Text

Fiber optic technology has transformed the way the world communicates. From lightning fast internet to real time data transfer, everything links on perfectly prepared fiber connections. But before any fiber can perform at its best, it must be stripped with perfection and that’s where a high quality thermal fiber stripping tool makes all the difference.

For More Tools:

Fiber thermal stripper

Thermal stripper

0 notes

Text

Torque Wrenches: The Unsung Heroes of Perfection and Safety

In today’s world of advanced telecommunications, electrical systems, and broadcast networks, precision isn’t just a requirement, it’s fixed. One small error in torque application can mean the difference between a solid, secure connection and a catastrophic failure. That’s where torque wrenches come in. These rugged tools ensure that every connection, bolt, or fastener is tightened to exact specifications, no more, no less.

Whether you’re working on coaxial cable systems, VDV lines, or high quality electrical gear, torque wrenches are essential for ensuring long term consistency and safety.

What Is a Torque Wrench?

A torque wrench is a specialized hand tool that applies a specific amount of torque to a fastener such as a nut or bolt. Unlike regular wrenches, which rely on your feel and judgement, a torque wrench gives you control and accuracy. This is crucial in fields where over tightening or under tightening can lead to stripped threads, loose connections, or even system failures.

From electrical contractors to CATV technicians, professionals across many industries use torque wrenches to maintain performance and safety standards.

Why Torque Wrenches Matter

Here are some major reasons why torque wrenches are valuable.

1. Prevent Equipment Damage

Over tightening can damage sensitive components, especially in connectors. Torque wrenches help avoid costly repairs and ensure compliance with manufacturer specifications.

2. Ensure Consistency

When you're installing dozens (or hundreds) of connectors, consistency is key. Torque wrenches deliver the same force every time, minimizing variations.

3. Meet Industry Standards

Many telecom, VDV, and broadcast applications have torque guidelines especially in coaxial cable systems. Using the right coax torque wrench guarantees that you meet those exact standards.

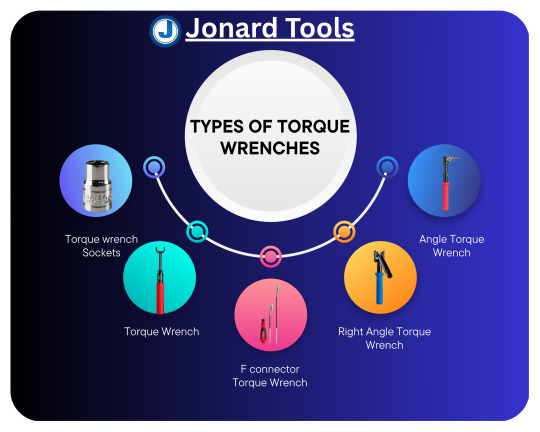

Types of Torque Wrenches You Should Know

Preset Torque Wrenches

These come with a factory set torque level, perfect for field technicians who need to move fast and stay accurate. They’re commonly used for coaxial cable terminations where perfection is mandatory.

Adjustable Torque Wrenches

These allow users to set a custom torque value. They’re ideal for technicians who deal with varying fastener specs across multiple systems.

Angle Torque Wrenches

An angle torque wrench adds an extra layer of control by measuring rotational degrees after initial torque. This is particularly helpful when working with bolts that need to be turned an additional angle post torque.

Torque Wrench Sockets

These interchangeable heads make it easy to switch between fastener sizes without switching tools, saving time in the field.

Application in the Real World

Telecom & CATV Installations

Torque wrenches are essential in telecom work, especially when dealing with coaxial connectors and splitters. A poorly torqued connector can lead to signal loss, interference, or damage to expensive equipment. A properly torqued connection ensures signal integrity and prevents callbacks.

Electrical Systems

In electrical panels, loose connections can overheat and pose fire risks. On the other hand, overtightened terminals can crush conductors or damage insulation. Torque wrenches ensure safe and reliable installations.

Broadcast & VDV Systems

Broadcast professionals rely on torque wrench sockets and angle based torque control to maintain equipment longevity and avoid micro failures in sensitive gear.

Why Professionals Trust Jonard Torque Wrenches

Jonard Tools has earned a reputation for manufacturing carefully made torque wrenches that meet the highest standards of durability, accuracy, and reliability.

Rugged Build: Built for field use, Jonard torque wrenches can withstand tough environments and repeated use.

Factory Calibrated: Each wrench is precisely calibrated to deliver accurate torque right out of the box.

Ergonomic Design: Comfortable grips reduce hand tiredness during extended use.

Specialty Options: Choose from a variety of options, including coax torque wrenches, angle torque wrenches, and compatible socket sets.

Whether you’re handling sensitive fiber terminations, setting up CATV networks, or maintaining industrial systems, Jonard’s range offers the right torque solution for your needs.

Tips for Using Torque Wrenches Effectively

Always calibrate your adjustable wrench before use.

Never use it as a breaker bar, doing so can damage the internal mechanisms.

Store properly in a dry place and in its protective case.

Avoid dropping even a slight impact can throw off calibration.

Use the correct torque rating for the application.

Final Thoughts

In the world of technical installations, precision equals performance. When your connections are torqued properly, your systems run better, last longer, and stay safer. Whether you’re an experienced field technician or a new installer, investing in a quality torque wrench is not just a smart choice, it’s a professional requirement.

Looking for Top quality tools?Explore Jonard’s full range of torque wrenches including coax torque wrenches, angle torque wrenches, and more built for CATV, telecom, and VDV professionals. Precision and performance start here.

0 notes

Text

Essential Insulated Tools for Safe and Efficient Electrical Work

When it comes to electrical installations, safety is non negotiable. Professionals rely on high quality tools not just for performance, but for protection against hazards. That’s where insulated tools from Jonard Tools come in, designed with precision, durability, and most importantly, user safety in mind.

For more Tools:

Insulated electrical tools

Insulated screwdrivers

Insulated screwdriver set

Insulated knife

Insulated pliers

#insulated knife#insulated pliers#insulated screwdriver set#insulated screwdrivers#insulated tools#insulated electrical tools

0 notes

Text

Jonard Tools offers a wide range of professional grade fiber optic tool kits designed to meet the demands of technicians working in telecom, data centers, and network installations.

For More Tools:

Fiber optic tool kit

Fiber tool kit

Fiber optic cleaning kit

0 notes

Text

For more Tools:

Fiber optic test equipment

Fiber optic testers

OTDR fiber tester

0 notes

Text

youtube

Jonard Tools torque wrenches are designed for the perfect tightening calibration. These tools are backed by our Made for Life, Lifetime Warranty policy.

For more Tools:

Torque wrenches

Angle torque wrench

Torque wrench sockets

0 notes

Text

For more Tools:

Wire stripping tool

Adjustable wire stripping tool

Wire stripper

0 notes

Text

For more Tools:

Insulated tools

Insulated electrical tools

Insulated screwdrivers

Insulated screwdriver set

Insulated knife

Insulated pliers

#insulated pliers#insulated screwdrivers#insulated screwdriver set#insulated knife#insulated tools#insulated electrical tools

0 notes

Text

Stay Safe, Work Smart: Why Every Electrician Needs Insulated Tools

Introduction

Electricity is powerful and dangerous. Whether you're fixing a circuit breaker or installing new wiring, one mistake can lead to serious injury. That's why professionals and careful about safety Do It Yourselfers rely on insulated tools. These tools are specially designed to protect you from electric shocks and give you the confidence to work around live circuits safely.

Let’s break down what insulated tools are, how they keep you safe, and which ones every electrician should have in their kit.

What Are Insulated Tools?

Insulated electrical tools have a protective coating, usually rubber or plastic that blocks electricity from passing through the tool into your hand. Unlike regular tools, these are tested and certified to handle high voltages (usually up to 1000V AC or 1500V DC).

That means even if you accidentally touch a live wire, the insulation acts like a barrier between you and the current.

Why Are Insulated Tools Important?

Without insulated tools, you’re directly exposed to the risk of:

Electric shock

Short circuits may lead to burns or damage from too much electricity.

Serious injuries from involuntary reactions (like falling or jerking)

These dangers are not just theoretical. Every year, thousands of professionals are injured because they use the wrong tools around electricity.

With certified insulated screwdrivers, pliers, and knives, you reduce those risks dramatically.

Graph Insight: Electrician Injury Risk

Here’s a simple comparison of the risk levels when using different tool types:

Tool Type-----------------Shock Risk (%)

Bare metal tool------------------90%

Regular plastic handle tool----- 50%

Certified insulated tool-----------5%

Using the right tools reduces your risk by over 85%. That’s not just safety, that’s smart work.

Must Have Insulated Tools

Every electrician should keep these tools in their kit

1. Insulated Screwdriver Set

Used daily, these screwdrivers protect your hand while working on panels, outlets, and switches. A full set ensures you have the right tip for every screw type.

2. Insulated Pliers

Cutting or twisting wires? These are your goto. They give you grip, control, and peace of mind when handling live wires.

3. Insulated Knife

Perfect for stripping cable jackets without putting your safety at risk. Unlike utility knives, these are built to handle electrical tasks.

Each tool in Jonard’s lineup is designed not just for safety, but also for comfort, grip, and durability.

Real World Application

Imagine this: you're working on a live breaker panel. One slip with a non insulated screwdriver could lead to a shock that knocks you off a ladder. But with the right insulated tool, that current never reaches your hand.

Thousands of electricians trust Jonard's insulated electrical tools because they’re not just built for performance, they’re built for protection.

How to Know a Tool is Truly Insulated

Look for these marks:

VDE or IEC 60900 certification

1000V rating printed on the handle

Two-color insulation (often red + yellow)

The double triangle safety symbol

If your tool doesn’t have these, don’t risk using it on electrical jobs.

Safety Tips for Using Insulated Tools

Even the best tool needs the right handling:

Inspect for cracks or wear before every job

Clean tools regularly to avoid dust buildup

Never use a tool with exposed metal where insulation should be

And always keep them in a dry, clean storage case to protect their insulation quality.

Final Thoughts

Electricity isn’t something to mess with. But with the right tools, you don’t have to fear it either. Whether you're a professional electrician or a serious home user, using insulated tools gives you the power to work with confidence and safety.Don’t take risks with your safety. Explore Jonard’s full range of insulated tools today and upgrade your toolbox with tools built to protect.

#insulated knife#insulated screwdriver set#insulated pliers#insulated tools#insulated screwdrivers#insulated electrical tool

0 notes

Text

Stop the Strain: How Torque Wrenches Solve the #1 Problem in Connector Installations

In the world of cable TV (CATV), VDV, satellite, and broadband installations, one of the most overlooked yet damaging issues is over tightening or under tightening connectors. When a connector isn’t torqued properly, it can lead to stripped threads, damaged ports, poor signal quality, or long term reliability issues. This is where torque wrenches become the unsung heroes of professional installation work.

Whether you're a seasoned installer or a technician just starting out, understanding the value of a torque wrench can save you time, money, and callbacks. In this article, we’ll explore the problem, how torque tools solve it, and why using the right type, such as a preset angle torque wrench or torque wrench sockets can improve your work quality instantly.

The Problem: Over Torque and Under Torque in Field Installs

Installers often tighten connectors by guessing, but this can cause uneven results. Over tightening can:

Damage expensive equipment ports

Strip connector threads

Break internal components of devices

On the flip side, under tightening leads to:

Loose connections

Signal degradation

Increased service calls

Signal Performance vs Torque Level

Improper torque directly impacts signal strength. Here’s what the data shows

Torque level------------Signal performance

Under Torqued---------------60

Optimal Torque--------------100

Over Torqued-----------------65

As you can see, both extremes cause signal loss. The optimal torque point is the only way to maintain good performance and that's where angle torque wrenches shine.

The Solution: Torque Wrenches

A coax torque wrench is a perfect tool that ensures connectors are tightened to an exact specification, no more guesswork, no more stripped ports. Tools like Jonard’s fixed torque wrenches are adjusted and tested at the factory and deliver a consistent torque value, clicking once the minimum level is reached.

Benefits of Using Torque Wrenches:

Protects equipment from overtightening

Reduces service recalls

Ensures following rules with manufacturer specifications

Improves long term performance and is trusted

Whether you’re installing F connectors in CATV systems or BNCs in VDV, torque wrench sockets ensure you're never too loose or too tight.

Types of Torque Wrenches and When to Use Them

1. Default Torque Wrenches

These are designed for specific torque values (e.g., 30 in-lb or 20 in-lb) and are ideal for field installers working with repetitive connector types. No adjustments are needed, just click and move on.

2. Adjustable Torque Wrenches

Offer flexibility when working on varying equipment specs, but it needs careful adjustment to make sure the tool works correctly. Best for technicians managing multiple connection types.

3. Angle Torque Wrenches

These make sure exactly correct torque based on rotational angle rather than pressure, often used where angle based torque specs are critical (e.g., in some coaxial connector systems).

4. Torque Wrench Sockets

Used in conjunction with power tools or hand tools, torque sockets deliver high efficiency, quick torque control, perfect for tight spaces or high volume jobs.

Common Mistakes Without Torque Tools

Depending on hand feel – leads to uneven results

Using generic tools – cause damage because they’re not calibrated.

No calibration checks – even torque tools need routine testing

Jonard's tools are already set up by the factory, so they work accurately from the start, you can avoid all three.

Real World Use Case

A major telecom service provider reported a 30% drop in repeat service calls after training technicians to use torque wrenches on all connector installations. The cost savings from reduced truck rolls alone justified the investment within 60 days.

ROI from Torque Tool Adoption

Benefit-----Before Torque wrenches---After Torque wrenches

Repeat service calls--------40/month---------28/month (-30%)

Connector Port Replacements-----12/month-----4/month (-66%)

Average Signal Quality Rating--------75%----------96%

These results show how torque tools can improve service quality and lower operational costs.

Educational Tip: How to Use a Default Torque Wrench

Insert the connector.

Fit the torque wrench to the connector nut.

Rotate until you hear or feel the “click.”

Stop turning, you’ve reached the optimal torque.

That’s it. No overthinking, no over torquing.

Final Thoughts

In the world of perfect cable installations, your work is only as strong as your weakest connection. Improper torque is a hidden but costly issue, one that can damage devices, hurt signal quality, and increase maintenance costs.

Using a torque wrench ensures every connector is tightened perfectly. From preset models to angle torque wrenches, Jonard’s tools help you work faster, safer, and smarter.Ready to cut down service calls and improve signal reliability? Explore Jonard’s full line of torque wrenches here and level up your installs today.

0 notes

Text

Thermal fiber stripping tool

Fiber thermal stripper

Thermal stripper

0 notes

Text

Jonard Tools Sets the Standard in Precision with Advanced Stripping Tools for Electrical and Cable Work

Jonard Tools Redefines Wire Stripping Precision with Professional Grade Tools

In today’s fast paced electrical and networking industries, perfection and reliability are non negotiable. Whether you're an experienced technician or a DIY enthusiast, choosing the right tools can dramatically impact efficiency and safety. That’s where Jonard Tools steps in a name trusted across industries for its robust engineering and dependable solutions. One of the standout categories in their product lineup is their range of high performance wire stripping tools, designed to make cable preparation faster, cleaner, and more accurate than ever.

From coaxial cables to Ethernet lines, the quality of a strip can determine the success of the entire installation. Jonard’s stripping tools are engineered to remove insulation cleanly without damaging the underlying conductor, helping professionals avoid costly rewiring or performance loss. Let’s dive into why Jonard’s products are fast becoming the goto solution for electrical and telecom professionals.

Advanced Engineering for High Performance Stripping

At the heart of Jonard Tools, Success is a commitment to precision engineering. Each wire stripper is built using premium materials such as heat treated carbon alloy steel, ensuring long-term durability and a consistent performance edge. These tools are crafted to meet stringent industry standards, offering a clean strip every time.

The user-friendly designed handles minimize hand tiredness and provide maximum comfort for prolonged use, a feature that technicians appreciate during large scale installations. In addition, the sharp, perfect ground blades ensure that insulation is stripped away cleanly without nicking or damaging the conductor inside.

Versatility and Compatibility in Every Toolbox

Whether you're working on RG6, RG59 coaxial cables, CAT5/6 data lines, or fiber optics, Jonard has a wire stripper and cutter designed for your specific needs. Their dual purpose tools not only strip insulation but also cut cables with ease, an ideal solution for contractors looking to reduce the number of tools they carry on site.

One of the key highlights is the company’s range of adjustable wire stripping tools, which allow users to fine tune the blade depth according to the wire gauge. This level of customization ensures that no matter what type of wire you're working with, you get a perfect strip every single time reducing the chances of mistakes and waste.

Trusted by Professionals Around the World

Professionals across telecommunications, electrical contracting, and cable installation fields consistently choose Jonard for one reason. The reliability of Jonard’s stripping tools means fewer project delays, better installation accuracy, and higher customer satisfaction. With a broad range of certifications and compliance to international safety standards, Jonard Tools are designed for both beginners and seasoned technicians who demand top tier performance.

Industry Applications of Jonard Stripping Tools

Jonard’s stripping tools serve a broad array of industry sectors, including:

Telecom Installations: For stripping coaxial cables, fiber optics, and telephone wires with precision.

Electrical Contracting: Ideal for residential and commercial electrical work where clean insulation removal is critical.

Networking & Data: Useful for preparing Ethernet cables, patch cords, and structured cabling installations.

Each tool is purpose built to address real world scenarios and applications, from dense panel terminations to field service installations.

Why Jonard Tools Stand Out

Innovation: Continuous product development ensures modern needs are met with next generation solutions.

Durability: Long life tools that perform under harsh field conditions.

Safety: Designed with non-slip grips and controlled blade depth to minimize accidents.

Affordability: Premium grade tools at accessible prices for both companies and independent technicians.

Additionally, Jonard offers detailed manuals and tutorial videos for each product, allowing users to unlock the full potential of their stripping tools quickly.

Customer Centric Support and Training

Jonard Tools believes that great tools deserve great support. The company offers extensive product support through online documentation, instructional videos, and responsive customer service. For those new to the trade or looking to train new hires, Jonard’s resources are invaluable for learning how to maximize tool performance and handle each job safely.

Sustainability and Responsibility

In a time when environmental sustainability is increasingly important, Jonard Tools ensures that its products are made using eco-friendly processes. Tool longevity reduces replacement rates, leading to less waste and greater value over time.

Conclusion: Make the Smart Strip with Jonard Tools

When precision, speed, and safety are non negotiable, professionals turn to Jonard. Their industry leading wire stripping tools help streamline installation processes while ensuring that every cable is prepared to perfection. Whether you’re looking for a reliable wire stripper, a multi purpose wire stripper and cutter, or an adjustable wire stripping tool for more specialized tasks Jonard has the right tool for your needs.

Invest in tools that professionals trust. Explore Jonard’s range of wire and cable stripping solutions today and experience a new standard in workmanship.

0 notes

Text

Jonard Tools Recreate Safety Standards with High Quality Insulated Tools for Professionals

Jonard Tools introduces its premium range of insulated tools, engineered for maximum safety and performance. Built for electricians, contractors, and technicians, the collection includes insulated screwdrivers, insulated pliers, and advanced tools like the insulated knife. All tools meet IEC and ASTM standards for high voltage protection.

Enhancing Electrical Safety with Jonard’s High Performance Insulated Tools

In an industry where precision meets danger, the importance of having the right equipment can never be overstated. Working with live electrical components demands not only expertise but tools that are engineered for absolute safety. Jonard Tools, a globally recognized name in professional grade hand tools, is making waves with its advanced range of insulated tools. Built for electricians, maintenance professionals, telecom technicians, and field engineers, these tools go beyond the basics delivering protection, performance, and peace of mind in every grip.

Electricians face countless challenges every day, tight spaces, live wires, unpredictable environments. One misstep or faulty tool could mean the difference between safety and serious injury. Jonard Tools addresses these challenges head on with its comprehensive lineup of insulated electrical tools that conform to global safety standards, including IEC 60900 and ASTM F1505.

Each tool is tested to 10,000 volts and certified for live use up to 1,000 volts AC or 1,500 volts DC. Whether you're repairing a panel, installing outlets, or managing high voltage systems, these tools are designed to ensure your protection without sacrificing productivity.

Engineered for Safety and Built for the Toughest Jobs

What sets Jonard Tools apart is their rigorous manufacturing process and attention to detail. The insulated screwdrivers are made with high grade chrome vanadium steel shafts and molded insulation directly bonded to the blade, eliminating any gaps that could allow voltage leakage.

Each insulated screwdriver set is assembled with an easy to understand design to reduce strain and improve control, even in the most confined workspaces. Perfect machined tips ensure a comfortable fit into fasteners, reducing slippage and rounding. These features make them a favorite among utility companies and industrial technicians worldwide.

For professionals who prefer variety in their toolkits, Jonard offers multiple insulated screwdriver set options flathead, Phillips, and combination tip formats making it easier to handle complex wiring and electronic repairs without switching brands or compromising on safety.

Cut, Strip, and Slice with Confidence

Beyond screwdrivers, Jonard’s line includes heavy duty insulated pliers and a razor sharp insulated knife. These aren’t just hand tools, they are engineered instruments designed to withstand high mechanical stress and extreme working conditions.

The insulated pliers are crafted for perfect gripping, twisting, and cutting. Their slip resistant handles and high leverage pivot points reduce hand tiredness while maximizing force. Available in long nose, combination, and diagonal cutting formats, these pliers are ideal for circuit installation, cable tie, and electrical panel service.

The insulated knife is a standout addition to the lineup. Designed specifically for stripping insulation and cutting cables, the blade is sharp, durable, and built to last. Its insulated handle gives users confidence to perform delicate tasks on live circuits without hesitation.

Tailored Toolkits for Professional Demands

Understanding that every job is different, Jonard Tools offers comprehensive insulated toolkits that bring multiple essentials together in one organized case. Their most popular kit, the 11 piece insulated tool set includes everything from insulated screwdrivers and insulated pliers to precision wire cutters and torque tested grips. This organized set is designed to provide full coverage for electricians who need portability without sacrificing quality.

Each kit comes with custom foam trays, tool labels, and safety guidelines to ensure quick access and proper storage vital in fast paced, high risk environments.

Tested, Trusted, and Certified

What makes Jonard a top choice for professionals isn’t just the quality of its tools, it's the reputation for accuracy, consistency, and compliance. All tools in the insulated range go through extensive quality assurance and testing in controlled environments. This includes insulation resistance, dielectric strength, and cold impact tests to confirm that they perform under stress, in extreme temperatures, and under continuous use.

With rising demand in smart buildings, electric vehicles, data centers, and renewable energy sectors, tools that meet industry standards are no longer optional, they're non negotiable. Jonard’s insulated tools rise to this challenge by offering not just safety but a performance edge.

Designed with Electricians in Mind

Every curve, every grip, every material used in Jonard’s insulated tools is thoughtfully selected with the user in mind. User friendly designs help reduce fatigue during long work sessions, while color coded handles assist in quick identification. Non slip coatings ensure stable handling even in humid or dusty conditions.

This user first approach makes Jonard Tools a staple not just for large companies, but also for independent electricians and field contractors who need reliable tools that perform every single time.

Conclusion: A Safer, Smarter Way to Work

The modern electrical landscape is evolving quickly with more advanced systems, higher voltages, and tighter regulations. In such a high stakes environment, Jonard Tools remains a trusted partner by offering equipment that empowers professionals to work safer, smarter, and more efficiently.

From insulated screwdrivers to high performance insulated pliers and the ultra reliable insulated knife, this product line is not just a toolbox addition, it's a long term safety investment. Ready to upgrade your toolkit with world class protection and performance? Explore the full range of insulated electrical tools at Jonard Tools today.

#Insulated tools#Insulated electrical Tools#insulated screwdrivers#insulated pliers#insulated screwdriver set#insulated knife

1 note

·

View note

Text

Why Perfection in Do It Your Projects Matters More Than You Think

Whether you're fixing a leaky water pipe or assembling your own custom furniture, there's something deeply satisfying about completing a Do It Yourself project with your own two hands. But here’s the thing, everything is perfect. And when it comes to mechanical or automotive tasks, the tools you use can determine whether the job is just “done” or “done right.”

That’s where torque wrenches come in.

Most casual DIYers may not immediately reach for a torque wrench. But once you understand how essential tightening to the correct torque is especially when it comes to mechanical safety you’ll never go back to guessing.

The Overlooked Hero in Your Toolbox

Let’s say you’re installing a bike rack to your car, mounting a new engine part, or assembling furniture with a perfect bolt. In each of these cases, over tightening or under tightening bolts can result in stripped threads, breakage, or even dangerous outcomes. That’s exactly why seasoned professionals rely on tools like the angle torque wrench for accuracy.

Unlike basic wrenches or screwdrivers, an angle torque wrench doesn’t just stop at a preset tension, it measures the angle of rotation after the bolt is snug, ensuring it's tightened perfectly to spec.

Not Just for Auto Mechanics

Think torque tools are only for auto shops? Think again. More and more homeowners and hobbyists are realizing that coax torque wrench are invaluable for a wide range of tasks.

From AC and ventilation installations and electronics assembly to bolting down components on your drone or bike, the need for accurate torque spans across industries and interests. Torque wrench sockets allow you to work with a variety of screw and bolts types, adapting to different torque values without needing an entire separate toolkit.

Safety Meets Simplicity

Perfection isn’t just a luxury, it’s a safety standard. Especially in critical applications like plumbing systems, structural bolts, or electrical panel installations, a torque wrench ensures that nothing is under tightened or over tightened. Using tools that offer clear, audible clicks or mechanical stops adds an extra layer of certainty.

What’s better? Many modern torque wrenches now offer lightweight, ergonomic builds with automatic adjustment settings, making them user friendly even for first timers.

Building Smarter, Not Just Harder

There’s a growing trend of people turning their homes into weekend workshops. The rise of smart home tech, hobby electronics, and home renovation challenges means DIYers now work with more advanced hardware than ever before.

So why not pair that complexity with tools designed for it?

The right torque tool lets you finish projects not just with passion, but with professional level quality. It's a difference you can feel literally. There’s peace of mind in knowing that every bolt is tightened just right.

Final Thoughts: Invest in Perfection

When people say it’s just a tool, they’ve probably never used a great one. A torque wrench might seem like a niche product but once you experience the ease, safety, and accuracy it offers, it quickly becomes essential.Whether you're a hobbyist or a hands-on professional, investing in a torque wrench and its compatible accessories like angle torque wrenches and torque wrench sockets could be one of the smartest upgrades you make to your toolkit.

1 note

·

View note

Text

Angle Torque Wrench

Overtightening connectors can lead to wrap, while insufficient torque may cause weak connections that compromise signal strength. That’s why using a customized Angle Torque Wrench is needed. Jonard Tools offers wrenches that apply just the right amount of force, protecting connectors and protecting the durability and endurance of the entire system.

Their angle torque wrenches are particularly useful in situations where access is limited, and perfect. With built in mechanisms that deliver an audible click or physical release at the correct torque value, users can work confidently without second guessing their force.

0 notes

Text

Torque wrench sockets

Why Choose Torque Wrench Sockets?

For professionals who regularly switch between tasks and connection types, Torque Wrench Sockets offer a flexible solution. These interchangeable heads allow users to adapt one torque wrench body to multiple sizes and connector types. This not only saves space in your toolbox but also smooths your workflow by reducing the need to switch between different wrenches.

Each socket is measured for accuracy and pairs seamlessly with Jonard’s torque wrench handles, ensuring consistent results across the board.

Benefits That Matter on the Job

Perfection – Apply consistent torque every time. Safety – Prevent damage to sensitive connectors and cables. Efficiency – Save time with tools designed for field conditions. Durability – Built to last with rust free materials. Human factors – Comfortable grips reduce strain during long work sessions.

1 note

·

View note