overheating during knitting operations. This safeguarding of needle integrity enhances their durability, enabling them to withstand prolonged use without compromising performance.

Increasing Needle Longevity:

By minimizing friction and wear, knitting oil significantly increases the lifespan of knitting needles. This translates into reduced need for frequent needle replacements, leading to cost savings and improved productivity in the long run.

Promoting Sustainable Manufacturing:

Extending needle durability with knitting oil aligns with sustainable manufacturing practices. The reduction in needle waste and the need for replacements contribute to a more environmentally-friendly approach in the textile industry.

Conclusion:

Knitting oil holds immense potential in enhancing needle durability and performance in textile manufacturing. By minimizing friction, ensuring smooth needle movement, protecting needle integrity, and increasing needle longevity, knitting oil significantly improves knitting operations. The investment in knitting oil proves to be a strategic move, offering benefits such as improved knitting quality, cost savings, and a more sustainable approach to textile manufacturing. As textile manufacturers unlock the benefits of knitting oil, they elevate their knitting processes to new levels of efficiency and performance, meeting the demands of a competitive textile market with ease.

0 notes

Text

Boost Productivity and Extend Tool Life with OEM Approved EDM Oils for Spark Erosion

In the realm of precision machining, Electrical Discharge Machining (EDM) is a highly valuable process for crafting intricate and complex components with unparalleled accuracy. To maximize productivity and ensure extended tool life in EDM operations, selecting the right dielectric fluid, commonly known as EDM oil, is of utmost importance. In this blog, we will delve into the benefits of using OEM approved EDM oils for spark erosion processes, and how they contribute to optimizing productivity and prolonging the life of your EDM tools.

Understanding the Role of EDM Oils:

EDM oils, also referred to as dielectric fluids, play a crucial role in the EDM process. During EDM operations, controlled electrical discharges occur between the electrode and the workpiece immersed in the dielectric fluid. The dielectric fluid acts as an insulator, facilitating the spark erosion process and cooling the electrode and workpiece. Selecting the appropriate dielectric fluid is vital, as it directly impacts machining speed, accuracy, and the overall surface finish of the machined parts.

The Significance of OEM Approval:

OEM (Original Equipment Manufacturer) approved EDM oils hold paramount importance in the EDM industry. These oils are formulated and rigorously tested by the manufacturers of EDM machines to meet their precise specifications. By utilizing OEM approved spark erosion EDM oils, you ensure that the dielectric fluid is specifically engineered to complement your EDM machine's design and engineering. This level of compatibility and approval guarantees optimal performance and protects your machinery from potential damage caused by non-approved fluids.

Benefits of OEM Approved Spark Erosion EDM Oils:

Enhanced Productivity: OEM approved EDM oils are carefully designed to deliver consistent and superior performance in a wide range of EDM applications. Their balanced dielectric properties facilitate efficient spark erosion, enabling faster material removal and increased machining speed, thereby boosting overall productivity.

Prolonged Tool Life: The right EDM oil reduces electrode wear, leading to prolonged tool life. By minimizing electrode degradation, OEM approved EDM oils contribute to cost savings, reduced downtime for electrode replacements, and increased tool longevity.

Superior Surface Finish: High-quality EDM oils possess excellent cooling properties, preventing overheating during the spark erosion process. As a result, machined parts exhibit a superior surface finish, reducing the need for extensive post-processing.

Effective Debris Flushing: OEM approved EDM oils are formulated with efficient flushing properties, effectively removing debris and eroded material from the machining area. This promotes a clean machining environment, reduces the risk of clogging, and ensures consistent performance.

Machine Compatibility: Opting for OEM approved spark erosion EDM oils guarantees compatibility with the specific requirements of your EDM machine, safeguarding your equipment and ensuring optimal functionality.

Cost-Effectiveness: Although OEM approved EDM oils may have a slightly higher initial cost, their performance benefits, prolonged tool life, and machine protection result in long-term cost savings and improved operational efficiency.

Conclusion:

Boosting productivity and extending tool life in spark erosion EDM processes is achievable with the use of OEM approved EDM oils. These dielectric fluids are meticulously formulated to meet the strict requirements of EDM machinery, ensuring consistent performance, superior surface finish, extended tool life, and cost-effectiveness. By harnessing the advantages of OEM approved spark erosion EDM oils, you can optimize productivity, reduce operational costs, and prolong the life of your EDM tools. Discover the power of OEM approved EDM oils and unlock the full potential of your EDM operations, elevating precision machining to new heights in today's competitive landscape.

0 notes