Don't wanna be here? Send us removal request.

Text

Contact Chanderpur Group for Advanced Waste to Power Generation

Turning waste into a valuable resource is a game-changer in sustainable energy solutions. Waste to power generation utilizes advanced technologies to convert municipal, industrial, and agricultural waste into electricity, reducing landfill dependence and carbon emissions. Chanderpur Group (CPG) specializes in developing high-efficiency gasification and combustion systems that maximize energy recovery. These systems not only contribute to cleaner energy but also support industries in achieving sustainability goals. By integrating cutting-edge engineering and environmental responsibility, CPG ensures reliable and cost-effective power solutions that promote a greener future while addressing global waste management challenges.

#Waste to Energy#Waste to Energy Plant#Waste to Energy Plant Technology#Waste to Power Plant#Waste to Power Generation#Generating Electricity from Waste#Waste to Energy Power Plant#Waste to Energy Through Gasification

0 notes

Text

Biomass to Electricity Generation with Advanced Technology

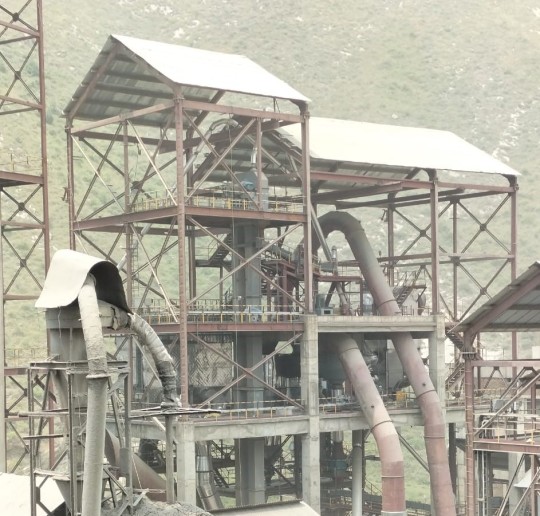

The transition to renewable energy sources has gained momentum worldwide, with biomass emerging as a sustainable and efficient solution. Biomass to electricity generation plays a crucial role in reducing carbon footprints and ensuring energy security. Our method utilizes organic materials like agricultural waste, wood chips, and other biodegradable substances to produce power efficiently.

Chanderpur Group (CPG) has established itself as a pioneer in the biomass to electricity generation sector, offering advanced gasification technologies for sustainable energy solutions. By leveraging cutting-edge engineering, CPG designs and manufactures biomass gasifiers that convert solid biomass into a combustible gas, which can be used for electricity production.

The Biomass Gasification Process

Biomass gasification is a thermal conversion process where organic materials are subjected to high temperatures in a controlled environment. This results in the production of syngas (a mixture of carbon monoxide, hydrogen, and methane), which can be used in gas engines or turbines to generate electricity. The key benefits of this process include:

High Efficiency: Biomass gasifiers ensure maximum energy extraction with minimal waste.

Reduced Emissions: Compared to fossil fuels, biomass gasification significantly lowers greenhouse gas emissions.

Versatile Fuel Sources: Agricultural residues, forestry waste, and even industrial byproducts can be utilized.

Advantages of Biomass-Based Electricity Generation

Eco-Friendly Energy Solution

Biomass is a renewable resource that helps in waste management while reducing dependency on fossil fuels. The gasification technology employed by CPG ensures clean and efficient energy conversion.

Cost-effective and Reliable

Unlike solar and wind energy, biomass power generation is not dependent on weather conditions, ensuring a steady and continuous electricity supply.

Rural Electrification and Industrial Applications

Biomass power plants can be established in remote areas, providing electricity access to communities while also supporting industries with an alternative energy source.

CPG’s Expertise in Biomass Gasification

With 60+ years of experience in the heavy engineering industry, Chanderpur Group specializes in designing and manufacturing high-quality biomass gasifiers. The company provides turnkey solutions, from feasibility studies to installation and commissioning of biomass power plants. Our expertise ensures optimal plant performance, efficiency, and longevity.

Conclusion

Biomass to electricity generation is a key player in the global shift toward sustainable energy solutions. With innovative gasification technologies and reliable engineering, CPG continues to contribute to the renewable energy sector, offering advanced solutions for industries and power generation units. Investing in biomass power not only ensures energy security but also supports a cleaner and greener future.

#Biomass to Electricity#Biomass Generate Electricity#Producing Electricity from Biomass#Biomass Energy Power Plant#Biomass Generation Plant#Biomass Power Generation Plant#Biomass Electricity Generation#Biomass Electric Power Generation#Biomass Electricity Production#Biomass Power Generation#Biomass Gasification Power Plant#Biomass Electricity Generation Plant

0 notes

Text

Why Selecting Reliable Heat Exchanger Manufacturers Matters

Heat exchangers are indispensable in industries that require precise temperature control and energy efficiency. Collaborating with experienced heat exchanger manufacturers ensures that your facility benefits from advanced designs and long-lasting products tailored to your needs.

Features of a Good Manufacturer

Engineering Excellence: Manufacturers with strong technical expertise design heat exchangers that maximize heat transfer while reducing energy loss.

Range of Products: A diverse product portfolio, including shell-and-tube, plate, and air-cooled exchangers, ensures you can find equipment for any application.

Quality Standards: Reliable manufacturers adhere to global standards like ASME or ISO, guaranteeing safe and durable equipment.

After-Sales Service: From installation support to regular maintenance, dependable manufacturers provide comprehensive customer assistance.

Why Choose Advanced Heat Exchangers?

Modern heat exchangers are built to enhance energy efficiency, reduce environmental impact, and offer seamless integration with industrial systems. Manufacturers using innovative designs help businesses achieve operational excellence.

Conclusion

Selecting the right heat exchanger manufacturers is a strategic move that ensures efficiency and reliability in thermal processes. Choose manufacturers with proven expertise, quality products, and excellent customer support to optimize your industrial operations.

#Heat Exchanger Manufacturer in India#Heat Exchanger Supplier in India#Heat Exchanger Manufacturer#Heat Exchanger Supplier#Heat Exchanger

0 notes

Text

Cement Plant Machinery Supplier for Delivering Excellence in Cement Production

Chanderpur Group stands as a leading cement plant machinery supplier, providing high-quality and efficient equipment designed for the cement manufacturing industry. With over six decades of experience, we specialize in delivering complete turnkey solutions, ensuring that each plant operates at optimal efficiency. From crushers and ball mills to rotary kilns and separators, our comprehensive range of machinery meets global quality and performance standards. As a trusted cement plant machinery supplier, we ensure timely delivery, reliable after-sales service, and continuous innovation to enhance the productivity of cement plants worldwide.

#Cement Plant Machinery Manufacturers in India#Cement Plant Machinery Suppliers in India#Cement Plant Machinery Manufacturers#Cement Plant Machinery Suppliers#Cement Plant Machinery

0 notes

Text

Prominent Manufacturers of MSW Gasifiers for Sustainable Energy

Municipal solid waste (MSW) gasifiers play a crucial role in waste-to-energy conversion, offering an effective solution for managing waste while generating valuable energy. Our systems convert organic waste materials into syngas, which can be utilized for electricity generation, heating, or as a feedstock for further chemical processing.

Components of MSW Gasifiers

MSW gasifiers typically consist of a feed system, gasification chamber, and gas cleaning equipment. The feed system introduces the waste into the gasification chamber, where it undergoes thermal decomposition in the presence of a controlled amount of oxygen or steam. Our process generates syngas, primarily composed of carbon monoxide, hydrogen, and methane. Following gasification, gas cleaning equipment removes impurities, ensuring the syngas meet quality standards for further use.

Benefits of MSW Gasification

Utilizing MSW gasifiers significantly reduces landfill waste while providing a renewable energy source. Our process not only mitigates environmental impact but also supports sustainable waste management practices, making it a valuable technology in today's energy landscape.

0 notes

Text

For all your fertilizer manufacturing needs, trust CPG, the leading SSP Fertilizer Plant suppliers, NPK Fertilizer Plant manufacturers, and Bulk Blending Fertilizer Projects experts. Contact us today to learn how we can help you elevate your agricultural production with cutting-edge solutions.

#Fertilizer Plant Manufacturers in India#Fertilizer Plant Suppliers in India#Fertilizer Plant Manufacturers#Fertilizer Plant Suppliers#Fertilizer Plant

0 notes

Text

Trusted Cement Plant Manufacturer in India with Latest Technology

When it comes to finding the best cement plant manufacturer in India, Chanderpur Group is a name that stands for innovation, quality, and reliability. With decades of experience in the industry, we become a leading supplier of state-of-the-art cement plants. Our comprehensive solutions cater to all your cement production needs, from designing and engineering to equipment supply and installation.

Our focus is on delivering customized solutions that meet the unique requirements of each client. we utilize the latest technologies and materials to ensure that every cement plant operates at maximum efficiency and sustainability. With a commitment to excellence and a passion for continuous improvement, we are dedicated to helping you achieve superior productivity and cost-effectiveness in your cement manufacturing operations.

0 notes

Text

High-Efficient Pressure Vessel Suppliers in India

Pressure vessels are indispensable in various industries, including chemical processing, oil and gas, power generation, and more. Our vessels are designed to hold gases or liquids at high pressures, making them critical for maintaining safety and efficiency in industrial operations. Selecting a reliable pressure vessel supplier is crucial to ensure our essential components' quality, durability, and safety. One name that stands out in this field is Chanderpur Group, known for its expertise, innovation, and commitment to excellence.

The Importance of Quality Pressure Vessels

Pressure vessels must adhere to stringent safety standards and regulations due to the high-risk nature of Our operation. A subpar pressure vessel can lead to catastrophic failures, endangering lives and causing significant financial losses. Therefore, choosing a supplier that guarantees top-notch quality and reliability is imperative. We are offering pressure vessels that meet the highest industry standards.

Why Choose Us?

Decades of Expertise

We bring decades of experience to the table, making them a trusted name in the industry. Our extensive knowledge and expertise enable them to design and manufacture pressure vessels that cater to the unique needs of various industries.

Innovative Solutions

Innovation is at the core of operations. we continuously invest in research and development to stay ahead of technological advancements. This commitment to innovation ensures that Our pressure vessels are built using the latest technologies and materials, providing superior performance and longevity.

Customization and Flexibility

Every industry has specific requirements when it comes to pressure vessels. We are providing customized solutions that align with the exact needs of our clients. Whether it's a small-scale operation or a large industrial plant, we can deliver tailored pressure vessels that enhance operational efficiency.

Stringent Quality Control

Quality assurance is a hallmark of us. We implement rigorous quality control measures at every stage of the manufacturing process, from raw material selection to final product testing. This ensures that every pressure vessel leaving Our facility is of the highest quality and reliability.

Comprehensive Support

We offer comprehensive support to Our clients, from initial consultation and design to installation and maintenance. Our team of experts is always ready to assist, ensuring that your pressure vessels operate smoothly and efficiently.

Applications of Pressure Vessels

Pressure vessels are used in a wide range of applications across various industries:

Chemical Processing: Safe and efficient storage and transfer of reactive and hazardous chemicals.

Oil and Gas: High-pressure storage and transportation of hydrocarbons.

Power Generation: Reliable operation of boilers, heat exchangers, and other critical components.

Food and Beverage: Maintaining the purity and safety of food-grade gases and liquids.

Conclusion

When it comes to pressure vessel suppliers, we stand out for our unmatched expertise, innovative solutions, and unwavering commitment to quality. Our ability to provide customized, high-performance pressure vessels makes them the preferred choice for industries looking to enhance Our operational efficiency and safety. Trust us to deliver the reliability and excellence you need for your pressure vessel requirements.

#Pressure Vessels Manufacturer in India#Pressure Vessels Supplier in India#Pressure Vessels Manufacturer#Pressure Vessels Supplier#Pressure Vessels

0 notes

Text

Professional Rotary Kilns Manufacturer for Industrial Applications

Chanderpur Group stands out in the industry for designing and manufacturing state-of-the-art rotary kilns. With a focus on efficiency and durability, our products cater to a variety of sectors, ensuring optimal performance and longevity. Customers trust our expertise and innovation, which have set a benchmark in the production of reliable Rotary kiln manufacturers for providing machinery to industries.

0 notes

Text

Slag Cement Grinding Units Plant Manufacturers in India

Slag cement is a hydraulic cement formed when granulated blast furnace slag is ground to fine pieces and used to replace a portion of Portland cement. It is a recovered byproduct of the iron manufacturing process. The use of slag cement demonstrated long-term performance enhancements enabling designers to decrease the environmental footprint of concrete while ensuring improved performance and enhanced durability.

As an iron byproduct, the molten slag diverted from the iron blast furnace is quickly chilled, creating glassy granules that yield desired reactive characteristics when ground into cement finesse.

The Benefits of Using Slag Cement

There are many different uses and applications of slag cement including ternary mixtures and soil stabilization to name a few. The advantages of using slag cement are:

Improved workability

Easier place ability and finish ability

Higher long-term compressive and flexural strengths

Decreased permeability.

ASR mitigation properties

Improved durability and resilience

More consistent performance

Lighter color

Strength and Durability of Slag Cement

Concrete made with slag cement offers greater compressive and flexural strengths as compared to Portland cement concrete. SCIC #14, Compressive and Flexural Strength analyses the factors that affect concrete strength and indicates how slag cement enhances both the compressive and flexural strength of concrete. advantages of higher strength include increased safety and reliability; optimized element designs that enable thinner, lighter, and fewer members in structures; optimized mixture designs that experience less shrinkage, curling, and heat; and lower life cycle costs through improved service life.

Slag Cement and Life Cycle Prediction Models, analyze how slag cement can positively affect some of the characteristics that enhance the useful life of a concrete structure and decrease life cycle cost. It includes low permeability, improved corrosion resistance, high strength, increased resistance to alkali-silica reactivity and sulfate attack and reduced thermal stress. This information sheet offers a short case study of a life cycle prediction model.

Slag Cement Specifications

A great primer for those new to the slag cement industry, SCIC #12, Terminology, and Specifications, provides definitions of 12 basic slag cement-related terms. It includes slag cement, granulated blast furnace slag, blended cement, hydraulic cement, and pozzolan. Standard ASTM specifications crucial for those working with slag cement are summarized, including ASTM C 989, ASTM C 595, and ASTM C 1157. Three pertinent ACI Committee reports also are combined. This information sheet is an amazing starting point for anyone who wants to learn more about using slag cement concrete.

The Bottom Line

So, there you have it. So, if you are looking for high-quality slag cement grinding units, visit our website to connect with our professionals.

#Cement Grinding Units Plant Manufacturers#Cement Grinding Units Manufacturers#Cement Grinding Plant Manufacturers#Cement Grinding Units#Cement Grinding Plant

0 notes

Text

Advanced Preheater Rotary Kiln for Sale in India

A preheater is a piece of equipment that extracts heat from the kiln gases to pre-heat the raw material before it is put into the kiln. In the Preheater, raw material is preheated to Calcination temperature. Rotary kilns are 7used to manufacture the following materials Titanium dioxide, Cement, Metakaolin, Vermiculite, Iron ore pellets, Lime, Refractories, etc.

Rotary kilns are classified into 5 types of kilns based on the materials processed and properties.

Cement Kilns

A cement rotary kiln is a type of lime kiln that belongs to the category of building a variety of materials. They are primarily used to calcine cement clinker and are classified into two types: dry cement kilns and wet cement kilns. The cement rotary kiln works at high temperatures with heavy-loaded materials.

Clinker Kiln

Clinker is a crushed metal or ore generated by the high-temperature crystallization of a thick powder and a metal-rich powder. It is a low-energy device that is in high demand in the manufacturing industry. A clinker rotary kiln is a high-end piece of equipment that is exclusively designed for clinker.

Bauxite Rotary Kiln

Bauxite rotary kiln is widely used to create bauxite or aluminum. It is made up of a steel shell, a tire, a driving gear, a kiln hood, a kiln seal, and a burner pipe. It is specially designed to operate in large volume mode, which is used for the industrial level.

Shaft Kiln

A shaft kiln is a type of cylindrical kiln. Materials are fed into the kiln from the top and drained from the bottom. It is divided into three different processes based on temperature ranges: preheating zone, calcining zone, and cooling zone. It has the special properties of converting waste into useful material.

Lime Rotary Kiln

A lime rotary kiln is also known as a roller rotary kiln. The process of preparing a lime is easy and adaptive. High-temperature gases can be utilized in a vertical preheater to convert lime into an initial decomposition stage.

The main function of preheater rotary kiln

Construction materials for industries

Cement manufacturing

Chemical industries

Environmental safeguards

Cost-effective factors to consider for preheater rotary kiln.

Model

CPG offers a unique line of small and medium-capacity Rotary Kilns for a variety of applications across the world. CPG’s unique design and manufacturing expertise create high-quality, creative, and cost-effective solutions based on the needs of customers.

Quality

The price of a rotary kiln is directly proportional to its quality. High-quality equipment has advanced features and advanced technology that affects the cost of equipment. The best kiln body material is moderate carbon steel or alloy steel plate. Inferior steel is used as a low-cost kiln body material. It is ideal if you are looking for low-cost equipment that saves money.

Buy preheater rotary kilns at CPG.

CPG’s enhanced inlet and outlet sealing to reduce undesired air intrusion.

CPG will determine rates based on the current scenario, making it more reasonable for customers.

CPG (Chanderpur Group) offers a unique line of small and medium-capacity Rotary Kilns across the world.

Conclusion

In this piece of content, you will find the basic use and comprehensive guide before buying a preheater rotary kiln. At the industrial level, a rotary kiln is widely used, and you should be aware of which equipment works best for you. CPG provides a wide range of preheater rotary kilns at affordable prices; you can buy high-end products from there.

0 notes

Text

Reliable Cement Plant Manufacturers for Better Performance

At Chanderpur Group, customer satisfaction is more than just a priority—it's a commitment. With a focus on transparency, reliability, and unparalleled support, the group goes above and beyond to ensure the success of its clients. Explore how our customer-centric approach is redefining the standards of excellence in cement plant manufacturers. With state-of-the-art technology and a focus on eco-friendly practices, we set the benchmark for excellence in the industry.

#cement plant manufacturers in india#cement plant suppliers in india#cement plant manufacturers#cement plant suppliers

0 notes

Text

Mineral Processing Grinding Solutions for Diverse Applications

We are your trusted partner for mineral processing grinding solutions. We offer a comprehensive range of mineral processing plants, ball mills, rod mills, and other equipment specifically designed for diverse applications. Our commitment to quality, innovation, and expert support ensures you achieve optimal grinding performance and maximize mineral processing efficiency.

0 notes

Text

Contact Our Professional Air Classifier Manufacturers

Air classifiers have an upper hand in giving great benefits to the users as compared to any ordinary form of particle classification such as ultrasonic screening and vibratory screening etc. Thinking how you would get benefits by investing in air classifiers? If yes, read further to get more details.

You get much higher throughput than traditional sieving in the fine particle size range.

Air classifiers can offer high-efficiency precision particle size cuts. You can get as fine as 1 micron in certain cases.

There are no issues with maintenance as these seek minimal maintenance and they are easy to clean too.

You can achieve narrower product size distributions.

It is also equipped with wear-resistant construction.

Overall, these air classifier separators are far better than traditional sieving and they are equipped with modern features to address the needs of modern times. When in need of the best air classifier manufacturer then you should look no further than CPG, which delivers supreme quality and proficient air classifiers.

#air classifier manufacturers#air classifier suppliers#air classifier manufacturers india#air classifier machine#air classifier#air classifier for sale#classifier equipment

0 notes

Text

Mineral Processing Plants Manufacturers and Suppliers in India

Chanderpur Group is one of the most trustworthy names in offering a myriad of high-end engineered products and turnkey products. We are a multi-solution, internationally recognized engineering company. The success lies behind many different factors such as a high level of consistency, standardization, and flexibility. Our forte is our experience of over 60 years and our dedicated skill set who are an asset to our company.

We have a great reputation for providing several cutting-edge products to different industries. Our products include ball mills, rotary kilns, material handling systems, fly ash grinding solutions, etc. Not only that, but we also have turnkey products such as cement plants, mineral processing plants, fertilizer plants, paper plants, etc. We have been supplying solutions to the industries for over 6 decades. This factor makes us the top choice for our clients.

Some exceptional factors which make us a successful company are mentioned below.

We have the specialized engineers of third and fourth engineering entrepreneurs with first-hand knowledge of technology.

We have a great expansion so we can serve our clients on the global level.

Capable, highly educated, and experienced skill-set who are working with us for prolonged years

A team of young, dedicated, and dynamic mechanical engineers, chemical engineers, process engineers, industrial engineers

Loyal vendors from micro and small companies

A flexible approach towards the industries and their needs

Our expertise in a wide array of operations such as engineering, procurement, and commissioning is matchless. Moreover, what makes us matchless is our ability to turn the success story of one industry into another sphere.

CPG has a welcoming attitude toward new mineral processing plants technologies and advancements and does not hesitate to provide our customers with the best technology. Additionally, our clients benefit from a highly advanced environment of electrical systems, energy-efficient products, and automation systems.

#mineral processing plants#mineral processing plant project#mineral processing project#mineral grinding plant

0 notes

Text

Chanderpur Group Offers the Best Vertical Shaft Cement Plants

The vertical shaft kiln, or vertical kiln, is a kind of clinker calcination equipment used in small and medium-sized cement industries. It can complete the extensive mechanized feeding, calcining, crushing, and discharging operations. The vertical shaft kiln (VSK), or vertical kiln, is a type of industrial machine used to calcinate cement clinker.

It is usually used in small and medium-sized cement plants for cement production. With the rapid development of cement production technology, the rotary kiln has replaced the shaft kiln in various regions of the world. It is a more advanced cement clinker calcination equipment. However, in the wide underdeveloped areas, the shaft kiln is still a crucial equipment for producing cement because of its low cost and simple design. If you are looking for the best vertical shaft cement plants, visit our website at Chanderpur Group.

#vertical shaft cement plants#cement manufacturing projects#cement plant project#cement project consultants#turnkey cement Projects

0 notes

Text

Contact for Fertilizer Projects with New Technology

India is the second largest producer of the firms' output where the majority of the population depends on agricultural activities for their livelihood. Growth of Industries and openings of MNCs have not yet declined the importance of agriculture in India. Economic development is not the sole function of Industrial development; it also includes the development of agriculture. Sustainable development is the need of the time and it can only be achieved through balanced growth of both the agriculture and Industrial sector. There is a popular saying “Countries are known for their greenery, and India is one of those countries. The growth of agriculture and the growth of the fertilizer Industry supplement each other. Both go hand in hand. The article attempts to present a broad view of the fertilizer Industry from an Indian perspective. Through the use of secondary data, attempts have been made to study issues like demand and supply position, consumption trends, and the growth factor of fertilizer in India.

The growth of agriculture and growth in the fertilizer Industry complement each other. The rise in agricultural output leads to increased consumption of fertilizers. Fertilizer Industry can be studied in terms of demand and supply conditions. More projects are being built in India as the demand increases.

India is now in 5th number in the consumption list of the world. So there is a need to build more fertilizer projects with new technology so that India can supply and outsource to other countries.

#fertilizer projects#fertilizer manufacturing plant#fertilizer plant manufacturers#types of fertilizer plant project#fertilizer plant project

0 notes