#Wet Temper Fluids For Steel Coil Manufacturing

Text

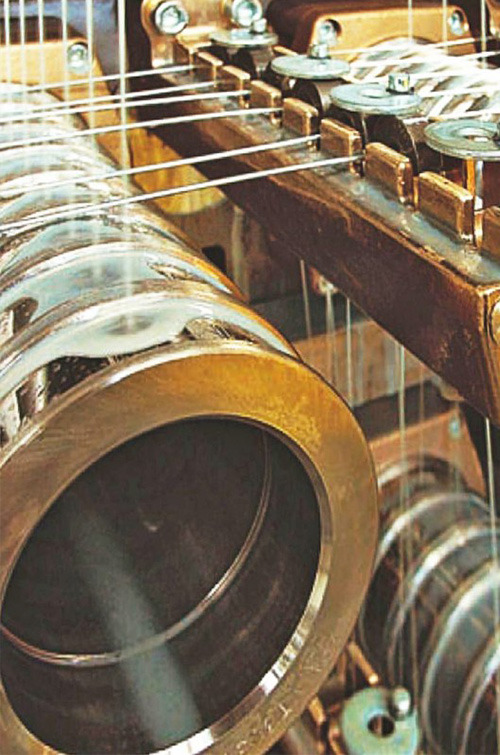

From Raw Material to Excellence: Wet Temper Fluids in Steel Coil Production

The journey from raw material to excellence in steel coil production is a meticulously orchestrated process that demands attention to detail at every stage. Among the myriad factors that contribute to this journey, the role of wet temper fluids is emerging as a critical element in achieving unparalleled quality and performance. In this article, we explore the transformative impact of wet temper fluids on the path from raw material to excellence in steel coil production.

The Starting Point: Raw Material and Ambitions

Steel coil production begins with raw materials that hold the potential for greatness. These materials undergo a series of refining and processing steps to reach their intended mechanical properties and characteristics. The ambition to create exceptional steel coils drives manufacturers to seek innovative methods that go beyond traditional manufacturing approaches.

Unlocking Potential Through Heat Treatment

Heat treatment is the cornerstone of steel coil production, where the raw material transforms into a material of exceptional strength and durability. Wet temper fluids step in at this critical juncture to provide precise control over the cooling process. By guiding the cooling rates, these fluids enable manufacturers to dictate the microstructure of the steel, thereby determining its final mechanical properties.

Customization: Tailoring Coils to Specific Demands

One of the remarkable features of wet temper fluids lies in their versatility. Different steel grades require distinct mechanical properties to meet the diverse demands of various industries. Wet temper fluids can be formulated and applied to cater to these specific requirements, ensuring that each coil is tailored to deliver the desired characteristics. This customization enriches the value that steel coil manufacturers can offer to their clients.

The Symphony of Consistency and Precision

In the pursuit of excellence, consistency and precision play a symphonic role. Wet temper fluids act as the conductors of this symphony, ensuring that every coil undergoes the same controlled cooling process. The result is a consistent microstructure that translates to uniform mechanical properties across the entire production batch. This consistency elevates the reliability and performance of the final products.

Elevating Efficiency and Quality

Efficiency and quality are inseparable companions in steel coil production. Wet temper fluids enhance efficiency by enabling rapid and controlled cooling, thus reducing the overall time required for heat treatment. This efficiency not only boosts productivity but also minimizes the risk of distortion and related post-treatment corrections. Ultimately, the combination of efficiency and quality enhances the competitiveness of manufacturers in a demanding market.

The Path to Excellence: Continuous Improvement and Innovation

Excellence is not a destination but a journey of continuous improvement and innovation. By embracing wet temper fluids and their transformative capabilities, steel coil manufacturers embark on a path of perpetual advancement. The integration of fluid precision not only enhances the immediate production process but also fosters an environment of innovation that paves the way for future breakthroughs.

Conclusion

From raw material to excellence, the role of wet temper fluids in steel coil production is both pivotal and transformative. These fluids guide the evolution of steel from its nascent state to a material of unparalleled strength and resilience. The utilization of wet temper fluids represents a commitment to precision, consistency, and customization – values that shape the journey towards producing steel coils that exceed expectations and set new standards of excellence in the industry.

0 notes