Qingdao CCS Electric Corporation, founded in 2011, is located the Qingdao West Coast Economic New Area, Shandong Province. The company covers an area of 110 acres with a construction area of 60,000 ㎡.The company, with a complete system for R&D, design, manufacturing, marketing and maintenance service, focuses on the development of the electrician transmission and control equipment in the industrial automation area, including integrated VFD motor, special converter, special high-performance VFD motor, electrical control and power supply products. The asynchronous integrated VFD motor and the permanent magnetic integrated synchronous VFD motor, as the core products of CCS, organically integrate the frequency converter and the motor, which can replace the separated transmission type of “converter+motor”, obtaining the market leading position in the high-end transmission equipment of minging industries of coal and oil&gas. With the increasing demand of electrification and intelligent of industrial field, the products of CCS have a broad market prospect in the industries of engineering, port, shipping, metallurgy, cement and other industries.The company has passed ISO 9001:2015 Quality System Certification, ISO 14001:2015 Environmental Management System Certification, OHSAS18001:2007 Occupational Health and Safety management System Certification and GB/ T 2949-2013 Intellectual Property Management System Certification. Through independent innovation, CCS is committed to becoming a world leader and provider of electrical transmission and control equipment. https://www.ccs-motors.com/

Don't wanna be here? Send us removal request.

Text

VFD MOTOR

https://www.ccs-motors.com/products/vfd-motor/

What is a VFD motor? Variable frequency drive (VFD) is a kind of power control equipment which uses frequency conversion technology and microelectronics technology to control AC motor by changing the speed of motor. The VFD is mainly composed of rectifier (AC to DC), filter, inverter (DC to AC), drive unit, detection unit, micro processing unit, etc. VFD motor is a combination of variable frequency drive and three-phase motor to be used with AC 50Hz/60Hz power supply system. The VFD motor can adjust the speed of motor under various load conditions, completely eliminate the mechanical and electrical shocks and prolong the service life of mechanical equipment. And the variable frequency drive motor also works to protect against overload, overvoltage, undervoltage, phase loss and overheating.

Types of Variable Frequency Drive Motor

Flame Proof Asynchronous VFD Motor

The power rating range of this kind of VFD motor is from 55kW to 3000kW and it can be designed as per IP 56 or higher which is able to withstand a certain degree of flooding.

PM Integrated VFD Motor

PM integrated VFD motor combined VFD and motor,can supply a big torque even in low speed.it can output most of VFD/motor parameters and curves to distribute control system.

High Ingress Protection VFD Motor

High Ingress Protection VFD motor is mainly used in excavators in the field of construction machinery, port bucket wheel stacker-reclaimer, and etc.

Flameproof Permanent Magnet Motorized Pulley

The pulley is a kind of motor with is used for conveyor. Voltage is from 380V to 1140V and power rating is less than 300kW.

VFD Motor Efficiency

Motor efficiency does change as speed and torque change and is also affected by voltage harmonics present in the VFD motor output. The magnitude of losses due to voltage harmonics will vary with the motor design. VFD motor efficiency decreases with decreasing motor load. The decline in efficiency is more pronounced with VFD motor of smaller horsepower ratings.

How does a VFD Control Motor Speed?

A variable frequency drive controls the motor speed by using PWM (Pulse Width Modulation) to alter the power supply frequency that's fed to the motor. The first step in this process is to convert the AC supply voltage into DC by the use of a rectifier. DC power contains voltage ripples which are smoothed using filter capacitors.

How to Change Motor Rotation on a VFD?

It is usually easy to change the direction of rotation with the VFD itself. Most VFD's have a simple toggle command for forward and reverse. Switching two of the power leads coming out of the VFD can solve the problem of which the motor is shut down and later restarted, it will restart running backwards again.

Application of the VFD Motor

The VFD motor can run in the explosion environment. Flameproof and intrinsically safe high-voltage integrated VFD Motor is a highly integrated product of the motor and the drive. It is widely applicable to belt conveyors, loaders, AFC's, emulsion pumping stations, and other equipment used in underground coal mining to achieve a soft-start under heavy load and dynamic speed control. CCS can offer a wide range of VFD motors for different scenarios, including motor with integrated VFD, VFD rated motors, VFD multiple motors, and other VFD compatible motors.

How to Select a VFD Motor

Choose the appropriate structure form of protection grade motor according to the application place.

Choose the appropriate power and voltage level according to the responsible ability.

According to the environmental temperature, humidity, above seal level, dust and gas conditions, special requirements such as explosion prevention are selected.

Choose a strong manufacturer to ensure the material quality and production process to the maximum extent.

FAQs of VFD Motors

What is power transmission equipment?

Electrical transmission equipment can realize the conversion between electric energy and mechanical energy, and conveniently control the torque, angular acceleration, speed of the motor output shaft according to the production process requirements.

What is the power control system?

The electric drive control system is usually composed of a motor, power conversion device, and control device. Electric drive is divided into constant speed and speed regulation, and speed regulation is divided into AC speed regulation and DC speed regulation.

Which kind of communication protocol can be available in the system?

There are several communication methods for your choice, Modbus, Profibus, Profinet, Internet.

How does the variable frequency drive (VFD) work for motor protection?

VFD can realize the protection of motor: 1. Overvoltage protection. 2. Undervoltage protection. 3. Overcurrent protection. 4. Lack of phase protection. 5. Reverse phase protection. 6. Overload protection. 7. Grounding protection. 8. Short circuit protection. The frequency converter is equipped with various detection systems to detect and protect various signals.

Can you run a VFD without a motor?

The VFD can be put into trial operation without motor, which is used to carry out relevant low-voltage tests, such as analog overcurrent protection, overvoltage protection, communication failure and so on.

What types of motors can be used with variable frequency drives?

Frequency converter usually needs to be equipped with special frequency conversion motor, because the special frequency conversion motor fully considers the problem of frequency change in design and manufacture, and can apply to larger frequency change; The traditional asynchronous motor can also be applied to frequency converter, but because it is designed according to power frequency, there are some problems such as low efficiency, high temperature, easy aging insulation and so on.

0 notes

Text

SPECIAL MOTOR

https://www.ccs-motors.com/products/special-motor/

We are focusing on tailor-made motors for our customers.

The special motor can be designed according to the working condition and customer’s demands, such as installation dimensions, space and environment, drive performance, power type, and ingress protection.

Our design covers a wide range of types: variable frequency motor,three-phase asynchronous motor,three-phase synchronous motor, two-speed motor, and so on.

High Ingress Motor

We can supply high ingress protection motors for excavators, bucket wheel stackers, reclaimers at ports, and fracturing machinery for oil and gas.

Flame Proof Motor

YBUS series flameproof three-phase asynchronous motor for roadheader is special for driving the cutting part of cantilever roadheader and other similar machinery in the coal mine. The motor has the ch...

0 notes

Text

Remote Control System

https://www.ccs-motors.com/products/remote-control-system.html

Remote Control System is used in mining industry and it was inbuilt with monitors of 21 inches.

Features of the Remote Control System

Perspective view of frame level and position;

Our remote control system has high broadband and low delay wireless data transmission;

Remote HD visualization operation;

Inertial Navigation, automatic Section cutting;

A remote control system can reduce worker occupational health hazards and improve operational safety.

Main Application of the Remote Control System

The remote control system can realize remote control and visual operation in mining machinery, construction machinery and other operating environments. The remote control system can be used in motor control system, VFD control system, converter system, etc.

0 notes

Text

Power Supply Unit

https://www.ccs-motors.com/products/power-supply-unit.html

The input voltage of the power supply unit is 10kV and the output voltage is 3300V.

And main applications of power supply unit are fracturing trucks in the oil and gas fields. CCS has various types of power supply unit for sale.

Parameters of the System Unit Power Supply Unit

Output Voltage

DC 1600V-800V/AC 380V

Output Power

120kVA-20000kVA

Features of the Power Supply Unit

The power supply unit is box-style structure, integrated functions of power transformation and rectification;

The power supply unit realizes the power supply distribution of oil and gas working site, provide power for the converter of DC power supply;

The power supply unit has lightning protection and anti-current protection;

Adopt air-cooling for transformer and air-water cooling for rectifier unit for heat dissipation.

0 notes

Text

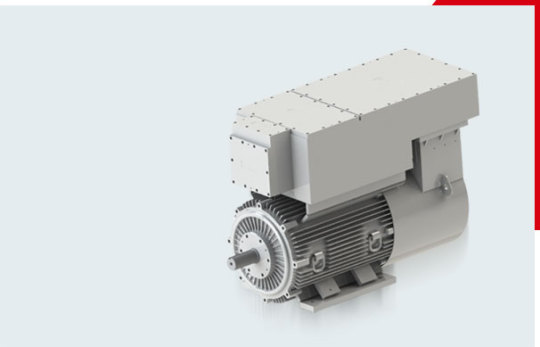

PM Integrated VFD Motor

https://www.ccs-motors.com/products/pm-integrated-vfd-motor.html

Intelligent permanent magnet direct drive system is a comprehensive solution for equipment drive and control technology. VFD synchronous motor takes permanent magnet direct drive technology as the core and adopts special frequency converter, permanent magnet synchronous frequency conversion motor, and water cooler to replace traditional mechanical drive devices such as asynchronous motor, reducer and hydraulic coupler. At present, VFD synchronous motor is widely used in mines, coal, ports, electric power, building materials, chemical industry, and other fields.

Specifications of the PM Integrated VFD for Synchronous Motor

Voltage range

380V/400V/600V/660V/3300V/4160V/6000V/6600V/10000V

Frequency

50Hz/60HZ

Voltage fluctuation range at grid

-15%-10%

Frequency fluctuation at grid

±0.2Hz

Speed range

60rpm,75rpm,90rmp and so on

Output frequency

0-50Hz/60Hz

Power rating

45kW-2000kW

VFD principle

Voltage source inverter

Motor type

Synchronous motor

Control method

V/F or DTC without sensor

Starting torque

2 times

Frequency resolution

0.01Hz

Ingress protection

IP54 pr IP55

Installation

IMB3 or IMB5

Communication

CAN、RS485、Profinet、Ethernet IP etc

PM Motor with Integrated VFD Schematic

Model Power(kW) Speed(rpm) Torque(Nm) weight(kg)

STJVFT55-2-**x**(1140) 55 75 7003 2100

TJVFT-250/40YC(1140) 250 90 26530 8000

TJVFT-315/60YC(1140) 315 60/75 50137/40110 10900

TJVFT-400/60YC(1140) 400 60/75 63666/50933 13500

TJVFT-450/60YC(1140) 450 60/75 71625/57300 13500

TJVFT-500/60YC(1140) 500 60/75 79583/63666 14000

TJVFT-560/60YC(1140) 560 60/75 89133/71306 14000

TJVFT-800/60YC(1140) 800 60/75 127333/101866 16000

TYJVFT-900L/80YC(10) 1000 60 159167 21000

Features of the PM Motor with Integrated VFD

The VFD synchronous motor has the characteristics of high VFD motor efficiency, energy-saving, large starting torque, excellent performance, small maintenance, and intelligent drive.

High efficiency and energy saving

The intermediate transmission link of the vfd synchronous motor is omitted, and the load is directly driven.

No rotor excitation, no rotor copper loss, high rated efficiency.

The light load area has excellent efficiency and high operation efficiency of the motor with integrated VFD.

Even VFD synchronous motor is at 0 speed, there is a relatively large torque

Heavy-duty starting: starting torque up to 2 times rated torque.

Smooth start to reduce the mechanical impact on load equipment.

Automatic step-less speed regulation according to load, reducing power consumption and prolonging the service life of load equipment.

Motor with integrated VFD has a Small starting current, reducing the impact on the power grid and reducing power grid failures.

VFD for synchronous motor has less footprint.

With integrated VFD motor technology, you can install the equipment in the narrow space as shown in our drawing.

0 notes

Text

Flame Proof Motor

https://www.ccs-motors.com/products/plame-proof-motor.html

YBUS series flameproof three-phase asynchronous motor for roadheader is special for driving the cutting part of cantilever roadheader and other similar machinery in the coal mine. The motor has the characteristics of high efficiency, largely locked torque, beautiful appearance, safe and reliable operation, long service life, excellent performance, convenient installation etc..

Parameters of the Flame Proof Motor

Voltage Range

380V-10kV

Current Range

22kW-3000kW

Advantages of the Flame Proof Motor

YBBP series flameproof three-phase asynchronous motor is matched with a variable frequency drive. The product has the advantages of high insulation, high protection level, good speed regulation performance, high starting torque, energy saving, large temperature rise margin, long service life, good performance, low noise, advanced flameproof structure, high reliability, convenient use, and maintenance, etc..

Features of the Flame Proof Motor

Robust mechanical structure with long service life;

High insulation performance and protection level;

Low noise;

High starting torque;

Deployable in hazardous environment;

Energy-efficiency;

The output frequency of the frequency converter is constant torque at 5-50Hz and constant power at 50-60Hz;

The protection grade is IP55;

The temperature resistance grade is H;

The cooling mode is shell water cooling.

Applications of the Flame Proof Motor

Applications on coal mining machinery including:

AFC

Stage Loader

Crusher

Shearer

Headroader

Belt Conveyor

Emulsion Pump

Pump Station

TBMs

Shield Machine

Winches

0 notes

Text

High IP Converter

https://www.ccs-motors.com/products/high-ip-converter.html

The solid state frequency converter adopts a relatively sealed structure, and the protection level can reach IP55. This solid state frequency converter is a high frequency to low frequency converter.

The frequency converter application is very extensive. This solid state frequency converter is suitable for dust environments, high-temperature environments, low-temperature environments, corrosive environments,s and other dangerous environments such as combustible gas and explosion.

Parameters of the High Frequency to Low Frequency Converter

Voltage Range

1140V-3300V

Power Range

1000kW-10000kW

What is a Static Frequency Converter

Static frequency converter is divided into AC-AC frequency converter and AC-DC-AC frequency converter in structure. It is divided into voltage source frequency converter and current source frequency converter from the nature of power supply.

Static Frequency Converter Working Principle

Static frequency converter is a kind of power electronic power supply device which can provide simultaneous change of frequency and voltage. It can be divided into two categories: indirect frequency converter and direct frequency converter. Indirect frequency converter first rectifies the power frequency AC power supply into DC with controllable voltage, and then converts it into variable frequency AC through inverter, which is also called AC-DC-AC frequency converter. Direct frequency converter converts power frequency AC into variable frequency AC at one time, so it can be called AC-AC frequency converter. Indirect frequency converter is widely used.

Features of the Power Frequency Converter

The power frequency converter has high-protection container structure;

Solid state frequency converter has multiple output converter;

Built-in lightning protection and surge protection;

Solid state frequency converter is small in size and high in power density;

High heat dissipation efficiency, low temperature and low noise of solid state frequency converter;

The freezing environment can be cooled by refrigerant;

Modular design is adopted inside the solid state frequency converter, which is good for mounting abd convenient for maintenance.

Static Frequency Converter Applications

Solid state frequency converter on fracturing equipment used to extract oil and shale gas. Fracturing truck should be used for various fracturing operations of oil, gas and water wells, and can also be used for hydraulic sandblasting, high-pressure hydraulic coal mining in coal mines, high-pressure hydraulic derusting in ships and other operations. Static stop frequency converter can be used to drive fracturing pump.

0 notes

Text

High Ingress Motor

https://www.ccs-motors.com/products/high-ingress-motor.html

We can supply high ingress protection motors for excavators, bucket wheel stackers, reclaimers at ports, and fracturing machinery for oil and gas.

Features of the High Ingress Motor

High insulation performance and large starting torque;

Small size and light weight;

Long service life.

1 note

·

View note

Text

FREQUENCY CONVERTER

https://www.ccs-motors.com/products/frequency-converter/

The frequency converter is also called voltage and frequency converter. CCS has mastered the most advanced frequency conversion speed regulation technology. We can provide customers with high ingress protection converter, high ingress protection transformation converter, and explosion-proof variable frequency converters, which are widely used in special environments such as oil and gas, chemical industry, and coal mines. The power frequency converter has the characteristics of high reliability, high protection, and high efficiency, and meets the needs of customized frequency converters.

Types of Electric Frequency Converter

High IP Converter

Because of its high cabinet protection level, the frequency converter can be installed outdoors and is suitable for complex outdoor operations.

Power Transformation High IP Converter

Input voltage is 11kV or 13.8KV and it can output 2 or 3 curcuits which runs 2 or 3 motors at same time.

Explosion Proof VFD

With explosion proof certificate,this kind of VFD is allowed to run in the undermining environment.The voltage is from 380V to 1140V.

Frequency Converter Application

1. Voltage and Frequency Converter for Cooling Tower: The use of a voltage and frequency converter on a cooling tower fan is the most useful means to control leaving water temperature on critical process water applications. Frequency Converter can help save energy and reduce the noise of cooling tower in non-peak periods and benefit the life of the frequency converter components with fewer starts, smoother starts, and built-in motor diagnostics.

2. Voltage and Frequency Converter in Mining Applications: Voltage and frequency converter are now finding wide use in mining applications.

3. Voltage and Frequency Converter for Water Pumps: The installation of voltage and frequency converter on water pumps can be an effective energy saving measurement. Voltage and frequency converter can be installed on all water pumps, including those associated with HVAC systems.

Benefits of Using Frequency Converters

1. Speed regulation and saving energy, which can save energy by lowering the motor speed when it is not necessary to run at full speed.

2. Soft start can be used to prolong the service life of the voltage and frequency converter.

3. The motor control system is simplified.

4. Reduce mechanical wear and loss.

How does A Frequency Converter Work?

The electric frequency converter mainly adopts AC-DC-AC mode, which first converts the power frequency AC power supply into DC power supply through the rectifier, and then converts the DC power supply into AC power supply with controllable frequency and voltage to supply the motor. The voltage and frequency converter converts a basic fixed-frequency, fixed voltage sine-wave power (line power) to a variable-frequency, variable-voltage output used to control speed of induction motors.

Frequency Converter VS VFD

1.Power Supply: VFD is composed of AC-DC- AC (modulation wave) circuits. Voltage and frequency change proportionally at the same time and can not be adjusted separately, which does not meet the requirements of the AC power supply. In principle, it can not be used for power supply, and VFD is generally used for speed regulation of three phase asynchronous motor. The whole circuit of frequency converter consists of AC-DC-AC-Filter Circuit, so the output voltage and current waveform are pure sinusoidal, which is very close to the ideal AC power supply. Voltage and frequency converter can output the power grid voltage and frequency of any country in the world.

2.Load Test: VFD(variable frequency drive motor) can't use in load tests because of high vibration and electromagnetic noise, large temperature rise, and the instruments can't work normally. So the voltage to frequency converter that can provide a pure sine wave output becomes indispensable power equipment in the laboratory.

3. Converter: A VFD is not a typical converter though it has conversions inside it. A voltage frequency converter would typically convert a DC signal to an AC signal.

FAQs of Frequency Converter

1

What is a frequency converter?

The frequency converter is one of the electrical control devices that uses frequency conversion technology and microelectronics technology to control AC motor by changing the frequency of the motor working power supply.

The inverter is mainly composed of a rectifier (AC to DC), filter, inverter (DC to AC), braking unit, driving unit, detection unit and micro-processing unit. The inverter adjusts the voltage and frequency of the output power supply by the interruption of IGBT, and provides the required power supply voltage according to the actual needs of the motor, so as to achieve the purpose of energy saving and speed regulation. In addition, the inverter has many protection functions, such as overcurrent, overvoltage and overload protection, etc.

What is static frequency converter?

Static inverters are devices that convert a fixed voltage and frequency to a different voltage and frequency. The working principle of the static frequency converter is to convert the fixed grid power supply from alternating current to direct current through internal electronic components.

What is frequency of conversion?

Frequency conversion can also be referred to as volt-to-frequency conversion. After the voltage signal is converted into a pulse signal, the anti-interference ability of the signal can be significantly enhanced, and it is also conducive to long-distance transmission.

What are the main parts of frequency converter?

1. Main circuit: "rectifier" for converting power supply into DC power, "smoothing loop" for absorbing voltage ripple generated by converter and inverter, and "inverter" for converting DC power into AC power.

2. Rectifier: The power frequency power supply is converted into a DC power supply.

3. Smoothing loop: Suppress voltage fluctuation.

4. Inverter: Contrary to a rectifier, the inverter converts DC power into AC power of the required frequency.

5. Control circuit: The loop where the main circuit provides control signals.

What is the frequency converter working principle?

How frequency converter works? The electric frequency converter mainly adopts AC-DC-AC mode (VVVF frequency conversion or vector control frequency conversion), which first converts the power frequency AC power supply into DC power supply through the rectifier, and then converts the DC power supply into AC power supply with controllable frequency and voltage to supply the motor.

Which industries need electric frequency converters?

The main function of the electric frequency converter is frequency conversion and speed regulation, which is widely used. Coal mine, port, metallurgy, chemical industry, paper making, machinery and other industries. The electric Frequency converters can be used in places where speed regulation is needed.

What is a frequency converter used for?

An electric frequency converter is a device that converts power. The fixed-voltage power can be converted into a variable voltage by using the frequency converter. Unlike the VFD (variable frequency drive motor), the electric frequency converter is more like an ideal AC power supply. Manufacturers manage to lower the price of electric frequency converters with new technologies, attracting more and more countries to choose it as the standard one for power supply.

0 notes

Text

Explosion Proof VFD

https://www.ccs-motors.com/products/explosion-proof-vfd.html

The explosion proof VFD is committed to intelligent control of mining. Our explosion proof electric motor can improve the efficiency of the equipment, and reduce the maintenance of the complete set of equipment. The explosion proof electric motor operates reliably to ensure production safety. Our ATEX and IEC explosion-proof motor has advanced design concepts and independent intellectual property rights, and have reached the international advanced level in terms of functionality and reliability.

Explosion Proof Motor Specifications

Input Voltage

660V/1140V

Input Frequency

50Hz/60Hz

Output Voltage

0-660V/1140V

Output frequency

0-50Hz/60Hz

Power semiconductor

IGBT, Diode

Input side of VFD

Standard:6 pulse diode rectifier

Option:6 pulse IGBT rectifier

Quadrant

Standard:2-Q

Option: 4-Q

Frequency Resolution

0.01Hz

Overload capacity

220%

Communication

Internet、CAN、RS485

IP

IP54, water cooling.

Features of the Explosion Proof VFD

The software system of explosion proof electrical equipment has built-in control programs such as a scraper, conveyor, and pumping station;

Direct torque control has high control precision, fast dynamic response speed, and output torque greater than 2.2 times rated torque, which is suitable for heavy load starting occasions.

Explosion proof VFD adopts CAN bus communication to realize master-slave control and power balance of multiple devices, and optical fiber communication is supported to realize data transmission and control;

ATEX explosion proof VFD uses Long-life thin-film capacitors;

This electrical transmission equipment has various protection functions such as overload, overvoltage, under-voltage, phase shortage, overheating, power imbalance, short circuit, etc.

Our ATEX explosion proof VFD is equipped with high quality explosion proof electrical panels, connectors, enclosures, junction boxes, outlets and other explosion proof electrical boxes and fittings.

Explosion Proof Electric Motor Classifications

The types of explosion-proof electric motors can be classified according to the following aspects:

1. Principle of motor

Explosion proof VFD motor can be divided into explosion-proof asynchronous motor, explosion-proof synchronous motor and explosion-proof DC motor.

2. Place of use

Explosion proof VFD motorcan be divided into explosion-proof motors used in coal mines and explosion-proof motors used in factories.

3. Explosion-proof principle

Explosion proof VFD motor can be divided into flameproof motor, increased safety motor, positive pressure motor, spark-free motor and dust explosion-proof motor.

4. Matching mainframe

Explosion proof VFD motor can be divided into explosion-proof motor for coal mine conveyor, explosion-proof motor for coal mine winch, explosion-proof motor for scraper, explosion-proof motor for local fan in coal mine, explosion-proof motor for fan, etc. In addition, it can also be divided according to technical indicators such as rated voltage and efficiency, such as high-voltage explosion-proof motor and low-voltage explosion-proof motor.

How to choose An Electric Explosion Proof Motor?

Selection principle of explosion-proof electric motor

1. Identify the nature and types of application places.

2. For gas explosive places, zoning should be determined according to the degree of danger.

3. Identify the temperature group of the application place.

4. For flameproof, safety-increasing and positive pressure ventilation explosion-proof motors, the use places should be considered are class or class; Spark-free motor and dust explosion-proof motor can only be used in similar places.

5. Identify the explosion-proof level.

6. If safety-increasing or positive pressure explosion-proof motors are selected, corresponding protection devices should be considered, otherwise the safety of explosion-proof cannot be guaranteed.

Application of the Explosion Proof VFD

Frequency converter application is very extensive, and explosion proof DC motor also has its own unique uses.

The explosion proof VFD is mainly used for heavy load starting and full speed regulation of scraper conveyor, transfer machine, belt conveyor, coal mine TBM and other equipment with rated voltage of 3300v / AC1140v / AC660V, and can be used for the emulsion pump station, water pump, endless rope winch, permanent magnet synchronous motor (including electric drum), ventilator and other occasions requiring frequency conversion speed regulation.

0 notes

Text

ELECTRICAL TRANSMISSION & POWER CONTROL EQUIPMENT IN CCS ELECTRIC

https://www.ccs-motors.com/products/

We at CCS can provide customers with a variety of electrical transmission equipment and electrical control solutions, which can meet the needs of various working conditions. We strictly control the quality, from raw material procurement to factory test, and all is in accordance with IEC standards.

As a professional power control equipment company, CCS has been providing mining with highly reliable electrical transmission equipment for more than 10 years. Recently, our customers have gradually expanded to oil and gas, port, steel, and other fields.

Types of Electrical Transmission & Power Control Devices

Why Choose Electrical Transmission & Power Control Equipments in CCS Electric

Professional Manfacturer

The company, with a complete system for R&D, design, manufacturing, marketing, and maintenance service, is professional in the manufacturing of high-quality electrical transmission equipment & electrical control equipment.

Well-equipped Production Facilities

We have a large-scale motor assembly machine, motor automatic assembly machine, intelligent CNC winding machine, iron core automatic stacking equipment, solid insulation vacuum casting equipment, inverter production line, vertical machining center, and other production equipment.

Complete Test Platform

CCS has an advanced 12MW loading test platform, high-precision power analyzer, power frequency, and turn to turn to withstand voltage tester, torque tester, and other facilities of the test and inspection center, and has obtained ISO9001 quality management system certification.

Good Development Prospect

With the increasing demand for electrification and intelligence in the industrial field, CCS electrical control devices have a broad market prospect in the industries of engineering, port, shipping, metallurgy, cement and other industries.

FAQs about Electrical Transmission & Power Control Equipments

Q.

What is electrical transmission equipment?

A.

Electrical power transmission equipment refers to various components that allow for internal parts to operate properly in machinery. These items typically include belts, chains, couplings, pulleys, sprockets, bushings, hubs, bearings, linear actuators, slide rails, bevel gears, worm gears, and various other components.

Q.

What are the types of power transmission system?

A.

4 Types of Power Transmission – Mechanical, Electrical, Hydraulic, and Pneumatic (Pros & Cons) The transmission method is an engineering method that matches the power machine and the working part of the machine in terms of energy configuration, movement speed, and motion form.

Q.

What material is used for electrical transmissions?

A.

Copper, aluminum, and steel are the primary conductor materials used in electrical power systems. Other types of conductors such as silver and gold are actually better conductors of electricity; however, cost prohibits wide use of these materials.

0 notes

Text

High Ingress Protection VFD Motor

High Ingress Protection VFD motor is mainly used in excavators in the field of construction machinery, port bucket wheel stacker-reclaimer, and electric drive fracturing complete sets of equipment matched with fracturing skids and sand mixers in oil well sites. The company's series of products have AC and DC, of which AC power supply products adopt AC power supply and adopt integrated design, with small volume, compact structure, saving installation space, high efficiency and energy saving, and are mainly used in construction machinery, ports and other fields; DC power supply products adopt DC power supply, inverter part, and motor part are combined into a whole, with high protection level, and are mainly used in oil well sites and other fields.

Specifications of the High Ingress Protection VFD Motor

Model

Power(kW)

Voltage(V)

Current(A)

Speed(r/min)

Insulation

Ingress

protection

YKVFT-450-6

400

600

450

580

H

IP44

YKVFT-450-6

500

600

565

690

H

IP44

YKVFT-630-6

1200

600

1337

580

H

IP44

YVFT-500-6

1500

600

1750

750

H

IP44

YKVFT-355-4

315

600

354

2200

H

IP54

YKVFT-315M-4

110

380

200

1485

H

IP44

YVFT-315M-4

132

380

260

1490

H

IP44

YKVFT-315L2-4

200

380

355

1490

H

IP54

YKVFT-315L3-4

280

380

500

1480

H

IP54

YKVFT-355L-4

315

380

600

1800

H

IP54

YKVFT-450-6

400

450

807

1000

H

IP44

Features of the High Ingress Protection VFD Motor

Optional AC or DC power supply

Compact structure for space saving

High efficiency and energy saving

High protection

Application of the High Ingress Protection VFD in Motor

Applications on electric frac spread for oil &gas and contruction equipment such as excavators,bucket wheel stacker.

https://www.ccs-motors.com/products/high-ingress-protection-vfd-motor.html

0 notes

Text

High Ingress Motor

We can supply high ingress protection motors for excavators, bucket wheel stackers, reclaimers at ports, and fracturing machinery for oil and gas.

Features of the High Ingress Motor

High insulation performance and large starting torque;

Small size and light weight;

Long service life.

https://www.ccs-motors.com/products/high-ingress-motor.html

0 notes

Text

FREQUENCY CONVERTER

CCS has mastered the most advanced frequency conversion speed regulation technology. We can provide customers with high ingress protection converter, high ingress protection transformation converter, and explosion-proof variable frequency converters, which are widely used in special environments such as oil and gas, chemical industry, and coal mines. The frequency converter has the characteristics of high reliability, high protection, and high efficiency, and meets the needs of customized frequency converters.

Types of Electric Frequency Converter

High IP Converter

Because of its high cabinet protection level, the frequency converter can be installed outdoors and is suitable for complex outdoor operations.

Power Transformation High IP Converter

Input voltage is 11kV or 13.8KV and it can output 2 or 3 curcuits which runs 2 or 3 motors at same time.

Explosion Proof VFD

With explosion proof certificate,this kind of VFD is allowed to run in the undermining environment. The voltage is from 380V to 1140V.

What Is a Frequency Converter Used For?

A frequency converter is a device that converts power. The fixed-voltage power can be converted into a variable voltage by using the frequency converter. Unlike the VFD, the frequency converter is more like an ideal AC power supply. Manufacturers manage to lower the price of frequency converters with new technologies, attracting more and more countries to choose it as the standard one for power supply.

https://www.ccs-motors.com/products/frequency-converter/

0 notes

Text

Flameproof Permanent Magnet Motorized Pulley

Flameproof Permanent Magnet Motorized Pulley is a further development of permanent magnet direct drive system, which integrates permanent magnet synchronous frequency conversion motor with belt conveyor drive drum and truly realizes mechatronics. The special frequency converter not only inherits the advantages of a permanent magnet direct drive system, but also has the characteristics of further eliminating low-speed coupling, occupying very little space, convenient installation, and construction, etc..

Features of the Flameproof Permanent Magnet AC Synchronous Motor Pulley

l The outer rotor structure has no reducer mechanism inside, the permanent magnet synchronous electric roller shaft is stationary and the outer rotor rotates when working;

l The outer rotor permanent magnet is embedded and installed, which effectively protects the permanent magnet, has no risk of falling off, and has high reliability;

l The low-speed coupling is omitted, and the transmission efficiency is higher;

l Ceramic encapsulation, good wear resistance.

Application of the HP Explosion Proof Permanent Magnet Motorized Pulley

Application on belt conveyors.

https://www.ccs-motors.com/products/flameproof-permanent-magnet-motorized-pulley.html

0 notes

Text

Flame Proof Asynchronous VFD Motor

The VFD motor can run in hazardous environments, such as Coal companies and chemical plants.

Flameproof and intrinsically safe high-voltage integrated VFD Motor is a highly integrated product of the motor and the drive. It is widely applicable to belt conveyors, loaders, AFC's, emulsion pumping stations, and other equipment used in underground coal mining that matches with the motor and has the same size, to achieve a soft start under heavy load and dynamic speed control.

We can provide all kinds of explosion-proof certification according to the needs of customers in different countries.

Specifications of the Flame Proof Asynchronous VFD Electric Motor

Voltage range

380V/400V/600V/660V/3300V/4160V/6000V/6600V/10000V

Frequency

50Hz/60HZ

Voltage fluctuation range at grid

-0.25

Frequency fluctuation at grid

±0.2Hz

Speed range

0-2200rpm

Output frequency

0-120Hz

Power rating

45kW-2000kW

VFD principle

Voltage source inverter

Motor type

Asynchronous motor

Control method

V/F or DTC without sensor

Starting torque

2 times

Frequency resolution

0.01Hz

Ingress protection

IP54 pr IP55

Installation

IMB3 or IMB5

Communication

CAN、RS485、Profinet、Ethernet IP etc

Features of the Flame Proof Asynchronous VFD Motor

l Small impact to the grid and the the machinery

l Less maintenance cost

l Improve system efficiency

l Space saving

l Anti-interference

Applications of the Flame Proof Asynchronous VFD Motor

Our manufacturing programme for induction asynchronous squirrel-cage motors includes motors used, among others, for:

l belt and armoured conveyors

l longwall shearers and roadheaders

l pumps

l fans

l plow systems

https://www.ccs-motors.com/products/flame-proof-asynchronous-vfd-motor.html

0 notes

Text

Explosion Proof VFD

The explosion proof VFD is ommitted to intelligent control of mining. Improve the efficiency of the equipment, reduce the maintenance of the complete set of equipment, reliable operation to ensure production safety. With advanced design concepts and independent intellectual property rights, it has reached the international advanced level in terms of functionality and reliability.

Specifications of the Explosion Proof VFD

Input Voltage

660V/1140V

Input Frequency

50Hz/60Hz

Output Voltage

0-660V/1140V

Output frequency

0-50Hz/60Hz

Power semiconductor

IGBT, Diode

Input side of VFD

Standard:6 pulse diode rectifier

Option:6 pulse IGBT rectifier

Quadrant

Standard:2-Q

Option: 4-Q

Frequency Resolution

0.01Hz

Overload capacity

220%

Communication

Internet、CAN、RS485

IP

IP54, water cooling.

Features of the Explosion Proof VFD

l The software system has built-in control programs such as a scraper, conveyor, and pumping station;

l Direct torque control has high control precision, fast dynamic response speed, and output torque greater than 2.2 times rated torque, which is suitable for heavy load starting occasions.

l CAN bus communication is adopted to realize master-slave control and power balance of multiple devices, and optical fiber communication is supported to realize data transmission and control;

l Long-life thin-film capacitors are used;

l The frequency converter has various protection functions such as overload, overvoltage, under-voltage, phase shortage, overheating, power imbalance, short circuit, etc.

Application of the Explosion Proof VFD

The explosion proof VFD is mainly used for heavy load starting and full speed regulation of scraper conveyor, transfer machine, belt conveyor, coal mine TBM and other equipment with rated voltage of 3300v / AC1140v / AC660V, and can be used for the emulsion pump station, water pump, endless rope winch, permanent magnet synchronous motor (including electric drum), ventilator and other occasions requiring frequency conversion speed regulation.

https://www.ccs-motors.com/products/explosion-proof-vfd.html

0 notes