Indolift's chain pulley blocks is available in the VC-B and VC-A series

Don't wanna be here? Send us removal request.

Text

What Safety Precautions Should Be Taken When Using a Chain Pulley?

Chain pulley, also known as hand chain hoists, are essential tools in various industries for lifting and moving heavy loads. While they offer mechanical advantages, imprope use can lead to accidents, equipment damage, or serious injuries. This guide outlines the critical safety precautions to ensure safe and efficient operation.

1. Understanding the Equipment

Familiarize yourself with the specific model of the chain pulley you're using. Refer to the manufacturer's for detailed instructions on operation, maintenance, and safety guidelines.

Key Components:

Hand Chain: Used to ly operate the hoist.

Load Chain: Bears the weight of the load.

Hooks: Connect the hoist to the load and the support structure.

Brake System: Prevents the load from slipping or falling

2. Pre-Operational Checks

Before using the chain pulley, conduct thorough inspections:

Visual Inspection: Check for any visible damage, wear, or deformities on the chains, hooks, and body of the hoist.

Load Chain Condition: Ensure the load chain is clean, lubricated, and free from twists or knots.

Hooks and Latches: Verify that hooks are not bent or cracked and that safety latches are functioning correctly.

Brake Functionality: Test the brake system to ensure it holds the load securely.

Identification and Markings: Confirm that the hoist has clear identification labels, including the Safe Working Load (SWL) and manufacturer's details.

3. Load Assessment and Planning

Determine Load Weight: Accurately assess the weight of the load to ensure it does not exceed the hoist's rated capacity. Overloading can lead to equipment failure and accidents.

Center of Gravity: Identify the load's center of gravity to ensure stable lifting and prevent swinging or tipping.

Path Clearance: Plan the lifting path to avoid obstacles and ensure a clear area for operation.

4. Proper Setup and Rigging

Secure Attachment: Attach the hoist to a suitable and stable support structure capable of handling the load's weight.

Use Appropriate Slings: Employ the correct slings or lifting attachments for the load, ensuring they are in good condition and properly rated.

Avoid Side Loading: Ensure the load is applied vertically to prevent side loading, which can damage the hoist and compromise safety.

5. Safe Operating Practices

Trained Personnel: Only trained and authorized individuals should operate the chain pulley.

Smooth Operation: Operate the hand chain smoothly to lift or lower the load, avoiding sudden jerks or rapid movements.

Stay Clear: Keep all personnel clear of the load during lifting operations. Never stand or pass under a suspended load.

Controlled Movement: Use tag lines to control the load's movement and prevent uncontrolled swinging.

Avoid Shock Loading: Do not allow the load to drop suddenly, as this can cause shock loading and damage the hoist.

6. Emergency Preparedness

Emergency Stop: Be familiar with the hoist's emergency stop mechanism and ensure it is functioning correctly.

Load Lowering: In case of power failure or malfunction, have a plan to safely lower the load without relying solely on the hoist's brake system.

First Aid: Ensure first aid kits are accessible, and personnel are trained to respond to potential injuries.

7. Maintenance and Storage

Regular Maintenance: Follow the manufacturer's maintenance schedule, including lubrication, part replacement, and thorough inspections.

Record Keeping: Maintain detailed records of inspections, maintenance, and any repairs conducted on the hoist.

Proper Storage: Store the hoist in a clean, dry environment to prevent corrosion and damage.

8. Common Mistakes to Avoid

Overloading: Never exceed the hoist's rated capacity.

Improper Use: Do not use the hoist for horizontal pulling or as a sling.

Unauthorized Modifications: Avoid making unauthorized modifications to the hoist.

Neglecting Inspections: Do not skip pre-use inspections, even if the hoist appears to be in good condition.

Untrained Operators: Ensure only trained personnel operate the hoist.

Safety is paramount when operating a chain pulley. By understanding the equipment, conducting thorough inspections, following proper setup and operating procedures, and adhering to maintenance schedules, you can ensure a safe and efficient lifting operation. Always prioritize safety to protect personnel and equipment.

#chain pulley blocks#industrial equipment#lifting solutions#material handling#chainblock#chainblockpulley#manualchainpulleyhoist#pulleyblocksystem#chainpulley#construction

0 notes

Text

How Does a Chain Pulley Work? | Simple Explanation with Animation

In this video, we break down the mechanics behind a chain pulley system – also known as a chain block or manual hoist. Learn how this simple yet powerful tool makes lifting heavy loads easier using gears, chains, and physics!

✅ Topics Covered:

What is a chain pulley? Parts of a chain pulley block How the gear mechanism multiplies force Real-life applications Advantages and safety tips

#chain pulley blocks#industrial equipment#lifting solutions#chainblockpulley#material handling#chainblock#manualchainpulleyhoist#pulleyblocksystem#chainpulley#construction

0 notes

Text

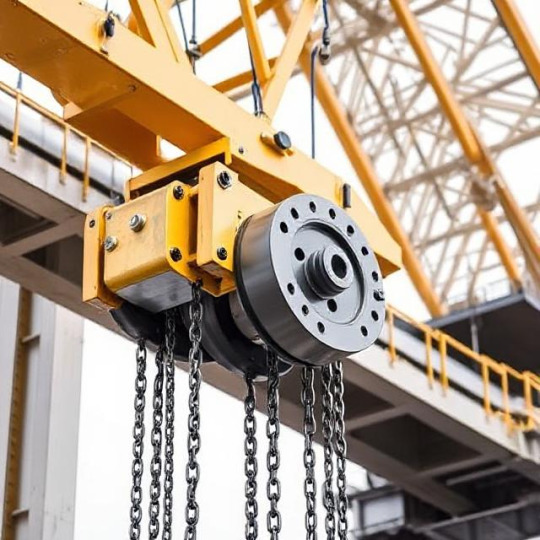

Optimizing Load Handling: The Role of Chain Pulleys in Modern Crane Design

In the world of heavy lifting, cranes are the undisputed giants—commanding skylines, dominating construction sites, and moving materials that would otherwise be impossible to handle. But inside these steel titans, there’s often an unsung hero doing the heavy work behind the scenes: the chain pulley.

Whether it's a compact jib crane in a factory or an overhead gantry system in a warehouse, chain pulleys are a vital component in many crane configurations.

What Is a Chain Pulley?

Before we dive into cranes, let’s start with the basics. A chain pulley—also known as a chain block or chain hoist—is a mechanical device used to lift, lower, or pull loads using a chain and gear mechanism. It works on the principle of mechanical advantage, allowing users to lift heavy objects with less effort.

The core components include:

Load Chain: Connects to the load and moves vertically.

Hand Chain: Pulled by the operator (or motorized in electric models).

Gearing System: Multiplies the input force.

Hook or Lifting Eye: Connects to the crane or lifting structure.

Chain pulleys come in manual and electric variants and are used in industries ranging from automotive and construction to warehousing and marine.

The Role of Chain Pulleys in Crane Operations

While large-scale tower cranes or mobile cranes typically use wire rope systems, many other crane types—especially for small to medium lifting tasks—utilize chain pulley blocks as their primary lifting mechanism.

Common Crane Types That Use Chain Pulleys:

Jib Cranes (Wall-mounted or Pillar-mounted)

Gantry Cranes (Mobile and Portable)

Overhead Cranes (Bridge cranes in warehouses)

Workstation Cranes

Portable Cranes used in workshops and maintenance areas

How Does a Chain Pulley Work Within a Crane?

In a crane setup, the chain pulley typically hangs from the trolley or boom of the crane. The lifting chain is connected to the load, and when the hand chain is pulled (or the motor is activated), the internal gears rotate, pulling the load chain and lifting the object.

This allows for:

Vertical lifting of loads

Precise control over lift height

Manual or powered operation

Safe, controlled movement of materials

Especially in environments where space is tight or power access is limited, chain pulley systems in cranes provide an elegant, efficient solution.

Benefits of Using Chain Pulleys in Cranes

1. Cost Efficiency

Chain pulley blocks are significantly cheaper than wire rope hoists or hydraulic systems. They are ideal for small operations, repair shops, and businesses on a budget.

2. Precision Lifting

Thanks to the gear mechanism, chain pulleys offer smooth and accurate lifting, which is essential in delicate assembly tasks or when aligning heavy components.

3. Compact & Space-Saving

Manual and electric chain hoists are compact in design, making them perfect for tight workspaces or cranes operating indoors.

4. Low Maintenance

Fewer moving parts mean less frequent breakdowns. Chain pulley systems are easy to inspect, maintain, and repair compared to complex hydraulic setups.

5. Versatile Applications

From hoisting engines to lifting molds, chain pulley-equipped cranes can handle a wide variety of materials and shapes.

Applications of Chain Pulley Cranes

1. Manufacturing Plants

A wall-mounted jib crane with a chain pulley hoist is ideal for lifting machine parts, dies, and equipment in small-scale manufacturing.

2. Construction Warehouses

Portable gantry cranes with chain pulley blocks can help move heavy bags of cement, steel bars, or prefabricated panels in temporary setups.

3. Automotive Workshops

Mechanics often use chain pulleys with engine hoists or small gantry cranes to lift vehicle engines safely and efficiently.

4. Shipbuilding Yards

Marine-grade electric chain hoists on overhead cranes help lift and position propellers, engines, and other bulky components.

5. Assembly Lines

Cranes fitted with chain pulleys offer repeatable, safe lifting in assembly processes, such as fitting gearboxes into machines.

Limitations of Chain Pulley Use in Cranes

While chain pulleys are incredibly useful, they do have limitations:

Slower Lifting Speeds compared to wire rope hoists

Limited Lift Height depending on the chain length

Not Ideal for Very Heavy Loads over 10+ tons

Manual Operation Can Be Fatiguing for frequent use

If your operation involves extreme lifting heights or very heavy loads, consider a wire rope hoist or hydraulic system instead. But for everything else—chain pulley blocks often offer the perfect balance.

Safety Tips for Using Chain Pulleys in Cranes

Safety is paramount in lifting. Here are best practices when using chain pulley systems in crane applications:

Inspect Before Each Use – Look for wear, deformation, or broken chains.

Check Load Capacity – Never exceed the rated WLL (Working Load Limit).

Use Proper Mounting – Ensure the chain pulley is securely attached to the crane’s hook or beam.

Wear PPE – Gloves, helmets, and steel-toe boots are essential.

Train Operators – Make sure only certified or trained personnel handle crane-lifting operations.

Choosing the Right Chain Pulley for Your Crane

When selecting a chain pulley block for your crane, consider the following:

Load Capacity: Match the heaviest load you’ll lift

Lift Height: Make sure the chain length suits your crane’s reach

Frequency of Use: Go electric for frequent tasks

Environmental Conditions: Opt for stainless steel or galvanized units for outdoor or marine use

Compliance: Ensure the product meets safety standards (IS 3832, EN 13157, ASME B30.16)

While they may not be the flashiest component on a crane, chain pulley systems are the quiet powerhouses behind many lifting operations. From construction to manufacturing, chain pulleys enable cranes to do what they do best: lift safely, precisely, and efficiently.

So next time you see a crane lifting a load with ease, remember—it might just be the humble chain pulley doing the hard work in the background.

#chain pulley blocks#industrial equipment#lifting solutions#chainblockpulley#chainblock#material handling#manualchainpulleyhoist#pulleyblocksystem#chainpulley#construction#crane

0 notes

Text

Chain Pulley vs. Lever Hoist: Which One is Right for Your Job?

Chain Pulley vs. Lever Hoist: Which One is Right for Your Job?

Lifting heavy loads is a common challenge in industrial and construction settings. To make the task easier and safer, chain pulleys and lever hoists are two widely used tools. While both serve the purpose of lifting and moving materials, they work differently and are suited for different tasks. Choosing between them depends on factors like effort, load capacity, stability, and precision. This article breaks down the key differences to help you decide which tool is best for your specific needs.

What is a Chain Pulley?

A chain pulley, also called a chain block or manual chain hoist, is a lifting tool that operates using a system of gears, a lifting chain, and a hook. The gear system provides mechanical advantage, allowing users to lift heavy loads with minimal effort. By pulling a hand chain, the load is raised in a smooth and controlled motion, making it an efficient choice for certain lifting applications.

Key Benefits of Chain Pulleys:

Requires less manual effort due to gear-assisted lifting.

Smooth and controlled movement reduces sudden shifts.

Can handle a range of load capacities (typically from 0.5 tons to over 20 tons).

Best for vertical lifting in warehouses, factories, and construction sites.

What is a Lever Hoist?

A lever hoist, also known as a come-along, is a hand-operated tool that lifts and pulls heavy objects using a ratcheting mechanism. Instead of a hand chain, a lever hoist requires the operator to repeatedly push and pull a handle to lift or move a load. These hoists are often used for positioning, pulling, and securing loads in addition to lifting.

Key Benefits of Lever Hoists:

Compact and portable, making them suitable for tight spaces.

Useful for pulling, securing, and adjusting loads in addition to lifting.

Typically designed for lighter loads (up to 5 tons).

Allows for precise load positioning, making it useful in assembly and rigging tasks.

Chain Pulley vs. Lever Hoist: A Side-by-Side Comparison

1. Effort and Efficiency

A chain pulley requires less effort since it uses gears to multiply force. This means a single operator can lift heavier loads without excessive strain. In contrast, a lever hoist requires more manual effort, but this can provide greater control in situations where precise load movement is necessary.

2. Best Applications

Chain Pulley: Best suited for vertical lifting in warehouses, construction sites, and factories.

Lever Hoist: Ideal for pulling, positioning, and securing loads, especially in horizontal applications.

For lifting heavy machinery, steel beams, or industrial equipment, a chain pulley may be more effective, while lever hoists are advantageous when repositioning or securing loads in place.

3. Load Capacity and Stability

Chain pulleys can handle heavier loads, with some models capable of lifting over 20 tons.

Lever hoists generally handle up to 5 tons, but offer greater flexibility in multi-directional movement.

Chain pulleys provide steady, controlled lifting, reducing the risk of sudden shifts, while lever hoists allow more control for incremental adjustments.

4. Safety and Operator Fatigue

Chain pulleys require less continuous physical effort, making them easier on the operator for prolonged use.

Their smooth lifting motion minimizes jerky movements, reducing the risk of injury.

Lever hoists require repeated manual operation, which can lead to fatigue but offers precise handling.

Both tools include built-in safety mechanisms to prevent unexpected load drops when used properly.

5. Maintenance and Durability

Chain pulleys have fewer moving parts, leading to lower maintenance needs in long-term use.

Lever hoists rely on a ratcheting mechanism, which may require more frequent maintenance due to wear over time.

Both tools should be inspected regularly to ensure safe operation.

6. Precision and Control

Chain pulleys provide smooth, stable lifting, making them ideal for:

Construction work (lifting beams into position).

Manufacturing plants (accurate positioning of heavy machinery).

Warehouses (lifting goods onto high racks).

Lever hoists excel in fine-tuned positioning, especially for pulling, securing, and incremental lifting adjustments.

When Might a Lever Hoist Be the Better Choice?

While chain pulleys are excellent for vertical lifting, a lever hoist may be the better tool for:

Working in tight spaces, where a chain pulley system is impractical.

Tasks involving pulling or securing loads rather than just lifting.

Lighter-duty applications (typically under 5 tons).

Situations where precise load positioning is needed, such as aligning machinery parts.

Both tools have their specific roles, and the best choice depends on the task at hand and the work environment.

Which One Should You Choose?

Both chain pulleys and lever hoists are valuable tools in material handling. Chain pulleys are efficient for lifting heavy loads vertically, while lever hoists provide more versatility for pulling, securing, and precise positioning.

When selecting between the two, consider load capacity, ease of use, safety, and precision. The right tool will increase productivity, reduce fatigue, and improve workplace safety, ensuring the job gets done efficiently and securely.

#chain pulley blocks#industrial equipment#lifting solutions#chainblockpulley#chainblock#material handling#pulleyblocksystem#chainpulley#manualchainpulleyhoist#indolift#construction#equipment#lever

0 notes

Text

Understanding Load Stress Calculations and Techniques to Prevent Overloading in Chain Pulley Blocks

Chain pulley blocks, also known as chain hoists, are essential tools for lifting heavy loads in industries like construction, warehousing, and manufacturing. However, improper use or overloading can lead to serious accidents, mechanical failures, and unnecessary wear and tear. Calculating load stress and adhering to load limits is vital to ensure safe and efficient operation. This article provides a detailed step-by-step guide to calculating load stress and preventing overloading on chain pulley blocks, while also exploring related safety practices.

Understanding Load Stress in Chain Pulley Blocks

Load stress refers to the force exerted on a chain pulley block when it is lifting or suspending a load. If the force exceeds the equipment's rated capacity, it can result in:

Chain deformation or breakage

Pulley malfunction

Workplace accidents or injuries

Load stress is influenced by factors such as the weight of the load, the angle of lift, the condition of the chain, and environmental factors like vibration or wind.

Step-by-Step Guide to Calculating Load Stress

Step 1: Determine the Weight of the Load

The first step in calculating load stress is knowing the total weight of the object being lifted. This information can often be found in product specifications, packaging, or through direct weighing.

Example: If you're lifting a pallet of steel rods weighing 500 kg, the load weight is 500 kg.

Step 2: Account for Additional Forces

If the load is being moved at an angle (e.g., not lifted vertically), additional forces come into play due to gravity and tension.

Use the formula for calculating the effective load based on the angle of lift:

Effective Load=Load Weightcos(θ)\text{Effective Load} = \frac{\text{Load Weight}}{\cos(\theta)}

Where:

θ\theta is the angle of the load from the vertical.

Example: If the load is lifted at a 30° angle, the effective load is:

Effective Load=500cos(30)=5000.866≈577.4 kg\text{Effective Load} = \frac{500}{\cos(30)} = \frac{500}{0.866} \approx 577.4 \, \text{kg}

Step 3: Include Dynamic Forces

Dynamic forces occur due to movement, such as accelerating or decelerating the lift. To account for this, add an extra 10–20% to the calculated load to ensure safety.

Dynamic Load:

Dynamic Load=Effective Load×1.2\text{Dynamic Load} = \text{Effective Load} \times 1.2

Example:

Dynamic Load=577.4×1.2=692.88 kg\text{Dynamic Load} = 577.4 \times 1.2 = 692.88 \, \text{kg}

Step 4: Compare with the Chain Pulley Block's Rated Capacity

The rated capacity, also called the Safe Working Load (SWL), is the maximum load a chain pulley block can safely handle. Ensure the dynamic load is within the SWL of the equipment.

Example: If your chain pulley block has an SWL of 1,000 kg, the calculated dynamic load of 692.88 kg is well within safe limits.

Preventing Overloading on Chain Pulley Blocks

Preventing overloading is not just about calculating load stress but also implementing proactive measures. Follow these best practices to ensure safety:

1. Always Know the Rated Capacity

Each chain pulley block has a rated capacity, typically marked on the equipment. Never exceed this capacity, even for short lifts or small loads.

Tip: Use a chain pulley block with a slightly higher capacity than your calculated load to allow for unexpected dynamic forces.

2. Perform Pre-Use Inspections

Regular inspections help identify potential issues that could compromise the equipment's load capacity.

Check for worn-out chains, frayed wires, and deformed hooks.

Look for signs of rust, corrosion, or misaligned components.

Ensure the load chain is properly lubricated to minimize friction.

3. Avoid Shock Loading

Shock loading occurs when a load is suddenly applied or dropped onto the chain pulley block, resulting in stress that exceeds the SWL.

Lift loads smoothly and steadily to avoid abrupt movements.

Never use the chain pulley block to catch falling loads.

4. Distribute Loads Evenly

When lifting irregularly shaped or unbalanced loads, ensure the weight is evenly distributed across the chains and hooks. Uneven weight distribution increases stress on specific components and can cause premature failure.

5. Use Safety Accessories

Enhance safety by using appropriate accessories, such as:

Load limiters: These devices automatically prevent the pulley from lifting loads beyond its rated capacity.

Overload indicators: Visual indicators that alert operators when the load exceeds safe limits.

6. Train Operators

Inadequate training is a leading cause of equipment misuse and overloading. Ensure that operators understand:

How to calculate load stress

The equipment’s SWL

Proper lifting techniques and safety protocols

7. Monitor the Environment

External factors like wind, vibration, or temperature can affect the performance of a chain pulley block. Always account for these when planning a lift.

Avoid using chain pulleys in high winds or extreme weather.

Ensure the ground is stable and free from vibrations.

Consequences of Overloading

Overloading chain pulley blocks can lead to severe consequences, including:

Equipment Failure: Overloading stresses the chain and gears, causing wear and breakage.

Workplace Accidents: Dropped loads can injure workers, damage property, or block operations.

Reduced Lifespan: Frequent overloading shortens the lifespan of the chain pulley, leading to costly replacements.

Legal Penalties: Operating overloaded equipment violates safety regulations, potentially resulting in fines or shutdowns.

Proactive Maintenance for Load Stress Prevention

In addition to calculating load stress, regular maintenance ensures the chain pulley operates at peak performance. Key maintenance practices include:

Chain Inspection: Look for elongation, kinks, or damage in the load chain.

Gear Lubrication: Regularly lubricate moving parts to reduce friction and wear.

Hook Checks: Inspect hooks for deformation or cracks.

Load Testing: Conduct periodic load tests to verify that the equipment can handle its rated capacity.

Proper calculation of load stress and adherence to load limits are critical for the safe and efficient use of chain pulley blocks. By following the steps outlined in this guide—such as calculating effective and dynamic loads, inspecting equipment, and implementing safety practices—you can significantly reduce the risk of overloading and mechanical failure. Incorporating proactive maintenance, operator training, and safety accessories further ensures that your equipment performs optimally and remains compliant with safety standards. Remember, safety in material handling isn’t just about protecting equipment—it’s about safeguarding lives and creating a more efficient work environment.

#chain pulley blocks#industrial equipment#lifting solutions#chainblockpulley#material handling#chainblock#manualchainpulleyhoist#chainpulley#pulleyblocksystem#construction#hoist

1 note

·

View note

Text

Design Considerations for Chain Pulley Blocks: Balancing Efficiency and Durability

Chain pulley blocks are indispensable tools in industries requiring the lifting and movement of heavy loads. These mechanical devices leverage pulleys, chains, and a block housing to allow operators to lift and lower loads with minimal effort. Used extensively in demanding environments like construction, manufacturing, and warehousing, their design must strike a balance between efficiency (ease of operation) and durability (long-lasting performance).

Core Functionality and Components

A chain pulley block amplifies human strength through mechanical advantage, enabling users to lift heavy loads with significantly reduced effort. Its core components include:

Pulley system: Reduces the effort required by distributing the load across multiple sections.

Load chain: Directly engages with the load and moves it vertically.

Housing: Encases and protects the internal components while ensuring structural integrity.

Drive mechanism: Operated manually or via a handle, it activates the pulley system.

The primary design goal is to ensure these components work seamlessly to deliver optimal efficiency while withstanding the rigors of heavy-duty use.

Load Capacity and Safety

The load capacity of a chain pulley block is a critical parameter influencing its safety and functionality. Designers must ensure the block can handle expected loads while maintaining stability and durability under strain. Key considerations include:

Working Load Limit (WLL): The maximum safe load the block can handle. A sufficient safety margin is essential to prevent failures caused by overloading.

Overload protection: Advanced blocks feature mechanisms such as slip clutches or safety pawls to prevent damage when loads exceed the rated capacity.

Material strength: Components like the load chain, housing, and pulleys must withstand wear, corrosion, and fatigue. High-strength steel is often used, with additional treatments or coatings for enhanced durability.

Adherence to testing standards: Compliance with standards (e.g., ISO, ANSI) ensures the block’s ability to endure frequent heavy use while maintaining safety.

Materials and Construction

The choice of materials directly impacts both the durability and efficiency of chain pulley blocks, especially in harsh industrial environments. Key material considerations include:

High-strength steel: Steel alloys are the preferred choice for frames, gears, and pulleys due to their excellent strength and resistance to deformation under heavy loads.

Corrosion resistance: For environments prone to moisture or chemicals (e.g., offshore platforms), components may be made of stainless steel or galvanized steel to prevent corrosion and extend the block’s lifespan.

Heat treatment: Components like chains and pulleys often undergo heat treatment to increase hardness, reduce wear, and prevent metal fatigue.

Lightweight housing materials: Aluminum alloys are used in housings to reduce overall weight while maintaining structural integrity, enhancing portability and ease of use.

Enhancing Efficiency and Ease of Use

Efficiency determines how much force the operator needs to lift a load. Well-designed chain pulley blocks minimize effort while maximizing usability. Key factors include:

Pulley arrangement: The number and configuration of pulleys determine the mechanical advantage. While more pulleys reduce effort, they must be balanced against size and practicality constraints.

Smooth operation: Bearings reduce friction within the pulley and chain system, ensuring smoother and more efficient operation.

Ergonomic design: Manual blocks should feature handles or ratchets designed for operator comfort, minimizing fatigue during prolonged use. For larger operations, motorized drive systems provide enhanced convenience.

Maintenance and Longevity

Durability is intertwined with maintainability. Chain pulley blocks must be easy to service to prolong their lifespan and ensure reliable performance. Design features that enhance maintainability include:

Accessible lubrication points: Gears and moving parts need regular lubrication to prevent friction and wear. Blocks with accessible lubrication ports simplify this process.

Modular design: Modular components, such as replaceable chains, pulleys, and gears, reduce the need to replace the entire unit when individual parts wear out.

Wear indicators: Some blocks feature built-in wear indicators or limit switches that alert operators to replace or repair components, preventing unexpected failures.

Regulatory Compliance

Chain pulley blocks must meet stringent safety and performance standards set by organizations like OSHA, ISO, and CE. Compliance ensures the equipment’s reliability and safety in industrial applications. Design considerations include:

Load testing standards: Blocks must be tested under conditions that simulate real-world stresses to verify their performance.

Safety features: Anti-slip mechanisms, overload protection, and fail-safe designs ensure that blocks operate safely under varying conditions.

Striking the Right Balance

Designing an effective chain pulley block requires balancing several factors:

Efficiency: By optimizing the mechanical advantage and reducing friction, manufacturers can ensure smooth operation and reduced effort for users.

Durability: High-strength materials, corrosion resistance, and modular designs extend the block’s lifespan.

Safety: Adhering to standards and incorporating overload protection safeguards users and enhances reliability.

The ideal chain pulley block is a fusion of robust construction, efficient operation, and user-friendly design. By carefully selecting materials, incorporating safety mechanisms, and optimizing the pulley system, manufacturers can create tools that perform reliably under heavy-duty conditions.

A well-designed chain pulley block not only meets the immediate needs of lifting and material handling but also minimizes downtime, reduces maintenance costs, and ensures long-term safety and reliability in industrial applications.

#chain pulley blocks#industrial equipment#lifting solutions#material handling#chainblockpulley#industrialequipment#ManualChainPulleyHoist#chainblock#chainpulley#ropeandpulley#pulleyblocksystem#hoistingequipment

0 notes

Text

Why are chain pulley blocks essential in heavy lifting operations?

Chain pulley blocks, also known as chain hoists, are indispensable tools in various industries where heavy lifting is a routine task. From construction sites to manufacturing plants, these devices are used to lift and lower heavy loads with precision, safety, and efficiency. But what makes chain pulley blocks so essential in heavy lifting operations? This article explores the critical role they play, their advantages over other lifting devices, and the specific features that make them a preferred choice in demanding industrial environments.

Understanding Chain Pulley Blocks

A chain pulley block is a mechanical device used to lift and lower heavy loads using a chain. The device operates on a simple principle: when the operator pulls the hand chain, it turns the internal gears, which then lift the load attached to the lifting chain. The mechanism is designed to multiply the force applied, allowing a person to lift heavy weights with minimal effort.

The Mechanism of Operation

The operation of a chain pulley block is straightforward yet highly effective. The device consists of several key components:

- Hand Chain: The operator pulls this to activate the lifting mechanism.

- Lifting Chain: This chain bears the load and moves it up or down.

- Gears and Sprockets: These internal components work together to multiply the input force, enabling the lifting of heavy loads.

- Hook: Attached to the lifting chain, this holds the load securely.

The simplicity of this mechanism makes chain pulley blocks not only reliable but also easy to maintain and operate, which is crucial in heavy lifting operations where downtime can be costly.

Why Chain Pulley Blocks Are Essential

High Load Capacity

One of the primary reasons chain pulley blocks are essential in heavy lifting is their ability to handle significant weights. These devices are designed to lift loads ranging from a few hundred kilograms to several tons, depending on the model. This makes them suitable for a wide range of applications, from lifting machinery in a factory to hoisting construction materials on a building site.

Precision Lifting

Chain pulley blocks allow for precise control over the lifting and lowering of loads. The hand chain mechanism gives the operator the ability to move the load slowly and accurately, which is vital when dealing with delicate or expensive equipment. This precision reduces the risk of accidents an damage, making chain pulley blocks a safer option compared to other lifting devices like forklifts or cranes, where control might be less granular.

Versatility

The versatility of chain pulley blocks is another factor that makes them indispensable. They can be used in various environments, including areas with limited space where larger lifting equipment cannot operate. Whether it’s a confined space within a factory or a remote construction site, chain pulley blocks can be adapted to fit the specific needs of the job.

Portability

Unlike many other heavy lifting devices, chain pulley blocks are relatively lightweight and portable. This portability allows them to be used in multiple locations without the need for complex installation procedures. Workers can easily move the device from one part of a job site to another, or even from one project to the next, providing flexibility and reducing the need for multiple lifting systems.

Safety Features

Safety is paramount in any lifting operation, and chain pulley blocks are designed with this in mind. Most models come equipped with safety latches on the hooks to prevent the load from slipping. Additionally, the hand chain mechanism allows the operator to maintain control of the load at all times, reducing the risk of sudden drops or shifts that could lead to accidents.

The mechanical advantage provided by the gears also means that the load is held securely even if the operator stops pulling the chain. This braking mechanism is crucial in preventing accidents, especially when lifting heavy loads that could cause significant damage or injury if they were to fall.

Advantages Over Other Lifting Devices

While there are various tools available for lifting heavy loads, chain pulley blocks offer several advantages that make them a preferred choice in many industries.

Cost-Effectiveness

Chain pulley blocks are generally more affordable than other lifting equipment, such as cranes or hydraulic lifts. Their lower cost, combined with their durability and low maintenance requirements, makes them a cost-effective solution for many businesses. This is especially important in industries where budget constraints are a concern, yet the need for reliable lifting equipment is non-negotiable.

Ease of Use

The simplicity of the chain pulley block’s design makes it easy to operate, even for workers who may not have specialized training in lifting equipment. This ease of use reduces the need for extensive training programs and allows workers to quickly become proficient in using the device. This is particularly beneficial in environments where time is a critical factor, and delays can lead to significant financial losses.

Minimal Maintenance

Chain pulley blocks require minimal maintenance compared to more complex lifting systems. Regular inspection and lubrication of the chains and gears are usually sufficient to keep the device in good working condition. This low maintenance requirement not only reduces downtime but also extends the lifespan of the equipment, providing a better return on investment.

Applications in Various Industries

The versatility and reliability of chain pulley blocks make them essential across a wide range of industries. Some of the key applications include:

Construction

In the construction industry, chain pulley blocks are used to lift heavy materials such as steel beams, concrete blocks, and construction machinery. Their ability to operate in tight spaces and lift heavy loads with precision makes them an invaluable tool on construction sites.

Manufacturing

Manufacturing plants often require the lifting and positioning of heavy machinery and components. Chain pulley blocks provide the necessary control and strength to handle these tasks safely and efficiently. They are also used in assembly lines to move parts into place, enhancing productivity.

Mining

The mining industry involves the extraction and processing of heavy materials from the earth. Chain pulley blocks are used to lift and transport these materials within the mine. Their robust design and ability to handle harsh conditions make them ideal for this demanding environment.

Warehousing and Logistics

In warehousing and logistics, chain pulley blocks are used to move heavy goods and equipment. Their portability and ease of use allow for quick and efficient handling of materials, improving workflow and reducing the risk of injury.

Marine and Offshore

The marine industry requires the lifting of heavy equipment and cargo in challenging conditions. Chain pulley blocks are used on ships and offshore platforms to manage these loads safely. Their corrosion-resistant materials ensure they perform well even in the harsh marine environment.

Future Developments and Innovations

As technology advances, chain pulley blocks continue to evolve, with manufacturers introducing new features to enhance performance and safety. Innovations such as ergonomic designs to reduce operator fatigue, and the use of advanced materials for improved durability, are making chain pulley blocks even more efficient and reliable.

In addition, digital technology is beginning to play a role in the operation of lifting equipment. Smart chain pulley blocks with sensors and connectivity features are being developed, allowing for real-time monitoring of load weight, operation time, and maintenance needs. These advancements promise to make heavy lifting operations safer and more efficient in the future.

Chain pulley blocks are essential tools in heavy lifting operations due to their high load capacity, precision, versatility, portability, and safety features. They offer significant advantages over other lifting devices, including cost-effectiveness, ease of use, and minimal maintenance requirements. Their wide range of applications across various industries underscores their importance in modern industrial operations.

As industries continue to demand efficient and safe lifting solutions, the role of chain pulley blocks is likely to grow. With ongoing innovations and improvements, these devices will continue to be a cornerstone of heavy lifting operations, ensuring that loads are moved safely, efficiently, and with the utmost precision.

#material handling#chain pulley blocks#industrial equipment#lifting solutions#industrialmachines#chainblockpulley#pulleyblocksystem

0 notes

Text

Indolift Chain Pulley Blocks – engineered for heavy-duty performance and maximum durability. With exceptional load-bearing capacity, these chain pulley blocks are perfect for extensive usage in various industrial applications.

#chain pulley blocks#industrial equipment#chainblockpulley#HandChainPulleyBlock#ManualChainPulleyHoist#chainblock

0 notes

Text

Indolift chain pulley blocks are manual lifting devices used for hoisting heavy loads. They feature a robust design with a hand-operated chain mechanism that provides mechanical advantage, making it easier to lift and lower heavy objects. These pulley blocks are commonly used in industrial settings, construction sites, and workshops. They typically include a durable steel housing, load chain, hand chain, and safety hooks. Indolift chain pulley blocks are valued for their reliability, ease of use, and ability to handle various weight capacities safely and efficiently.

#chain pulley blocks#industrial equipment#equipment#machinery#lifting solutions#material handling#indolift#industries#manufacturing#wholesale#india#kolkata

0 notes

Text

Indolift's chain pulley blocks, available in the VC-B and VC-A series, deliver dependable and effective lifting solutions across diverse applications. Engineered to accommodate varying load capacities, they ensure seamless and secure lifting operations.

#Chain Pulley Blocks#chain pulley blocks manufacturers#Steel Chain India#Lifting solutions#material handling#industrial equipment#oil and gas

0 notes